Current Sustainable Trends of Using Waste Materials in Concrete—A Decade Review

Abstract

:1. Introduction

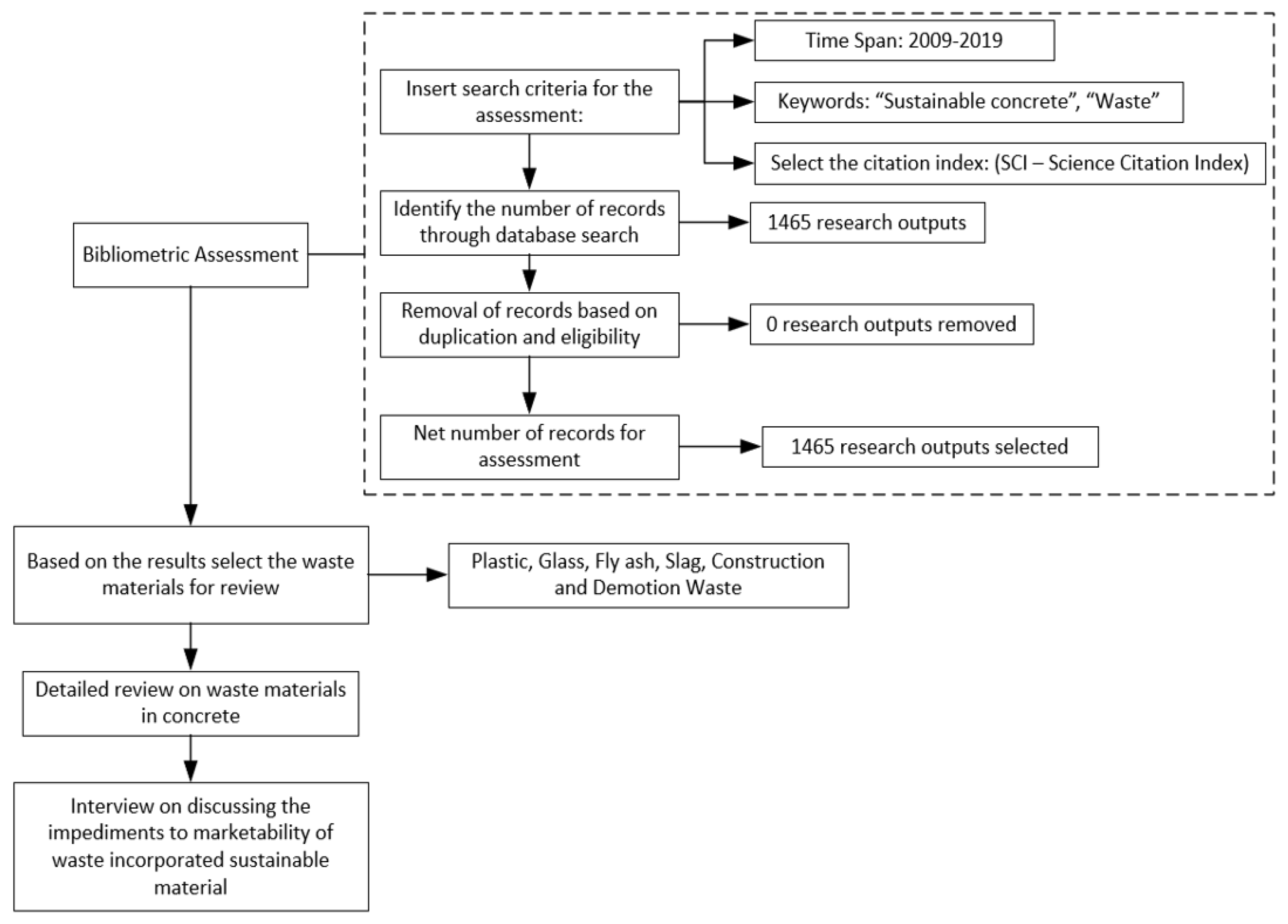

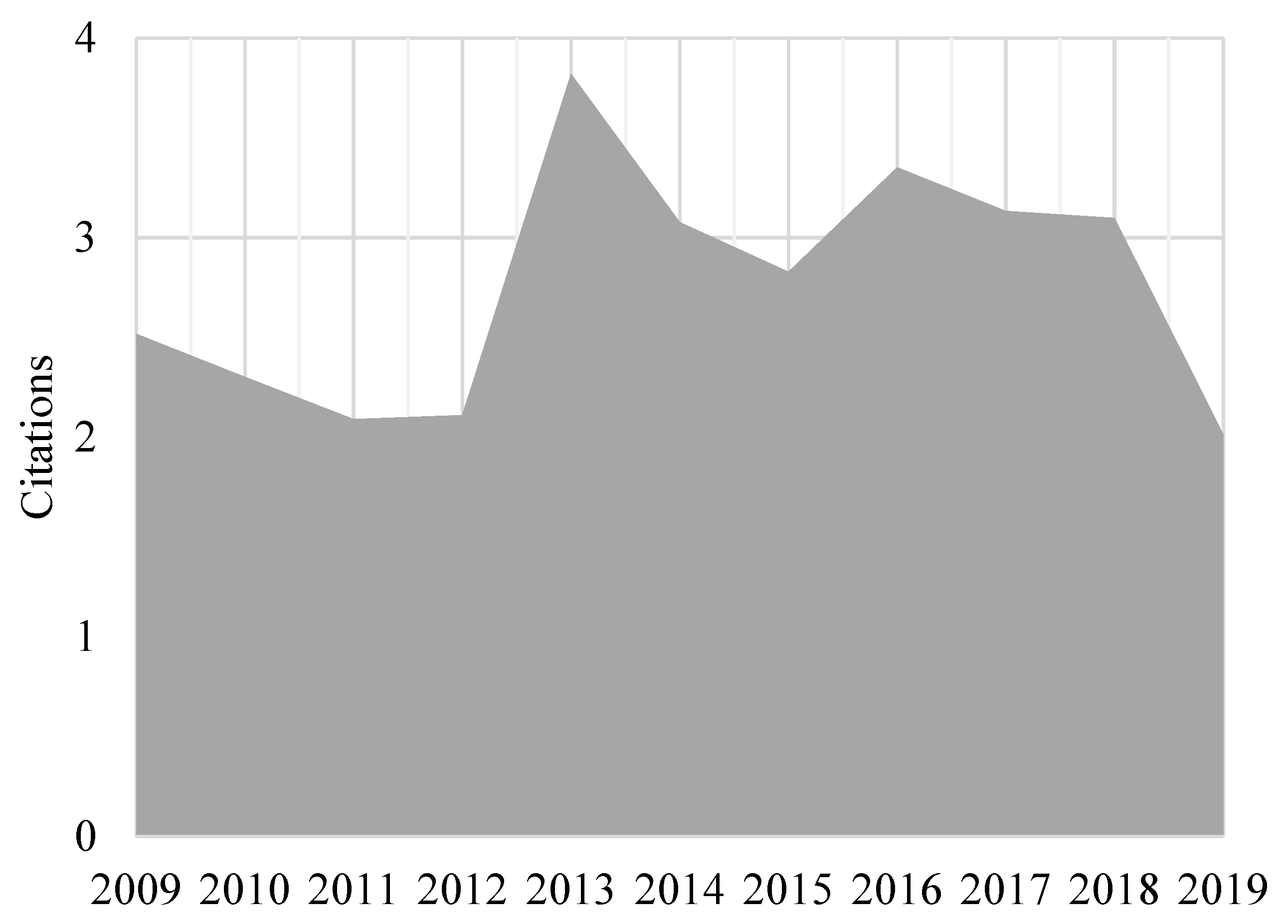

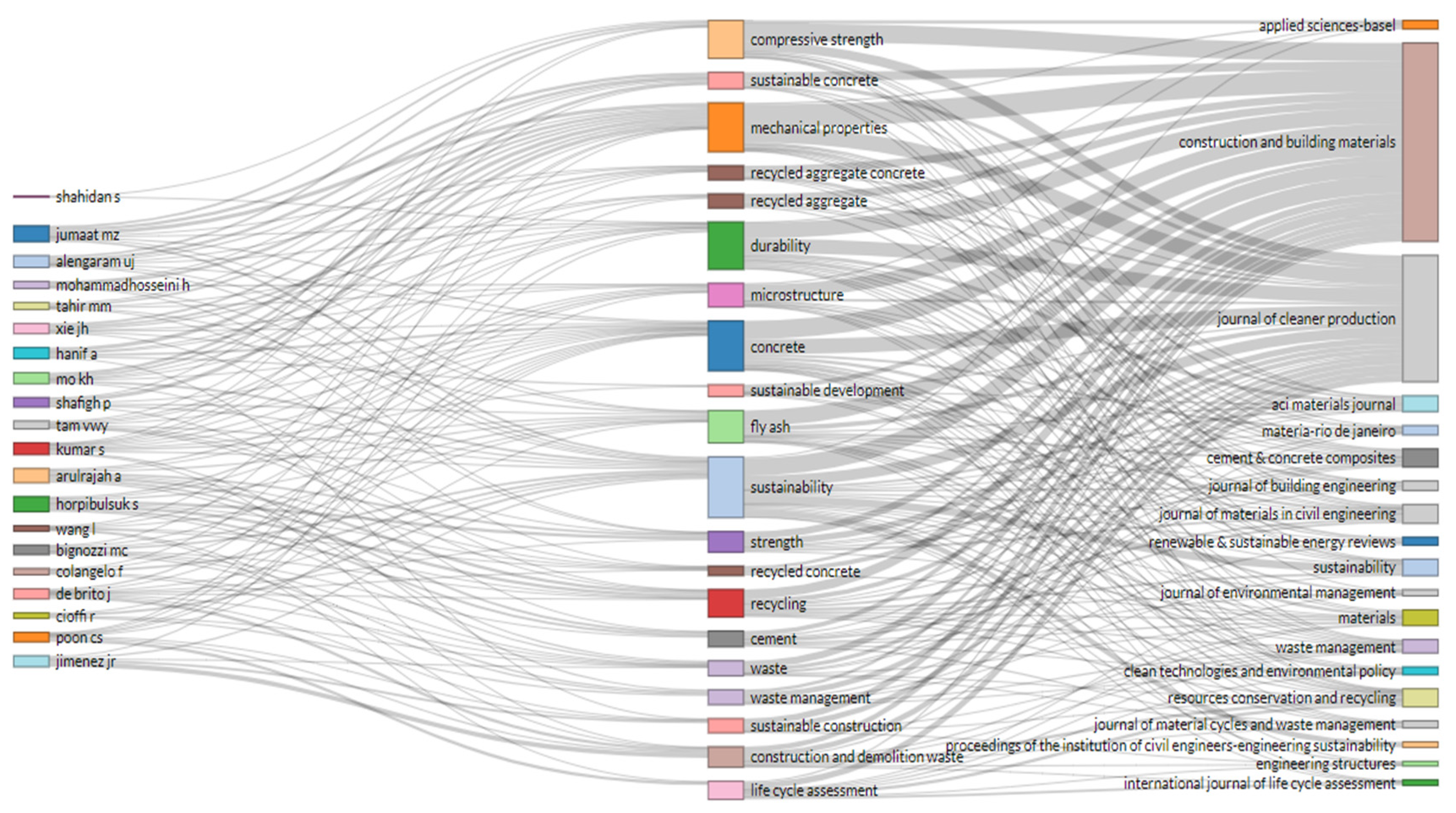

2. Research Significance and Methodologies

3. Bibliometric Analysis Findings

Summary of Findings

- Fly ash and recycled aggregate used in concrete production are the two major extensively researched waste materials;

- Use of waste materials in concrete as cement replacement and aggregate replacement are the major research focus of the sample;

- Only a handful of studies considered environmental benefits by using life cycle assessment to benchmark environmental sustainability benefits;

- Other sustainable benefits including economic benefits, social impacts, and other sustainable criterion were seldom considered in the available publications;

- Mechanical properties (mainly compressive strength) in waste-incorporated concrete were mostly researched in Asian countries while European countries (Italy, USA, and United Kingdom) focused more on waste management and sustainable development of these materials;

- Journal of Construction and Building Materials and Journal of Cleaner Production are the two prominent journals with research publications related to concrete with waste materials;

