Lessons Learnt from Bridge Collapse: A View of Sustainable Management

Abstract

1. Introduction

2. Bridge Failures from 2009 to 2019

3. Case of Zijin Bridge

Collapse Process and Direct Reason Analysis

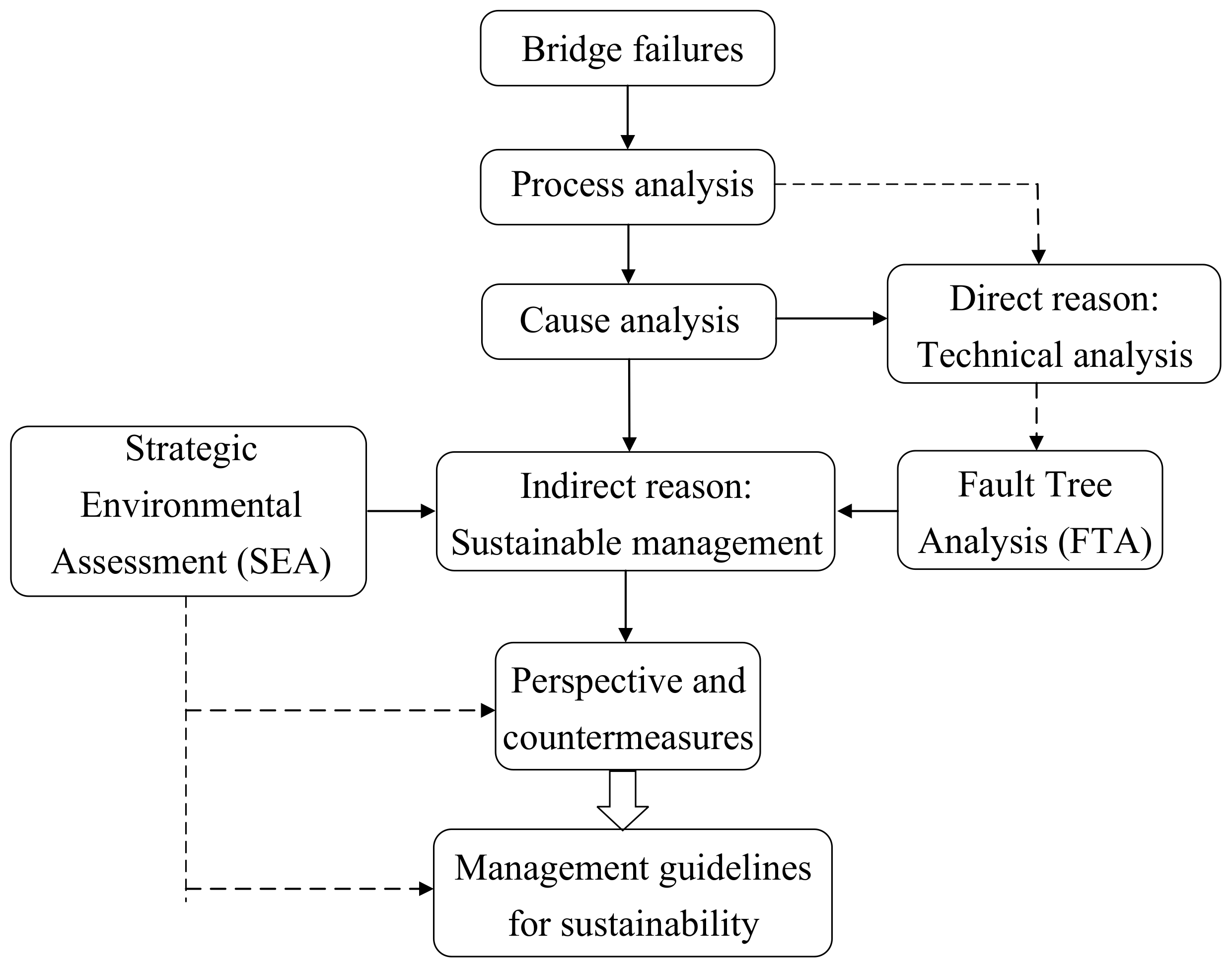

