Environmental Footprint of Cementitious Adhesives—Components of ETICS

Abstract

1. Introduction

- Reuse of recyclability of the construction works, their materials, and parts after demolition;

- The durability of the construction works;

- Use of environmentally compatible raw and secondary materials in the construction works.

2. Materials and Methods

2.1. ETICS and Components: Cement-Based Adhesives

2.2. Environmental Impact—Assessment Method

3. Results

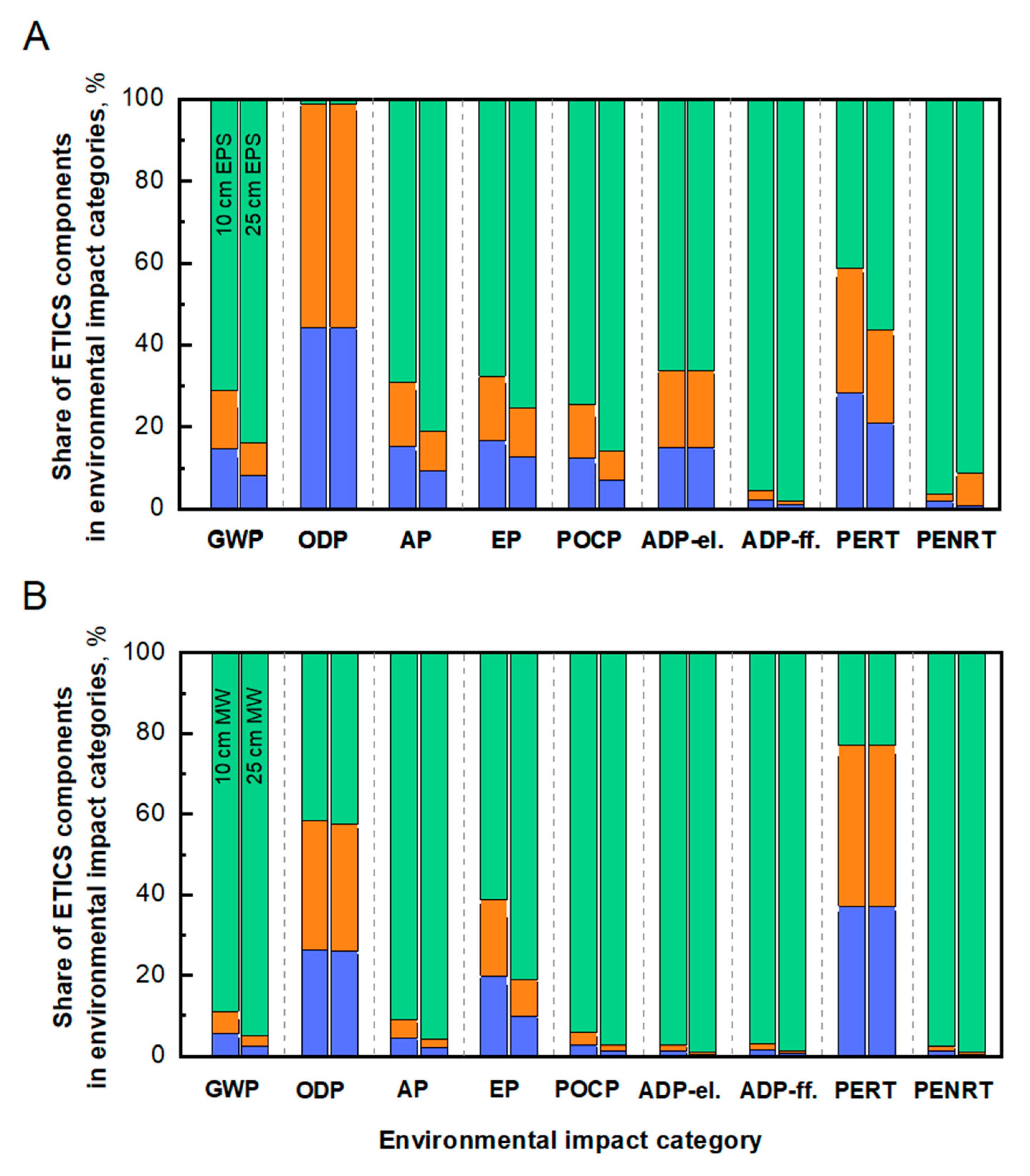

- Global warming potential (GWP);