4. Plastic Waste in Concrete and Mortar

4.1. Plastic Aggregates and Fibers

4.2. Other Applications of Plastic in Concrete

4.3. Sustainability Aspects of Using Plastic Waste in Concrete

4.3.1. Environmental Performance of Using Plastic Waste

4.3.2. Durability Properties and Thermal/Fire Performance

5. Glass Waste in Concrete

5.1. Introduction

5.2. Sustainability Aspects of Using Glass Waste in Concrete

5.2.1. Environmental Performance

5.2.2. Durability Properties and Thermal/Fire Performance

6. Fly Ash and Slag in Concrete

6.1. Fly Ash in Concrete Materials

6.2. Sustainability Aspects of Using Fly Ash in Concrete

6.3. Slag in Concrete Materials

6.4. Sustainability Aspects of Using Slag in Concrete

| No | Waste Type | Main Study Focuses | Application/s | Reference/s |

|---|---|---|---|---|

| 1 | Glass Aggregates | Mechanical, physical, durability, and thermal properties Mechanical, physical, durability, and thermal properties Mechanical, physical, durability, and thermal properties Mechanical, physical, durability, and thermal properties Mechanical, physical, and durability properties Mechanical, physical, and durability properties Mechanical, physical, and durability properties Mechanical, physical, and durability properties Mechanical, physical, durability, and thermal properties Mechanical, physical, and durability properties Mechanical and physical properties | OPC Concrete Lightweight Concrete SC Concrete Polymer Concrete Concrete paving blocks Concrete tiles, Translucent and Photocatalytic Concrete Dry-mix Pervious Concrete OPC Mortar SC Mortar Adhesive Mortar | [98,106,107,118,127,136,137,138,141,143,165,166,167,168,169,170,171,172,173,174] [134,142,175,176,177,178] [100,147,179,180,181] [115,144,182] [115,116,183,184] [102] [139] [146] [101,103,104,105,108,113,114,117,126,132,135,145,185,186,187,188,189,190,191,192,193,194,195,196,197,198] [199,200] [201] |

| 2 | Glass Cement | Mechanical, physical, durability, and thermal properties Mechanical, physical, and durability properties Mechanical and physical properties Mechanical, physical, and thermal properties Mechanical, physical, and durability properties Mechanical, physical, and durability properties Mechanical, physical, and durability properties Mechanical properties Mechanical, physical, durability, and thermal properties Mechanical, physical, and durability properties Mechanical, physical, and durability properties Mechanical and physical properties | OPC Concrete SC Concrete High-performance Concrete Polymer Concrete Concrete Pavements Concrete slabs and walls Dry-cast Concrete blocks Concrete Beams and Columns OPC Mortar Geopolymer Mortar Reinforced and repair Mortar Alkali-activated Mortar and cement | [107,119,120,124,128,131,133,176,202,203,204,205,206,207,208,209,210,211,212,213,214,215,216,217,218,219,220,221] [121,222,223] [224,225,226,227] [228] [229] [230] [60] [231,232] [109,111,112,122,123,125,129,130,191,192,193,194,195,196,197,233,234,235,236,237,238,239,240] [241,242,243,244,245,246] [110,247] [248,249,250,251,252,253] |

| 3 | Plastic Aggregates | Mechanical, physical, durability, and thermal properties Mechanical and durability properties Mechanical, physical, and durability properties Mechanical, physical, and durability properties Mechanical, physical, durability, thermal, and acoustic properties Mechanical, physical, and durability properties Mechanical Mechanical, physical, durability, and thermal properties Mechanical, physical, and durability properties | OPC Concrete and mortar Concrete footpaths Concrete for dam repair Dry-cast concrete blocks Lightweight concrete SC concrete and mortar Polymer Concrete OPC mortar Lightweight mortar | [62,64,70,72,83,87,90,254,255,256,257,258,259,260,261,262,263,264,265] [266] [79] [60] [63,73,82,267] [66,268,269,270] [271] [61,67,71,81,272,273] [73,80] |

| 4 | Plastic Fibers | Mechanical, physical, durability, and thermal properties Mechanical, physical, and durability properties Mechanical and physical properties Mechanical, durability, and environmental properties Mechanical and durability properties Durability properties Durability properties Mechanical properties Mechanical properties Durability properties Mechanical, physical, and durability properties Mechanical and physical properties Mechanical and physical properties | OPC Concrete Lightweight Concrete SC Concrete Concrete footpaths Concrete beams Concrete slabs Pre-cast concrete panels Geopolymer Concrete High-performance Concrete Recycled aggregate Concrete OPC Mortar Strain-hardening cementitious composite Wet-mix shotcrete | [68,69,75,76,77,84,85,88,89,274,275,276,277,278,279,280,281,282,283,284,285,286,287,288,289,290,291,292,293,294,295,296,297,298] [65,267,299] [300,301,302] [58,303] [74,304] [305] [59,306] [59] [307] [78] [308,309] [310] [311] |

| 7 | Fly ash & slag | Mechanical, physical, thermal, and durability properties Mechanical and physical properties Mechanical properties Mechanical and durability properties Mechanical and thermal properties Mechanical and physical properties Mechanical and physical properties Mechanical and durability properties Mechanical, physical, and durability properties Mechanical, physical, thermal, and durability properties Mechanical and physical properties Mechanical, physical, and durability properties Mechanical and durability properties Physical properties Mechanical and physical properties Mechanical and physical properties Mechanical properties Mechanical properties Mechanical and physical properties Mechanical, physical, and durability properties Mechanical properties Mechanical and physical properties Mechanical and physical properties Mechanical, physical, and durability properties | FA Pre-cast concrete FA RCA concrete beams FA waste tile aggregate concrete FA concrete roof tiles FA masonry bricks FA concrete beams and slabs FA tunnel lining FA fiber concrete beams FA road concrete FA dam reinforced concrete FA and tire asphalt mix FA railway roadbeds FA with SL concrete pavements FA cement mortar spray coating FA with rubber concrete pavements FA with SL geopolymer bricks SL concrete bridges SL with RCA asphalt SL cement mortar SL fiber prestressed concrete SL concrete columns SL concrete spray SL concrete and fiber pavements SL aggregate base course | [312] [313,314] [315] [316] [317] [318,319] [320] [321] [322] [323] [324,325] [326] [327] [328] [329] [330] [331] [332] [333,334] [335,336] [337] [338] [339,340,341] [342] |

7. Construction and Demolition (C&D) Waste Reuse in Concrete

7.1. Introduction

7.2. Sustainability Aspects of Using C&D Waste in Concrete

8. Findings and Further Analysis

8.1. Future Considerations and Discussions on Using Waste Products in Concrete

8.1.1. Investigation of Compliance Requirements of Materials

8.1.2. Economic Benefits of Sustainable Materials

8.1.3. Availability of Waste Material and Demand

8.1.4. Quality Control Considerations

8.1.5. Social Acceptability

8.1.6. Government Initiatives

9. Conclusions, Limitations, and Future Research

- The current study aimed to review a decade of research studies on sustainable concrete which uses waste materials to replace virgin raw materials. Firstly, a bibliometric assessment was performed to identify the key research trends associated with sustainable concrete with waste materials. In the bibliometric assessment, 1465 research publications identified the most influential countries in undertaking experimental and analytical studies related to sustainable concrete. The results also highlighted journals with the most publications on sustainable concrete, authors with the most publications, and the publication trend within the last decade. Additionally, it was found that fly ash and recycled aggregate are the most researched waste materials, and that cement and aggregate substitutes have been the most popular applications. Only a few studies investigated the sustainable performance of concrete, with the research focus of majority of the studies consisting of experimental testing of mechanical and durability properties. Hence, it is recommended that future research efforts are made towards analyzing the economic, environmental, and social impacts of incorporating waste products in mortar and concrete mixes.

- The findings of the review were based on the reviewed publications undertaken in the past decade only. Further analyses and interpretations can be undertaken by conducting reviews with a large timescale;

- The focus group interview included limited number of experts in the field and therefore further validation is encouraged in future studies to further justify or criticize the observations highlighted in the current study;

- The review only focused on the major waste types highlighted through the bibliometric analysis from Bibiliometrix.org. There could be other studies that use different waste materials in concrete and these could be of key relevance;

- The review investigated the current issues and considerations that could affect the commercialization of the building products manufactured from waste materials. However, these issues can change based on future changes in regulations.

Author Contributions

Funding

Conflicts of Interest

References

- Department of the Envrionment and Energy, Australian Government. Analysis of Australia’s Municipal Recycling Infrastructure Capacity October 2018 Commonwealth of Australia 2018. Available online: https://www.environment.gov.au/system/files/resources/f0196d2e-9040-4547-8cb6-8b433923b53d/files/waste-stocktake-report.pdf (accessed on 11 August 2020).

- Guo, Z.; Kong, X.; Zhang, J.; Sun, Y.; Tu, A.; Jiang, T. Life-cycle assessment of concrete building blocks incorporating recycled concrete aggregates—A case study in China. In Advances in Construction and Demolition Waste Recycling; Elsevier: Amsterdam, The Netherlands, 2020; pp. 515–535. [Google Scholar]

- Birtles, B. Beijing Churns out 25,000 Tonnes of Rubbish Every Day—Here’s How It Deals With its Waste Crisis. Available online: https://www.abc.net.au/news/2018-08-07/how-beijing-deals-with-waste-crisis/10078026 (accessed on 28 August 2020).

- Luo, W.; Sandanayake, M.; Zhang, G. Direct and indirect carbon emissions in foundation construction—Two case studies of driven precast and cast-in-situ piles. J. Clean. Prod. 2019, 211, 1517–1526. [Google Scholar] [CrossRef]

- Sandanayake, M.; Gunasekara, C.; Law, D.; Zhang, G.; Setunge, S. Greenhouse gas emissions of different fly ash based geopolymer concretes in building construction. J. Clean. Prod. 2018, 204, 399–408. [Google Scholar] [CrossRef]

- Sandanayake, M.S. Models and Toolkit to Estimate and Analyse the Emissions and Environmental Impacts of Building Construction; Rmit University: Melbourne, Asutrlia, 2016. [Google Scholar]

- Chau, C.K.; Yik, F.W.H.; Hui, W.K.; Liu, H.C.; Yu, H.K. Environmental impacts of building materials and building services components for commercial buildings in Hong Kong. J. Clean. Prod. 2007, 15, 1840–1851. [Google Scholar] [CrossRef]

- Chau, C.K.; Hui, W.K.; Ng, W.Y.; Powell, G. Assessment of CO2 emissions reduction in high-rise concrete office buildings using different material use options. Resour. Conserv. Recycl. 2012, 61, 22–34. [Google Scholar] [CrossRef]

- Ruth, M. Technology change in US iron and steel production: Implications for material and energy use, and CO2 emissions. Resour. Policy 1995, 21, 199–214. [Google Scholar] [CrossRef]

- Hong, J.; Shen, G.Q.; Feng, Y.; Lau, W.S.-t.; Mao, C. Greenhouse gas emissions during the construction phase of a building: A case study in China. J. Clean. Prod. 2015, 103, 249–259. [Google Scholar] [CrossRef] [Green Version]

- Yan, H.; Shen, Q.; Fan, L.C.H.; Wang, Y.; Zhang, L. Greenhouse gas emissions in building construction: A case study of One Peking in Hong Kong. Build. Environ. 2010, 45, 949–955. [Google Scholar] [CrossRef] [Green Version]

- García-Segura, T.; Yepes, V.; Alcalá, J. Life cycle greenhouse gas emissions of blended cement concrete including carbonation and durability. Int. J. Life Cycle Assess. 2014, 19, 3–12. [Google Scholar] [CrossRef]

- Fan, C.; Miller, S.A. Reducing greenhouse gas emissions for prescribed concrete compressive strength. Constr. Build. Mater. 2018, 167, 918–928. [Google Scholar] [CrossRef]

- Sandanayake, M.; Lokuge, W.; Zhang, G.; Setunge, S.; Thushar, Q. Greenhouse gas emissions during timber and concrete building construction—A scenario based comparative case study. Sustain. Cities Soc. 2018, 38, 91–97. [Google Scholar] [CrossRef] [Green Version]

- Huang, B.; Chen, Y.; McDowall, W.; Türkeli, S.; Bleischwitz, R.; Geng, Y. Embodied GHG emissions of building materials in Shanghai. J. Clean. Prod. 2019, 210, 777–785. [Google Scholar] [CrossRef]

- Sandanayake, M.; Gunasekara, C.; Law, D.; Zhang, G.; Setunge, S.; Wanijuru, D. Sustainable criterion selection framework for green building materials—An optimisation based study of fly-ash Geopolymer concrete. Sustain. Mater. Technol. 2020, 25, e00178. [Google Scholar] [CrossRef]

- Hossain, M.U.; Poon, C.S. Comparative LCA of wood waste management strategies generated from building construction activities. J. Clean. Prod. 2018, 177, 387–397. [Google Scholar] [CrossRef]

- Meyer, C. The greening of the concrete industry. Cem. Concr. Compos. 2009, 31, 601–605. [Google Scholar] [CrossRef]

