Energy Renovation of Residential Buildings in Cold Mediterranean Zones Using Optimized Thermal Envelope Insulation Thicknesses: The Case of Spain

Abstract

1. Introduction

2. Methodology

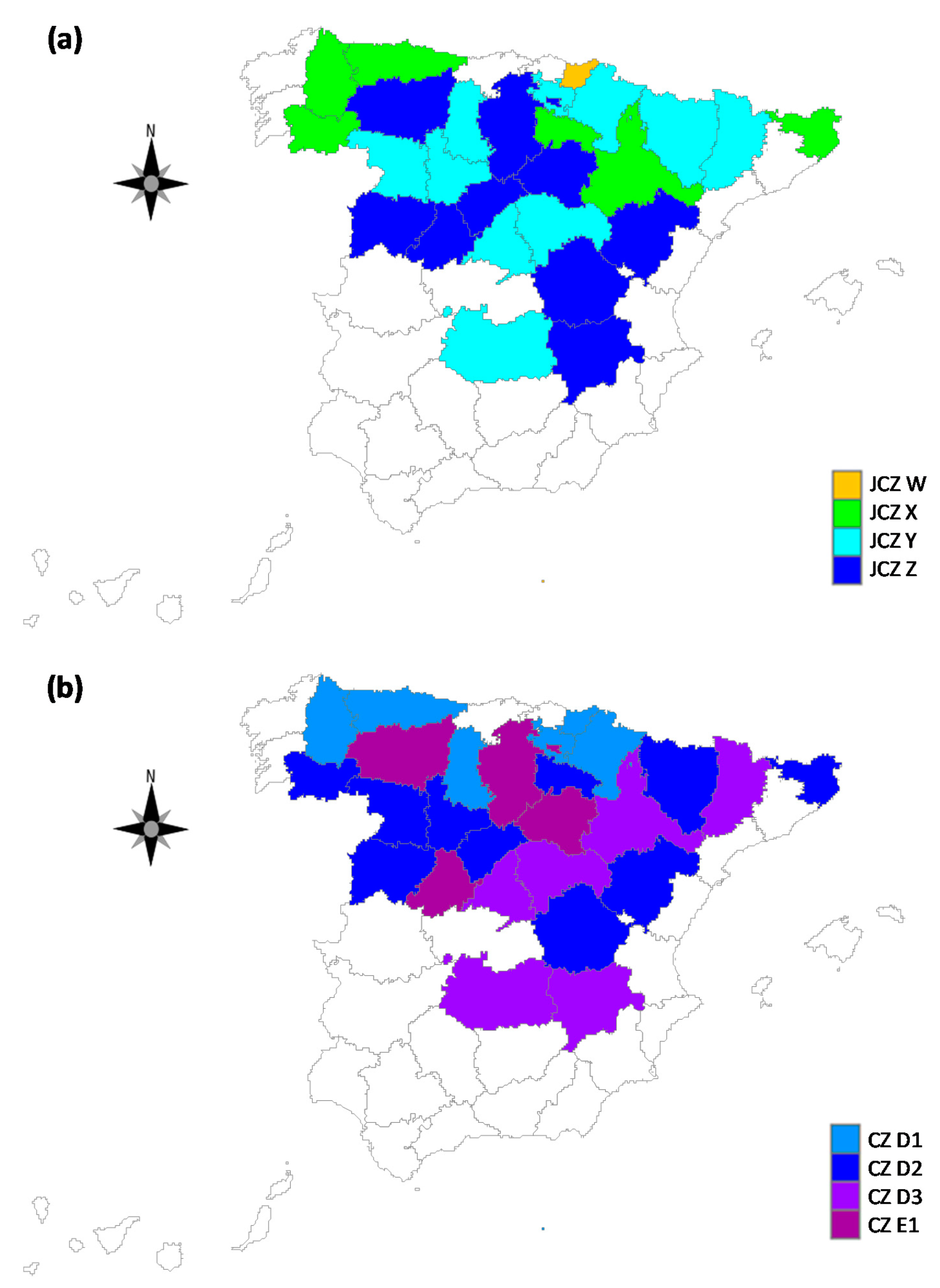

2.1. Climate Zones

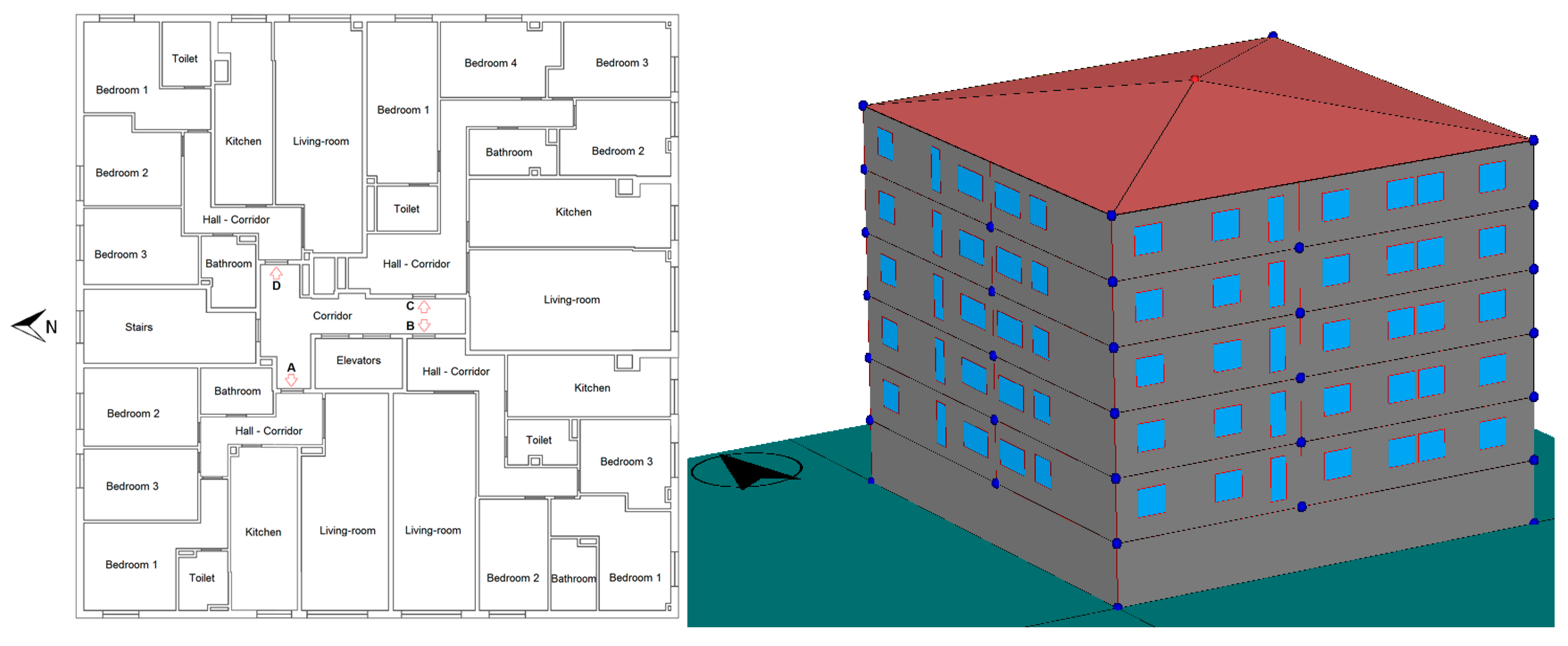

2.2. Main Characteristics of the Studied Building

2.3. Case Studies

- System 1: Heating oil boilers with thermal performances of 0.85 to meet the heating and domestic hot water (DHW) requirements and electric cooling systems with thermal efficiencies of 2.00.

- System 2: Natural gas boilers with thermal performances of 0.92 to meet the heating and DHW requirements and electric cooling systems with thermal efficiencies of 2.00.

- System 3: Biomass boilers with thermal performances of 0.85 to meet the heating and DHW requirements and electric cooling systems with thermal efficiencies of 2.00.

- System 4: Electric heat pumps with seasonal coefficients of performance of 2.50 and seasonal energy efficiency ratios of 3.00 to meet the heating, cooling and DHW requirements.

