Optimization of Insulation Thickness of External Walls of Residential Buildings in Hot Summer and Cold Winter Zone of China

Abstract

:1. Introduction

2. Materials and Methods

2.1. Hypothetical Building

2.1.1. Physical Information of the Typical Building

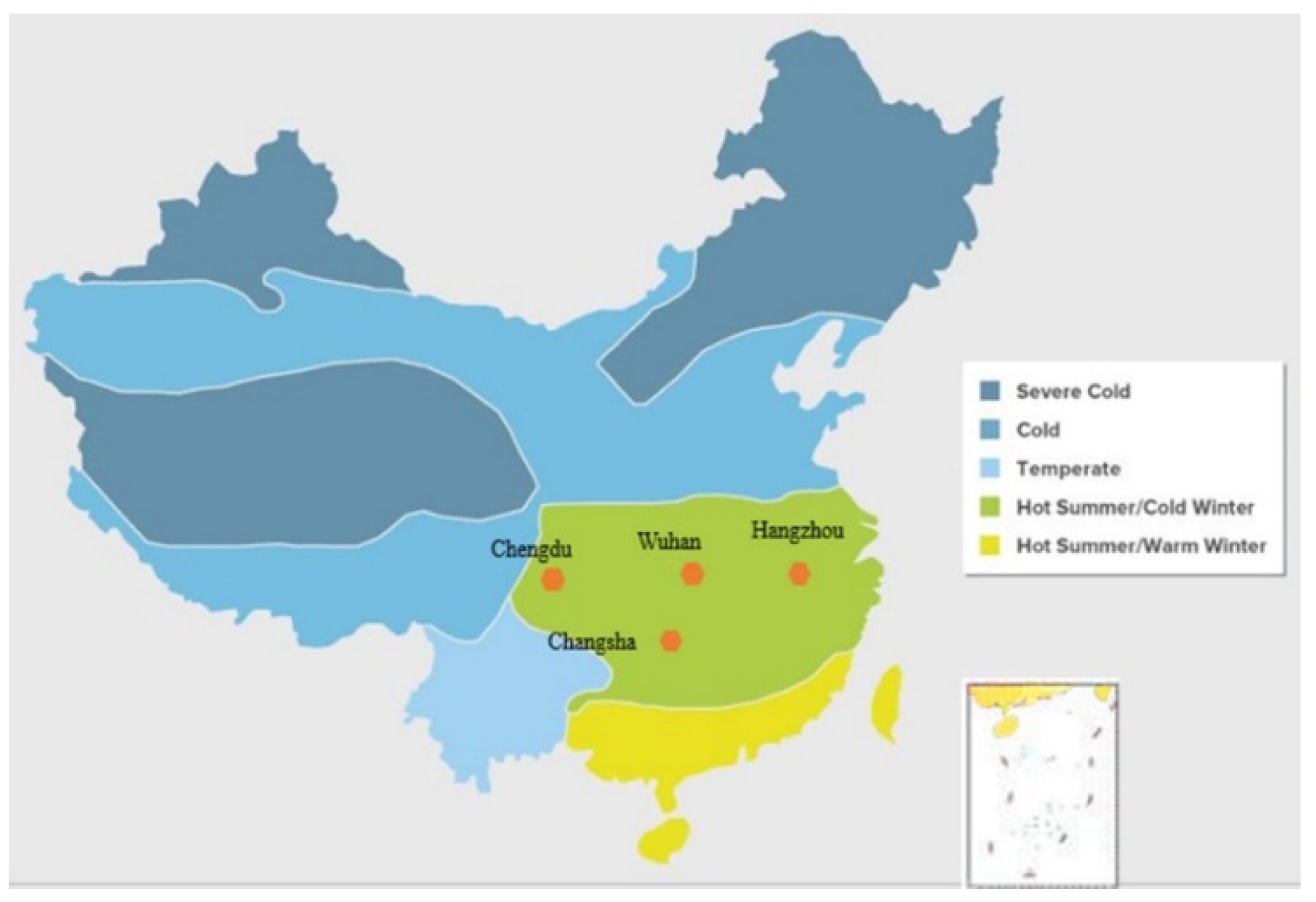

2.1.2. Meteorological Information of the Typical Building

2.2. Calculation of Operational Energy Consumption of the Hypothetical Building

2.3. Integrated Estimation Method to Select the OTWRB

2.3.1. Evaluation of the Impacts of ITEWB on Building Performance with Regard to the Economic, Energy and Greenhouse Gas Emissions Aspects.

- Life cycle cost (LCC)

