4.1. Research Design and Methods

This study has adopted a case-based approach [

70,

71]. The main reasons for this are as follows: firstly, the case study is a useful method to explain “why” and “how”. As Sun et al.’s research on how to build business model through simple rules shows [

72], this paper focuses on how enterprises can realize the transformation of the sustainable business model based on a digital twin platform network, so it is suitable to adopt a case study. Secondly, considering that the creation process of the three benefits belongs to exploratory research, this paper chooses an exploratory case study method which is helpful to summarize and refine the general strategy behind the business phenomena.

Following the principle of sampling, the selected sample cases should meet the requirements of typicality, content adaptability, replicability [

73] and data availability. In view of this, this paper chooses Haier as the case study object. The specific reasons for this are as follows: firstly, enterprise typicality—focusing on being user-centered, Haier Smart Home has experienced the development stage from a single product to a complete set of smart solutions, then to full-scene solution. It continuously leads the development of the industry through “extreme product experience”, “strong platform capability” and “comprehensive landing capability”. Second, content adaptability—against the background of digital economy, Haier has shifted to intellectualization in an all-round way. It leads in the fields of artificial intelligence, cloud computing, big data, and so on. At the same time, it subverts traditional thinking and builds an open entrepreneurial platform. Based on the advantages of global layout, brand and network, Haier provides users with the concept of life X.0, and their strategy in the IoT era brings convenience, health, safety and comfort to customers with one-stop, full-scene solutions. Third, replicability—Haier COSMOPlat is a cross-industry, cross-domain, cross-cultural replication platform with global universality. This means that it is not only applicable to the household appliances industry and manufacturing industry, but also can achieve cross-industry, cross-domain, cross-cultural comprehensive replication. All walks of life can enhance the competitiveness of the whole industrial process on COSMOPlat, and share its value for the users’ life experience. Fourth, as a representative enterprise of the manufacturing industry, Haier, with its advanced management concept and strategy which are at the forefront of the industry, has abundant materials such as case study articles, external reports and books, which all conform to the data availability principle of the case study.

Based on the “evidence triangle or multi-angle” principle of the case study [

74], this study seeks to collect case-related information as comprehensively as possible through feasible channels for theoretical research and problem exploration. Data were collected from multiple sources. The sources of first-hand information mainly include in-depth interviews, informal discussions, field visits, and informal conversations. For potential customers, some first-hand information can be obtained through the experience of the enterprise’s official platform, physical stores, and anonymous interactions with the enterprise. Other first-hand data used in this case study come from the official website, annual report, prospectus, official Wechat public account, official microblog and other sources of enterprise information. The collected second-hand information includes news reports and literature journals related to Haier in authoritative databases (such as CNKI and Wanfang), and a large number of official publications.

4.2. Overview of Haier

Haier is the world’s leading brand of major household appliances and is now transforming from a traditional manufacturer to an open entrepreneurship platform. Based on the “RenDanHeYi” model, it actively promotes the Internet transformation from the directions of strategy, management models, a research and development system, and a manufacturing system and service system.

On 1 July 2019, Qingdao Haier Co., Ltd. has officially changed its name to “Haier Smart Home Co., Ltd.”. The change in name has released an important signal that Haier has entered into the Internet of things smart home ecology. It also demonstrates that Haier embraces the smart home, seizes the commanding point of the smart home market, and is realizing the creation of an ecological brand in the Internet of Things era with the smart home.

4.2.1. Haier’s Transformation Mechanism

In March 2019, Haier launched the brand’s first full-scene Smart Home Solution [

75]. Haier smart home uses digital technologies, including the Internet of Things, artificial intelligence and big data. Through the Open Internet of Things platform

, it transforms traditional electrical appliances into smart appliances, provides users with a full-scene solution and connects an entire household into one system, as well as following the concept of 5 + 7 + N to achieve a new experience of the smart home. In the system, 5 represents the living scenarios of a smart living room, smart kitchen, smart bathroom, smart balcony and smart bedroom; 7 represents whole-house solutions for air, water, clothes care, security, voice control, health and information; and N is the variable that allows users to customize the smart home experience to best suit their needs.