2.4. Thermal Transmittance and Overall Thermal Transmittance

2.5. Energy and Environmental Impacts of the Existing Building

2.6. Energy, Environmental and Economic Impacts of the Renovated Building

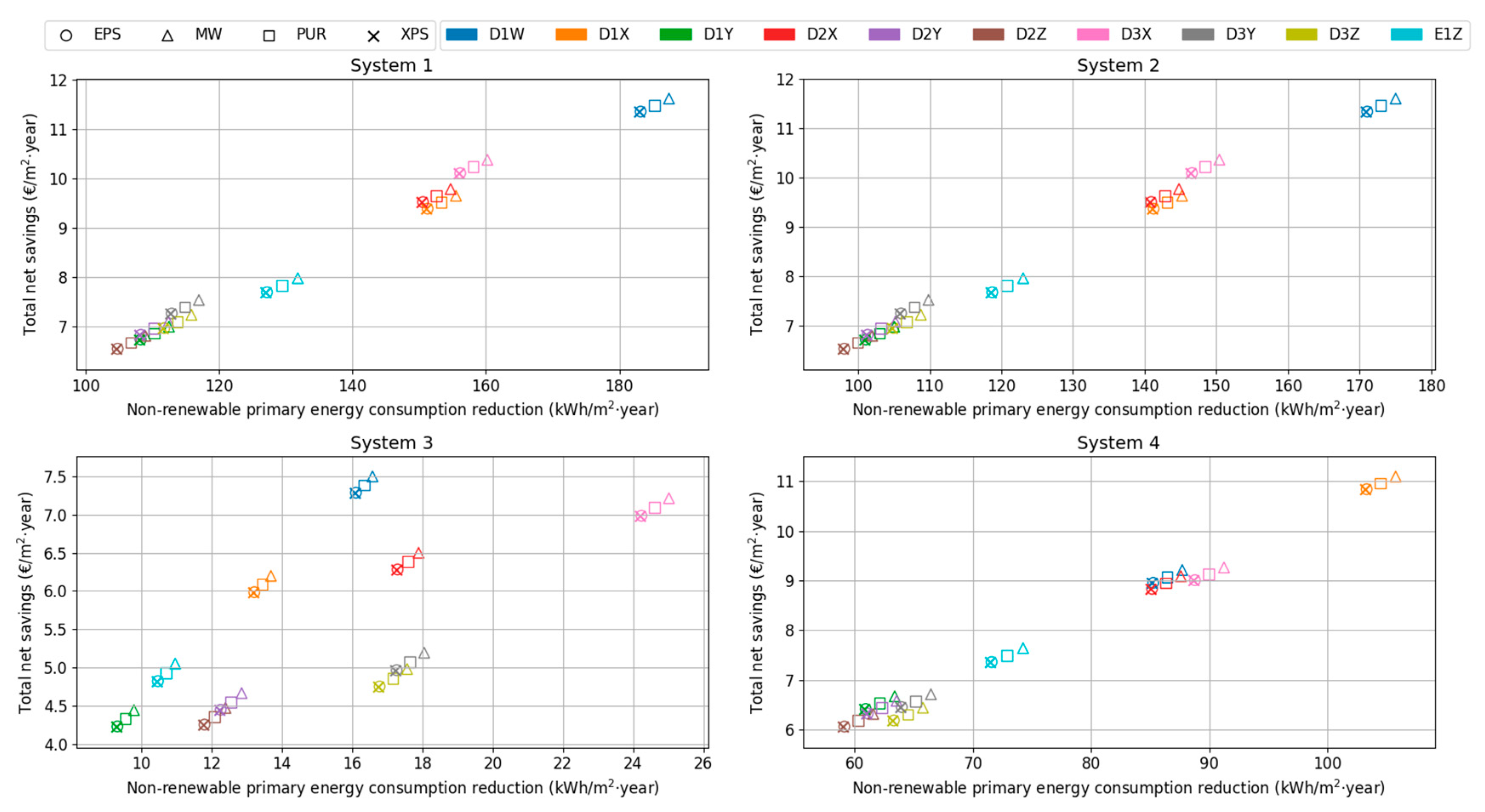

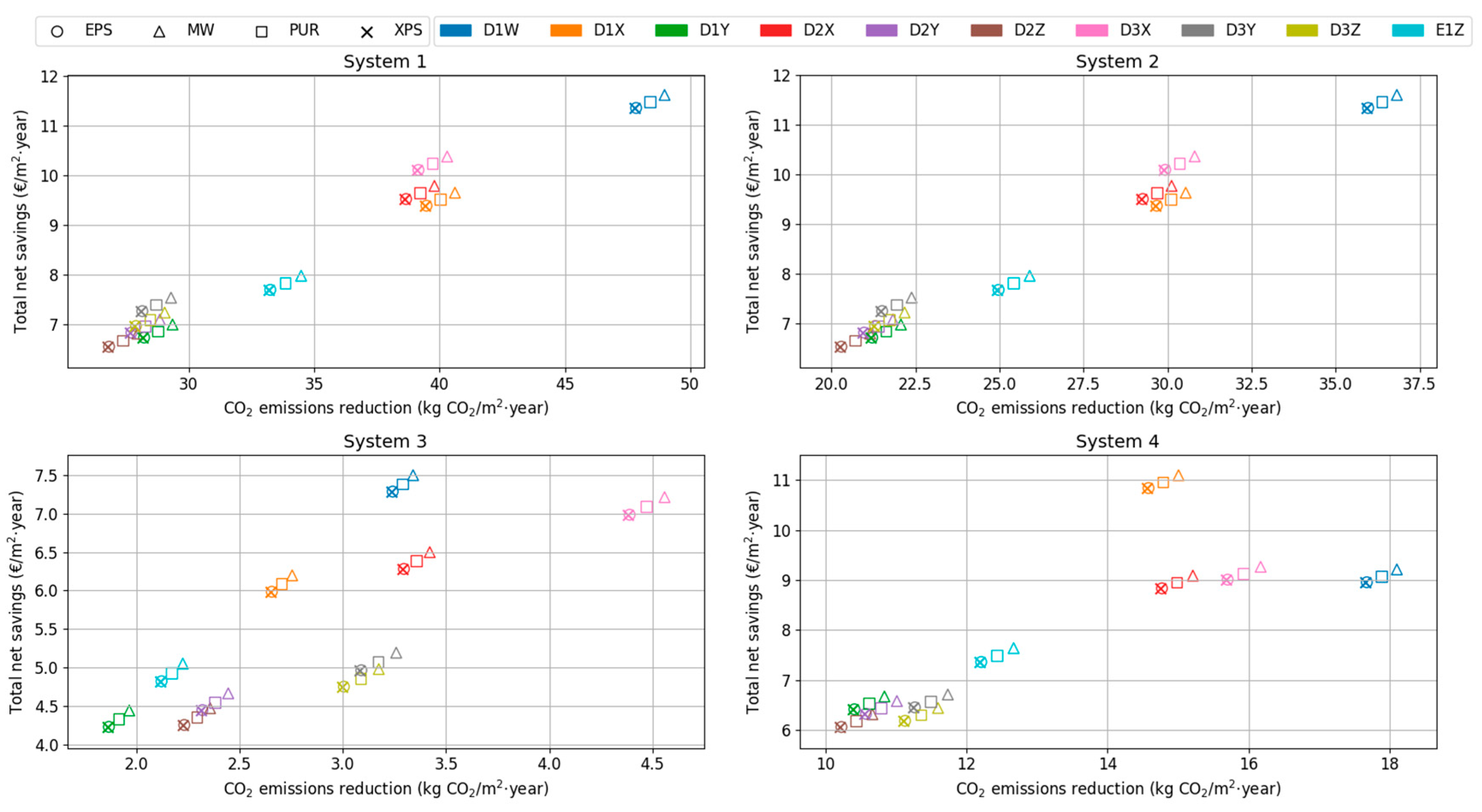

