Durability Characteristics of Concrete Mixture Based on Red Ceramic Waste Aggregate

Abstract

:1. Introduction

2. Materials, Mixture Composition and Preparation of Specimens

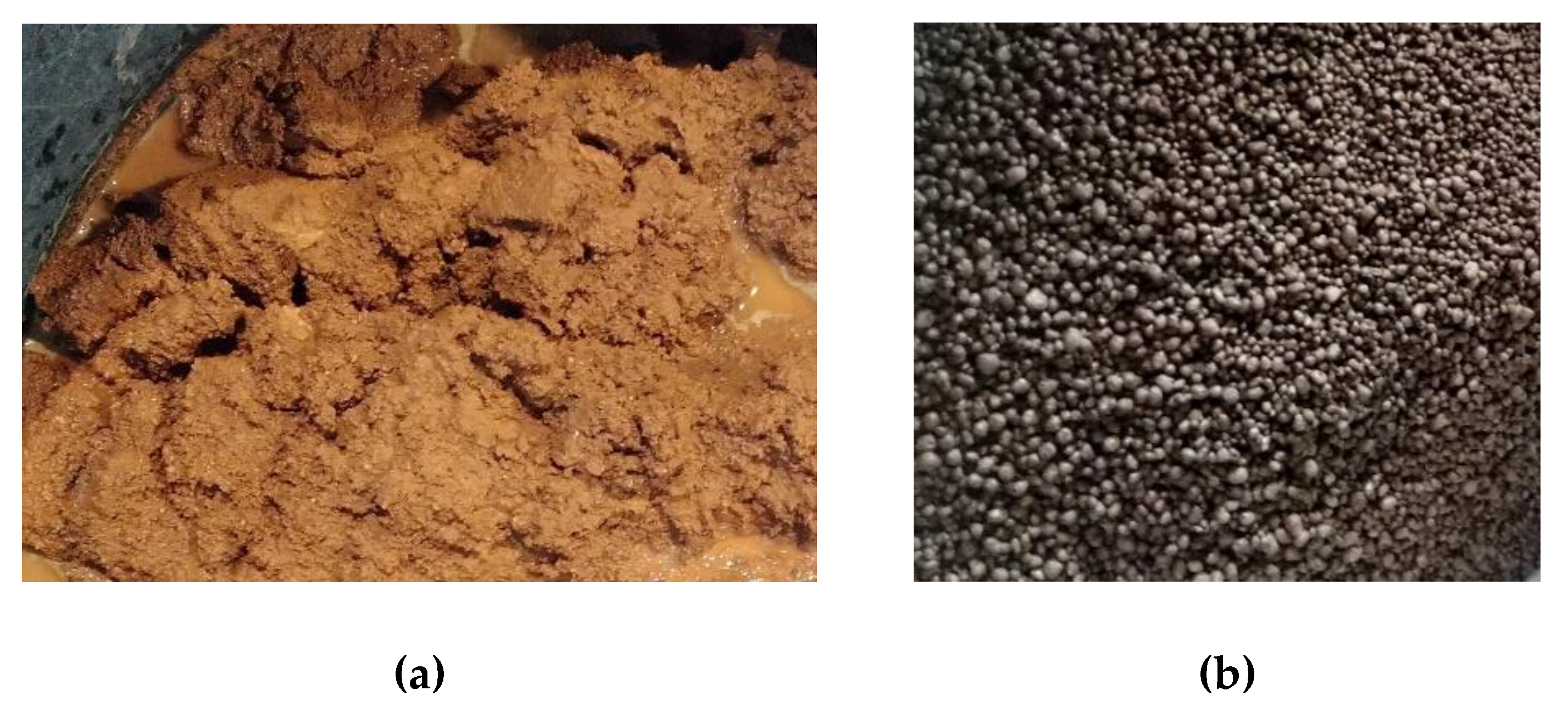

2.1. Materials

2.2. Mixture Composition

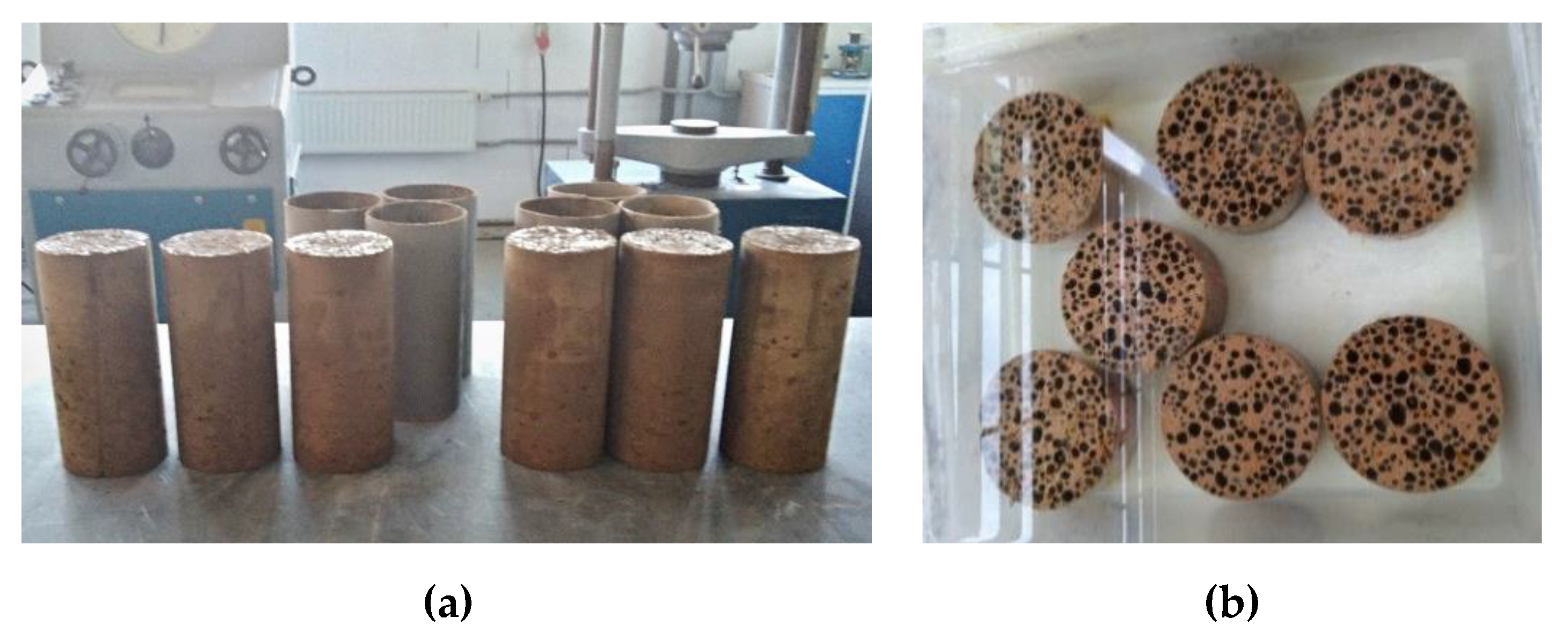

2.3. Preparation of Specimens

3. Chloride Ingress into Concrete and Durability Test Methods

3.1. Resistivity Measurement

3.2. NT Build 443

4. Results and Discussion

4.1. Comparison of Mechanical Properties

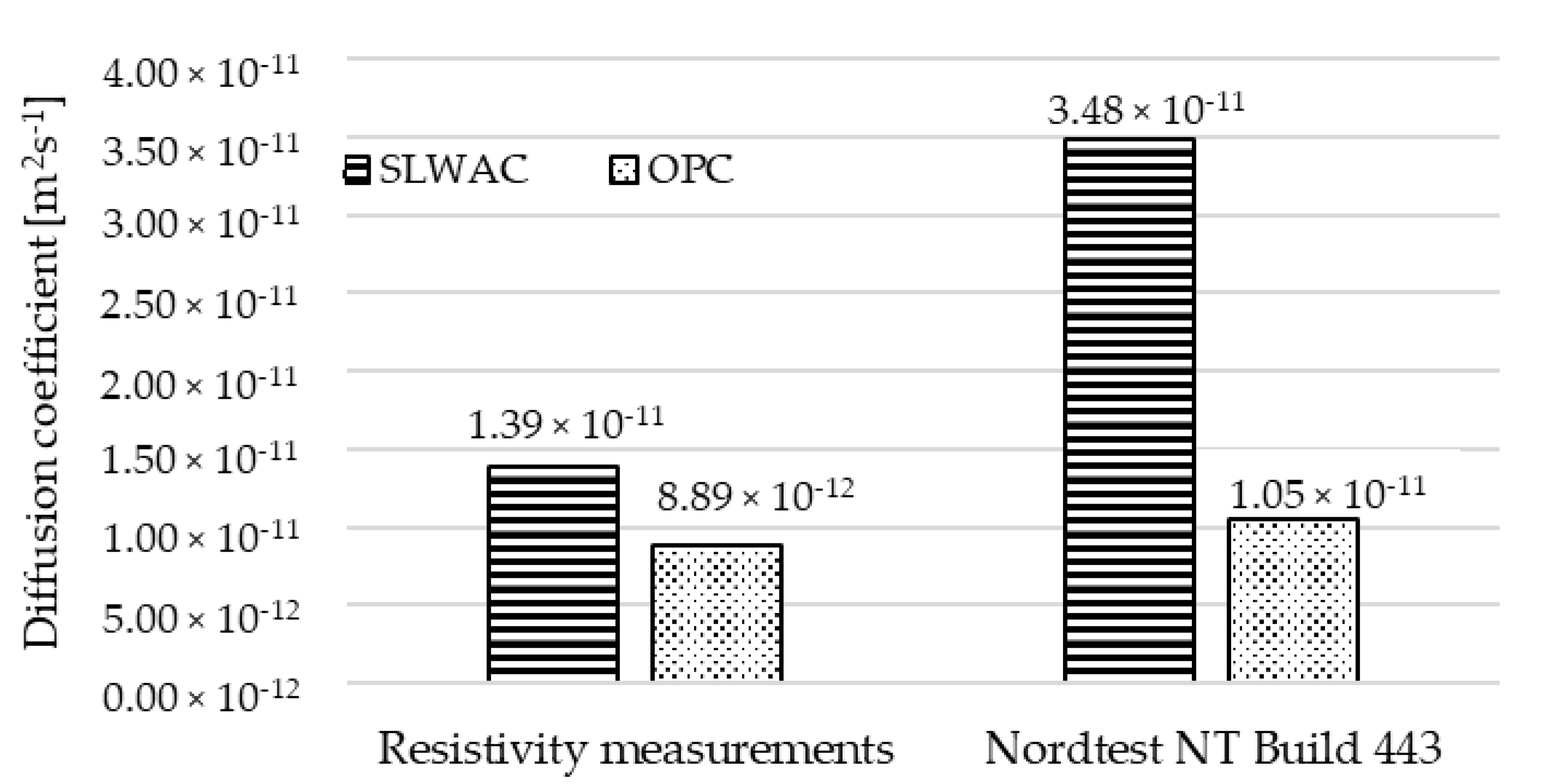

4.2. Resistivity Measurements

4.3. Penetration Test (NT Build 443)

4.4. Correlation Coefficient

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Assi, L.; Carter, K.; Deaver, E.E.; Anay, R.; Ziehl, P. Sustainable concrete: Building a greener future. J. Clean. Prod. 2018, 198, 1641–1651. [Google Scholar] [CrossRef]

- Latawiec, R.; Woyciechowski, P.; Kowalski, K.J. Sustainable Concrete Performance—CO2-Emission. Environments 2018, 5, 27. [Google Scholar] [CrossRef] [Green Version]

- Ghosh, P.; Quang, T.; Tuan, L. Compressive Strength and Surface Electrical Resistivity of HPC Mixtures. Int. J. Eng. Sci. Manag. 2014, 4, 1–10. [Google Scholar]

- Tran, Q.; Ghosh, P. Influence of pumice on mechanical properties and durability of high performance concrete. Constr. Build. Mater. 2020, 249, 118741. [Google Scholar] [CrossRef]

- Lin, G.; Liu, Y.; Xiang, Z.-H. Numerical modeling for predicting service life of reinforced concrete structures exposed to chloride environments. Cem. Concr. Compos. 2010, 32, 571–579. [Google Scholar] [CrossRef]

