A Sensitivity and Robustness Analysis of GPR and ANN for High-Performance Concrete Compressive Strength Prediction Using a Monte Carlo Simulation

Abstract

:1. Introduction

2. Research Novelty and Significance

3. Materials and Methods

3.1. Preparation of Data

3.2. Artificial Intelligence Approaches

3.2.1. Gaussian Process Regression

3.2.2. Artificial Neural Network (ANN)

3.3. Monte Carlo Approach and Statistical Analysis

3.4. Quality Assessment

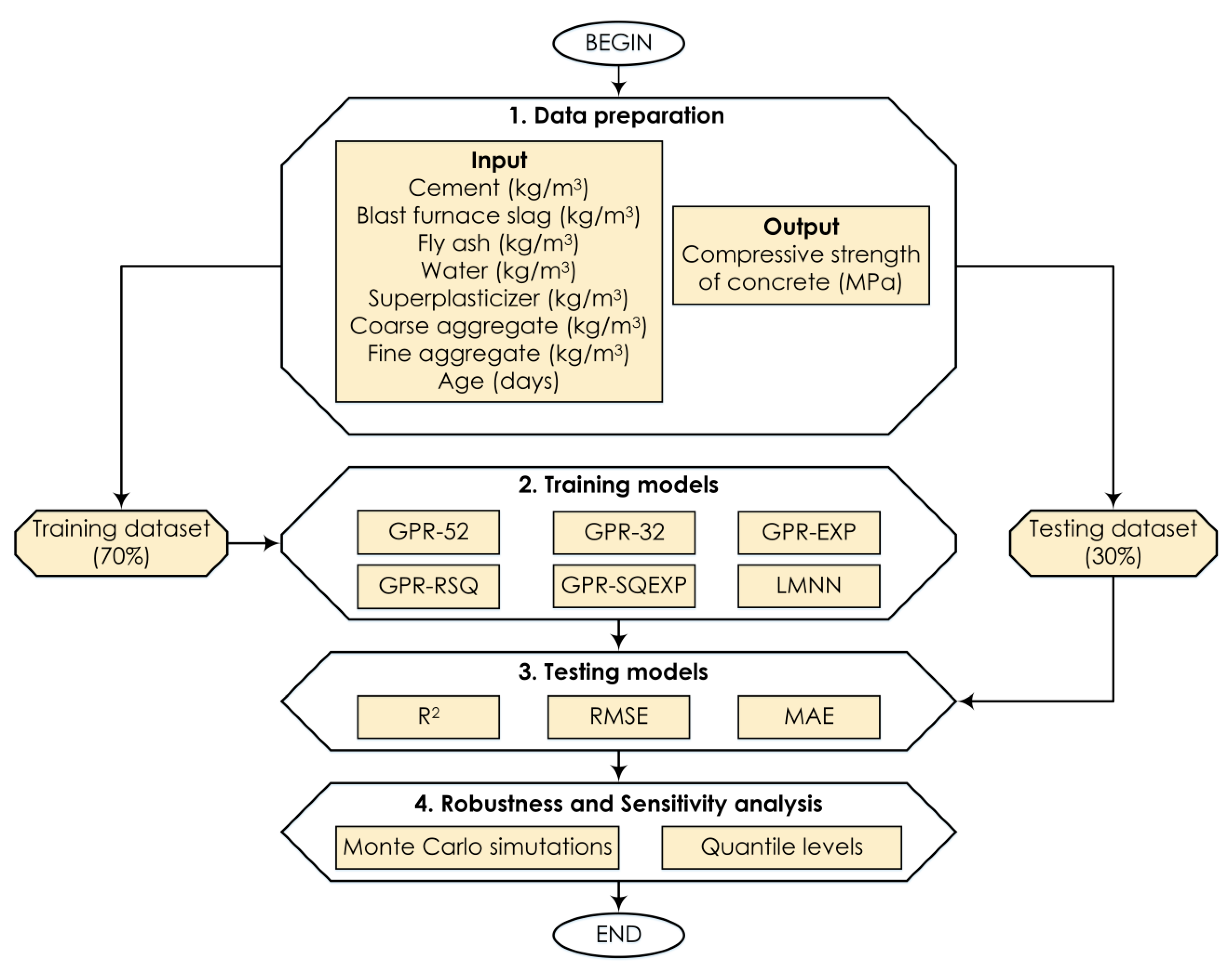

3.5. Methodology Flowchart

4. Results and Discussion

4.1. Prediction Capability of the AI Models

4.2. Robustness Analysis of the AI Models

4.3. Input Parameter Sensitivity Analysis

5. Conclusions

Supplementary Materials

Author Contributions

Conflicts of Interest

References

- Aïtcin, P.-C. High Performance Concrete; CRC Press: Boca Raton, FL, USA, 1998; ISBN 1-135-82357-X. [Google Scholar]

- Nawy, E.G. Fundamentals of High-Performance Concrete; John Wiley & Sons: Hoboken, NJ, USA, 2001. [Google Scholar]

- Huchante, S.R.; Chandupalle, S.; Ghorpode, V.G. Mix design of high performance concrete using silica fume and superplasticizer. Pan 2014, 18, 100. [Google Scholar]

- Chang, P.-K.; Peng, Y.-N. Influence of mixing techniques on properties of high performance concrete. Cem. Concr. Res. 2001, 31, 87–95. [Google Scholar] [CrossRef]