- Pahlevani, F.; Sahajwalla, V. From waste glass to building materials–An innovative sustainable solution for waste glass. J. Clean. Prod. 2018, 191, 192–206. [Google Scholar]

- Lu, J.-X.; Poon, C.S. 6—Recycling of waste glass in construction materials. In New Trends in Eco-Efficient and Recycled Concrete; de Brito, J., Agrela, F., Eds.; Woodhead Publishing: Oxford, UK, 2019; pp. 153–167. [Google Scholar] [CrossRef]

- Chandra, S. Waste Materials Used in Concrete Manufacturing; Elsevier: Amsterdam, The Netherlands, 1996. [Google Scholar]

- Yahya, K.; Halim Boussabaine, A. Eco-costing of construction waste. Manag. Environ. Qual. Int. J. 2006, 17, 6–19. [Google Scholar] [CrossRef]

- Solís-Guzmán, J.; Marrero, M.; Montes-Delgado, M.V.; Ramírez-de-Arellano, A. A Spanish model for quantification and management of construction waste. Waste Manag. 2009, 29, 2542–2548. [Google Scholar] [CrossRef]

- Silva, R.V.; de Brito, J.; Dhir, R.K. Properties and composition of recycled aggregates from construction and demolition waste suitable for concrete production. Constr. Build. Mater. 2014, 65, 201–217. [Google Scholar] [CrossRef]

- Sandanayake, M.; Zhang, G.; Setunge, S. Estimation of environmental emissions and impacts of building construction—A decision making tool for contractors. J. Build. Eng. 2018. [Google Scholar] [CrossRef]

- Callejas, I.J.A.; Durante, L.C.; Oliveira, A.S.d. Thermal resistance and conductivity of recycled construction and demolition waste (RCDW) concrete blocks. Rem-Int. Eng. J. 2017, 70, 167–173. [Google Scholar] [CrossRef]

- Cardoso, R.; Silva, R.V.; de Brito, J.; Dhir, R. Use of recycled aggregates from construction and demolition waste in geotechnical applications: A literature review. Waste Manag. 2016, 49, 131–145. [Google Scholar] [CrossRef] [PubMed]

- Tabsh, S.W.; Abdelfatah, A.S. Influence of recycled concrete aggregates on strength properties of concrete. Constr. Build. Mater. 2009, 23, 1163–1167. [Google Scholar] [CrossRef]

- Rao, A.; Jha, K.N.; Misra, S. Use of aggregates from recycled construction and demolition waste in concrete. Resour. Conserv. Recycl. 2007, 50, 71–81. [Google Scholar] [CrossRef]

- Flower, D.J.; Sanjayan, J.G. Green house gas emissions due to concrete manufacture. Int. J. Life Cycle Assess. 2007, 12, 282–288. [Google Scholar] [CrossRef]

- Kong, D.L.; Sanjayan, J.G. Effect of elevated temperatures on geopolymer paste, mortar and concrete. Cem. Concr. Res. 2010, 40, 334–339. [Google Scholar] [CrossRef]

- Akadiri, P.O.; Olomolaiye, P.O.; Chinyio, E.A. Multi-criteria evaluation model for the selection of sustainable materials for building projects. Autom. Constr. 2013, 30, 113–125. [Google Scholar] [CrossRef]

- Florez, L.; Castro-Lacouture, D. Optimization model for sustainable materials selection using objective and subjective factors. Mater. Des. 2013, 46, 310–321. [Google Scholar] [CrossRef]

- Ramezanianpour, A.; Ghahari, S.; Ramezaninapour, A.; Esmaeili, K. Effect of steam curing on mechanical properties of self-compacting concrete containing pozzolan. Spec. Publ. 2015, 303, 45–56. [Google Scholar]

- Ghahari, S.; Mohammadi, A.; Ramezanianpour, A. Performance assessment of natural pozzolan roller compacted concrete pavements. Case Stud. Constr. Mater. 2017, 7, 82–90. [Google Scholar] [CrossRef]

- Sargam, Y.; Wang, K.; Alleman, J.E. Effects of modern concrete materials on thermal conductivity. J. Mater. Civ. Eng. 2020, 32, 04020058. [Google Scholar] [CrossRef]

- Liu, J.-W.; Huang, L.-C. Detecting and visualizing emerging trends and transient patterns in fuel cell scientific literature. In Proceedings of the 2008 4th International Conference on Wireless Communications, Networking and Mobile Computing, Dalian, China, 12–17 October 2008; pp. 1–4. [Google Scholar]

- Van Eck, N.J.; Waltman, L. Visualizing bibliometric networks. In Measuring Scholarly Impact; Springer: Berlin/Heidelberg, Germany, 2014; pp. 285–320. [Google Scholar]

- Synnestvedt, M.B.; Chen, C.; Holmes, J.H. CiteSpace II: Visualization and knowledge discovery in bibliographic databases. In Proceedings of the AMIA Annual Symposium, Washington, DC, USA, 22–26 October 2005; p. 724. [Google Scholar]

- Aria, M.; Cuccurullo, C. bibliometrix: An R-tool for comprehensive science mapping analysis. J. Informetr. 2017, 11, 959–975. [Google Scholar] [CrossRef]

- Saikia, N.; De Brito, J. Use of plastic waste as aggregate in cement mortar and concrete preparation: A review. Constr. Build. Mater. 2012, 34, 385–401. [Google Scholar] [CrossRef]

- De Brito, J.; Saikia, N. Recycled Aggregate in Concrete: Use of Industrial, Construction and Demolition Waste; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Gu, L.; Ozbakkaloglu, T. Use of recycled plastics in concrete: A critical review. Waste Manag. 2016, 51, 19–42. [Google Scholar] [CrossRef]

- Sharma, R.; Bansal, P.P. Use of different forms of waste plastic in concrete–a review. J. Clean. Prod. 2016, 112, 473–482. [Google Scholar] [CrossRef]

- Usman, A.; Sutanto, M.H.; Napiah, M. Effect of Recycled Plastic in Mortar and Concrete and the Application of Gamma Irradiation-A Review. In Proceedings of the E3S Web of Conferences, Polanica-Zdrój, Poland, 16–18 April 2018; p. 05027. [Google Scholar]

- Merli, R.; Preziosi, M.; Acampora, A.; Lucchetti, M.C.; Petrucci, E. Recycled fibers in reinforced concrete: A systematic literature review. J. Clean. Prod. 2019, 248, 119207. [Google Scholar] [CrossRef]

- Li, X.; Ling, T.-C.; Mo, K.H. Functions and impacts of plastic/rubber wastes as eco-friendly aggregate in concrete–A review. Constr. Build. Mater. 2020, 240, 117869. [Google Scholar] [CrossRef]

- Faraj, R.H.; Ali, H.F.H.; Sherwani, A.F.H.; Hassan, B.R.; Karim, H. Use of recycled plastic in self-compacting concrete: A comprehensive review on fresh and mechanical properties. J. Build. Eng. 2020, 30, 101283. [Google Scholar] [CrossRef]

- Jassim, A.K. Recycling of polyethylene waste to produce plastic cement. Procedia Manuf. 2017, 8, 635–642. [Google Scholar] [CrossRef]

- Gesoglu, M.; Güneyisi, E.; Hansu, O.; Etli, S.; Alhassan, M. Mechanical and fracture characteristics of self-compacting concretes containing different percentage of plastic waste powder. Constr. Build. Mater. 2017, 140, 562–569. [Google Scholar] [CrossRef]

- Schaefer, C.E.; Kupwade-Patil, K.; Ortega, M.; Soriano, C.; Büyüköztürk, O.; White, A.E.; Short, M.P. Irradiated recycled plastic as a concrete additive for improved chemo-mechanical properties and lower carbon footprint. Waste Manag. 2018, 71, 426–439. [Google Scholar] [CrossRef]

- Mahdi, F.; Abbas, H.; Khan, A. Strength characteristics of polymer mortar and concrete using different compositions of resins derived from post-consumer PET bottles. Constr. Build. Mater. 2010, 24, 25–36. [Google Scholar] [CrossRef]

- Mahdi, F.; Abbas, H.; Khan, A.A. Flexural, shear and bond strength of polymer concrete utilizing recycled resin obtained from post consumer PET bottles. Constr. Build. Mater. 2013, 44, 798–811. [Google Scholar] [CrossRef]

- Agyeman, S.; Obeng-Ahenkora, N.; Assiamah, S.; Twumasi, G. Exploiting recycled plastic waste as an alternative binder for paving blocks production. Case Stud. Constr. Mater. 2019, 11, e00246. [Google Scholar] [CrossRef]

- Foti, D.; Paparella, F. Impact behavior of structural elements in concrete reinforced with PET grids. Mech. Res. Commun. 2014, 57, 57–66. [Google Scholar] [CrossRef]

- Foti, D. Innovative techniques for concrete reinforcement with polymers. Constr. Build. Mater. 2016, 112, 202–209. [Google Scholar] [CrossRef]

- Dai, J.-G.; Bai, Y.-L.; Teng, J. Behavior and modeling of concrete confined with FRP composites of large deformability. J. Compos. Constr. 2011, 15, 963–973. [Google Scholar] [CrossRef]

- Yin, S.; Tuladhar, R.; Sheehan, M.; Combe, M.; Collister, T. A life cycle assessment of recycled polypropylene fibre in concrete footpaths. J. Clean. Prod. 2016, 112, 2231–2242. [Google Scholar] [CrossRef]

- Bhogayata, A.C.; Arora, N.K. Utilization of metalized plastic waste of food packaging articles in geopolymer concrete. J. Mater. Cycles Waste Manag. 2019, 21, 1014–1026. [Google Scholar] [CrossRef]

- Chidiac, S.; Mihaljevic, S. Performance of dry cast concrete blocks containing waste glass powder or polyethylene aggregates. Cem. Concr. Compos. 2011, 33, 855–863. [Google Scholar] [CrossRef]

- Hannawi, K.; Kamali-Bernard, S.; Prince, W. Physical and mechanical properties of mortars containing PET and PC waste aggregates. Waste Manag. 2010, 30, 2312–2320. [Google Scholar] [CrossRef]

- Silva, R.V.; de Brito, J.; Saikia, N. Influence of curing conditions on the durability-related performance of concrete made with selected plastic waste aggregates. Cem. Concr. Compos. 2013, 35, 23–31. [Google Scholar] [CrossRef]

- Colangelo, F.; Cioffi, R.; Liguori, B.; Iucolano, F. Recycled polyolefins waste as aggregates for lightweight concrete. Compos. Part B Eng. 2016, 106, 234–241. [Google Scholar] [CrossRef]

- Ruiz-Herrero, J.L.; Nieto, D.V.; López-Gil, A.; Arranz, A.; Fernández, A.; Lorenzana, A.; Merino, S.; De Saja, J.A.; Rodríguez-Pérez, M.Á. Mechanical and thermal performance of concrete and mortar cellular materials containing plastic waste. Constr. Build. Mater. 2016, 104, 298–310. [Google Scholar] [CrossRef]

- Sadrmomtazi, A.; Sobhani, J.; Mirgozar, M.; Najimi, M. Properties of multi-strength grade EPS concrete containing silica fume and rice husk ash. Constr. Build. Mater. 2012, 35, 211–219. [Google Scholar] [CrossRef]

- Sadrmomtazi, A.; Dolati-Milehsara, S.; Lotfi-Omran, O.; Sadeghi-Nik, A. The combined effects of waste Polyethylene Terephthalate (PET) particles and pozzolanic materials on the properties of self-compacting concrete. J. Clean. Prod. 2016, 112, 2363–2373. [Google Scholar] [CrossRef]

- Ge, Z.; Huang, D.; Sun, R.; Gao, Z. Properties of plastic mortar made with recycled polyethylene terephthalate. Constr. Build. Mater. 2014, 73, 682–687. [Google Scholar] [CrossRef]

- Mohammadhosseini, H.; Yatim, J.M.; Sam, A.R.M.; Awal, A.A. Durability performance of green concrete composites containing waste carpet fibers and palm oil fuel ash. J. Clean. Prod. 2017, 144, 448–458. [Google Scholar] [CrossRef]

- Mohammadhosseini, H.; Tahir, M.M. Durability performance of concrete incorporating waste metalized plastic fibres and palm oil fuel ash. Constr. Build. Mater. 2018, 180, 92–102. [Google Scholar] [CrossRef]

- Zéhil, G.-P.; Assaad, J.J. Feasibility of concrete mixtures containing cross-linked polyethylene waste materials. Constr. Build. Mater. 2019, 226, 1–10. [Google Scholar] [CrossRef]

- Ghernouti, Y.; Rabehi, B. Strength and durability of mortar made with plastics bag waste (MPBW). Int. J. Concr. Struct. Mater. 2012, 6, 145–153. [Google Scholar] [CrossRef] [Green Version]

