Abstract

As bulking agents (BA) affect the composting process, this work examined the impact of combinations of different organic components in order to obtain an efficient co-substrate for food waste (FW) in-vessel composting. To boost the occurrence of microorganisms inhabiting the compost, mature compost was firstly coupled with wheat straw, added to FW, and considered as a control (BC0). Then, two trials (BC10, BC20) including 10% and 20% of biochar were monitored. The results indicated that the temperature of the amended bioreactors was notably increased compared to the unamended one. Thermophilic temperatures were achieved at 14, 34, and 78 h after the experimental setup for BC20, BC10, and BC0, which lasted for 14, 17, and 12 days, respectively. When it came to an assessment of maturity and stability, the quality of the compost was evaluated against several indicators and compared with the compost quality standards of the UK, France, Canada, the USA, Poland, and Germany. BC10 illustrated a high-quality product in relation to the heavy metal concentration, a C:N ratio which reached 14.97, an AT4 which was lower than 6 (4.36 mg O2/g TS), and a nitrification index of 2.61 (<3). Consequently, the addition of 10% of biochar as a co-substrate showed an improvement of the process evolution and the characteristics of the biofertilizer produced.

1. Introduction

In recent decades, a major worldwide challenge has been to ensure a sustainable energy–environment nexus by exploiting different sources of waste while cutting air and waterborne pollution, greenhouse gas emissions (GHG), and producing green energy simultaneously. Furthermore, increased amounts of solid organic waste, such as food and lignocellulosic wastes, have become an alarming global issue [1]. Approximately 1.3 billion tons, a third of the global food generated for human consumption, is discarded each year [2]. Additionally, according to The Food and Agriculture Organization Corporate Statistical Database (FAOSTAT), 529 million tons of wheat straw (WS) has also been estimated to be part of agricultural residue [3]. One of the various solutions suggested for reusing organic and lignocellulosic waste is to convert the complex constituent into simpler ones, ultimately generating gaseous products and a residual solid carbon referred to as “biochar” (BC) via pyrolysis. In addition, it is an appropriate way to ensure carbon and energy exploitation [4]. Many of these materials are by-products of agricultural yield or municipal waste management, frequently classified as waste which has to be discarded. However, any improper disposal practices with regard to organic waste such as food waste (FW), will result in serious environmental problems as it contains a high moisture content, volatile solids, and salinity [5]. Furthermore, there are several techniques used worldwide to exploit this kind of waste in terms of converting it into a value-added product in the form of compost (biofertilizer), biogas, animal feed, and chemicals [6].

Composting is an ecofriendly biochemical process and a practical option to ensure feasible waste management. It transforms organic residue into a valuable material exploited in the agricultural field as a biofertilizer [7]. Gathering a stable humus-like material is indeed an effective way to use waste as a soil stabilizer and a crop booster [8,9]. However, the malodor and leachate, which can be due to the unbalanced characteristics of the organic nutrients, impose secondary environmental pollution [10]. The disproportionate nutrients, such as carbon and nitrogen, high moisture content, and compact structure of food waste restrains its utilization as a mono-substrate in the composting process [11]. Therefore, food wastes are traditionally proceeded with green waste or bulking agents [12]. The bulking agent (BA) may adjust structural properties, chemical characteristics, composting duration, and leachate formation [13]. It can hold out against the organic acids generated during the early stages of the aerobic digestion, and absorbs part of the leachate produced during the decomposition process in such a way as to ensure a sustainable moisture content and strengthen the microbial activity [14]. Different kinds of agricultural and green wastes are used as an efficient BA for FW composting such as rice husk, wood chip, and wheat straw [15]. However, there has been little research into the enhancement of the evolution of the process by mixing different components to improve the efficiency of the BA used [16]. Given the focus of several studies on the convenience of wheat straw as a bulking agent for FW composting [12,16], a second constituent of the mixture should be thereafter well selected.

As the organisms responsible for material stabilization are naturally developed, the addition of inoculating agents can enhance the biological process [17]. Indeed, it has been stated that the inclusion of inoculating agents can enhance the biodegradability of organic materials (OM), advance the thermophilic phase, and shorten the whole composting process time [14]. Some materials can both provide the microorganisms and the structure needed. One of these materials is mature compost (Mc). Despite its numerous benefits, only rarely has it been exploited to enhance the aerobic process. Considering its capacity to create inter-particle voids, furnishing air space needed in composting matrices, and adjusting the water content of waste, Mc could be chosen as one of the most suitable BAs for FW composting [7]. Indeed, a few researchers have investigated the effectiveness of Mc as an inoculant on reducing the composting period or decreasing offensive odor during composting, reporting that the microbial community is considerably affected by the insertion of such kinds of OM [18]. Consequently, Mc has been identified, not only as a good bulking agent for composting, but also as a great source of desirable microorganism communities that contribute to a faster biodegradation of OM. Consequently, as it plays a double primordial role for a well-developed biological process, Mc could be the most attractive co-substrate to be selected and coupled with WS in order to constitute the ideal BA mixture.

Regarding the agricultural field, the majority of research conducted in the last decade has focused on the effectiveness of biochar when it was directly applied for soil remediation [19]. Admittedly, this application improves land quality, increases crops yield, and sequestrates atmospheric carbon to the soil [20]. Indeed, the ‘Terra Preta’ phenomenon proved that the black carbon seemed to be a carbon sink storage and considered as a key factor for fertile soils, particularly in the humid tropics [21]. Thus, a great combination and a considerable aspect connecting biochar with agriculture is the composting processes of various organic wastes such as FW and WS in conjunction with biochar [22]. Some trials report testing the addition of biochar, even in small quantities, and the results prove that biochar can change the composting process and the properties of the end product [23]. Studies on biochar report that its performance as a BA plays a crucial role in assuring the aerobic conditions necessary for composting materials [24]. However, there is still a lack of information concerning the impact of biochar on heavy metal contents (HM), compost respiratory activity, and the quality of the end product of the composting process in terms of Compost Quality Standards.

This work aims to develop quantitative relationships between the physical properties of the composting material and the performance of the composting process. To achieve this goal, the effects of mixing BA on the aerobic digestion of food waste were studied and used as a control trial. Then, special attention was paid to elucidating whether and how the application of different doses of biochar affected the course of the composting process and the quality of the biofertilizer produced. Furthermore, the assessment was planned to observe how some physicochemical properties would change, with a particular focus on the maturity and stability indicator tendencies. Additionally, the final product (biofertilizer) was analyzed to determine the content of some HM, which was essential in terms of the assessment of the resulting compost.

2. Materials and Methods

2.1. Feedstock Characterization

In this study, FW is considered as the main substrate of the aerobic process. Wheat straw (WS), mature compost (Mc), and biochar (BC) were chosen as potential co-substrates for in-vessel composting. FW was collected from the canteen at the University of Rostock, Germany. This primarily consisted of rice, noodles, fruit or vegetable peelings, and cooked potatoes. Once collected, it was stored in small containers and kept at −20 °C to prevent any microbiological reaction. WS was gathered from a farm in the vicinity of Rostock, chopped (<10 mm) and stored in plastic airtight buckets kept in an ambient temperature. Mc was collected from a local composting facility, where green and garden waste and biowaste from separate collections from the city of Rostock are composted. Because the inoculum plays a vital role in providing an initial microbial population for better process development, to achieve this, Mc was added [18]. Indeed, to give the structure and the porosity needed, and to maintain air spaces for oxygen transfer, WS and Mc were mixed and considered as a bulking agent [25]. The biochar used was obtained from an industrial manufacturer of charcoal and consisted of undersized particles with a nominal diameter of 4 mm which are not marketable. It was produced from natural beechwood. Moreover, the carbonization was realized under 400 °C and the activation was achieved by adding water steam in the system under 900 °C.

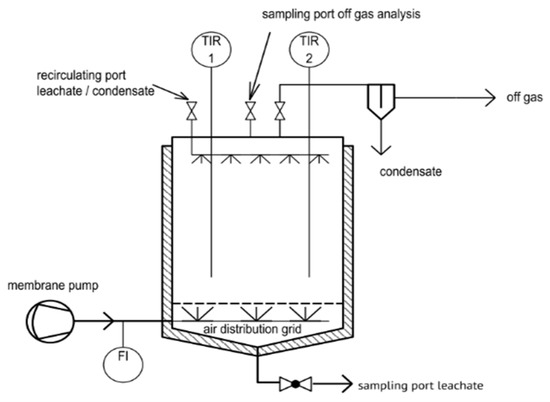

2.2. Experimental Setup

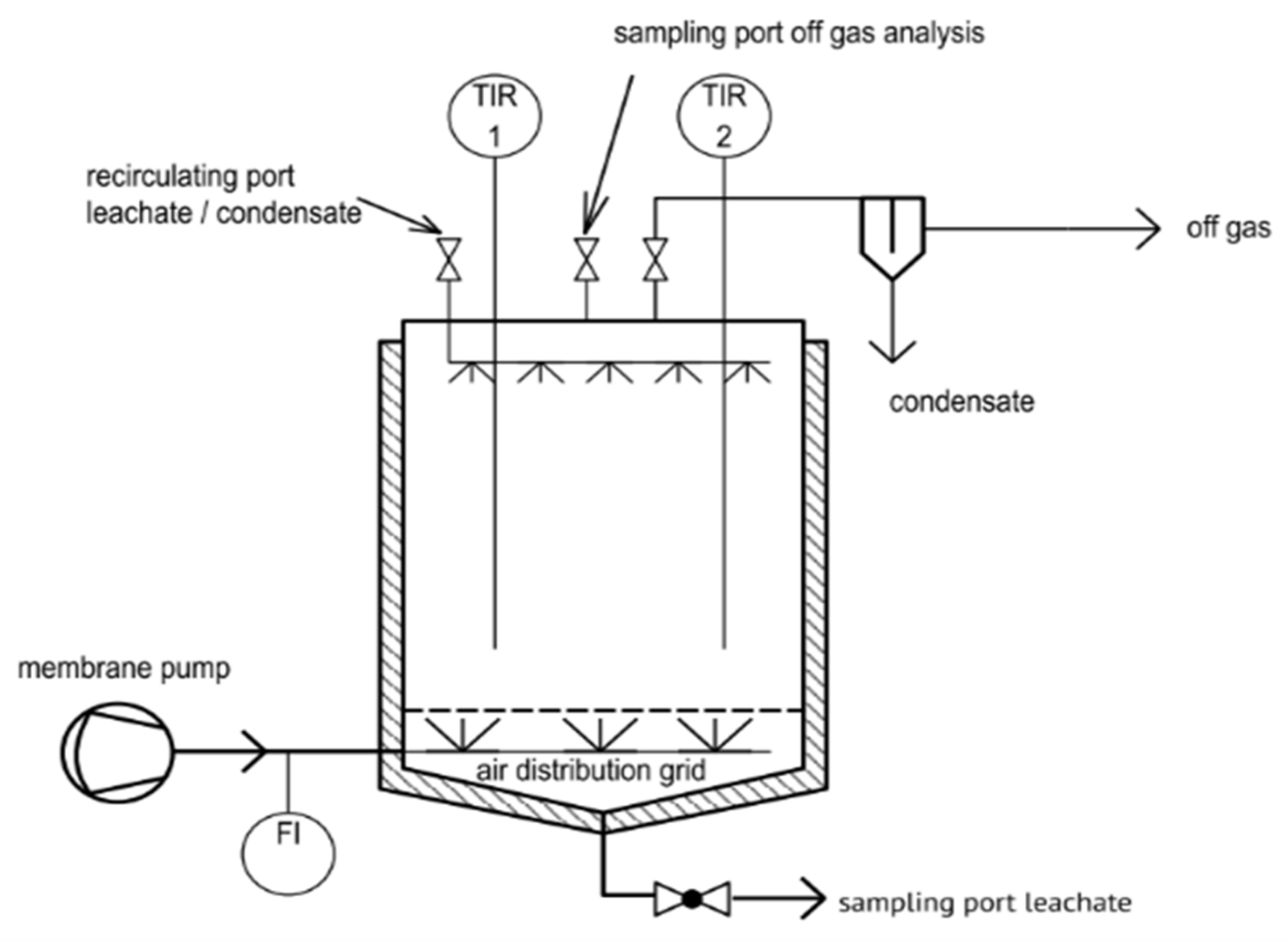

A laboratory-scale in-vessel compost bioreactor was constructed of stainless steel with a total working capacity of 200 L (Figure 1). The nominal inside diameter of the column was 700 mm, with a heat insulation layer of 50 mm to reduce heat loss to the surroundings. A stainless-steel cap was fitted on the top of the reactor with two ports for inserting the temperature sensor and one for the collection of condensates. At the bottom of the reactor, a metal grid with small holes for equalizing air distribution was attached. To collect the leachate, the rector has a conical bottom with a bottom valve. The reactor was filled with mixed feedstock up to 75%, with 25% of the area being maintained as a head space. Two thermocouples (TIR1) and (TIR2) were fixed at different depths of the compost bioreactor to assess temperature variations during the process. The temperature was automatically recorded every 10 min using an ALMEMO® data logger system (Ahlborn, German). The rate of airflow was maintained at 10 L/min at the beginning, controlled by a diaphragm pump. The gas flow was measured using a variable area flowmeter and protocolled daily during the whole composting experiment.

