Autogenous Healing of Cracked Mortar Using Modified Steady-State Migration Test against Chloride Penetration

Abstract

:1. Introduction

2. Experimental Program

2.1. Test Outline

2.2. Materials and Mix Proportions

2.3. Specimen Preparations

2.4. Steady-State Chloride Migration Test

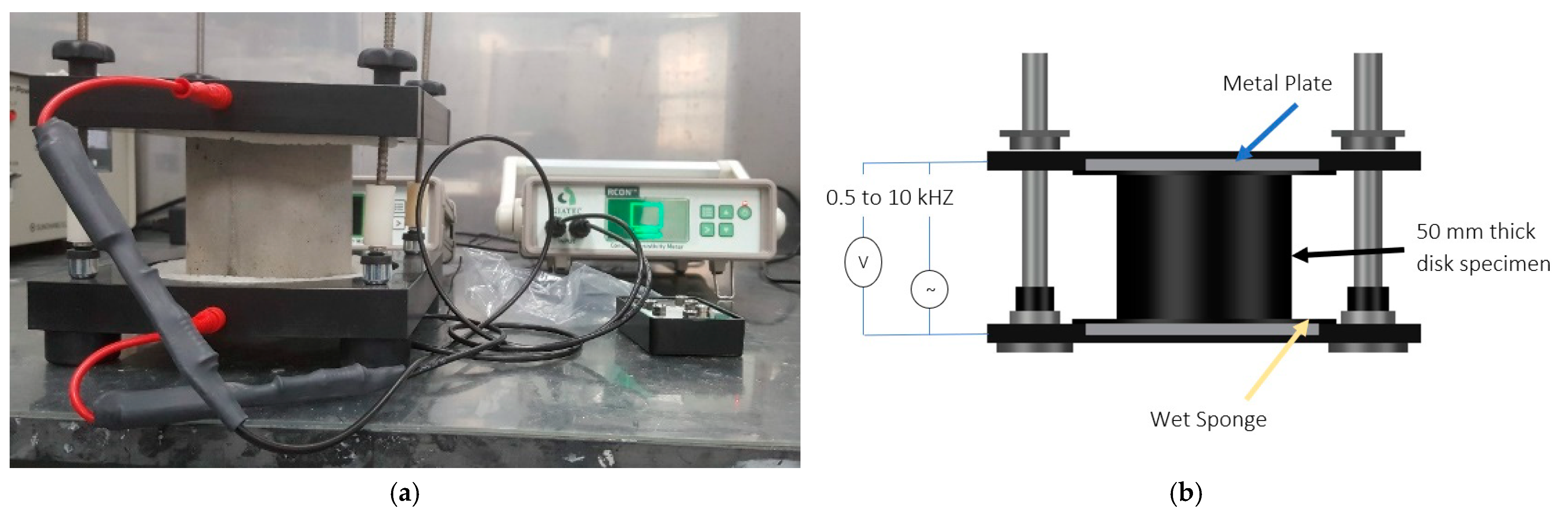

2.5. Electrical Conductivity

3. Results and Discussion

3.1. Effect of Self-Healing Materials on the Crack Healing

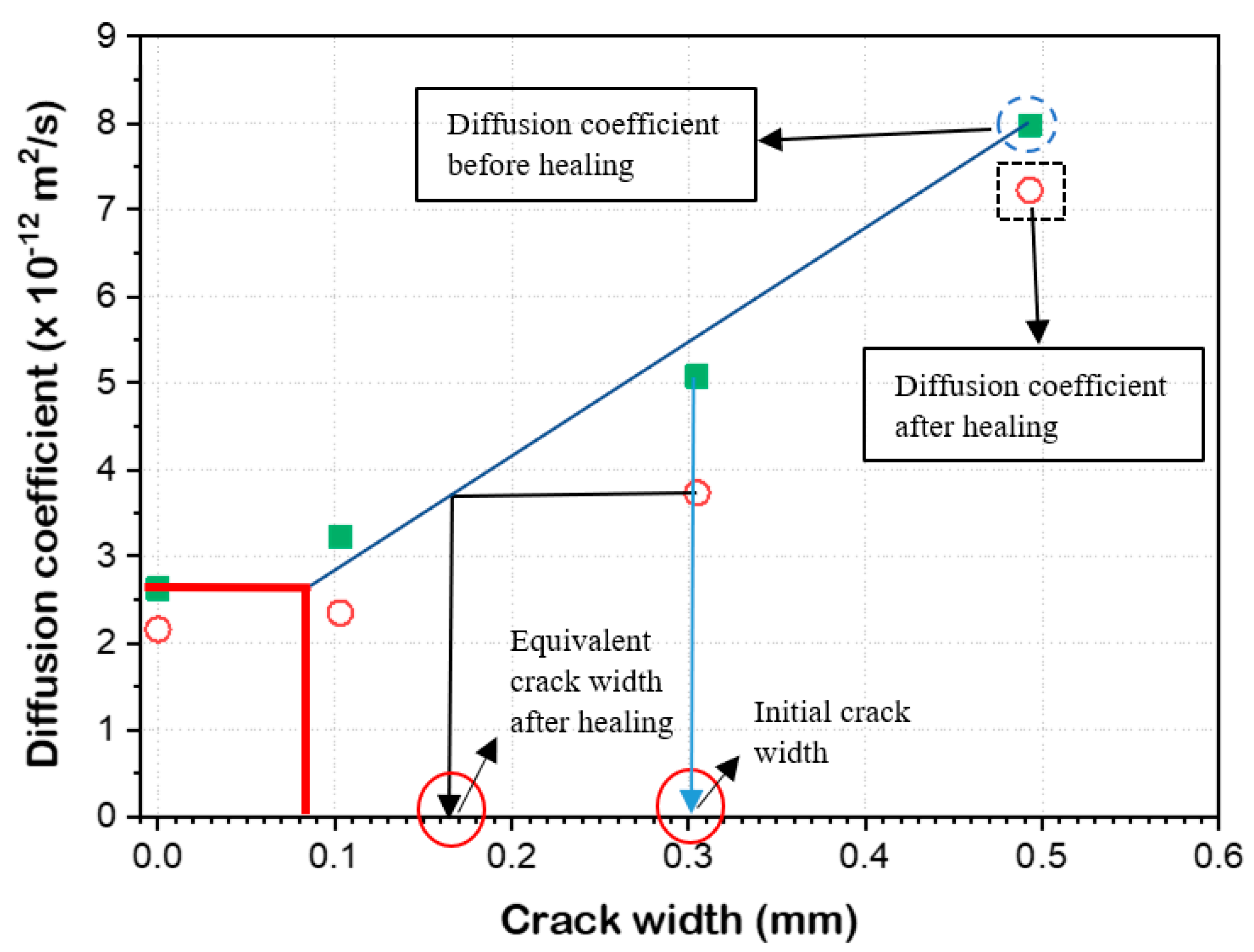

3.2. Index of Self-Healing Capacity and Equivalent Crack Width

3.3. Electrical Conductivity Test Results

4. Conclusions

- The proposed modified migration test method is a suitable method that can be used to examine the degree of self-healing of the cracked mortars in a very short time. The degree of self-healing of the crack is strongly associated to the crack width, the type of mortar, and the healing age.

- For the cracked specimens with 0 day(s) of healing, the transport properties are highly modified for all the specimens irrespective of their materials. It will not be wrong to say that the main parameter which influences the chloride penetration at an early age is the crack width, regardless of material.

- There is a strong linear relationship between crack width and chloride migration coefficients. The total chloride diffusion has multiplied when the specimen has large crack width because the chloride diffusion in crack is much faster than in mortar.

- The equivalent crack width is effective to evaluate the suitability of self-healing technology, whether the crack width after self-healing is smaller than the target crack width of the structure, such as allowable crack width by design code. It is possible to compare the self-healing performance with the degree of self-healing quantitatively.

