Long High-Performance Sustainable Bolt Technology for the Deep Coal Roadway Roof: A Case Study

Abstract

:1. Introduction

2. Engineering Geological Conditions

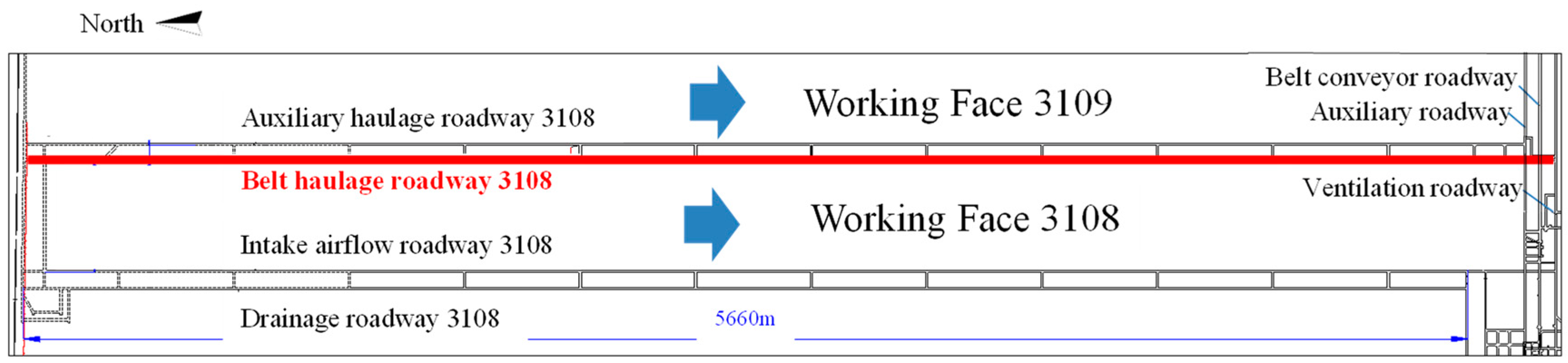

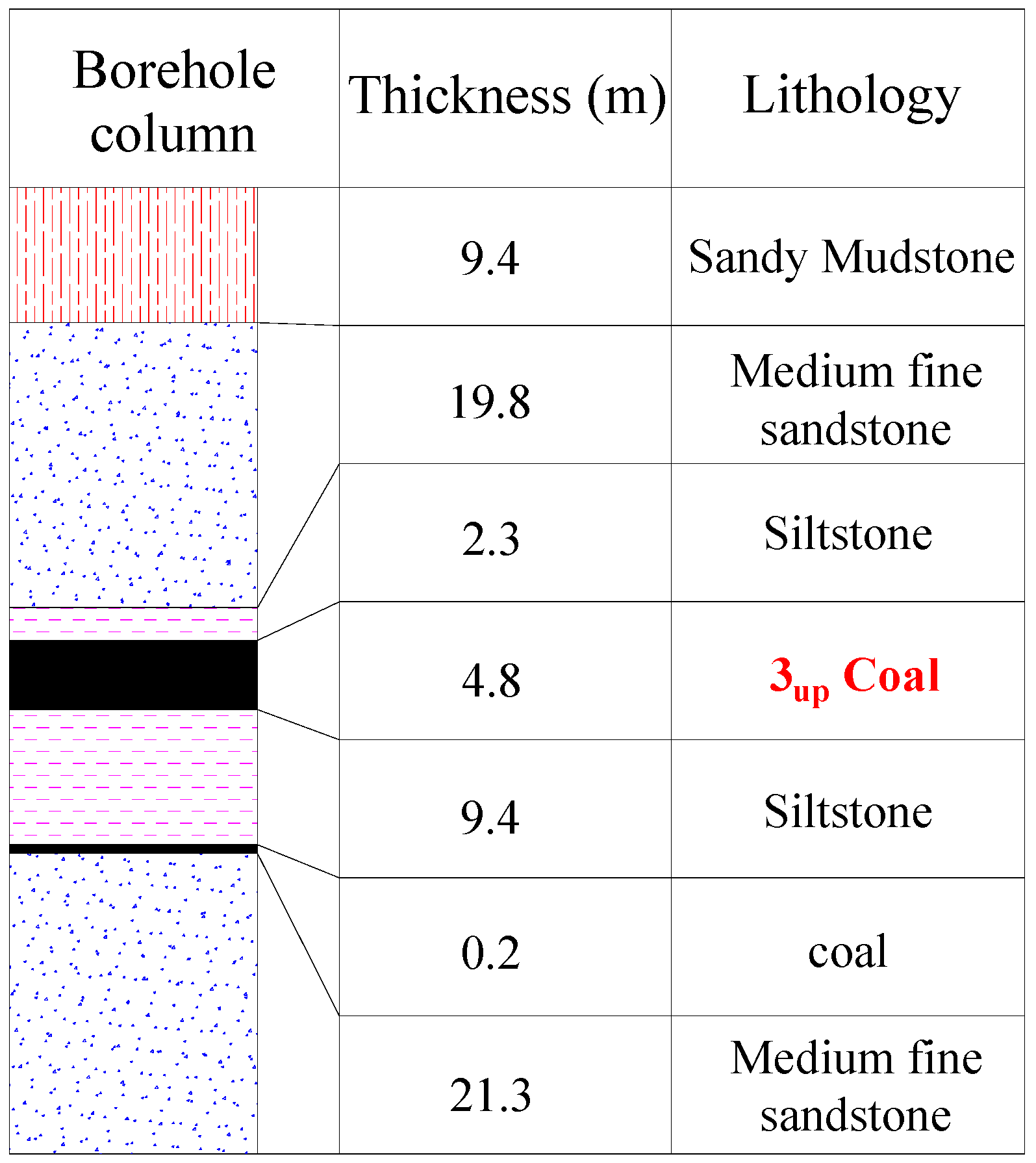

2.1. Roadway Location and Lithology of Roof, Floor

2.2. Original Support Scheme and Maintenance Effect

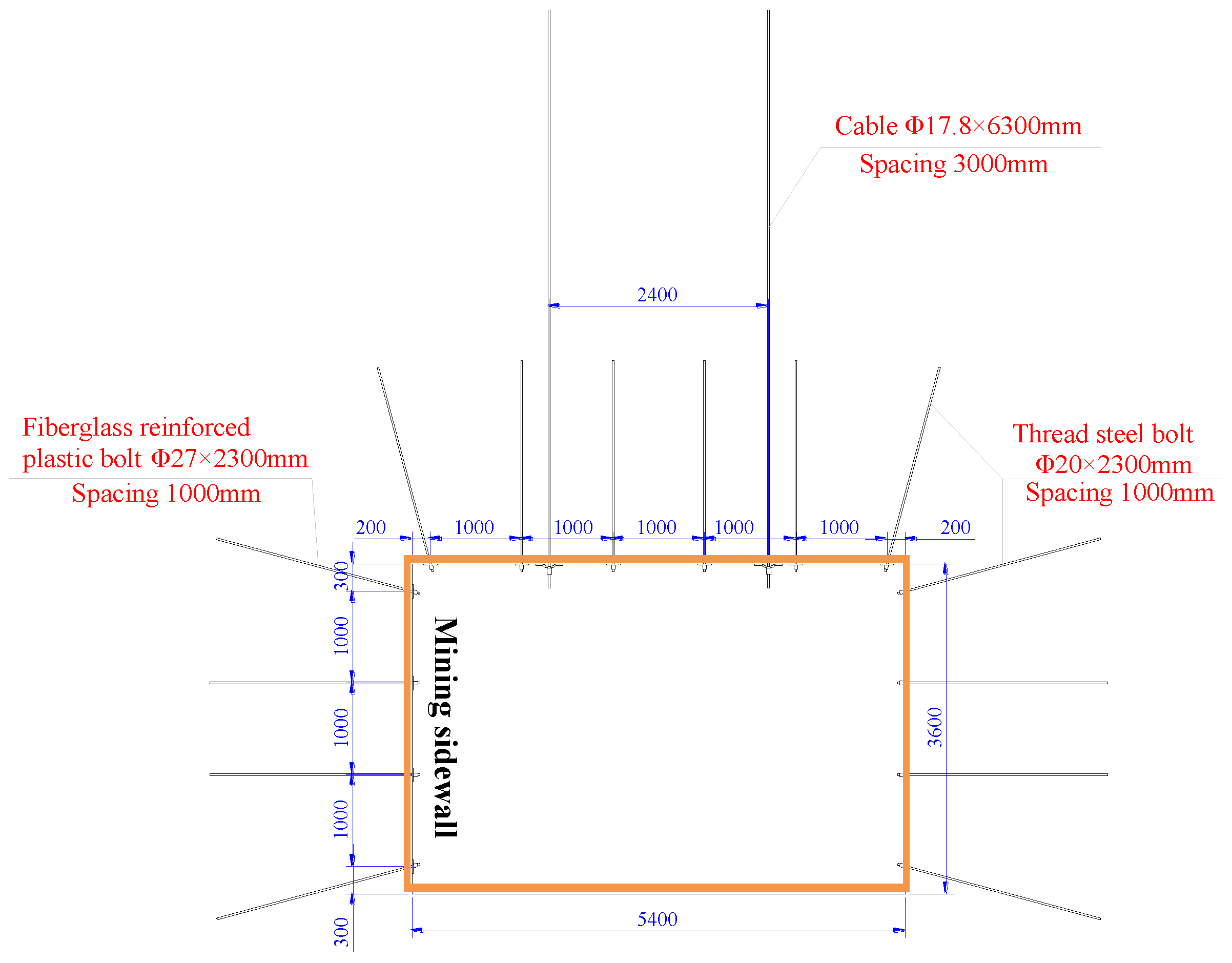

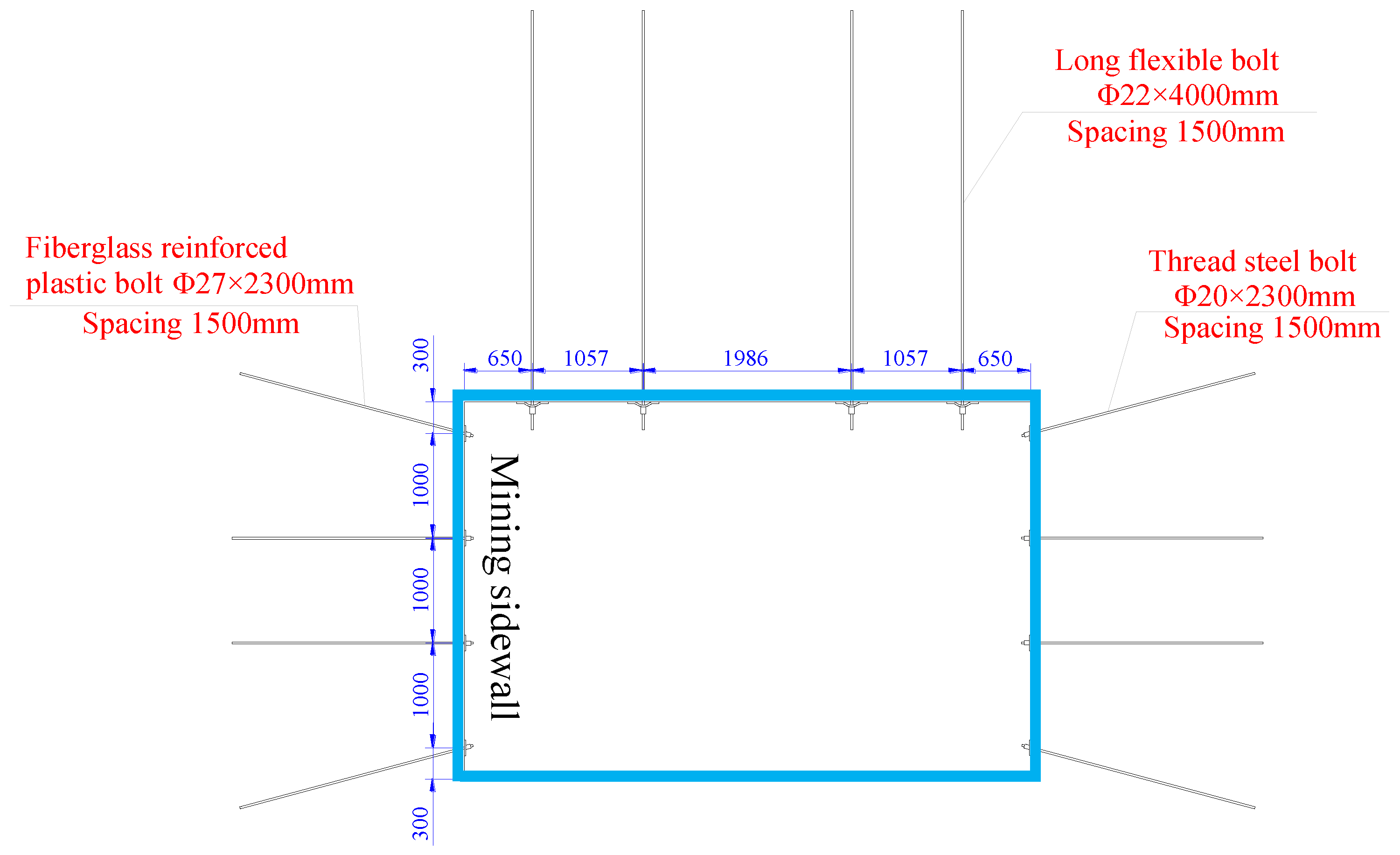

2.2.1. Original Support Scheme