4. Analysis Methods

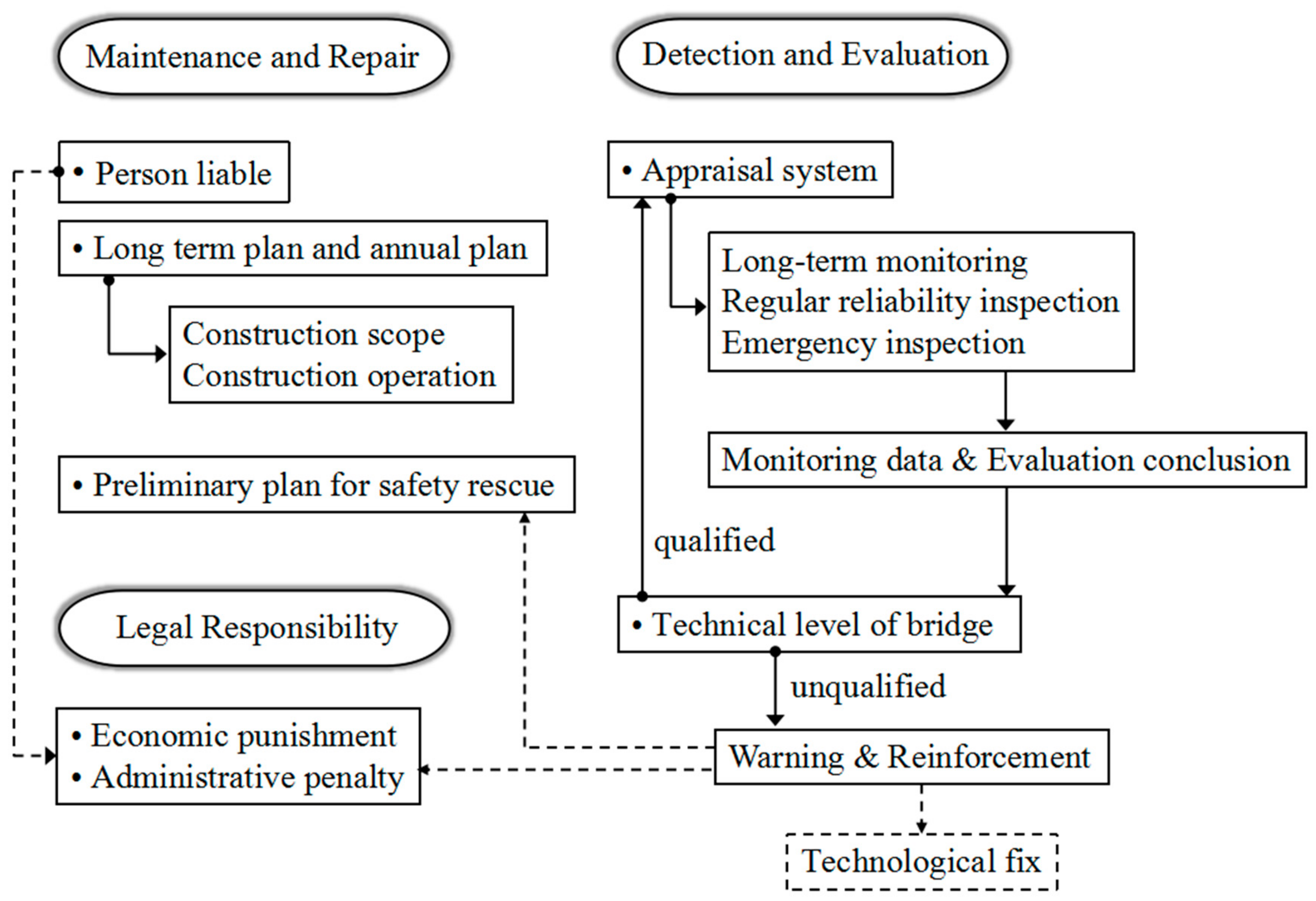

5. Fault Tree Analysis (FTA)

6. SEA Analysis

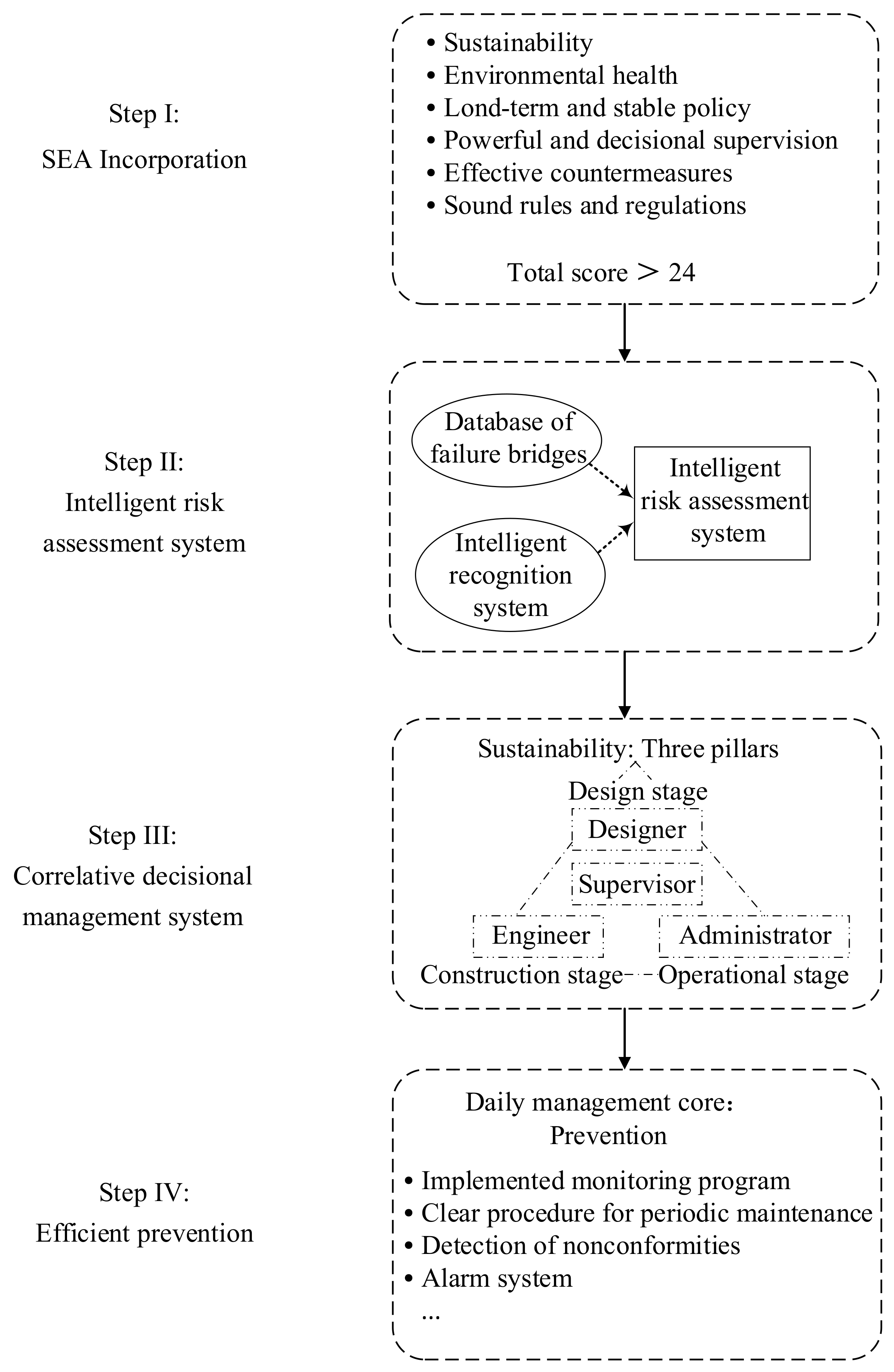

7. Discussion: Guideline of Sustainable Management

- Step I

- Improve the management system with modern and adjusted SEA principles; SEA is recommended to be incorporated into comprehensive project management. According to the Environmental Protection Law of the People’s Republic of China, the total score of the SEA should be higher than 24 [59];

