The presentation and discussion of results was carried out according to the variety of levels of detail involved by the different codes used to represent economic areas, types of waste and product uses. In this vein, the results achieved according to the NACE code were explored by using one, two or four digits, involving increasingly narrow clusters to indicate the activity of companies. In the case of the EWC and CPA codes, the analysis tightened from generic to specific by considering two and six digits.

3.1. Analysis According to Business Areas (NACE Codes)

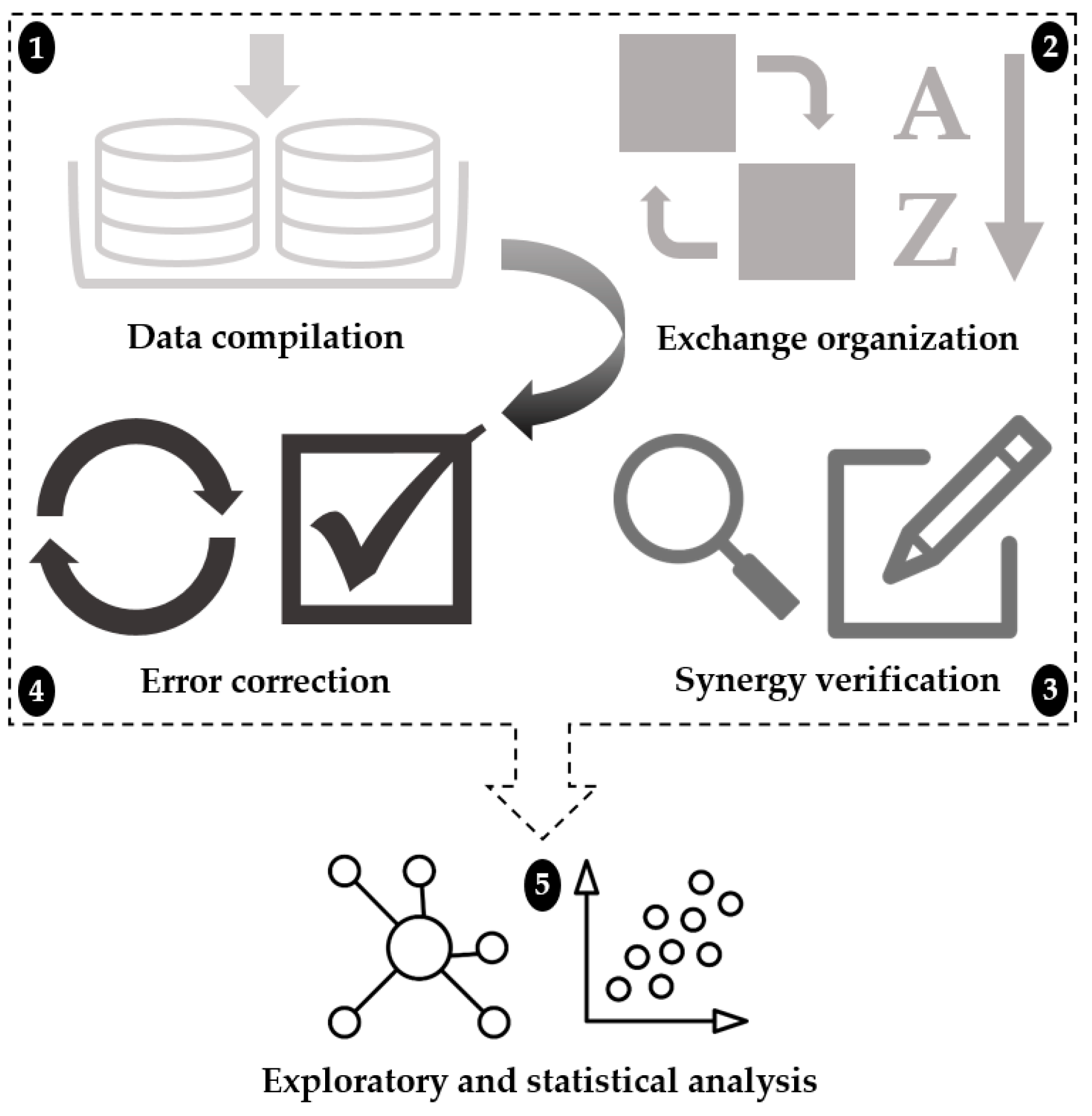

As a first step, a simple correspondence analysis was undertaken to examine the interactions between donor and recipient companies according to their 1-digit NACE codes.

