Inventory Share Policy Designs for a Sustainable Omni-Chanel E-Commerce Network

Abstract

:1. Introduction

2. Literature Review

3. Materials and Methods

3.1. Problem Definition

3.2. Simulation Model Assumptions

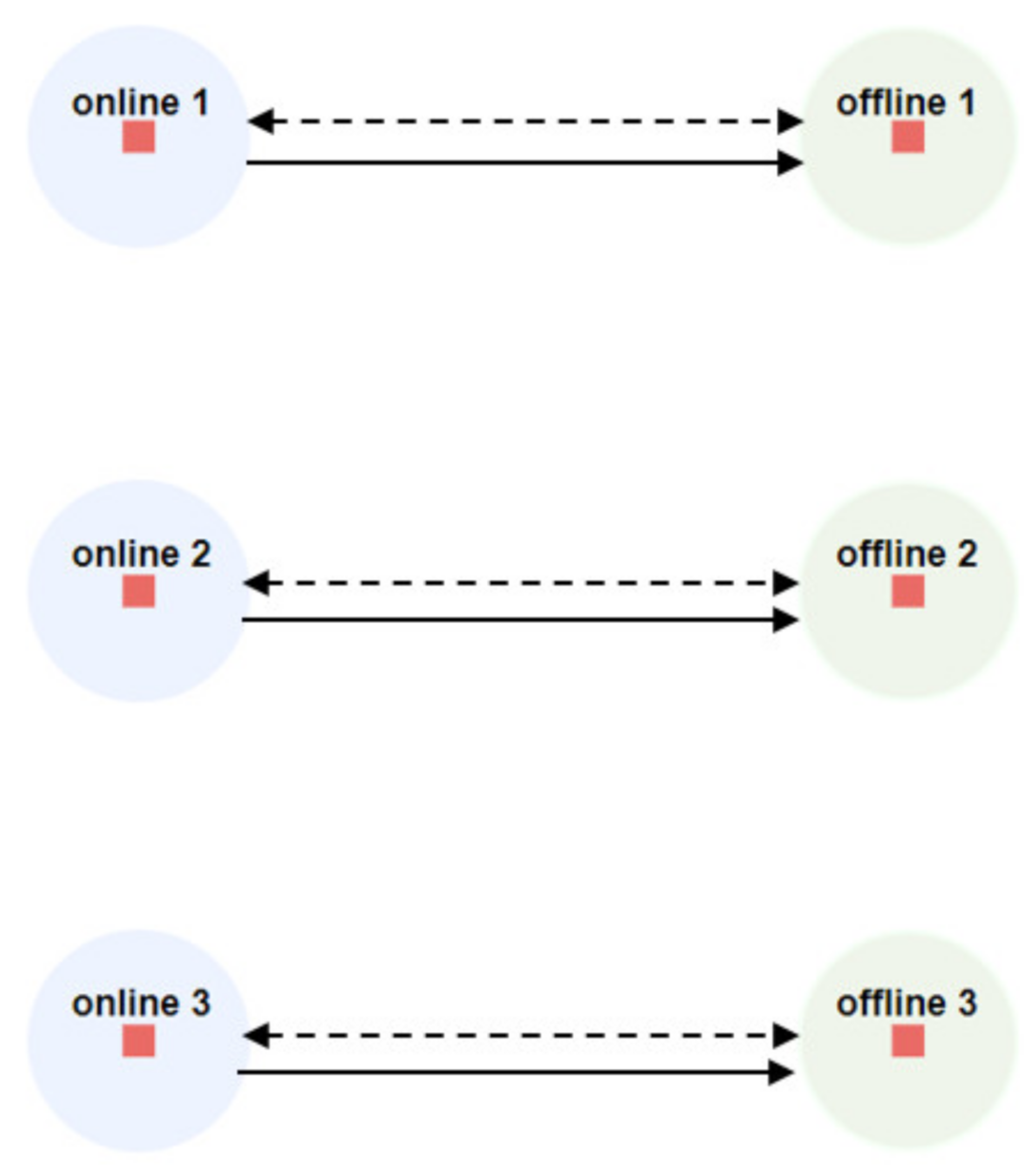

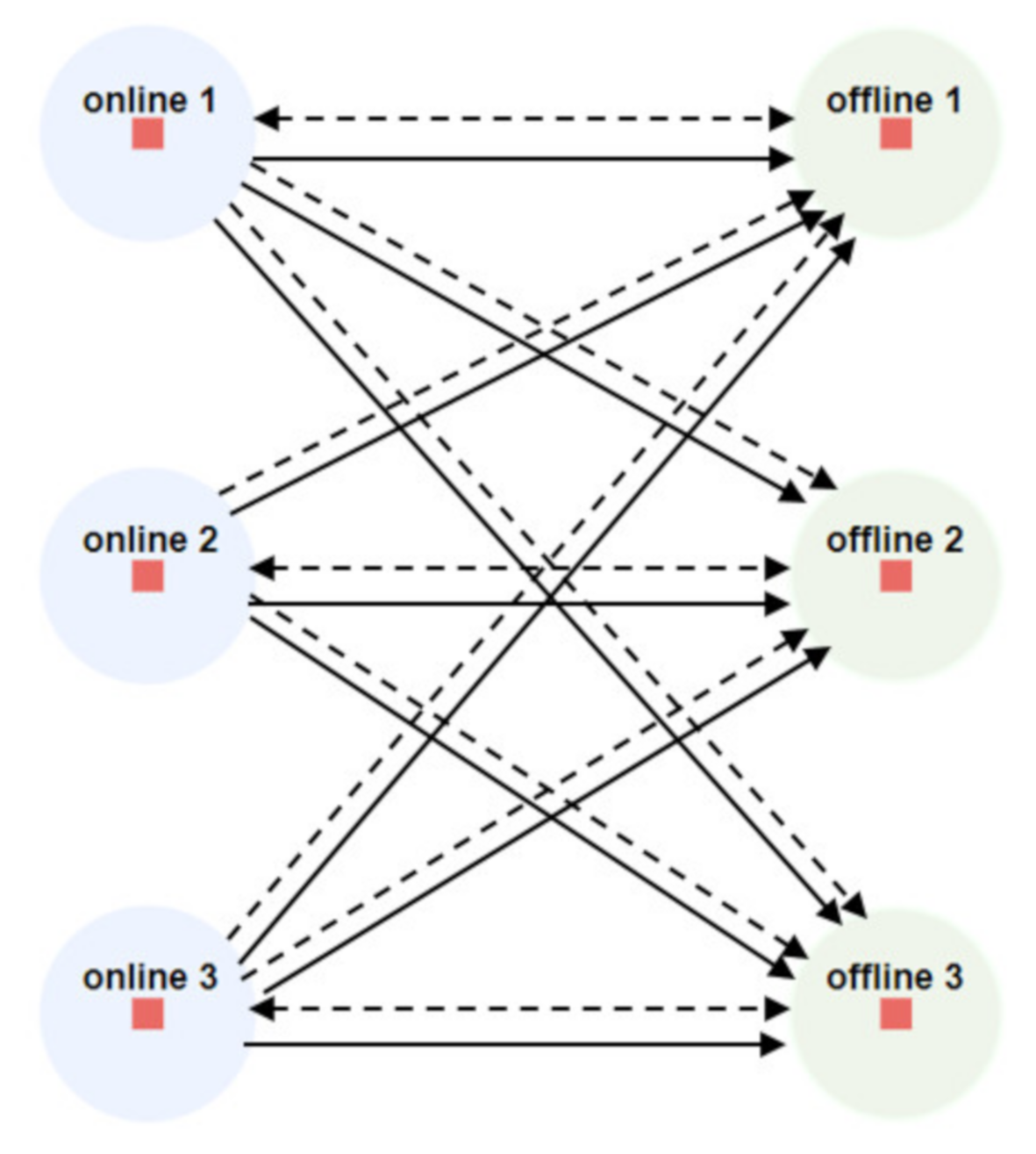

- There are three different companies in the system, each of which has its offline and online stores. Hence, there are six store locations at the same echelon as offline and online stores.

- There is a single type of product in the system.

- Mean demand amount distribution for online stores is considered to be larger than the mean demand amount distribution from offline stores.

- Demand arrivals at stores follow a Poisson distribution with mean one day.

- Demand amount distributions for stores are considered to be a normal distribution. Specifically, these values are: Online 1 Normal (70, 20), Online 2 Normal (50, 20), Online 3 Normal (90, 20), Offline 1 Normal (35, 20), Offline 2 Normal (25, 20), and Offline 3 Normal (45, 20).

- Inventory replenishments are done by the main warehouse with unlimited capacity.

- Lead time distribution for product arrivals from the main warehouse to the stores follows Uniform (1, 2) days.

- While calculating the replenishment amounts for store i at time t, Qit, products on road are counted as on hand.

- Capacity of a truck sent from the main warehouse is considered to be 100 items per truck.

- The number of trucks sent from the main warehouse is considered to be infinite.

- For unmet offline store orders, it is assumed that with 75% probability, the customers accept that those orders can be met from any other stores. Namely, with 75% probability, customers accept to wait to meet their orders from another store in the network. Otherwise, it becomes a lost sale.