Figure 1.

The experimental scheme of the in-vessel compost bioreactor.

For each assay, FW was considered as the main substrate. Thus, it represented at least 50% (w/w) of the added feedstock mixture [26]. Three experimental trials were carried out to evaluate the impact of biochar on FW composting using in-vessel compost bioreactors. Biochar at ratios of 10% and 20% of the total weight of the mixture were added as an amendment, and labeled as BC10 and BC20, respectively. As a controlled trial, FW, WS, and Mc co-composting without any amendment (BC0) was also performed in order to compare the results. Before proceeding to the composting experiments, bulking and composting materials were well mixed manually and then placed in the compost bioreactors. The moisture content of the initial starting material was adjusted to be in the range of 60–65% [27].

The performed experimental trials based on total weight were as follows:

- BC0: FW (50%) + WS (25%) + Mc (25%)

- BC10: FW (50%) + WS (20%) + Mc (20%) + BC (10%)

- BC20: FW (50%) + WS (15%) + Mc (15%) + BC (20%)

2.3. Sampling and Analysis

The trial period lasted 32 days. As the sampling is the most crucial point in allowing the assessment of the process evolution, it was done weekly at regular intervals, approximately every five days, with the aim of determining the moisture content (MC) (%), total carbon (TC), total nitrogen (TN), pH, electrical conductivity (EC), total solid (TS) (%), ash content (%), and mineral nitrogen content, such as ammonium (NH4+) and nitrate (NO3−). However, the additional parameters, such as respiration activity (AT4) and heavy metal content (HM), were measured at the end of the process to assess the stability and the maturity of the compost. All these parameters were determined in triplicate to ensure the preciseness of the measurements. Thus, each collected sample was divided into three representative specimens for different analyses to evaluate the performance of the process. It was either analyzed directly or stored (at −20 °C) for future analysis. For MC determination, the European Standard DIN EN 15934 was applied. The fresh compost sample collected was dried at 105 °C until the constancy of weight and the percentage net loss in terms of weight was measured. The ash content was determined according to DIN EN 15934 by ignition at 550 °C for 6 h. The pH and EC were analyzed in terms of the European Standards DIN EN 15933 (pH) and DIN EN 15937 (EC), respectively. Both parameters were measured using a sample in the form of an aqueous extract of fresh compost. The analysis of mineral nitrogen was carried out using the same extract and a photometric measure was obtained using a spectra photometer Hach Nano-color UV/VIS. The nitrification index (NI) is an important indicator of compost maturity. It is the ratio between NH4 +and NO3−. Once NI is below 0.5, this suggests a fully mature compost, up to 3 indicates a mature compost, and a value above 3 indicates an immature compost. Indeed, to check the compost stability, AT4 was determined using the Oxi-Top system (WTW, Germany), following the international standard DIN ISO 16072. This method consists of placing 40 g of waste in a sealed container with a volume of 1 L equipped with a pressure sensor. Inside is a vessel containing 50 mL of 1N NaOH solution absorbing carbon dioxide (CO2). The container is stored at a constant temperature (20 °C). The pressure drop due to oxygen consumption and the release of carbon dioxide is recorded for a period of 5 days [28]. Moreover, to ensure the high quality of the end product, heavy metals content was measured in an external lab, to be then compared to the German quality requirements for compost, as used in gardening and agriculture. These quality regulations set thresholds for the following heavy metals: Pb, Cu, Ni, Zn, Cd, Cr, Hg, and As. Analysis was performed following the Standard DIN EN ISO 11885 and 12846 after microwave-assisted disintegration.

3. Results

3.1. Characteristics of Raw Materials and Initial Blends

The physical and chemical characteristics of the residues are summarized in Table 1. The dry matter contents were 22.6%, 93.5%, 46.7%, and 97.6%, and the volatile solid contents reached 94.6%, 95%, 43.2%, and 83% for FW, WS, Mc, and BC, respectively. FW characterization closely matched the findings of some existing research [29]. Microorganisms have a certain demand for carbon and nitrogen in any growth environment, therefore the C:N ratios were evaluated for each substrate. These were corrected at a later stage and regulated in the range of 20–30 for different feedstocks with the addition of WS, Mc, and BC as co-substrates [15]. For BC0, BC10, and BC20, C:N ratios were 20.73, 27.05, and 31.28, respectively. Indeed, the pH was determined for each initial blend to reach 5.87, 7.38, and 7.94 for 0%, 10%, and 20% of biochar addition. Minor minerals as micronutrients or essential supplements for the microorganisms’ communities were also measured. The presence of minor elements such as Cu, Ni, and Zn were detected in varying quantities, with Zn recording the highest quantities in the different substrate. This finding notwithstanding, the presence of major constituents such as P, K, and Mg was also observed.

Table 1.

Characterization of raw materials and initial blends.