- Depletion potential of the stratospheric ozone layer (ODP);

- Acidification potential of soil and water (AP);

- Eutrophication potential (EP);

- Formation potential of tropospheric ozone (POCP);

- Abiotic depletion potential (ADP-elements) for non-fossil resources;

- Abiotic depletion potential (ADP-fossil fuels) for fossil resources;

- Total use of renewable primary energy resources (primary energy and primary energy resources used as raw materials) (PERT);

- Total use of non-renewable primary energy resources (primary energy and primary energy resources used as raw materials) (PENRT).

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Thant, U. Problems of the Human Environment; Report of the Secretary-General; United Nations Economic and Social Council: New York, NY, USA, 1969.

- Brundtland, G.H. Report of the World Commission on Environment and Development: Our Common Future. 1987. Available online: http://www.un-documents.net/our-common-future.pdf (accessed on 26 July 2020).

- European Commission. The European Green Deal; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- European Commission. Energy Performance of Buildings Directive. Available online: https://ec.europa.eu/energy/topics/energy-efficiency/energy-efficient-buildings/energy-performance-buildings-directive_en (accessed on 26 July 2020).

- Building Performance Institute Europe, Brussels, Belgium. 2020. Available online: http://bpie.eu/wp-content/uploads/2017/12/State-of-the-building-stock-briefing_Dic6.pdf (accessed on 26 July 2020).

- Esser, A.; Dunne, A.; Meeusen, T.; Quaschning, S.; Wegge, D.; Hermelink, A.; Schimschar, S.; Offermann, M.; John, A.; Reiser, M.; et al. Comprehensive Study of Building Energy Renovation Activities and the Uptake of Nearly Zero-Energy Buildings in the EU. Final Report; European Commission: Brussels, Belgium, 2019; Available online: https://ec.europa.eu/energy/sites/ener/files/documents/1.final_report.pdf (accessed on 27 July 2020).

- Anderson, J.; Moncaster, A. Embodied carbon of concrete in buildings, Part 1: Analysis of published EPD. Build. Cities 2020, 1, 198–217. [Google Scholar] [CrossRef]

- Pasker, R. The European ETICS market–Do ETICS sufficiently contribute to meet political objectives? In Proceedings of the 4th European ETICS Forum, Warsaw, Poland, 5 October 2017; European Association for External Thermal Insulation Composite Systems (EAE): Baden-Baden, Germany, 2017. [Google Scholar]

- Künzel, H.; Künzel, H.M.; Sedlbauer, K. Long-term performance of external thermal insulation systems (ETICS). Acta Archit. 2006, 5, 11–24. [Google Scholar]

- Kienzlen, V.; Erhorn, H.; Krapmeier, H.; Lutzkendorf, T.; Werner, J.; Wagner, A. The Significance of Thermal Insulation Arguments Aimed at Overcoming Misunderstandings, 3rd ed.; Fraunhofer-Publica: Karlsruhe, Germany, 2014; p. 35. [Google Scholar]

- Kvande, T.; Bakken, N.; Bergheim, E.; Thue, J.V. Durability of ETICS with rendering in Norway—Experimental and field investigations. Buildings 2018, 8, 93. [Google Scholar] [CrossRef]

- Lembo, F.; Marino, F.P.R. The pathologies of the ETICS. In Recent Developments in Building Diagnosis Techniques; Springer: Singapore, 2016; pp. 37–49. [Google Scholar]

- Sulakatko, V.; Lill, I.; Witt, E. Methodological framework to assess the significance of External Thermal Insulation Composite System (ETICS) on-site activities. Energy Procedia 2016, 96, 446–454. [Google Scholar] [CrossRef]

- Sulakatko, V.; Liisma, E.; Soekov, E. Increasing construction quality of external thermal insulation composite system (ETICS) by revealing on-site degradation factors. Procedia Environ. Sci. 2017, 38, 765–772. [Google Scholar] [CrossRef]

- Regulation (EU) No 305/2011 of the European Parliament and of the Council. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=uriserv:OJ.L_.2011.088.01.0005.01.ENG&toc=OJ:L:2011:088:TOC (accessed on 26 July 2020).