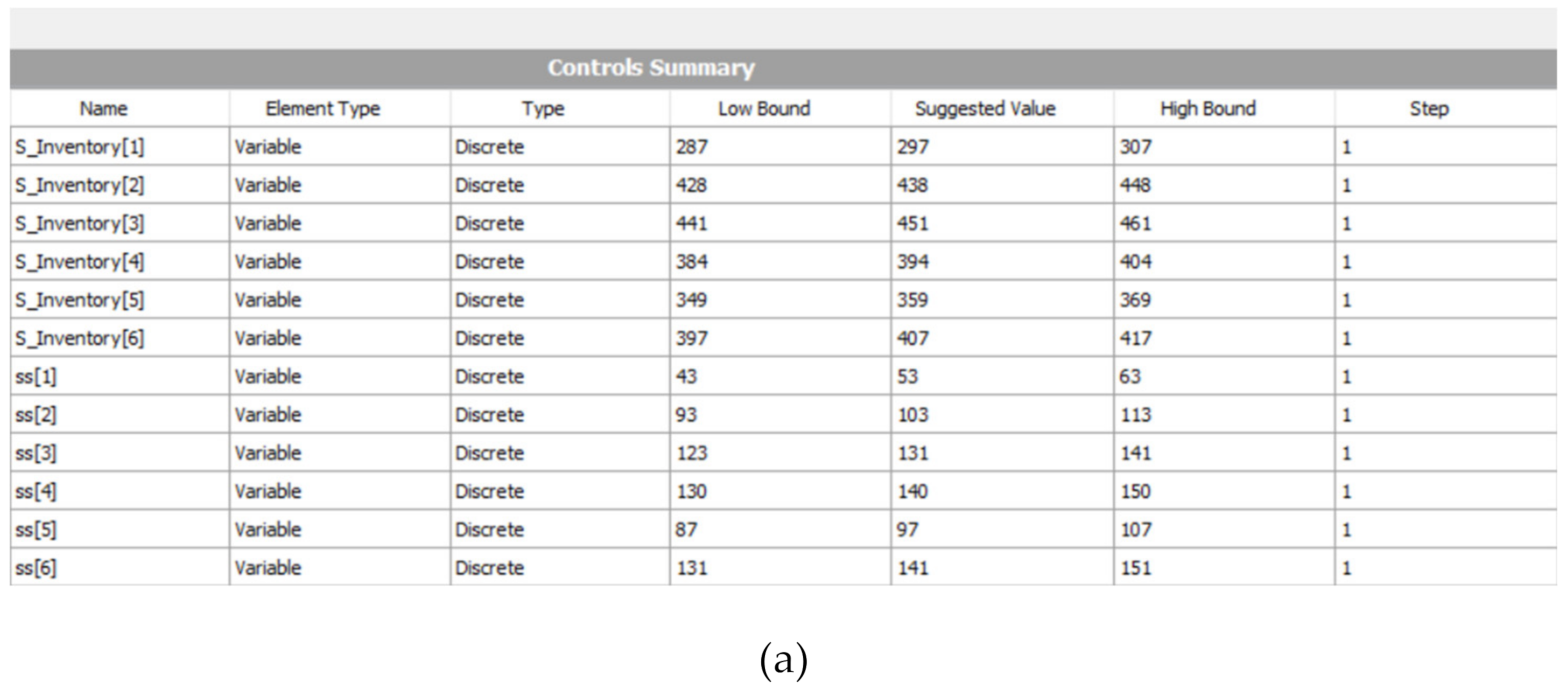

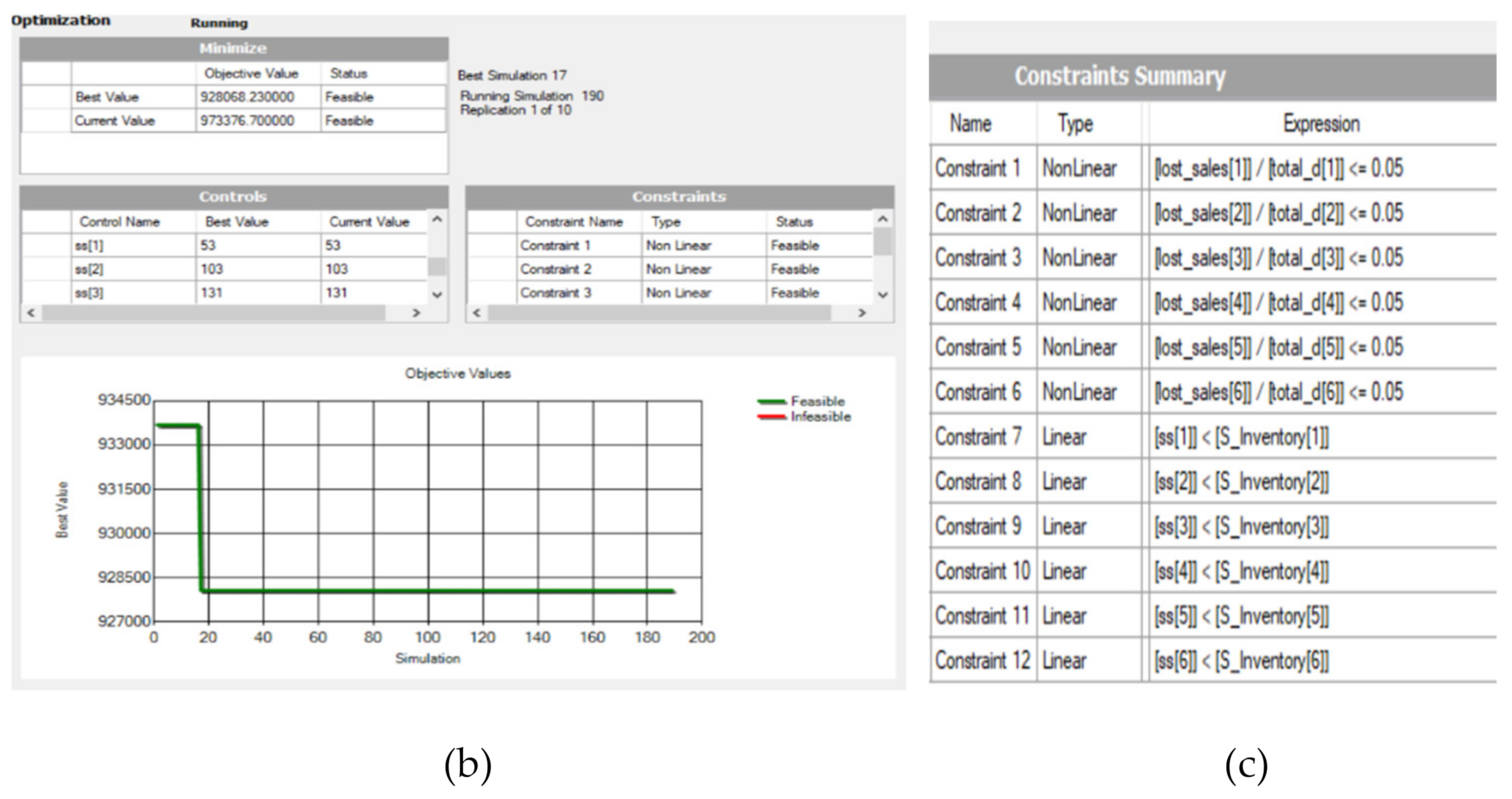

- In each store, the (s, S) levels are optimized under 95% customer service level constraint.

- Simulation models are run for one year.

- Warm-up periods are two months for the all models.

- Total cost of the network is computed by considering holding, ordering, transportation, fixed and variable inventory share costs, as well as lost sale costs.

- Ten independent replications are performed for each scenario.

- The common random numbers (CRN) variance reduction technique is used to ensure that the random numbers in the simulation models were consistent with each other for all scenarios.