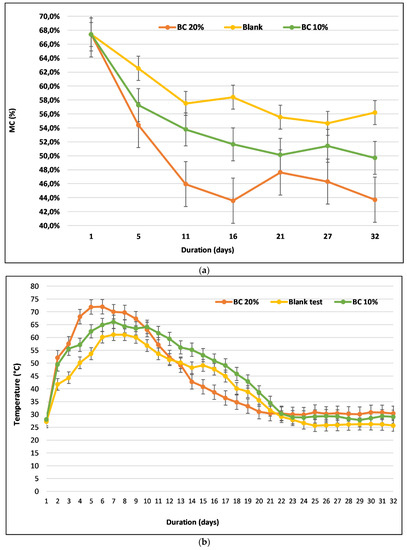

3.2. Effect of Biochar on the Temperature and Moisture Content Evolution

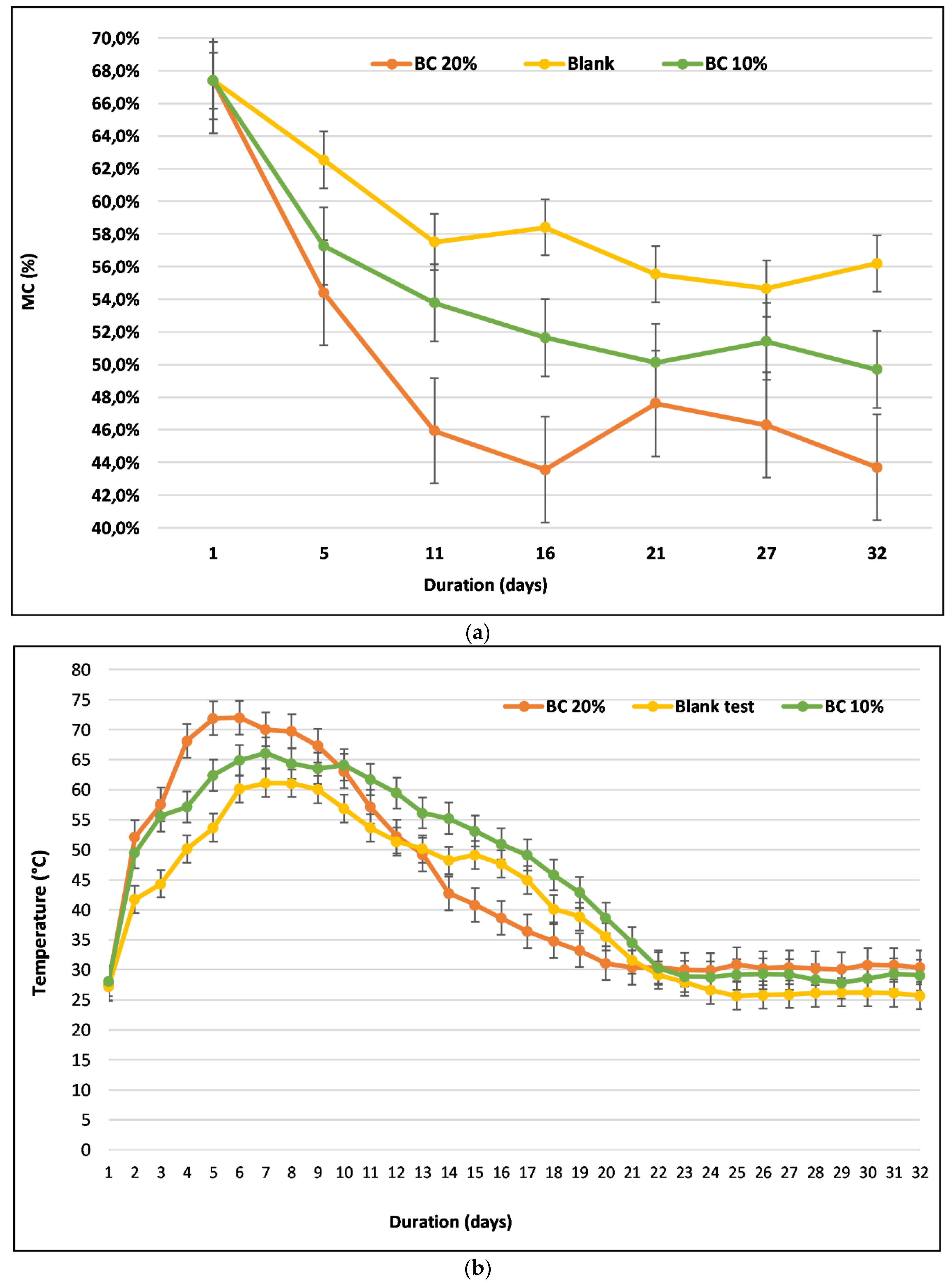

To ensure a performed process, temperature was considered as a crucial factor in terms of monitoring the rate of biological succession during composting. Indeed, the progress of microbiological communities that proliferate in the composting matrix was influenced by the fluctuation of the temperature [7]. Due to the variations in the microbial communities during the composting process, compost temperatures were divided into three phases; mesophilic, thermophilic, and cooling phases [30]. In the current study, the temperature was recorded automatically every 30 min throughout the whole process. Figure 2a shows the temperature evolution in the compost bioreactor treated with a biochar rate of 0%, 10%, and 20%. Each mixture had a different temperature tendency. It was noted that the temperature of the in-vessel compost amended with biochar was swiftly augmented in comparison to the unamended control. Thermophilic temperatures were achieved in different periods for each trial. It started at the 14, 34, and 78 h after the experimental setup for BC20, BC10, and BC0 and lasted 11, 14, and 9 days, respectively. Moreover, current research findings also indicate that the addition of biochar to the composting mixture rapidly increased the temperature to the thermophilic range within 12 h of application [19]. Furthermore, compared to the other trials, BC20 reached a maximum temperature of around 72 °C (Figure 2a), which occurred on days 5 and 6 of the process. Nevertheless, 66 °C was found to be the maximum temperature for BC10 and 61 °C for BC0. Indeed, the thermophilic phase of BC20 and BC0 ended relatively quickly and was earlier than BC10. However, in all variants of the experiment, the cooling phase was reached at almost the same period of composting (day 22 of the experiment), while the temperature of the bioreactors decreased gradually to the ambient temperature and remained at this level until the end of the composting process. Consequently, the addition of the biochar influenced the speed of warming up of the composted material and the maximum temperature attained. At a rate of 10%, biochar caused a prolongation of the thermophilic phase by a length in the range of 5 days, while at a rate of 20%, the thermophilic phase lasted only 2 days more than BC0, indicating that biochar had a meaningless effect on the duration of the thermophilic phase. However, it had a notable impact on the degree of the temperature attained during the thermophilic phase (Tmax (BC0) < Tmax (BC10) < Tmax (BC20)). Despite this, it should be noted that several researchers have shown a lack of influence of a small amount of biochar on the temperature course and have observed slightly longer thermophilic phases while composting an organic fraction of municipal solid waste [23,29]. According to the hygiene standards of Germany with regard to compost, the thermophilic temperature achieved in the current compost experiments was sufficient to eliminate the threat posed by pathogens. By reason of the fact that the temperature was maintained higher than 55 °C for more than one week, all the trials ensured the sanitization of the end product.

Figure 2.

(a)Temperature content evolution during the process. (b) Moisture content evolution during the process.

As one of the main factors determining the effectiveness of the composting process, moisture was also monitored [27]. Figure 2b shows changes in MC during the whole process. The initial amount was 67.4% but changed during the experimental period as a result of microorganism activity, temperature variation, and water evaporation. An apparent decrease in MC was observed in different compost systems. However, at the end of the process, the results showed that the lowest MC of 43.7% and 49.7% were observed in BC20 and BC10, respectively. As such, with the intensified proportion of biochar supplement, water loss was accelerated and the final moisture content of all biochar-amended treatments were optimally within the range of 40% to 50% [24]. Such a moisture reduction may be explained by different reasons. Firstly, the addition of biochar, which was characterized by a well-developed pore structure, lead to an increase in the capture of moisture from the mixture. Then, similarly, as the porous nature of biochar constitutes a suitable habitat for microbial proliferation and provides aerobic conditions to the degrading microbes, its high surface area promoted microbial activities and then a rise in temperature and a release of water vapors were provoked [31]. Indeed, the forced aeration had to be taken into consideration regarding the water losses. Figure 2a shows the correlation between the temperature and the moisture content evolutions during the composting tests and illustrates that after the thermophilic stage, no significant changes in MC were recorded, which proves the strong link between those two parameters. These results are in line with some previous research that has concluded that biochar addition leads to a drop-off in moisture retention [24]. These authors reported that high doses of biochar (20%), especially with larger biochar particle size (3–5 cm), caused a lack of moisture in the composed mixtures and a break off in microbial activity [32]. This was probably as a consequence of the developed porosity of the material, that promoted air flow through the pile, and therefore the loss of water due to the forced aeration [33].

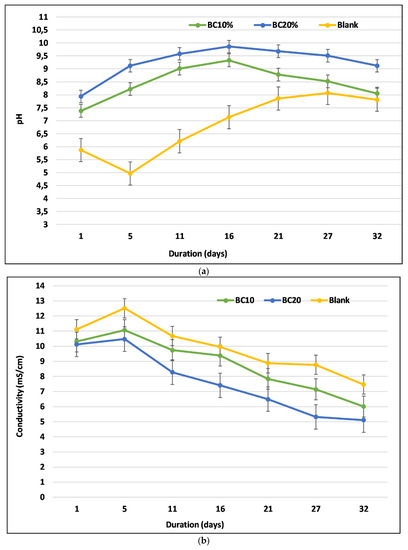

3.3. Effect of Biochar on pH and Electrical Conductivity (EC)

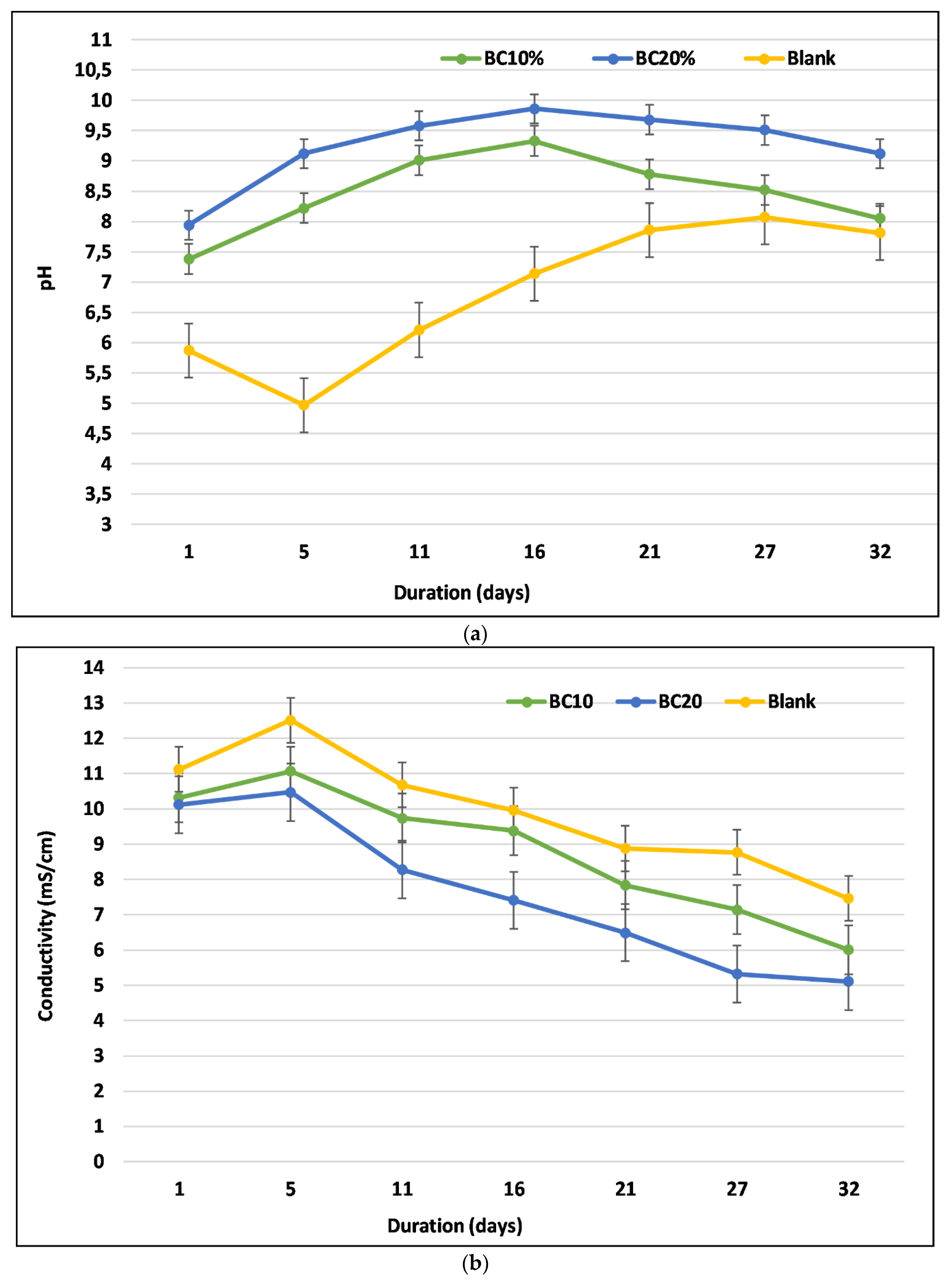

Figure 3a shows one of the important environmental aspects that can be modified by the presence of biochar. As a key parameter to characterize the process evolution, pH was monitored during the experiments. The matrix pH of all treatments involving biochar amendment started with a quasi-neutral pH for BC10 and BC20 and an acidic pH for BC0, which can be explained by the acidic character of the FW used and the basic pH of the BC introduced. Then, pH increased progressively throughout the whole process, except for BC0. In terms of the unamended trial (BC0), the pH dropped initially from 5.87 to 4.97 (Figure 3a). This was possibly due to the production of organic acids and their volatilization during the thermophilic phase. By the end of the cooling phase, the pH value increased from 6.41 to 8.07 and attained a neutral value of 7.81 at the end of the composting process. However, for BC20 and BC10, once the temperature increased, the pH increased simultaneously to attain, respectively, 9.27 and 9.06, and then drop to 9.12 and 8.05 by the end of the process. The pH trends were influenced by the significant alkalinity of the biochar, and its capacity to buffer against both the acidification produced from the organic acids at the early stages and the nitrification in the final stages of the process [34]. Similar results were found by some researchers focusing on the effect of biochar on kitchen waste composting, who confirmed that a certain amount of biochar addition leads to an increase in pH during the whole process, leading to the creation of a biofertilizer with a pH in the range of 8.5 to 9 [35]. However, with a small amount of biochar being introduced to the composting process of the organic fraction of municipal solid waste, the final pH obtained from 1.5%, 3%, and 5% of biochar supplements ranged between 4.7 and 5.7, which proved that, once it was added in an appropriate amount, the buffering capacity of biochar had a notable effect on pH. The rise in pH could result from the generation and emission of NH3 [36]. Similar pH tendencies have been reported during the composting of food waste and biochar at the rate of 10% to 15%. However, the inconsistent results exist in terms of an intact mixture without any biochar addition, where the final pH was 8.8 [19].

Figure 3.

(a) pH evolution during the process. (b) Conductivity evolution during the process.

The pH also determines the mobility of heavy metals, which can be described by the degree of electrical conductivity (EC). Electrical conductivity is an index of the salinity of the compost, which should be quite low to respond to the need for plant growth [37]. Indeed, it is a method to pursue the alteration of organic and inorganic ions such as SO42−, Na+, NH4+, K+, Cl−, and NO3− during the composting process [7]. The electrical conductivity of all the trials is described in Figure 3b. The fluctuations in EC were almost the same for all the experimental trials during the thermophilic phase. This decline may be due to the humification of organic materials which transformed salt and micro-molecular organic acids to macro-molecular humus [24]. Thus, the EC dropped progressively for the blank test to final level of 7.46 mS/cm, which was above the standard limit (4 mS/cm) [38]. Hence, EC can be correlated to degradation and mineralization, with higher EC values in the control trials compared to amended trials being linked to lower degradation and mineralization [39]. However, in the case of BC10 and BC20, the end products were characterized by an EC of 6.01 and 5.11 mS/cm, respectively. Biochar itself contains many characteristics conducive to the decline of the salinity. For example, the extractable inorganic nutrients such as phosphorus, potassium, calcium, and magnesium in biochar, which are mostly alkaline and lead to an increase in the pH, immobilized heavy metal activation, and consequently decreased the conductivity [40]. In this study, biochar was characterized by a pH of 10.21 and a conductivity of 12.73. As reported by different researchers, a similar trend for EC during the composting process was proven [41].