- Frigione, M. Recycling of PET bottles as fine aggregate in concrete. Waste Manag. 2010, 30, 1101–1106. [Google Scholar] [CrossRef] [PubMed]

- Akçaözoğlu, S.; Atiş, C.D.; Akçaözoğlu, K. An investigation on the use of shredded waste PET bottles as aggregate in lightweight concrete. Waste Manag. 2010, 30, 285–290. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.B.; Yi, N.H.; Kim, H.Y.; Kim, J.-H.J.; Song, Y.-C. Material and structural performance evaluation of recycled PET fiber reinforced concrete. Cem. Concr. Compos. 2010, 32, 232–240. [Google Scholar] [CrossRef]

- Awal, A.; Mohammadhosseini, H.; Hossain, M.Z. Strength, modulus of elasticity and shrinkage behaviour of concrete containing waste carpet fiber. Int. J. Geomate 2015, 9, 1441–1446. [Google Scholar]

- Ozger, O.; Girardi, F.; Giannuzzi, G.; Salomoni, V.; Majorana, C.; Fambri, L.; Baldassino, N.; Di Maggio, R. Effect of nylon fibres on mechanical and thermal properties of hardened concrete for energy storage systems. Mater. Des. 2013, 51, 989–997. [Google Scholar] [CrossRef]

- Pešić, N.; Živanović, S.; Garcia, R.; Papastergiou, P. Mechanical properties of concrete reinforced with recycled HDPE plastic fibres. Constr. Build. Mater. 2016, 115, 362–370. [Google Scholar] [CrossRef] [Green Version]

- Wu, X.; Zhou, J.; Kang, T.; Wang, F.; Ding, X.; Wang, S. Laboratory Investigation on the Shrinkage Cracking of Waste Fiber-Reinforced Recycled Aggregate Concrete. Materials 2019, 12, 1196. [Google Scholar] [CrossRef] [Green Version]

- Galvão, J.C.A.; Portella, K.F.; Joukoski, A.; Mendes, R.; Ferreira, E.S. Use of waste polymers in concrete for repair of dam hydraulic surfaces. Constr. Build. Mater. 2011, 25, 1049–1055. [Google Scholar] [CrossRef]

- Coppola, B.; Courard, L.; Michel, F.; Incarnato, L.; Scarfato, P.; Di Maio, L. Hygro-thermal and durability properties of a lightweight mortar made with foamed plastic waste aggregates. Constr. Build. Mater. 2018, 170, 200–206. [Google Scholar] [CrossRef]

- Iucolano, F.; Liguori, B.; Caputo, D.; Colangelo, F.; Cioffi, R. Recycled plastic aggregate in mortars composition: Effect on physical and mechanical properties. Mater. Des. (1980–2015) 2013, 52, 916–922. [Google Scholar] [CrossRef]

- D’Alessandro, F.; Asdrubali, F.; Baldinelli, G. Multi-parametric characterization of a sustainable lightweight concrete containing polymers derived from electric wires. Constr. Build. Mater. 2014, 68, 277–284. [Google Scholar] [CrossRef]

- Akçaözoğlu, S.; Akçaözoğlu, K.; Atiş, C.D. Thermal conductivity, compressive strength and ultrasonic wave velocity of cementitious composite containing waste PET lightweight aggregate (WPLA). Compos. Part B Eng. 2013, 45, 721–726. [Google Scholar] [CrossRef]

- Fraternali, F.; Ciancia, V.; Chechile, R.; Rizzano, G.; Feo, L.; Incarnato, L. Experimental study of the thermo-mechanical properties of recycled PET fiber-reinforced concrete. Compos. Struct. 2011, 93, 2368–2374. [Google Scholar] [CrossRef]

- Poonyakan, A.; Rachakornkij, M.; Wecharatana, M.; Smittakorn, W. Potential Use of Plastic Wastes for Low Thermal Conductivity Concrete. Materials 2018, 11, 1938. [Google Scholar] [CrossRef] [Green Version]

- Saxena, R.; Siddique, S.; Gupta, T.; Sharma, R.K.; Chaudhary, S. Impact resistance and energy absorption capacity of concrete containing plastic waste. Constr. Build. Mater. 2018, 176, 415–421. [Google Scholar] [CrossRef]

- Correia, J.; Lima, J.; de Brito, J. Post-fire mechanical performance of concrete made with selected plastic waste aggregates. Cem. Concr. Compos. 2014, 53, 187–199. [Google Scholar] [CrossRef]

- Mohammadhosseini, H.; Yatim, J.M. Microstructure and residual properties of green concrete composites incorporating waste carpet fibers and palm oil fuel ash at elevated temperatures. J. Clean. Prod. 2017, 144, 8–21. [Google Scholar] [CrossRef]

- Mohammadhosseini, H.; Tahir, M.M.; Alyousef, R.; Alabduljabbar, H.; Samadi, M. Effect of elevated temperatures on properties of sustainable concrete composites incorporating waste metalized plastic fibres. Sn Appl. Sci. 2019, 1, 1520. [Google Scholar] [CrossRef] [Green Version]

- Liguori, B.; Iucolano, F.; Capasso, I.; Lavorgna, M.; Verdolotti, L. The effect of recycled plastic aggregate on chemico-physical and functional properties of composite mortars. Mater. Des. 2014, 57, 578–584. [Google Scholar] [CrossRef]

- Paul, S.C.; Šavija, B.; Babafemi, A.J. A comprehensive review on mechanical and durability properties of cement-based materials containing waste recycled glass. J. Clean. Prod. 2018, 198, 891–906. [Google Scholar] [CrossRef]

- Jani, Y.; Hogland, W. Waste glass in the production of cement and concrete–A review. J. Environ. Chem. Eng. 2014, 2, 1767–1775. [Google Scholar] [CrossRef]

- Rashad, A.M. Recycled waste glass as fine aggregate replacement in cementitious materials based on Portland cement. Constr. Build. Mater. 2014, 72, 340–357. [Google Scholar] [CrossRef]

- Paris, J.M.; Roessler, J.G.; Ferraro, C.C.; DeFord, H.D.; Townsend, T.G. A review of waste products utilized as supplements to Portland cement in concrete. J. Clean. Prod. 2016, 121, 1–18. [Google Scholar] [CrossRef]

- Jiang, Y.; Ling, T.-C.; Mo, K.H.; Shi, C.J.J.O.E.M. A critical review of waste glass powder–Multiple roles of utilization in cement-based materials and construction products. J. Environ. Manag. 2019, 242, 440–449. [Google Scholar] [CrossRef] [PubMed]

- Yao, Z.; Ling, T.-C.; Sarker, P.; Su, W.; Liu, J.; Wu, W.; Tang, J. Recycling difficult-to-treat e-waste cathode-ray-tube glass as construction and building materials: A critical review. Renew. Sustain. Energy Rev. 2018, 81, 595–604. [Google Scholar] [CrossRef]

- Hossain, M.U.; Poon, C.S.; Lo, I.M.; Cheng, J.C. Comparative environmental evaluation of aggregate production from recycled waste materials and virgin sources by LCA. Resour. Conserv. Recycl. 2016, 109, 67–77. [Google Scholar] [CrossRef]

- Rashid, K.; Hameed, R.; Ahmad, H.A.; Razzaq, A.; Ahmad, M.; Mahmood, A. Analytical framework for value added utilization of glass waste in concrete: Mechanical and environmental performance. Waste Manag. 2018, 79, 312–323. [Google Scholar] [CrossRef]

- Jiang, M.; Chen, X.; Rajabipour, F.; Hendrickson, C.T. Comparative life cycle assessment of conventional, glass powder, and alkali-activated slag concrete and mortar. J. Infrastruct. Syst. 2014, 20, 04014020. [Google Scholar] [CrossRef]

- Wang, H.-Y.; Huang, W.-L. Durability of self-consolidating concrete using waste LCD glass. Constr. Build. Mater. 2010, 24, 1008–1013. [Google Scholar] [CrossRef]

- Hui, Z.; Sun, W. Study of properties of mortar containing cathode ray tubes (CRT) glass as replacement for river sand fine aggregate. Constr. Build. Mater. 2011, 25, 4059–4064. [Google Scholar] [CrossRef]

- Penacho, P.; de Brito, J.; Veiga, M.R. Physico-mechanical and performance characterization of mortars incorporating fine glass waste aggregate. Cem. Concr. Compos. 2014, 50, 47–59. [Google Scholar] [CrossRef]

- Ling, T.-C.; Poon, C.-S.; Kou, S.-C. Feasibility of using recycled glass in architectural cement mortars. Cem. Concr. Compos. 2011, 33, 848–854. [Google Scholar] [CrossRef]

- Ling, T.-C.; Poon, C.-S. Properties of architectural mortar prepared with recycled glass with different particle sizes. Mater. Des. 2011, 32, 2675–2684. [Google Scholar] [CrossRef]

- Ling, T.-C.; Poon, C.-S. Utilization of recycled glass derived from cathode ray tube glass as fine aggregate in cement mortar. J. Hazard. Mater. 2011, 192, 451–456. [Google Scholar] [CrossRef] [PubMed]

- Wright, J.R.; Cartwright, C.; Fura, D.; Rajabipour, F. Fresh and hardened properties of concrete incorporating recycled glass as 100% sand replacement. J. Mater. Civ. Eng. 2014, 26, 04014073. [Google Scholar] [CrossRef]

- Wang, H.-Y.; Zeng, H.-h.; Wu, J.-Y. A study on the macro and micro properties of concrete with LCD glass. Constr. Build. Mater. 2014, 50, 664–670. [Google Scholar] [CrossRef]

- Choi, S.Y.; Choi, Y.S.; Yang, E.I. Characteristics of volume change and heavy metal leaching in mortar specimens recycled heavyweight waste glass as fine aggregate. Constr. Build. Mater. 2018, 165, 424–433. [Google Scholar] [CrossRef]

- Wang, H.-Y. The effect of the proportion of thin film transistor–liquid crystal display (TFT–LCD) optical waste glass as a partial substitute for cement in cement mortar. Constr. Build. Mater. 2011, 25, 791–797. [Google Scholar] [CrossRef]

- Calmon, J.L.; Sauer, A.S.; Vieira, G.L.; Teixeira, J.E.S.L. Effects of windshield waste glass on the properties of structural repair mortars. Cem. Concr. Compos. 2014, 53, 88–96. [Google Scholar] [CrossRef]

- Patel, D.; Tiwari, R.; Shrivastava, R.; Yadav, R. Effective utilization of waste glass powder as the substitution of cement in making paste and mortar. Constr. Build. Mater. 2019, 199, 406–415. [Google Scholar] [CrossRef]

- Liu, G.; Florea, M.; Brouwers, H.J.C.; Materials, B. Performance evaluation of sustainable high strength mortars incorporating high volume waste glass as binder. Constr. Build. Mater. 2019, 202, 574–588. [Google Scholar] [CrossRef]

- Lu, J.-X.; Zhan, B.-J.; Duan, Z.-H.; Poon, C.S. Improving the performance of architectural mortar containing 100% recycled glass aggregates by using SCMs. Constr. Build. Mater. 2017, 153, 975–985. [Google Scholar] [CrossRef]

- Mardani-Aghabaglou, A.; Tuyan, M.; Ramyar, K. Mechanical and durability performance of concrete incorporating fine recycled concrete and glass aggregates. Mater. Struct. 2015, 48, 2629–2640. [Google Scholar] [CrossRef]

- Zegardło, B.; Szeląg, M.; Ogrodnik, P.; Bombik, A. Physico-mechanical properties and microstructure of polymer concrete with recycled glass aggregate. Materials 2018, 11, 1213. [Google Scholar] [CrossRef] [Green Version]

- De Castro, S.; de Brito, J. Evaluation of the durability of concrete made with crushed glass aggregates. J. Clean. Prod. 2013, 41, 7–14. [Google Scholar] [CrossRef]

- Ling, T.-C.; Poon, C.-S. Effects of particle size of treated CRT funnel glass on properties of cement mortar. Mater. Struct. 2013, 46, 25–34. [Google Scholar] [CrossRef]

- Bisht, K.; Ramana, P. Sustainable production of concrete containing discarded beverage glass as fine aggregate. Constr. Build. Mater. 2018, 177, 116–124. [Google Scholar] [CrossRef]

- Elaqra, H.A.; Abou Haloub, M.A.; Rustom, R.N.J.C.; Materials, B. Effect of new mixing method of glass powder as cement replacement on mechanical behavior of concrete. Constr. Build. Mater. 2019, 203, 75–82. [Google Scholar] [CrossRef]

- Du, H.; Tan, K.H. Transport properties of concrete with glass powder as supplementary cementitious material. Aci Mater. J. 2015, 112, 429. [Google Scholar] [CrossRef]