- European Organization for Technical Assessment (EOTA). ETAG 004: Guideline for European Technical Approval of External Thermal Insulation Composite Systems (ETICS) with Rendering; European Organization for Technical Assessment (EOTA): Brussels, Belgium, 2013. [Google Scholar]

- Anderson, J. Construction LCA’s 2020 Guide to Environmental Product Declarations. Available online: https://infogram.com/constructionlcas-2020-guide-to-epd-1h7g6kgqx9zo4oy?live (accessed on 23 July 2020).

- Gelowitz, M.D.C.; McArthur, J.J. Investigating the effect of environmental product declaration adoption in LEED® on the construction industry: A case study. Procedia Eng. 2016, 145, 58–65. [Google Scholar] [CrossRef]

- Andersen, S.C.; Larsen, H.F.; Raffnsøe, L.; Melvang, C. Environmental product declarations (EPDs) as a competitive parameter within sustainable buildings and building materials. IOP Conf. Ser. Earth Environ. Sci. 2019, 323, 012145. [Google Scholar] [CrossRef]

- Bitsiou, E.; Giarma, C. Parameters related to building components’ life-cycle analysis in methods for buildings’ environmental performance assessment. IOP Conf. Ser. Earth Environ. Sci. 2020, 410, 012066. [Google Scholar] [CrossRef]

- Galindro, B.M.; Welling, S.; Bey, N.; Olsen, S.I.; Soares, S.R.; Ryding, S.-O. Making use of life cycle assessment and environmental product declarations. A survey with practitioners. J. Ind. Ecol. 2020, 24, 1–11. [Google Scholar] [CrossRef]

- Passer, A.; Kreiner, H.; Maydl, P. Assessment of the environmental performance of buildings: A critical evaluation of the influence of technical building equipment on residential buildings. Int. J. Life Cycle Assess. 2012, 17, 1116–1130. [Google Scholar] [CrossRef]

- Passer, A.; Lasvaux, S.; Allacker, K.; De Lathauwer, D.; Spirinckx, C.; Wittstock, B.; Kellenberger, D.; Gschösser, F.; Wall, J.; Wallbaum, H. Environmental product declarations entering the building sector: Critical reflections based on 5 to 10 years’ experience in different European countries. Int. J. Life Cycle Assess. 2015, 20, 1199–1212. [Google Scholar] [CrossRef]

- Božiček, D.; Kunič, R.; Košir, M. Interpreting environmental impacts in building design: Application of a comparative assertion method in the context of the EPD scheme for building products. J. Clean. Prod. 2020, 279, 123399. [Google Scholar] [CrossRef]

- Bisegna, F.; Mattoni, B.; Gori, P.; Asdrubali, F.; Guattari, C.; Evangelisti, L.; Sambuco, S.; Bianchi, F. Influence of insulating materials on green building rating system results. Energies 2016, 9, 712. [Google Scholar] [CrossRef]

- Potrč, T.; Malovrh Rebec, K.; Kneza, F.; Kuničb, R.; Legata, A. Environmental footprint of external thermal insulation composite systems with different insulation types. Energy Procedia 2016, 96, 312–322. [Google Scholar] [CrossRef]

- Dylewski, R.; Adamczyk, J. Study on ecological cost-effectiveness for the thermal insulation of building external vertical walls in Poland. J. Clean. Prod. 2016, 133, 467–478. [Google Scholar] [CrossRef]

- Sierra-Pérez, J.; Boschmonart-Rives, J.; Gabarrell, X. Environmental assessment of façade-building systems and thermal insulation materials for different climatic conditions. J. Clean. Prod. 2016, 113, 102–113. [Google Scholar] [CrossRef]