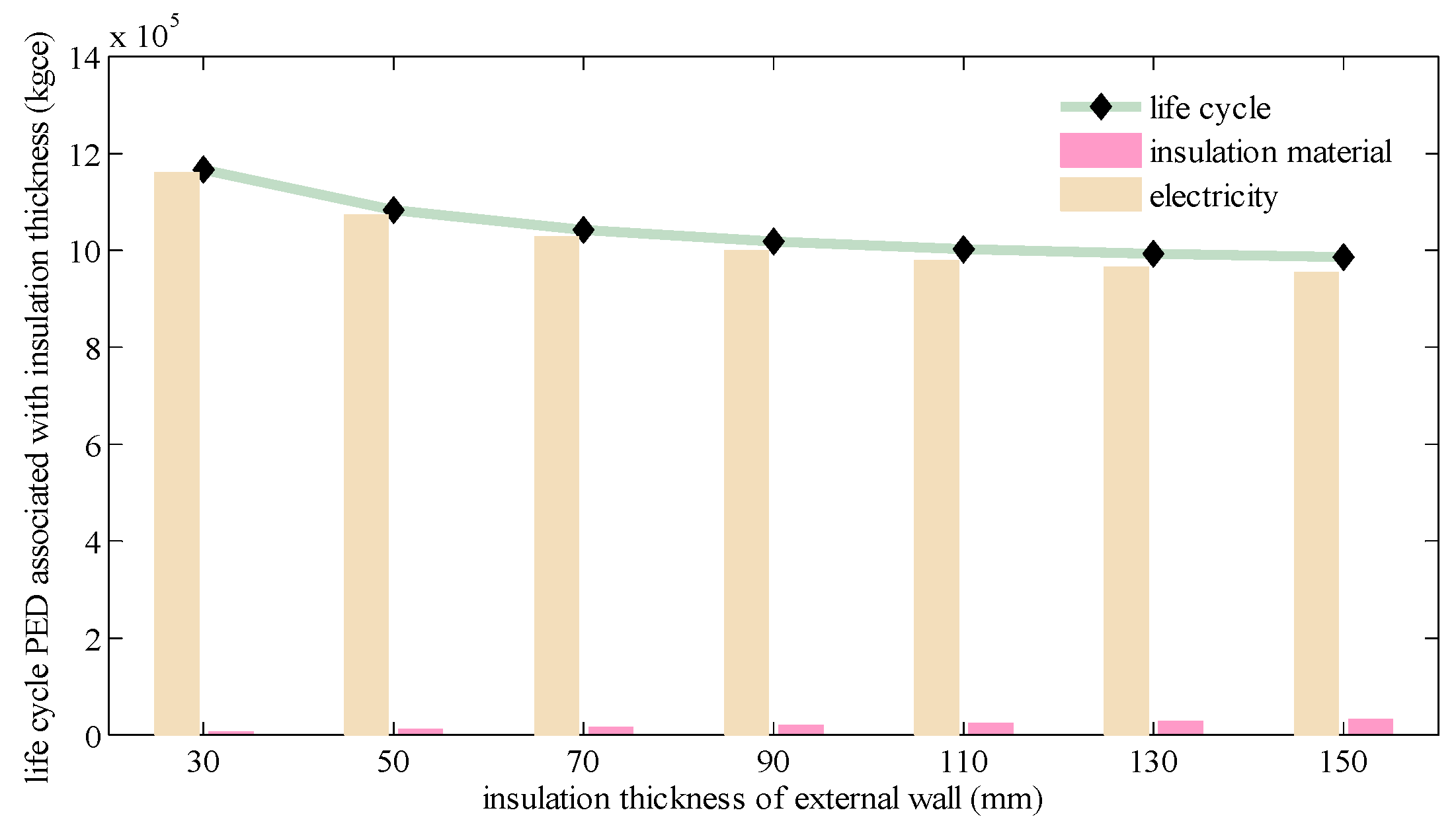

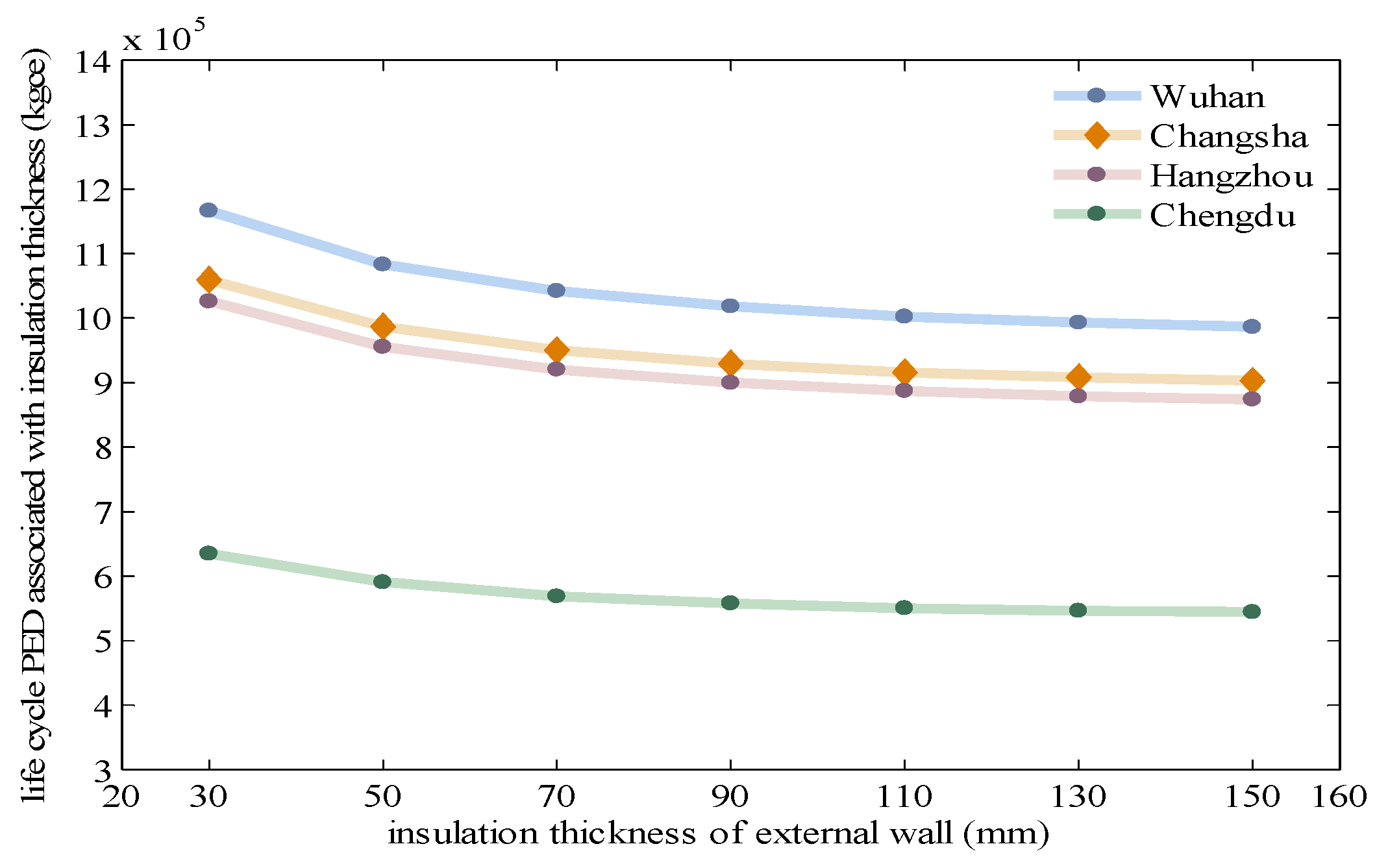

- Life cycle primary energy demand (LPED)