The smart home is not a new concept. As early as 2014, Haier built the world’s first smart life platform , based on the technology and data support of . The “netcraft” of Haier smart home solutions can realize self-perception, self-judgment, proactive decision-making and connectivity.

Haier’s smart home exploration has experienced four stages of development: single-product smart stage, complete-set smart stage, scene smart stage and ecological smart stage. In the single product smart stage, Haier completed the transformation from electrical appliances to netcraft, allowing products to provide smart services and solutions through a network. In the complete set-smart stage, the netcrafts can connect with each other and actively provide smart life services. In the scene smart stage, Haier released a smart home composed of a whole set of interconnected smart appliances in 2017, involving 161 smart life scenes in different physical spaces such as the living room, kitchen, bathroom and bedroom. After that, they further released the ‘5 + 7 + N’ smart, full-scene, customized, full-set program, and quickly implemented it. In the ecological smart stage, smart home appliances not only satisfy users’ basic needs, but also connect third-party resources to build an ecosystem of food, clothing, housing and entertainment, providing a constantly enriched and iterative ecological scene experience.

Externally, Haier built a smart home platform, through the exploration and practice of the business model of “netcraft + application + service + platform”, to achieve an ecological scene experience; internally, COSMOPlat platform combined Haier’s Interconnected factory model with the digitization and productization of knowledge to build an industrial Internet platform. It integrates Haier’s existing functionalities, such as intelligent equipment, intelligent control, mold and research institutes, and has already collaborated with relevant companies in 15 industries, and offered comprehensive solutions and value-added services through the combination of software and hardware, as well as click-and-mortar for the enterprises’ upgrading and smart manufacturing transformation.

Haier’s original “RenDanHeYi” model has played a supporting role. ‘Ren’ refers to employees who have the spirit of entrepreneurship and innovation, ‘Dan’ refers to order, that is, the value of users, and “HeYi” means zero distance connection between employees and users. Each employee creates value for the users in a different self-employed business, thereby realizing their own value, and the corporate’s value and the shareholder’s value is naturally realized. In this model, employees compete for jobs, and their salary is determined by the user value they create. The mode of “RenDanHeYi” subverts enterprises from traditional, huge organizations to entrepreneurial platforms. The interconnection between entrepreneurial platforms breaks through the boundaries of the way organizations obtain resources, and the circulation of multi-factor resources within organizations optimizes the production costs of enterprises and creates greater synergy. Haier’s “RenDanHeYi” mode changes the way of value creation and value acquisition. It not only realizes the change in production model and pays attention to the needs of personalized customization, but also creates the conditions needed for employees to realize their own value.

Haier has already established three major platforms in its smart home business—the smart home sector’s first IoT platform

, the first IoT social app Shunguang, and the world’s first industrial Internet platform COSMOPlat [

76] (as shown in

Figure 2). This has built up a robust foundation for its world-leading smart home network and brand portfolio, ensuring that Haier continues to deliver innovative smart home experiences and devices to users.

Haier will manufacture its smart home appliances through COSMOPlat, the largest-scale customizable solution platform, which integrates global resources, cross-validates with users to achieve all-around interactive control of household appliances, customizes living scenarios, individualizes appliance functions intelligently and centralizes a family’s information in one hub.

The upgrading of Haier household appliances includes not only the internal construction of interconnected factories to achieve the real-time interconnection of the personalized needs of consumers, but also the external construction of the open platform of smart life, aiming at providing consumers with solutions for a smart life in an Internet age, so as to realize the best experience of interaction, transaction and delivery for consumers.

Haier also extends its networks to social networks and community economies while building the smart home networks, and continuously enhances the user value of Haier products and services, to provide interconnected smart home experiences and qualitied products globally.