- The electrical conductivity of concrete is an indirect test method for determining its permeability, which does not give accurate information about the healing process of the different cement-based materials. It also depends upon the moisture available in the pores of specimens, which is quite critical.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yoo, K.; Jang, S.; Lee, K.-M. Recovery of Chloride Penetration Resistance of Cement-Based Composites Due to Self-Healing of Cracks. Materials 2021, 14, 2501. [Google Scholar] [CrossRef]

- Van Belleghem, B.; Kessler, S.; van den Heede, P.; van Tittelboom, K.; de Belie, N. Chloride induced reinforcement corrosion behavior in self-healing concrete with encapsulated polyurethane. Cem. Concr. Res. 2018, 113, 130–139. [Google Scholar] [CrossRef]

- Van Tittelboom, K.; De Belie, N. Self-healing in cementitious materials—A review. Materials 2013, 6, 2182–2217. [Google Scholar] [CrossRef] [Green Version]

- Azarsa, P.; Gupta, R.; Biparva, A. Assessment of self-healing and durability parameters of concretes incorporating crystalline admixtures and Portland Limestone Cement. Cem. Concr. Compos. 2019, 99, 17–31. [Google Scholar] [CrossRef]

- Roig-Flores, M.; Pirritano, F.; Serna, P.; Ferrara, L. Effect of crystalline admixtures on the self-healing capability of early-age concrete studied by means of permeability and crack closing tests. Constr. Build. Mater. 2016, 114, 447–457. [Google Scholar] [CrossRef]

- Li, M.; Li, V.C. Cracking and Healing of Engineered Cementitious Composites under Chloride Environment. ACI Mater. J. 2011, 108, 333–340. [Google Scholar] [CrossRef]

- Şahmaran, M.; Keskin, S.B.; Ozerkan, G.; Yaman, I.O. Self-healing of mechanically-loaded self consolidating concretes with high volumes of fly ash. Cem. Concr. Compos. 2008, 30, 872–879. [Google Scholar] [CrossRef]

- Reinhardt, H.-W.; Jooss, M. Permeability and self-healing of cracked concrete as a function of temperature and crack width. Cem. Concr. Res. 2003, 33, 981–985. [Google Scholar] [CrossRef]

- Granger, S.; Loukili, A.; Pijaudier-Cabot, G.; Chanvillard, G. Experimental characterization of the self-healing of cracks in an ultra high performance cementitious material: Mechanical tests and acoustic emission analysis. Cem. Concr. Res. 2007, 37, 519–527. [Google Scholar] [CrossRef] [Green Version]

- Hearn, N. Self-sealing, autogenous healing and continued hydration: What is the difference? Mater. Struct. 1998, 31, 563–567. [Google Scholar] [CrossRef]

- Jacobsen, S.; Sellevold, E.J. Self healing of high strength concrete after deterioration by freeze/thaw. Cem. Concr. Res. 1996, 26, 55–62. [Google Scholar] [CrossRef]

- Aldea, C.-M.; Song, W.-J.; Popovics, J.S.; Shah, S.P. Extent of healing of cracked normal strength concrete. J. Mater. Civ. Eng. 2000, 12, 92–96. [Google Scholar] [CrossRef]

- Sahmaran, M.; Li, M.; Li, V.C. Transport properties of engineered cementitious composites under chloride exposure. ACI Mater. J. 2007, 104, 604–611. [Google Scholar]

- Jacobsen, S.; Marchand, J.; Boisvert, L. Effect of cracking and healing on chloride transport in OPC concrete. Cem. Concr. Res. 1996, 26, 869–881. [Google Scholar] [CrossRef]

- Buller, A.S.; Abro, F.U.R.; Lee, K.-M.; Jang, S.Y. Mechanical recovery of cracked fiber-reinforced mortar incorporating crystalline admixture, expansive agent, and geomaterial. Adv. Mater. Sci. Eng. 2019, 2019, 3420349. [Google Scholar] [CrossRef] [Green Version]

- Lee, H.; Wong, H.; Buenfeld, N. Self-sealing of cracks in concrete using superabsorbent polymers. Cem. Concr. Res. 2016, 79, 194–208. [Google Scholar] [CrossRef] [Green Version]