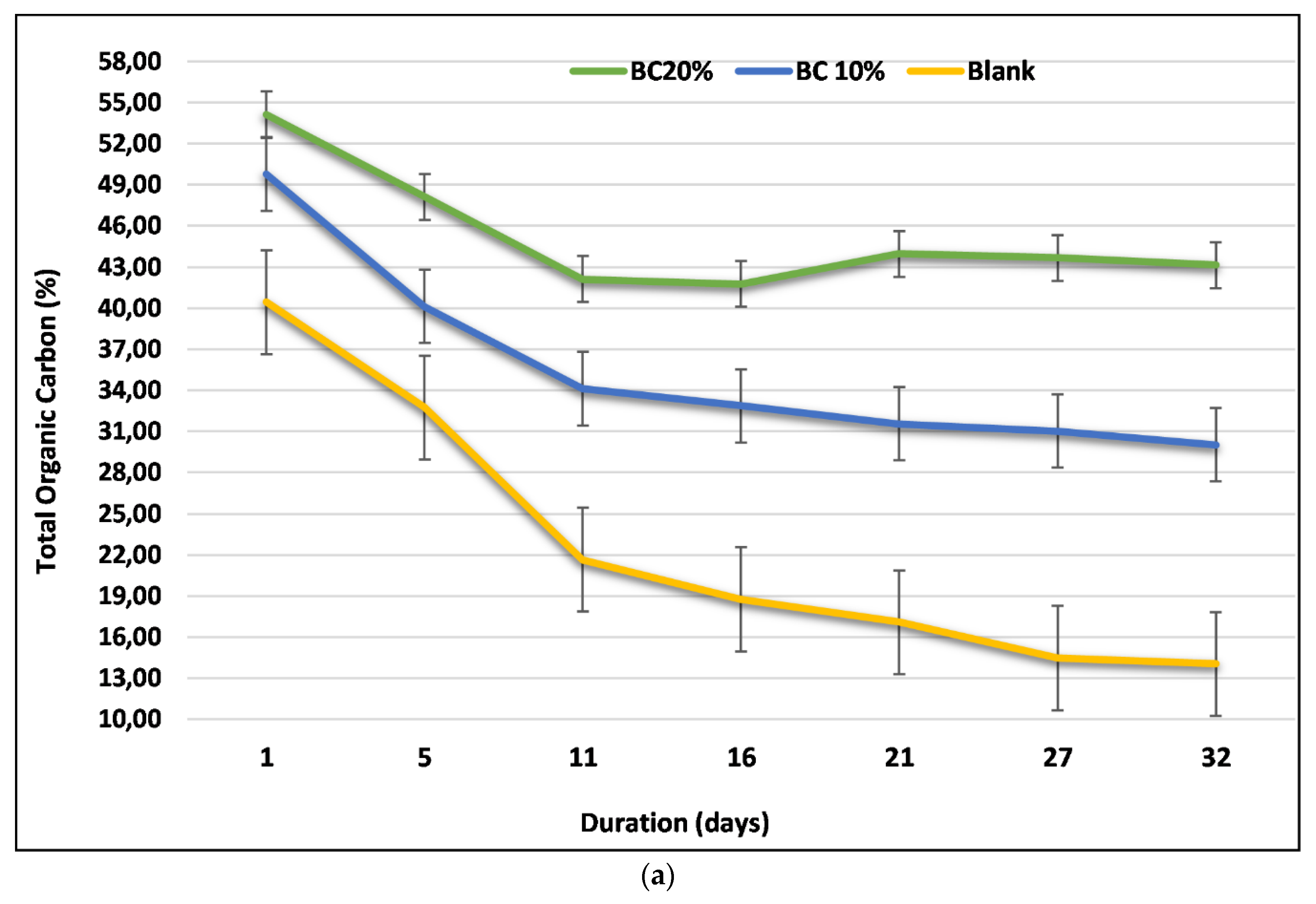

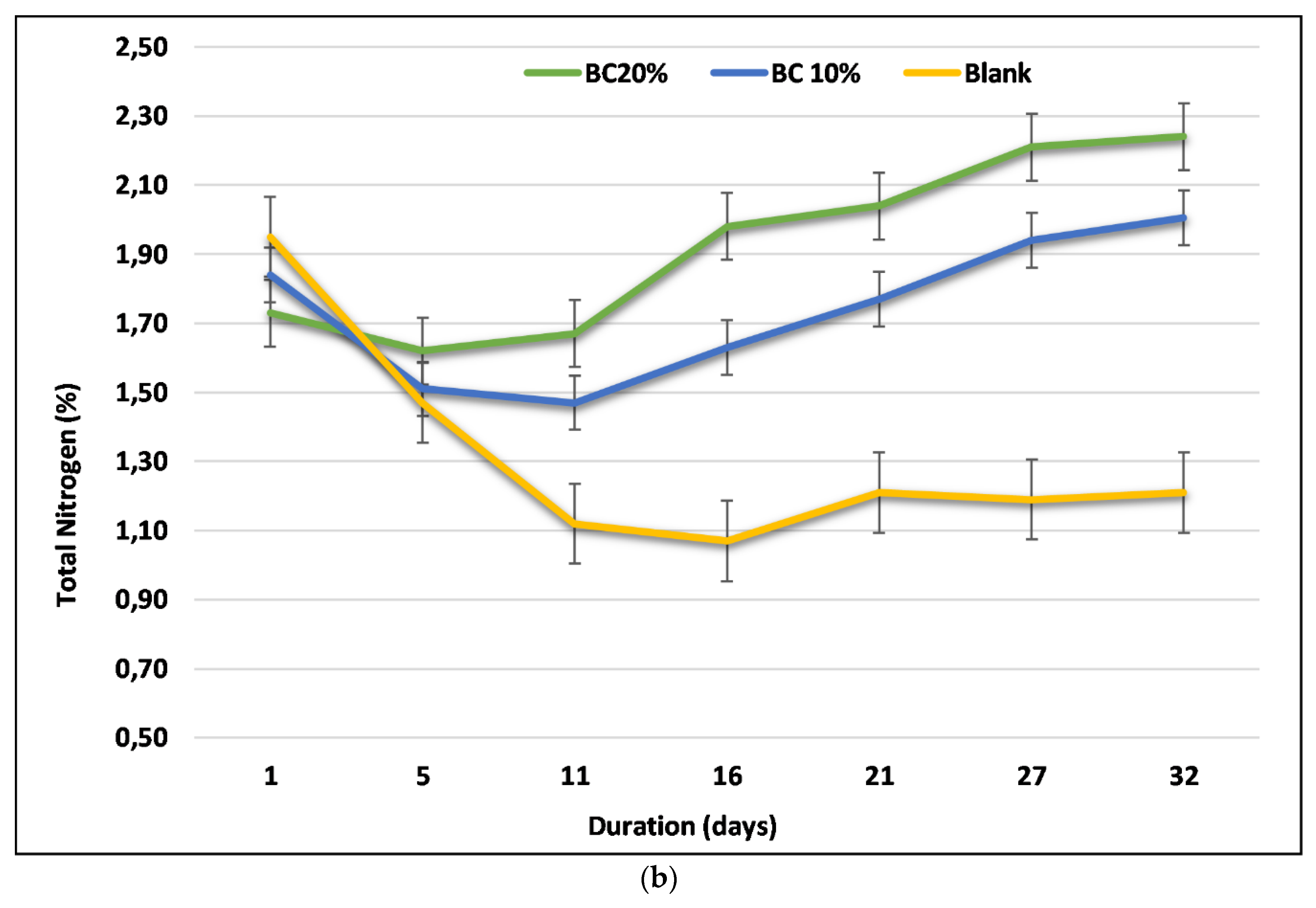

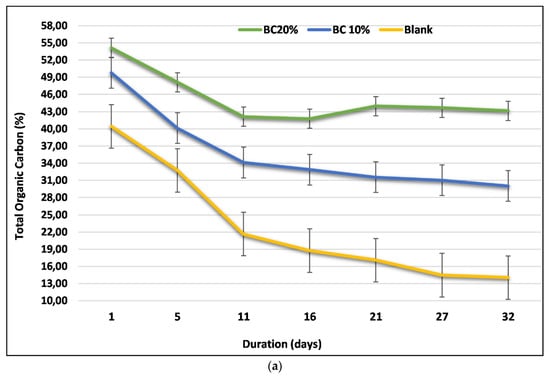

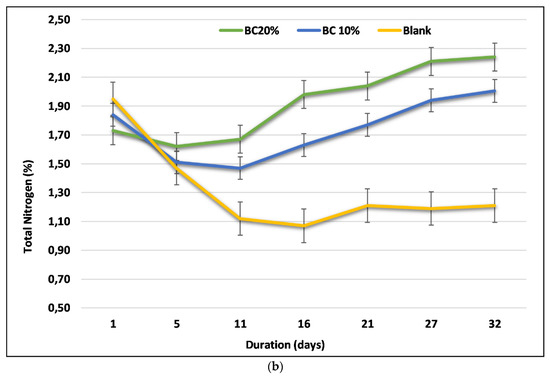

3.4. Biochar Effect on TOC and TN

In general, all composting feedstocks might comprise all the nutritional elements required by the soil, but in a certain range. Consequently, several components, particularly TOC and TN, should be monitored during the biological process. The tendencies of TOC and TN variations were observed in Figure 4. During the composting experiment, Figure 4a shows a sharp decrease of total organic carbon contents, however, the notable decline of TOC content was registered in the case of biologically-treated wastes without biochar (BC0) started at 40% to finalize at 14%. Such a TOC profile can be explained by an instable fraction of OM which was mineralized, and it can also be directly related to the rate of microbial actions, because microorganisms consume these organic elements during the process [42]. However, regarding the bioreactors which included biochar, the TOC contents determined initially were 54% and 49%, which reduced to 43% and 30% for BC20 and BC10, respectively. As the biochar used during the experiments was produced from natural beechwood, it can be considered as a supplementary source of carbon for the amended mixtures, which highlighted the different TOC contents in each combination [41]. Thus, biochar is known to have a recalcitrant structure which is strongly reduced during the process, but leads to a slightly higher amount of carbon content at the end of the process, especially for the mixture with 20% of biochar added [43]. Comparable results showed that the TOC content decreased to 29% and 30% in piles treating food waste containing 10% and 15% of biochar, which are very close of the values of the BC10 trial tested in this work [19].

Figure 4.

(a) Total organic carbon evolution during the process. (b) Total nitrogen evolution during the process.

Although nitrogen could be released from different mixtures in the form of nitrogenous gases, such as NH3 and N2O, the TN content decreased gradually for all the trials, especially those that did not include biochar, which is likely due to nitrogen losses at high temperatures. TN values ranged from 1.73%, 1.84%, and 1.95% to 2.24%, 2.01%, and 1.21% for BC20, BC10, and BC0, respectively. This investigation had to be associated to the concentration effect due to mass contraction with the biodegradation of organic substances. It is noteworthy that the addition of biochar increased the TN content, given its performance in terms of reducing the emission of nitrogenous gases and the trapping of aqueous nitrogenous components [44]. The same TN profiles and almost close values were established during the co-composting of kitchen waste and biochar to finally obtain approximatively 3% and 2.5% for the pile with and without biochar, respectively [35].