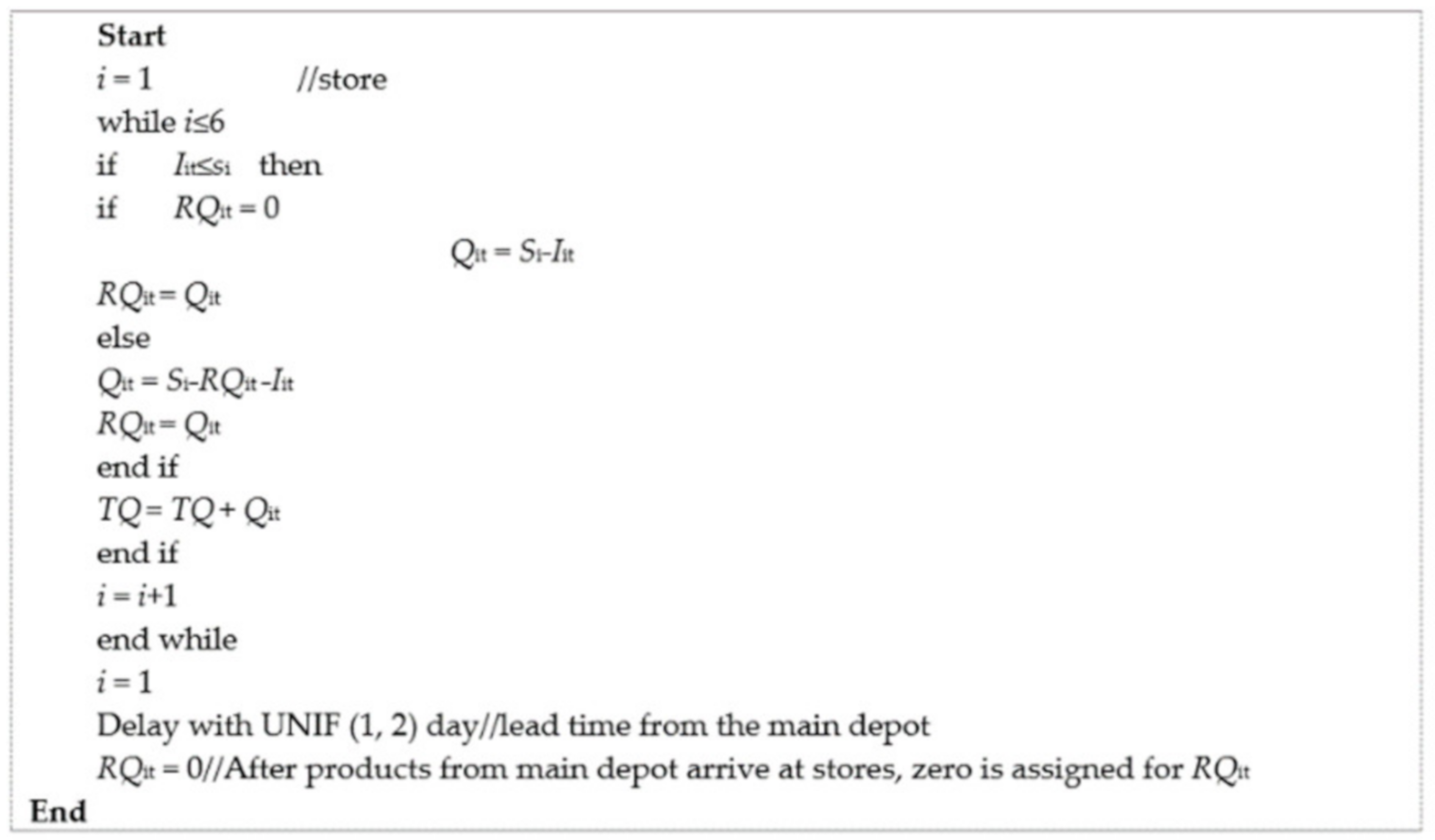

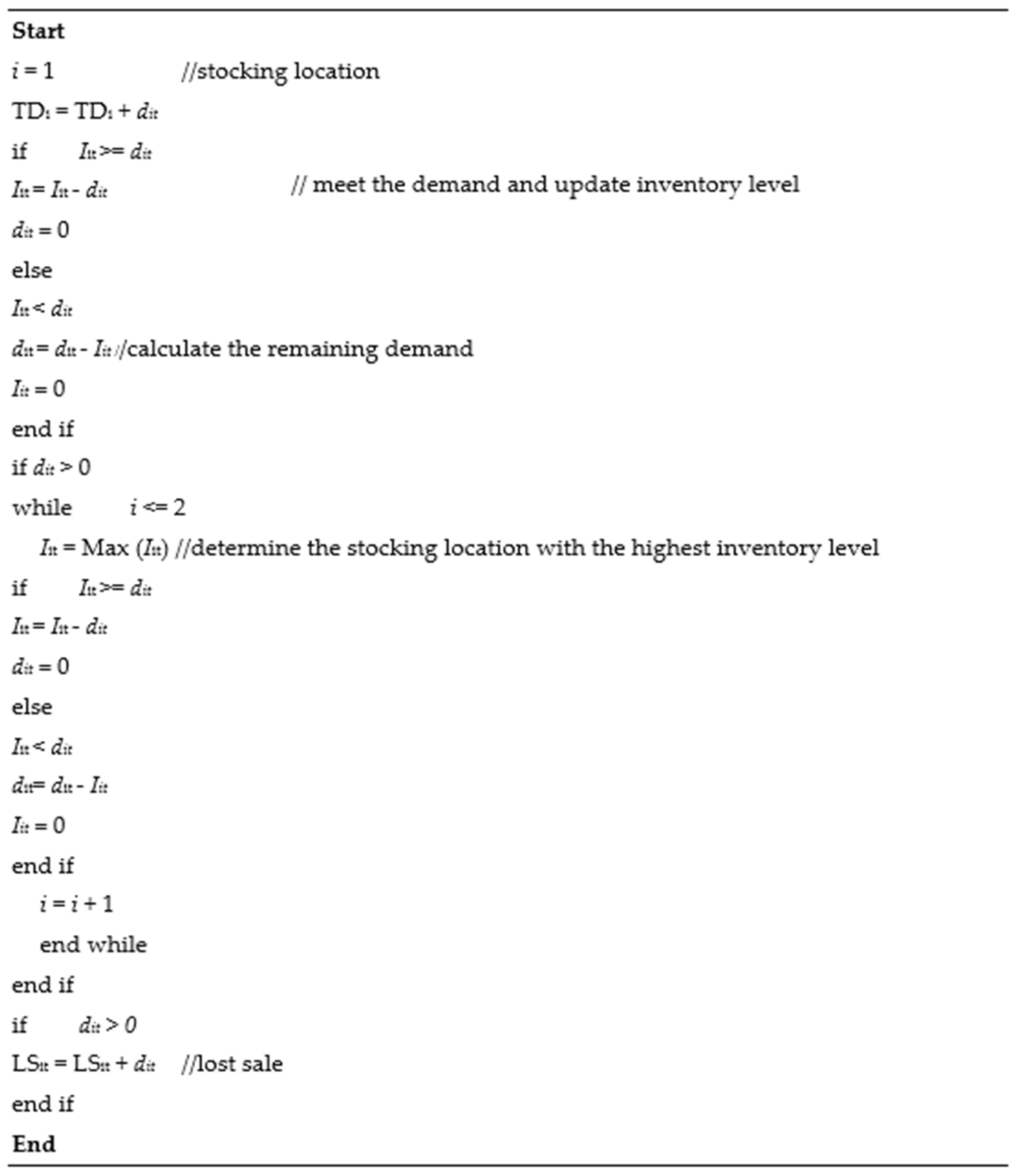

3.3. Notations and Pseudo-Codes Considered in the Simulation Models

- si: re-order stock level of store i, i = {1, 2, 3, 4, 5, 6}.

- Si: up-to-level of store i, i = {1, 2, 3, 4, 5, 6}.

- k: number of stores (i.e., k = 6).

- dit: amount of demand arrived at store i at time t, i = {1, 2, 3, 4, 5, 6}.

- TDi: total demand for store i during simulation, i = {1, 2, 3, 4, 5, 6}.

- CT: truck capacity for main depot (i.e., 100 products per truck).

- Iit: current inventory level at store i, at time t.

- LCji: inventory share cost per item from store j to i, j ≠ i, i = {1, 2, 3, 4, 5, 6}, j = {1, 2, 3, 4, 5, 6}.

- Ljit: total product amount sent from store j to i by inventory share at time t.

- LFji: total number of shipments based on inventory share takes place from store j for store i, during simulation, i = {1, 2, 3, 4, 5, 6}, j = {1, 2, 3, 4, 5, 6}.

- CFL: fixed inventory share cost.

- TC: fixed truck cost (i.e., $450/truck).

- LSit: total amount of lost sale at store i at time t, i = {1, 2, 3, 4, 5, 6}.

- Qit: ordering amount of store i from main depot at time t, i = {1, 2, 3, 4, 5, 6}.

- nit: number of trucks shipped from main depot to store i at day t, (nit is an integer value) i = {1, 2, 3, 4, 5, 6}.

- TQ: total amount of products sent from main depot during the simulation run.

- RQit: amount of products on road from main depot to the store i, i = {1, 2, 3, 4, 5, 6} at time t.