- Ferrara, L.; Van Mullem, T.; Alonso, M.C.; Antonaci, P.; Borg, R.P.; Cuenca, E.; Jefferson, A.; Ng, P.; Peled, A.; Roig-Flores, M.; et al. Experimental characterization of the self-healing capacity of cement based materials and its effects on the material performance: A state of the art report by COST Action SARCOS WG2. Constr. Build. Mater. 2018, 167, 115–142. [Google Scholar] [CrossRef] [Green Version]

- Souradeep, G.; Kua, H.W. Encapsulation technology and techniques in self-healing concrete. J. Mater. Civ. Eng. 2016, 28, 04016165. [Google Scholar] [CrossRef]

- De Belie, N.; Gruyaert, E.; Al-Tabbaa, A.; Antonaci, P.; Baera, C.; Bajare, D.; Darquennes, A.; Davies, R.; Ferrara, L.; Jefferson, T.; et al. A review of self-healing concrete for damage management of structures. Adv. Mater. Interfaces 2018, 5, 1800074. [Google Scholar] [CrossRef]

- Buller, A.S.; Abro, F.-R.; Ali, T.; Jakhrani, S.H.; Ul-Abdin, Z. Stimulated autogenous-healing capacity of fiber-reinforced mortar incorporating healing agents for recovery against fracture and mechanical properties. Mater. Sci. 2021. [Google Scholar] [CrossRef]

- Sisomphon, K.; Copuroglu, O.; Koenders, E. Effect of exposure conditions on self healing behavior of strain hardening cementitious composites incorporating various cementitious materials. Constr. Build. Mater. 2013, 42, 217–224. [Google Scholar] [CrossRef]

- Kang, S.-H.; Hong, S.-G.; Moon, J. Absorption kinetics of superabsorbent polymers (SAP) in various cement-based solutions. Cem. Concr. Res. 2017, 97, 73–83. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Wyrzykowski, M.; Schröfl, C.; Snoeck, D.; Lura, P.; De Belie, N.; Mignon, A.; Van Vlierberghe, S.; Klemm, A.J.; Almeida, F.C.R.; et al. Application of super absorbent polymers (SAP) in concrete construction—Update of RILEM state-of-the-art report. Mater. Struct. 2021, 54. [Google Scholar] [CrossRef]

- Tenório Filho, J.R.; Mannekens, E.; van Tittelboom, K.; van Vlierberghe, S.; de Belie, N.; Snoeck, D. Innovative SuperAbsorbent Polymers (iSAPs) to construct crack-free reinforced concrete walls: An in-field large-scale testing campaign. J. Build. Eng. 2021, 43, 102639. [Google Scholar] [CrossRef]

- Mors, R.M.; Jonkers, H.M. Bacteria-based self-healing concrete—An introduction. In Proceedings of the V International PhD Student Workshop on Durability of Reinforced Concrete; From Composition to Service Life Design, Espoo, Finland, 9–10 February 2012; pp. 32–39. [Google Scholar]

- Van Mullem, T.; Anglani, G.; Dudek, M.; Vanoutrive, H.; Bumanis, G.; Litina, C.; Kwiecień, A.; Al-Tabbaa, A.; Bajare, D.; Stryszewska, T.; et al. Addressing the need for standardization of test methods for self-healing concrete: An inter-laboratory study on concrete with macrocapsules. Sci. Technol. Adv. Mater. 2020, 21, 661–682. [Google Scholar] [CrossRef] [PubMed]

- De Belie, N.; Van Belleghem, B.; Erşan, Y.Ç.; van Tittelboom, K. Durability of self-healing concrete. MATEC Web Conf. 2019, 289, 01003. [Google Scholar] [CrossRef]

- Peng, C.; Wu, Q.; Shen, J.; Mo, R.; Xu, J. Numerical study on the effect of transverse crack self-healing on the corrosion rate of steel bar in concrete. J. Build. Eng. 2021, 41, 102767. [Google Scholar] [CrossRef]

- Maes, M.; van Tittelboom, K.; de Belie, N. The efficiency of self-healing cementitious materials by means of encapsulated polyurethane in chloride containing environments. Constr. Build. Mater. 2014, 71, 528–537. [Google Scholar] [CrossRef]

- Nordtest. Concrete, Hardened: Accelerated Chloride Penetration (NT BUILD 443); Nordtest Method; Nordtest: Serravalle Scrivia, Italy, 1995. [Google Scholar]