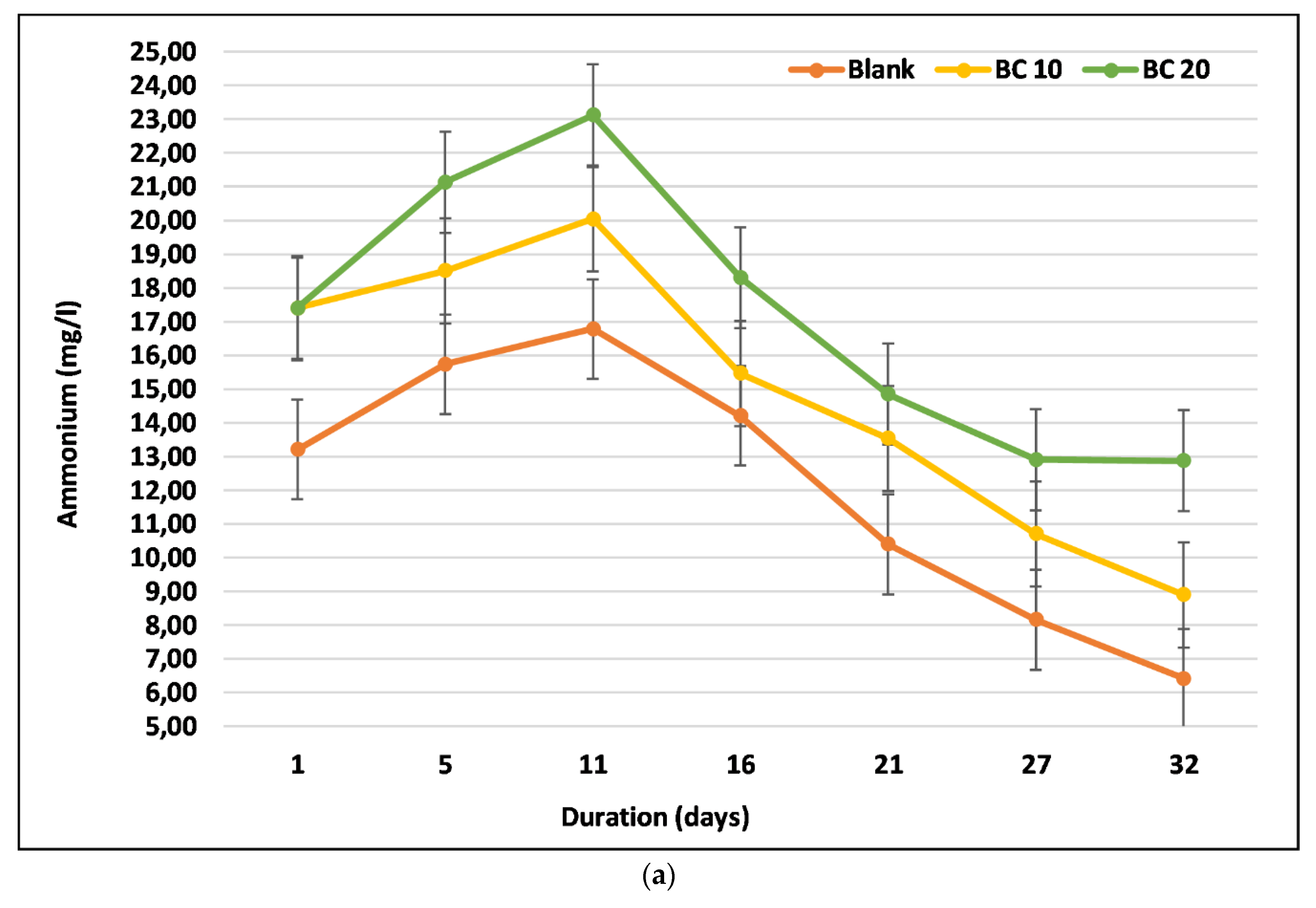

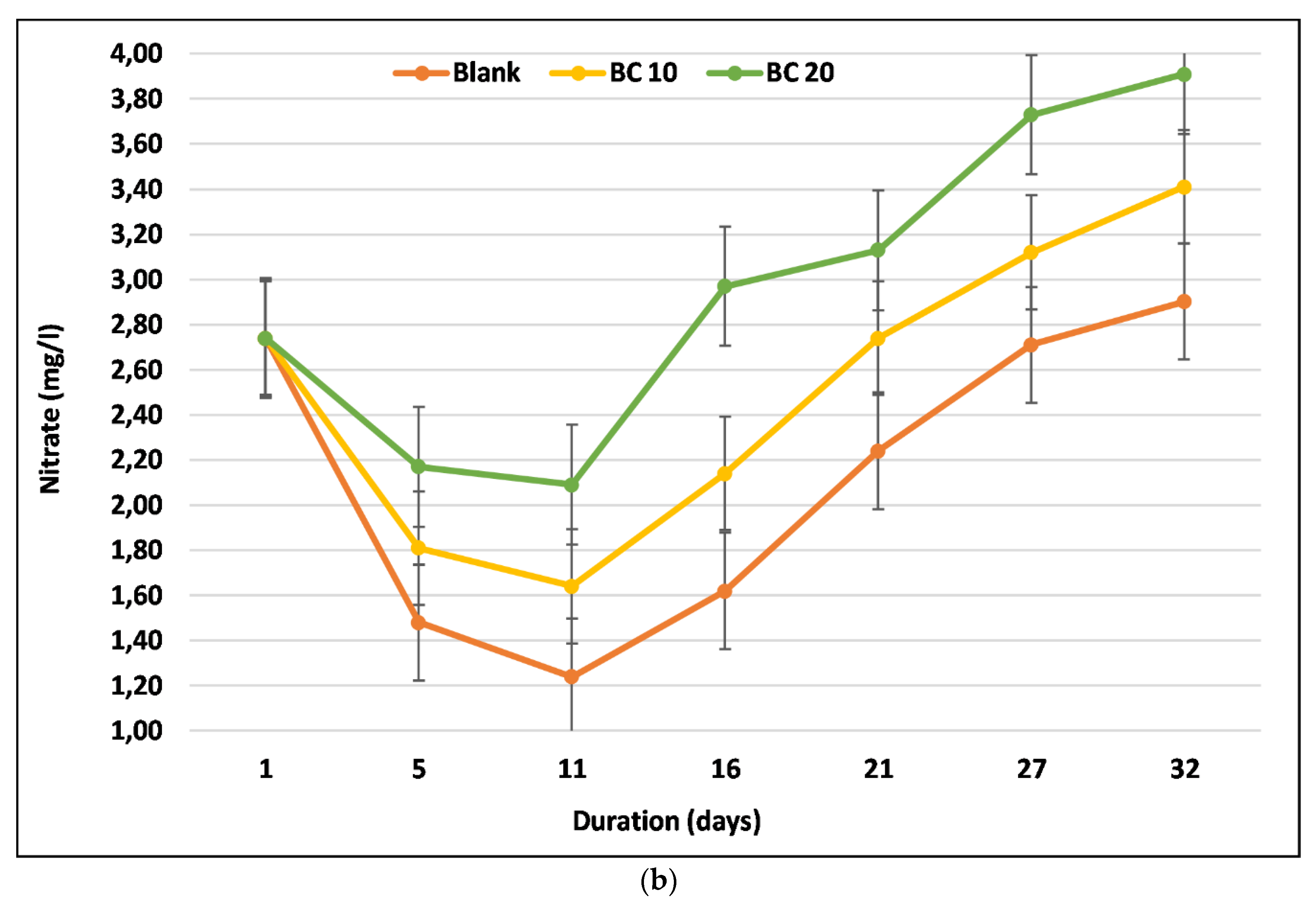

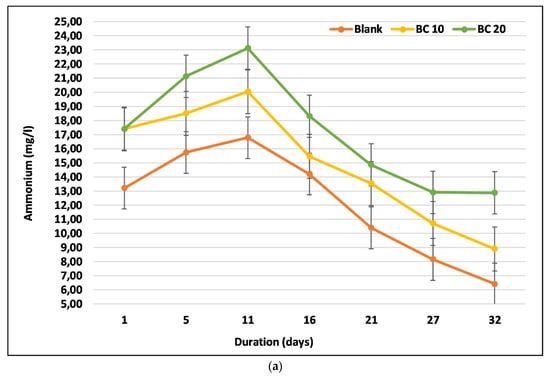

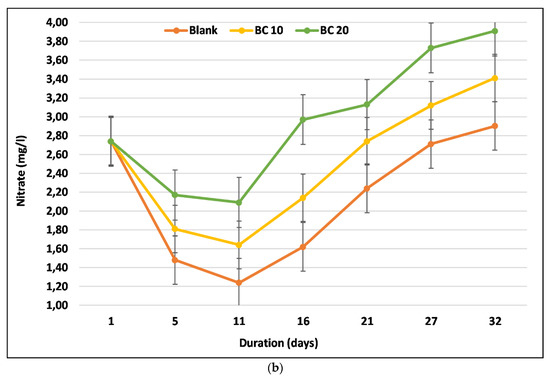

3.5. Impact of Biochar on Compost Mineralization

Nitrogen mineralization involves two biological processes—ammonification and nitrification. During the thermophilic phase, protein-rich materials are decomposed until they release NH4+-N [45]. Ammonification then takes place at the first stages of the composting process, presenting an initial peak that mostly occurs simultaneously with the optimal biodegradation period [46]. For BC0, the NH4+-N content increased to 16.78 mg/L, and then decreased to 6.41 mg/L at the end of the process (Figure 5a). A rise in NH4+ content within the thermophilic phase was observed, probably due to the enhanced mineralization of organic nitrogen, which is slightly high in FW (2.8% of total solids), as well as the high temperature during the thermophilic phase, or possibly, the inoculation of the mixture with the mature compost [18]. However, for materials like biochar, the density of ammonifiers is high, and the ammonification process can proceed very quickly [36]. Figure 5a shows a marked increase in NH4+ concentration for BC10 and BC20 compared to BC0, with a notable peak on the 11th day. The concentrations started at 17.40 mg/L and rose to 23.12 and 20.04 mg/L at the end of the thermophilic phase for BC20 and BC10, respectively. Thereafter, the NH4+ content fell to 12.87 and 10.37 mg/L. These results could be explained by the decrease of NH3 volatilization, and the capacity of biochar for the retention of nitrogenous components might be also underlining. At a later stage, with the biodegradation of nitrogen and NH3 emission, the NH4+ content decreased gradually to let the NO3− content increase, especially during the cooling phase [47].

Figure 5.

(a) Ammonium evolution during the process. (b) Nitrate evolution during the process.

As the elevated temperature environment of the compost during the first few days powerfully frustrated the activity of nitrifying bacteria, the NO3− concentration decreased notably from around 2.74 to 1.24 mg/L before a remarkable rise was detected, increasing to 2.90 mg of NO3−/L at the end of the process (Figure 5b). However, for amended reactors, regarding the NO3− concentration, a significant rise was recorded for the amended mixtures with 20% of biochar, particularly during the curing phase. The temperature peaks were followed by sharp declines, which were noted (from the 5th to the 11th day) and attained 1.64 and 2.09 mg/L for BC20 and BC10, respectively, which were higher as compared to the nitrate concentration in BC0. Consequently, biochar exhibited an adsorption capacity with regard to organic nitrogen, and enhanced the nitrification mechanism, notably during the maturation phase. This could be due to an advantageous microenvironment for the nitrifying bacteria, that converts ammonia into nitrate [24]. Comparable NH4+ and NO3− aspects were found by several researchers focusing on poultry litter and biochar co-composting, who affirmed that the NH4 -N level was balanced at the end of the biological process, and that compost without any amendments was characterized by a lower NH4+ content than the amended composts [48].

Organic wastes provide the required nutrients to plant roots, promote their growth rate, and improve the organic matter content of the soil. Thus, they enhance all of the physicochemical resources of the soil [20]. They also add useful microorganisms and provide supplements for the current soil microorganisms, and reinforce the soil fertility self-renewal and wellness [43].