- Folic, R.; Zenunovic, D. Durability design of concrete structures, Part 2: Modelling and structural assessment. Facta Univ. Ser. Arch. Civ. Eng. 2010, 8, 45–66. [Google Scholar] [CrossRef]

- Konecny, P.; Lehner, P.; Brozovsky, J.; Krejsa, M. Multilevel Durability Analysis of Concrete Bridge Deck Exposed to Chlorides. Fifteenth Int. Conf. Civ. Struct. Environ. Eng. 2015, 108. [Google Scholar] [CrossRef]

- Horn, L. Targeted/Emerging Therapies for Metastatic Non–Small Cell Lung Cancer. J. Natl. Compr. Cancer Netw. 2015, 13, 676–678. [Google Scholar] [CrossRef]

- Hornakova, M.; Katzer, J.; Kobaka, J.; Konecny, P. Lightweight SFRC Benefitting from a Pre-Soaking and Internal Curing Process. Materials 2019, 12, 4152. [Google Scholar] [CrossRef] [Green Version]

- Mehta, P.K.; Monteiro, P.J. Concrete Structures, Properties and Materials; McGraw Hill Education: New York, NY, USA, 2017. [Google Scholar]

- Lencioni, J.W.; De Lima, M.G.; Büyüköztürk, O.; Taşdemir, M.A. A Study of the Parameters that Affect the Measurements of Superficial Electrical Resistivity of Concrete. In RILEM Bookseries; Springer: Dordrecht, The Netherlands, 2011; Volume 6. [Google Scholar] [CrossRef]

- Hooton, R.D.; Thomas, M.D.A.; STANDISH, K. Prediction of Chloride Penetration in Concrete; Federal Highway Administration: Washington, DC, USA, 2001; p. 405.

- Tikalsky, P.J.; Scheetz, B.E.; Tepke, D.G. Statewide high performance concrete initiative, task 6, Final report. In Penndot Research; Pennsylvania State University: State College, PA, USA, 2007. [Google Scholar]

- Ramezanianpour, A.A.; Pilvar, A.; Mahdikhani, M.; Moodi, F. Practical evaluation of relationship between concrete resistivity, water penetration, rapid chloride penetration and compressive strength. Constr. Build. Mater. 2011, 25, 2472–2479. [Google Scholar] [CrossRef]

- Ghosh, P.; Tran, Q. Correlation Between Bulk and Surface Resistivity of Concrete. Int. J. Concr. Struct. Mater. 2014, 9, 119–132. [Google Scholar] [CrossRef]

- Lübeck, A.; Gastaldini, A.; Barin, D.; Siqueira, H. Compressive strength and electrical properties of concrete with white Portland cement and blast-furnace slag. Cem. Concr. Compos. 2012, 34, 392–399. [Google Scholar] [CrossRef]

- Nordtest. Nordtest NT BUILD 443, Concrete, Hardened: Accelerated Chloride Penetration; Nordtest: Espoo, Finland, 1995. [Google Scholar]

- Sorensen, H.E. Nordtest Project 1154-94, Determination of Chloride Penetration Parameters for Concrete; AEC Laboratory Report No. 94-019; AEC Consulting Engineers Ltd.: Vedbek, Denmark, 1995. [Google Scholar]

- Luping, T.; Sørensen, H. Evaluation of the Rapid Test Methods for Measuring the Chloride Diffusion Coefficients of Concrete; NORDTEST Project No. 1388-98; Swedish National Testing and Research Institute Building Technology: Borås, Sweden, 1998. [Google Scholar]

- Gao, P.; Wei, J.; Zhang, T.; Hu, J.; Yu, Q. Modification of chloride diffusion coefficient of concrete based on the electrical conductivity of pore solution. Constr. Build. Mater. 2017, 145, 361–366. [Google Scholar] [CrossRef]

- Hornakova, M.; Konecny, P.; Lehner, P.; Katzer, J. Durability of structural lightweight waste aggregate concrete—Electrical resistivity. In MATEC Web of Conferences; EDP Sciences: Ulis, France, 2020. [Google Scholar] [CrossRef]