- Co: ordering cost per item from main depot.

- CLS: lost sale cost per item.

- h: annual holding cost.

- Rit: remaining demand amount that could not be met by store i, at time t.

- rjt: ratio for store j at time t for inventory share amount calculation.

3.4. Inventory Share Policies

3.4.1. Inventory Share Policy 1 Considered for Online Stores

3.4.2. Inventory Share Policy 2 Considered for Online Stores

3.4.3. Inventory Share Policy 3 Considered for Online Stores

3.4.4. Inventory Share Policy 4 Considered for Offline Stores

3.4.5. Inventory Share Policy 5 Considered for Offline Stores

- Step 1:

- Demand arrives at an offline store i. If demand cannot be fully met by that store,

- Step 2:

- With 75% probability, it tends to meet the lacking amount from online stores in this order:

- Step 3:

- The online stores are checked in the order of having the highest inventory levels. The online store having the highest inventory level starts sending its inventory until the remaining demand is met.

- Step 4:

- The last remaining amount becomes a lost sale.

3.4.6. Policy 6 for No Inventory Share

3.5. Simulation Modeling

4. Results

5. Discussion

- From Table 2 and Table 3, it is observed that total cost tends to decrease when inventory share is allowed more in the network. For instance, the Policy 1 and 5 combination provides the least total cost one. In that scenario, total inventory share cost is the highest one. Hence, we may focus on developing scenarios where more inventory share takes place.

- When inventory share happens more, the ordering frequency from the main depot decreases as expected. This contributes to a sustainable network design by the decreased truck travels from the main depot.

- From Table 2, it is observed that the combination of Policy 1 and 5 produces the best result in terms of the total cost.

- From the result tables, it is also observed that there is a negative correlation between inventory share and a lost sale. When inventory share cost increases, lost sale cost tends to decrease.

- As inventory share increases, total transportation cost and holding cost also tend to decrease in all policies.

- There is also a negative correlation between the total amount of inventory share and the total number of trucks sent from the main depot. This situation not only affects the cost but also gains importance in terms of decreasing CO2 released by trucks. By inventory sharing, companies can fulfil their environmental responsibilities by reducing CO2 emissions, while meeting customer demand rapidly and ensuring customer sustainability.

- When there is no inventory share in the system, ordering from the main depot increases drastically compared to any other scenarios.

- (s, S) levels tend to increase when there is no inventory share in the network. This also leads to increased holding cost in the system.

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Hoppner, J.; Griffith, D. Looking Back to Move Forward: A Review Of The Evolution Of Research in International Marketing Channels. J. Retail. 2015, 91, 610–626. [Google Scholar] [CrossRef]

- Brynjolfsson, E.; Jeffrey, Y.; Rahman, M. Competing in the Age of Omni-Channel Retailing. MIT Sloan Manag. Rev. 2013, 54, 23–29. [Google Scholar]

- Rangaswamy, A.; Van Bruggen, G. Opportunities and Challenges in Multichannel Marketing: An Introduction to the Special Issue. J. Interact. Mark. 2005, 19, 5–11. [Google Scholar] [CrossRef] [Green Version]

- Rigby, D. The Future of Shopping. Harv. Bus. Rev. 2011, 89, 65–76. [Google Scholar]

- Piotrowicz, W.; Cuthbertson, R. Introduction to the Special Issue Information Technology in Retail: Toward Omnichannel Retailing. Int. J. Electron. Commer. 2014, 18, 5–16. [Google Scholar] [CrossRef]

- Zhang, J.; Farris, P.; Irvin, J.; Kushwaha, T.; Steenburgh, T.; Weitz, B. Crafting Integrated Multichannel Retailing Strategies. J. Interact. Mark. 2010, 24, 168–180. [Google Scholar] [CrossRef]

- Shen, X.; Li, Y.; Sun, Y.; Wang, N. Channel Integration Quality, Perceived Fluency and Omnichannel Service Usage: The Moderating Roles of Internal and External Usage Experience. Decis. Support Syst. 2018, 109, 61–73. [Google Scholar] [CrossRef]

- Melero, I.; Sese, F.; Verhoef, P. Recasting the Customer Experience in Today’s Omni-Channel Environment. Universia Bus. Rev. 2016, 50, 18–37. [Google Scholar] [CrossRef]

- Cao, L.; Li, L. The Impact of Cross-Channel Integration on Retailers’ Sales Growth. J. Retail. 2015, 91, 198–216. [Google Scholar] [CrossRef]

- Wisner, J. A Structural equation model of supply chain management strategies and firm performance. J. Bus. Logist. 2003, 24, 1–26. [Google Scholar] [CrossRef]

- Mangal, D.; Chandna, P. Inventory Control in Supply Chain through Lateral Transhipment—A Case Study in Indian Industry. Int. J. Eng. Sci. 2009, 3, 443–457. [Google Scholar]

- Belgasmi, N.; Saïd, L.B.; Ghédira, K. Evolutionary Multiobjective Optimization Of The Multi-Location Transshipment Problem. Oper. Res. 2008, 8, 167–183. [Google Scholar] [CrossRef] [Green Version]

- Burton, S.; Soboleva, A. Interactive or Reactive? Marketing With Twitter. J. Consum. Mark. 2011, 28, 491–499. [Google Scholar] [CrossRef]