- Tran, V.Q.; Nguyen, H.L.; Dao, V.D.; Hilloulin, B.; Nguyen, L.K.; Nguyen, Q.H.; Le, T.-T.; Ly, H.-B. Temperature effects on chloride binding capacity of cementitious materials. In Magazine of Concrete Research; ICE: London, UK, 2019; pp. 1–39. [Google Scholar]

- Zhou, F.P.; Lydon, F.D.; Barr, B.I.G. Effect of coarse aggregate on elastic modulus and compressive strength of high performance concrete. Cem. Concr. Res. 1995, 25, 177–186. [Google Scholar] [CrossRef]

- Duval, R.; Kadri, E.H. Influence of Silica Fume on the Workability and the Compressive Strength of High-Performance Concretes. Cem. Concr. Res. 1998, 28, 533–547. [Google Scholar] [CrossRef]

- Chan, Y.N.; Luo, X.; Sun, W. Compressive strength and pore structure of high-performance concrete after exposure to high temperature up to 800 °C. Cem. Concr. Res. 2000, 30, 247–251. [Google Scholar] [CrossRef]

- Rashid, M.A.; Mansur, M.A.; Paramasivam, P. Correlations between Mechanical Properties of High-Strength Concrete. J. Mater. Civ. Eng. 2002, 14, 230–238. [Google Scholar] [CrossRef]

- Ramezanianpour, A.A.; Pilvar, A.; Mahdikhani, M.; Moodi, F. Practical evaluation of relationship between concrete resistivity, water penetration, rapid chloride penetration and compressive strength. Constr. Build. Mater. 2011, 25, 2472–2479. [Google Scholar] [CrossRef]

- Adeli, H.; Yeh, C. Perceptron Learning in Engineering Design. Comput. Aided Civ. Infrastruct. Eng. 1989, 4, 247–256. [Google Scholar] [CrossRef]

- Adeli, H. Neural networks in civil engineering: 1989–2000. Comput. Aided Civ. Infrastruct. Eng. 2001, 16, 126–142. [Google Scholar] [CrossRef]

- Amezquita-Sanchez, J.P.; Valtierra-Rodriguez, M.; Aldwaik, M.; Adeli, H. Neurocomputing in civil infrastructure. Sci. Iran. Trans. A Civ. Eng. 2016, 23, 2417. [Google Scholar] [CrossRef] [Green Version]

- Erdal, H.I.; Karakurt, O.; Namli, E. High performance concrete compressive strength forecasting using ensemble models based on discrete wavelet transform. Eng. Appl. Artif. Intell. 2013, 26, 1246–1254. [Google Scholar] [CrossRef]

- Chou, J.-S.; Pham, A.-D. Enhanced artificial intelligence for ensemble approach to predicting high performance concrete compressive strength. Constr. Build. Mater. 2013, 49, 554–563. [Google Scholar] [CrossRef]

- Cheng, M.-Y.; Firdausi, P.M.; Prayogo, D. High-performance concrete compressive strength prediction using Genetic Weighted Pyramid Operation Tree (GWPOT). Eng. Appl. Artif. Intell. 2014, 29, 104–113. [Google Scholar] [CrossRef]

- Erdal, H.I. Two-level and hybrid ensembles of decision trees for high performance concrete compressive strength prediction. Eng. Appl. Artif. Intell. 2013, 26, 1689–1697. [Google Scholar] [CrossRef]

- Pham, A.D.; Hoang, N.D.; Nguyen, Q.T. Predicting Compressive Strength of High-Performance Concrete Using Metaheuristic-Optimized Least Squares Support Vector Regression. J. Comput. Civ. Eng. 2016, 30, 06015002. [Google Scholar] [CrossRef]

- Asteris, P.G.; Roussis, P.C.; Douvika, M.G. Feed-Forward Neural Network Prediction of the Mechanical Properties of Sandcrete Materials. Sensors 2017, 17, 1344. [Google Scholar] [CrossRef] [Green Version]

- Asteris, P.G.; Moropoulou, A.; Skentou, A.D.; Apostolopoulou, M.; Mohebkhah, A.; Cavaleri, L.; Rodrigues, H.; Varum, H. Stochastic Vulnerability Assessment of Masonry Structures: Concepts, Modeling and Restoration Aspects. Appl. Sci. 2019, 9, 243. [Google Scholar] [CrossRef] [Green Version]

- Asteris, P.G.; Apostolopoulou, M.; Skentou, A.D.; Moropoulou, A. Application of artificial neural networks for the prediction of the compressive strength of cement-based mortars. Comput. Concr. 2019, 24, 329–345. [Google Scholar]

- Cavaleri, L.; Chatzarakis, G.E.; Di Trapani, F.; Douvika, M.G.; Roinos, K.; Vaxevanidis, N.M.; Asteris, P.G. Modeling of surface roughness in electro-discharge machining using artificial neural networks. Adv. Mater. Res. 2017, 6, 169–184. [Google Scholar]

- Pham, B.T.; Le, L.M.; Le, T.-T.; Bui, K.-T.T.; Le, V.M.; Ly, H.-B.; Prakash, I. Development of advanced artificial intelligence models for daily rainfall prediction. Atmos. Res. 2020, 237, 104845. [Google Scholar] [CrossRef]