- Lehner, P.; Konečný, P.; Ponikiewski, T. Comparison of Material Properties of SCC Concrete with Steel Fibres Related to Ingress of Chlorides. Crystals 2020, 10, 220. [Google Scholar] [CrossRef] [Green Version]

- Nilsson, L.O.; Poulsen, E.; Sandberg, P.; Sorensen, H.E. Klinghoffer, O. Chloride Penetration into Concrete. State of the Art. Transport Processes, Corrosion Initiation and Prediction Models; Danish Road Directorate: Copenhagen, Denmark, 1996; ISBN 8774917366. [Google Scholar]

- Tang, C.-W. Effect of presoaking degree of lightweight aggregate on the properties of lightweight aggregate concrete. Comput. Concr. 2017, 19, 69–78. [Google Scholar] [CrossRef]

- Katzer, J.; Kobaka, J. Harnessing Waste Fine Aggregate for Sustainable Production of Concrete Precast Elements. Rocz. Ochr. Sr. 2010, 12, 33–45. [Google Scholar]

- Suzuki, M.; Meddah, M.S.; Sato, R. Use of porous ceramic waste aggregates for internal curing of high-performance concrete. Cem. Concr. Res. 2009, 39, 373–381. [Google Scholar] [CrossRef]

- Cichocki, K.; Domski, J.; Katzer, J.; Ruchwa, M. Mechanical Properties and Numerical Approach to Fibre Reinforced Wca Concrete Slabs. In Brittle Matrix Composites 11, Proceedings of the 11th International Symposium on Brittle Matrix Composites (BMC 2015), Warsaw, Poland, 28–30 September 2015; Institute of Fundamental Technological Research, Polish Academy of Sciences: Warsaw, Poland.

- Rahhal, V.F.; Trezza, M.A.; Tironi, A.; Castellano, C.C.; Pavlíková, M.; Pokorný, J.; Irassar, E.F.; Jankovský, O.; Pavlík, Z. Complex Characterization and Behavior of Waste Fired Brick Powder-Portland Cement System. Materials 2019, 12, 1650. [Google Scholar] [CrossRef] [Green Version]

- Katzer, J.; Kuźmińska, E. Optimal Composition of Blended Waste Ceramic Aggregate. Sustain. Constr. Mater. Technol. 2016, 145. [Google Scholar] [CrossRef]

- EN 12350-2. Testing Fresh Concrete, Part 2: SLUMP Test; British Standard Institution: London, UK, 2009. [Google Scholar]

- EN 206-1. Performance-Based Specifications and Control of Concrete Durability. Concrete. Part 1, Specification, Performance, Production and Conformity; British Standard Institution: London, UK, 2006. [Google Scholar]

- Liu, J.; Shi, C.; Ma, X.; Khayat, K.H.; Zhang, J.; Wang, D. An overview on the effect of internal curing on shrinkage of high performance cement-based materials. Constr. Build. Mater. 2017, 146, 702–712. [Google Scholar] [CrossRef] [Green Version]

- Dyer, T. Concrete Durability; CRC Press: London, UK, 2014; ISBN 978-0415564755. [Google Scholar]

- Poulsen, E.; Mejlbro, L. Diffusion of Chloride in Concrete: Theory and Application; Taylor & Francis: London, UK, 2010. [Google Scholar]

- Thomas, M.; Hooton, R.; Scott, A.; Zibara, H. The effect of supplementary cementitious materials on chloride binding in hardened cement paste. Cem. Concr. Res. 2012, 42, 1–7. [Google Scholar] [CrossRef]

- Saillio, M.; Baroghel-Bouny, V.; Barberon, F. Chloride binding in sound and carbonated cementitious materials with various types of binder. Constr. Build. Mater. 2014, 68, 82–91. [Google Scholar] [CrossRef]

- Lu, X. Application of the Nernst-Einstein equation to concrete. Cem. Concr. Res. 1997, 27, 293–302. [Google Scholar] [CrossRef]

- Konecny, P.; Lehner, P.; Ponikiewski, T.; Miera, P. Comparison of Chloride Diffusion Coefficient Evaluation Based on Electrochemical Methods. Procedia Eng. 2017, 190, 193–198. [Google Scholar] [CrossRef]