In this study, the overall P-content increased by 7.9%, 44.44%, and 80.64% for BC0, BC10, and BC20, respectively. For the same mixtures, the K-content rose from 1.17%, 1.55%, and 1.78% to a final value of 1.59%, 3.66%, and 4.08%, respectively. The higher amount of P and K in the amended mixtures compared to the control, was expected, as biochar itself contains extractable inorganic nutrients such as phosphorus, potassium, and magnesium [49]. However, as the initial concentration of potassium in biochar was reached, highlighted improvements in the final amended composts, achieving 136% and 129% for BC10 and BC20, were recorded.

3.6. Discussion

Co-composting food waste with a mixture of bulking agents essentially composed of wheat, straw, and mature compost, with and without biochar additions, was confirmed to be an appropriate alternative for organic waste management, with safe and stable biofertilizer targeting occurring in organic farming and/or as soil amendments. Supervising the composting conditions during the aerobic digestion of FW and the variations in the physicochemical aspects established the growth of the microbial community. However, the degree of attainment of the process can be estimated by checking various fluctuations in the chemical, physical, and biological features of the substrate. Maturity and stability are factors often quantified to judge the quality of the compost obtained. However, it is difficult to evaluate the end-product quality by referring to a single parameter. In fact, the assessment of stability served to determine the end of the steadiness process (i.e., maturation). Some indicators such as pH, temperature, C:N ratio, nitrification index (NI), and respiration activity (AT4) were used to determine both maturity and stability [50].

3.6.1. pH and Temperature

Four typical composting phases were clearly identified during the bioprocess: a brief initial mesophilic phase, a thermophilic phase, a cooling phase, and a maturation phase. The thermophilic phase was considered to be the most important one. Moreover, the maintenance of a temperature above 50 °C more that the biofertilizer generated met the requirements of compost assessment, to ensure a pathogen-free end product [51]. According to the profiles of the different trials, it seems probable that a thermophilic phase of sufficient duration was recorded to ensure the sanitization of the biofertilizer produced from each mixture, as well as high temperatures reached in all the trials, especially the amended ones. However, higher rates of biochar lead to higher temperatures attained—72 °C for BC20 and 66 °C for BC10 against 61 °C for BC0.

As the variation in temperature has a direct effect on pH evolution, the low pH values obtained at the start of the experiment of BC0 could be caused by the organic acid emissions. A rise in pH was then observed due to organic nitrogen mineralization, finishing with almost satisfactory values for both BC10 and BC0 in the range of pH 7–8, with an exception of a high pH of 9.02 for BC20. This can be explained by the alkalinity of biochar, which influenced the evolution of pH during the process at a high rate [32].

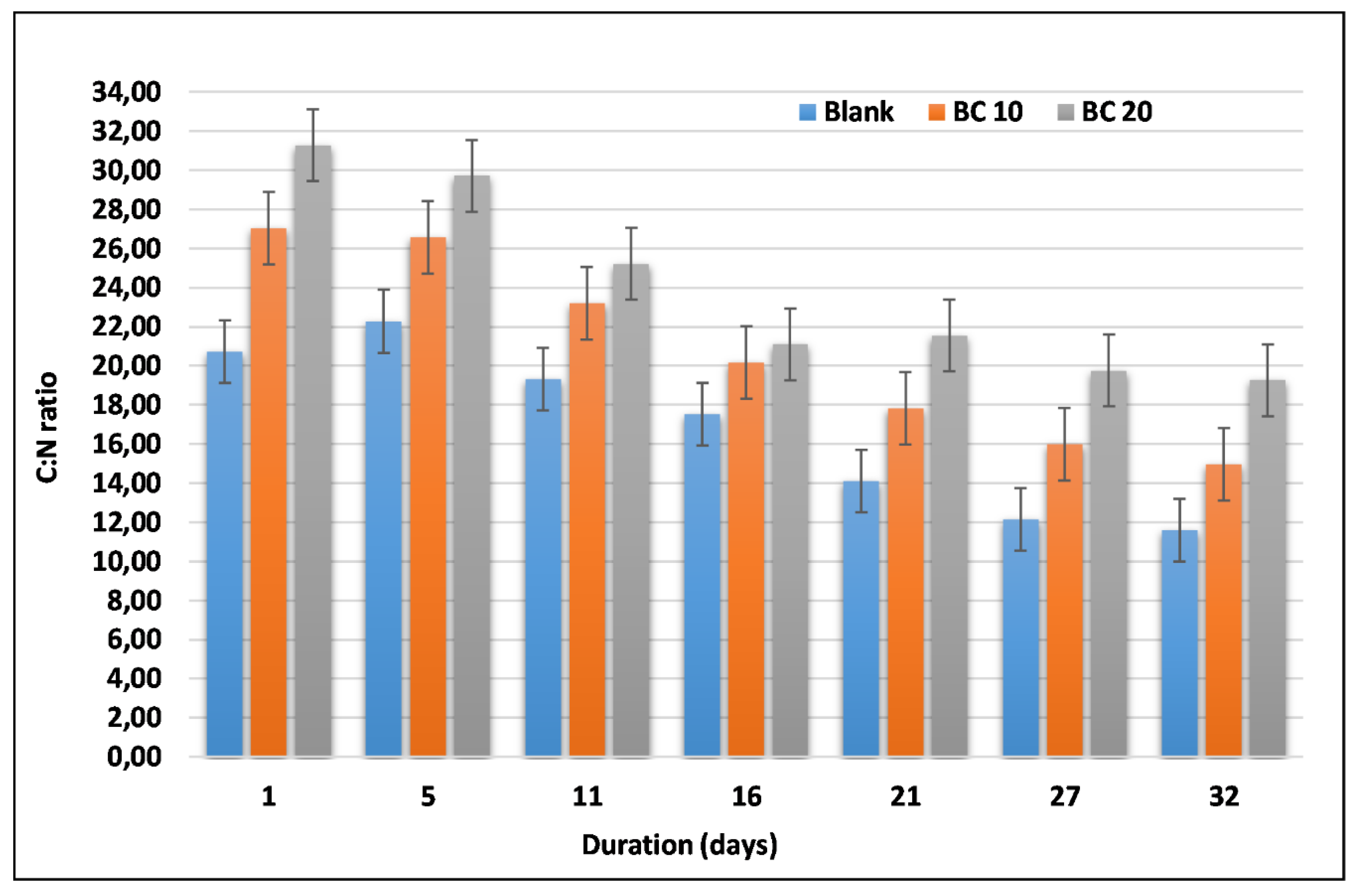

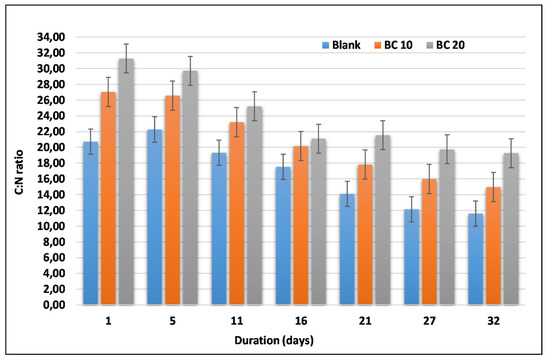

3.6.2. C:N Ratio

On average, microorganisms use 30 carbon atoms per nitrogen atom to ensure the evolution of an efficient process. Therefore, the C:N ratio at the beginning of the bioprocess is generally between 20 and 30 [52]. Starting with adjusted C:N ratios, which were within the limit suggested, BC0 had the lowest ratio of 20.73, followed by BC10 and BC20 with 27.05 and 29.71, respectively. The amended mixtures had a higher C:N ratio due to the biochar contribution to the increase in carbon content. Moreover, during the biological decomposition of the substrates, a remarkable decline in the C:N ratio, especially with regard to BC0, was due to the excessive carbon and nitrogen losses compared to the mixtures that including biochar (Figure 6). The matrix C:N ratio fell markedly during the composting of all the trials to reach 19.26, 14.97, and 11.60 for BC20, BC10, and BC0, respectively. Higher C:N ratios for amended bioreactors were expected because of the high carbon intake. As the C:N ratio is an important parameter affecting compost microbiology, it is considered as one of the indicator parameters which can be used to detect the degree of maturity, and to classify the quality of the biofertilizer produced. A range from 10 to 15 is recommended as a means of characterizing the end product generated, therefore, the compost gathered from BC0 and BC10 met these requirements [13]. However, the high C:N ratio of BC20 should be due to the high carbon content, which is not actually digestible and, hence, the maturity requested was not reached [53]. As such, considering the C:N ratio as an indicator of maturity, 32 days were not enough for BC20 to achieve this maturity. The same results have been noted by several researchers who have exploited biochar as a co-substrate and proved the improvement of the carbon and nitrogen retention, and of the C:N ratio of the end product [45].

Figure 6.

C:N ratio evolution during the process.