- Van den Heede, P.; van Belleghem, B.; Araújo, M.A.; Feiteira, J.; de Belie, N. Screening of different encapsulated polymer-based healing agents for chloride exposed self-healing concrete using chloride migration tests. Key Eng. Mater. 2018, 761, 152–158. [Google Scholar] [CrossRef]

- Darquennes, A.; Olivier, K.; Benboudjema, F.; Gagné, R. Self-healing at early-age, a way to improve the chloride resistance of blast-furnace slag cementitious materials. Constr. Build. Mater. 2016, 113, 1017–1028. [Google Scholar] [CrossRef]

- Şahmaran, M. Effect of flexure induced transverse crack and self-healing on chloride diffusivity of reinforced mortar. J. Mater. Sci. 2007, 42, 9131–9136. [Google Scholar] [CrossRef]

- ASTM C1202. Standard Test Method for Electrical Indication of Concrete ’s Ability to Resist Chloride; ASTM: West Conshohocken, PA, USA, 1981; pp. 1–6. [Google Scholar] [CrossRef] [Green Version]

- Abro, F.R.; Buller, A.S.; Lee, K.-M.; Jang, S.Y. Using the steady-state chloride migration test to evaluate the self-healing capacity of cracked mortars containing crystalline, expansive, and swelling admixtures. Materials 2019, 12, 1865. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shin, K.J.; Bae, W.; Choi, S.-W.; Son, M.; Lee, K.M. Parameters influencing water permeability coefficient of cracked concrete specimens. Constr. Build. Mater. 2017, 151, 907–915. [Google Scholar] [CrossRef]

- Nordtest. Chloride Migration Coefficient from Non-Steady-State Migration Experiments (NT Build 492); Nordtest Method; Nordtest: Serravalle Scrivia, Italy, 1999. [Google Scholar]

- Nordtest. Concrete, Mortar and Cement-Based Repair Materials: Chloride Diffusion Coefficient from Migration Cell Experiments (NT Build 355); Nordtest Method; Nordtest: Espoo, Finland, 1997. [Google Scholar]

- Tang, L.; Nilsson, L.-O. Rapid determination of the chloride diffusivity in concrete by applying an electrical field. ACI Mater. J. 1993, 89, 49–53. [Google Scholar]

- Sahmaran, M.; Yildirim, G.; Erdem, T.K. Self-healing capability of cementitious composites incorporating different supplementary cementitious materials. Cem. Concr. Compos. 2013, 35, 89–101. [Google Scholar] [CrossRef] [Green Version]

- Jang, S.Y.; Kim, B.S.; Oh, B.H. Effect of crack width on chloride diffusion coefficients of concrete by steady-state migration tests. Cem. Concr. Res. 2011, 41, 9–19. [Google Scholar] [CrossRef]

- Thermo Fisher Scientific. User Guide Chloride Ion Selective Electrode; Thermo Fisher Scientific: Waltham, MA, USA, 2008. [Google Scholar]

- AASHTO TP-95-11. Standard Test Method for Surface Resistivity of Concrete’s Ability to Resist Chloride Ion Penetration; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2011; Volume 4. [Google Scholar]

- Yildirim, G.; Aras, G.H.; Banyhussan, Q.; Şahmaran, M.; Lachemi, M. Estimating the self-healing capability of cementitious composites through non-destructive electrical-based monitoring. NDT E Int. 2015, 76, 26–37. [Google Scholar] [CrossRef]