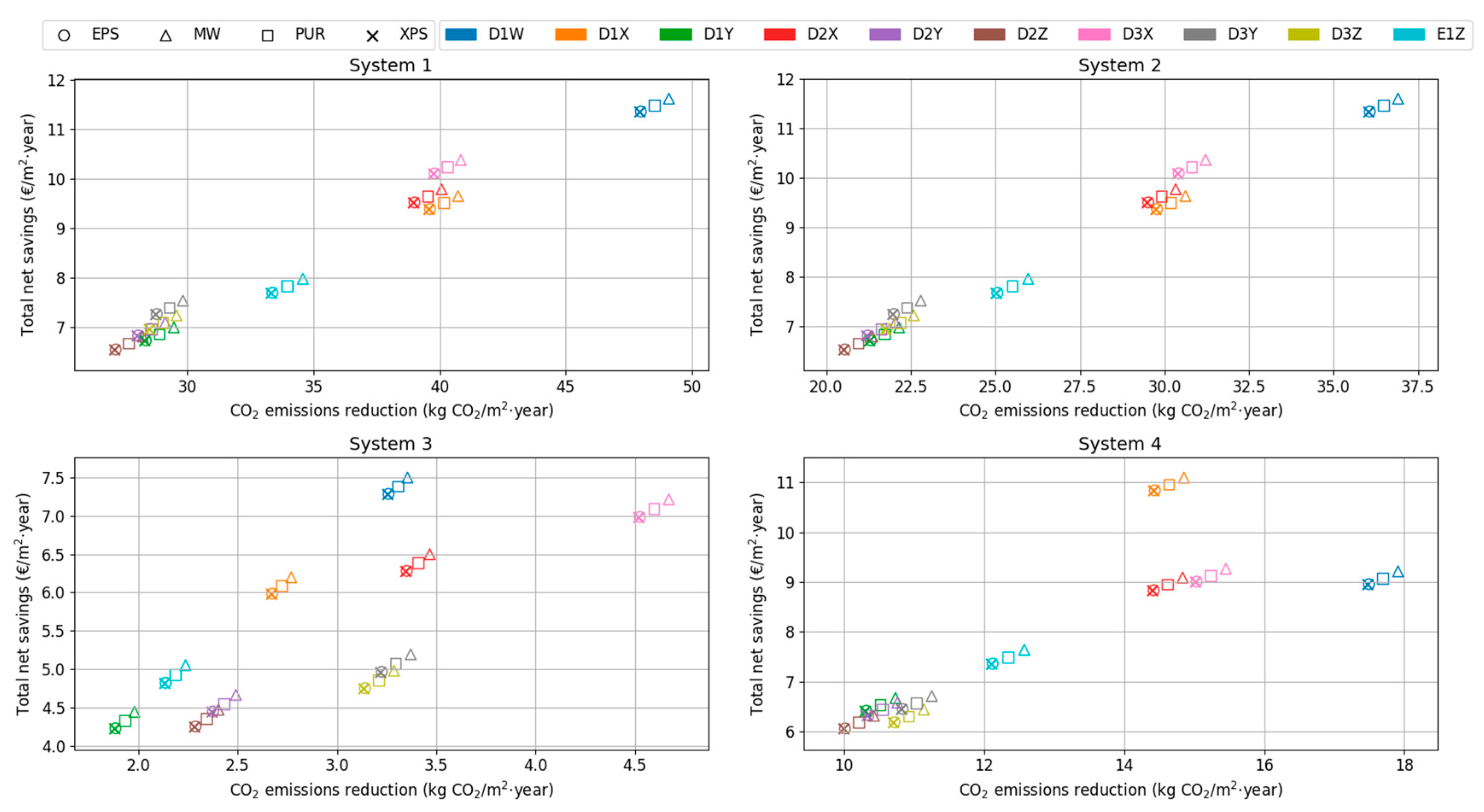

3. Results and Discussion

- Those located in climate zone D1 that use system 1 or 2 and MW insulation and in which the insulation thickness is optimized to minimize the total heating and cooling costs.