- Dao, D.V.; Jaafari, A.; Bayat, M.; Mafi-Gholami, D.; Qi, C.; Moayedi, H.; Phong, T.V.; Ly, H.-B.; Le, T.-T.; Trinh, P.T.; et al. A spatially explicit deep learning neural network model for the prediction of landslide susceptibility. CATENA 2020, 188, 104451. [Google Scholar] [CrossRef]

- Bang, S.; Park, S.; Kim, H.; Kim, H. Encoder–decoder network for pixel-level road crack detection in black-box images. Comput. Aided Civ. Infrastruct. Eng. 2019. [Google Scholar] [CrossRef]

- Maeda, H.; Sekimoto, Y.; Seto, T.; Kashiyama, T.; Omata, H. Road damage detection and classification using deep neural networks with smartphone images. Comput. Aided Civ. Infrastruct. Eng. 2018, 33, 1127–1141. [Google Scholar] [CrossRef]

- Zhang, A.; Wang, K.C.; Li, B.; Yang, E.; Dai, X.; Peng, Y.; Fei, Y.; Liu, Y.; Li, J.Q.; Chen, C. Automated pixel-level pavement crack detection on 3D asphalt surfaces using a deep-learning network. Comput. Aided Civ. Infrastruct. Eng. 2017, 32, 805–819. [Google Scholar] [CrossRef]

- Gao, Y.; Mosalam, K.M. Deep transfer learning for image-based structural damage recognition. Comput. Aided Civ. Infrastruct. Eng. 2018, 33, 748–768. [Google Scholar] [CrossRef]

- Kang, D.; Cha, Y.-J. Autonomous UAVs for Structural Health Monitoring Using Deep Learning and an Ultrasonic Beacon System with Geo-Tagging. Comput. Aided Civ. Infrastruct. Eng. 2018, 33, 885–902. [Google Scholar] [CrossRef]

- Lin, Y.; Nie, Z.; Ma, H. Structural damage detection with automatic feature-extraction through deep learning. Comput. Aided Civ. Infrastruct. Eng. 2017, 32, 1025–1046. [Google Scholar] [CrossRef]

- Ly, H.-B.; Pham, B.T.; Dao, D.V.; Le, V.M.; Le, L.M.; Le, T.-T. Improvement of ANFIS Model for Prediction of Compressive Strength of Manufactured Sand Concrete. Appl. Sci. 2019, 9, 3841. [Google Scholar] [CrossRef] [Green Version]

- Chen, H.; Asteris, P.G.; Jahed Armaghani, D.; Gordan, B.; Pham, B.T. Assessing Dynamic Conditions of the Retaining Wall: Developing Two Hybrid Intelligent Models. Appl. Sci. 2019, 9, 1042. [Google Scholar] [CrossRef] [Green Version]

- Asteris, P.G.; Mokos, V.G. Concrete compressive strength using artificial neural networks. In Neural Computing and Applications; Springer: Berlin/Heidelberg, Germany, 2019. [Google Scholar]

- Asteris, P.G.; Ashrafian, A.; Rezaie-Balf, M. Prediction of the compressive strength of self-compacting concrete using surrogate models. Comput. Concr. 2019, 24, 137–150. [Google Scholar]

- Asteris, P.G.; Armaghani, D.J.; Hatzigeorgiou, G.D.; Karayannis, C.G.; Pilakoutas, K. Predicting the shear strength of reinforced concrete beams using Artificial Neural Networks. Comput. Concr. 2019, 24, 469–488. [Google Scholar]

- Apostolopoulou, M.; Armaghani, D.J.; Bakolas, A.; Douvika, M.G.; Moropoulou, A.; Asteris, P.G. Compressive strength of natural hydraulic lime mortars using soft computing techniques. Procedia Struct. Integr. 2019, 17, 914–923. [Google Scholar] [CrossRef]

- Armaghani, D.J.; Hatzigeorgiou, G.D.; Karamani, C.; Skentou, A.; Zoumpoulaki, I.; Asteris, P.G. Soft computing-based techniques for concrete beams shear strength. Procedia Struct. Integr. 2019, 17, 924–933. [Google Scholar] [CrossRef]

- Gao, Y.; Kong, B.; Mosalam, K.M. Deep leaf-bootstrapping generative adversarial network for structural image data augmentation. Comput. Aided Civ. Infrastruct. Eng. 2019, 34, 755–773. [Google Scholar] [CrossRef]

- Huang, Y.; Beck, J.L.; Wu, S.; Li, H. Robust Bayesian compressive sensing for signals in structural health monitoring. Comput. Aided Civ. Infrastruct. Eng. 2014, 29, 160–179. [Google Scholar] [CrossRef] [Green Version]

- Rafiei, M.H.; Adeli, H. A novel unsupervised deep learning model for global and local health condition assessment of structures. Eng. Struct. 2018, 156, 598–607. [Google Scholar] [CrossRef]

- Xue, Y.; Li, Y. A fast detection method via region-based fully convolutional neural networks for shield tunnel lining defects. Comput. Aided Civ. Infrastruct. Eng. 2018, 33, 638–654. [Google Scholar] [CrossRef]

- Hashemi, H.; Abdelghany, K. End-to-end deep learning methodology for real-time traffic network management. Comput. Aided Civ. Infrastruct. Eng. 2018, 33, 849–863. [Google Scholar] [CrossRef]

- Nabian, M.A.; Meidani, H. Deep learning for accelerated seismic reliability analysis of transportation networks. Comput. Aided Civ. Infrastruct. Eng. 2018, 33, 443–458. [Google Scholar] [CrossRef] [Green Version]