- Minarovičová, K.; Dlhý, D. Environmentally safe system for treatment of biocorrosion of ETICS. MATEC Web Conf. 2018, 146, 03005. [Google Scholar] [CrossRef][Green Version]

- Sattler, S.; Österreicher, D. Assessment of sustainable construction measures in building refurbishment-life cycle comparison of conventional and Multi-Active Façade systems in a social housing complex. Sustainability 2019, 11, 4487. [Google Scholar] [CrossRef]

- Silvestre, J.D.; Castelo, A.M.P.; Silva, J.J.B.C.; Brito, J.M.C.L.; Pinheiro, M.D. Retrofitting a building’s envelope: Sustainability performance of ETICS with ICB or EPS. Appl. Sci. 2019, 9, 1285. [Google Scholar] [CrossRef]

- Michałowski, B.; Marcinek, M.; Tomaszewska, J.; Czernik, S.; Piasecki, M.; Geryło, R.; Michalak, J. Charakterystyka środowiskowa systemów ETICS w latach 2014-2019 (Environmental characteristics of the ETICS systems between 2014 and 2019). Mater. Bud. 2019, 12, 22–25. [Google Scholar]

- Michałowski, B.; Marcinek, M.; Tomaszewska, J.; Czernik, S.; Piasecki, M.; Geryło, R.; Michalak, J. Influence of rendering type on the environmental characteristics of expanded polystyrene-based external thermal insulation composite system. Buildings 2020, 10, 47. [Google Scholar] [CrossRef]

- Librelotto, L.I.; Kekez, M.; Bártolo, H.M.G. The environmental impact of ETICS layer: A case of study with life cycle assessment (LCA) from environmental product declaration (EPD) in Portugal. MIX Sustentável 2020, 6, 139–148. [Google Scholar]

- Michalak, J.; Czernik, S.; Marcinek, M.; Michałowski, B. Environmental burdens of external thermal insulation systems. expanded polystyrene vs. mineral wool: Case study from Poland. Sustainability 2020, 12, 4532. [Google Scholar] [CrossRef]

- Kraus, M.; Žáková, K.; Žák, J. Economic-environmental and technological assessment of ETICS. EasyChair 2020, 3425. [Google Scholar]

- Matos, M.; Soares, L.; Silva, L.; Sequeira, P.; Carvalho, J. Life cycle assessment of an ETICS system composed of a natural insulation material: A case study of a system using an insulation cork board (ICB). In Portugal SB13 Contribution of Sustainable Building to Meet EU 20-20-20 Targets; Multicomp - Artes Gráficas, Lda: Guimarães, Portugal, 2013; Chapter 11; pp. 855–862. Available online: https://www.irbnet.de/daten/iconda/CIB_DC26483.pdf (accessed on 26 July 2020).

- Sierra-Pérez, J.; Boschmonart-Rives, J.; Gabarrell, X. Comparative Combinations of Façade-Building Systems and Thermal Insulation Materials for Different Climatic Conditions: An Environmental Assessment. Available online: https://pdfs.semanticscholar.org/89ba/d242f4b3480f363bd3851590bd433746d556.pdf (accessed on 26 July 2020).

- Braulio-Gonzalo, M.; Bovea, M.D. Environmental and cost performance of building’s envelope insulation materials to reduce energy demand: Thickness optimization. Energy Build. 2017, 150, 527–545. [Google Scholar] [CrossRef]

- Akadiri, P.O.; Chinyio, E.A.; Olomolaiye, P.O. Design of a sustainable building: A conceptual framework for implementing sustainability in the building sector. Buildings 2012, 2, 126–152. [Google Scholar] [CrossRef]

- Alhaddi, H. Triple bottom line and sustainability: A literature review. Bus. Manag. Stud. 2015, 1, 6–10. [Google Scholar] [CrossRef]

- Rezai, S.H.; Allard, F.; Abelé, C.; Doya, M. Evaluating external thermal insulation composite systems (ETICS) regarding the building’s global performance. Energy Procedia 2015, 78, 1562–1567. [Google Scholar] [CrossRef]