- Matos, A.M.; Ramos, T.; Nunes, S.; Sousa-Coutinho, J.J.M.R. Durability enhancement of SCC with waste glass powder. Mater. Res. 2016, 19, 67–74. [Google Scholar] [CrossRef] [Green Version]

- Parghi, A.; Alam, M.S. Physical and mechanical properties of cementitious composites containing recycled glass powder (RGP) and styrene butadiene rubber (SBR). Constr. Build. Mater. 2016, 104, 34–43. [Google Scholar] [CrossRef]

- Matos, A.M.; Sousa-Coutinho, J.J.A.I.C.R. Waste glass powder in cement: Macro and micro scale study. Adv. Cem. Res. 2016, 28, 423–432. [Google Scholar] [CrossRef]

- Ramakrishnan, K.; Pugazhmani, G.; Sripragadeesh, R.; Muthu, D.; Venkatasubramanian, C.J.C.; Materials, B. Experimental study on the mechanical and durability properties of concrete with waste glass powder and ground granulated blast furnace slag as supplementary cementitious materials. Constr. Build. Mater. 2017, 156, 739–749. [Google Scholar] [CrossRef]

- Younes, M.; Abdel-Rahman, H.; Khattab, M.M. Utilization of rice husk ash and waste glass in the production of ternary blended cement mortar composites. J. Build. Eng. 2018, 20, 42–50. [Google Scholar] [CrossRef]

- Guo, M.-Z.; Chen, Z.; Ling, T.-C.; Poon, C.S. Effects of recycled glass on properties of architectural mortar before and after exposure to elevated temperatures. J. Clean. Prod. 2015, 101, 158–164. [Google Scholar] [CrossRef]

- Limbachiya, M.; Meddah, M.S.; Fotiadou, S. Performance of granulated foam glass concrete. Constr. Build. Mater. 2012, 28, 759–768. [Google Scholar] [CrossRef]

- Jain, J.A.; Neithalath, N.J.C.; Composites, C. Chloride transport in fly ash and glass powder modified concretes–influence of test methods on microstructure. Cem. Concr. Compos. 2010, 32, 148–156. [Google Scholar] [CrossRef]

- Matos, A.M.; Sousa-Coutinho, J. Durability of mortar using waste glass powder as cement replacement. Constr. Build. Mater. 2012, 36, 205–215. [Google Scholar] [CrossRef]

- Carsana, M.; Frassoni, M.; Bertolini, L. Comparison of ground waste glass with other supplementary cementitious materials. Cem. Concr. Compos. 2014, 45, 39–45. [Google Scholar] [CrossRef]

- Kim, J.; Moon, J.-H.; Shim, J.W.; Sim, J.; Lee, H.-G.; Zi, G. Durability properties of a concrete with waste glass sludge exposed to freeze-and-thaw condition and de-icing salt. Constr. Build. Mater. 2014, 66, 398–402. [Google Scholar] [CrossRef]

- Du, H.; Tan, K.H. Use of waste glass as sand in mortar: Part I – Fresh, mechanical and durability properties. Cem. Concr. Compos. 2013, 35, 109–117. [Google Scholar] [CrossRef]

- Du, H.; Tan, K.H. Properties of high volume glass powder concrete. Cem. Concr. Compos. 2017, 75, 22–29. [Google Scholar] [CrossRef]

- Lee, G.; Ling, T.-C.; Wong, Y.-L.; Poon, C.-S. Effects of crushed glass cullet sizes, casting methods and pozzolanic materials on ASR of concrete blocks. Constr. Build. Mater. 2011, 25, 2611–2618. [Google Scholar] [CrossRef]

- Du, H.; Tan, K.H. Effect of particle size on alkali–silica reaction in recycled glass mortars. Constr. Build. Mater. 2014, 66, 275–285. [Google Scholar] [CrossRef]

- Zhao, H.; Poon, C.S.; Ling, T.C. Utilizing recycled cathode ray tube funnel glass sand as river sand replacement in the high-density concrete. J. Clean. Prod. 2013, 51, 184–190. [Google Scholar] [CrossRef]

- Almesfer, N.; Ingham, J. Effect of waste glass on the properties of concrete. J. Mater. Civ. Eng. 2014, 26, 06014022. [Google Scholar] [CrossRef]

- Cota, F.P.; Melo, C.C.D.; Panzera, T.H.; Araújo, A.G.; Borges, P.H.R.; Scarpa, F. Mechanical properties and ASR evaluation of concrete tiles with waste glass aggregate. Sustain. Cities Soc. 2015, 16, 49–56. [Google Scholar] [CrossRef]

- Spiesz, P.; Rouvas, S.; Brouwers, H. Utilization of waste glass in translucent and photocatalytic concrete. Constr. Build. Mater. 2016, 128, 436–448. [Google Scholar] [CrossRef]

- Du, H.; Tan, K.H. Use of waste glass as sand in mortar: Part II–Alkali–silica reaction and mitigation methods. Cem. Concr. Compos. 2013, 35, 118–126. [Google Scholar] [CrossRef]

- Borhan, T.M. Properties of glass concrete reinforced with short basalt fibre. Mater. Des. 2012, 42, 265–271. [Google Scholar] [CrossRef]

- Al-Sibahy, A.; Edwards, R. Mechanical and thermal properties of novel lightweight concrete mixtures containing recycled glass and metakaolin. Constr. Build. Mater. 2012, 31, 157–167. [Google Scholar] [CrossRef]

- Krishnamoorthy, R.R.; Zujip, J.A. Thermal conductivity and microstructure of concrete using recycle glass as a fine aggregate replacement. Int. J. Emerg. Technol. Adv. Eng. 2013, 3, 463–471. [Google Scholar]

- Chung, S.-Y.; Abd Elrahman, M.; Sikora, P.; Rucinska, T.; Horszczaruk, E.; Stephan, D. Evaluation of the effects of crushed and expanded waste glass aggregates on the material properties of lightweight concrete using image-based approaches. Materials 2017, 10, 1354. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sikora, P.; Horszczaruk, E.; Skoczylas, K.; Rucinska, T. Thermal properties of cement mortars containing waste glass aggregate and nanosilica. Procedia Eng. 2017, 196, 159–166. [Google Scholar] [CrossRef]

- Lu, J.-X.; Yan, X.; He, P.; Poon, C.S. Sustainable design of pervious concrete using waste glass and recycled concrete aggregate. J. Clean. Prod. 2019, 234, 1102–1112. [Google Scholar] [CrossRef]

- Ling, T.-C.; Poon, C.-S.; Kou, S.-C. Influence of recycled glass content and curing conditions on the properties of self-compacting concrete after exposure to elevated temperatures. Cem. Concr. Compos. 2012, 34, 265–272. [Google Scholar] [CrossRef]

- Karahan, O. Transport properties of high volume fly ash or slag concrete exposed to high temperature. Constr. Build. Mater. 2017, 152, 898–906. [Google Scholar] [CrossRef]

- Zanjani Zadeh, V.; Bobko, C.P. Nanoscale mechanical properties of concrete containing blast furnace slag and fly ash before and after thermal damage. Cem. Concr. Compos. 2013, 37, 215–221. [Google Scholar] [CrossRef]

- Guo, Z.; Jiang, T.; Zhang, J.; Kong, X.; Chen, C.; Lehman, D.E. Mechanical and durability properties of sustainable self-compacting concrete with recycled concrete aggregate and fly ash, slag and silica fume. Constr. Build. Mater. 2020, 231, 117115. [Google Scholar] [CrossRef]

- Gopalakrishnan, R.; Chinnaraju, K. Durability of ambient cured alumina silicate concrete based on slag/fly ash blends against sulfate environment. Constr. Build. Mater. 2019, 204, 70–83. [Google Scholar] [CrossRef]

- Assi, L.N.; Carter, K.; Deaver, E.; Ziehl, P. Review of availability of source materials for geopolymer/sustainable concrete. J. Clean. Prod. 2020, 263, 121477. [Google Scholar] [CrossRef]

- Miller, S.A.; Horvath, A.; Monteiro, P.J.M. Readily implementable techniques can cut annual CO2 emissions from the production of concrete by over 20%. Environ. Res. Lett. 2016, 11. [Google Scholar] [CrossRef] [Green Version]

- Xu, G.; Shi, X. Characteristics and applications of fly ash as a sustainable construction material: A state-of-the-art review. Resour. Conserv. Recycl. 2018, 136, 95–109. [Google Scholar] [CrossRef]

- Nath, P.; Sarker, P.K.; Biswas, W.K. Effect of fly ash on the service life, carbon footprint and embodied energy of high strength concrete in the marine environment. Energy Build. 2018, 158, 1694–1702. [Google Scholar] [CrossRef] [Green Version]

- Durán-Herrera, A.; Juárez, C.A.; Valdez, P.; Bentz, D.P. Evaluation of sustainable high-volume fly ash concretes. Cem. Concr. Compos. 2011, 33, 39–45. [Google Scholar] [CrossRef]

- Kaufman, R. Seeking A Safer Future for Electricity’s Coal Ash Waste National Geographic [WWW Document] URL. 2011. Available online: https://www.nationalgeographic.com/news/energy/2011/08/110815-safer-ways-to-reycle-fly-ash-from-coal/ (accessed on 12 August 2020).

- Fisher, L.V.; Barron, A.R. The recycling and reuse of steelmaking slags—A review. Resour. Conserv. Recycl. 2019, 146, 244–255. [Google Scholar] [CrossRef] [Green Version]

- Jiang, Y.; Ling, T.-C.; Shi, C.; Pan, S.-Y. Characteristics of steel slags and their use in cement and concrete—A review. Resour. Conserv. Recycl. 2018, 136, 187–197. [Google Scholar] [CrossRef]

- Habert, G.; d’Espinose de Lacaillerie, J.B.; Roussel, N. An environmental evaluation of geopolymer based concrete production: Reviewing current research trends. Clean. Prod. 2011, 19, 1229–1238. [Google Scholar] [CrossRef]

- Guo, J.; Bao, Y.; Wang, M. Steel slag in China: Treatment, recycling, and management. Waste Manag. 2018, 78, 318–330. [Google Scholar] [CrossRef]

- Berndt, M.L. Influence of concrete mix design on CO2 emissions for large wind turbine foundations. Renew. Energy 2015, 83, 608–614. [Google Scholar] [CrossRef]

- Wang, X.-Y.; Lee, H.-S. Effect of global warming on the proportional design of low CO2 slag-blended concrete. Constr. Build. Mater. 2019, 225, 1140–1151. [Google Scholar] [CrossRef]

- Qasrawi, H. The use of steel slag aggregate to enhance the mechanical properties of recycled aggregate concrete and retain the environment. Constr. Build. Mater. 2014, 54, 298–304. [Google Scholar] [CrossRef]

- Saccani, A.; Bignozzi, M.C. ASR expansion behavior of recycled glass fine aggregates in concrete. Cem. Concr. Res. 2010, 40, 531–536. [Google Scholar] [CrossRef]

- Rajabipour, F.; Maraghechi, H.; Fischer, G. Investigating the alkali-silica reaction of recycled glass aggregates in concrete materials. J. Mater. Civ. Eng. 2010, 22, 1201–1208. [Google Scholar] [CrossRef]

- Mageswari, M.; Vidivelli, D.B. The use of sheet glass powder as fine aggregate replacement in concrete. Open Civ. Eng. J. 2010, 4, 65–71. [Google Scholar] [CrossRef]

- Tuan, B.L.A.; Hwang, C.-L.; Lin, K.-L.; Chen, Y.-Y.; Young, M.-P. Development of lightweight aggregate from sewage sludge and waste glass powder for concrete. Constr. Build. Mater. 2013, 47, 334–339. [Google Scholar] [CrossRef]

- Saribiyik, M.; Piskin, A.; Saribiyik, A. The effects of waste glass powder usage on polymer concrete properties. Constr. Build. Mater. 2013, 47, 840–844. [Google Scholar] [CrossRef]

- Adaway, M.; Wang, Y. Recycled glass as a partial replacement for fine aggregate in structural concrete–Effects on compressive strength. Electron. J. Struct. Eng. 2015, 14, 116–122. [Google Scholar]

- Choi, S.Y.; Choi, Y.S.; Yang, E.I. Effects of heavy weight waste glass recycled as fine aggregate on the mechanical properties of mortar specimens. Ann. Nucl. Energy 2017, 99, 372–382. [Google Scholar] [CrossRef]

- Malik, M.I.; Bashir, M.; Ahmad, S.; Tariq, T.; Chowdhary, U. Study of concrete involving use of waste glass as partial replacement of fine aggregates. Iosr J. Eng. 2013, 3, 8–13. [Google Scholar] [CrossRef]