- Qi, C.; Ly, H.-B.; Chen, Q.; Le, T.-T.; Le, V.M.; Pham, B.T. Flocculation-dewatering prediction of fine mineral tailings using a hybrid machine learning approach. Chemosphere 2020, 244, 125450. [Google Scholar] [CrossRef]

- Ly, H.-B.; Le, L.M.; Phi, L.V.; Phan, V.-H.; Tran, V.Q.; Pham, B.T.; Le, T.-T.; Derrible, S. Development of an AI Model to Measure Traffic Air Pollution from Multisensor and Weather Data. Sensors 2019, 19, 4941. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liang, X. Image-based post-disaster inspection of reinforced concrete bridge systems using deep learning with Bayesian optimization. Comput. Aided Civ. Infrastruct. Eng. 2019, 34, 415–430. [Google Scholar] [CrossRef]

- Luo, X.; Li, H.; Yang, X.; Yu, Y.; Cao, D. Capturing and Understanding Workers’ Activities in Far-Field Surveillance Videos with Deep Action Recognition and Bayesian Nonparametric Learning. Comput. Aided Civ. Infrastruct. Eng. 2019, 34, 333–351. [Google Scholar] [CrossRef]

- Rafiei, M.H.; Khushefati, W.H.; Demirboga, R.; Adeli, H. Supervised Deep Restricted Boltzmann Machine for Estimation of Concrete. ACI Mater. J. 2017, 114, 237–244. [Google Scholar] [CrossRef]

- Nguyen, T.; Kashani, A.; Ngo, T.; Bordas, S. Deep neural network with high-order neuron for the prediction of foamed concrete strength. Comput. Aided Civ. Infrastruct. Eng. 2019, 34, 316–332. [Google Scholar] [CrossRef]

- Rafiei, M.H.; Khushefati, W.H.; Demirboga, R.; Adeli, H. Novel Approach for Concrete Mixture Design Using Neural Dynamics Model and Virtual Lab Concept. ACI Mater. J. 2017, 114, 117–127. [Google Scholar] [CrossRef]

- Adeli, H.; Park, H.S. A neural dynamics model for structural optimization—Theory. Comput. Struct. 1995, 57, 383–390. [Google Scholar] [CrossRef]

- Park, H.S.; Adeli, H. A neural dynamics model for structural optimization—Application to plastic design of structures. Comput. Struct. 1995, 57, 391–399. [Google Scholar] [CrossRef]

- Yeh, I.-C. Modeling concrete strength with augment-neuron networks. J. Mater. Civ. Eng. 1998, 10, 263–268. [Google Scholar] [CrossRef]

- Yeh, I.-C. Design of high-performance concrete mixture using neural networks and nonlinear programming. J. Comput. Civ. Eng. 1999, 13, 36–42. [Google Scholar] [CrossRef]

- Yeh, I.-C. A mix proportioning methodology for fly ash and slag concrete using artificial neural networks. Chung Hua J. Sci. Eng. 2003, 1, 77–84. [Google Scholar]

- Yeh, I.-C. Analysis of strength of concrete using design of experiments and neural networks. J. Mater. Civ. Eng. 2006, 18, 597–604. [Google Scholar] [CrossRef]

- Yeh, I.-C. Modeling of strength of high-performance concrete using artificial neural networks. Cem. Concr. Res. 1998, 28, 1797–1808. [Google Scholar] [CrossRef]

- Indian Standard Code of Practice-Methods of Test for Strength of Concrete; BIS: Basel, Switzerland, 1959.

- Code for Acceptance of Construction Quality of Steel Structures; National Standard of the People’s Republic of China: Beijing, China, 2001.

- Khorsheed, M.S.; Al-Thubaity, A.O. Comparative evaluation of text classification techniques using a large diverse Arabic dataset. Lang Resour. Eval. 2013, 47, 513–538. [Google Scholar] [CrossRef]

- Leema, N.; Nehemiah, H.K.; Kannan, A. Neural network classifier optimization using Differential Evolution with Global Information and Back Propagation algorithm for clinical datasets. Appl. Soft Comput. 2016, 49, 834–844. [Google Scholar] [CrossRef]

- Banerjee, S.; Gelfand, A.E.; Finley, A.O.; Sang, H. Gaussian predictive process models for large spatial data sets. J. R. Stat. Soc. Ser. B (Stat. Methodol.) 2008, 70, 825–848. [Google Scholar] [CrossRef] [Green Version]

- Rasmussen, C.E. Gaussian Processes in Machine Learning. In Advanced Lectures on Machine Learning; Lecture Notes in Computer Science; Springer: Berlin/Heidelberg, Germany, 2003; Volume 3176. [Google Scholar]

- MacKay, D.J. Introduction to Gaussian processes. NATO ASI Ser. F Comput. Syst. Sci. 1998, 168, 133–166. [Google Scholar]

- Bishop, C.M. Pattern Recognition and Machine Learning; Springer: Berlin/Heidelberg, Germany, 2006. [Google Scholar]

- Higham, N.J. Analysis of the Cholesky Decomposition of a Semi-Definite Matrix; Oxford University Press: Oxford, UK, 1990; pp. 161–185. [Google Scholar]

- Hofmann, T.; Schölkopf, B.; Smola, A.J. Kernel Methods in Machine Learning. Ann. Stat. 2008, 36, 1171–1220. [Google Scholar] [CrossRef] [Green Version]