- Cirami, S.; Evola, G.; Gagliano, A.; Margani, G. Thermal and economic analysis of renovation strategies for a historic building in mediterranean area. Buildings 2017, 7, 60. [Google Scholar] [CrossRef]

- Sulakatko, V. Modelling the technical–economic relevance of the ETICS construction process. Buildings 2018, 8, 155. [Google Scholar] [CrossRef]

- Biolek, V.; Hanák, T. LCC estimation model: A construction material perspective. Buildings 2019, 9, 182. [Google Scholar] [CrossRef]

- Sulakatko, V.; Lill, I. The economic relevance of on-site construction activities with the External Thermal Insulation Composite System (ETICS). Int. J. Strateg. Prop. Manag. 2019, 23, 213–226. [Google Scholar] [CrossRef]

- Meschede, C. The sustainable development goals in scientific literature: A bibliometric overview at the meta-level. Sustainability 2020, 12, 4461. [Google Scholar] [CrossRef]

- Rozporządzeniu Ministra Infrastruktury i Budownictwa z Dnia 17 Listopada 2016 r. w Sprawie Sposobu Deklarowania Właściwości Użytkowych Wyrobów Budowlanych Oraz Sposobu Znakowania ich Znakiem Budowlanym (Dz. U. poz. 1966 oraz z 2018 r. poz. 1233). Available online: http://isap.sejm.gov.pl/isap.nsf/download.xsp/WDU20160001966/O/D20161966.pdf (accessed on 27 July 2020).

- Building Research Institute (ITB); Institute of Ceramics and Building Materials (ICiMB); Institute of Mechanized Construction and Rock Mining (IMBiGS). Warunki Oceny Właściwości Użytkowych Wyrobu Budowlanego WO-KOT/04/02–Złożone Zestawy Izolacji Cieplnej z Wyprawami Tynkarskimi (ETICS) z Zastosowaniem Wyrobów ze Styropianu, 1st ed.; Building Research Institute (ITB): Warsaw, Poland, 2018. [Google Scholar]

- Building Research Institute (ITB); Institute of Ceramics and Building Materials (ICiMB); Institute of Mechanized Construction and Rock Mining (IMBiGS). Warunki Oceny Właściwości Użytkowych Wyrobu Budowlanego WO-KOT/04/01—Złożone Zestawy Izolacji Cieplnej z Wyprawami Tynkarskimi (ETICS) z Zastosowaniem Wyrobów z Wełny Mineralnej, 1st ed.; Building Research Institute (ITB): Warsaw, Poland, 2018. [Google Scholar]

- Building Research Institute (ITB). National Technical Approval ITB-AT-9090/2016 Zestaw Wyrobów do Wykonywania Ociepleń Ścian Zewnętrznych Budynków Systemem Atlas ETICS; Building Research Institute (ITB): Warsaw, Poland, 2016. [Google Scholar]

- Building Research Institute (ITB). National Technical Approval ITB-AT15-2930/2016 Zestaw Wyrobów do Wykonywania Ociepleń Ścian Zewnętrznych Budynków Systemem Atlas ROKER; Building Research Institute (ITB): Warsaw, Poland, 2016. [Google Scholar]

- Atlas. Environmental Product Declaration. Atlas ETICS External Thermal Insulation Composite System with Expanded Polystyrene Boards (EPS), Certificate No 078/2019; Atlas: Warsaw, Poland, 2019. [Google Scholar]

- Atlas. Environmental Product Declaration. Atlas ETICS External Thermal Insulation Composite System with Mineral Wool Boards (MW), Certificate No 080/2019; Atlas: Warsaw, Poland, 2019. [Google Scholar]

- European Committee for Standardization (CEN). EN 15804:2012+A2:2019 Sustainability of Construction Works—Environmental Product Declarations—Core Rules for the Product Category of Construction Products; European Committee for Standardization (CEN): Brussels, Belgium, 2019. [Google Scholar]

- International Organization for Standardization (ISO). ISO 14025:2006 Environmental Labels and Declarations—Type III Environmental Declarations—Principles and Procedures; International Organization for Standardization (ISO): Geneva, Switzerland, 2006. [Google Scholar]

