A Didactic Pedagogical Approach toward Sustainable Architectural Education through Robotic Tectonics

Abstract

:1. Introduction

2. A Pedagogical Framework for Robotic Tectonics

2.1. Parametric Design: A Parametric Model-Based Design Conception

2.2. Cross-Data Simulation: A Robot-Oriented Integral Data Virtual Simulation

2.3. Robotic Application: Construction-Aimed Robot End Effector Development

2.4. Robotic Construction: Robotic Tectonics Represented through Automated Construction

3. Robotic Tectonics Teaching Practices: Toward a Sustainable Architectural Education

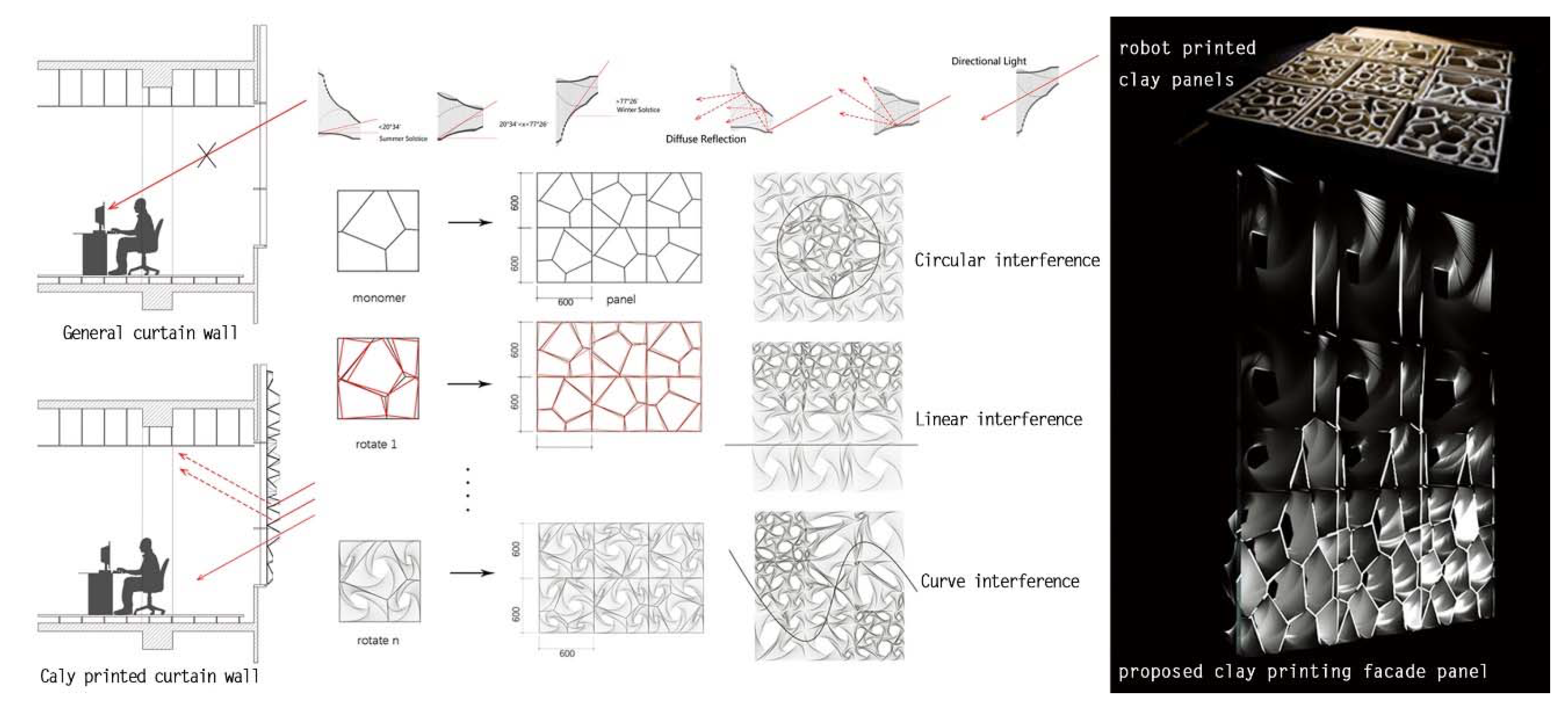

3.1. Robotic Clay Printing

3.2. Robotic Foam Cutting

3.3. Robotic 3D Spatial Printing

3.4. Robotic Wood Assembly

4. Discussion and Conclusions

- Parametric design has already had a remarkable effect on sustainable architectural design. Its logical workflow could easily bring interdisciplinary techniques of design and construction together for testing, generating, and analysis in a digital environment. As the first component of the pedagogy, parametric design asks students to focus on the digital modeling of design concepts through the lens of parametric logic. In this stage, the logic-based digital architectural model is established and becomes a platform for the upcoming simulation, application, experimentation, and modification of the design. By benefiting the user in time-sensitive, dynamic design scenarios, parametric design could help students explore more design possibilities. Take “Robotic Clay Printing” as an example. Through parametric design, we guided students to experiment with the Voronoi algorithm in order to achieve a creative solution for building more efficient ventilation panels. Once printed and analyzed, it was clear that this experiment brought novel sustainability and critical thinking concepts into their design processes.