- Abdallah, S.; Fan, M. Characteristics of concrete with waste glass as fine aggregate replacement. Int. J. Eng. Tech. Res. (Ijetr) 2014, 2, 11–17. [Google Scholar]

- Ling, T.-C.; Poon, C.-S. Feasible use of recycled CRT funnel glass as heavyweight fine aggregate in barite concrete. J. Clean. Prod. 2012, 33, 42–49. [Google Scholar] [CrossRef]

- Hunag, L.-J.; Wang, H.-Y.; Wang, S.-Y. A study of the durability of recycled green building materials in lightweight aggregate concrete. Constr. Build. Mater. 2015, 96, 353–359. [Google Scholar] [CrossRef]

- Liu, S.; Xie, G.; Wang, S. Effect of curing temperature on hydration properties of waste glass powder in cement-based materials. J. Therm. Anal. Calorim. 2015, 119, 47–55. [Google Scholar] [CrossRef]

- Liu, S.; Wang, S.; Tang, W.; Hu, N.; Wei, J. Inhibitory effect of waste glass powder on ASR expansion induced by waste glass aggregate. Materials 2015, 8, 6849–6862. [Google Scholar] [CrossRef] [Green Version]

- Yu, R.; Van Onna, D.; Spiesz, P.; Yu, Q.; Brouwers, H. Development of ultra-lightweight fibre reinforced concrete applying expanded waste glass. J. Clean. Prod. 2016, 112, 690–701. [Google Scholar] [CrossRef]

- Liu, M. Incorporating ground glass in self-compacting concrete. Constr. Build. Mater. 2011, 25, 919–925. [Google Scholar] [CrossRef]

- Arabi, N.; Meftah, H.; Amara, H.; Kebaïli, O.; Berredjem, L. Valorization of recycled materials in development of self-compacting concrete: Mixing recycled concrete aggregates–Windshield waste glass aggregates. Constr. Build. Mater. 2019, 209, 364–376. [Google Scholar] [CrossRef]

- Ali, E.E.; Al-Tersawy, S.H. Recycled glass as a partial replacement for fine aggregate in self compacting concrete. Constr. Build. Mater. 2012, 35, 785–791. [Google Scholar] [CrossRef]

- Kou, S.-C.; Poon, C.-S. A novel polymer concrete made with recycled glass aggregates, fly ash and metakaolin. Constr. Build. Mater. 2013, 41, 146–151. [Google Scholar] [CrossRef]

- Ling, T.-C.; Poon, C.-S. Use of recycled CRT funnel glass as fine aggregate in dry-mixed concrete paving blocks. J. Clean. Prod. 2014, 68, 209–215. [Google Scholar] [CrossRef]

- Chen, Z.; Li, J.S.; Poon, C.S. Combined use of sewage sludge ash and recycled glass cullet for the production of concrete blocks. J. Clean. Prod. 2018, 171, 1447–1459. [Google Scholar] [CrossRef]

- Liu, T.; Song, W.; Zou, D.; Li, L. Dynamic mechanical analysis of cement mortar prepared with recycled cathode ray tube (CRT) glass as fine aggregate. J. Clean. Prod. 2018, 174, 1436–1443. [Google Scholar] [CrossRef]

- Ling, T.-C.; Poon, C.-S. A comparative study on the feasible use of recycled beverage and CRT funnel glass as fine aggregate in cement mortar. J. Clean. Prod. 2012, 29, 46–52. [Google Scholar] [CrossRef]

- Ling, T.-C.; Poon, C.-S.; Lam, W.-S.; Chan, T.-P.; Fung, K.K.-L. Utilization of recycled cathode ray tubes glass in cement mortar for X-ray radiation-shielding applications. J. Hazard. Mater. 2012, 199, 321–327. [Google Scholar] [CrossRef]

- Maraghechi, H.; Fischer, G.; Rajabipour, F. The role of residual cracks on alkali silica reactivity of recycled glass aggregates. Cem. Concr. Compos. 2012, 34, 41–47. [Google Scholar] [CrossRef]

- Serpa, D.; Silva, A.S.; De Brito, J.; Pontes, J.; Soares, D. ASR of mortars containing glass. Constr. Build. Mater. 2013, 47, 489–495. [Google Scholar] [CrossRef]

- Arulrajah, A.; Disfani, M.M.; Haghighi, H.; Mohammadinia, A.; Horpibulsuk, S. Modulus of rupture evaluation of cement stabilized recycled glass/recycled concrete aggregate blends. Constr. Build. Mater. 2015, 84, 146–155. [Google Scholar] [CrossRef]

- Afshinnia, K.; Rangaraju, P.R. Influence of fineness of ground recycled glass on mitigation of alkali–silica reaction in mortars. Constr. Build. Mater. 2015, 81, 257–267. [Google Scholar] [CrossRef]

- Guo, S.; Dai, Q.; Sun, X.; Xiao, X.; Si, R.; Wang, J. Reduced alkali-silica reaction damage in recycled glass mortar samples with supplementary cementitious materials. J. Clean. Prod. 2018, 172, 3621–3633. [Google Scholar] [CrossRef]

- Lu, J.-x.; Duan, Z.-H.; Poon, C.S. Combined use of waste glass powder and cullet in architectural mortar. Cem. Concr. Compos. 2017, 82, 34–44. [Google Scholar] [CrossRef]

- Lu, J.-x.; Duan, Z.-h.; Poon, C.S. Fresh properties of cement pastes or mortars incorporating waste glass powder and cullet. Constr. Build. Mater. 2017, 131, 793–799. [Google Scholar] [CrossRef]

- Lu, J.-X.; Zhan, B.-J.; Duan, Z.-H.; Poon, C.S. Using glass powder to improve the durability of architectural mortar prepared with glass aggregates. Mater. Des. 2017, 135, 102–111. [Google Scholar] [CrossRef]

- Lu, J.-X.; Poon, C.S. Improvement of early-age properties for glass-cement mortar by adding nanosilica. Cem. Concr. Compos. 2018, 89, 18–30. [Google Scholar] [CrossRef]

- Lu, J.-X.; Poon, C.S. Use of waste glass in alkali activated cement mortar. Constr. Build. Mater. 2018, 160, 399–407. [Google Scholar] [CrossRef]

- Tan, K.H.; Du, H. Concrete with Recycled Glass as Fine Aggregates. ACI Mater. J. 2014, 111, 47–57. [Google Scholar]

- Idir, R.; Cyr, M.; Tagnit-Hamou, A. Use of fine glass as ASR inhibitor in glass aggregate mortars. Constr. Build. Mater. 2010, 24, 1309–1312. [Google Scholar] [CrossRef]

- Tuaum, A.; Shitote, S.; Oyawa, W. Experimental study of self-compacting mortar incorporating recycled glass aggregate. Buildings 2018, 8, 15. [Google Scholar] [CrossRef] [Green Version]

- De Azevedo, A.R.G.; Alexandre, J.; Zanelato, E.B.; Marvila, M.T. Influence of incorporation of glass waste on the rheological properties of adhesive mortar. Constr. Build. Mater. 2017, 148, 359–368. [Google Scholar] [CrossRef]

- Aly, M.; Hashmi, M.; Olabi, A.; Messeiry, M.; Hussain, A. Effect of nano clay particles on mechanical, thermal and physical behaviours of waste-glass cement mortars. Mater. Sci. Eng. A 2011, 528, 7991–7998. [Google Scholar] [CrossRef]

- Aly, M.; Hashmi, M.; Olabi, A.; Messeiry, M.; Abadir, E.; Hussain, A. Effect of colloidal nano-silica on the mechanical and physical behaviour of waste-glass cement mortar. Mater. Des. 2012, 33, 127–135. [Google Scholar] [CrossRef]

- Khatib, J.; Negim, E.; Sohl, H.; Chileshe, N. Glass powder utilisation in concrete production. Eur. J. Appl. Sci. 2012, 4, 173–176. [Google Scholar]

- Vijayakumar, G.; Vishaliny, H.; Govindarajulu, D. Studies on glass powder as partial replacement of cement in concrete production. Int. J. Emerg. Technol. Adv. Eng. 2013, 3, 153–157. [Google Scholar]

- Madandoust, R.; Ghavidel, R. Mechanical properties of concrete containing waste glass powder and rice husk ash. Biosyst. Eng. 2013, 116, 113–119. [Google Scholar] [CrossRef]

- Du, H.; Tan, K.H. Waste glass powder as cement replacement in concrete. J. Adv. Concr. Technol. 2014, 12, 468–477. [Google Scholar] [CrossRef] [Green Version]

- Jang, H.; Jeon, S.; So, H.; So, S. Properties of different particle size of recycled TFT-LCD waste glass powder as a cement concrete binder. Int. J. Precis. Eng. Manuf. 2015, 16, 2591–2597. [Google Scholar] [CrossRef]

- Kara, P. The influence of waste glass slurry on the properties of concrete. Int. J. Appl. Innov. Eng. Manag. (Ijaiem) 2013, 2, 325–330. [Google Scholar]

- Aliabdo, A.A.; Abd Elmoaty, M.; Aboshama, A.Y. Utilization of waste glass powder in the production of cement and concrete. Constr. Build. Mater. 2016, 124, 866–877. [Google Scholar] [CrossRef]

- Afshinnia, K.; Rangaraju, P.R. Impact of combined use of ground glass powder and crushed glass aggregate on selected properties of Portland cement concrete. Constr. Build. Mater. 2016, 117, 263–272. [Google Scholar] [CrossRef]

- Sakale, R.; Jain, S.; Singh, S. Experimental investigation on strength of glass powder replacement by cement in concrete with different dosages. Int. J. Adv. Res. Comput. Sci. Softw. Eng. 2015, 5, 386–390. [Google Scholar]

- Anwar, A. The influence of waste glass powder as a pozzolanic material in concrete. Int. J. Civ. Eng. Technol. (Ijciet) 2016, 7, 131–148. [Google Scholar]

- Islam, G.S.; Rahman, M.; Kazi, N. Waste glass powder as partial replacement of cement for sustainable concrete practice. Int. J. Sustain. Built Environ. 2017, 6, 37–44. [Google Scholar] [CrossRef] [Green Version]

- AL-Zubaid, A.B.; Shabeeb, K.M.; Ali, A.I. Study the effect of recycled glass on the mechanical properties of green concrete. Energy Procedia 2017, 119, 680–692. [Google Scholar] [CrossRef]

- Kim, S.K.; Kang, S.T.; Kim, J.K.; Jang, I.Y.J.A.i.M.S. Effects of particle size and cement replacement of LCD glass powder in concrete. Adv. Mater. Sci. Eng. 2017, 2017, 3928047. [Google Scholar] [CrossRef] [Green Version]

- Olofinnade, O.M.; Ede, A.N.; Ndambuki, J.M.J.I.J.O.E.; Innovation, T. Experimental investigation on the effect of elevated temperature on compressive strength of concrete containing waste glass powder. Int. J. Eng. Technol. Innov. 2017, 7, 280–291. [Google Scholar]

- Lee, H.; Hanif, A.; Usman, M.; Sim, J.; Oh, H. Performance evaluation of concrete incorporating glass powder and glass sludge wastes as supplementary cementing material. J. Clean. Prod. 2018, 170, 683–693. [Google Scholar] [CrossRef]

- Ramdani, S.; Guettala, A.; Benmalek, M.; Aguiar, J.B.J.J.O.B.E. Physical and mechanical performance of concrete made with waste rubber aggregate, glass powder and silica sand powder. J. Build. Eng. 2019, 21, 302–311. [Google Scholar] [CrossRef]

- He, Z.-H.; Zhan, P.-M.; Du, S.-G.; Liu, B.-J.; Yuan, W.-B.J.C.P.B.E. Creep behavior of concrete containing glass powder. Compos. Part B Eng. 2019, 166, 13–20. [Google Scholar] [CrossRef]

- Khan, Q.S.; Sheikh, M.N.; McCarthy, T.J.; Robati, M.; Allen, M.J.C.; Materials, B. Experimental investigation on foam concrete without and with recycled glass powder: A sustainable solution for future construction. Constr. Build. Mater. 2019, 201, 369–379. [Google Scholar] [CrossRef]

- Kara, P. Recycling of Glass Wastes in Latvia–Its Application as Cement Substitute in Self-Compacting Concrete. J. Sustain. Archit. Civ. Eng. 2014, 6, 42–49. [Google Scholar] [CrossRef]

- Sharifi, Y.; Afshoon, I.; Firoozjaie, Z.J.J.O.A.C.T. Fresh properties of self-compacting concrete containing ground waste glass microparticles as cementing material. J. Adv. Concr. Technol. 2015, 13, 50–66. [Google Scholar] [CrossRef] [Green Version]