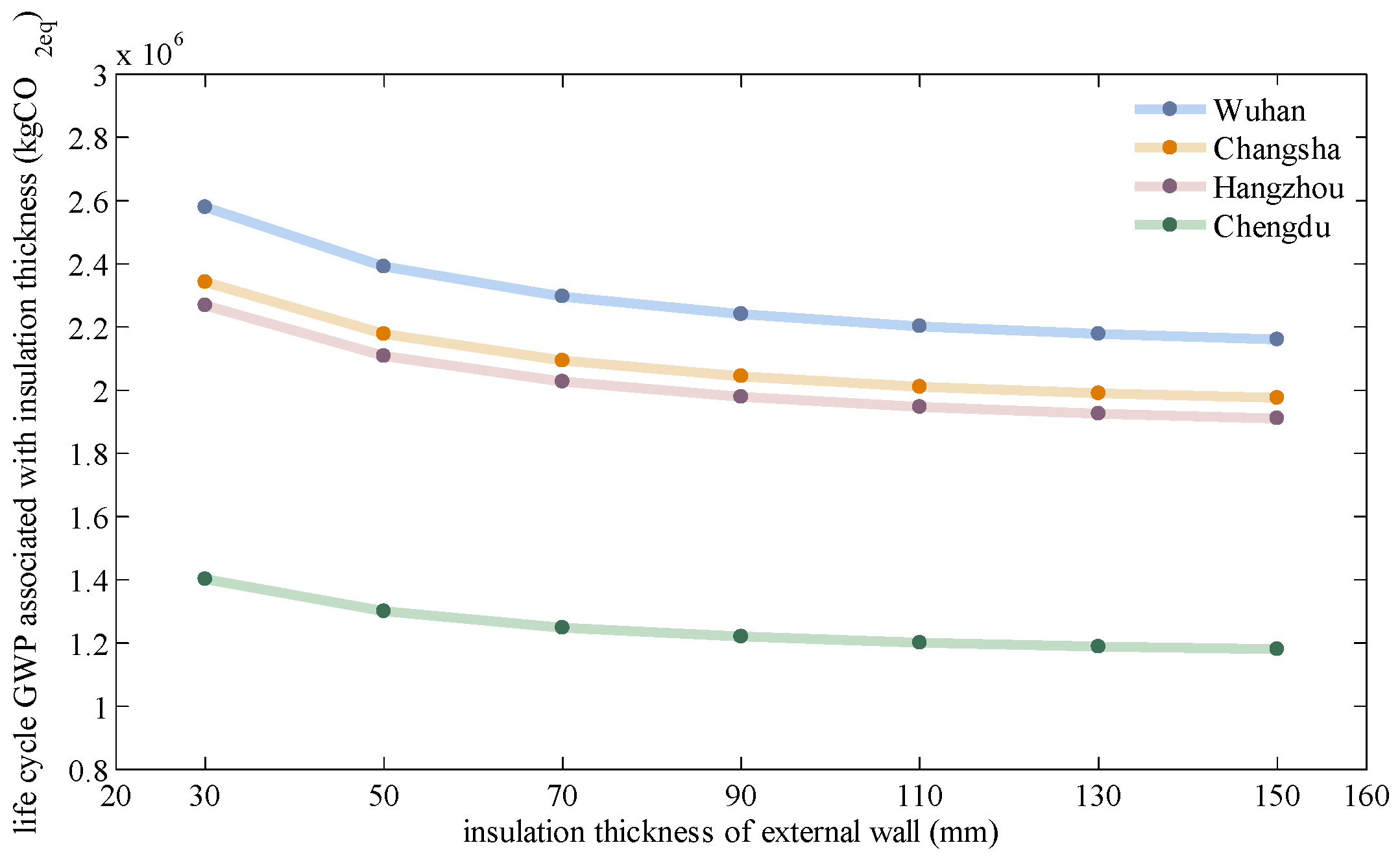

- Life cycle global warming potential (LGWP)

2.3.2. Integrated Estimation Method to Select the OTWRB

3. Results and Discussion

3.1. Operational Energy Consumption and the ITEWB

3.1.1. Impact of Different Cities on the Operational Energy Consumption

3.1.2. Impact of Different Operation Modes of Air Conditioners on the Operational Energy Consumption

3.2. Result of the OTWRB for Four Cities

3.2.1. The OTWRB When Considering Only One Criterion

- Impact of different cities on the OTWRB when only considering one criterion

- Impact of different operation modes on the OTWRB when only considering one criterion