In sum, based on the smart home, Haier has established a platform network of mutual connection and support. Among them are the Shunguang social platform, which functions as the user contact end, the COSMOPlat platform, which enables products, services and solutions to be implemented quickly, and the platform, which gathers more developers and resources. The case study of this paper is mainly about how Haier’s digital twin platform network, based on these three major platforms, can help enterprises to innovate the sustainable business model.

4.2.2. Haier’s Achievement in Economic, Social and Environmental Benefits

As previously mentioned in the literature review, the research on the topic of sustainability concerns the implications of the digital transformation in terms of economic, environmental, and social benefits, referring to the triple bottom line (TBL) dimensions of a sustainable business model. Enterprises have to rely on a new business paradigm and have to directly or indirectly generate economic, social, and environmental benefits. Therefore, this paper takes the three benefits as the criterion for selecting Haier as the case study object of a sustainable business model. Since Haier started to build the smart home in 2014, it collects Haier’s historical data of three benefits from 2014 to 2018.

As the world’s leading producer of major household appliances, Haier Group builds a global selling network comprised of 143,300 sales outlets spanning more than 160 countries. The following

Figure 3 is a broken line chart of Haier’s revenue growth from 2014 to 2018. As shown in

Figure 3, Haier’s global revenues in 2018 were 183.317 billion RMB, with a year-on-year growth of 15%.

For a long time, Haier has invested in the improvement of the treatment capacity of pollutants discharged from production. It also focuses on reducing the consumption of non-renewable energy. In 2018, Haier deepened the implementation of the “green design, green manufacturing, green marketing, green recycling” 4G green strategy, which continued to promote environmental development and actively promote environmental consumption, achieving a 16.67% reduction in energy consumption per unit output value (As shown in

Figure 4), which meant five consecutive years of decline, saving 16,787 tons of standard coal, and reducing carbon dioxide emissions by 44,221 tons. Moreover, the disposal rate of waste has reached 100%.

Haier has always believed in the unshakable responsibility of enterprises to actively fulfill social responsibility. Haier’s social responsibility model includes nine types of stakeholders: government, consumers, employees, suppliers, distributors, shareholders, industry peers, social groups and the public. In the process of continuously improving the digital twin platform network, Haier has brought benefits to more stakeholders. Haier’s original RenDanHeYi model has transformed employees into self-employed businesses, creating value for users and helping them to realize their own value. Moreover, Haier implements the intelligent HSE6S cloud platform system, and realizes the construction of a safety culture to ensure the personal safety of employees. It achieves a recordable injury rate of 0.07 per 200,000 working hours, which has continued to decline for two consecutive years, and fell by 46.58% in 2018. In addition, Haier promotes the integration of supply and demand from the perspective of user demand, and built an ecological user platform for the whole process of home appliance service. It subverts and reengineers the whole process of service, and creates a visual, digital and intelligent integrity service to bring users a faster, closer and more intelligent service experience. Haier’s characteristic supplier management emphasizes sharing information between cooperative suppliers. Haier has realized more information exchanges with suppliers, and assisted suppliers in reducing costs, improving quality, speeding up the product development progress, and replacing short-term contracts with long-term trust cooperation, thus reducing transaction costs and management costs. For shareholders, Haier is committed to protecting the legitimate rights and interests of shareholders and actively returning investors through sustained and steady performance growth. At the same time, Haier actively participates in public welfare undertakings and vigorously supports education. Haier uses the Internet to build a public welfare ecosystem, linking scattered social resources with charity. The Shunguang platform builds a public welfare community network through community interaction, and publishes and displays public welfare projects on the platform. It not only presents information truthfully and transparently, but also facilitates the online interaction and participation of partners, users, fans, etc. Haier’s exploration of public welfare model innovation provides more personalized platforms for people from all walks of life to participate in public welfare, which helps to improve the overall level of charity. The following are the historical indicators of Haier’s social benefits, which are provided in Haier’s Social Responsibility Report (as shown in

Figure 5). Haier’s social contribution value has continued to grow since 2015. In 2014, in order to further protect the interests of shareholders, Haier established a long-term mechanism of share repurchase, intending to use its own funds to repurchase the circulating A-shares through centralized bidding.

