Response Surface Methodology to Optimize Methane Production from Mesophilic Anaerobic Co-Digestion of Oily-Biological Sludge and Sugarcane Bagasse

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Pre-treatment of Oily-Biological Sludge and Sugarcane Bagasse

2.3. Analytical Methods

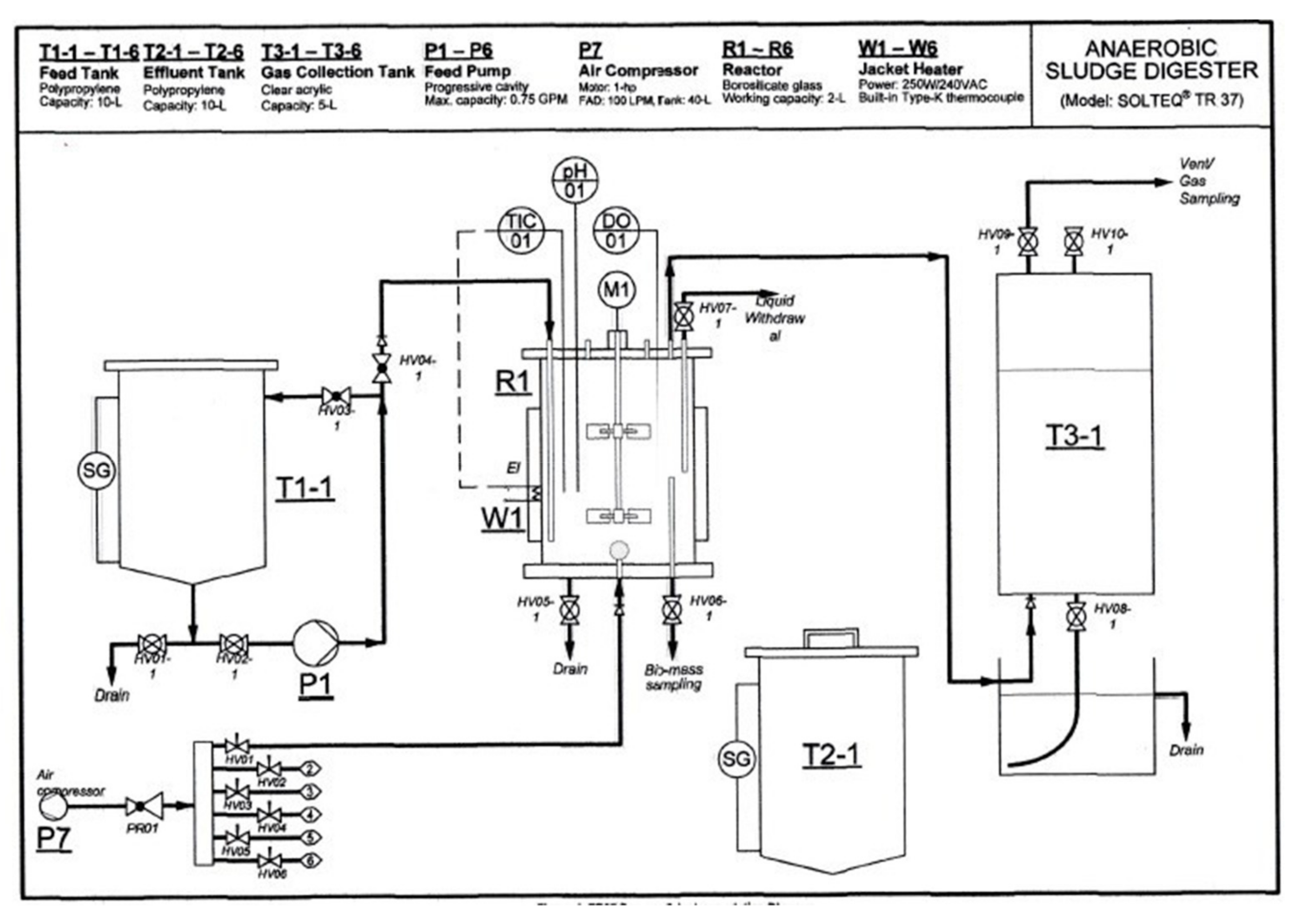

2.4. Experimental Procedures

2.5. Experimental Design Through CCD-RSM

| R | = C/N ratio; |

| Q1, Q2 | = mass of materials “as is” or wet weight; |

| C1, C2 | = carbon content of materials (%); |

| N1, N2 | = nitrogen content of materials (%); |

| M1, M2 | = moisture content of materials. |

2.6. Setup of Experiment Operational Conditions

3. Results and Discussion

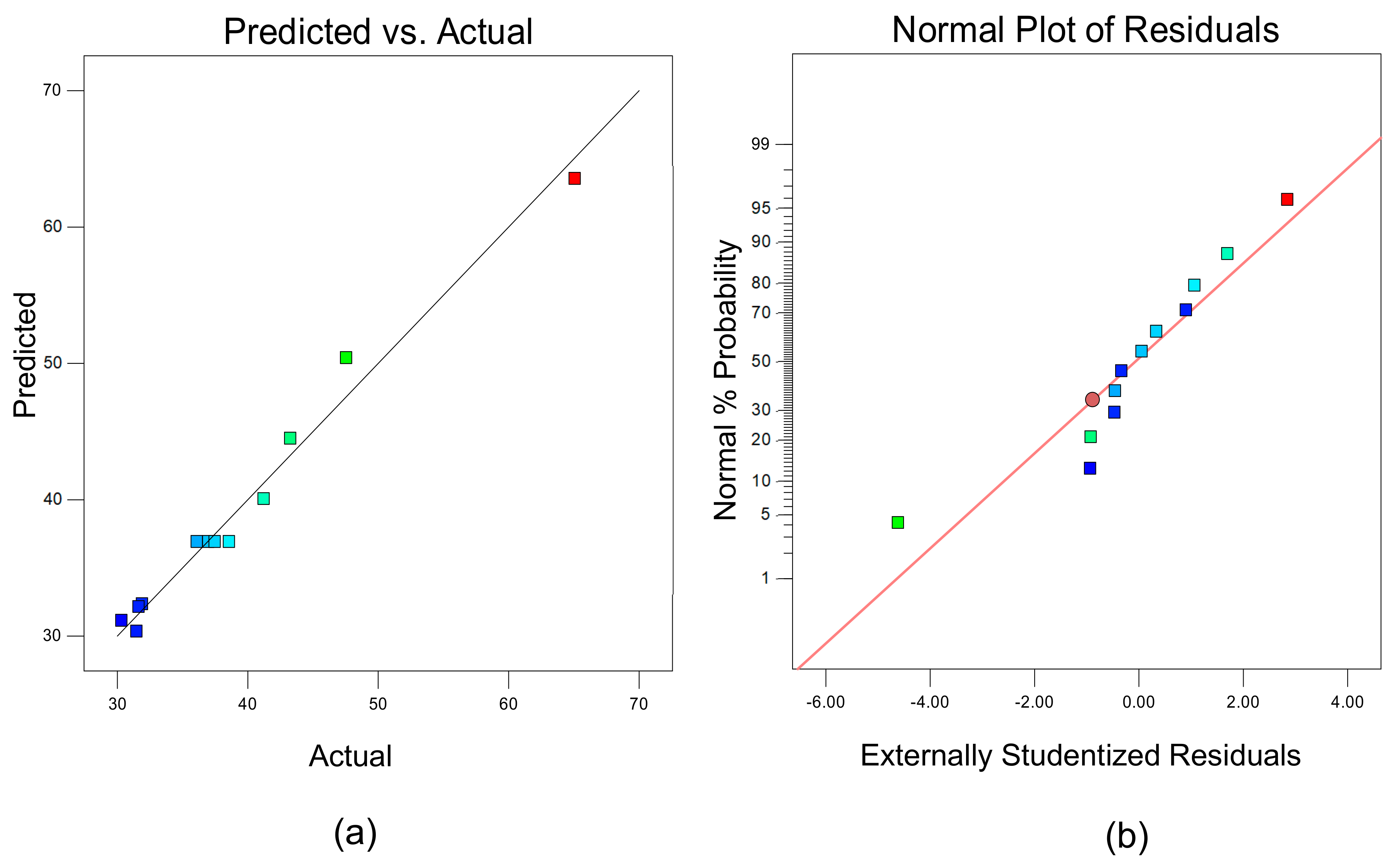

3.1. Statistical Analysis of Co-Digestion Process Optimization through CCD-RSM

3.2. Interactive Effect of Process Variables’ Ratios on Methane Yield

3.3. Model Validation for Optimum Conditions

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Liew, L.N.; Shi, J.; Li, Y. Enhancing the solid-state anaerobic digestion of fallen leaves through simultaneous alkaline treatment. Bioresour. Technol. 2011, 102, 8828–8834. [Google Scholar] [CrossRef] [PubMed]

- Ebner, J.H.; Labatut, R.A.; Rankin, M.J.; Pronto, J.L.; Gooch, C.A.; Williamson, A.A.; Trabold, T.A. Lifecycle greenhouse gas analysis of an anaerobic codigestion facility processing dairy manure and industrial food waste. Environ. Sci. Technol. 2015, 49, 11199–11208. [Google Scholar] [CrossRef] [PubMed]