- Kotler, P.; Keller, K.L.; Goodman, M.; Brady, M.; Hansen, T. Marketing Management, 3rd ed.; Pearson Education Limited: Harlow, UK, 2016; ISBN 9781292142357. [Google Scholar]

- Lazaris, C.; Vrechopoulos, A. From Multichannel to “Omnichannel” Retailing: Review of the Literature and Calls for Research. In Proceedings of the 2nd International Conference on Contemporary Marketing Issues, Athens, Greece, 18–20 June 2014. [Google Scholar]

- Rodríguez-Torrico, P.; Cabezudo, R.S.J.; San-Martín, S. Tell Me What They Are Like And I Will Tell You Where They Buy. An Analysis of Omnichannel Consumer Behavior. Comput. Hum. Behav. 2017, 68, 465–471. [Google Scholar] [CrossRef] [Green Version]

- Xing, Y.; Grant, D.; McKinnon, A.; Fernie, J. Physical Distribution Service Quality in Online Retailing. Int. J. Phys. Distrib. Logist. Manag. 2010, 40, 415–432. [Google Scholar] [CrossRef]

- Janka, P. Embedded Plugins and Mobile Apps for Ecommerce. Available online: https://blog.monkeydata.com/6-benefits-of-choosing-an-omnichannel-strategy-e8a019506857 (accessed on 9 October 2020).

- Juaneda-Ayensa, E.; Mosquera, A.; Murillo, Y.S. Omnichannel Customer Behavior: Key Drivers of Technology Acceptance and Use and Their Effects on Purchase Intention. Front. Psychol. 2016, 7, 1117. [Google Scholar] [CrossRef] [Green Version]

- Hübner, A.; Holzapfel, A.; Kuhn, H. Distribution Systems in Omni-Channel Retailing. Bus. Res. 2016, 9, 255–296. [Google Scholar] [CrossRef] [Green Version]

- Ishfaq, R.; Defee, C.; Gibson, B.; Raja, U. Realignment of the Physical Distribution Process in Omni-Channel Fulfillment. Int. J. Phys. Distrib. Logist. Manag. 2016, 46, 543–561. [Google Scholar] [CrossRef]

- Maltz, A.B.; Sinha, R.; Rabinovich, E. Logistics: The key to e-retail success. Supply Chain Manag. Rev. 2004, 8, 48–54. [Google Scholar]

- Lee, H. A Multi-Echelon Inventory Model For Repairable Items With Emergency Lateral Transshipments. Manag. Sci. 1987, 33, 1302–1316. [Google Scholar] [CrossRef]

- Cohen, M.; Lee, H. Out of touch with customer needs? Spare parts and after sales service. Sloan Manag. Rev. 1990, 31, 55–66. [Google Scholar]

- Lau, H.; Chan, T.; Tsui, W.; Ho, G. Cost Optimization Of The Supply Chain Network Using Genetic Algorithms—Withdrawn. IEEE Trans. Knowl. Data. Eng. 2009, 1–36. [Google Scholar] [CrossRef]

- Van Wijk, A.; Adan, I.; van Houtum, G. Optimal Lateral Transshipment Policies for a Two Location Inventory Problem with Multiple Demand Classes. Eur. J. Oper. Res. 2019, 272, 481–495. [Google Scholar] [CrossRef]

- Alvarez, E.; van der Heijden, M.; Vliegen, I.; Zijm, W. Service Differentiation through Selective Lateral Transshipments. Eur. J. Oper. Res. 2014, 237, 824–835. [Google Scholar] [CrossRef] [Green Version]

- Paterson, C.; Kiesmüller, G.; Teunter, R.; Glazebrook, K. Inventory Models with Lateral Transshipments: A Review. Eur. J. Oper. Res. 2011, 210, 125–136. [Google Scholar] [CrossRef] [Green Version]

- Banerjee, A.; Burton, J.; Banerjee, S. A Simulation Study of Lateral Shipments in Single Supplier, Multiple Buyers Supply Chain Networks. Int. J. Prod. Econ. 2003, 81–82, 103–114. [Google Scholar] [CrossRef]

- Amiri-Aref, M.; Klibi, W.; Babai, M. The Multi-Sourcing Location Inventory Problem with Stochastic Demand. Eur. J. Oper. Res. 2018, 266, 72–87. [Google Scholar] [CrossRef]

- Ekren, B.Y.; Ornek, M. Determining Optimum (s, S) Levels Of Floor Stock Items In A Paint Production Environment. Simul. Model. Pract. Theory 2015, 57, 133–141. [Google Scholar] [CrossRef]

- Ekren, B.Y.; Ornek, M.A. Simulation-Based Inventory Control in a Chemical Industry. In Industrial Engineering Applications in Emerging Countries, 1st ed.; Sabuncuoglu, I., Kara, B.Y., Bidanda, B., Eds.; CRC Press: Boca Raton, FL, USA, 2015; ISBN 978-1-4822-2689-8. [Google Scholar]

- Ekren, B.Y.; Arslan, B. Simulation-Based Lateral Transshipment Policy Optimization for S, S Inventory Control Problem in A Single-Echelon Supply Chain Network. Int. J. Optim. Control: Theor. Appl. (IJOCTA) 2019, 10, 9–16. [Google Scholar] [CrossRef] [Green Version]