- Murray, I.; Adams, R.P. Slice sampling covariance hyperparameters of latent Gaussian models. In Advances in Neural Information Processing Systems; NIPS Proceedings; Hyatt Regency: Vancouver, BC, Canada, 2010; pp. 1732–1740. [Google Scholar]

- Hammoudi, A.; Moussaceb, K.; Belebchouche, C.; Dahmoune, F. Comparison of artificial neural network (ANN) and response surface methodology (RSM) prediction in compressive strength of recycled concrete aggregates. Constr. Build. Mater. 2019, 209, 425–436. [Google Scholar] [CrossRef]

- Alexandridis, A.; Triantis, D.; Stavrakas, I.; Stergiopoulos, C. A neural network approach for compressive strength prediction in cement-based materials through the study of pressure-stimulated electrical signals. Constr. Build. Mater. 2012, 30, 294–300. [Google Scholar] [CrossRef]

- Behnood, A.; Golafshani, E.M. Predicting the compressive strength of silica fume concrete using hybrid artificial neural network with multi-objective grey wolves. J. Clean. Prod. 2018, 202, 54–64. [Google Scholar] [CrossRef]

- Phong, T.V.; Phan, T.T.; Prakash, I.; Singh, S.K.; Shirzadi, A.; Chapi, K.; Ly, H.-B.; Ho, L.S.; Quoc, N.K.; Pham, B.T. Landslide susceptibility modeling using different artificial intelligence methods: A case study at Muong Lay district, Vietnam. Geocarto Int. 2019. [Google Scholar] [CrossRef]

- Bayat, M.; Ghorbanpour, M.; Zare, R.; Jaafari, A.; Thai Pham, B. Application of artificial neural networks for predicting tree survival and mortality in the Hyrcanian forest of Iran. Comput. Electron. Agric. 2019, 164, 104929. [Google Scholar] [CrossRef]

- Le, T.-T.; Pham, B.T.; Ly, H.-B.; Shirzadi, A.; Le, L.M. Development of 48-hour Precipitation Forecasting Model using Nonlinear Autoregressive Neural Network. In CIGOS 2019, Innovation for Sustainable Infrastructure; Ha-Minh, C., Dao, D.V., Benboudjema, F., Derrible, S., Huynh, D.V.K., Tang, A.M., Eds.; Springer: Singapore, 2020; Volume 54, pp. 1191–1196. ISBN 9789811508011. [Google Scholar]

- Pham, B.T.; Nguyen, M.D.; Ly, H.-B.; Pham, T.A.; Hoang, V.; Van Le, H.; Le, T.-T.; Nguyen, H.Q.; Bui, G.L. Development of Artificial Neural Networks for Prediction of Compression Coefficient of Soft Soil. In CIGOS 2019, Innovation for Sustainable Infrastructure; Ha-Minh, C., Dao, D.V., Benboudjema, F., Derrible, S., Huynh, D.V.K., Tang, A.M., Eds.; Springer: Singapore, 2020; Volume 54, pp. 1167–1172. ISBN 9789811508011. [Google Scholar]

- Adeli, H.; Park, H.S. Method and Apparatus for Efficient Design Automation and Optimization, and Structure Produced Thereby. U.S. Patent No 5,815,394, 29 September 1998. [Google Scholar]

- Cavaleri, L.; Asteris, P.G.; Psyllaki, P.P.; Douvika, M.G.; Skentou, A.D.; Vaxevanidis, N.M. Prediction of Surface Treatment Effects on the Tribological Performance of Tool Steels Using Artificial Neural Networks. Appl. Sci. 2019, 9, 2788. [Google Scholar] [CrossRef] [Green Version]

- Psyllaki, P.; Stamatiou, K.; Iliadis, I.; Mourlas, A.; Asteris, P.; Vaxevanidis, N. Surface treatment of tool steels against galling failure. In Proceedings of the MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2018; Volume 188. [Google Scholar]

- Asteris, P.G.; Argyropoulos, I.; Cavaleri, L.; Rodrigues, H.; Varum, H.; Thomas, J.; Paulo, B.; Lourenço, P.B. Masonry Compressive Strength Prediction using Artificial Neural Networks. In Proceedings of the International Conference on Transdisciplinary Multispectral Modeling and Cooperation for the Preservation of Cultural Heritage, Athens, Greece, 10–13 October 2018; Volume 1, pp. 10–13. [Google Scholar]

- Apostolopoulou, M.; Douvika, M.G.; Kanellopoulos, I.N.; Moropoulou, A.; Asteris, P.G. Prediction of Compressive Strength of Mortars using Artificial Neural Networks. In Proceedings of the 1st International Conference TMM_CH, Transdisciplinary Multispectral Modelling and Cooperation for the Preservation of Cultural Heritage, Athens, Greece, 10–13 October 2018; Volume 1, pp. 10–13. [Google Scholar]

- Al-Shamiri, A.K.; Kim, J.H.; Yuan, T.-F.; Yoon, Y.S. Modeling the compressive strength of high-strength concrete: An extreme learning approach. Constr. Build. Mater. 2019, 208, 204–219. [Google Scholar] [CrossRef]

- Nguyen, H.-L.; Le, T.-H.; Pham, C.-T.; Le, T.-T.; Ho, L.S.; Le, V.M.; Pham, B.T.; Ly, H.-B. Development of Hybrid Artificial Intelligence Approaches and a Support Vector Machine Algorithm for Predicting the Marshall Parameters of Stone Matrix Asphalt. Appl. Sci. 2019, 9, 3172. [Google Scholar] [CrossRef] [Green Version]