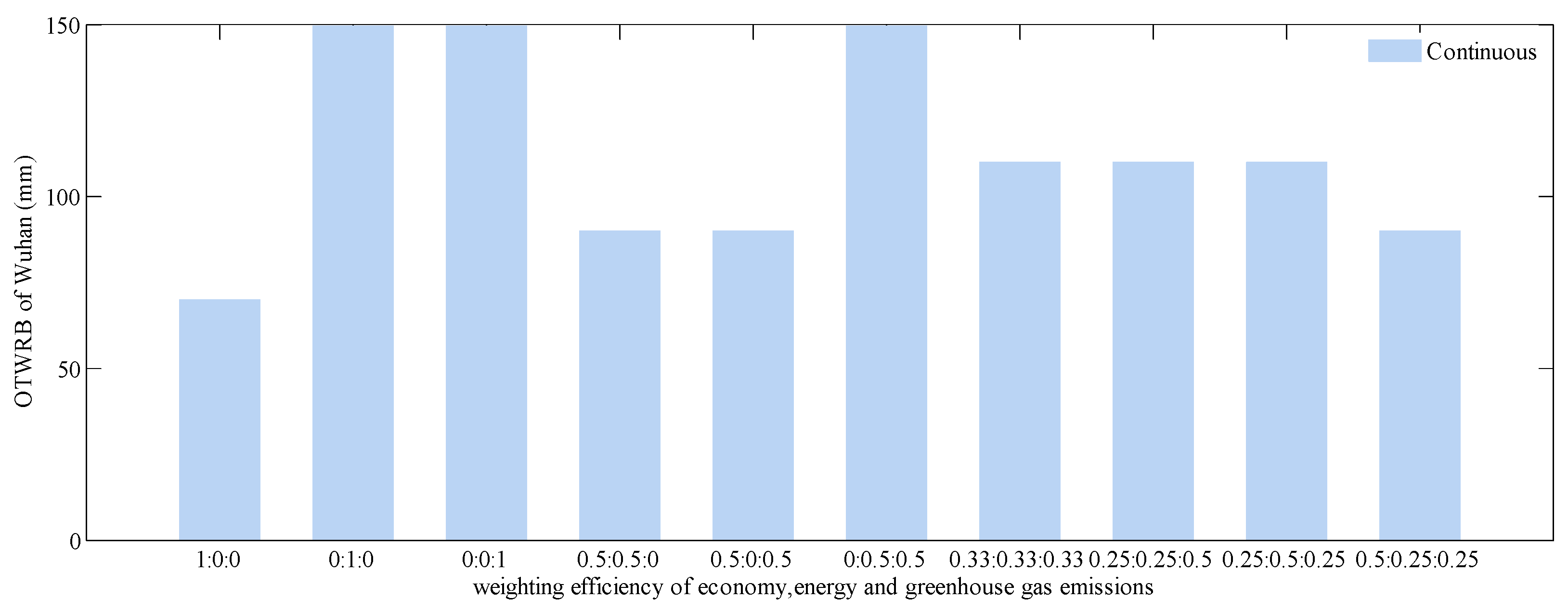

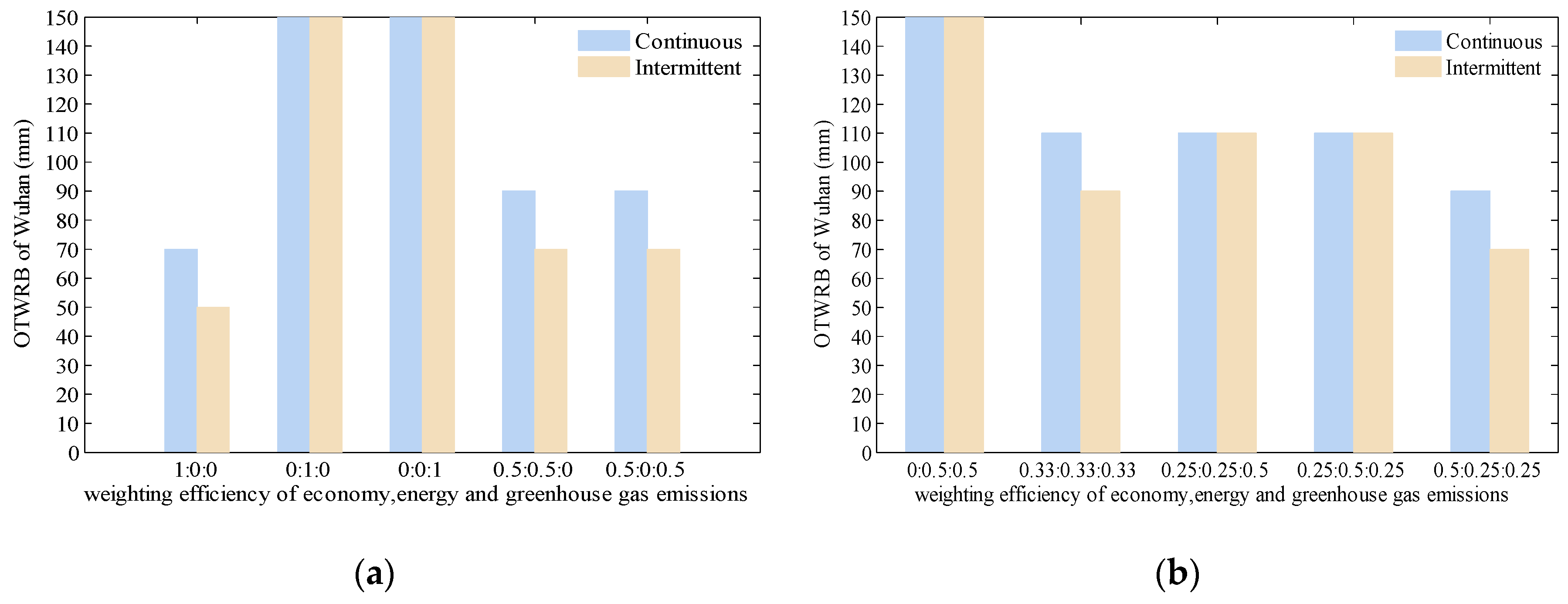

3.2.2. The OTWRB When Considering Different Weighting Efficiencies

- Impact of different cities on the OTWRB when considering different weighting efficiencies

- Impact of different operation modes on the OTWRB when considering different weighting efficiencies

4. Conclusion and Limitations

4.1. Conclusions

- For the continuous operation mode of air conditioners in Wuhan, the optimal economic insulation thickness is 70 mm. When considering only the aspects of energy consumption and greenhouse gas emissions, the optimal value is 150 mm. For different weighting efficiencies assigned to the economy, energy and greenhouse gas emissions, the OTWRB is determined to be 70, 90, 110, or 150 mm. For all these weighting systems, the OTWRB is larger than the current insulation thickness, which is 30 mm.

- When the weighting efficiencies assigned to the economy, energy and greenhouse gas emissions change, the OTWRB might also change. In this paper, when the range of insulation thickness is 30 mm to 150 mm, the minimum OTWRB is achieved when the economic factor is the only criterion. On the other hand, the maximum OTWRB is obtained when sufficient weighting efficiencies are assigned to the energy and greenhouse gas emissions factors. When larger weighting efficiencies applied to the energy and greenhouse gas emissions factors, the OTWRB did not become smaller.

- The different operation modes of air conditioners have a certain impact on the OTWRB based on the results of this study.

- The OTWRB is almost the same for these four cities based on the results of this study. The OTWRB is found to be the largest for Wuhan, which consumes the most operational energy, and smallest for Chengdu, which consumes the least operational energy for the same weighting system.