- Cross-data simulation requires students to understand different types of data (such as fabrication constraints and tool-path data) and merge them into one virtual simulated environment, which provides a safe method for students or architects to analyze every detailed step of the construction process before its implementation. There is no doubt that doing so will significantly reduce the risk of production error, thereby saving material, labor, time, and cost. In the case of “Robotic Foam Cutting,” the simulation revealed the process of cutting an infinite complex surface via its tool path. Through this robot-oriented simulation process, we are helping students to create new forms and spaces with minimum material use and almost zero waste in fabrication.

- Robotic application acts as a critical component of the robotic construction process in that it is the main bridge between digital simulation and physical construction. Only with an end effector’s exquisite design and efficient operation can the project achieve the precision necessary for more sustainable design. This stage helps students to realize how to deal with new materials, fabrication tools, operation constraints, mechanical and electronic design, and tool development. It is an interdisciplinary stage where the physicality of the final product must finally be considered. In the case of “Robotic 3D Spatial Printing,” we helped students develop the PLA extruder end effector, which dealt with sensitive control of the printing temperature and coordination between the extruding speed and tool path. This experiment was able to improve the sustainability of the project through the fabrication of complex components without a support system, in less time, and with minimal material.

- Robotic construction exemplifies how robotic tectonic practices might achieve our goal of architectural sustainability in the digital era. It represents the comprehensive stage for students to operate, test, build, collaborate, and ultimately achieve their initial design concept. Here, the students may also garner the most insight for new design concepts, as the constraints of the physical world are most obvious. For “Robotic Wood Assembly,” precision, efficiency, material economy, and human–robot collaboration processes gave all the participants remarkable insight for the potential for sustainability through robotic tectonics and automated construction.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Healey, P.; Shaw, T. Planners, plans and sustainable development. Reg. Stud. 1993, 27, 769–776. [Google Scholar] [CrossRef]

- UN General Assembly. 2005 World Summit Outcome; UN General Assembly: New York, NY, USA, 2005. [Google Scholar]

- Porritt, J. Capitalism as If the World Matters; Routledge: Abingdon-on-Thames, UK, 2005. [Google Scholar]

- Capra, F.; Luisi, P.L. The Systems View of Life: A Unifying Vision; Cambridge University Press: Cambridge, UK, 2014. [Google Scholar]

- Ayres, R.U.; Turton, H.; Casten, T. Energy efficiency, sustainability and economic growth. Energy 2007, 32, 634–648. [Google Scholar] [CrossRef]

- Chang, J.; Leung, D.Y.C.; Wu, C.Z.; Yuan, Z.H. A review on the energy production, consumption, and prospect of renewable energy in China. Renew. Sustain. Energy Rev. 2003, 7, 453–468. [Google Scholar] [CrossRef]

- Du Pisani, J.A. Sustainable development—Historical roots of the concept. Environ. Sci. 2006, 3, 83–96. [Google Scholar] [CrossRef]

- Mokyr, J. Chapter 2—The contribution of economic history to the study of innovation and technical change: 1750–1914. In Handbook of the Economics of Innovation; Hall, B.H., Rosenberg, N., Eds.; North-Holland: Amsterdam, The Netherlands, 2010; Volume 1, pp. 11–50. [Google Scholar]

- Gerbert, P.; Castagnino, S.; Rothballer, C.; Renz, A.; Filitz, R. Digital-in-Engineering-and-Construction; Boston Consulting Group: Boston, MA, USA, 2016; pp. 1–22. [Google Scholar]

- Parliament, E. Directive 2010/31/EU of the European parliament and of the council of 19 May 2010 on the energy performance of buildings. Off. J. Eur. Union 2010, 18, 153. [Google Scholar]

- U.S. Bureau of Labor Statistics. Construction Laborers and Helpers_Occupational Outlook Handbook; U.S. Bureau of Labor Statistics: Washington, DC, USA, 2019. [Google Scholar]

- Chen, Q.; García de Soto, B.; Adey, B.T. Construction automation: Research areas, industry concerns and suggestions for advancement. Autom. Constr. 2018, 94, 22–38. [Google Scholar] [CrossRef]