- Step II

- Establish and update an intelligent risk assessment system [63,64]. Today’s risk assessment performed by inspectors is insufficient and inconsistent. Intelligence recognition systems that are applied to the unified database for failed bridges can assist in improving the accuracy and effectiveness of the risk assessment. Hence, knowledge-based expert systems (KBE) and artificial intelligence (AI) systems are the key technical procedures for the intelligence recognition systems, which can be used for accurate and reliable post-disaster condition assessments like crack and stress concentration identification [51].

- Step III

- Adopt the correlative decisional management system. The adaptive management system consists of the designer in the design stage, the engineer in the construction stage, the administrator in the operational stage, and the supervisor during the whole period. Each level of management has corresponding responsibilities and should take the three pillars of sustainability into consideration. It is crucial to establish a correlative decisional and cooperation mechanism for the whole management.

- Step IV

- Adopt efficient and diversified means of prevention, which are the essence of daily management. The monitoring and clear procedures for periodic maintenance are an important part of preventing failures. In addition, the detection of nonconformities and alarm systems play a major role in emergency situations, helping to establish a complete daily management system.

8. Conclusions

- The statistical analysis on the bridge failures from 2009 to 2019 showed that about 70% of bridge failures were due to anthropic factors, which is a much larger proportion than those caused by natural factors (30%). These safety accidents cause great losses of life and property, which expose the problems in bridge construction management hindering the sustainable development of society.

- Zijin bridge failure was used as a case study to analyze the reasons relating to a lack of sustainable management. The FTA results show that the arch foot failure was the direct triggering cause of the Zijin bridge collapse. Moreover, a lack of real-time monitoring, risk assessment and other management issues were potential comprehensive factors causing the bridge collapse.

- The SEA method was conducted to evaluate the management risk of Zijin Bridge. The low scores illustrated the high risk and negative impact on the community for this case. It is verified that SEA is an effective method for integrating sustainability principles related to societal, economic, cultural, human health and environmental factors in decision making relating to the development of bridge projects;

- To improve the bridge sustainability, the following management guidelines on the basis of SEA were proposed: (i) a management system improved by SEA; (ii) an intelligent risk assessment system; (iii) perfecting the correlative decisional management system; (iv) efficient and diversified means of prevention.

Author Contributions

Funding

Conflicts of Interest

References

- Wu, H.-N.; Shen, S.-L.; Yang, J. Identification of tunnel settlement caused by land subsidence in soft deposit of Shanghai. J. Perform. Constr. Facil. 2017, 31, 04017092. [Google Scholar] [CrossRef]

- Wu, H.-N.; Shen, S.-L.; Yang, J.; Zhou, A. Soil-tunnel interaction modelling for shield tunnels considering shearing dislocation in longitudinal joints. Tunn. Undergr. Space Technol. 2018, 78, 168–177. [Google Scholar] [CrossRef]

- Lyu, H.M.; Sun, W.J.; Shen, S.L.; Arulrajah, A. Flood risk assessment in metro systems of mega-cities using a GIS-based modeling approach. Sci. Total Environ. 2018, 626, 1012–1025. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.X.; Shen, S.L.; Lyu, H.M.; Zhou, A.N. Analyses of leakage effect of waterproof curtain during excavation dewatering. J. Hydrol. 2020, 583, 124582. [Google Scholar] [CrossRef]

- Lyu, H.M.; Sun, W.J.; Shen, S.L.; Zhou, A.N. Risk assessment using a new consulting process in fuzzy AHP. J. Constr. Eng. Manag. 2020, 146, 04019112. [Google Scholar] [CrossRef]

- Ruiz, A.; Guevara, J. Sustainable Decision-Making in Road Development: Analysis of Road Preservation Policies. Sustainability 2020, 12, 872. [Google Scholar] [CrossRef]