4.2. Limitations

- The impact of different kinds of intermittent operation modes of space heating and cooling systems on the OTWRB is not considered in this paper.

- A general formula to optimize ITEWB related to meteorological data is not provided in this paper.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Liu, X.; Hu, W. Attention and sentiment of Chinese public toward green buildings based on Sina Weibo. Sustain. Cities Soc. 2019, 44, 550–558. [Google Scholar] [CrossRef]

- Liang, D.; Hanwei, L.; Liguo, Z.; Zhaowen, L.; Zhiqiu, G.; Mingming, H. Highlighting regional eco-industrial development: Life cycle benefits of an urban industrial symbiosis and implications in China. Ecol. Modell. 2017, 164–176. [Google Scholar] [CrossRef]

- Mi, Z.; Wei, Y.M.; Wang, B.; Meng, J.; Liu, Z.; Shan, Y.; Liu, J.; Guan, D. Socioeconomic impact assessment of China’s CO2 emissions peak prior to 2030. J. Clean. Prod. 2017, 142, 2227–2236. [Google Scholar] [CrossRef] [Green Version]

- Huo, T.; Ren, H.; Cai, W. Estimating urban residential building-related energy consumption and energy intensity in China based on improved building stock turnover model. Sci. Total Environ. 2019, 650, 427–437. [Google Scholar] [CrossRef] [PubMed]

- MOHURD. Code of Thermal Design of Civil Building GB 50176-93; Ministry of Housing and Urban-Rural Development, People’s Republic of China: Beijing, China, 1995.

- Cui, Y.; Yan, D.; Chen, C. Exploring the factors and motivations influencing heating behavioral patterns and future energy use intentions in the hot summer and cold winter climate zone of China. Energy Build. 2017, 153, 99–110. [Google Scholar] [CrossRef]

- China National Bureau of Statistics. China Statistical Yearbook 2013; China National Bureau of Statistics: Beijing, China, 2013.

- Gao, Y.; Wu, J.; Cheng, Y. Study on the heating modes in the hot summer and cold winter region in China. Procedia Eng. 2015, 121, 262–267. [Google Scholar] [CrossRef]

- Du, C.; Li, B.; Yu, W.; Liu, H.; Yao, R. Energy flexibility for heating and cooling based on seasonal occupant thermal adaptation in mixed-mode residential buildings. Energy 2019, 189, 116339. [Google Scholar] [CrossRef]

- BERC. China Building Energy Use 2018; BERC: Beijing, China, 2018.

- Ichinose, T.; Lei, L.; Lin, Y. Impacts of shading effect from nearby buildings on heating and cooling energy consumption in hot summer and cold winter zone of China. Energy Build. 2017, 136, 199–210. [Google Scholar] [CrossRef]

- Guo, S.; Yan, D.; Peng, C.; Cui, Y.; Zhou, X.; Hu, S. Investigation and analyses of residential heating in the HSCW climate zone of China: Status quo and key features. Build. Environ. 2015, 94, 532–542. [Google Scholar] [CrossRef]

- Lang, S. Progress in energy-efficiency standards for residential buildings in China. Energy Build. 2004, 36, 1191–1196. [Google Scholar] [CrossRef]

- Barrau, J.; Ibañez, M.; Badia, F. Impact of the optimization criteria on the determination of the insulation thickness. Energy Build. 2014, 76, 459–469. [Google Scholar] [CrossRef]

- Saafi, K.; Daouas, N. A life-cycle cost analysis for an optimum combination of cool coating and thermal insulation of residential building roofs in Tunisia. Energy 2018, 152, 925–938. [Google Scholar] [CrossRef]

- Densley Tingley, D.; Hathway, A.; Davison, B. An environmental impact comparison of external wall insulation types. Build. Environ. 2015, 85, 182–189. [Google Scholar] [CrossRef]

- Nematchoua, M.K.; Raminosoa, C.R.R.; Mamiharijaona, R.; René, T.; Orosa, J.A.; Elvis, W.; Meukam, P. Study of the economical and optimum thermal insulation thickness for buildings in a wet and hot tropical climate: Case of Cameroon. Renew. Sustain. Energy Rev. 2015, 50, 1192–1202. [Google Scholar] [CrossRef] [Green Version]

- Kayfeci, M.; Keçebaş, A.; Gedik, E. Determination of optimum insulation thickness of external walls with two different methods in cooling applications. Appl. Therm. Eng. 2013, 50, 217–224. [Google Scholar] [CrossRef]

- Çomakli, K.; Yüksel, B. Optimum insulation thickness of external walls for energy saving. Appl. Therm. Eng. 2003, 23, 473–479. [Google Scholar] [CrossRef]

- Yu, J.-H.; Yang, C.-Z.; Tian, L.-W.; Liao, D. Research on the optimum insulation thickness of the external wall for residential buildings in Changsha region. Hunan Daxue Xuebao/J. Hunan Univ. Nat. Sci. 2009, 36, 16–21. [Google Scholar]

- Carreras, J.; Boer, D.; Cabeza, L.F.; Jiménez, L.; Guillén-Gosálbez, G. Eco-costs evaluation for the optimal design of buildings with lower environmental impact. Energy Build. 2016, 119, 189–199. [Google Scholar] [CrossRef] [Green Version]

- Lin, F.; Delin, D.; Fuzhen, L. Calculation of economic thermal insulation thicknesses on roof and walls of air-conditionerd buildings. Acta Energiae Solaris Sin. 2002, 23, 711–716. [Google Scholar]

- Huang, R.; Li, L.; Wu, H.L.Z. The economic analysis of building exterior wall thermal insulation material thickness in hot summer and cold winter zone. New Build. Mater. 2017, 9, 105–110. [Google Scholar]

- Fang, R. Theoretical research on envelope insulation effect for residential building with compartmental and intermittent energy consuming method. Ph.D. Thesis, Zhejiang University, Hangzhou, China, 2017. [Google Scholar]

- Li, N.; Chen, Q. Experimental study on heat transfer characteristics of interior walls under partial-space heating mode in hot summer and cold winter zone in China. Appl. Therm. Eng. 2019, 162, 114264. [Google Scholar] [CrossRef]