- Kou, S.C.; Xing, F. The effect of recycled glass powder and reject fly ash on the mechanical properties of fibre-reinforced ultrahigh performance concrete. Adv. Mater. Sci. Eng. 2012, 2012, 263243. [Google Scholar] [CrossRef] [Green Version]

- Soliman, N.; Tagnit-Hamou, A. Development of ultra-high-performance concrete using glass powder–Towards ecofriendly concrete. Constr. Build. Mater. 2016, 125, 600–612. [Google Scholar] [CrossRef]

- Soliman, N.; Tagnit-Hamou, A.J.C.; Materials, B. Partial substitution of silica fume with fine glass powder in UHPC: Filling the micro gap. Constr. Build. Mater. 2017, 139, 374–383. [Google Scholar] [CrossRef]

- Vaitkevičius, V.; Šerelis, E.; Hilbig, H. The effect of glass powder on the microstructure of ultra high performance concrete. Constr. Build. Mater. 2014, 68, 102–109. [Google Scholar] [CrossRef]

- Xuan, D.; Tang, P.; Poon, C.S. MSWIBA-based cellular alkali-activated concrete incorporating waste glass powder. Cem. Concr. Compos. 2019, 95, 128–136. [Google Scholar] [CrossRef]

- Nassar, R.-U.-D.; Soroushian, P. Field investigation of concrete incorporating milled waste glass. J. Solid Waste Technol. Manag. 2011, 37, 307–319. [Google Scholar] [CrossRef] [Green Version]

- Omran, A.F.; Etienne, D.; Harbec, D.; Tagnit-Hamou, A.J.C.; Materials, B. Long-term performance of glass-powder concrete in large-scale field applications. Constr. Build. Mater. 2017, 135, 43–58. [Google Scholar] [CrossRef]

- Hama, S.M.; Mahmoud, A.S.; Yassen, M.M. Flexural behavior of reinforced concrete beam incorporating waste glass powder. In Proceedings of the Structures, Orlando, FL, USA, 24–29 April 2019; pp. 510–518. [Google Scholar]

- Niang, A.; Roy, N.; Tagnit-Hamou, A.J.J.O.S.E. Structural behavior of concrete incorporating glass powder used in reinforced concrete columns. J. Struct. Eng. 2015, 141, B4014007. [Google Scholar] [CrossRef]

- Jang, B.-K.; Lee, J.-C.; Kim, J.-H.; Chung, C.-W.J.A.R. Enhancement of thermal neutron shielding of cement mortar by using borosilicate glass powder. Appl. Radiat. Isot. 2017, 123, 1–5. [Google Scholar] [CrossRef]

- Pereira-de-Oliveira, L.A.; Castro-Gomes, J.P.; Santos, P.M. The potential pozzolanic activity of glass and red-clay ceramic waste as cement mortars components. Constr. Build. Mater. 2012, 31, 197–203. [Google Scholar] [CrossRef]

- Khmiri, A.; Samet, B.; Chaabouni, M. A cross mixture design to optimise the formulation of a ground waste glass blended cement. Constr. Build. Mater. 2012, 28, 680–686. [Google Scholar] [CrossRef]

- Idir, R.; Cyr, M.; Tagnit-Hamou, A. Pozzolanic properties of fine and coarse color-mixed glass cullet. Cem. Concr. Compos. 2011, 33, 19–29. [Google Scholar] [CrossRef]

- Khmiri, A.; Chaabouni, M.; Samet, B. Chemical behaviour of ground waste glass when used as partial cement replacement in mortars. Constr. Build. Mater. 2013, 44, 74–80. [Google Scholar] [CrossRef]

- Mirzahosseini, M.; Riding, K.A. Effect of curing temperature and glass type on the pozzolanic reactivity of glass powder. Cem. Concr. Res. 2014, 58, 103–111. [Google Scholar] [CrossRef] [Green Version]

- Kim, J.; Yi, C.; Zi, G. Waste glass sludge as a partial cement replacement in mortar. Constr. Build. Mater. 2015, 75, 242–246. [Google Scholar] [CrossRef]

- Šimonová, H.; Zahálková, J.; Rovnaníková, P.; Bayer, P.; Keršner, Z.; Schmid, P.J.P.E. Mechanical fracture parameters of cement based mortars with waste glass powder. Procedia Eng. 2017, 190, 86–91. [Google Scholar] [CrossRef]

- Pascual, A.B.; Tognonvi, M.T.; Tagnit-Hamou, A. Waste glass powder-based alkali-activated mortar. Int. J. Res. Eng. Technol 2014, 3, 32–36. [Google Scholar]

- Torres-Carrasco, M.; Puertas, F.J.J.O.C.P. Waste glass in the geopolymer preparation. Mechanical and microstructural characterisation. J. Clean. Prod. 2015, 90, 397–408. [Google Scholar] [CrossRef]

- Vafaei, M.; Allahverdi, A.J.J.O.M.I.C.E. Durability of geopolymer mortar based on waste-glass powder and calcium aluminate cement in acid solutions. J. Mater. Civ. Eng. 2017, 29, 04017196. [Google Scholar] [CrossRef]

- Vafaei, M.; Allahverdi, A. High strength geopolymer binder based on waste-glass powder. Adv. Powder Technol. 2017, 28, 215–222. [Google Scholar] [CrossRef]

- Vafaei, M.; Allahverdi, A.; Dong, P.; Bassim, N.J.C.; Materials, B. Acid attack on geopolymer cement mortar based on waste-glass powder and calcium aluminate cement at mild concentration. Constr. Build. Mater. 2018, 193, 363–372. [Google Scholar] [CrossRef]

- Tho-In, T.; Sata, V.; Boonserm, K.; Chindaprasirt, P.J.J.O.C.P. Compressive strength and microstructure analysis of geopolymer paste using waste glass powder and fly ash. J. Clean. Prod. 2018, 172, 2892–2898. [Google Scholar] [CrossRef]

- Criado, M.; García-Díaz, I.; Bastidas, J.; Alguacil, F.J.; López, F.; Monticelli, C.J.C.; Materials, B. Effect of recycled glass fiber on the corrosion behavior of reinforced mortar. Constr. Build. Mater. 2014, 64, 261–269. [Google Scholar] [CrossRef] [Green Version]

- Vinai, R.; Soutsos, M.J.C.; Research, C. Production of sodium silicate powder from waste glass cullet for alkali activation of alternative binders. Cem. Concr. Res. 2019, 116, 45–56. [Google Scholar] [CrossRef] [Green Version]

- Torres-Carrasco, M.; Rodríguez-Puertas, C.; del Mar Alonso, M.; Puertas, F.J.B.D.L.S.E.D.C.Y.V. Alkali activated slag cements using waste glass as alternative activators. Rheological behaviour. Boletín Soc. Española Ceram. Vìdrio 2015, 54, 45–57. [Google Scholar] [CrossRef] [Green Version]

- Zhang, S.; Keulen, A.; Arbi, K.; Ye, G. Waste glass as partial mineral precursor in alkali-activated slag/fly ash system. Cem. Concr. Res. 2017, 102, 29–40. [Google Scholar] [CrossRef] [Green Version]

- Bignozzi, M.; Saccani, A.; Barbieri, L.; Lancellotti, I. Glass waste as supplementary cementing materials: The effects of glass chemical composition. Cem. Concr. Compos. 2015, 55, 45–52. [Google Scholar] [CrossRef]

- Zheng, K.J.C.; Composites, C. Pozzolanic reaction of glass powder and its role in controlling alkali–silica reaction. Cem. Concr. Compos. 2016, 67, 30–38. [Google Scholar] [CrossRef]

- Mirzahosseini, M.; Riding, K.A.J.C.; Composites, C. Influence of different particle sizes on reactivity of finely ground glass as supplementary cementitious material (SCM). Cem. Concr. Compos. 2015, 56, 95–105. [Google Scholar] [CrossRef]

- Rahmani, E.; Dehestani, M.; Beygi, M.; Allahyari, H.; Nikbin, I. On the mechanical properties of concrete containing waste PET particles. Constr. Build. Mater. 2013, 47, 1302–1308. [Google Scholar] [CrossRef]

- Senthil Kumar, K.; Baskar, K. Response surfaces for fresh and hardened properties of concrete with e-waste (HIPS). J. Waste Manag. 2014. [Google Scholar] [CrossRef] [Green Version]

- Aldahdooh, M.; Jamrah, A.; Alnuaimi, A.; Martini, M.; Ahmed, M.; Ahmed, A. Influence of various plastics-waste aggregates on properties of normal concrete. J. Build. Eng. 2018, 17, 13–22. [Google Scholar] [CrossRef]

- De la Colina Martínez, A.L.; Barrera, G.M.; Díaz, C.E.B.; Córdoba, L.I.Á.; Núñez, F.U.; Hernández, D.J.D. Recycled polycarbonate from electronic waste and its use in concrete: Effect of irradiation. Constr. Build. Mater. 2019, 201, 778–785. [Google Scholar] [CrossRef]

- Ferreira, L.; de Brito, J.; Saikia, N. Influence of curing conditions on the mechanical performance of concrete containing recycled plastic aggregate. Constr. Build. Mater. 2012, 36, 196–204. [Google Scholar] [CrossRef]

- Liu, F.; Yan, Y.; Li, L.; Lan, C.; Chen, G. Performance of recycled plastic-based concrete. J. Mater. Civ. Eng. 2013, 27, A4014004. [Google Scholar] [CrossRef]

- Mohammed, A.A.; Mohammed, I.I.; Mohammed, S.A. Some properties of concrete with plastic aggregate derived from shredded PVC sheets. Constr. Build. Mater. 2019, 201, 232–245. [Google Scholar] [CrossRef]

- Thorneycroft, J.; Orr, J.; Savoikar, P.; Ball, R. Performance of structural concrete with recycled plastic waste as a partial replacement for sand. Constr. Build. Mater. 2018, 161, 63–69. [Google Scholar] [CrossRef]

- Saikia, N.; Brito, J.d. Waste polyethylene terephthalate as an aggregate in concrete. Mater. Res. 2013, 16, 341–350. [Google Scholar] [CrossRef] [Green Version]

- Islam, M.J.; Meherier, M.S.; Islam, A.R. Effects of waste PET as coarse aggregate on the fresh and harden properties of concrete. Constr. Build. Mater. 2016, 125, 946–951. [Google Scholar] [CrossRef]

- Manjunath, B.A. Partial replacement of E-plastic Waste as Coarse-aggregate in Concrete. Procedia Environ. Sci. 2016, 35, 731–739. [Google Scholar] [CrossRef]

- Saikia, N.; de Brito, J. Mechanical properties and abrasion behaviour of concrete containing shredded PET bottle waste as a partial substitution of natural aggregate. Constr. Build. Mater. 2014, 52, 236–244. [Google Scholar] [CrossRef]

- Mohammadinia, A.; Wong, Y.C.; Arulrajah, A.; Horpibulsuk, S. Strength evaluation of utilizing recycled plastic waste and recycled crushed glass in concrete footpaths. Constr. Build. Mater. 2019, 197, 489–496. [Google Scholar] [CrossRef]

- Guendouz, M.; Debieb, F.; Boukendakdji, O.; Kadri, E.; Bentchikou, M.; Soualhi, H. Use of plastic waste in sand concrete. J. Mater. Env. Sci. 2016, 7, 382–389. [Google Scholar]

- Hama, S.M.; Hilal, N.N. Fresh properties of self-compacting concrete with plastic waste as partial replacement of sand. Int. J. Sustain. Built Environ. 2017, 6, 299–308. [Google Scholar] [CrossRef]

- Yang, S.; Yue, X.; Liu, X.; Tong, Y. Properties of self-compacting lightweight concrete containing recycled plastic particles. Constr. Build. Mater. 2015, 84, 444–453. [Google Scholar] [CrossRef]

- Safi, B.; Saidi, M.; Aboutaleb, D.; Maallem, M. The use of plastic waste as fine aggregate in the self-compacting mortars: Effect on physical and mechanical properties. Constr. Build. Mater. 2013, 43, 436–442. [Google Scholar] [CrossRef]

- Bulut, H.A.; Şahin, R. A study on mechanical properties of polymer concrete containing electronic plastic waste. Compos. Struct. 2017, 178, 50–62. [Google Scholar] [CrossRef]

- Ge, Z.; Sun, R.; Zhang, K.; Gao, Z.; Li, P. Physical and mechanical properties of mortar using waste Polyethylene Terephthalate bottles. Constr. Build. Mater. 2013, 44, 81–86. [Google Scholar] [CrossRef]

- da Silva, A.M.; de Brito, J.; Veiga, R. Incorporation of fine plastic aggregates in rendering mortars. Constr. Build. Mater. 2014, 71, 226–236. [Google Scholar] [CrossRef]