- Ghosh, P. Computation of Diffusion Coefficients and Prediction of Corrosion Initiation in Concrete Structures. Ph.D. Thesis, The University of Utah, Salt Lake City, UT, USA, 2011. [Google Scholar]

- Lehner, P.; Turicová, M.; Konecny, P. Comparison of selected methods for measurement of the concrete electrical resistance to chloride penetration. ARPN J. Eng. Appl. Sci. 2017, 12, 937–944. [Google Scholar]

- ČSN EN 14629. Products and Systems for the Protection and Repair of Concrete Structures. Test Methods. Determination of Chloride Content in Hardened Concrete; ČNI: Prague, Czech Republic, 2008. [Google Scholar]

- Collepardi, M.; Marcialis, A.; Turriziani, R. Penetration of Chloride Ions into Cement Pastes and Concretes. J. Am. Ceram. Soc. 1972, 55, 534–535. [Google Scholar] [CrossRef]

- Boddy, A.; Bentz, E.; Thomas, M.; Hooton, R. An overview and sensitivity study of a multimechanistic chloride transport model. Cem. Concr. Res. 1999, 29, 827–837. [Google Scholar] [CrossRef]

- Luping, T.; Nilsson, L.O. Rapid Determination of the Chloride Diffusivity in Concrete by Applying an Electrical Field. ACI Mater. J. 1992, 89, 40–53. [Google Scholar]

- Konečný, P.; Lehner, P.; Ghosh, P.; Morávková, Z.; Tran, Q. Comparison of procedures for the evaluation of time dependent concrete diffusion coefficient model. Constr. Build. Mater. 2020, 258, 119535. [Google Scholar] [CrossRef]

| Mixture | SLWAC [9] [kg/m3] | OPC [22] [kg/m3] |

|---|---|---|

| WRCFA–dry | 379 | - |

| ECCA–dry | 247 | - |

| Cement I 42.5 | 321 | 313 |

| Absorbed water | 461 | - |

| Water | - | 164 |

| Sand | - | 387 |

| River gravel | - | 1546 |

| Diffusion Coefficient [m2 s−1] × 10−11 | m [−] | ||||||

|---|---|---|---|---|---|---|---|

| Time [Days] | 7 | 14 | 28 | 56 | 91 | 161 | |

| SLWAC | 2.37 | 2.07 | 2.03 | 2.00 | 1.65 | 1.39 | 0.139 |

| OPC [22] | 1.31 | 1.19 | 0.987 | 0.980 | 0.961 | 0.889 | 0.126 |

| Mixture | SLWAC | OPC [22] |

|---|---|---|

| Time | t = 168 days | t = 159 days |

| Diffusion coefficient Dc,t [m2 s−1] | 3.48 × 10−11 | 1.05 × 10−11, |

| Mixture | SLWAC | OPC |

|---|---|---|

| Dc,res,28 [m2 s−1] in 28 days–resistivity | 2.03 × 10−11 | 0.987 × 10−11 |

| Dc,NT443,28 [m2 s−1] in 28 days–NT Build 443 | 4.46 × 10−11 | 1.31 × 10−11 |

| Ratio Dc,NT443,28/Dc,res,28 | 2.20 | 1.32 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Horňáková, M.; Lehner, P.; Le, T.D.; Konečný, P.; Katzer, J. Durability Characteristics of Concrete Mixture Based on Red Ceramic Waste Aggregate. Sustainability 2020, 12, 8890. https://doi.org/10.3390/su12218890

Horňáková M, Lehner P, Le TD, Konečný P, Katzer J. Durability Characteristics of Concrete Mixture Based on Red Ceramic Waste Aggregate. Sustainability. 2020; 12(21):8890. https://doi.org/10.3390/su12218890

Chicago/Turabian StyleHorňáková, Marie, Petr Lehner, Tuan Duc Le, Petr Konečný, and Jacek Katzer. 2020. "Durability Characteristics of Concrete Mixture Based on Red Ceramic Waste Aggregate" Sustainability 12, no. 21: 8890. https://doi.org/10.3390/su12218890