- Those located in climate zone D2 that use system 1, 2 or 4 and MW insulation.

- Those located in climate zone D3 that use MW insulation and in which the insulation thickness is optimized to minimize the total heating and cooling costs; those that use system 1, 2 or 4 and PUR insulation and in which the insulation thickness is optimized to minimize the total heating and cooling costs, or that use MW insulation and in which the insulation thickness is optimized to minimize the total heating costs; those that use system 1 or 2 and EPS insulation and in which the insulation thickness is optimized to minimize the total heating and cooling costs, or that use XPS insulation and in which the insulation thickness is optimized to minimize the total heating and cooling costs; and those that use system 1 and PUR insulation and in which the insulation thickness is optimized to minimize the total heating costs.

- Those located in climate zone E1.

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- European Union. EU Energy in figures. In Statistical Pocketbook 2019; Publications Office of the European Union: Luxembourg, 2019. [Google Scholar] [CrossRef]

- European Commission. EU Buildings Database. Available online: https://ec.europa.eu/energy/en/eu-buildings-database (accessed on 24 October 2019).

- ENTRANZE. Available online: http://www.entranze.enerdata.eu/ (accessed on 24 October 2019).

- European Union. Directive (EU) 2018/844 of the European Parliament and of the Council of 30 May 2018 Amending Directive 2010/31/EU on the Energy Performance of Buildings and Directive 2012/27/EU on Energy Efficiency, 2018. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32018L0844&from=EN (accessed on 24 October 2019).

- European Union. Directive 2010/31/EU of the European Parliament and of the Council of 19 May 2010 on the Energy Performance of Buildings (recast), 2010. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32010L0031&from=EN (accessed on 24 October 2019).

- European Union. Directive 2012/27/EU of the European Parliament and of the Council of 25 October 2012 on Energy Efficiency, Amending Directives 2009/125/EC and 2010/30/EU and Repealing Directives 2004/8/EC and 2006/32/EC, 2012. Available online: http://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32012L0027&from=EN (accessed on 24 October 2019).

- López-Ochoa, L.M.; Las-Heras-Casas, J.; López-González, L.M.; Olasolo-Alonso, P. Towards nearly zero-energy buildings in Mediterranean countries: Energy Performance of Buildings Directive evolution and the energy rehabilitation challenge in the Spanish residential sector. Energy 2019, 176, 335–352. [Google Scholar] [CrossRef]

- Salvalai, G.; Masera, G.; Sesana, M.M. Italian local codes for energy efficiency of buildings: Theoretical definition and experimental application to a residential case study. Renew. Sustain. Energy Rev. 2015, 42, 1245–1259. [Google Scholar] [CrossRef]

- Gaglia, A.G.; Tsikaloudaki, A.G.; Laskos, C.M.; Dialynas, E.N.; Argiriou, A.A. The impact of the energy performance regulations’ updated on the construction technology, economics and energy aspects of new residential buildings: The case of Greece. Energy Build. 2017, 155, 225–237. [Google Scholar] [CrossRef]

- Fokaides, P.A.; Polycarpou, K.; Kalogirou, S. The impact of the implementation of the European Energy Performance of Buildings Directive on the European building stock: The case of the Cyprus Land Development Corporation. Energy Policy 2017, 111, 1–8. [Google Scholar] [CrossRef]

- Araújo, C.; Almeida, M.; Bragança, L. Analysis of some Portuguese thermal regulation parameters. Energy Build. 2013, 58, 141–150. [Google Scholar] [CrossRef]

- Ballarini, I.; Corrado, V.; Madonna, F.; Paduos, S.; Ravasio, F. Energy refurbishment of the Italian residential building stock: Energy and cost analysis through the application of the building typology. Energy Policy 2017, 105, 148–160. [Google Scholar] [CrossRef]

- Aguacil, S.; Lufkin, S.; Rey, E.; Cuchi, A. Application of the cost-optimal methodology to urban renewal projects at the territorial scale based on statistical data—A case study in Spain. Energy Build. 2017, 144, 42–60. [Google Scholar] [CrossRef]

- Luján, S.V.; Arrebola, C.V.; Sánchez, A.R.; Benito, P.A.; Cortina, M.G. Experimental comparative study of the thermal performance of the façade of a building refurbished using ETICS, and quantification of improvements. Sustain. Cities Soc. 2019, 51, 101713. [Google Scholar] [CrossRef]

- Çengel, Y.A. Heat and Mass Transfer: A practical Approach, 3rd ed.; McGraw Hill: New York, NY, USA, 2007. [Google Scholar]

- Kurekci, N.A. Determination of optimum insulation thickness for building walls by using heating and cooling degree-day values of all Turkey’s provincial centers. Energy Build. 2016, 118, 197–213. [Google Scholar] [CrossRef]

- Sisman, N.; Kahya, E.; Aras, N.; Aras, H. Determination of optimum insulation thicknesses of the external walls and roof (ceiling) for Turkey’s different degree-day regions. Energy Policy 2007, 35, 5151–5155. [Google Scholar] [CrossRef]