- Albrecht, W.; Schwitalla, C. Rückbau, Recycling und Verwertung von WDVS: Möglichkeiten der Wiederverwertung von Bestandteilen des WDVS nach dessen Rückbau durch Zuführung in den Produktionskreislauf der Dämmstoffe bzw. Downcycling in die Produktion minderwertiger Güter bis hin zur energetischen Verwertung; Fraunhofer IRB Verlag: Stuttgart, Germany, 2015. [Google Scholar]

- Eurostat. The statistical office of the European Union. NACE Rev. 2 Statistical Classification of Economic Activities in the European Community; Publications Office of the European Union: Luxembourg, 2020. [Google Scholar]

- Muntean, M.; Guizzardi, D.; Schaaf, E.; Crippa, M.; Solazzo, E.; Olivier, J.G.J.; Vignati, E. Fossil CO2 Emissions of All World Countries–2018 Report; European Commission, EU Science Hub: Luxembourg, 2018. [Google Scholar]

- European Environment Agency (EEA). The European Environment–State and Outlook 2020. Knowledge for the Transition to a Sustainable Europe; Publications Office of the European Union: Luxembourg, 2019; ISBN 9789294800909. [Google Scholar]

- European Committee for Standardization (CEN). EN 197-1:2012 Cement Part 1: Composition, Specifications and Conformity Criteria for Common Cements; European Committee for Standardization (CEN): Brussels, Belgium, 2012. [Google Scholar]

- Stowarzyszenie Producentów Cementu. Environmental Product Declaration, Cements CEM I, CEM II, CEM III, CEM IV, CEM V Produced in Poland, Certificate No 116/2020; Stowarzyszenie Producentów Cementu: Cracow, Poland, 2020. [Google Scholar]

- Palumbo, E.; Soust-Verdaguer, B.; Llatas, C.; Traverso, M. How to obtain accurate environmental impacts at early design stages in BIM when using environmental product declaration. A method to support decision-making. Sustainability 2020, 12, 6927. [Google Scholar] [CrossRef]

- Czarnecki, L.; Kaproń, M. Sustainable construction as a research area. Int. J. Soc. Mater. Eng. Resour. 2010, 17, 99–106. [Google Scholar] [CrossRef]

- Czarnecki, L.; Van Gemert, D. Innovation in construction materials engineering versus sustainable development. Bull. Pol. Acad. Sci. Tech. 2017, 65, 765–771. [Google Scholar] [CrossRef][Green Version]

| Component | Component Description | Quantity/m2 ETICS with EPS | Quantity/m2 ETICS with MW |

|---|---|---|---|

| Adhesive for bonding | Modified cementitious adhesives | 4.5 kg | 4.5–5.5 kg |

| Insulation 1 | Prefabricated EPS board or MW panel. 2 | ≈1.35 kg | 3.5–4.5 kg |

| Adhesive for base coat | Modified cementitious adhesives | 5.5 kg | 5.5–6.5 kg |

| Glass fiber mesh 1 | Alkaline-resistant glass mesh with nominal weight of 150 or 165 g/cm2. | ≥0.15 kg | ≥0.15 kg |

| Key coat | Dispersion-based key coat with mineral/quartz fillers. | ≈0.2 kg | ≈0.3 kg |

| Finishing coat | Modified cementitious render. | 2.0–4.5 kg | 2.0–4.5 kg |

| Ancillary materials 1 | Anchors, special fittings. | - | - |

| Indicator [unit] | A1–A3 | ||||

|---|---|---|---|---|---|

| Adhesive for Bonding A 1 | Adhesive for Bonding B 1 | Adhesive for a Base Coat X | Adhesive for a Base Coat Y 2 | Adhesive for a Base Coat Z 2 | |

| Environmental impacts per 1 kg of product | |||||

| GWP [kg CO2 equations] | 3.09 × 10−1 | 3.34 × 10−1 | 2.87 × 10−1 | 3.32 × 10−1 | 3.55 × 10−1 |

| ODP [kg CFC 11 equations] | 2.28 × 10−6 | 6.76 × 10−6 | 5.45 × 10−6 | 8.03 × 10−6 | 12.0 × 10−6 |