- Elbaz, K.; Shen, S.L.; Zhou, A.N.; Yuan, D.J.; Xu, Y.S. Optimization of EPB shield performance with adaptive neuro-fuzzy inference system and genetic algorithm. Appl. Sci. 2019, 9, 780. [Google Scholar] [CrossRef]

- Shen, S.-L.; Wu, H.-N.; Cui, Y.-J.; Yin, Z.-Y. Long-term settlement behavior of metro tunnels in the soft deposits of Shanghai. Tunn. Undergr. Space Technol. 2014, 40, 309–323. [Google Scholar] [CrossRef]

- De Luca, S.; Di Pace, R.; Memoli, S.; Pariota, L. Sustainable Traffic Management in an Urban Area: An Integrated Framework for Real-Time Traffic Control and Route Guidance Design. Sustainability 2020, 12, 726. [Google Scholar] [CrossRef]

- He, X.C.; Yang, T.L.; Shen, S.L.; Xu, Y.S.; Arulrajah, A. Land subsidence control zone and policy for the environmental protection of Shanghai. Int. J. Environ. Res. Public Health 2019, 16, 2729. [Google Scholar] [CrossRef]

- Lyu, H.M.; Cheng, W.C.; Shen, J.; Arulrajah, A. Investigation of Collapsed Building Incidents on Soft Marine Deposit: Both from Social and Technical Perspectives. Land 2018, 7, 20. [Google Scholar] [CrossRef]

- Xu, H.T.; Guo, G.Z.; Pu, H.L.; Yuan, M. Causes and Lessons of Bridge Accidents in China in Recent Years. China Saf. Sci. J. 2007, 17, 90–95+176. [Google Scholar] [CrossRef]

- Zhou, X.H.; Shen, S.L.; Xu, Y.S.; Zhou, A.N. Analysis of Production Safety in the Construction Industry of China in 2018. Sustainability 2019, 11, 4537. [Google Scholar] [CrossRef]

- Wu, Y.X.; Lyu, H.M.; Han, J.; Shen, S.L. Dewatering-induced building settlement around a deep excavation in soft deposit in Tianjin, China. J. Geotech. Geoenvironmental Eng. 2019, 145, 05019003. [Google Scholar] [CrossRef]

- Lyu, H.M.; Shen, S.L.; Zhou, A.N.; Zhou, W.H. Flood risk assessment of metro systems in a subsiding environment using the interval FAHP-FCA approach. Sustain. Cities Soc. 2019, 50, 101682. [Google Scholar] [CrossRef]

- Yan, T.; Shen, S.L.; Zhou, A.N.; Chen, J. A Brief Report of Pingdi Landslide (23 July 2019) in Guizhou Province, China. Geosciences 2019, 9, 368. [Google Scholar] [CrossRef]

- Lyu, H.M.; Shen, S.L.; Yang, J.; Yin, Z.Y. Inundation analysis of metro systems with the storm water management model incorporated into a geographical information system: A case study in Shanghai. Hydrol. Earth Syst. Sci. 2019, 23, 4293–4307. [Google Scholar] [CrossRef]

- Chai, J.; Shen, S.; Ding, W.; Zhu, H.; Carter, J. Numerical investigation of the failure of a building in Shanghai, China. Comput. Geotech. 2014, 55, 482–493. [Google Scholar] [CrossRef]

- Atangana Njock, P.G.; Shen, S.L.; Zhou, A.N.; Lyu, H.M. Evaluation of soil liquefaction using AI technology incorporating a coupled ENN/t-SNE model. Soil Dyn. Earthq. Eng. 2020, 130, 105988. [Google Scholar] [CrossRef]

- Lyu, H.M.; Shen, S.L.; Yang, J.; Zhou, A.N. Risk assessment of earthquake-triggered geohazards surrounding Wenchuan, China. Nat. Hazards Rev. 2019. [Google Scholar] [CrossRef]

- Zhang, N.; Shen, S.-L.; Zhou, A.-N.; Chen, J. A brief report on the March 21, 2019 explosions at a chemical factory in Xiangshui, China. Process Saf. Prog. 2019, 38, e12060. [Google Scholar] [CrossRef]