- Bui, D.-K.; Nguyen, T.; Chou, J.-S.; Nguyen-Xuan, H.; Ngo, T.D. A modified firefly algorithm-artificial neural network expert system for predicting compressive and tensile strength of high-performance concrete. Constr. Build. Mater. 2018, 180, 320–333. [Google Scholar] [CrossRef]

- Wang, X.; Yang, Z.; Jivkov, A.P. Monte Carlo simulations of mesoscale fracture of concrete with random aggregates and pores: A size effect study. Constr. Build. Mater. 2015, 80, 262–272. [Google Scholar] [CrossRef]

- Jaskulski, R.; Wiliński, P. Probabilistic Analysis of Shear Resistance Assured by Concrete Compression. Procedia Eng. 2017, 172, 449–456. [Google Scholar] [CrossRef]

- Kostić, S.; Vasović, N.; Marinković, B. Robust optimization of concrete strength estimation using response surface methodology and Monte Carlo simulation. Eng. Optim. 2017, 49, 864–877. [Google Scholar] [CrossRef]

- Pham, B.T.; Nguyen, M.D.; Dao, D.V.; Prakash, I.; Ly, H.-B.; Le, T.-T.; Ho, L.S.; Nguyen, K.T.; Ngo, T.Q.; Hoang, V.; et al. Development of artificial intelligence models for the prediction of Compression Coefficient of soil: An application of Monte Carlo sensitivity analysis. Sci. Total Environ. 2019, 679, 172–184. [Google Scholar] [CrossRef]

- Dao, D.V.; Ly, H.-B.; Trinh, S.H.; Le, T.-T.; Pham, B.T. Artificial Intelligence Approaches for Prediction of Compressive Strength of Geopolymer Concrete. Materials 2019, 12, 983. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ly, H.-B.; Monteiro, E.; Le, T.-T.; Le, V.M.; Dal, M.; Regnier, G.; Pham, B.T. Prediction and Sensitivity Analysis of Bubble Dissolution Time in 3D Selective Laser Sintering Using Ensemble Decision Trees. Materials 2019, 12, 1544. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ly, H.-B.; Desceliers, C.; Le, L.M.; Le, T.-T.; Pham, B.T.; Nguyen-Ngoc, L.; Doan, V.T.; Le, M. Quantification of Uncertainties on the Critical Buckling Load of Columns under Axial Compression with Uncertain Random Materials. Materials 2019, 12, 1828. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mordechai, S. Applications of Monte Carlo Method in Science and Engineering; InTech Open: London, UK, 2011; ISBN 978-953-307-691-1. [Google Scholar]

- Thanh, T.T.M.; Ly, H.-B.; Pham, B.T. A Possibility of AI Application on Mode-choice Prediction of Transport Users in Hanoi. In Proceedings of the CIGOS 2019, Innovation for Sustainable Infrastructure; Ha-Minh, C., Dao, D.V., Benboudjema, F., Derrible, S., Huynh, D.V.K., Tang, A.M., Eds.; Springer: Singapore, 2020; pp. 1179–1184. [Google Scholar]

- Soize, C. Uncertainty Quantification: An Accelerated Course with Advanced Applications in Computational Engineering; Interdisciplinary Applied Mathematics; Springer: Berlin, Germany, 2017; ISBN 978-3-319-54338-3. [Google Scholar]

- Cunha, A.; Nasser, R.; Sampaio, R.; Lopes, H.; Breitman, K. Uncertainty quantification through the Monte Carlo method in a cloud computing setting. Comput. Phys. Commun. 2014, 185, 1355–1363. [Google Scholar] [CrossRef] [Green Version]

- Le, T.T.; Guilleminot, J.; Soize, C. Stochastic continuum modeling of random interphases from atomistic simulations. Application to a polymer nanocomposite. Comput. Methods Appl. Mech. Eng. 2016, 303, 430–449. [Google Scholar] [CrossRef] [Green Version]

- Adeli, H.; Kumar, S. Distributed genetic algorithm for structural optimization. J. Aerosp. Eng. 1995, 8, 156–163. [Google Scholar] [CrossRef]

- Adeli, H.; Kumar, S. Distributed Computer Aided Engineering; CRC Press: Boca Raton, FL, USA, 1998; Volume 2. [Google Scholar]

- Kumar, S.; Adeli, H. Distributed finite-element analysis on network of workstations—Implementation and applications. J. Struct. Eng. 1995, 121, 1456–1462. [Google Scholar] [CrossRef]

- Le, L.M.; Ly, H.-B.; Pham, B.T.; Le, V.M.; Pham, T.A.; Nguyen, D.-H.; Tran, X.-T.; Le, T.-T. Hybrid Artificial Intelligence Approaches for Predicting Buckling Damage of Steel Columns Under Axial Compression. Materials 2019, 12, 1670. [Google Scholar] [CrossRef] [Green Version]

- Guilleminot, J.; Le, T.T.; Soize, C. Stochastic framework for modeling the linear apparent behavior of complex materials: Application to random porous materials with interphases. Acta Mech. Sin. 2013, 29, 773–782. [Google Scholar] [CrossRef] [Green Version]