Figure 3 shows the asymmetric row plot stemming from this analysis, which displays a row of principal coordinates (donor) and a column of standardized coordinates (recipient). The main information provided by this diagram is that the further categories are from the origin, the more distinct they are, and vice versa. In this case, this means that NACE donor H (transportation and storage) and recipients F (construction), H and E (water supply) are less likely to participate in exchanges with other sectors. Instead, NACE codes like C (manufacturing) and D (electricity gas, steam and air conditioning) are located close to the origin, indicating more chances to create synergies with other businesses. The strength of the relationships between donor and recipient areas increased proportionally to the acuteness of the angles between the lines connecting their positions with the origin. Hence, a couple of examples of strong relationships were those between donor D (electricity) and recipient C (manufacturing) or donor C and recipient A (agriculture), since the virtual lines connecting their coordinates with the origin of the plot were acute.

A more detailed arrangement of the data according to the NACE codes is depicted in

Figure 4, which represents donor and recipient companies through 2 digits. Thicker links represent the more frequent exchanges between the 49 NACE codes included in the 496 cases that formed the processed database. Hence, the chemical industry (20) was found to participate in 26% of the total exchanges, followed by the supply of electricity, gas, steam and air conditioning (35), the manufacture of basic metals (24), the food industry (10) and the manufacture of other non-metallic mineral products (23), which amounted to 23%, 20%, 16% and 15% of the synergies considered, respectively.

As further proof of their importance, the exchanges among these 5 economic areas concentrated a third of the registered synergies. This figure increased up to 75% when taking into account the participation of these sectors in any exchange, which corroborates their great importance in terms of IS due to the type of waste they generate and their high reusability. As introduced before,

Figure 1 shows a distributed network, since there is neither a single node centralizing the relationships with the others nor a decentralized tree-shaped structure where the generation of exchanges is sequential.

As a consequence of the impossibility of fill or complete some the absent data, there were 42 and 23 unknown registers involving the participating companies (NA), which amounts to 13% of the exchanges under study. Still, these results highlighted the complexity of the connectivity between the nodes of the networks, defined as the capacity of the companies of the same or different economic areas to communicate with each other, share information and establish mutually beneficial relationships.

The analysis of data from the perspective of donor and recipient companies resulted in some differences with respect to

Figure 4, as observed in

Figure 5a,b. For instance, areas 01 (crop and animal production), 20 (manufacture of chemicals) and 23 (manufacture of other non-metallic products) were found to be unbalanced in favor of their role as recipients, and vice versa for area 24 (manufacture of basic metals). On the one hand, those donor areas reaching top positions both in

Figure 4 and

Figure 5a experienced a decrease in the number of NACE codes to which they donate in comparison with their participations in exchanges, due to the existence of repeated donations to the same areas. For instance, category 24 (metallurgy) donates 67 times to 14 different sectors, among which code 23 (other non-metallic mineral products) highlights as a recipient with 21 exchanges. This fact is exacerbated in those areas participating in less synergies, such as code 16 (wood), which had a 100% diversity in its donations to 6 different areas.

On the other hand, code 20 (manufacture of chemicals) highlighted by being the greatest recipient in

Figure 4; however,

Figure 2b indicated that the receptions in this area stemmed only from 14 different sectors, of which 91% related to NACE codes 20 (chemicals), 24 (basic metals), 35 (electricity, gas, steam and air conditioning) and 19 (coke and refined petroleum products). Instead, the high number of participations of code 01 (agriculture) as a recipient from different donors was due to the variety of sectors producing waste that can be used to fertilize soils. This trend is consistent with many research studies aimed at assessing the suitability of a variety of waste types stemming from different sources to perform as fertilizers, such as iron [

30], volcanic rocks [

31], coffee [

32], wine [

33] or seaweed and fish [

34].

The validity of the synergies between donor and recipient companies was further analyzed by determining their Phi correlation coefficients, whose values proving to be statistically significant are compiled in

Table 3. The implications of these results differed from those of previous analyses, since high correlation coefficients are associated with exclusivity rather than capacity for establishing a lot of synergies. The greatest exponents of this situation are exchanges 26–26 (manufacture of computer, electronic and optical products) and 47–31 (Retail trade, except for motor vehicles and motorcycles—manufacture of furniture), which only favored exchanges with each other and, therefore, resulted in the highest possible correlation coefficient. By contrast, donor companies with codes 11 (manufacture of beverages) and 24 (manufacture of basic metals) diversified their synergies a lot, thereby leading to weaker correlations. Hence, the results in

Table 3 provide an excellent complement to the data depicted in

Figure 3 and

Figure 4, since they enable moving from the quantitative characteristics of exchanges to their representativeness.