- Surendra, K.C.; Takara, D.; Hashimoto, A.G.; Khanal, S.K. Biogas as a sustainable energy source for developing countries: Opportunities and challenges. Renew. Sustain. Energy Rev. 2014, 31, 846–859. [Google Scholar] [CrossRef]

- Weiland, P. Biogas production: Current state and perspectives. Appl. Microbiol. Biotechnol. 2010, 85, 849–860. [Google Scholar] [CrossRef] [PubMed]

- Demichelis, F.; Piovano, F.; Fiore, S. Biowaste Management in Italy: Challenges and Perspectives. Sustainability 2019, 11, 4213. [Google Scholar] [CrossRef] [Green Version]

- Tanimu, M.I.; Ghazi, T.I.; Harun, M.R.; Idris, A. Effects of feedstock carbon to nitrogen ratio and organic loading on foaming potential in mesophilic food waste anaerobic digestion. Appl. Microbiol. Biotechnol. 2015, 99, 4509–4520. [Google Scholar] [CrossRef]

- Sreekrishnan, T.; Kohli, S.; Rana, V. Enhancement of biogas production from solid substrates using different techniques––A review. Bioresour. Technol. 2004, 95, 1–10. [Google Scholar]

- Maharaj, I.; Elefsiniotis, P. The role of HRT and low temperature on the acid-phase anaerobic digestion of municipal and industrial wastewaters. Bioresour. Technol. 2001, 76, 191–197. [Google Scholar] [CrossRef]

- Lettinga, G. Anaerobic digestion and wastewater treatment systems. Antonie Van Leeuwenhoek 1995, 67, 3–28. [Google Scholar] [CrossRef]

- Rudolfs, W.; Amberg, H.R. White Water Treatment: I. Factors Affecting Anaerobic Digestion. Sew. Ind. Wastes 1952, 24, 1108–1120. [Google Scholar]

- Chen, L.; Neibling, H. Anaerobic Digestion Basics; University of Idaho Extension: Moscow, Russia, 2014; p. 6. [Google Scholar]

- Henard, C.A.; Smith, H.K.; Guarnieri, M.T. Phosphoketolase overexpression increases biomass and lipid yield from methane in an obligate methanotrophic biocatalyst. Metab. Eng. 2017, 41, 152–158. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gerardi, M.H. The Microbiology of Anaerobic Digesters; John Wiley & Sons: Hoboken, NJ, USA, 2003. [Google Scholar]

- Rohlich, G.; Walbot, V. Methane Generation from Human, Animal, and Agricultural wastes-Report of an Ad Hoc Panel (on Methane Generation) of the Advisory Committee on Technology Innovation, Board on Science and Technology for International Development, Commission on International Relations; NRC: Washington, DC, USA, 1977. [Google Scholar]

- Mata-Alvarez, J.; Dosta, J.; Macé, S.; Astals, S. Codigestion of solid wastes: A review of its uses and perspectives including modeling. Crit. Rev. Biotechnol. 2011, 31, 99–111. [Google Scholar] [CrossRef] [PubMed]

- Xie, S.; Lawlor, P.G.; Frost, J.P.; Hu, Z.; Zhan, X. Effect of pig manure to grass silage ratio on methane production in batch anaerobic co-digestion of concentrated pig manure and grass silage. Bioresour. Technol. 2011, 102, 5728–5733. [Google Scholar] [CrossRef] [PubMed]

- Ravindran, R.; Jaiswal, A.K. A comprehensive review on pre-treatment strategy for lignocellulosic food industry waste: Challenges and opportunities. Bioresour. Technol. 2016, 199, 92–102. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Agbor, V.B.; Cicek, N.; Sparling, R.; Berlin, A.; Levin, D.B. Biomass pretreatment: Fundamentals toward application. Biotechnol. Adv. 2011, 29, 675–685. [Google Scholar] [CrossRef]

- McMillan, J.D. Pretreatment of Lignocellulosic Biomass; ACS Publications: Washington, DC, USA, 1994. [Google Scholar]

- Shimizu, T.; Kudo, K.; Nasu, Y. Anaerobic waste-activated sludge digestion–a bioconversion mechanism and kinetic model. Biotechnol. Bioeng. 1993, 41, 1082–1091. [Google Scholar] [CrossRef]

- Bhattacharyya, J.; Shekdar, A. Treatment and disposal of refinery sludges: Indian scenario. Waste Manag. Res. 2003, 21, 249–261. [Google Scholar] [CrossRef]