- Cheng, F.; Zhang, X.X.S. Thermal performance analysis of internal and external insulation for exterior wall of residential building in hot summer and cold winter zone. J. Tongji Univ. Nat. Sci. 2017, 45, 827–832. [Google Scholar]

- Yao, R.; Costanzo, V.; Li, X.; Zhang, Q.; Li, B. The effect of passive measures on thermal comfort and energy conservation. A case study of the hot summer and cold winter climate in the Yangtze River region. J. Build. Eng. 2018, 15, 298–310. [Google Scholar] [CrossRef] [Green Version]

- Fu, X.; Qian, X.; Wang, L. Energy efficiency for airtightness and exterior wall insulation of passive houses in hot summer and cold winter zone of China. Sustainability 2017, 9, 1097. [Google Scholar] [CrossRef] [Green Version]

- Yu, J.; Tian, L.; Yang, C.; Xu, X.; Wang, J. Optimum insulation thickness of residential roof with respect to solar-air degree-hours in hot summer and cold winter zone of china. Energy Build. 2011, 43, 2304–2313. [Google Scholar] [CrossRef]

- Liu, X.; Chen, Y.; Ge, H.; Fazio, P.; Chen, G.; Guo, X. Determination of optimum insulation thickness for building walls with moisture transfer in hot summer and cold winter zone of China. Energy Build. 2015, 109, 361–368. [Google Scholar] [CrossRef]

- Çomaklı, K.; Yüksel, B.; Çomakli, K. Environmental impact of thermal insulation thickness in buildings. Appl. Therm. Eng. 2004, 24, 933–940. [Google Scholar] [CrossRef]

- Ashouri, M.; Astaraei, F.R.; Ghasempour, R.; Ahmadi, M.H.; Feidt, M. Optimum insulation thickness determination of a building wall using exergetic life cycle assessment. Appl. Therm. Eng. 2016, 106, 307–315. [Google Scholar] [CrossRef]

- Jie, P.; Zhang, F.; Fang, Z.; Wang, H.; Zhao, Y. Optimizing the insulation thickness of walls and roofs of existing buildings based on primary energy consumption, global cost and pollutant emissions. Energy 2018, 159, 1132–1147. [Google Scholar] [CrossRef]

- Li, X. Study on the energy saving design of urban heating residential building in southern area of Shaanxi province. Ph.D. Thesis, Xi’an University of Architecture and Technology, Xi’an, China.

- Xiong, Y.; Liu, J.; Kim, J. Understanding differences in thermal comfort between urban and rural residents in hot summer and cold winter climate. Build. Environ. 2019, 165, 106393. [Google Scholar] [CrossRef]

- Liu, H.; Wu, Y.; Li, B.; Cheng, Y.; Yao, R. Seasonal variation of thermal sensations in residential buildings in the Hot Summer and Cold Winter zone of China. Energy Build. 2017, 140, 9–18. [Google Scholar] [CrossRef]

- Li, B.; Du, C.; Yao, R.; Yu, W.; Costanzo, V. Indoor thermal environments in Chinese residential buildings responding to the diversity of climates. Appl. Therm. Eng. 2018, 129, 693–708. [Google Scholar] [CrossRef]

- Ren-da, H.; Li, L.; Huijun, W.; Hui, Z. Analysis on thermal insulation thickness of different wall structures in hot summer and cold winter zone. Bull. Chin. Creamic Soc. 2018, 37, 1829–1835. [Google Scholar]

- Ge, J.; Wu, J.; Chen, S.; Wu, J. Energy efficiency optimization strategies for university research buildings with hot summer and cold winter climate of China based on the adaptive thermal comfort. J. Build. Eng. 2018, 18, 321–330. [Google Scholar] [CrossRef]

- Wang, Y.; Iskandar Jobli, M.; Zheng, C.; Yang, X.; Li, K. Thickness of building external insulation in Chongqing based on intermittent heating supply. Procedia Eng. 2017, 205, 2755–2761. [Google Scholar] [CrossRef]

- Hu, S.; Yan, D.; Cui, Y.; Guo, S. Urban residential heating in hot summer and cold winter zones of China-Status, modeling, and scenarios to 2030. Energy Policy 2016, 92, 158–170. [Google Scholar] [CrossRef]

- Yu, J.; Yang, C.; Tian, L.; Liao, D. Evaluation on energy and thermal performance for residential envelopes in hot summer and cold winter zone of China. Appl. Energy 2009, 86, 1970–1985. [Google Scholar] [CrossRef]

- Jinghua, Y.; Liwei, T.; Changzhi, Y.; Xinhua, X.; Jinbo, W. Sensitivity analysis of energy performance for high-rise residential envelope in hot summer and cold winter zone of China. Energy Build. 2013, 64, 264–274. [Google Scholar] [CrossRef]

- MOHURD. Code of Thermal Design of Civil Buidling GB50176-2016; Ministry of Housing and Urban-Rural Development, People’s Republic of China: Beijing, China, 2016.

- Li, X.; Yao, R.; Yu, W.; Meng, X.; Liu, M.; Short, A.; Li, B. Low carbon heating and cooling of residential buildings in cities in the hot summer and cold winter zone - A bottom-up engineering stock modeling approach. J. Clean. Prod. 2019, 220, 271–288. [Google Scholar] [CrossRef]

- Lihang, Y. The influence of occupant behavior on building energy consumption of residential buildings in hot summer and cold winter zone. Master’s Thesis, Zhejiang University, Hangzhou, China, 2016. [Google Scholar]

- Chen, S.; Wang, X.; Lun, I.; Chen, Y.; Wu, J.; Ge, J. Effect of inhabitant behavioral responses on adaptive thermal comfort under hot summer and cold winter climate in China. Build. Environ. 2020, 168, 106492. [Google Scholar] [CrossRef]

- Zhang, G.; Li, X.; Shi, W.; Wang, B.; Li, Z.; Cao, Y. Simulations of the energy performance of variable refrigerant flow system in representative operation modes for residential buildings in the hot summer and cold winter region in China. Energy Build. 2018, 174, 414–427. [Google Scholar] [CrossRef]