- Ekici, B.; Gulten, A.; Aksoy, U.T. A study on the optimum insulation thicknesses of various types of external walls with respect to different materials, fuels and climate zones in Turkey. Appl. Energy 2012, 92, 211–217. [Google Scholar] [CrossRef]

- Ozel, M. The influence of exterior surface solar absorptivity on thermal characteristics and optimum insulation thickness. Renew. Energy 2012, 39, 347–355. [Google Scholar] [CrossRef]

- Ozel, M. Cost analysis for optimum thicknesses and environmental impacts of different insulation materials. Energy Build. 2012, 49, 552–559. [Google Scholar] [CrossRef]

- Ozel, M. Thermal, economical and environmental analysis of insulated building walls in a cold climate. Energy Convers. Manag. 2013, 76, 674–684. [Google Scholar] [CrossRef]

- Ozel, M. Influence of glazing area on optimum thickness of insulation for different wall orientations. Appl. Therm. Eng. 2019, 147, 770–780. [Google Scholar] [CrossRef]

- Sagbansua, L.; Balo, F. Ecological impact & financial feasibility of Energy Recovery (EIFFER) Model for natural insulation material optimization. Energy Build. 2017, 148, 1–14. [Google Scholar] [CrossRef]

- Annibaldi, V.; Cucchiella, F.; De Berardinis, P.; Rotilio, M.; Stornelli, V. Environmental and economic benefits of optimal insulation thickness: A life-cycle cost analysis. Renew. Sustain. Energy Rev. 2019, 116, 109441. [Google Scholar] [CrossRef]

- Derradji, L.; Imessad, K.; Amara, M.; Errebai, F.B. A study on residential energy requirement and the effect of the glazing on the optimum insulation thickness. Appl. Therm. Eng. 2017, 112, 975–985. [Google Scholar] [CrossRef]

- Yuan, J.; Farnham, C.; Emura, K. Optimal combination of thermal resistance of insulation materials and primary fuel sources for six climate zones of Japan. Energy Build. 2017, 153, 403–411. [Google Scholar] [CrossRef]

- Nematchoua, M.K.; Raminosoa, C.R.R.; Mamiharijaona, R.; René, T.; Orosa, J.A.; Elvis, W.; Meukam, P. Study of the economical and optimum thermal insulation thickness for buildings in a wet and hot tropical climate: Case of Cameroon. Renew. Sustain. Energy Rev. 2015, 50, 1192–1202. [Google Scholar] [CrossRef]

- López-Ochoa, L.M.; Las-Heras-Casas, J.; López-González, L.M.; García-Lozano, C. Environmental and energy impact of the EPBD in residential buildings in cold Mediterranean zones: The case of Spain. Energy Build. 2017, 150, 567–582. [Google Scholar] [CrossRef]

- López-Ochoa, L.M.; Las-Heras-Casas, J.; López-González, L.M.; Olasolo-Alonso, P. Environmental and energy impact of the EPBD in residential buildings in hot and temperate Mediterranean zones: The case of Spain. Energy 2018, 161, 618–634. [Google Scholar] [CrossRef]

- Las-Heras-Casas, J.; López-Ochoa, L.M.; Paredes-Sánchez, J.P.; López-González, L.M. Implementation of biomass boilers for heating and domestic hot water in multi-family buildings in Spain: Energy, environmental, and economic assessment. J. Clean. Prod. 2018, 176, 590–603. [Google Scholar] [CrossRef]

- Spanish Ministry of Development. Basic Document on Energy Saving of the Technical Building Code (Documento Básico de Ahorro de Energía del Código Técnico de la Edificación, CTE-DB-HE), 2017. Available online: https://www.codigotecnico.org/images/stories/pdf/ahorroEnergia/DBHE.pdf (accessed on 24 October 2019).

- Institute for Diversification and Saving of Energy. Frequencies software, Version 1.2 (Programa Frecuencias, Versión 1.2), 2014. Available online: https://www.idae.es/sites/default/files/documentos/publicaciones_idae/documentos_FRECUENCIAS_71e4fba3.exe (accessed on 24 October 2019).

- HULC. LIDER-CALENER Unified Tool, Version 1.0.1564.1124 (Herramienta Unificada LIDER-CALENER, Versión 1.0.1564.1124), 2017. Available online: https://www.codigotecnico.org/images/stories/pdf/aplicaciones/lider-calener/iCTEHE2013_last (accessed on 24 October 2019).

- Presidency of the Government of Spain. Royal Decree 2429/1979 approving the Basic Building Norm on Thermal Conditions in Buildings (Real Decreto 2429/1979, de 6 de Julio, por el que se Aprueba la Norma Básica de Edificación NBE-CT-79, Sobre Condiciones Térmicas en Los Edificios), 1979. Available online: http://www.boe.es/boe/dias/1979/10/22/pdfs/A24524-24550.pdf (accessed on 24 October 2019).

- CE3X. CE3X software, Version 2.3, 2016. Available online: http://www6.mityc.es/aplicaciones/calener/setupCE3Xv2.3.exe (accessed on 24 October 2019).