- Staber, B.; Guilleminot, J.; Soize, C.; Michopoulos, J.; Iliopoulos, A. Stochastic modeling and identification of a hyperelastic constitutive model for laminated composites. Comput. Methods Appl. Mech. Eng. 2019, 347, 425–444. [Google Scholar] [CrossRef] [Green Version]

- Thanh, T.T.M.; Van Dao, D.; Ly, H.-B. Analysis of Tourist Travel Behavior and Recommendation for Active Transport Encouragement Strategies, the Case of Hue City. In CIGOS 2019, Innovation for Sustainable Infrastructure; Ha-Minh, C., Dao, D.V., Benboudjema, F., Derrible, S., Huynh, D.V.K., Tang, A.M., Eds.; Springer: Singapore, 2020; Volume 54, pp. 1049–1055. ISBN 9789811508011. [Google Scholar]

- Khosravi, K.; Daggupati, P.; Alami, M.T.; Awadh, S.M.; Ghareb, M.I.; Panahi, M.; Pham, B.T.; Rezaie, F.; Qi, C.; Yaseen, Z.M. Meteorological data mining and hybrid data-intelligence models for reference evaporation simulation: A case study in Iraq. Comput. Electron. Agric. 2019, 167, 105041. [Google Scholar] [CrossRef]

- Nguyen, H.-L.; Pham, B.T.; Son, L.H.; Thang, N.T.; Ly, H.-B.; Le, T.-T.; Ho, L.S.; Le, T.-H.; Tien Bui, D. Adaptive Network Based Fuzzy Inference System with Meta-Heuristic Optimizations for International Roughness Index Prediction. Appl. Sci. 2019, 9, 4715. [Google Scholar] [CrossRef] [Green Version]

- Pham, B.T.; Son, L.H.; Hoang, T.-A.; Nguyen, D.-M.; Tien Bui, D. Prediction of shear strength of soft soil using machine learning methods. CATENA 2018, 166, 181–191. [Google Scholar] [CrossRef]

- Ly, H.-B.; Le, L.M.; Duong, H.T.; Nguyen, T.C.; Pham, T.A.; Le, T.-T.; Le, V.M.; Nguyen-Ngoc, L.; Pham, B.T. Hybrid Artificial Intelligence Approaches for Predicting Critical Buckling Load of Structural Members under Compression Considering the Influence of Initial Geometric Imperfections. Appl. Sci. 2019, 9, 2258. [Google Scholar] [CrossRef] [Green Version]

- Dao, D.V.; Trinh, S.H.; Ly, H.-B.; Pham, B.T. Prediction of Compressive Strength of Geopolymer Concrete Using Entirely Steel Slag Aggregates: Novel Hybrid Artificial Intelligence Approaches. Appl. Sci. 2019, 9, 1113. [Google Scholar] [CrossRef] [Green Version]

- Ly, H.-B.; Le, T.-T.; Le, L.M.; Tran, V.Q.; Le, V.M.; Vu, H.-L.T.; Nguyen, Q.H.; Pham, B.T. Development of Hybrid Machine Learning Models for Predicting the Critical Buckling Load of I-Shaped Cellular Beams. Appl. Sci. 2019, 9, 5458. [Google Scholar] [CrossRef] [Green Version]

- Gupta, R.; Kewalramani, M.A.; Goel, A. Prediction of Concrete Strength Using Neural-Expert System. J. Mater. Civ. Eng. 2006, 18, 462–466. [Google Scholar]

- Fazel Zarandi, M.H.; Türksen, I.B.; Sobhani, J.; Ramezanianpour, A.A. Fuzzy polynomial neural networks for approximation of the compressive strength of concrete. Appl. Soft Comput. 2008, 8, 488–498. [Google Scholar] [CrossRef]

- Prasad, B.K.R.; Eskandari, H.; Reddy, B.V.V. Prediction of compressive strength of SCC and HPC with high volume fly ash using ANN. Constr. Build. Mater. 2009, 23, 117–128. [Google Scholar] [CrossRef]

- Deepa, C.; SathiyaKumari, K.; Sudha, V.P. Prediction of the Compressive Strength of High Performance Concrete Mix using Tree Based Modeling. Int. J. Comput. Appl. IJCA 2010, 6, 18–24. [Google Scholar] [CrossRef]

- Chou, J.-S.; Chiu, C.-K.; Farfoura, M.; Al-Taharwa, I. Optimizing the Prediction Accuracy of Concrete Compressive Strength Based on a Comparison of Data-Mining Techniques. J. Comput. Civ. Eng. 2011, 25, 242–253. [Google Scholar] [CrossRef]

- Hoang, N.-D.; Pham, A.-D.; Nguyen, Q.-L.; Pham, Q.-N. Estimating Compressive Strength of High Performance Concrete with Gaussian Process Regression Model. Adv. Civ. Eng. 2016, 2016, 2861380. [Google Scholar] [CrossRef] [Green Version]