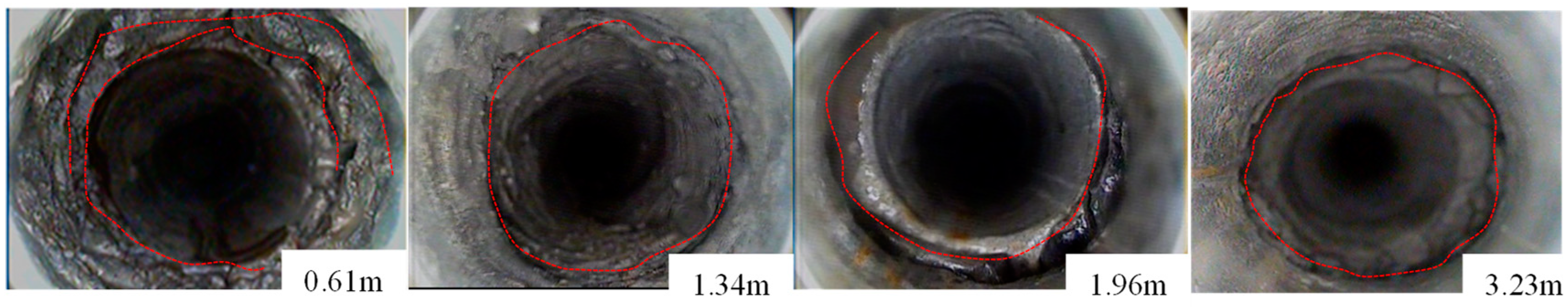

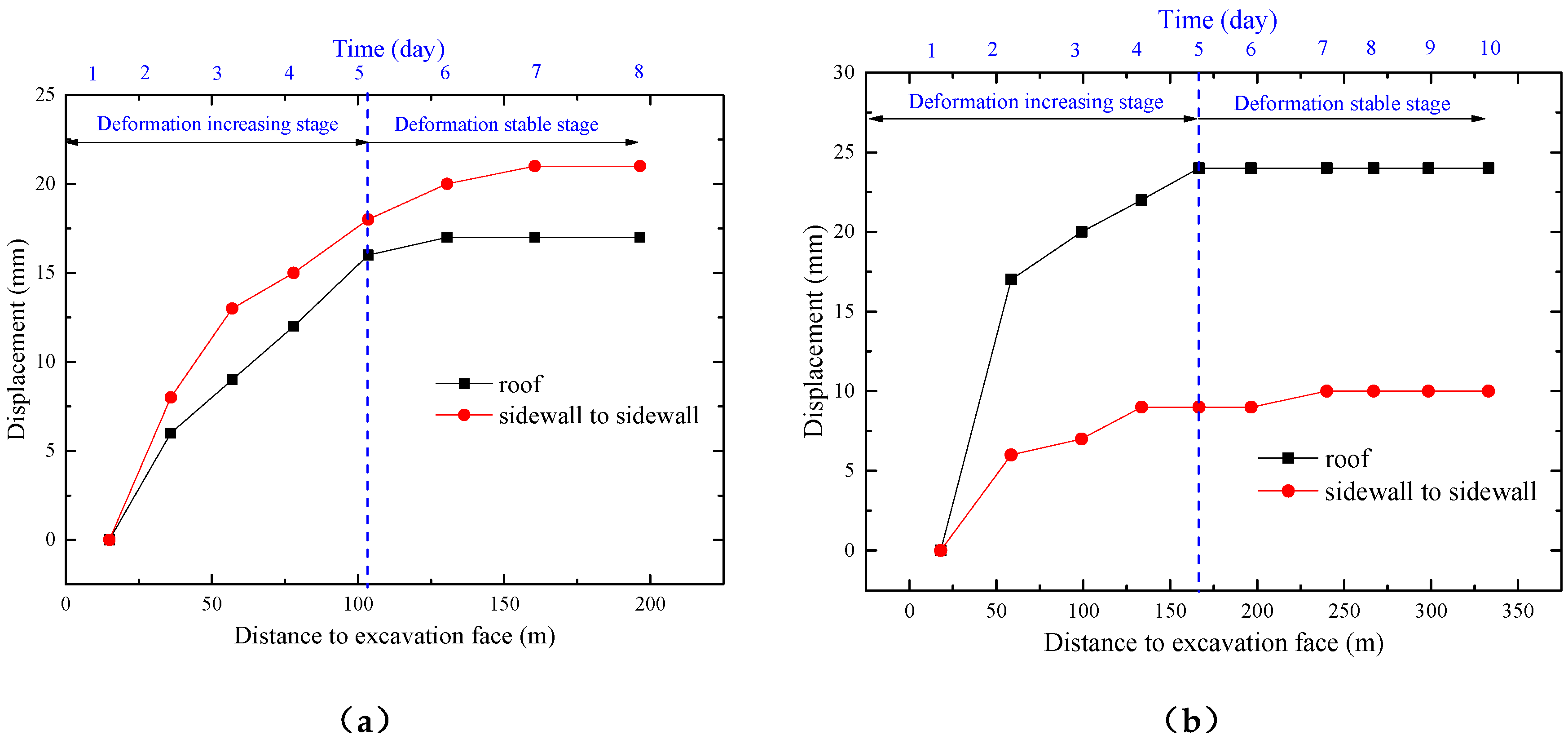

2.2.2. Maintenance Effect of Roadway Roof

2.2.3. Analysis of Existing Problems

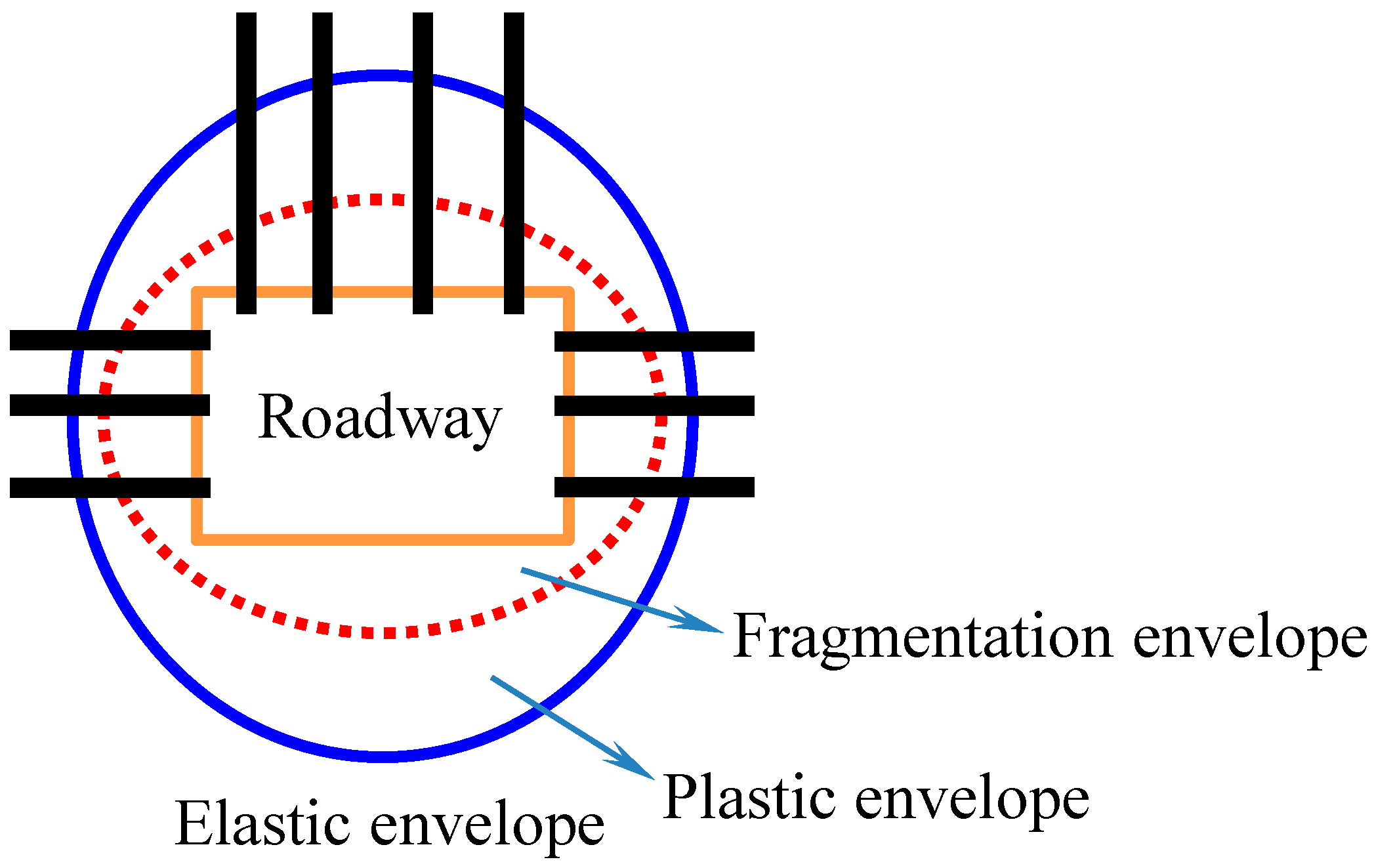

3. Control Law of High Efficiency and Long Anchorage of Roof

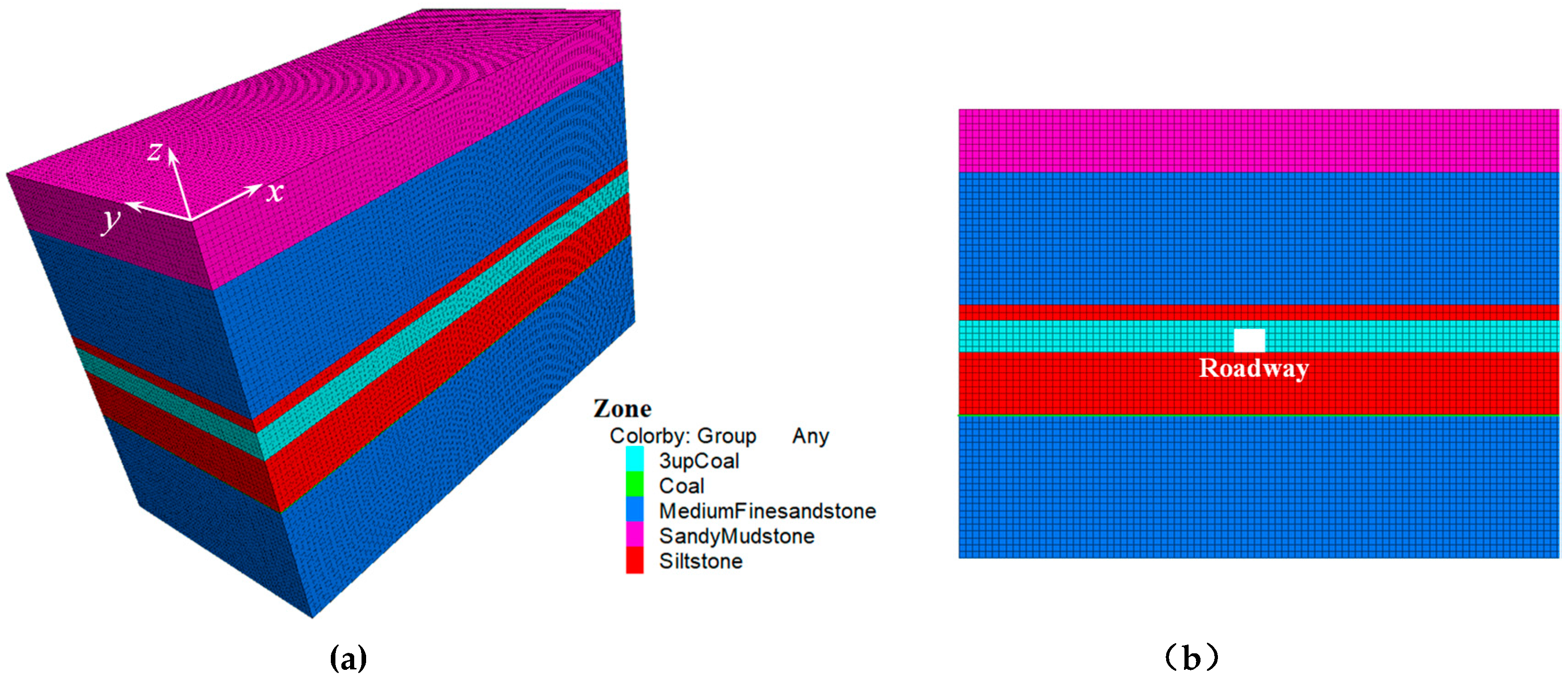

3.1. Setting Up the Numerical Model

3.2. Calculation Method and Results

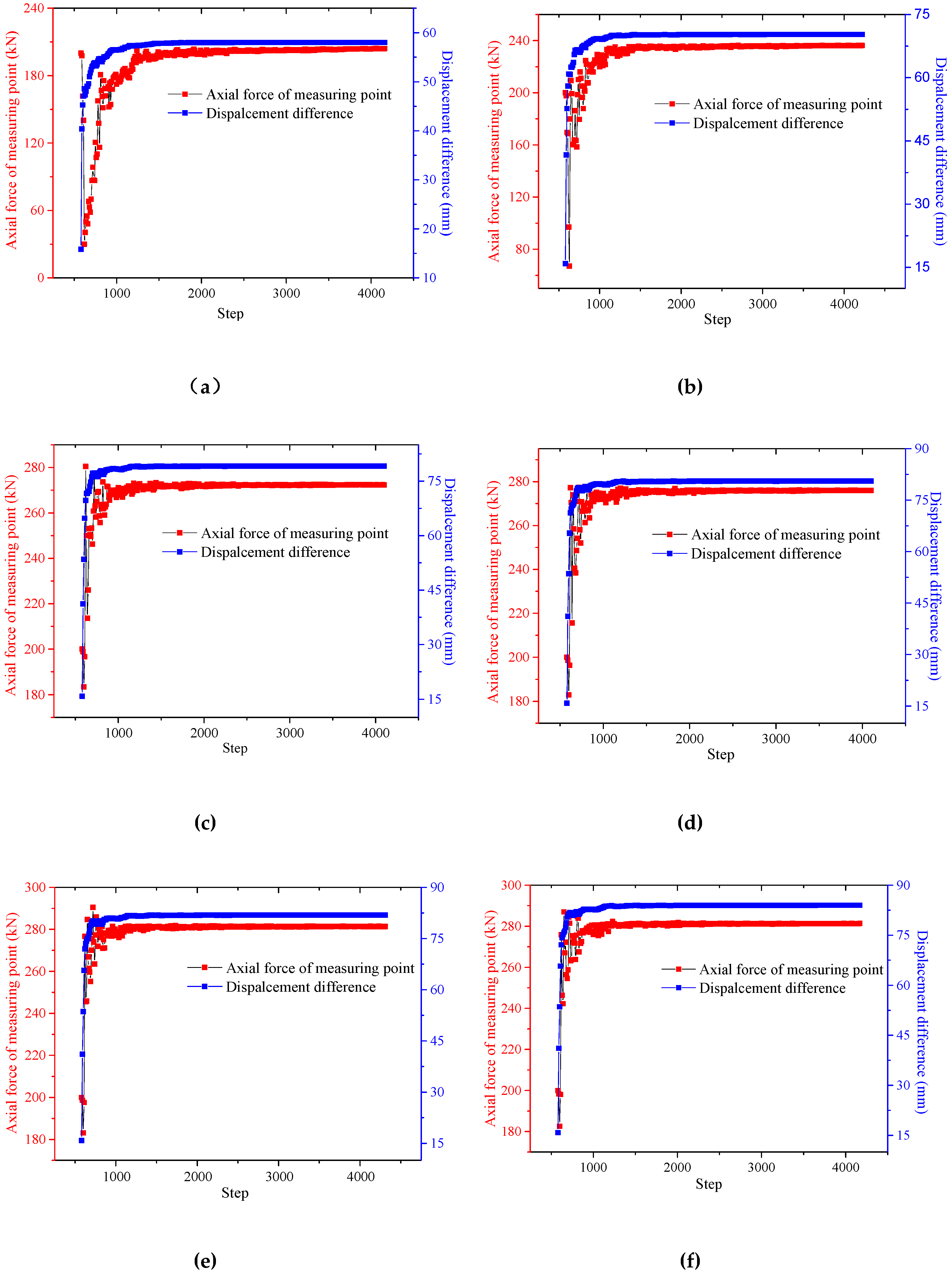

3.2.1. Calculation Method

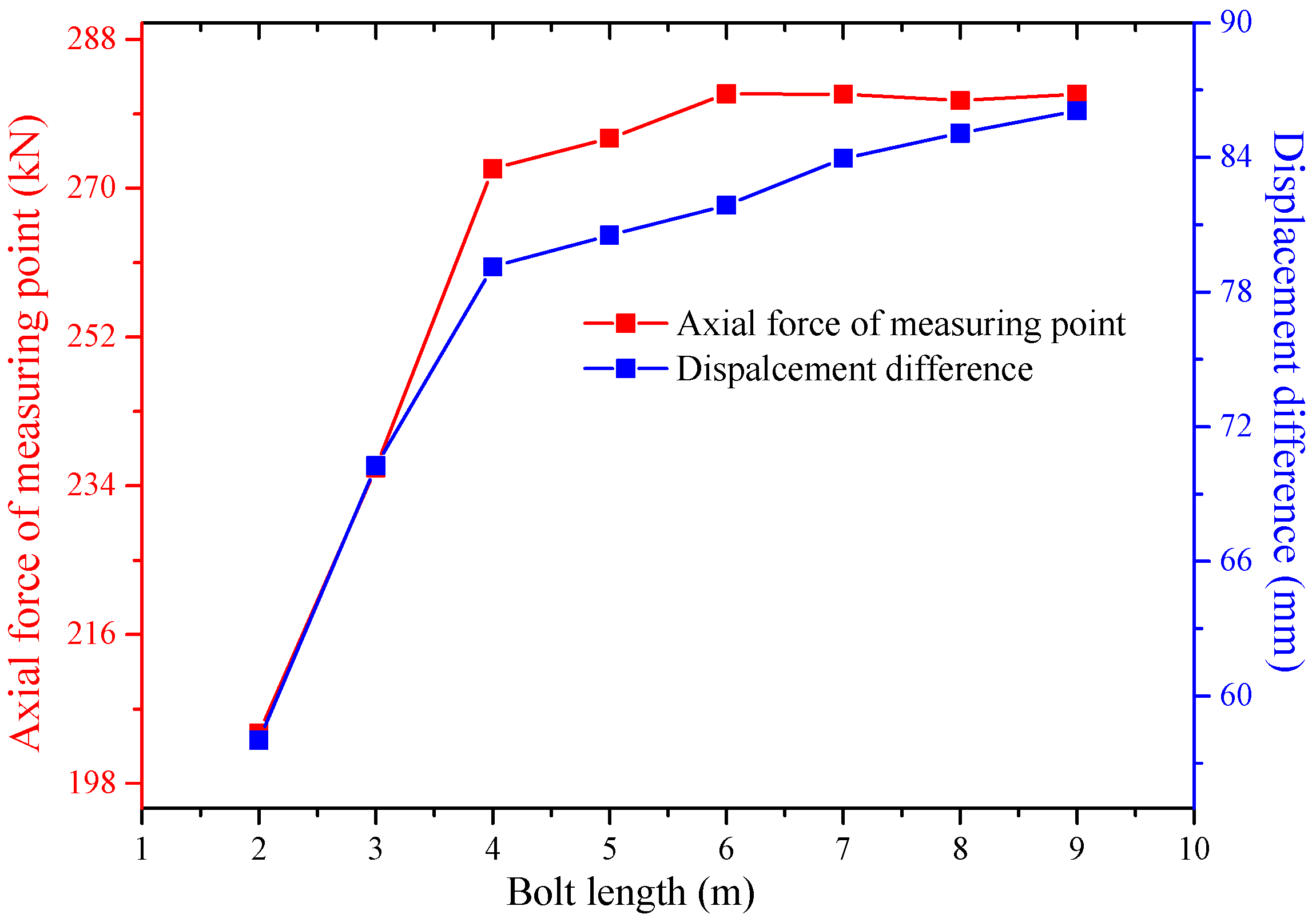