- García de Soto, B.; Agustí-Juan, I.; Hunhevicz, J.; Joss, S.; Graser, K.; Habert, G.; Adey, B.T. Productivity of digital fabrication in construction: Cost and time analysis of a robotically built wall. Autom. Constr. 2018, 92, 297–311. [Google Scholar] [CrossRef]

- Yuan, P.F.; Leach, N.; Menges, A. Digital Fabrication; Tongji University Press Co., Ltd.: Shanghai, China, 2018. [Google Scholar]

- Yuan, P.F.; Meng, H.; Devadass, P. Performative tectonics. In Robotic Fabrication in Architecture, Art and Design 2014; McGee, W., Ponce de Leon, M., Eds.; Springer International Publishing: Cham, Switzerland, 2014; pp. 181–195. [Google Scholar] [CrossRef]

- Austern, G.; Capeluto, I.G.; Grobman, Y.J. Rationalization methods in computer aided fabrication: A critical review. Autom. Constr. 2018, 90, 281–293. [Google Scholar] [CrossRef]

- Leach, N.; Yuan, P.F. Computational Design; Tongji University Press Company Limited: Shanghai, China, 2018. [Google Scholar]

- Leach, N.; Xu, W.G. Emerging Talents, Emerging Technologies; China Architecture & Building Press: Beijing, China, 2006; pp. 6–15. [Google Scholar]

- Yuan, P. Parametric regionalism. Archit. Des. 2016, 86, 92–99. [Google Scholar] [CrossRef]

- Gramazio, F.; Kohler, M. Digital Materiality in Architecture; Lars Müller Publishers: Baden, Switzerland, 2008. [Google Scholar]

- Mavromatidis, L. Constructal macroscale thermodynamic model of spherical urban greenhouse form with double thermal envelope within heat currents. Sustainability 2019, 11, 3897. [Google Scholar] [CrossRef] [Green Version]

- Mavromatidis, L. Linking wide-ranging geometrical and non-geometrical glazing options for daylight effectiveness estimation at an early design stage. Energy Procedia 2015, 78, 711–716. [Google Scholar] [CrossRef] [Green Version]

- Mavromatidis, L. Coupling architectural synthesis to applied thermal engineering, constructal thermodynamics and fractal analysis: An original pedagogic method to incorporate “sustainability” into architectural education during the initial conceptual stages. Sustain. Cities Soc. 2018, 39, 689–707. [Google Scholar] [CrossRef]

- Bejan, A. Sustainability: The water and energy problem, and the natural design solution. Eur. Rev. 2015, 23, 481–488. [Google Scholar] [CrossRef]

- Bock, T. The future of construction automation: Technological disruption and the upcoming ubiquity of robotics. Autom. Constr. 2015, 59, 113–121. [Google Scholar] [CrossRef]

- Bock, T.; Linner, T. Construction Robots—Elementary Technologies and Single-Task Construction Robots; Cambridge University Press: Cambridge, UK, 2017. [Google Scholar] [CrossRef]

- Gramazio, F.; Kohler, M.; Willmann, J. The Robotic Touch. How Robots Change Architecture: Gramazio & Kohler Research ETH Zurich 2005–2013; Park Books: Zürich, Switzerland, 2014. [Google Scholar]

- Mateus, R.; Bragança, L. Sustainability assessment and rating of buildings: Developing the methodology SBToolPT–H. Build. Environ. 2011, 46, 1962–1971. [Google Scholar] [CrossRef]

- Ursprung, P. Matter and Memory: Archi-Union’s Surfaces; Yuan, P.F., Ed.; Oscar Riera Ojeda Publishers: Shenzhen, China, 2018; p. 219. [Google Scholar]

- Picon, A. Futurism and nostalgia aside: Digital design and fabrication according to Archi-Union”, préface à Philip F. Yuan. In Collaborative laboratory Works of Archi-Union and Fab-Union; Oscar Riera Publishers: Hong Kong, China, 2018; pp. 12–17. [Google Scholar]

- Bock, T.; Linner, T. Robotic Industrialization: Automation and Robotic Technologies for Customized Component, Module, and Building Prefabrication; Cambridge University Press: Cambridge, UK, 2015; pp. 1–238. [Google Scholar] [CrossRef] [Green Version]

- Yablonina, A.; Prado, M.; Baharlou, M.; Schwinn, E.; Menges, T. Fabricate rethinking design and construction. In Proceedings of the Fabricate Conference, Stuttgart, Germany, 2017; pp. 202–209. [Google Scholar]

- Leach, N. Digital morphogenesis. Archit. Des. 2009, 79, 32–37. [Google Scholar] [CrossRef]

- Bechthold, M. The return of the future: A second go at robotic construction. Archit. Des. 2010, 80, 116–121. [Google Scholar] [CrossRef]

- Wei-Guo, X. Parametric Non-linear Architecture Design; Tsinghua University: Beijing, China, 2016; pp. 190–191. [Google Scholar]