- López-González, L.M.; López-Ochoa, L.M.; Las-Heras-Casas, J.; García-Lozano, C. Energy performance certificates as tools for energy planning in the residential sector. The case of La Rioja (Spain). J. Clean. Prod. 2016, 137, 1280–1292. [Google Scholar] [CrossRef]

- Valencia Institute of Building. Construction Database of the Valencia Institute of Building 2018. Available online: https://www.five.es/productos/herramientas-on-line/visualizador-2018/ (accessed on 24 October 2019).

- Corporation of Strategic Reserves of Petroleum Products. Annual Statistical Report CORES 2018 (Informe Estadístico Anual CORES 2018), 2019. Available online: https://www.cores.es/sites/default/files/archivos/publicaciones/informe-estadistico-anual-2018.pdf (accessed on 24 October 2019).

- European Commission. Weekly Oil Bulletin, Prices over Time, 2005 Onwards. Available online: http://ec.europa.eu/energy/observatory/reports/Oil_Bulletin_Prices_History.xlsx (accessed on 24 October 2019).

- EUROSTAT. Gas Prices for Household Consumers-bi-Annual Data (from 2007 Onwards) (nrg_pc_202). Available online: https://appsso.eurostat.ec.europa.eu/nui/show.do?dataset=nrg_pc_202&lang=en (accessed on 24 October 2019).

- Institute for Energy Diversification and Saving. Biomass Price Report for Thermal Uses. 4th Quarter of 2018 (Informe de Precios de la Biomasa Para Usos Térmicos. 4° Trimestre de 2018), 2019. Available online: https://www.idae.es/sites/default/files/estudios_informes_y_estadisticas/informe_precios_biomasa_usos_termicos_4t_2018.v2.pdf (accessed on 24 October 2019).

- EUROSTAT. Electricity Prices for Household Consumers-bi-Annual Data (from 2007 onwards) (nrg_pc_204). Available online: https://appsso.eurostat.ec.europa.eu/nui/show.do?dataset=nrg_pc_204&lang=en (accessed on 24 October 2019).

- Spanish Ministry of Development. Supporting Document 1 Associated with the CTE-DB-HE: Calculation of Characteristic Envelope Parameters (Documento de Apoyo 1 al CTE-DB-HE: Cálculo de Parámetros Característicos de la Envolvente), 2015. Available online: https://www.codigotecnico.org/images/stories/pdf/ahorroEnergia/DA-DB-HE-1-Calculo_de_parametros_caracteristicos.pdf (accessed on 24 October 2019).

- Institute for Energy Diversification and Saving. Energy Performance Rating for Existing Buildings (Escala de Calificación Energética Para Edificios Existentes), 2011. Available online: http://www.minetad.gob.es/energia/desarrollo/EficienciaEnergetica/CertificacionEnergetica/DocumentosReconocidos/OtrosDocumentos/Calificaci%C3%B3n%20energ%C3%A9tica.%20Viviendas/Escala_Calif%20_Edif%20_Existentes_accesible.pdf (accessed on 24 October 2019).

- Spanish Ministry of Industry, Energy and Tourism; Spanish Ministry of Public Works. Recognized Document from the Regulations for Thermal Installations in Buildings (RITE): CO2 Emission Factors and Primary Energy Conversion Coefficients of Different Final Energy Sources Consumed in the Building Sector in Spain (Joint Resolution of the Ministry of Industry, Energy, and Tourism and the Ministry of Public Works) (Documento Reconocido del Reglamento de Instalaciones Térmicas en los Edificios (RITE): Factores de Emisión de CO2 y Coeficientes de Paso a Energía primaria de Diferentes Fuentes de Energía Final Consumidas en el Sector de Edificios en España (Resolución conjunta de los Ministerios de Industria, Energía y Turismo, y Ministerio de Fomento)), 2016. Available online: http://www.minetad.gob.es/energia/desarrollo/EficienciaEnergetica/RITE/Reconocidos/Reconocidos/Otros%20documentos/Factores_emision_CO2.pdf (accessed on 24 October 2019).

- Institute for Energy Diversification and Saving. Energy Performance Rating for Buildings (Calificación de la Eficiencia Energética de los Edificios), 2015. Available online: https://energia.gob.es/desarrollo/EficienciaEnergetica/CertificacionEnergetica/DocumentosReconocidos/normativamodelosutilizacion/20151123-Calificacion-eficiencia-energetica-edificios.pdf (accessed on 24 October 2019).