3.2.2. Calculation Results

4. Control Technology and Engineering Practice

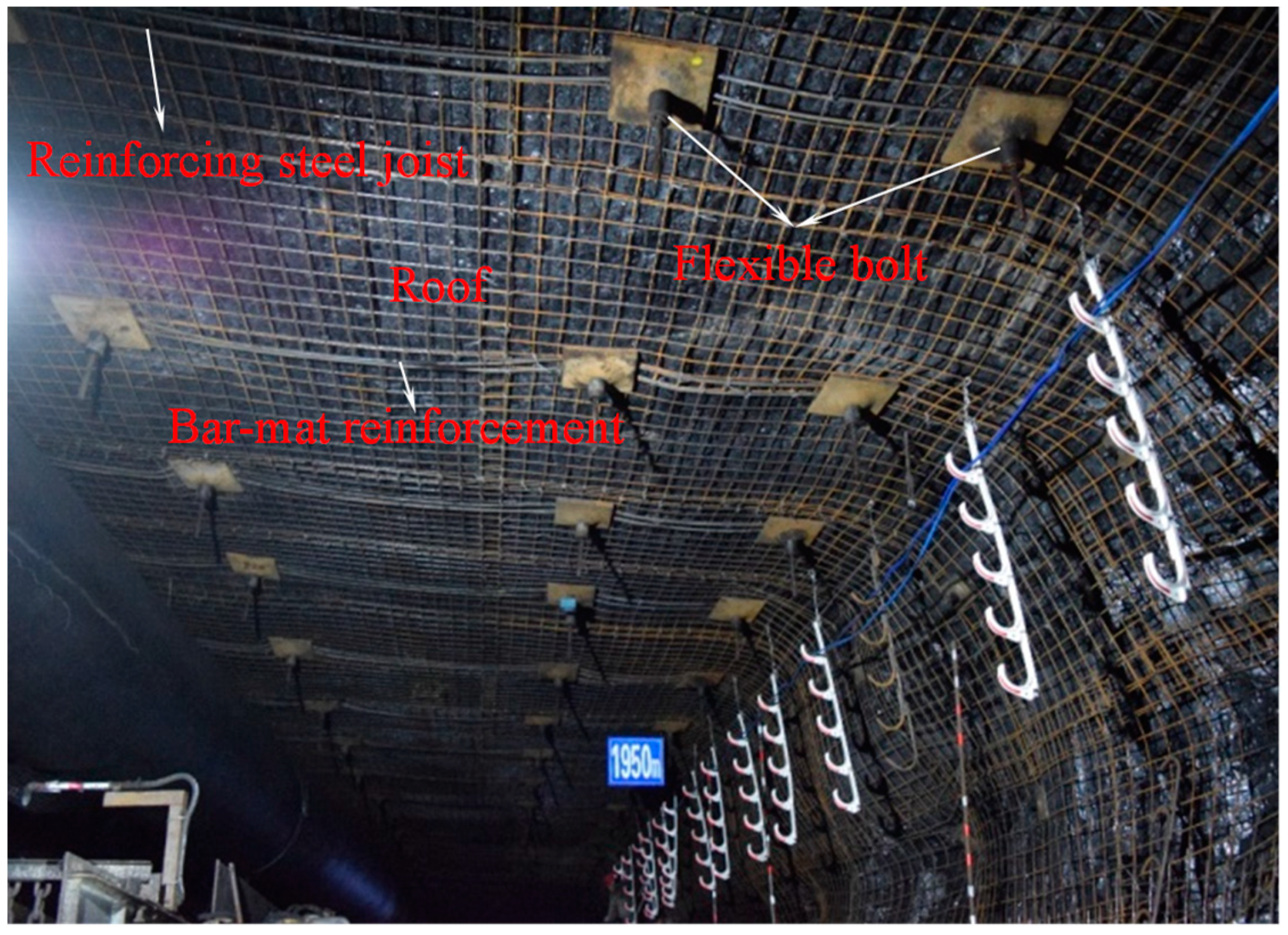

4.1. Long High-Performance Sustainable Bolt Technology

4.2. Support Scheme Design

4.3. Supporting Effects Analysis

4.3.1. Monitoring of Roadway Surface Displacement

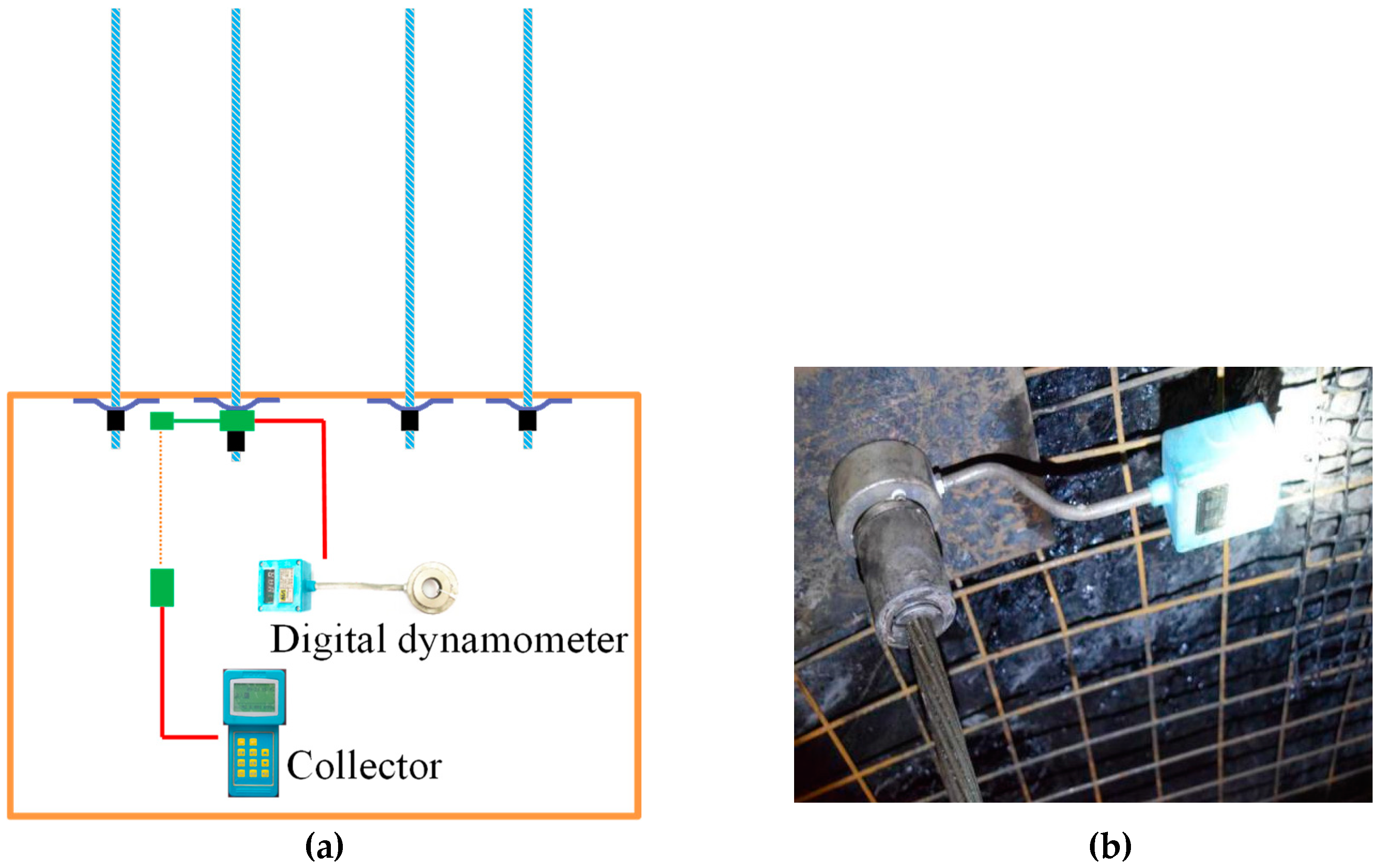

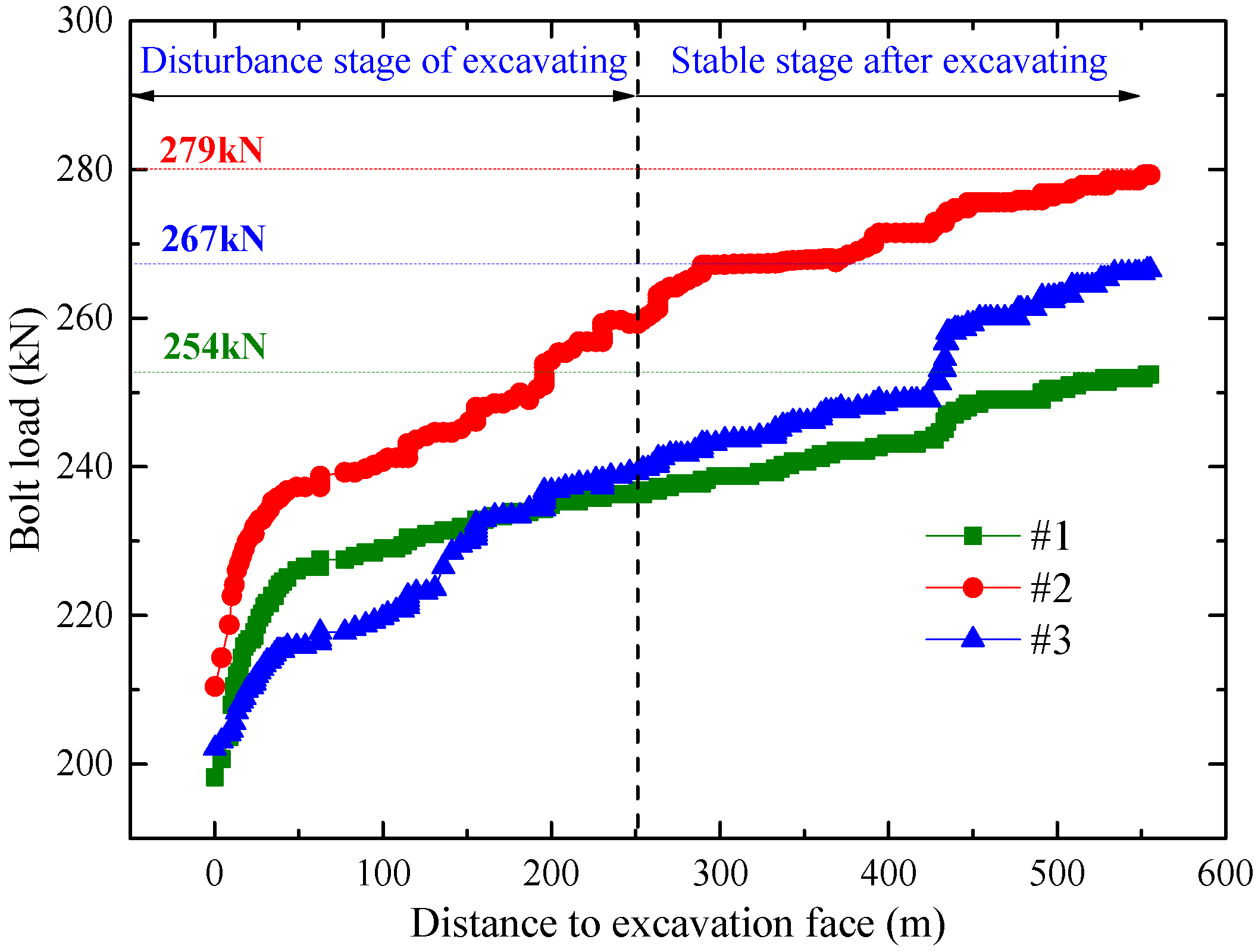

4.3.2. Monitoring of Working Resistance of Bolt

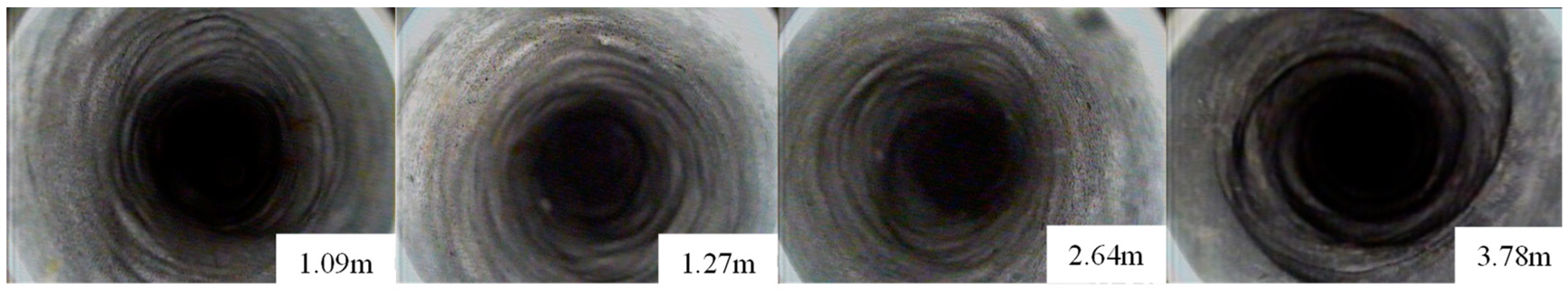