| Component | Minimum | Maximum | Mean | StD * |

|---|---|---|---|---|

| X1—Cement (kg/m3) | 102.00 | 540.00 | 281.17 | 104.51 |

| X2—Blast furnace slag (kg/m3) | 0.00 | 359.40 | 73.90 | 86.28 |

| X3—Fly ash (kg/m3) | 0.00 | 200.10 | 54.19 | 64.00 |

| X4—Water (kg/m3) | 121.80 | 247.00 | 181.57 | 21.35 |

| X5—Superplasticizer (kg/m3) | 0.00 | 32.20 | 6.20 | 5.97 |

| X6—Coarse aggregate (kg/m3) | 801.00 | 1145.00 | 872.92 | 77.75 |

| X7—Fine aggregate (kg/m3) | 594.00 | 992.60 | 773.58 | 80.18 |

| X8—Age (days) | 1.00 | 365.00 | 45.66 | 63.17 |

| Y—Compressive strength (MPa) | 2.33 | 82.60 | 35.82 | 16.71 |

| Component | R2 | RMSE | MAE |

|---|---|---|---|

| Training part GPR-52 | 0.881 | 5.757 | 4.137 |

| GPR-32 | 0.888 | 5.590 | 3.996 |

| GPR-EXP | 0.873 | 5.953 | 4.221 |

| GPR-SQEXP | 0.882 | 5.736 | 4.143 |

| GPR-RSQ | 0.882 | 5.731 | 4.184 |

| LMNN | 0.893 | 5.511 | 4.286 |

| Testing part GPR-52 | 0.884 | 5.702 | 4.058 |

| GPR-32 | 0.888 | 5.597 | 3.913 |

| GPR-EXP | 0.888 | 5.600 | 3.924 |

| GPR-SQEXP | 0.878 | 5.849 | 4.242 |

| GPR-RSQ | 0.880 | 5.793 | 4.182 |

| LMNN | 0.890 | 5.447 | 4.274 |

| Validation Criteria | R2 | RMSE | MAE | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Models | Min | Max | Mean | StD * | Min | Max | Mean | StD * | Min | Max | Mean | StD * |

| GPR- 52 | 0.774 | 0.927 | 0.890 | 0.016 | 4.65 | 7.46 | 5.53 | 0.38 | 3.40 | 4.64 | 3.96 | 0.21 |

| GPR- 32 | 0.815 | 0.931 | 0.893 | 0.015 | 4.58 | 6.75 | 5.46 | 0.37 | 3.30 | 4.58 | 3.86 | 0.21 |

| GPR- EXP | 0.837 | 0.922 | 0.886 | 0.015 | 4.74 | 6.83 | 5.65 | 0.37 | 3.33 | 4.77 | 3.92 | 0.22 |

| GPR- SQEXP | 0.748 | 0.923 | 0.886 | 0.017 | 4.75 | 7.87 | 5.63 | 0.37 | 3.55 | 4.72 | 4.10 | 0.21 |

| GPR- RSQ | 0.763 | 0.923 | 0.887 | 0.016 | 4.71 | 7.64 | 5.60 | 0.38 | 3.48 | 4.68 | 4.04 | 0.21 |

| LMNN | 0.780 | 0.923 | 0.876 | 0.020 | 4.68 | 7.99 | 5.87 | 0.46 | 3.43 | 6.20 | 4.42 | 0.36 |

| Nr | Reference | Number of Data | Prediction Model (Artificial Intelligence Approaches) | Average Value of R2 | Gain in % |

|---|---|---|---|---|---|

| 1 | [109] | 864 | Neural-Expert System | 0.760 | +14.89 |

| 2 | [110] | 458 | Fuzzy Polynomial Neural Networks | 0.8209 | +8.07 |

| 3 | [111] | 24 | Artificial Neural Network | 0.84 | +5.94 |

| 4 | [112] | 300 | Multilayer Perceptron | 0.6254 | +29.97 |

| Linear Regression | 0.4913 | +44.98 | |||

| M5P Model Tree | 0.7871 | +11.86 | |||

| 5 | [113] | 1030 | Artificial Neural Network | 0.9091 | -1.80 |

| Multiple Regression | 0.6112 | +31.56 | |||

| Support Vector Machine | 0.8858 | +0.81 | |||

| Bagging Regression Trees | 0.8904 | +0.29 | |||

| 6 | [18] | 239 | Artificial Neural Network | 0.81 | +9.29 |

| Support Vector Machine | 0.83 | +7.05 | |||

| Firefly Algorithm - Least Squares Support Vector Regression | 0.89 | +0.34 | |||

| 7 | [114] | 239 | Least Squares Support Vector Machine | 0.87 | +2.58 |

| Artificial Neural Network | 0.81 | +9.29 | |||

| 8 | Our study | 1030 | Best model: GPR-32 | 0.893 | - |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dao, D.V.; Adeli, H.; Ly, H.-B.; Le, L.M.; Le, V.M.; Le, T.-T.; Pham, B.T. A Sensitivity and Robustness Analysis of GPR and ANN for High-Performance Concrete Compressive Strength Prediction Using a Monte Carlo Simulation. Sustainability 2020, 12, 830. https://doi.org/10.3390/su12030830

Dao DV, Adeli H, Ly H-B, Le LM, Le VM, Le T-T, Pham BT. A Sensitivity and Robustness Analysis of GPR and ANN for High-Performance Concrete Compressive Strength Prediction Using a Monte Carlo Simulation. Sustainability. 2020; 12(3):830. https://doi.org/10.3390/su12030830

Chicago/Turabian StyleDao, Dong Van, Hojjat Adeli, Hai-Bang Ly, Lu Minh Le, Vuong Minh Le, Tien-Thinh Le, and Binh Thai Pham. 2020. "A Sensitivity and Robustness Analysis of GPR and ANN for High-Performance Concrete Compressive Strength Prediction Using a Monte Carlo Simulation" Sustainability 12, no. 3: 830. https://doi.org/10.3390/su12030830