- Yu, J.; Yang, C.; Tian, L.; Liao, D. A study on optimum insulation thicknesses of external walls in hot summer and cold winter zone of China. Appl. Energy 2009, 86, 2520–2529. [Google Scholar] [CrossRef]

- Wang, Z.; Zhao, Z.; Lin, B.; Zhu, Y.; Ouyang, Q. Residential heating energy consumption modeling through a bottom-up approach for China’s Hot Summer-Cold Winter climatic region. Energy Build. 2015, 109, 65–74. [Google Scholar] [CrossRef]

- Songqin, L.; Changzhi, Y.; Hongqiang, L.; Yingjie, M. Analysis on influence of solar radiation on building envelope energy consumption in hot summer and cold winter zone. J. Hunan Univ. 2018, 45, 149–156. [Google Scholar]

- Kheiri, F. A review on optimization methods applied in energy-efficient building geometry and envelope design. Renew. Sustain. Energy Rev. 2018, 92, 897–920. [Google Scholar] [CrossRef]

- Amiri Rad, E.; Fallahi, E. Optimizing the insulation thickness of external wall by a novel 3E (energy, environmental, economic) method. Constr. Build. Mater. 2019, 205, 196–212. [Google Scholar] [CrossRef]

- Ozel, M. Effect of insulation location on dynamic heat-transfer characteristics of building external walls and optimization of insulation thickness. Energy Build. 2014, 72, 288–295. [Google Scholar] [CrossRef]

- He, L.-s.; Jian, G.; Hua-cun, L.; Chuan-hong, J. Optimization of insulation layer thickness of inward-outward combined insulation enclosure system in hot summer and cold winter zone. Archit. Technol. 2016, 47, 75–76. [Google Scholar]

- Blight, T.S.; Coley, D.A. Sensitivity analysis of the effect of occupant behaviour on the energy consumption of passive house dwellings. Energy Build. 2013, 66, 183–192. [Google Scholar] [CrossRef]

- Kandar, M.Z.; Nimlyat, P.S.; Abdullahi, M.G.; Dodo, Y.A. Influence of inclined wall self-shading strategy on office building heat gain and energy performance in hot humid climate of Malaysia. Heliyon 2019, 5. [Google Scholar] [CrossRef]

- Xi, C.; Hongxing, Y. Combined thermal and daylight analysis of a typical public rental housing development to fulfil green building guidance in Hong Kong. Energy Build. 2015, 108, 420–432. [Google Scholar] [CrossRef]

- Zune, M.; Rodrigues, L.; Gillott, M. Vernacular passive design in Myanmar housing for thermal comfort. Sustain. Cities Soc. 2020, 54, 101992. [Google Scholar] [CrossRef]

- Lu, S.; Tang, X.; Ji, L.; Tu, D. Research on energy-saving optimization for the performance parameters of rural-building shape and envelope by trnsys-genopt in hot summer and cold winter zone of China. Sustainability 2017, 9, 294. [Google Scholar] [CrossRef] [Green Version]

- Linsen, M. Energy saving effect of internal and external themal insulation in hot summer and cold winter area. Archit. Cult. 2016, 4, 158–159. [Google Scholar]

- Çetintaş, K.F.; Yılmaz, Z. A new approach to determine insulation material and thickness from a life-cycle perspective. Proc. Inst. Civ. Eng. - Energy 2017, 171, 171–181. [Google Scholar] [CrossRef]

- Sartori, I.; Hestnes, A.G. Energy use in the life cycle of conventional and low-energy buildings: A review article. Energy Build. 2007, 39, 249–257. [Google Scholar] [CrossRef]

- Tian, X.; Wu, Y.; Hou, P.; Liang, S.; Qu, S.; Xu, M.; Zuo, T. Environmental impact and economic assessment of secondary lead production: Comparison of main spent lead-acid battery recycling processes in China. J. Clean. Prod. 2017, 144, 142–148. [Google Scholar] [CrossRef]

- Shariah, A.; Tashtoush, B.; Rousan, A. Cooling and heating loads in residential buildings in Jordan. Energy Build. 1997, 26, 137–143. [Google Scholar] [CrossRef]

- Lianying, Z.; Yuan, W.; Jiyuan, Z.; Xing, L.; Linhua, Z. Numerical study of effects of wall’s insulation thickness on energy performance for different climatic regions of China. Energy Procedia 2015, 75, 1290–1298. [Google Scholar] [CrossRef] [Green Version]

- Masoso, O.T.; Grobler, L.J. A new and innovative look at anti-insulation behaviour in building energy consumption. Energy Build. 2008, 40, 1889–1894. [Google Scholar] [CrossRef]

- Yuan, J. Impact of insulation type and thickness on the dynamic thermal characteristics of an external wall structure. Sustainability 2018, 10, 2835. [Google Scholar] [CrossRef] [Green Version]

- Miaomiao, X.; Zhou, J. Life cycle assessment on insulation board of expanded polystyrene. New Build. Mater. 2015, 42, 74–77. [Google Scholar]

- Dombayci, Ö.A.; Gölcü, M.; Pancar, Y. Optimization of insulation thickness for external walls using different energy-sources. Appl. Energy 2006, 83, 921–928. [Google Scholar] [CrossRef]

| Resource | Storey | Construction | Plane Form | Floor Area per Household |

|---|---|---|---|---|

| This paper | 12 (multi-story) | reinforced concrete | three bedrooms, one living room and one dining room | around 112 m2 (about 100 m2) |

| Reference | [35] | [9,36,37] | [9] | [12] |

| Resource | U Value of the Building Component (w/m2k) | ||

|---|---|---|---|

| Ground/Exposed Floor | Roof | Window | |

| this paper | 1.79 | 0.77 | 2.67 |

| [34] | ------ | 0.785 | 2.8 |

| Layer (Outside to Inside) | Thickness (mm) |

|---|---|

| Cement mortar | 20 |

| Expanded polystyrene | 30 |

| Reinforced concrete | 200 |

| Cement mortar | 20 |

| Factor | Assumption | Reference |

|---|---|---|

| Equipment heat gain | 4.3 W/m2 | [43] |

| Heating space | Living room and bedroom | [44] |

| Cooling space | Living room and bedroom | [44] |

| Heating period | From 1st December to 28th February of the following year | [45] |