Subanalysis Using 4-digit NACE Codes

A more exhaustive breakdown of the data through the 4-digit NACE codes of the companies is provided in

Table 4. This subanalysis revealed that the production of electricity (35.11) appeared in 99 of the 496 exchanges. This is in line with the findings of Rattner and Garimella (2011) [

35], who found that there was sufficient waste heat from power plant outlet streams to satisfy all the USA space and water heating needs. Other important areas were the manufacture of basic iron and steel and of ferro-alloys (24.10) with 61 participations, the manufacture of refined petroleum products (19.20) with 56 and the manufacture of cement (23.51) with 46. This contrasts with the results obtained for the 2-digit NACE codes, whereby the chemical industry (20) was in the first place. This singularity was due to the disaggregation of this economic area into multiple codes, such as 20.11 (industrial gases), 20.12 (dyes and pigments), 20.13 (other inorganic basic chemicals), 20.14 (other organic basic chemicals) or 20.15 (fertilizers and nitrogen compounds). Instead, the emergence of 19.20 (manufacture of refined petroleum products) when considering 4 digits was a consequence of the division of the manufacture of coke and refined petroleum products (19) into only two categories, which favored the concentration of cases for this particular code.

The predominant trio of areas according to the 4-digit NACE code, namely 35.11 (production of electricity), 24.10 (manufacture of basic iron and steel and of ferro-alloys) and 19.20 (refined petroleum products), persisted when exploring the frequency of exchanges per donor, with remarkable differences with subsequent codes. The main exception to this trend was 10.81 (manufacture of sugar), which performed as a donor in 21 exchanges addressed to 14 different sectors. In this vein, code 35.11 (production of electricity) highlighted by both its centrality and diversity, since its 59 donations were distributed across 24 different sectors. By contrast, 24.10 (basic iron and steel) was less diverse due to the repeated linkages with the same areas, such as its 12 donations to the manufacture of cement.

The business area with the highest number of exchanges as a recipient remained 35.11. However, the differences between the 2–3 most frequent codes and the remaining ones was not so abrupt as in the case of exchanges per donor, which is logical due to the versatility of some types of waste in terms of new uses. Agricultural companies did not highlight when considering the 4-digit NACE codes, due to their aforementioned distribution across different activities such as 01.13 (vegetables and melons, roots and tubers) or 01.50 (mixed farming). One of the most striking cases at this stage of the study was the presence of 38.21 (treatment and disposal of non-hazardous waste), which performed sixth as the sector with more receptions registered (18) and almost 100% diversity (17 different origins), as a result of its capacity for admitting both organic and inorganic waste. Another example of diversity was 01.10 (growing of non-perennial crops), whose 8 exchanges were with 8 different business areas. These cases illustrate how versatile some areas are when it comes to make new uses of a variety of types of waste, thereby providing them with different business opportunities to exploit.

3.2. Analysis According to Material Exchanges (EWC and CPA Codes)

Similarly to the previous subsection, the asymmetric row plot (

Figure 6) yielded by a simple correspondence analysis enabled exploring the relationships between waste (EWC code) and new uses (CPA code). In this case, EWC 14 (organic solvents, refrigerants and propellants) and CPA 28 (machinery and equipment) were very far from the origin of the chart, which indicated their almost null compatibility with the remaining waste types and new uses. On the contrary, waste types such as 07 (organic chemical processes) or 19 (human or animal health care) highlighted by their versatility, lacking narrow or specific new uses.

The sharp angles formed between the origin of

Figure 6 with the combos EWC 02 (agriculture) –CPA 10 (food products) and EWC 10 (thermal processes)–CPA 35 (electricity, gas, steam and air conditioning) suggested that these were the strongest interactions between waste and new uses. This inference was confirmed by the thick arrows connecting these elements in the network diagram represented in

Figure 7. Other examples of powerful links were EWC 10 (thermal processes) and CPA 08 (mining and quarrying products) or EWC 06 (petroleum refining, gas purification and coal treatment) and CPA 20 (chemicals), as shown in

Figure 6 and

Figure 7. Moreover, the intensity and frequency of the links in which EWC 20 (waste management) and CPA 38 (waste collection and treatment) were involved was also remarkable.