- Kandasamy, R.; Murugesan, R. Fibre reinforced concrete using domestic waste plastics as fibres. Arpn J. Eng. Appl. Sci. 2011, 6, 75–82. [Google Scholar]

- Foti, D. Preliminary analysis of concrete reinforced with waste bottles PET fibers. Constr. Build. Mater. 2011, 25, 1906–1915. [Google Scholar] [CrossRef]

- Foti, D. Use of recycled waste pet bottles fibers for the reinforcement of concrete. Compos. Struct. 2013, 96, 396–404. [Google Scholar] [CrossRef]

- Machovič, V.; Lapčák, L.; Borecka, L.; Lhotka, M.; Andertova, J.; Kopecký, L.; Mišková, L. Microstructure of interfacial transition zone between pet fibres and cement paste. Acta Geodyn. Et Geomater. 2013, 10, 121–127. [Google Scholar] [CrossRef] [Green Version]

- Karthik, M.; Maruthachalam, D. Experimental study on shear behaviour of hybrid Fibre Reinforced Concrete beams. Ksce J. Civ. Eng. 2015, 19, 259–264. [Google Scholar] [CrossRef]

- Baldenebro-Lopez, F.; Castorena-Gonzalez, J.; Velazquez-Dimas, J.; Ledezma-Sillas, J.; Gómez-Esparza, C.; Martinez-Sanchez, R.; Herrera-Ramirez, J. Influence of continuous plastic fibers reinforcement arrangement in concrete strengthened. Iosr J. Eng 2014, 4, 15–23. [Google Scholar] [CrossRef]

- Taherkhani, H. An Investigation on the Properties of the Concrete Containing Waste PET Fibers. Int. J. Sci. Eng. Investig. 2014, 3, 37–43. [Google Scholar]

- Fraternali, F.; Spadea, S.; Berardi, V.P. Effects of recycled PET fibres on the mechanical properties and seawater curing of Portland cement-based concretes. Constr. Build. Mater. 2014, 61, 293–302. [Google Scholar] [CrossRef]

- Spadea, S.; Farina, I.; Berardi, V.P.; Dentale, F.; Fraternali, F. Energy dissipation capacity of concretes reinforced with recycled PET fibers. Ing. Sismica 2014, 31, 61–70. [Google Scholar]

- Koo, B.-M.; Kim, J.-H.J.; Kim, S.-B.; Mun, S. Material and structural performance evaluations of Hwangtoh admixtures and recycled PET fiber-added eco-friendly concrete for CO2 emission reduction. Materials 2014, 7, 5959–5981. [Google Scholar] [CrossRef]

- Bhogayata, A.; Arora, N.; Nakum, A. Strength characteristics of concrete containing post consumer metalized plastic waste. Inter. J. Res. Eng. Tech. 2015, 4, 430–434. [Google Scholar]

- Bhogayata, A.C.; Arora, N.K. Fresh and strength properties of concrete reinforced with metalized plastic waste fibers. Constr. Build. Mater. 2017, 146, 455–463. [Google Scholar] [CrossRef]

- Bhogayata, A.C.; Arora, N.K. Impact strength, permeability and chemical resistance of concrete reinforced with metalized plastic waste fibers. Constr. Build. Mater. 2018, 161, 254–266. [Google Scholar] [CrossRef]

- Bhogayata, A.C.; Arora, N.K. Workability, strength, and durability of concrete containing recycled plastic fibers and styrene-butadiene rubber latex. Constr. Build. Mater. 2018, 180, 382–395. [Google Scholar] [CrossRef]

- Borg, R.P.; Baldacchino, O.; Ferrara, L. Early age performance and mechanical characteristics of recycled PET fibre reinforced concrete. Constr. Build. Mater. 2016, 108, 29–47. [Google Scholar] [CrossRef] [Green Version]

- Pereira, E.L.; de Oliveira Junior, A.L.; Fineza, A.G. Optimization of mechanical properties in concrete reinforced with fibers from solid urban wastes (PET bottles) for the production of ecological concrete. Constr. Build. Mater. 2017, 149, 837–848. [Google Scholar] [CrossRef]

- Mohammadhosseini, H.; Awal, A.A.; Yatim, J.B.M. The impact resistance and mechanical properties of concrete reinforced with waste polypropylene carpet fibres. Constr. Build. Mater. 2017, 143, 147–157. [Google Scholar] [CrossRef]

- Mohammadhosseini, H.; Tahir, M.M.; Sam, A.R.M. The feasibility of improving impact resistance and strength properties of sustainable concrete composites by adding waste metalized plastic fibres. Constr. Build. Mater. 2018, 169, 223–236. [Google Scholar] [CrossRef]

- Kurup, A.R.; Senthil Kumar, K. Effect of recycled PVC fibers from electronic waste and silica powder on shear strength of concrete. J. Hazard. ToxicRadioact. Waste 2017, 21, 06017001. [Google Scholar] [CrossRef]

- Kurup, A.R.; Kumar, K.S. Novel fibrous concrete mixture made from recycled PVC fibers from electronic waste. J. Hazard. ToxicRadioact. Waste 2017, 21, 04016020. [Google Scholar] [CrossRef]

- Karanth, S.S.; Ghorpade, V.G.; Rao, H.S. Shear and impact strength of waste plastic fibre reinforced concrete. Adv. Concr. Constr. 2017, 5, 173–182. [Google Scholar] [CrossRef]

- Bui, N.K.; Satomi, T.; Takahashi, H. Recycling woven plastic sack waste and PET bottle waste as fiber in recycled aggregate concrete: An experimental study. Waste Manag. 2018, 78, 79–93. [Google Scholar] [CrossRef] [PubMed]

- Khalid, F.; Irwan, J.; Ibrahim, M.W.; Othman, N.; Shahidan, S. Splitting tensile and pullout behavior of synthetic wastes as fiber-reinforced concrete. Constr. Build. Mater. 2018, 171, 54–64. [Google Scholar] [CrossRef]

- Kiyanets, A. Concrete with recycled polyethylene terephthalate fiber. Mag. Civ. Eng. 2018, 84, 109–118. [Google Scholar]

- Meza, A.; Siddique, S. Effect of aspect ratio and dosage on the flexural response of FRC with recycled fiber. Constr. Build. Mater. 2019, 213, 286–291. [Google Scholar] [CrossRef]

- Hama, S.M. Improving mechanical properties of lightweight Porcelanite aggregate concrete using different waste material. Int. J. Sustain. Built Environ. 2017, 6, 81–90. [Google Scholar] [CrossRef]

- Kandasamy, R.; Murugesan, R. Fiber Reinforced Self Compacting Concrete using domestic waste plastics as fibres. Jeas-J. Eng. Appl. Sci. 2012, 7, 405–410. [Google Scholar] [CrossRef] [Green Version]

- Ghernouti, Y.; Rabehi, B.; Bouziani, T.; Ghezraoui, H.; Makhloufi, A. Fresh and hardened properties of self-compacting concrete containing plastic bag waste fibers (WFSCC). Constr. Build. Mater. 2015, 82, 89–100. [Google Scholar] [CrossRef]

- Al-Hadithi, A.I.; Hilal, N.N. The possibility of enhancing some properties of self-compacting concrete by adding waste plastic fibers. J. Build. Eng. 2016, 8, 20–28. [Google Scholar] [CrossRef]

- Yin, S.; Tuladhar, R.; Collister, T.; Combe, M.; Sivakugan, N.; Deng, Z. Post-cracking performance of recycled polypropylene fibre in concrete. Constr. Build. Mater. 2015, 101, 1069–1077. [Google Scholar] [CrossRef]

- Khalid, F.; Irwan, J.; Ibrahim, M.W.; Othman, N.; Shahidan, S. Performance of plastic wastes in fiber-reinforced concrete beams. Constr. Build. Mater. 2018, 183, 451–464. [Google Scholar] [CrossRef]

- Pelisser, F.; Neto, A.B.d.S.S.; La Rovere, H.L.; de Andrade Pinto, R.C. Effect of the addition of synthetic fibers to concrete thin slabs on plastic shrinkage cracking. Constr. Build. Mater. 2010, 24, 2171–2176. [Google Scholar] [CrossRef]

- Yin, S.; Tuladhar, R.; Riella, J.; Chung, D.; Collister, T.; Combe, M.; Sivakugan, N. Comparative evaluation of virgin and recycled polypropylene fibre reinforced concrete. Constr. Build. Mater. 2016, 114, 134–141. [Google Scholar] [CrossRef]

- Smarzewski, P. Influence of basalt-polypropylene fibres on fracture properties of high performance concrete. Compos. Struct. 2019, 209, 23–33. [Google Scholar] [CrossRef]

- de Oliveira, L.A.P.; Castro-Gomes, J.P. Physical and mechanical behaviour of recycled PET fibre reinforced mortar. Constr. Build. Mater. 2011, 25, 1712–1717. [Google Scholar] [CrossRef]

- Al-Tulaian, B.; Al-Shannag, M.; Al-Hozaimy, A. Recycled plastic waste fibers for reinforcing Portland cement mortar. Constr. Build. Mater. 2016, 127, 102–110. [Google Scholar] [CrossRef]

- Lin, X.; Yu, J.; Li, H.; Lam, J.Y.; Shih, K.; Sham, I.M.; Leung, C.K. Recycling polyethylene terephthalate wastes as short fibers in strain-hardening cementitious composites (SHCC). J. Hazard. Mater. 2018, 357, 40–52. [Google Scholar] [CrossRef]

- Cheng, W.; Liu, G.; Chen, L. Pet fiber reinforced wet-mix shotcrete with walnut shell as replaced aggregate. Appl. Sci. 2017, 7, 345. [Google Scholar] [CrossRef] [Green Version]

- Alghazali, H.H.; Aljazaeri, Z.R.; Myers, J.J. Effect of accelerated curing regimes on high volume Fly ash mixtures in precast manufacturing plants. Cem. Concr. Res. 2020, 131, 105913. [Google Scholar] [CrossRef]

- Sunayana, S.; Barai, S.V. Flexural performance and tension-stiffening evaluation of reinforced concrete beam incorporating recycled aggregate and fly ash. Constr. Build. Mater. 2018, 174, 210–223. [Google Scholar] [CrossRef]

- Sadati, S.; Arezoumandi, M.; Khayat, K.H.; Volz, J.S. Shear performance of reinforced concrete beams incorporating recycled concrete aggregate and high-volume fly ash. J. Clean. Prod. 2016, 115, 284–293. [Google Scholar] [CrossRef]

- Ogawa, Y.; Bui, P.T.; Kawai, K.; Sato, R. Effects of porous ceramic roof tile waste aggregate on strength development and carbonation resistance of steam-cured fly ash concrete. Constr. Build. Mater. 2020, 236, 117462. [Google Scholar] [CrossRef]

- Pati, P.; Sahu, S.K. Innovative utilization of fly ash in concrete tiles for sustainable construction. Mater. Today Proc. 2020. [Google Scholar] [CrossRef]

- Krishnaraj, L.; Niranjan, R.; Kumar, G.P.; Kumar, R.S. Numerical and experimental investigation on mechanical and thermal behaviour of brick masonry: An efficient consumption of ultrafine fly ash. Constr. Build. Mater. 2020, 253, 119232. [Google Scholar] [CrossRef]

- Tošić, N.; Marinković, S.; Pecić, N.; Ignjatović, I.; Dragaš, J. Long-term behaviour of reinforced beams made with natural or recycled aggregate concrete and high-volume fly ash concrete. Constr. Build. Mater. 2018, 176, 344–358. [Google Scholar] [CrossRef]

- Fuzail Hashmi, A.; Shariq, M.; Baqi, A. Flexural performance of high volume fly ash reinforced concrete beams and slabs. Structures 2020, 25, 868–880. [Google Scholar] [CrossRef]

- Šejnoha, M.; Brouček, M.; Novotná, E.; Keršner, Z.; Lehký, D.; Frantík, P. Fracture properties of cement and alkali activated fly ash based concrete with application to segmental tunnel lining. Adv. Eng. Softw. 2013, 62–63, 61–71. [Google Scholar] [CrossRef]

- Swathi, V.; Asadi, S.S.; Poluraju, P. An integrated methodology for structural performance of high-volume fly ash concrete beams using hybrid fibers. Mater. Today Proc. 2020, 27, 1630–1635. [Google Scholar] [CrossRef]

- Gao, Y.; He, B.; Li, Y.; Tang, J.; Qu, L. Effects of nano-particles on improvement in wear resistance and drying shrinkage of road fly ash concrete. Constr. Build. Mater. 2017, 151, 228–235. [Google Scholar] [CrossRef]