- Al-Dahawi, A.; Sarwary, M.H.; Öztürk, O.; Yıldırım, G.; Akın, A.; Şahmaran, M.; Lachemi, M. Electrical percolation threshold of cementitious composites possessing self-sensing functionality incorporating different carbon-based materials. Smart Mater. Struct. 2016, 25, 105005. [Google Scholar] [CrossRef]

| Binder | Mixture Proportions (by Mass) | 28-Day Compressive Strength (MPa) | Slump Flow (mm) | |||||

|---|---|---|---|---|---|---|---|---|

| Water | Cement | SH Materials % (2:1) | Sand | SP (%) | ||||

| CSA | Na2CO3 | |||||||

| OPC | 0.4 | 1 | - | 2 | 0.3 | 50.60 | 165 | |

| SH4 | 0.4 | 1 | 0.04 | 1.96 | 0.5 | 42.69 | 160 | |

| SH6 | 0.4 | 1 | 0.06 | 1.94 | 0.5 | 41.87 | 155 | |

| SH8 | 0.4 | 1 | 0.08 | 1.92 | 0.5 | 40.35 | 135 | |

| Binder | Target Crack Width (μm) | Achieved Crack Width (μm) | Difference (%) |

|---|---|---|---|

| OPC | 200 | 193 | −3.5 |

| 300 | 284 | −5.3 | |

| 400 | 393 | −1.8 | |

| SH4 | 200 | 188 | −6.0 |

| 300 | 273 | −9.0 | |

| 400 | 378 | −5.5 | |

| SH6 | 200 | 196 | −2.0 |

| 300 | 296 | −1.3 | |

| 400 | 364 | −9.0 | |

| SH8 | 200 | 201 | 0.5 |

| 300 | 293 | −2.3 | |

| 400 | 400 | 0.0 |

| Mix ID | Wcr,i (µm) | Wcr,28-d (µm) | Wcr,56-d (µm) | Wcr,120-d (µm) |

|---|---|---|---|---|

| OPC | 193 | 121 | 107 | 95 |

| 284 | 194 | 182 | 170 | |

| 393 | 251 | 261 | 230 | |

| SH4 | 188 | 121 | 107 | 95 |

| 273 | 190 | 135 | 80 | |

| 378 | 269 | 239 | 210 | |

| SH6 | 196 | 108 | ≤80 | ≤80 |

| 296 | 162 | 138 | 105 | |

| 364 | 248 | 172 | 158 | |

| SH8 | 201 | 130 | ≤80 | ≤80 |

| 293 | 200 | 130 | 105 | |

| 400 | 290 | 260 | 240 |

| Specimen Length (mm) | Test No. | Electrical Conductivity (mS/s) | Mean | Standard Deviation | Coefficient of Variation (%) |

|---|---|---|---|---|---|

| 200 | 1 | 24.50 | 24.32 | 0.17 | 0.70 |

| 2 | 24.31 | ||||

| 3 | 24.16 | ||||

| 100 | 1 | 26.08 | 25.98 | 0.086 | 0.33 |

| 2 | 25.97 | ||||

| 3 | 25.91 | ||||

| 50 | 1 | 24.97 | 25.13 | 0.152 | 0.60 |

| 2 | 25.16 | ||||

| 3 | 25.27 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abro, F.u.R.; Buller, A.S.; Ali, T.; Ul-Abdin, Z.; Ahmed, Z.; Memon, N.A.; Lashari, A.R. Autogenous Healing of Cracked Mortar Using Modified Steady-State Migration Test against Chloride Penetration. Sustainability 2021, 13, 9519. https://doi.org/10.3390/su13179519

Abro FuR, Buller AS, Ali T, Ul-Abdin Z, Ahmed Z, Memon NA, Lashari AR. Autogenous Healing of Cracked Mortar Using Modified Steady-State Migration Test against Chloride Penetration. Sustainability. 2021; 13(17):9519. https://doi.org/10.3390/su13179519

Chicago/Turabian StyleAbro, Fahad ul Rehman, Abdul Salam Buller, Tariq Ali, Zain Ul-Abdin, Zaheer Ahmed, Noor Ahmed Memon, and Ali Raza Lashari. 2021. "Autogenous Healing of Cracked Mortar Using Modified Steady-State Migration Test against Chloride Penetration" Sustainability 13, no. 17: 9519. https://doi.org/10.3390/su13179519

APA StyleAbro, F. u. R., Buller, A. S., Ali, T., Ul-Abdin, Z., Ahmed, Z., Memon, N. A., & Lashari, A. R. (2021). Autogenous Healing of Cracked Mortar Using Modified Steady-State Migration Test against Chloride Penetration. Sustainability, 13(17), 9519. https://doi.org/10.3390/su13179519