- Hammami, R.; Nouira, I.; Frein, Y. Carbon Emissions In A Multi-Echelon Production-Inventory Model With Lead Time Constraints. Int. J. Prod. Econ. 2015, 164, 292–307. [Google Scholar] [CrossRef]

- Manupati, V.; Jedidah, S.; Gupta, S.; Bhandari, A.; Ramkumar, M. Optimization Of A Multi-Echelon Sustainable Production-Distribution Supply Chain System With Lead Time Consideration Under Carbon Emission Policies. Comput. Ind. Eng. 2019, 135, 1312–1323. [Google Scholar] [CrossRef]

- Wang, M.; Ouyang, J.; Zhao, L. Production Planning With Transshipment in A Global Supply Chain Under Different Carbon Trading Mechanisms. Oper. Res. 2019. [Google Scholar] [CrossRef]

- Visconti, R.M.; Morea, D. Healthcare Digitalization and Pay-For-Performance Incentives in Smart Hospital Project Financing. Int. J. Environ. Res. Public Health 2020, 17, 2318. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Visconti, R.M.; Morea, D. Big Data for the Sustainability of Healthcare Project Financing. Sustainability 2019, 11, 3748. [Google Scholar] [CrossRef] [Green Version]

- Kleijnen, J.; Wan, J. Optimization of Simulated Systems: Optquest and Alternatives. Simul. Model. Pract. Theory 2007, 15, 354–362. [Google Scholar] [CrossRef]

| Online Store 1 | Online Store 2 | Online Store 3 | Offline Store 1 | Offline Store 2 | Offline Store 3 | |

|---|---|---|---|---|---|---|

| Policy | s1, S1 | s2, S2 | s3, S3 | S4, S4 | S5, S5 | S6, S6 |

| 1&4 | (125, 394) | (95, 354) | (171, 464) | (188, 411) | (85, 323) | (193, 448) |

| 2&4 | (140, 453) | (135, 419) | (189, 519) | (169, 308) | (159, 292) | (179, 346) |

| 3&4 | (153, 479) | (112, 395) | (188, 503) | (155, 371) | (128, 367) | (198, 439) |

| 1&5 | (53, 297) | (103, 438) | (131, 451) | (140, 394) | (97, 359) | (141, 407) |

| 2&5 | (111, 450) | (70, 420) | (105, 500) | (200, 346) | (117, 350) | (120, 368) |

| 3&5 | (160, 397) | (110, 300) | (186, 499) | (141, 406) | (103, 360) | (170, 430) |

| 6 | (278, 399) | (248, 318) | (347, 522) | (191, 299) | (199, 250) | (200, 346) |

| Policy | Total Lost Sale ($) | Total Holding ($) | Total Transportation ($) | Total Inventory Share ($) | Total Ordering ($) | Total ($) |

|---|---|---|---|---|---|---|

| 1&4 | 12,366 | 152,060 | 589,010 | 16,023 | 171,310 | 940,769 |

| 2&4 | 15,200 | 154,710 | 601,560 | 12,058 | 172,000 | 955,528 |

| 3&4 | 16,570 | 153,310 | 593,730 | 14,115 | 172,840 | 950,565 |

| 1&5 | 11,368 | 148,820 | 573,390 | 23,770 | 170,720 | 928,068 |

| 2&5 | 13,187 | 151,110 | 583,650 | 20,293 | 171,880 | 940,120 |

| 3&5 | 10,954 | 152,200 | 589,140 | 14,419 | 171,870 | 938,583 |

| 6 | 40,819 | 164,790 | 654,890 | 0 | 169,090 | 1,029,589 |

| Policy | Total Number of Inventory Share Completed | Total Amount of Products by Inventory Share | Total Number of Orders Given to the Main Depot | Total Number of Trucks Sent From the Main Depot |

|---|---|---|---|---|

| 1&4 | 309.50 | 14,680 | 423.70 | 1308.9 |

| 2&4 | 226.50 | 10,349 | 483.60 | 1336.8 |

| 3&4 | 273.20 | 12,577 | 407.70 | 1319.4 |

| 1&5 | 421.30 | 20,330 | 402.00 | 1274.2 |

| 2&5 | 357.90 | 16,529 | 391.90 | 1297.0 |

| 3&5 | 293.30 | 12,269 | 432.60 | 1309.2 |

| 6 | 0 | 0 | 822.20 | 1455.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

İzmirli, D.; Ekren, B.Y.; Kumar, V. Inventory Share Policy Designs for a Sustainable Omni-Chanel E-Commerce Network. Sustainability 2020, 12, 10022. https://doi.org/10.3390/su122310022

İzmirli D, Ekren BY, Kumar V. Inventory Share Policy Designs for a Sustainable Omni-Chanel E-Commerce Network. Sustainability. 2020; 12(23):10022. https://doi.org/10.3390/su122310022

Chicago/Turabian Styleİzmirli, Damla, Banu Yetkin Ekren, and Vikas Kumar. 2020. "Inventory Share Policy Designs for a Sustainable Omni-Chanel E-Commerce Network" Sustainability 12, no. 23: 10022. https://doi.org/10.3390/su122310022

APA Styleİzmirli, D., Ekren, B. Y., & Kumar, V. (2020). Inventory Share Policy Designs for a Sustainable Omni-Chanel E-Commerce Network. Sustainability, 12(23), 10022. https://doi.org/10.3390/su122310022