This calculation index is derived from the files of the Shanghai Stock Exchange. The calculation formula is: social contribution value per share = earnings per share + (total tax payment + employee expenses + interest expense + total public welfare investment − social cost)/capitalization. Among them, the employee expenses include the cash paid to and for the employees.

4.3. Case Study of Haier

Digital twin can comprehensively improve the whole life cycle management of products by establishing the digital mapping of physical products and based on the data generated in the use of products, it can form closed-loop of feedback and optimization. It can get through different functional departments such as R&D, supply chain, manufacturing, marketing, and even the ecosystem of enterprises. It can sense the needs of customers all the time and drive an efficient, interconnected and customer-centric operation model which can improve product experience, reduce cost and increase benefits.

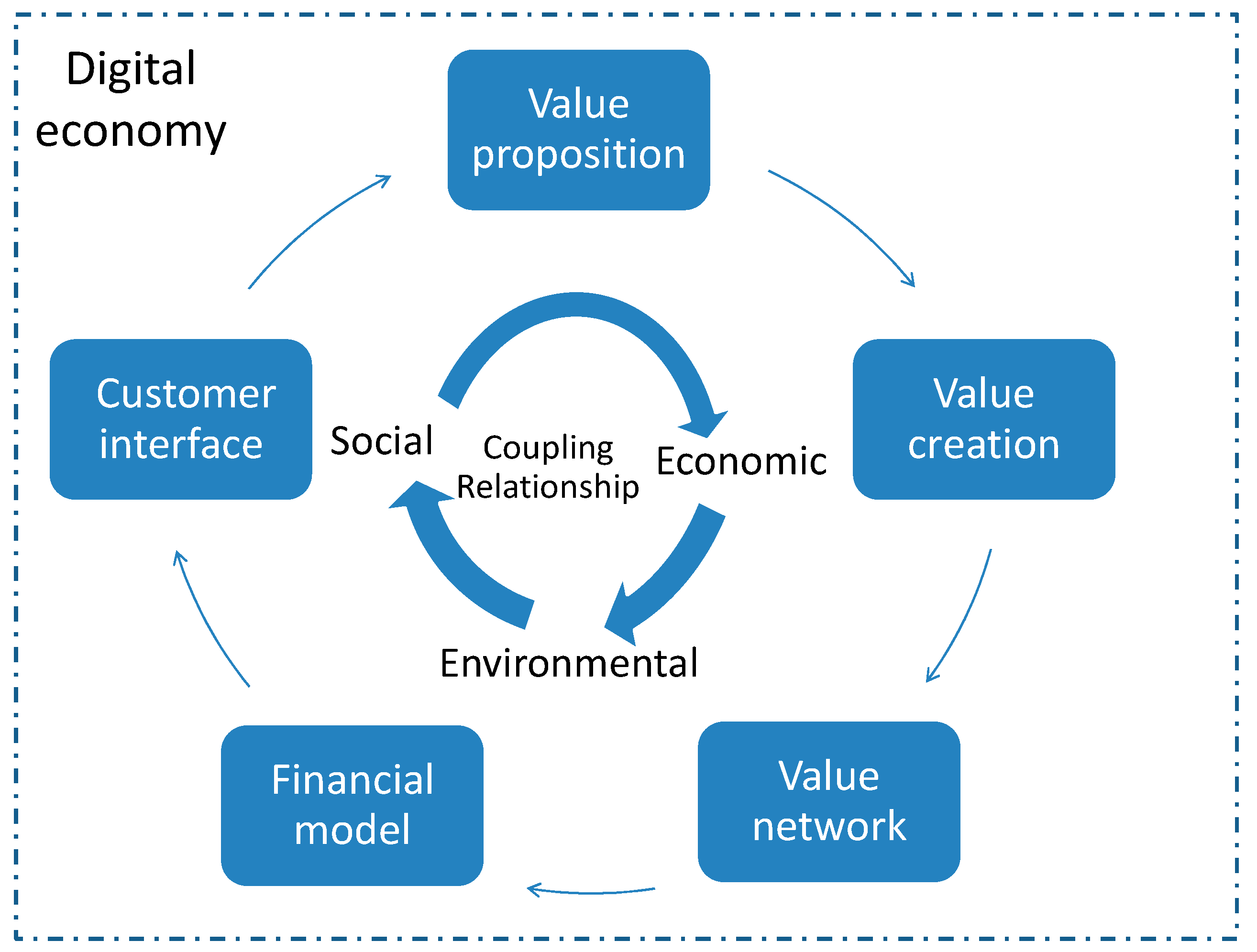

Haier integrates all kinds of user information, product information, equipment information, logistics service information, technical resources, supplier resources and other information on a unified cloud platform, and integrates the technical resources of R&D, procurement and other links in the upstream production process, so that users can interact with all smart products and the whole production process. Haier has built interconnected factories based on this cloud platform. The form of interconnected factory not only changes the dimensions of value creation but also the dimensions of the of value network. Through more efficient cross-border information sharing and resource allocation, enterprises can greatly improve the utilization rate of resources and reduce the waste of resources. On the one hand, Haier’s interconnected factory realizes internal and external interconnection, and the interconnection between users, design and the production department. On the other hand, it realizes the interconnection of information between equipment and product. Operators can communicate with technical experts in remote real-time audio and video, while experts can give feedback information to the operator through virtual entities. Using digital twin to get through all the value links of the enterprise and establish the coupling relationship between the dimensions of the business model (as shown in

Figure 6), to a certain extent. It can also strengthen the information communication of the enterprise and improve the resource allocation, thus contributing to the production of the economic and social environmental benefits of the enterprise.