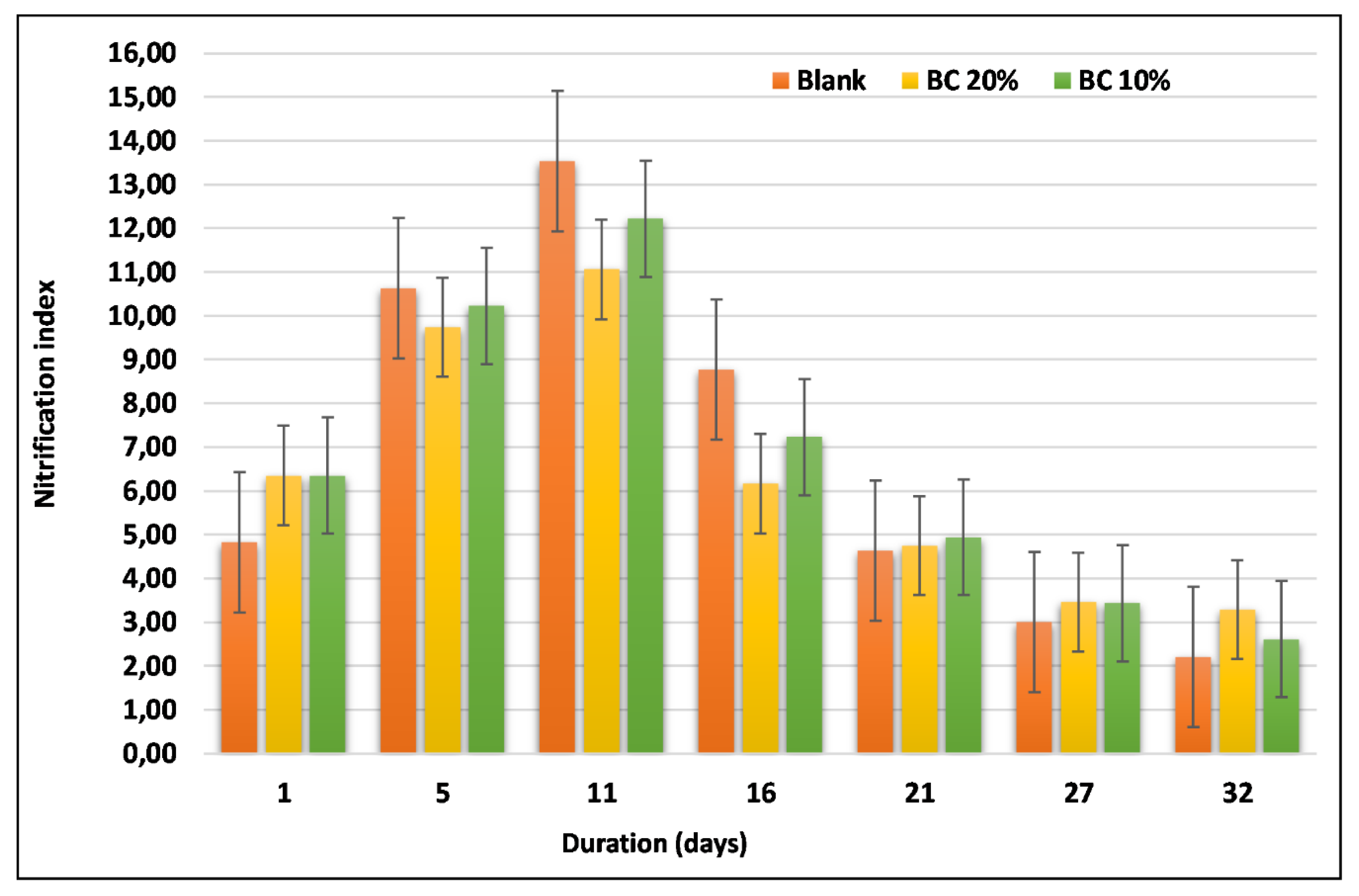

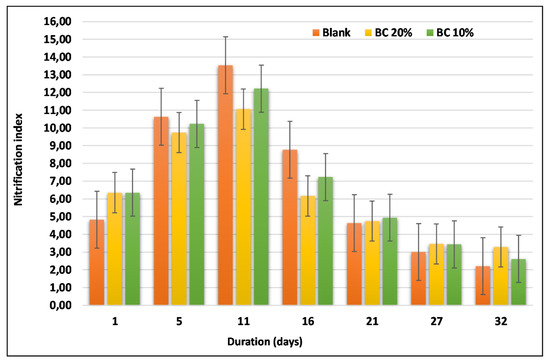

3.6.3. Nitrification Index

The quality of the compost generated could be rated by the nitrification degree which was examined in several research activities. Therefore, NH4+and NO3− are interlinked. An index related to nitrification and referred to as the nitrification index (NI = NH4+/NO3−) served to assay compost maturity. If the value of this ratio is less than 0.5, the compost is deemed to be very mature; values around 0.5–3 indicate that the product is mature, and if values exceed 3.0, the compost would be considered to be immature [54]. The evolution of the NI ratio is shown in Figure 7. The highest ratio in all the treatments was obtained during the thermophilic phase, and reached 11.06, 12.22, and 13.53, while after the peak, the rate decreased rapidly until the end of the composting when it attained 3.29, 2.61, and 2.21 for BC20, BC10, and BC0, respectively. NI indicated that for different mixtures and under the same conditions, a biochar addition of 20% restricted the maturity of the end product compared to the rate of 10% and 0%, which achieved the maturity intended, possibly due to the abundance of nitrifying bacteria colonizing the microporous of biochar, especially for overfed bioreactor (BC20). Thus, NI of BC10 underlines the effect of biochar as a co-substrate to improve the compost maturity, but its addition should be within a certain range. Close NI indexes were reported while incorporating 10% and 15% of biochar in the form of FW in vessel composting, and the NI of each mixture were finished by 1.8 and 2.7, respectively [19].

Figure 7.

Nitrification index evolution during the process.

3.6.4. Respiration Activity (AT4)

The results of the AT4 analysis for the tested samples were compared with the German classification of composts (Table 2). According to this standard, the limits for stabilization is a respiration activity (AT4) below 16 mg O2/g TS. Moreover, the finished compost can be classified into two classes depending on the range of AT4 determined. The tested compost samples could be classified as a finished compost in the IV class for BC20 with 7.32 mg O2/g TS and a finished compost in the V class for BC0 and BC10 with 4.84 and 4.36 mg O2/g TS, respectively. According to German standards, differences between class IV and V have not been clarified [51]. Consequently, the biofertilizer generated from different mixtures was considered to be finished, but BC10, which was characterized by the lowest value of AT4, was considered to be the most stable compost compared to BC0 and BC20.

Table 2.

Classification of the compost samples according to German standards based on respiration activity (AT4) analysis.

3.6.5. Heavy Metal Contents vs. Compost Quality

The significant amounts of heavy metals (HM) are indispensable for plant growth, but their excessive concentrations can inhibit plant metabolism. Indeed, some researchers proven that the quality of compost should be assessed in terms of its nutritional value during the composting process, which depends on additive amendments and organic matter degradation [41,55]. During the current experiments, the speciation of seven heavy metal elements, Pb, Ni, Cu, Zn, Hg, Cr, and Cd, was determined to examine the effects of different biochar additions to the passivation of heavy metals compared to the unamended mixture. Table 3 summarizes the results of the analysis of HM and presents the limits on each content in accordance with the law applicable in several countries, including Germany. A standard is a demanding quality indicator and may be used as quality reference indicator [56]. Dependent on the maximum content of heavy metals (Hg, Cd, Pb, Cr, Ni, Cu, and Zn), two classes—Class A and Class B—have been established as German standards. For BC0, BC10, and BC20, the average values for all samples were lower than the limits established with regard to Class B. Consequently, it clearly indicates the high quality of the compost obtained. With reference to the amended bioreactors, the concentration of chrome was highlighted as compared to the unamended one. This aspect was predicted, as the unamended trial consisted initially of almost clean feedstocks. Table 1 showed the poor contribution of FW and WS in terms of HM contents, compared to the biochar tenors. However, focusing on the concentrations of some HM in the end product generated from each reactor, Table 3 illustrated that certain amounts of Pb, Cu, Zn, and Ni still highly persist in the control trial, which might be due to the initial Mc contribution regarding those elements. This aspect might be due to the aptitude of biochar to fix HM and to reduce its bioavailability [48]. The results obtained in our study are similar to the other findings referring to the effect of biochar on HM concentration, but other researchers have arrived at different conclusions in term of the bioavailability of different contents during the process.

Table 3.

The limits of total metal content (mg/kg total solid (TS)) regarding the standards of certain countries.

3.6.6. Evaluation of Biochar Effect on FW Composting

The above results show that high quality composts can be obtained by co-composting FW and BC with a mixture of Mc and WS as a bulking agent. However, it should be mentioned that the compost obtained had different properties, which is due to the different amounts of biochar added. Among the all biochar amended composts, 10% of biochar addition showed overall better maturity and stability indicators and generated a high-quality compost with regard to HM contents. Table 4 summarizes the results obtained.

Table 4.

Characteristics of biofertilizers gathered from each bioreactor.

4. Conclusions

Our research clearly shows that the choice of bulking agent for the FW composting process can be a useful element with regard to improving the process evolution. However, it should be emphasized that the efficiency of the process, and the quality of the biofertilizer, are influenced not only by the structure of the matrix but also by the abundance of the microorganism communities present. The conducted research suggests that the mixture of different bulking agents is the most convenient method for targeting, simultaneously, inoculated and well-structured compost. It was observed that as a co-substrate, biochar enhanced the thermophilic phase, which affected the sanitization of the end product. However, biochar amounts should be initially adjusted. The results indicate that BC10 and BC20 had different effects on compost maturity and stability. Regarding the physiochemical parameters, BC20 showed the highest temperature (Tmax) during the thermophilic phase, and also the highest pH at the end of composting. However, when it comes to the maturity and the stability of the compost, BC10 presented the most frequently-requested indicators, such as the C:N ratio, NI, and AT4, when comparing the different trials. The results proved that the addition of 10% of biochar as a co-substrate showed an improvement of the process evolution and the end product quality. Moreover, biofertilizers gathered from all the trials illustrated a high-quality product in relation to the heavy metal concentrations, in agreement with the compost quality standards of the UK, France, Canada, the USA, Poland, and Germany. Therefore, it can be concluded that in order to definitively confirm the positive influence of biochar to the FW composting process, further investigations are required to find the optimal dosing of biochar, which may be conducted under different experimental conditions or from another feedstock or use of different types of food wastes and inocula. As such, further works will be done in this regard.

Author Contributions

Conceptualization, N.E.H.C.; methodology, N.E.H.C.; formal analysis, N.E.H.C. and N.E.; investigation, N.E.H.C.; data curation, N.E.H.C. and N.E.; writing—original draft preparation, N.E.H.C.; writing—review and editing, N.E.H.C. and M.C.; supervision, A.N., M.N., M.C., and M.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Acknowledgments

The authors express their sincere appreciation to Technical Lab for Waste Management and Bioenergy, University of Rostock, Germany, for co-funding this study. We are also grateful to AdFiS products GmbH for providing us with the biochar needed.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Slorach, P.C.; Jeswani, H.K.; Cuéllar-Franca, R.; Azapagic, A. Environmental sustainability of anaerobic digestion of household food waste. J. Environ. Manag. 2019, 236, 798–814. [Google Scholar] [CrossRef] [PubMed]

- FAO. 2014. Available online: http://www.fao.org/news/archive/newsbydate/2014/fr/ (accessed on 27 April 2019).

- FAOSTAT. 2017. Available online: http://www.fao.org/faostat/en/#data/EMN/visualize (accessed on 3 July 2019).

- Kalus, K.; Koziel, J.A.; Opaliński, S. A Review of Biochar Properties and Their Utilization in Crop Agriculture and Livestock Production. Appl. Sci. 2019, 9, 3494. [Google Scholar] [CrossRef]

- Wu, D.; Li, L.; Zhao, X.; Peng, Y.; Yang, P.; Peng, X. Anaerobic digestion: A review on process monitoring. Renew. Sustain. Energy Rev. 2019, 103, 1–12. [Google Scholar] [CrossRef]

- Corrado, S.; Caldeira, C.; Eriksson, M.; Hanssen, O.J.; Hauser, H.E.; van Holsteijn, F.; Liu, G.; Östergren, K.; Parry, A.; Secondi, L.; et al. Food waste accounting methodologies: Challenges, opportunities, and further advancements. Glob. Food Secur. 2019, 20, 93–100. [Google Scholar] [CrossRef] [PubMed]

- Azim, K. Composting parameters and compost quality: A literature review. Org. Agric. 2017, 8, 1–18. [Google Scholar] [CrossRef]

- Barthod, J.; Rumpel, C.; Dignac, M.F. Composting with additives to improve organic amendments. A review. Agron. Sustain. Dev. 2018, 38, 17. [Google Scholar] [CrossRef]

- Fan, H.; Liao, J.; Abass, O.K.; Liu, L.; Huang, X.; Wei, L.; Li, J.; Xie, W.; Liu, C. Effects of compost characteristics on nutrient retention and simultaneous pollutant immobilization and degradation during co-composting process. Bioresour. Technol. 2019, 275, 61–69. [Google Scholar] [CrossRef] [PubMed]

- Calabi-Floody, M.; Medina, J.; Suazo, J.; Ordiqueo, M.; Aponte, H.; Mora, M.D.; Rumpel, C. Optimization of wheat straw co-composting for carrier material development. Waste Manag. 2019, 98, 37–49. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.-T. A Cost Analysis of Food Waste Composting in Taiwan. Sustainability 2016, 8, 1210. [Google Scholar] [CrossRef]

- Yang, F.; Li, G.X.; Yang, Q.Y.; Luo, W.H. Effect of bulking agents on maturity and gaseous emissions during kitchen waste composting. Chemosphere 2013, 93, 1393–1399. [Google Scholar] [CrossRef]

- Reyes-Torres, M.; Oviedo-Ocaña, E.R.; Dominguez, I.; Komilis, D.; Sánchez, A. A systematic review on the composting of green waste: Feedstock quality and optimization strategies. Waste Manag. 2018, 77, 486–499. [Google Scholar] [CrossRef] [PubMed]

- Karnchanawong, S.; Nissaikla, S. Effects of microbial inoculation on composting of household organic waste using passive aeration bin. Int. J. Recycl. Org. Waste Agric. 2014, 3, 113–119. [Google Scholar] [CrossRef]