- Zhang, N.; Shen, J.S.; Lin, C.; Arulrajah, A.; Chai, J.-C. Investigation of a large ground collapse and countermeasures during mountain tunnelling in Hangzhou: A case study. Bull. Eng. Geol. Environ. 2019, 78, 991–1003. [Google Scholar] [CrossRef]

- Zhang, N.; Shen, S.L.; Zhou, A.N.; Xu, Y.S. Investigation on performance of neural network using quadratic relative error cost function. IEEE Access 2019, 7, 106642–106652. [Google Scholar] [CrossRef]

- Wang, X.W.; Yang, T.L.; Xu, Y.S.; Shen, S.L. Evaluation of optimized depth of waterproof curtain to mitigate negative impacts during dewatering. J. Hydrol. 2019, 577, 123969. [Google Scholar] [CrossRef]

- Lyu, H.M.; Shen, S.L.; Zhou, A.N.; Yang, J. Risk assessment of mega-city infrastructures related to land subsidence using improved trapezoidal FAHP. Sci. Total Environ. 2019, 135310. [Google Scholar] [CrossRef]

- Xu, Y.S.; Shen, S.L.; Lai, Y.; Zhou, A.N. Design of Sponge City: Lessons learnt from an ancient drainage system in Ganzhou, China. J. Hydrol. 2018, 563, 900–908. [Google Scholar] [CrossRef]

- Elbaz, K.; Shen, S.L.; Arulrajah, A.; Horpibulsuk, S. Geohazards induced by anthropic activities of geoconstruction: A review of recent failure cases. Arab. J. Geosci. 2016, 9. [Google Scholar] [CrossRef]

- Lyu, H.M.; Wang, G.F.; Cheng, W.C.; Shen, S.L. Tornado hazards on June 23rd in Jiangsu Province, China: Preliminary investigation and analysis. Nat. Hazards 2017, 85, 597–604. [Google Scholar] [CrossRef]

- Hersi, M.I. Analysis of bridge failures in the United States (2000–2008). Master’s Thesis, Ohio State University, Columbus, OH, USA, 2009. [Google Scholar]

- Zhao, X.-H.; Cheng, W.-C.; Shen, J.S.; Arulrajah, A. Platform collapse incident of a power plant in Jiangxi, China. Nat. Hazards 2017, 87, 1259–1265. [Google Scholar] [CrossRef]

- Xu, Y.-S.; Yan, X.-X.; Shen, S.-L.; Zhou, A.-N. Experimental investigation on the blocking of groundwater seepage from a waterproof curtain during pumped dewatering in an excavation. Hydrogeol. J. 2019, 27, 2659–2672. [Google Scholar] [CrossRef]

- Yu, C.; Zhou, A.; Chen, J.; Arulrajah, A.; Horpibulsuk, S. Analysis of a tunnel failure caused by leakage of the shield tail seal system. Undergr. Space 2019. [Google Scholar] [CrossRef]

- Meng, W.L.; Shen, S.L.; Zhou, A.N. Investigation on fatal accidents in Chinese construction industry between 2004 and 2016. Nat. Hazards 2018. [Google Scholar] [CrossRef]

- Dong, Y.; Frangopol, D.M.; Sabatino, S. Optimizing bridge network retrofit planning based on cost-benefit evaluation and multi-attribute utility associated with sustainability. Earthq. Spectra 2015, 31, 2255–2280. [Google Scholar] [CrossRef]

- Blockley, D.I.; Henderson, J.R. Structural failures and the growth of engineering knowledge. Proc. Inst. Civ. Eng. 1980, 68, 719–728. [Google Scholar] [CrossRef]

- Xu, F.Y.; Zhang, M.J.; Wang, L.; Zhang, J.R. Recent highway bridge collapses in China: Review and discussion. J. Perform. Constr. Facil. 2016, 30, 04016030. [Google Scholar] [CrossRef]

- Cook, W. Bridge failure rates, consequences, and predictive trends. Ph.D. Thesis, Utah State University, Logan, UT, USA, 2014. [Google Scholar]