4.3.3. Monitoring of Roof Separated Fissures

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| SRDC | surrounding rock deformation control |

| TCS | three-soft coal seams |

| MSCK | fast setting resin cartridge |

| 3up | the upper coal of the third coal series in the stratum. |

| f | the axial force of bolt. |

| △u | displacement difference within anchorage range. |

| d1 | the displacement of the lower surface of the bearing structure. |

| d2 | the displacement of the upper surface of the bearing structure. |

References

- Zhang, J.X.; Zhang, Q.; Ju, F.; Zhou, N.; Li, M.; Zhang, W.Q. Practice and technique of green mining with integration of mining, dressing, backfilling and X in coal resources. J. China Coal Soc. 2019, 44, 64–73. [Google Scholar]

- Wang, J.H.; Xie, H.P.; Liu, J.Z.; Wu, L.X.; Ren, S.H.; Jiang, P.F.; Zhou, H.W. Coal development and utilization theory and technical system of near-zero ecological environment impact. J. China Coal Soc. 2018, 43, 1198–1209. [Google Scholar]

- Miu, X.X.; Qian, M.G. Research on Green Mining of Coal Resources in China: Current Status and Future Prospects. J. Min. Saf. Eng. 2009, 26, 1–14. [Google Scholar]

- Yuan, L. Strategic thinking of simultaneous exploitation of coal and gas in deep mining. J. China Coal Soc. 2016, 41, 1–6. [Google Scholar]

- Xie, H.P.; Gao, F.; Ju, Y. Research and Development of Rock Mechanics Deep Ground Engineering. Chin. J. Rock Mech. Eng. 2015, 34, 2161–2178. [Google Scholar]

- Feng, X.W.; Zhang, N.; Xue, F.; Xie, Z.Z. Practices, experience, and lessons learned based on field observations of support failures in some Chinese coal mines. Int. J. Rock Mech. Min. Sci. 2019, 123. [Google Scholar] [CrossRef]

- Kang, H. Support technologies for deep and complex roadways in underground coal mines: a review. Int. J. Coal Sci. Technol. 2014, 1, 261–277. [Google Scholar] [CrossRef] [Green Version]