- Adhikari, B.K.; Barrington, S.; Martinez, J.; King, S. Characterization of food waste and bulking agents for composting. Waste Manag. 2008, 28, 795–804. [Google Scholar] [CrossRef] [PubMed]

- Guidoni, L.L.; Marques, R.V.; Moncks, R.B.; Botelho, F.T.; da Paz, M.F.; Corrêa, L.B.; Corrêa, É.K. Home composting using different ratios of bulking agent to food waste. J. Environ. Manag. 2018, 207, 141–150. [Google Scholar] [CrossRef] [PubMed]

- Vargas-Garcı, M.C.; Suárez-Estrella, F.; López, M.J.; Moreno, J. Effect of inoculation in composting processes: Modifications in lignocellulosic fraction. Waste Manag. 2007, 27, 1099–1107. [Google Scholar] [CrossRef]

- Kato, K.; Miura, N. Effect of matured compost as a bulking and inoculating agent on the microbial community and maturity of cattle manure compost. Bioresour. Technol. 2008, 99, 3372–3380. [Google Scholar] [CrossRef]

- Waqas, M.; Nizami, A.S.; Aburiazaiza, A.S.; Barakat, M.A.; Ismail, I.M.I.; Rashid, M.I. Optimization of food waste compost with the use of biochar. J. Environ. Manag. 2018, 216, 70–81. [Google Scholar] [CrossRef]

- Du, C.; Abdullah, J.J.; Greetham, D.; Fu, D.; Yu, M.; Ren, L.; Li, S.; Lu, D. Valorization of food waste into biofertiliser and its field application. J. Clean. Prod. 2018, 187, 273–284. [Google Scholar] [CrossRef]

- Glaser, B.; Haumaier, L.; Guggenberger, G.; Zech, W. The ‘Terra Preta’ phenomenon: A model for sustainable agriculture in the humid tropics. Naturwissenschaften 2001, 88, 37–41. [Google Scholar] [CrossRef]

- Agegnehu, G.; Bass, A.M.; Nelson, P.N.; Bird, M.I. Benefits of biochar, compost and biochar–compost for soil quality, maize yield and greenhouse gas emissions in a tropical agricultural soil. Sci. Total Environ. 2016, 543, 295–306. [Google Scholar] [CrossRef]

- Malinowski, M.; Wolny-Koładka, K.; Vaverková, M.D. Effect of biochar addition on the OFMSW composting process under real conditions. Waste Manag. 2019, 84, 364–372. [Google Scholar] [CrossRef] [PubMed]

- Sanchez-Monedero, M.A.; Cayuela, M.L.; Roig, A.; Jindo, K.; Mondini, C.; Bolan, N. Role of biochar as an additive in organic waste composting. Bioresour. Technol. 2018, 247, 1155–1164. [Google Scholar] [CrossRef] [PubMed]

- Adhikari, B.K.; Barrington, S.; Martinez, J.; King, S. Effectiveness of three bulking agents for food waste composting. Waste Manag. 2009, 29, 197–203. [Google Scholar] [CrossRef] [PubMed]

- Jolanun, B.; Towprayoon, S. Novel bulking agent from clay residue for food waste composting. Bioresour. Technol. 2010, 101, 4484–4490. [Google Scholar] [CrossRef] [PubMed]

- Makan, A.; Assobhei, O.; Mountadar, M. Effect of initial moisture content on the in-vessel composting under air pressure of organic fraction of municipal solid waste in Morocco. Iran. J. Environ. Health Sci. Eng. 2013, 10, 3. [Google Scholar] [CrossRef] [PubMed]

- Kopeć, M.; Baran, A.; Mierzwa-Hersztek, M.; Gondek, K.; Chmiel, M.J. Effect of the Addition of Biochar and Coffee Grounds on the Biological Properties and Ecotoxicity of Composts. Waste Biomass Valor 2018, 9, 1389–1398. [Google Scholar] [CrossRef]

- Zhang, J.; Lü, F.; Shao, L.; He, P. The use of biochar-amended composting to improve the humification and degradation of sewage sludge. Bioresour. Technol. 2014, 168, 252–258. [Google Scholar] [CrossRef]

- Franke-Whittle, I.H.; Confalonieri, A.; Insam, H.; Schlegelmilch, M.; Körner, I. Changes in the microbial communities during co-composting of digestates. Waste Manag. 2014, 34, 632–641. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, G.; Sun, H.; Zhou, S.; Zou, G. Straw biochar hastens organic matter degradation and produces nutrient-rich compost. Bioresour. Technol. 2016, 200, 876–883. [Google Scholar] [CrossRef]

- Lasaridi, K.; Protopapa, I.; Kotsou, M.; Pilidis, G.; Manios, T.; Kyriacou, A. Quality assessment of composts in the Greek market: The need for standards and quality assurance. J. Environ. Manag. 2006, 80, 58–65. [Google Scholar] [CrossRef]

- Prost, K.; Borchard, N.; Siemens, J.; Kautz, T.; Séquaris, J.M.; Möller, A.; Amelung, W. Biochar Affected by Composting with Farmyard Manure. J. Environ. Qual. 2013, 42, 164–172. [Google Scholar] [CrossRef] [PubMed]

- Awasthi, M.K.; Wang, Q.; Chen, H.; Wang, M.; Awasthi, S.K.; Ren, X.; Cai, H.; Li, R.; Zhang, Z. In-vessel co-composting of biosolid: Focusing on mitigation of greenhouse gases emissions and nutrients conservation. Renew. Energy 2018, 129, 814–823. [Google Scholar] [CrossRef]

- Yang, F.; Li, Y.; Han, Y.; Qian, W.; Li, G.; Luo, W. Performance of mature compost to control gaseous emissions in kitchen waste composting. Sci. Total Environ. 2019, 657, 262–269. [Google Scholar] [CrossRef] [PubMed]

- Agyarko-Mintah, E.; Cowie, A.; Van Zwieten, L.; Singh, B.P.; Smillie, R.; Harden, S.; Fornasier, F. Biochar lowers ammonia emission and improves nitrogen retention in poultry litter composting. Waste Manag. 2017, 61, 129–137. [Google Scholar] [CrossRef] [PubMed]

- Jain, M.S.; Jambhulkar, R.; Kalamdhad, A.S. Biochar amendment for batch composting of nitrogen rich organic waste: Effect on degradation kinetics, composting physics and nutritional properties. Bioresour. Technol. 2018, 253, 204–213. [Google Scholar] [CrossRef] [PubMed]

- Xu, Z.; Zhao, B.; Wang, Y.; Xiao, J.; Wang, X. Composting process and odor emission varied in windrow and trough composting system under different air humidity conditions. Bioresour. Technol. 2020, 297, 122482. [Google Scholar] [CrossRef] [PubMed]

- Dias, B.O.; Silva, C.A.; Higashikawa, F.S.; Roig, A.; Sánchez-Monedero, M.A. Use of biochar as bulking agent for the composting of poultry manure: Effect on organic matter degradation and humification. Bioresour. Technol. 2010, 101, 1239–1246. [Google Scholar] [CrossRef]

- Liu, W.; Huo, R.; Xu, J.; Liang, S.; Li, J.; Zhao, T.; Wang, S. Effects of biochar on nitrogen transformation and heavy metals in sludge composting. Bioresour. Technol. 2017, 235, 43–49. [Google Scholar] [CrossRef]

- Liu, N.; Zhou, J.; Han, L.; Ma, S.; Sun, X.; Huang, G. Role and multi-scale characterization of bamboo biochar during poultry manure aerobic composting. Bioresour. Technol. 2017, 241, 190–199. [Google Scholar] [CrossRef]

- Al-Bataina, B.B.; Young, T.M.; Ranieri, E. Effects of compost age on the release of nutrients. Int. Soil Water Conserv. Res. 2016, 4, 230–236. [Google Scholar] [CrossRef]

- Domingues, R.R.; Trugilho, P.F.; Silva, C.A.; de Melo, I.C.; Melo, L.C.; Magriotis, Z.M.; Sanchez-Monedero, M.A. Properties of biochar derived from wood and high-nutrient biomasses with the aim of agronomic and environmental benefits. PLoS ONE 2017, 12, e0176884. [Google Scholar] [CrossRef] [PubMed]

- Yu, H.; Xie, B.; Khan, R.; Shen, G. The changes in carbon, nitrogen components and humic substances during organic-inorganic aerobic co-composting. Bioresour. Technol. 2019, 271, 228–235. [Google Scholar] [CrossRef] [PubMed]

- Fidel, R.B.; Laird, D.A.; Thompson, M.L.; Lawrinenko, M. Characterization and quantification of biochar alkalinity. Chemosphere 2017, 167, 367–373. [Google Scholar] [CrossRef] [PubMed]

- Cáceres, R.; Malińska, K.; Marfà, O. Nitrification within composting: A review. Waste Manag. 2018, 72, 119–137. [Google Scholar] [CrossRef] [PubMed]

- Yin, Y.; Yang, C.; Gu, J.; Wang, X.; Zheng, W.; Wang, R.; Wang, X.; Chen, R. Roles of nxrA-like oxidizers and nirS-like reducers in nitrite conversion during swine manure composting. Bioresour. Technol. 2020, 297, 122426. [Google Scholar] [CrossRef] [PubMed]

- Awasthi, M.K.; Wang, Q.; Chen, H.; Wang, M.; Ren, X.; Zhao, J.; Li, J.; Guo, D.; Li, D.S.; Awasthi, S.K.; et al. Evaluation of biochar amended biosolids co-composting to improve the nutrient transformation and its correlation as a function for the production of nutrient-rich compost. Bioresour. Technol. 2017, 237, 156–166. [Google Scholar] [CrossRef] [PubMed]

- Godlewska, P.; Schmidt, H.P.; Ok, Y.S.; Oleszczuk, P. Biochar for composting improvement and contaminants reduction. A review. Bioresour. Technol. 2017, 246, 193–202. [Google Scholar] [CrossRef]

- Bożym, M.; Siemiątkowski, G. Assessment of Composition Changes, Stability Degree and the Potential of Biogas Formation of Sewage Sludge Composts During Maturation Process. Waste Biomass Valor 2019. [Google Scholar] [CrossRef]

- Hemidat, S.; Jaar, M.; Nassour, A.; Nelles, M. Monitoring of Composting Process Parameters: A Case Study in Jordan. Waste Biomass Valor 2018, 9, 2257–2274. [Google Scholar] [CrossRef]

- Bian, B.; Hu, X.; Zhang, S.; Lv, C.; Yang, Z.; Yang, W.; Zhang, L. Pilot-scale composting of typical multiple agricultural wastes: Parameter optimization and mechanisms. Bioresour. Technol. 2019, 287, 121482. [Google Scholar] [CrossRef]

- Jien, S.-H. Chapter 2—Physical Characteristics of Biochars and Their Effects on Soil Physical Properties. In Biochar from Biomass and Waste; Ok, Y.S., Tsang, D.C.W., Bolan, N., Novak, J.M., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 21–35. [Google Scholar]

- Meng, L.; Li, W.; Zhang, S.; Wu, C.; Lv, L. Feasibility of co-composting of sewage sludge, spent mushroom substrate and wheat straw. Bioresour. Technol. 2017, 226, 39–45. [Google Scholar] [CrossRef] [PubMed]

- Lin, L.; Xu, F.; Ge, X.; Li, Y. Chapter Four—Biological treatment of organic materials for energy and nutrients production—Anaerobic digestion and composting. In Advances in Bioenergy; Li, Y., Ge, X., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; Volume 4, pp. 121–181. [Google Scholar]

- Vázquez, M.A.; Soto, M. The efficiency of home composting programmes and compost quality. Waste Manag. 2017, 64, 39–50. [Google Scholar] [CrossRef] [PubMed]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).