- Wardhana, K.; Hadipriono, F.C. Analysis of recent bridge failures in the United States. J. Perform. Constr. Facil. 2003, 17, 144–150. [Google Scholar] [CrossRef]

- Imam, B.M.; Chryssanthopoulos, M.K. Causes and consequences of metallic bridge failures. Struct. Eng. Int. 2012, 22, 93–98. [Google Scholar] [CrossRef]

- Gonen, H.; Dogan, M.; Karacasu, M.; Ozbasaran, H.; Gokdemir, H. Structural failures in refrofit historical murat masonry arch bridge. Eng. Fail. Anal. 2013, 35, 334–342. [Google Scholar] [CrossRef]

- Dong, Y.H. Research on bridge maintenance management system. Master’s Thesis, Chang’an University, Xi’an, China, 2014. (In Chinese). [Google Scholar]

- Rokneddin, K.; Ghosh, J.; Dueñas-Osorio, L.; Padgett, J.E. Seismic reliability assessment of aging highway bridge networks with field instrumentation data and correlated failures, II: Application. Earthq. Spectra 2014, 30, 819–843. [Google Scholar] [CrossRef]

- Bridle, R.J.; Sims, F. The effect of bridge failures on UK technical policy and practice. Proc. Inst. Civ. Eng. Eng. Hist. Herit. 2009, 162, 39–49. [Google Scholar] [CrossRef]

- Tapia, C.; Padgett, J.E. Multi-objective optimization of bridge retrofit and post-event repair selection to enhance sustainability. Struct. Infrastruct. Eng. 2016, 12, 93–107. [Google Scholar] [CrossRef]

- Markus, E.; Emmelin, L. Applying good EIA practice criteria to SEA: The Öresund Bridge as a case. In Proceedings of the 5th Nordic Environmental Assessment Conference, Reykjavik, Iceland, 25–26 August 2003. [Google Scholar]

- Bao, C.K.; Lu, Y.S.; Shang, J.C. Framework and operational procedure for implementing strategic environmental assessment in china. Environ. Impact Assess. Rev. 2004, 24, 27–46. [Google Scholar] [CrossRef]

- Liu, M.M. Bridge Accident Analysis. Master’s Thesis, Southwest Jiaotong University, Chengdu, China, 2013. (In Chinese). [Google Scholar]

- Xing, J.X. The Whole Life Risk Assessment of Bridge Engineering. Master’s Thesis, Taiyuan University of Science and Technology, Taiyuan, China, 2015. (In Chinese). [Google Scholar]

- Audenaert, A.; Fanning, P.; Sobczak, L.; Peremans, H. 2-D analysis of arch bridges using an elasto-plastic material model. Eng. Struct. 2008, 30, 845–855. [Google Scholar] [CrossRef]

- Kim, S.E.; Choi, S.H.; Ma, S.S. Performance based design of steel arch bridges using practical inelastic nonlinear analysis. J. Constr. Steel Res. 2003, 59, 91–108. [Google Scholar] [CrossRef]

- Bocchini, P.; Frangopol, D.M.; Ummenhofer, T.; Zinke, T. Resilience and sustainability of civil infrastructure: Toward a unified approach. J. Infrastruct. Syst. 2013, 20, 04014004. [Google Scholar] [CrossRef]

- Wu, X.; Gu, D. Local stress analysis of arch foot for trough girder and arch composite bridge. Appl. Mech. Mater. 2014, 638, 961–964. [Google Scholar] [CrossRef]

- Peng, W.B. Collapse Analysis of Dongjiang Bridge in Heyuan, Guangdong Province. J. China Highw. 2019. Available online: https://dwz.cn/xmpCHuBW (accessed on 15 June 2019). (In Chinese).