| Cooling period | From 15th June to 15th September | [34] |

| Heating setpoint temperature | 18 °C | [43,45] |

| Heating trigger temperature | 16 °C | [46] |

| Cooling setpoint temperature | 26 °C | [43,45] |

| Cooling trigger temperature | 29 °C | [47] |

| Infiltration rate (ach) | 1.0/h | [43,48] |

| Coefficient of performance (COP) of Heating system | 1.9 | [30,43,49] |

| Coefficient of performance (COP) of Cooling system | 2.3 | [30,43,49] |

| Scenario | Space | Daily Operation Time | Reference |

|---|---|---|---|

| Continuous | Bedroom | 0:00–24:00 | [44] |

| Living room | 0:00–24:00 | ||

| Intermittent | Bedroom | 0:00–8:00 | [50] |

| 22:00–24:00 | |||

| Living room | 17:00–22:00 |

| Location | Annual Average | HDD | CDD | |||

|---|---|---|---|---|---|---|

| Dry-Bulb Temperature (°C) | Wind Speed (m/s) | Global Radiation (W/m2) | External RH (%) | |||

| Wuhan | 15.89 | 2.32 | 163.14 | 76.55 | 1122.62 | 224.12 |

| Changsha | 16.31 | 2.36 | 151.28 | 80.91 | 1020.10 | 220.78 |

| Hangzhou | 15.51 | 2.50 | 152.97 | 77.72 | 1094.81 | 169.78 |

| Chengdu | 15.76 | 1.08 | 146.03 | 81.04 | 949.50 | 14.40 |

| Paper Resource | U Value of the External Wall (w/m2k) | Heating Energy Consumption (kwh/m2) | Cooling Energy Consumption (kwh/m2) | Annual Energy Consumption (kwh/m2) |

|---|---|---|---|---|

| This paper | 0.75 | 25.11 | 12.06 | 39.40 |

| [46] | 0.72 | 26 | 12.5 | 38.5 |

| [60] | 0.87 | ---- | ---- | 18–38 |

| [61] | 0.84 | --- | ---- | 43.42 |

| Abbreviation | Explain | Units |

|---|---|---|

| Life cycle cost of the ITEWB | yuan | |

| Life cycle cost of insulation material associated with the ITEWB | yuan | |

| Life cycle cost of operational energy associated with the ITEWB | yuan | |

| Cost of insulation material per unit | yuan/m3 | |

| Area of external wall | m2 | |

| The thickness of the insulation layer | mm | |

| Cost of operational energy per unit | yuan/kwh | |

| Annual operational energy consumption | kwh/year | |

| Insulation layer lifetime | year | |

| Present worth factor (PWF) | -- | |

| Interest rate | -- | |

| Inflation rate | -- |

| Abbreviation | Definition | Units |

|---|---|---|

| The density of the insulation material | kg/m3 | |

| Life cycle primary energy demand of the ITEWB | kgce | |

| Life cycle primary energy demand of insulation material associated with the ITEWB | kgce | |

| Life cycle primary energy demand of operational energy associated with the ITEWB | kgce | |

| Primary energy demand of insulation material per unit | kgce/kg | |

| Primary energy demand of operational energy per unit | kgce/kwh |

| Abbreviation | Definition | Units |

|---|---|---|

| Life cycle global warming potential of the ITEWB | kgCO2eq | |

| Life cycle global warming potential of insulation material associated with the ITEWB | kgCO2eq | |

| Life cycle global warming potential of operational energy associated with the ITEWB | kgCO2eq | |

| Global warming potential of insulation material per unit | kgCO2eq/kg | |

| Global warming potential of operational energy per unit | kgCO2eq/kwh |

| Abbreviation | Definition |

|---|---|

| Normalized life cycle cost of the ITEWB | |

| Normalized life cycle primary energy demand of ITEWB | |

| Normalized life cycle global warming potential of ITEWB | |

| The minimum life cycle cost of ITEWB | |

| The maximum life cycle cost of ITEWB | |

| The minimum life cycle primary energy demand of ITEWB | |

| The maximum life cycle primary energy demand of ITEWB | |

| The minimum life cycle global warming potential of ITEWB | |

| The maximum life cycle global warming potential of ITEWB | |

| Weighting efficiency assigned to economy, energy and greenhouse gas emissions | |

| r | Insulation thickness, which is 30, 50, 70, 90, 110, 130, 150 mm in this paper |

| Parameter | Value | Unit |

|---|---|---|

| i | 1% | --- |

| d | 5% | --- |

| 20 | year | |

| 13.50 | --- | |

| 30 | kg/m3 | |

| 600 | yuan/m3 | |

| 0.52 | yuan/kwh | |

| 3.95 | kgce/kg | |

| 0.46 | kgce/kwh | |

| 5.64 | kgCO2eq/kg | |

| 1.01 | kgCO2eq/kwh |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Chen, X.; Shahrestani, M. Optimization of Insulation Thickness of External Walls of Residential Buildings in Hot Summer and Cold Winter Zone of China. Sustainability 2020, 12, 1574. https://doi.org/10.3390/su12041574

Liu X, Chen X, Shahrestani M. Optimization of Insulation Thickness of External Walls of Residential Buildings in Hot Summer and Cold Winter Zone of China. Sustainability. 2020; 12(4):1574. https://doi.org/10.3390/su12041574

Chicago/Turabian StyleLiu, Xiaojun, Xin Chen, and Mehdi Shahrestani. 2020. "Optimization of Insulation Thickness of External Walls of Residential Buildings in Hot Summer and Cold Winter Zone of China" Sustainability 12, no. 4: 1574. https://doi.org/10.3390/su12041574

APA StyleLiu, X., Chen, X., & Shahrestani, M. (2020). Optimization of Insulation Thickness of External Walls of Residential Buildings in Hot Summer and Cold Winter Zone of China. Sustainability, 12(4), 1574. https://doi.org/10.3390/su12041574