- Zhang, C.; Pu, C.; Cao, R.; Jiang, T.; Huang, G. The stability and roof-support optimization of roadways passing through unfavorable geological bodies using advanced detection and monitoring methods, among others, in the Sanmenxia Bauxite Mine in China’s Henan Province. Bull. Int. Assoc. Eng. Geol. 2019, 78, 5087–5099. [Google Scholar] [CrossRef]

- Zhang, X.; Gong, P.; Wang, K.; Li, J.; Jiang, Y. Characteristic and Mechanism of Roof Fracture Ahead of the Face in an LTCC Panel When Passing an Abandoned Roadway: A Case Study from the Shenghua Coal Mine, China. Rock Mech. Rock Eng. 2019, 52, 2775–2788. [Google Scholar] [CrossRef]

- Ma, W.; Wang, T. Instability Mechanism and Control Countermeasure of a Cataclastic Roadway Regenerated Roof in the Extraction of the Remaining Mineral Resources: A Case Study. Rock Mech. Rock Eng. 2019, 52, 2437–2457. [Google Scholar] [CrossRef]

- Wang, W.J.; Yuan, C.; Yu, W.J.; Wu, H.; Peng, W.Q.; Peng, G.; Liu, X.S.; Dong, E.Y. Stability control method of surrounding rock in deep roadway with large deformation. J. China Coal Soc. 2016, 12, 2921–2931. [Google Scholar]

- Wang, W.J.; Yuan, C.; Yu, W.J.; Zhao, Y.L.; Peng, W.Q.; Wu, H.; Peng, G.; Qu, Y.S. Control technology of reserved surrounding rock deformation in deep roadway under high stress. J. China Coal Soc. 2016, 41, 2156–2164. [Google Scholar]

- Xie, Z.; Zhang, N.; Meng, F.; Han, C.; An, Y.; Zhu, R. Deformation Field Evolution and Failure Mechanisms of Coal–Rock Combination Based on the Digital Speckle Correlation Method. Energies 2019, 12, 2511. [Google Scholar] [CrossRef] [Green Version]

- Xie, Z.; Zhang, N.; Yuan, Y.; Xu, G.; Wei, Q. Study on Safety Control of Composite Roof in Deep Roadway Based on Energy Balance Theory. Sustainability 2019, 11, 3688. [Google Scholar] [CrossRef] [Green Version]

- Qin, D.; Wang, X.; Zhang, D.; Chen, X. Study on Surrounding Rock-Bearing Structure and Associated Control Mechanism of Deep Soft Rock Roadway Under Dynamic Pressure. Sustainability 2019, 11, 1892. [Google Scholar] [CrossRef] [Green Version]

- Li, G.; Ma, F.; Liu, G.; Zhao, H.; Guo, J. A Strain-Softening Constitutive Model of Heterogeneous Rock Mass Considering Statistical Damage and Its Application in Numerical Modeling of Deep Roadways. Sustainability 2019, 11, 2399. [Google Scholar] [CrossRef] [Green Version]

- Qi, F.; Ma, Z. Investigation of the Roof Presplitting and Rock Mass Filling Approach on Controlling Large Deformations and Coal Bumps in Deep High-Stress Roadways. Lat. Am. J. Solids Struct. 2019, 16, 16. [Google Scholar] [CrossRef]

- Guo, W.H.; Chang, Q.L.; Sun, X.K.; Zhou, H.Q.; Yang, H.Y. Instability Mechanism and Control Technology for Deep-Buried Large-Span Complex Roof Coal Roadway for the Prevention of Coal Pollution. Ekoloji Dergisi 2019, 28, 1401–1410. [Google Scholar]

- Zhang, W.; He, Z.; Zhang, N.; Qi, D.; Zhang, W. Surrounding rock deformation control of asymmetrical roadway in deep three-soft coal seam: a case study. J. Geophys. Eng. 2018, 15, 1917–1928. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.; Liu, Y.; Li, W.; Zhang, X.; Xin, C. Measures to deal roof-shock during tunneling at deep and extra-thick coal. Arab. J. Geosci. 2019, 12, 189. [Google Scholar] [CrossRef]

- Xie, S.; Pan, H.; Zeng, J.; Wang, E.; Chen, D.; Zhang, T.; Peng, X.; Yang, J.; Chen, F.; Qiao, S. A case study on control technology of surrounding rock of a large section chamber under a 1200-m deep goaf in Xingdong coal mine, China. Eng. Fail. Anal. 2019, 104, 112–125. [Google Scholar] [CrossRef]

- Tian, S.; Xu, X.; Li, Z. Disaster-inducing mechanism in a roadway roof near the driving face and its safety-control criteria. Saf. Sci. 2019, 115, 208–214. [Google Scholar] [CrossRef]

- Skrzypkowski, K.; Korzeniowski, W.; Zagórski, K.; Zagórska, A. Flexibility and Load-Bearing Capacity of Roof Bolting as Functions of Mounting Depth and Hole Diameter. Energies 2019, 12, 3754. [Google Scholar] [CrossRef] [Green Version]

- Skrzypkowski, K. The Influence of Room and Pillar Method Geometry on the Deposit Utilization Rate and Rock Bolt Load. Energies 2019, 12, 4770. [Google Scholar] [CrossRef] [Green Version]

- Shen, Y.J.; Xu, G.L.; Zhang, L.; Zhu, K.J. Research on Characteristics OF Rock Deformation Caused by Excavation Disturbance Based on Hoek-Brown Criterion. Chin. J. Rock Mech. Eng. 2010, 29, 1355–1362. [Google Scholar]

- Guo, X.; Zhao, Z.; Gao, X.; Wu, X.; Ma, N. Analytical solutions for characteristic radii of circular roadway surrounding rock plastic zone and their application. Int. J. Min. Sci. Technol. 2019, 29, 263–272. [Google Scholar] [CrossRef]

- Xie, Z.; Zhang, N.; Feng, X.; Liang, D.; Wei, Q.; Weng, M. Investigation on the evolution and control of surrounding rock fracture under different supporting conditions in deep roadway during excavation period. Int. J. Rock Mech. Min. Sci. 2019, 123, 104122. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, H.; Han, C.; Zhang, N.; Sun, Y.; Pan, D.; Sun, C. Long High-Performance Sustainable Bolt Technology for the Deep Coal Roadway Roof: A Case Study. Sustainability 2020, 12, 1375. https://doi.org/10.3390/su12041375

Yang H, Han C, Zhang N, Sun Y, Pan D, Sun C. Long High-Performance Sustainable Bolt Technology for the Deep Coal Roadway Roof: A Case Study. Sustainability. 2020; 12(4):1375. https://doi.org/10.3390/su12041375

Chicago/Turabian StyleYang, Houqiang, Changliang Han, Nong Zhang, Yuantian Sun, Dongjiang Pan, and Changlun Sun. 2020. "Long High-Performance Sustainable Bolt Technology for the Deep Coal Roadway Roof: A Case Study" Sustainability 12, no. 4: 1375. https://doi.org/10.3390/su12041375

APA StyleYang, H., Han, C., Zhang, N., Sun, Y., Pan, D., & Sun, C. (2020). Long High-Performance Sustainable Bolt Technology for the Deep Coal Roadway Roof: A Case Study. Sustainability, 12(4), 1375. https://doi.org/10.3390/su12041375