Digital twin enables enterprises to turn products into a dynamic platform, continuously acquire customers’ needs, take appropriate actions at the right time and in the right scene, provide customers with better products and services, and promote the disruptive upgrading of core processes and customer experience. Haier’s smart appliances can intelligently adjust the life scene according to the user’s habits, and can feed back the user’s usage habits and usage information to the production device in real time, so as to use the information in the R&D, design and procurement links.

Therefore, the next part will specifically analyze how Haier innovates the sustainable business model through the digital twin platform network from the perspective of the above-mentioned sustainable business model framework and the relationship between dimensions.

4.3.1. Value Proposition

Value proposition refers to the value embedded in the products and services provided by enterprises. When providing products and services, enterprises should not only include economic value, but also social value and environmental value, such as the consumption of resources and energy of products, and the actual value to users.

On one hand, Haier guides consumers to create environmental benefits by providing green products. Haier Maglev Central Air Conditioner has the advantages of 50% energy saving, three-year maintenance, 2 ampere low current start-up, a 30 year service life, etc. It has greatly improved the green environmental protection demand of buildings, and continues to lead the green development of central air conditioning. Haier smart refrigerator reduces product deterioration through temperature control induction technology, prolongs shelf life, and consequently saves energy. There will be an automatic reminder before food materials expire, to ensure the quality and freshness of food but also to make the best use of food.

On the other hand, the Haier smart home makes use of the Internet of Things, AI and big data to turn traditional electrical appliances into smart appliances through platform. Through scenario business combined with ecological services, Haier smart home provides users with a full-scene solution and connects an entire household into one system following the concept of 5 + 7 + N to achieve a new experience of the smart home. Users can enjoy seven whole-house solutions, such as air, security, water, washing and so on, in the five continuous iteration physical spaces of the kitchen and bedroom, so that users can enjoy customized life scenarios, and improve their experience.

4.3.2. Value Creation

Enterprises create value by utilizing resources and capabilities within the enterprise in a new and sustainable way, and focus on the transformation of production and management modes. Haier COSMOPlat platform is the industry’s first independent research and development, independent innovative and intelligent manufacturing of the Chinese industrial Internet platform.