As suggested by

Figure 7, EWCs 10 (thermal processes) and 02 (agriculture) were the two types of waste most widely involved in the network, to the extent that they participated in 29% (144/496) and 21% (102/496) of the exchanges registered. The distribution of waste according to donor and recipient NACE codes is explored in

Figure 8a. From the point of view of donors, the importance of EWC 16 (waste not otherwise specified in the list) was logical, since this code agglutinates every type of waste that is not included in other categories. The preponderance of EWC 10 (thermal processes) pointed out to the importance of thermal processes in the production activities of different industrial sectors, such as extraction, chemicals, metal, electricity, paper, wood or cement. Next was EWC 02 (agricultural and food waste), which were generated by 8 different donor areas. Their presence in these terms is interesting, since agricultural companies were not among the greatest donors in

Figure 4. However, the food industry played an important role as a donor, to the extent of being responsible for 61% of the exchanges in which EWC 02 (agricultural and food waste) was involved.

From the perspective of recipients, thermal processes (EWC 10) also generated the most usable waste by a greater number of companies. A large proportion of this waste was slags used as additives in cement, road construction and other civil engineering activities. The literature provides multiple examples corroborating how common this relationship is [

36,

37,

38,

39,

40], in consistency with the predominance of the construction sector as the largest consumer of raw materials [

41]. Another part was steam and hot gases used as energy in petroleum refineries, factories and the chemical industry. Agricultural waste (EWC 02) was distributed among 19 recipients, thanks to its versatility to act as fertilizers, an energy source or animal food. Waste management (EWC 20) and wood–paper waste (EWC 03) also achieved a high degree of variety with 16 and 14 recipient areas, respectively. EWC 20 (waste management) is very varied, including plastics, clothes, batteries or paint, which increases its suitability for a large range of business areas. The high diversity of wood and paper waste was explained by their ability to produce energy, which is a much-demanded source in different sectors. At the opposite side, EWC 06 (waste from inorganic chemical processes), which was the third most frequent waste with 47 participations, was only received by 10 different recipients. This is justified by the fact that most of the waste types in this code are fertilizers, gases or water, which in most cases end up in the chemical industry or in power plants in the form of energy (NACE 20).

As illustrated in

Figure 6 and

Figure 7, the most frequent CPA codes, namely 10 (food products), 38 (waste collection, treatment and disposal) and 08 (other mining and quarrying products), were not directly proportional to the NACE codes of recipient companies. In consequence,

Figure 8b was prepared to observe the relationships between CPA and recipient NACE codes. Chemical products (CPA 20) were used by 23 different recipients; however, 36% of these areas corresponded to NACE 20 (chemicals). This fact, which might seem logical, did not apply for CPA 35 (electricity, gas, steam and air conditioning), since there were only 12 times out of 77 in which these raw materials ended up in the energy sector (NACE 35). The remaining 65 times were distributed across 15 different NACE recipients, highlighting the importance of energy in almost every business sector. CPA 08 (mining and quarrying products) also had an uneven distribution, although on this occasion it involved that more than half of the exchanges involving this code were related to its correspondent NACE code (08). Other relevant raw materials in this sense, such as CPAs 38 (waste collection and treatment) or 10 (food products), were more balanced in what concerns frequency and number of recipient areas.

The statistically significant Phi correlation coefficients derived from the relationships between 2-digit EWC and CPA codes are collected in

Table 5. As a remarkable difference with respect to the results listed in

Table 3, the analysis yielded several negative correlation coefficients in this case. This fact emphasized the existence of incompatibilities between several types of waste and some potential new uses registered by the recipient companies. The interactions between waste types 02 (agriculture), 06 (inorganic chemical processes) and 10 (thermal processes) with the new uses 35 (electricity, gas, steam and air conditioning), 38 (waste collection, treatment and disposal) and 20 (chemicals), respectively, epitomized this situation. Although the inferences derived from these relationships might be obvious, sometimes the potential new uses that can be assigned to waste are unclear. Therefore, this type of information is useful to discard options straightforwardly when thinking of potential synergies aimed at valorizing waste. The highest correlation coefficients corroborated the strength of some of the links identified in

Figure 7, such as those between EWC 02 (agriculture) with CPA 06 (crude petroleum and natural gas) and EWC 10 (thermal processes) with CPA 35 (electricity, gas, steam and air conditioning). Other coefficients like those between EWC 01 (waste from mining and quarrying) and CPAs 05 (coal and lignite) and 06 (crude petroleum and natural gas) indicated that mineral waste is most likely to become raw materials used for combustible purposes, thereby suggesting a clear search pattern for donor companies. It is also worth mentioning the highest correlation coefficient in

Table 5, which corresponded to the association between EWC 14 (wearing apparel) and CPA 28 (machinery and equipment). This is completely aligned with

Figure 6, in which the location of these two elements suggested a strong independent symbiosis between both of them.