- Zhai, W.; Xia, H.; Cai, C.; Gao, M.; Li, X.; Guo, X.; Wang, K. High-speed train–track–bridge dynamic interactions–Part I: Theoretical model and numerical simulation. Int. J. Rail Transp. 2013, 1, 3–24. [Google Scholar] [CrossRef]

- Deng, L.; Wang, W.; Yu, Y. State-of-the-art review on the causes and mechanisms of bridge collapse. J. Perform. Constr. Facil. 2015, 04015005. [Google Scholar] [CrossRef]

- Johnson, P.A. Fault tree analysis of bridge failure due to scour and channel instability. J. Infrastruct. Syst. 1999, 5, 35–41. [Google Scholar] [CrossRef]

- Retief, F.A. performance evaluation of strategic environmental assessment (SEA) processes within the south African context. Environ. Impact Assess. Rev. 2007, 27, 84–100. [Google Scholar] [CrossRef]

- Wu, Y.X.; Shen, J.S.; Cheng, W.C.; Hino, T. Semi-analytical solution to pumping test data with barrier, wellbore storage, and partial penetration effects. Eng. Geol. 2017, 226, 44–51. [Google Scholar] [CrossRef]

- Ministry of Ministry of Construction of the People’s Republic of China (MMCPRC). Management Measures for Inspection, Maintenance and Repair of Urban Bridges. Available online: http://www.gd.gov.cn/zwgk/zcfgk/content/post_2531698.html (accessed on 20 December 2019). (In Chinese)

- Vulnerability and failure analysis of hybrid cable-stayed suspension bridges subjected to damage mechanisms. Eng. Fail. Anal. 2014, 45, 470–495. [CrossRef]

- A numerical study on the structural integrity of self-anchored cable-stayed suspension bridges. Frat. Integrità Strutt. 2016, 10, 359–376. [CrossRef]

- Dynamic analysis of cable-stayed bridges affected by accidental failure mechanisms under moving loads. Math. Probl. Eng. 2013, 2013, 302706. [CrossRef]

- Shang, H.; Anumba, C.J.; Bouchlaghem, D.M.; Miles, J.C.; Cen, M.; Taylor, M. An intelligent risk assessment system for distributed construction teams. Eng. Constr. Archit. Manag. 2005. [Google Scholar] [CrossRef]

- Shang, H.; Anumba, C.J.; Bouchlaghem, D.M. An Intelligent Risk Assessment System for AEC. In Proceedings of the 2006 10th International Conference on Computer Supported Cooperative Work in Design, Nanjing, China, 3–5 May 2006; pp. 1–6. [Google Scholar] [CrossRef]

| SEA Principle | Project Management of Zijin Bridge | Score out of 5 |

|---|---|---|

| 1 | Yes: Sustainability principles were considered | 3 |

| 2 | Not perfect: Professional monitoring mechanisms after 2008 | 1 |

| 3 | Not perfect: Powerful administrative law enforcement and criminal justice; Proper emergency inspection | 2 |

| 4 | Not perfect: Consideration of environmental integrity and assessment of the environmental bearing capacity | 2 |

| 5 | Not perfect: Effective management decision-making and measures; | 1 |

| 6 | Not perfect: Positive social impact | 2 |

| Total score | 11 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, J.-S.; Elbaz, K.; Wang, Z.-F.; Shen, J.S.; Chen, J. Lessons Learnt from Bridge Collapse: A View of Sustainable Management. Sustainability 2020, 12, 1205. https://doi.org/10.3390/su12031205

Tan J-S, Elbaz K, Wang Z-F, Shen JS, Chen J. Lessons Learnt from Bridge Collapse: A View of Sustainable Management. Sustainability. 2020; 12(3):1205. https://doi.org/10.3390/su12031205

Chicago/Turabian StyleTan, Ji-Shuang, Khalid Elbaz, Zhi-Feng Wang, Jack Shui Shen, and Jun Chen. 2020. "Lessons Learnt from Bridge Collapse: A View of Sustainable Management" Sustainability 12, no. 3: 1205. https://doi.org/10.3390/su12031205

APA StyleTan, J.-S., Elbaz, K., Wang, Z.-F., Shen, J. S., & Chen, J. (2020). Lessons Learnt from Bridge Collapse: A View of Sustainable Management. Sustainability, 12(3), 1205. https://doi.org/10.3390/su12031205