- Diya’uddeen, B.H.; Daud, W.M.A.W.; Aziz, A.A. Treatment technologies for petroleum refinery effluents: A review. Process Saf. Environ. Prot. 2011, 89, 95–105. [Google Scholar] [CrossRef]

- Xie, S.; Hai, F.I.; Zhan, X.; Guo, W.; Ngo, H.H.; Price, W.E.; Nghiem, L.D. Anaerobic co-digestion: A critical review of mathematical modelling for performance optimization. Bioresour. Technol. 2016, 222, 498–512. [Google Scholar] [CrossRef]

- Wang, X.; Yang, G.; Li, F.; Feng, Y.; Ren, G.; Han, X. Evaluation of two statistical methods for optimizing the feeding composition in anaerobic co-digestion: Mixture design and central composite design. Bioresour. Technol. 2013, 131, 172–178. [Google Scholar] [CrossRef]

- Reungsang, A.; Pattra, S.; Sittijunda, S. Optimization of key factors affecting methane production from acidic effluent coming from the sugarcane juice hydrogen fermentation process. Energies 2012, 5, 4746–4757. [Google Scholar] [CrossRef] [Green Version]

- Niladevi, K.N.; Sukumaran, R.K.; Jacob, N.; Anisha, G.S.; Prema, P. Optimization of laccase production from a novel strain—Streptomyces psammoticus using response surface methodology. Microbiol. Res. 2009, 164, 105–113. [Google Scholar] [CrossRef] [PubMed]

- Jacob, S.; Banerjee, R. Modeling and optimization of anaerobic codigestion of potato waste and aquatic weed by response surface methodology and artificial neural network coupled genetic algorithm. Bioresour. Technol. 2016, 214, 386–395. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Yang, G.; Feng, Y.; Ren, G.; Han, X. Optimizing feeding composition and carbon–nitrogen ratios for improved methane yield during anaerobic co-digestion of dairy, chicken manure and wheat straw. Bioresour. Technol. 2012, 120, 78–83. [Google Scholar] [CrossRef]

- Salihi, I.U.; Kutty, M.; Rahman, S.; Hasnain Isa, M.; Umar, U.A.; Olisa, E. Sorption of Copper and Zinc from Aqueous Solutions by Microwave Incinerated Sugarcane Bagasse Ash (MISCBA). Appl. Mech. Mater. 2016, 835, 378–385. [Google Scholar] [CrossRef]

| Parameter | Unit | Oily-Biological Sludge | Unit | Dry Sugarcane Bagasse |

|---|---|---|---|---|

| Moisture Content | % | 94.20 | % | 0 |

| pH | N/A | 8.70 | N/A | 7.21 |

| TS | g/L | 58.00 | % | 100 |

| VS | g/L | 50.46 | % | 87.80 |

| C | % of TS | 4.31 | % | 34.70 |

| N | % of TS | 0.30 | % | 0.26 |

| C/N | N/A | 14.42 | N/A | 132.69 |

| Hemicellulose | N/A | N/A | % | 10.25 |

| Cellulose | N/A | N/A | % | 62.05 |

| Lignin | N/A | N/A | % | 13.50 |

| Independent Variable | Unit | Variable Level | ||

|---|---|---|---|---|

| −1 (Min) | 0 | 1 (Max) | ||

| X1 Sugarcane Bagasse | g | 1 | 1.5 | 2 |

| X2 Oily-biological Sludge | g | 193 | 243.5 | 294 |

| Run Order | Real Values | C/N Ratio | OBS VS Content (g) | SB VS Content (g) | Co-Substrate/Inoculum | |

|---|---|---|---|---|---|---|

| X1 | X2 | |||||

| 1 | 1.5 | 243.5 | 24.2 | 100.1 | 10.8 | 0.11 |

| 2 | 1.5 | 243.5 | 24.2 | 100.1 | 10.8 | 0.11 |

| 3 | 1.0 | 243.5 | 21.1 | 100.1 | 7.2 | 0.07 |

| 4 | 1.5 | 294.0 | 22.6 | 100.1 | 9.0 | 0.09 |

| 5 | 1.0 | 294.0 | 20.0 | 100.1 | 6.0 | 0.06 |

| 6 | 2.0 | 294.0 | 25.1 | 100.1 | 11.9 | 0.12 |

| 7 | 1.0 | 193.0 | 22.8 | 100.1 | 9.1 | 0.09 |

| 8 | 2.0 | 193.0 | 30.0 | 100.1 | 18.2 | 0.18 |

| 9 | 1.5 | 243.5 | 24.2 | 100.1 | 10.8 | 0.11 |

| 10 | 1.5 | 243.5 | 24.2 | 100.1 | 10.8 | 0.11 |

| 11 | 2.0 | 243.5 | 27.1 | 100.1 | 14.4 | 0.14 |

| 12 | 1.5 | 193.0 | 26.5 | 100.1 | 13.5 | 0.13 |

| Run Order | Real Values | Volatile Solids Removed Per Batch (g) | Experimental Methane Yield (mL CH4/g VSremoved) | Predicted Methane Yield (mL CH4/g VSremoved) | |