Subanalysis Using 6-digit EWC and CPA Codes

When taking into account the 6-digit version of the EWC code, a total of 170 different waste types were found. Since 89 of them only participated in one single case, 48% of the waste types were involved in several exchanges. In line with the trend observed in

Figure 7, the most widely present waste types were 100202 (unprocessed slag) and 100118 (waste from gas cleaning containing hazardous substances), as highlighted in

Table 6. Therefore, the most widely involved waste belonged to two of the three most frequent donor areas: metallurgy (NACE 24) and electric energy (NACE 35). Instead, the relevance of other types of waste highlighted in

Figure 7, such as 06, was diluted when considering the whole EWC codes due to its balanced distribution over different categories such as 060204 (sodium and potassium hydroxide) or 061002 (hazardous substances).

In terms of the number of donors that produced each type of waste, EWCs 020103 (plant-tissue waste) and 150102 (plastic packaging) highlighted by being produced by 9 and 6 different business areas, respectively. Regarding plastic packages, these areas belonged to 5 NACE groups (2-digits), namely 01 (agriculture), 10 (food), 18 (printing), 20 (chemicals) and 25 (metal products), which indicates that special attention must be paid to this type of waste due to its high degree of extension in the industry. The situation for plant-tissue waste was the opposite, such that the 2-digit NACE codes associated with its generation were only agriculture (01), fishing (03) and food (10). Hence, these groups conformed much more to the type of waste.

Regarding the distribution of waste according to the recipients, the sixth most repeated EWC codes were 100118 (gas cleaning containing hazardous substances), 020499 (general sugar waste), 020103 (plant-tissue waste), 020399 (general waste from fruit, vegetables, cereals, edible oils, etc.), 100202 (unprocessed slag) and 100199 (general waste from power stations). Their ratios of number of times produced to number of recipient areas were 22/15, 16/12, 12/10, 25/11 and 18/10, respectively. These figures highlighted the scarce diversity of 100202 (unprocessed slag), which was due to the great number of cases in which this type of waste went to NACE codes 24.10 (manufacture of iron) and 23.51 (manufacture of cement).

In what concerns new uses, 122 different categories emerged when considering the 6-digit CPA code. In this case, the number of singly used raw materials was 60, which implied that almost 50% of them were unique. CPA codes like 353011 (steam and hot water), 360012 (non-drinking water) and 081213 (slags and industrial waste products for construction use) were among the most widely observed new uses, as shown in

Table 7. Code 360012 (non-drinking water) contrasted with the trend whereby every category highlighted in

Figure 7 kept having important representatives when taking into account 6 digits. This was favored by the characteristics of its root group (water), whose new use was non-drinking water in most cases.

The analysis of CPA codes based on the recipient areas was consistent with the aforementioned trend, since steam and hot water (353011) and non-drinking water (360012), which amounted to 53 exchanges in 25 different sectors and 32 exchanges in 17 different sectors, respectively, were primarily used by NACE 35.11 companies (production of electricity). Some materials such as 081213 (mixtures of slags and similar products) and 244530 (other non-ferrous metals) were more centralized, with most of their exchanges associated with construction companies (NACE codes 23.51 and 23.61). By contrast, CPA 201111 (hydrogen, argon, rare gases, nitrogen and oxygen) participated in 7 exchanges with 7 different NACE codes as recipients, such as refineries, coal power plants or production of gases and chemicals.

3.3. Analysis of Industrial Symbyosis (IS) Synergies

Taking into account the large amount of information contained in the refined database, the essence of some exchanges might be repeated. This would not apply to the exchanges themselves because of their belonging to different companies, but synergies could indeed be repeated. The networks in

Figure 4 and

Figure 7 reveal the existence of some repetitions, whereby either the same business areas are involved in exchanges or a new use is assigned to the same type of waste more than once. This circumstance suggested that simplifying the information might be beneficial to reach essential ideas and, therefore, facilitate the access to knowledge about IS opportunities based on real cases involving other companies with similar characteristics.

Therefore, those waste types with a single presence in the database participated in only one synergy, excluding any chance of repetition. The existence of repeated synergies was also discarded in those cases in which waste frequency and the number of different donor or recipient areas were the same. Regarding those waste types with more than one participation in synergies involving only one donor and recipient, repetitions were identified by checking that the CPA codes remained constant. These three steps led to a first simplification of synergies.