Firstly, the COSMOPlat platform can provide a platform for users to participate in the whole process of mass customization. Users can also view every manufacturing scene in real time. This enables global consumers to participate in the design and production of products in the whole process, successfully breaking through the thick wall between manufacturers and users. Through this platform, enterprises can accurately acquire users’ needs, satisfy users’ experience, change the traditional enterprise-centered model to the user-centered Internet model and realize collaboration with uses. COSMOPlat platform can greatly improve the efficiency of enterprises and meet the value of users.

Secondly, the COSMOPlat platform helps enterprises to become capable of all-factor interconnection and realize zero-distance interaction between users and enterprises, enterprises and resources. Through the internal and external all-factor interconnection, equipment data, industrial data and user data are linked together to form a resource system to interact and meet the user’s demand. Timely information transmission and resource allocation help Haier save a lot of the unnecessary waste of resources.

Moreover, in 2018, Haier Smart Energy Center has been upgraded iteratively to become a customized platform for smart energy. With equipment, instruments and cloud computing as technical support, it dialyzes the production links of factories and builds the energy industry chain. The Haier Smart Energy Center, a leading energy data analysis system in the industry, has been set up. By means of automation, information technology and a centralized management model, it realizes centralized dynamic monitoring and the digital management of water, electricity, gas and other major sources of energy consumption, and the data have been collected automatically and accurately for 24 h. At the same time, through the system algorithm module, it can predict and analyze energy consumption data, optimize energy scheduling, reduce energy consumption per unit, improve the operation performance of energy management, and truly realize low-carbon production.

4.3.3. Value Network

Smart ecosystems need advanced solutions which require support from open innovation systems. Haier’s five R&D centers in the United States, Europe, Japan, Australia and China form an innovation resource network spreading across the whole world. At the same time, the open online platform, Haier Open Partnership Ecosystem (HOPE), provides an environment for global users and resources to conduct zero-distance interaction and continuously create innovative solutions. Moreover, the COSMOPlat platform not only gathers millions of user resources, but also aggregates more than 3 million ecological resources, forming three bilateral markets. Through horizontal, vertical and end-to-end integration, it forms an open, collaborative and win-win new industry ecosystem.

Furthermore, Haier also exerts a considerable influence on its stakeholders, while generating social and environmental benefits in the whole supply chain. Take the Clothing Network of Haier (as shown in

Figure 7), for example. Haier clothing network takes clothes as the medium, and absorbs relevant resources such as clothing enterprises, fitting mirror manufacturers, and clothing technology providers. It realizes the customization of exclusive clothing washing, care procedures and the whole process service from clothing purchase to wearing, and extends the technology of RFID to the whole industry chain of intelligent traceability and intelligent manufacturing. It makes full use of the upstream and downstream links of clothing network to meet the needs of intelligent clothing management for manufacturers, stores and other scenarios. For clothing manufacturers, RFID technology solves the efficiency problem of large quantities of clothes in and out of warehouse, brings several times greater efficiency improvement for each logistics identification link, greatly reduces the cost, and realizes the data sharing of the entire clothing supply chain. At the same time, with the help of the clothing network ecological digital management platform, stores can quickly obtain user feedback information, adjust marketing strategies according to users’ personalized needs, and achieve mutual benefit.

4.3.4. Customer Interface

While many industry players focus on standard models, Haier is delivering consumers the possibility of customizing both products and solutions, as well as realize intelligent upgrades according to their actual habits and needs.

“User personalization” is a driving force of open innovation. In the age of Internet, it’s getting easier and easier for users to get detailed product information. With the growth of Internet natives, user demands are getting more and more personalized and fragmental, and there is a growing requirement for customized products. Therefore, in order to meet user’s personalized demands, enterprises have to change the traditional innovation method and co-create with users and first-class resources.