- Wei-Guo, X. Ditigal Architecture Design Works; Tsinghua University: Beijing, China, 2016. [Google Scholar]

- Karslı, U.T.; Özker, S. The contributions of workshops on formal interior architecture education. Procedia Soc. Behav. Sci. 2014, 152, 47–52. [Google Scholar] [CrossRef] [Green Version]

- Fien, J.; Tilbury, D. The global challenge of sustainability. Educ. Sustain. Respond. Glob. Chall. 2002, 1, 204. [Google Scholar]

- Porras Álvarez, S.; Lee, K.; Park, J.; Rieh, S.Y. A comparative study on sustainability in architectural education in Asia—With a focus on professional degree curricula. Sustainability 2016, 8, 290. [Google Scholar] [CrossRef] [Green Version]

- Rahman, A. Greening the architectural curriculum in all the malaysian institutes of higher learning—It is not an option. Archnet Int. J. Archit. Res. 2010, 4. [Google Scholar] [CrossRef]

- Altomonte, S. Sustainable Architectural Education—White Paper; EDUCATE Press: Nottingham, UK, 2012; p. 38. [Google Scholar]

- Hensel, M.; Menges, A.; Weinstock, M. Emergence: Morphogenetic Design Strategies; Wiley-Academy: Chichester, UK, 2004. [Google Scholar]

- Stumm, S.; Braumann, J.; von Hilchen, M.; Brell-Cokcan, S. On-site robotic construction assistance for assembly using a-priori knowledge and human-robot collaboration. In Proceedings of the Advances in Robot Design and Intelligent Control, Belgrade, Serbia, 30 June–2 July 2016; pp. 583–592. [Google Scholar]

- Keating, S.; Oxman, N. Compound fabrication: A multi-functional robotic platform for digital design and fabrication. Robot. Comput. Integr. Manuf. 2013, 29, 439–448. [Google Scholar] [CrossRef]

- Friedman, J.; Kim, H.; Mesa, O. Experiments in additive clay depositions. In Robotic Fabrication in Architecture, Art and Design 2014; McGee, W., Ponce de Leon, M., Eds.; Springer International Publishing: Cham, Switzerland, 2014; pp. 261–272. [Google Scholar] [CrossRef]

- Melnikova, R.; Ehrmann, A.; Finsterbusch, K. 3D printing of textile-based structures by Fused Deposition Modelling (FDM) with different polymer materials. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Ningbo, China, 27–29 May 2014; p. 012018. [Google Scholar]

- Yuan, P.F.; Meng, H.; Yu, L.; Zhang, L. Robotic Multi-dimensional Printing Based on Structural Performance. In Robotic Fabrication in Architecture, Art and Design 2016; Reinhardt, D., Saunders, R., Burry, J., Eds.; Springer International Publishing: Cham, Switzerland, 2016; pp. 92–105. [Google Scholar] [CrossRef]

- Gaub, H. Customization of mass-produced parts by combining injection molding and additive manufacturing with Industry 4.0 technologies. Reinf. Plast. 2016, 60, 401–404. [Google Scholar] [CrossRef]

- Menges, A.; Schwinn, T.; Krieg, O.D. Advancing Wood Architecture: A Computational Approach; Routledge: Abingdon, UK, 2016. [Google Scholar]

- Willmann, J.; Knauss, M.; Bonwetsch, T.; Apolinarska, A.A.; Gramazio, F.; Kohler, M. Robotic timber construction—Expanding additive fabrication to new dimensions. Autom. Constr. 2016, 61, 16–23. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, X.; Fang, X.; Chen, Z.; Phillips, T.K.; Fukuda, H. A Didactic Pedagogical Approach toward Sustainable Architectural Education through Robotic Tectonics. Sustainability 2020, 12, 1757. https://doi.org/10.3390/su12051757

Shi X, Fang X, Chen Z, Phillips TK, Fukuda H. A Didactic Pedagogical Approach toward Sustainable Architectural Education through Robotic Tectonics. Sustainability. 2020; 12(5):1757. https://doi.org/10.3390/su12051757

Chicago/Turabian StyleShi, Xinyu, Xue Fang, Zhoufan Chen, Tyson Keen Phillips, and Hiroatsu Fukuda. 2020. "A Didactic Pedagogical Approach toward Sustainable Architectural Education through Robotic Tectonics" Sustainability 12, no. 5: 1757. https://doi.org/10.3390/su12051757

APA StyleShi, X., Fang, X., Chen, Z., Phillips, T. K., & Fukuda, H. (2020). A Didactic Pedagogical Approach toward Sustainable Architectural Education through Robotic Tectonics. Sustainability, 12(5), 1757. https://doi.org/10.3390/su12051757