3.3.1. Synergies Between Donor-Recipient Areas and Waste-Recipient Areas

Those exchanges including coincidences in their NACE, EWC and CPA codes were identified as repeated synergies. To illustrate this process,

Table 8. includes the most repeated synergies in the refined database. As observed throughout all the steps in the analysis, the relationships between the production of iron and steel (NACE 24.10) and the production of cement (NACE 23.51) through the connections involving EWC 100202 (steel slags) and CPA 081213 (slags to be used in construction) were very frequent.

To a lesser extent, the exchanges representing synergies between the donations of coal fly ash (EWC 100102) and steam (EWC 100118) to cement plants and oil refineries, respectively, were also remarkable. Overall, this process of simplification reduced the number of exchanges in the refined database from 496 to 435, of which 58 were incomplete because of the absence of some codes, as mentioned in previous subsections. Thus, 435 exchanges in the database were concluded to represent completely different synergies.

3.3.2. Synergies Between Waste and New Uses

An additional simplification of the database was conducted by focusing on the EWC and CPA codes. The coincidences found as a result of this process were partial, since complete repetitions also considered the business areas involves in the exchanges. However, the exclusion of partial synergies contributed to ensuring that final synergies did not contain any exchange in which the type of waste and its new use were repeated.

Unlike

Table 8, the most frequent coincidences according to this procedure corresponded to EWC 100118 (steam) and CPA 353011 (steam and hot water), as demonstrated in

Table 9. This was due to the specifics of steam, which was exclusively generated by power plants. However, this waste was reused by 15 different NACE areas, which used it straightforwardly as a raw material to provide heat for the production processes of companies.

The main novelty in

Table 9 concerned the presence of EWC 100199 (generic waste from power and combustion plants), which was used as electric energy (CPA 353011) by recipient companies. In this case, the simplification procedure led to a further reduction of the database from 435 to 285 exchanges, among which 35 contained unknown codes. In consequence, 285 exchanges in the database were found to represent partially different synergies.

3.4. Discussion

The difficulties to replicate the emergence of IS opportunities from place to place by conducting repeated experiments highlight the need for carrying out investigations devoted to facilitate access to IS information [

15]. As pointed out by Grant et al. (2010) [

42], the communication of IS knowledge can be divided into explicit and tacit, such that the latter is difficult to transmit because of its know-how nature. In the same vein, Lombardi and Laybourn (2012) [

43] highlighted the importance of trust, mutual learning and access to knowledge as three of the main aspects influencing the existence of IS experiences. These ideas are completely in line with the purpose and initial hypothesis of this research, since the aim was to synthetize large amounts of data in the form of previous IS exchanges to produce easy-to-understand and yet comprehensive information to support the existence of new IS opportunities.

This contrasts with the traditional approach was taken more frequently in previous studies, which consisted of analyzing particular exchanges in eco-industrial parks or limited geographical regions [

44]. The results presented throughout this section demonstrate how the application of the proposed methodology enables extracting relevant information from raw data, thereby facilitating access to knowledge and, by extension, increasing trust through learning from previous and successful cases. The relevance of this tiered process has been corroborated by authors like Bansal and Mcknight (2009) [

45], who put a focus on the key role played by trust and data sharing in fostering IS. In this sense, this investigation contributes to increasing these aspects through an approach that yields novel contributions to the state of the art in which it is framed, especially in what concerns the use of statistical methods to identify significant relationships between companies and materials. This line of action enables providing mathematical evidence about the reliability of some exchanges, which is helpful to establish proved references to support the creation of IS guidelines for companies [

46].

The outputs of this study are not limited to its own boundaries, but can also affect existing tools [

25] aimed at facilitating IS according to the geographic context of the companies involved. Therefore, depending on the type of company, these tools might provide general recommendations tailored to their corresponding business sectors using the refined information produced in this research, such as compatible donor and recipient companies, useful waste to be either donated or received, etc. Furthermore, the opportunities identified using these tools might be supported with data about how common the suggested exchanges are, as well as with their statistical significance. The implications of this research go beyond the generation of benefits for companies. The simplification of processing of raw data enables contributing to broader purposes related to IS and sustainability, since the explicitness of these results can also help boost the involvement by governing bodies as well as their close cooperation with stakeholders and the general public, thereby improving IS public acceptance [

47]. The use of a common EU nomenclature to codify companies, waste and products based on its types and characteristics is also helpful in facilitating communication between the parties involved.