Based on Cloud Brain and the knowledge atlas, Haier smart appliances can conduct deep learning, independent thinking and decision-making, and actively provide services for users. Take the smart water heater, for example. Using big data to collect and analyze information, using the cloud brain deep learning model, the heating time and temperature of the water heater can be automatically adjusted. In addition, the data will be uploaded to the cloud. After calculation, water habits and energy-saving models will be established to further help machine learning and analysis of control operation strategies. Finally, through long-term machine learning, and according to the user’s living habits, smart appliances can actively provide personalized customized solutions: the water will be heated when needed, the water temperature will be appropriate and will not cause the waste of water, so that users can receive a comfortable smart home experience.

Haier’s innovative MFOP quality model has greatly improved product quality and reliability through the integration of the Internet of Things and the household appliances industry. Its advantages are mainly embodied by two aspects: first, through PHM core technology to pre-diagnose the functional status and service life of product components or systems, and in combination with users’ needs, to provide users with product maintenance, remote maintenance and correcting problems beforehand. Secondly, the product comprehensively analyses the user’s habits through big data, excavates the core points of demand, provides precise guidance for the further upgrading of products and services, and continuously iterates to provide the best user experience.

4.3.5. Financial Model

The financial model reflects the appropriate distribution of benefits and costs among stakeholders involved in the whole value chain of business model. Enterprises should think about how to make use of consumers’ awareness of social responsibility and environmental responsibility to transform their own environmental responsibility and social responsibility into consumers’ demand. At the same time, enterprises should also consider the vulnerable groups in the value chain. Haier’s “RenDanHeYi” model allows more capable employees to serve higher orders, create higher user value, forming a mechanism for sharing value between users and employees. The “RenDanHeYi” model gives employees more autonomy and stimulates their vitality. Employees become their own CEO, creating value for customers and realizing value for themselves at the same time. The original win-win mode of “RenDanHeYi” stimulates the internal motivation of employees, turns them into masters, and realizes their own value when creating value for users.

4.3.6. Coupling Relationship of Five Dimensions

Through the above analysis of the Haier smart home case, combining a digital twin platform network and sustainable business model, the paper draws a four-tier integrated framework, which are operation mechanism, digital twin platform network, a sustainable business model and a triple bottom line (as shown in the

Figure 8).

The Haier smart home can use the Internet of things, artificial intelligence and big data, through the platform, turn traditional electrical appliances into smart network devices, and provide users with a full range of software and hardware solutions through scene store and the digital twin platform network, so as to achieve the best life experience for users. With the goal of leading smart homes in the era of Internet of things, Haier builds the cloud, through natural human–computer interaction and distributed scene netcraft, it provides the industry with full-scene ecological solutions for the smart home. As shown in the operation mechanism layer, Haier takes smart household appliances as the entrance, and obtains user information and requirements with the Internet of things technology. Digital twin platform networks and netcrafts are used to define, manage and operate the life scene. Through interaction with the scene store, the cloud could download scenes and give feedback, therefore the smart home appliance can provide users with customized service.

The Haier smart home is supported by three platforms, which are the Shunguang social network, IOT platform and COSMOPlat platform. Among them, the Shunguang social platform works as the user contact end, the COSMOPlat platform enables products, services and solutions to be implemented quickly, while the platform gathers more developers and resources. Combined with the third layer of sustainable business models, we can see the connection between Haier’s platform network and the sustainable business model. The Shungang social network platform focuses on social interaction and subverts traditional e-commerce, aiming to build an Internet of things platform that integrates online stores, offline stores and micro stores and provides home solutions through personalized data. The Shungang platform becomes the entrance of the connection between users and enterprises, which changes the dimension of the customer interface. The platform provides customized services for customers through smart appliances and cloud brain, which forms the development of Haier’s value proposition.

Haier COSMOPlat has built 11 connected factories, connected by seven modules through the platform network, and enabled 15 industries, such as the Internet of food, the Internet of clothes, and the Internet of agriculture. The form of connected factory not only changes the dimension of value creation but also the dimension of the value network. Through more efficient cross-border information sharing and resource allocation, enterprises can greatly improve the utilization rate of resources and reduce the waste of resources, which is consistent with our concept of sustainability.