|---|---|---|---|---|---|

| X1 | X2 | ||||

| 1 | 1.5 | 243.5 | 34.8 | 36.1 | 36.9 |

| 2 | 1.5 | 243.5 | 35.1 | 37.5 | 36.9 |

| 3 | 1.0 | 243.5 | 32.5 | 31.5 | 30.3 |

| 4 | 1.5 | 294.0 | 33.2 | 31.7 | 32.1 |

| 5 | 1.0 | 294.0 | 32.3 | 30.3 | 31.1 |

| 6 | 2.0 | 294.0 | 39.2 | 41.2 | 40.0 |

| 7 | 1.0 | 193.0 | 33.4 | 31.9 | 32.3 |

| 8 | 2.0 | 193.0 | 46.2 | 65.1 | 63.5 |

| 9 | 1.5 | 243.5 | 36.1 | 38.6 | 36.9 |

| 10 | 1.5 | 243.5 | 35.6 | 37.0 | 36.9 |

| 11 | 2.0 | 243.5 | 42.2 | 47.6 | 50.3 |

| 12 | 1.5 | 193.0 | 39.8 | 43.3 | 44.4 |

| Source | df | Sum of Squares | Mean Square | F-Value | p-Value Prob > F |

|---|---|---|---|---|---|

| Model | 5 | 1007.75 | 201.56 | 62.19 | <0.0001 |

| X1 | 1 | 603.61 | 603.61 | 186.26 | <0.0001 |

| X2 | 1 | 229.03 | 229.03 | 70.67 | 0.0002 |

| X1X2 | 1 | 123.88 | 123.88 | 38.23 | 0.0008 |

| X12 | 1 | 31.79 | 31.79 | 9.81 | 0.0203 |

| X22 | 1 | 5.21 | 5.21 | 1.61 | 0.2519 |

| R2 | 0.98 | ||||

| Adj-R2 | 0.97 | ||||

| CVp | 4.58 | ||||

| Std. Dev. | 1.80 | ||||

| Lack of Fit | 3 | 16.26 | 5.42 | 5.11 | 0.1067 |

| Pure Error | 3 | 3.18 | 1.06 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghaleb, A.A.S.; Kutty, S.R.M.; Ho, Y.-C.; Jagaba, A.H.; Noor, A.; Al-Sabaeei, A.M.; Almahbashi, N.M.Y. Response Surface Methodology to Optimize Methane Production from Mesophilic Anaerobic Co-Digestion of Oily-Biological Sludge and Sugarcane Bagasse. Sustainability 2020, 12, 2116. https://doi.org/10.3390/su12052116

Ghaleb AAS, Kutty SRM, Ho Y-C, Jagaba AH, Noor A, Al-Sabaeei AM, Almahbashi NMY. Response Surface Methodology to Optimize Methane Production from Mesophilic Anaerobic Co-Digestion of Oily-Biological Sludge and Sugarcane Bagasse. Sustainability. 2020; 12(5):2116. https://doi.org/10.3390/su12052116

Chicago/Turabian StyleGhaleb, Aiban Abdulhakim Saeed, Shamsul Rahman Mohamed Kutty, Yeek-Chia Ho, Ahmad Hussaini Jagaba, Azmatullah Noor, Abdulnaser Mohammed Al-Sabaeei, and Najib Mohammed Yahya Almahbashi. 2020. "Response Surface Methodology to Optimize Methane Production from Mesophilic Anaerobic Co-Digestion of Oily-Biological Sludge and Sugarcane Bagasse" Sustainability 12, no. 5: 2116. https://doi.org/10.3390/su12052116

APA StyleGhaleb, A. A. S., Kutty, S. R. M., Ho, Y.-C., Jagaba, A. H., Noor, A., Al-Sabaeei, A. M., & Almahbashi, N. M. Y. (2020). Response Surface Methodology to Optimize Methane Production from Mesophilic Anaerobic Co-Digestion of Oily-Biological Sludge and Sugarcane Bagasse. Sustainability, 12(5), 2116. https://doi.org/10.3390/su12052116