| AP [kg SO2 equations] | 8.70 × 10−4 | 1.01 × 10−3 | 9.10 × 10−4 | 1.17 × 10−3 | 1.33 × 10−3 |

| EP [kg (PO4)3- equations] | 2.27 × 10−4 | 1.74 × 10−4 | 1.78 × 10−4 | 2.15 × 10−4 | 2.04 × 10−4 |

| POCP [kg Ethene equations] | 6.57 × 10−5 | 6.79 × 10−5 | 6.89 × 10−5 | 10.8 × 10−5 | 9.00 × 10−5 |

| (ADP-elements) [kg Sb equations] | 1.67 × 10−4 | 4.96 × 10−4 | 4.77 × 10−4 | 5.89 × 10−4 | 8.77 × 10−4 |

| (ADP-fossil fuels) [MJ] | 8.23 × 10−1 | 5.81 × 10−1 | 7.39 × 10−1 | 8.66 × 10−1 | 6.85 × 10−1 |

| Environmental aspects related to the consumption of raw materials per 1 kg of product | |||||

| PERT [MJ] | 4.66 × 10−1 | 2.24 × 10−1 | 4.54 × 10−1 | 1.31 × 10−1 | 4.54 × 10−1 |

| PENRT [MJ] | 6.68 × 10−1 | 4.98 × 10−1 | 6.69 × 10−1 | 7.59 × 10−1 | 5.76 × 10−1 |

| Indicator [Unit] | A1–A3 | |

|---|---|---|

| Adhesive for Bonding | Adhesive for Base Coat | |

| Environmental impacts per 1 kg of product | ||

| GWP [kg CO2 equations] | 3.57 × 10−1 | 4.12 × 10−1 |

| ODP [kg CFC 11 equations] | 8.01 × 10−6 | 1.00 × 10−5 |

| AP [kg SO2 equations] | 1.06 × 10−3 | 1.28 × 10−3 |

| EP [kg (PO4)3− equations] | 1.41 × 10−4 | 1.96× 10−4 |

| POCP [kg Ethene equations] | 8.38 × 10−5 | 9.40 × 10−5 |

| (ADP-elements) [kg Sb equations] | 5.87 × 10−4 | 7.37 × 10−4 |

| (ADP-fossil fuels) [MJ] | 5.73 × 10−1 | 6.18 × 10−1 |

| Environmental aspects related to the consumption of raw materials per 1 kg of product | ||

| PERT [MJ] | 4.61 × 10−1 | 4.74 × 10−1 |

| PENRT [MJ] | 5.69 × 10−1 | 5.29 × 10−1 |

| Insulation Material Thickness in ETICS [cm] | GWP [t CO2 Equations] | |

|---|---|---|

| EPS | MW | |

| 10 | 348,000 | 1,060,000 |

| 25 | 628,000 | 2,348,000 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Czernik, S.; Marcinek, M.; Michałowski, B.; Piasecki, M.; Tomaszewska, J.; Michalak, J. Environmental Footprint of Cementitious Adhesives—Components of ETICS. Sustainability 2020, 12, 8998. https://doi.org/10.3390/su12218998

Czernik S, Marcinek M, Michałowski B, Piasecki M, Tomaszewska J, Michalak J. Environmental Footprint of Cementitious Adhesives—Components of ETICS. Sustainability. 2020; 12(21):8998. https://doi.org/10.3390/su12218998

Chicago/Turabian StyleCzernik, Sebastian, Marta Marcinek, Bartosz Michałowski, Michał Piasecki, Justyna Tomaszewska, and Jacek Michalak. 2020. "Environmental Footprint of Cementitious Adhesives—Components of ETICS" Sustainability 12, no. 21: 8998. https://doi.org/10.3390/su12218998

APA StyleCzernik, S., Marcinek, M., Michałowski, B., Piasecki, M., Tomaszewska, J., & Michalak, J. (2020). Environmental Footprint of Cementitious Adhesives—Components of ETICS. Sustainability, 12(21), 8998. https://doi.org/10.3390/su12218998