Furthermore, Haier’s original “RenDanHeYi” model subverts the enterprise from the traditional organization to the entrepreneurial platform. The interconnection between the platforms breaks through the boundary of the enterprise’s way of obtaining resources, and introduces the market mechanism into the traditional links of R&D, production, manufacturing and sales. “RenDanHeYi” connects employees and users, as employees could realize their own value through creating value for users, and it also helps to maintain the stickiness of users. In this model, employees’ compensation is determined by the user value they create. This is Haier’s innovation in value creation and financial model.

Haier’s three platforms are interconnected and mutually supportive, forming a sustainable platform network. As a user community, the Shunguang platform can help enterprises to collect users’ value propositions and obtain users’ needs. The user requirements will be summarized by the COSMOplat cloud platform. Under the mode of RenDanHeYi, the solution will be formed through employee competing, and then the partners in the platform will provide the corresponding resources. Finally, they will be delivered to the interconnected factory for production. During this period, users can see the whole production process. The coupling between platforms and the sharing of information resources saves a lot of manpower and material resources, and also generates new social and environmental benefits.

4.4. Digital Platform Network Construction of Haier, Midea and Gree

As the “three giants” of China’s home appliance industry, Midea and Gree have also opened the road of digital transformation.

Midea’s digital transformation adopts the strategy of “two intelligences”, that is, smart home and intelligent manufacturing. Different from Haier’s idea of user interaction and resource integration, Midea focuses on the automatic transformation of production lines to achieve the goal of efficiency improvement and scale customization. In the production line, Meida focuses on automation and information technology. Midea’s intelligent manufacturing can not only improve the production efficiency, but also meet the user’s one-to-one personalized customization needs. According to the construction of production lines in different workshops, Midea improves the interconnection and digital construction of each workshop by comprehensively using the core intelligent manufacturing equipment to transform the production line and improve the information network construction. Since 2011, Midea has established “632” strategy, namely six operation platforms, three management platforms, and two portals and integrated technology platforms. At present, Midea also actively wants to build a digital twin platform network and an industrial Internet. All business units comprehensively carry out industrial Internet reform, promote automation and intelligence, realize the digital operation of the whole value chain, drive management with data, and promote the continuous and in-depth digital transformation of businesses.

Gree mainly conducts independent research and development in the two directions of robot and precision machine tools, hoping to expand from the pure household appliance manufacturing industry to the new energy and equipment manufacturing industries. In addition, regarding the digital factory, it focuses on the interconnection between the manufacturing execution system and other systems, which can ensure that all relevant product information is kept synchronous from the beginning to the end, and realize real-time updates. Based on this, Gree has built a collaborative cloud (to create a standardized, transparent and dehumanized supply chain ecosystem, and to achieve the goal of opening up resources and reducing expenditure, improving efficiency management), Intelligent Cloud (to deliver accurately, improve efficiency and quality, reduce inventory, and make digital transparency), equipment cloud (to visualize equipment capacity, to maintain information, to prevent maintenance, to analyze abnormal closed-loop equipment, and to design full-state visualization) and smart human cloud (smart recruitment, smart access control, smart attendance, smart collaboration, smart cloud digitalization, visual application management) and other cloud platforms.

Haier’s digital twin platform network mainly focuses on intelligent production and user ecology, aiming to get through the whole process node of interaction with users. Therefore, Haier has built the COSMOplat platform, which can realize the mass customization of products and improve the capacity of intelligent manufacturing around the needs of users. Unlike the other two enterprises, Haier has built a platform network to get through the whole process, making all dimensions coupled with each other, realizing the circulation of information in different functional departments, and improving the allocation efficiency of resources in various value links. Secondly, both Haier and Midea use digital twin technology to develop smart products and enhance user experience, which is helpful to increase social benefit. This is a point that Gree has not achieved at present. However, in terms of digital management, both Haier’s RenDanHeYi model and Gree’s smart human cloud have human management through the network platform. The construction of this platform can improve the financial model of enterprises, and realize the fair distribution of value among enterprises, employees and suppliers.