- Cabeza, L.F.; Rincón, L.; Vilariño, V.; Pérez, G.; Castell, A. Life cycle assessment (LCA) and life cycle energy analysis (LCEA) of buildings and the building sector: A review. Renew. Sustain. Energy Rev. 2014, 29, 394–416. [Google Scholar] [CrossRef]

- Fokaides, P.A.; Papadopoulos, A.M. Cost-optimal insulation thickness in dry and mesothermal climates: Existing models and their improvement. Energy Build. 2014, 68, 203–212. [Google Scholar] [CrossRef]

| CZ | HDD | CDD | JCZ | Cities |

|---|---|---|---|---|

| D1 | 3004 | 87 | W | San Sebastián/Donostia |

| Y | Palencia, Pamplona/Iruña, Vitoria/Gasteiz | |||

| X | Lugo, Oviedo | |||

| D2 | 2857 | 217 | X | Gerona/Girona, Logroño, Orense/Ourense |

| Y | Huesca, Valladolid, Zamora | |||

| Z | Cuenca, Salamanca, Segovia, Teruel | |||

| D3 | 2743 | 420 | X | Zaragoza |

| Y | Ciudad Real, Guadalajara, Lérida/Lleida, Madrid | |||

| Z | Albacete | |||

| E1 | 3548 | 81 | Z | Ávila, Burgos, León, Soria |

| Type of Dwelling | Space | Area (m2) |

|---|---|---|

| A | Living room | 27.24 |

| Kitchen | 14.55 | |

| Hall/corridor | 7.98 | |

| Toilet | 3.99 | |

| Bathroom | 4.98 | |

| Bedroom 1 | 15.78 | |

| Bedroom 2 | 12.31 | |

| Bedroom 3 | 13.23 | |

| B | Living room | 27.19 |

| Kitchen | 13.87 | |

| Hall/corridor | 14.15 | |

| Toilet | 4.33 | |

| Bathroom | 4.81 | |

| Bedroom 1 | 14.46 | |

| Bedroom 2 | 11.71 | |

| Bedroom 3 | 11.42 | |

| C | Living room | 31.08 |

| Kitchen | 18.76 | |

| Hall/corridor | 20.69 | |

| Toilet | 4.40 | |

| Bathroom | 5.80 | |

| Bedroom 1 | 17.83 | |

| Bedroom 2 | 12.40 | |

| Bedroom 3 | 13.31 | |

| Bedroom 4 | 13.36 | |

| D | Living room | 28.30 |

| Kitchen | 14.37 | |

| Hall/corridor | 9.78 | |

| Toilet | 4.78 | |

| Bathroom | 5.42 | |

| Bedroom 1 | 14.44 | |

| Bedroom 2 | 12.20 | |

| Bedroom 3 | 12.65 |

| January Climate Zone | Walls | Roof | First Floor Framework | Openings | |

|---|---|---|---|---|---|

| U (W/m2·K) | W | 1.80 | 1.40 | 2.17 | 5.70 |

| X | 1.60 | 1.20 | 1.40 | 5.70 | |

| Y | 1.40 | 0.90 | 1.20 | 3.50 | |

| Z | 1.40 | 0.70 | 1.20 | 3.50 | |

| Exchange surface (m2) | 1107.16 | 491.93 | 484.00 | 212.84 | |

| Insulation Material | Thermal Conductivity (W/m·K) | Price (€/m3) |

|---|---|---|

| EPS | 0.034 | 263.78 |

| MW | 0.034 | 181.50 |

| PUR | 0.025 | 302.50 |

| XPS | 0.034 | 267.00 |

| Energy Carrier | Price (€/kWh) | Source |

|---|---|---|

| Heating oil | 0.0713 | [38,39] |

| Natural gas (annual consumption between 20 and 200 GJ) | 0.0770 | [40] |

| Biomass (A1 certified pellets in bulk) | 0.0462 | [41] |

| Electricity 1 (annual consumption between 2500 and 5000 kWh) | 0.2430 | [42] |

| Electricity 2 (annual consumption between 5000 and 15,000 kWh) | 0.2042 | [42] |

| NRPE Conversion Factor (kWhNRPE/kWhFE) | TPE Conversion Factor (kWhTPE/kWhFE) | CO2 Emissions Conversion Factor (kg CO2/kWhFE) | |

|---|---|---|---|

| Mainland electricity | 1.954 | 2.368 | 0.331 |

| Heating oil | 1.179 | 1.182 | 0.311 |

| Natural gas | 1.190 | 1.195 | 0.252 |

| Densified biomass (pellets) | 0.085 | 1.113 | 0.018 |

| Non-Renewable Primary Energy Consumption (kWh/m2·year) | CO2 Emissions (kg CO2/m2·year) | |||||||

|---|---|---|---|---|---|---|---|---|

| D1 | D2 | D3 | E1 | D1 | D2 | D3 | E1 | |

| A | P < 37.5 | P < 35.3 | P < 37.1 | P < 46.9 | E < 8.4 | E < 7.9 | E < 8.4 | E < 10.4 |

| B | 37.5 ≤ P < 57.7 | 35.3 ≤ P < 57.2 | 37.1 ≤ P < 60.1 | 46.9 ≤ P < 72.1 | 8.4 ≤ E < 12.9 | 7.9 ≤ E < 12.9 | 8.4 ≤ E < 13.6 | 10.4 ≤ E < 16.1 |

| C | 57.7 ≤ P < 86.1 | 57.2 ≤ P < 88.7 | 60.1 ≤ P < 93.2 | 72.1 ≤ P < 107.5 | 12.9 ≤ E < 19.3 | 12.9 ≤ E < 20.0 | 13.6 ≤ E < 21.1 | 16.1 ≤ E < 24.0 |

| D | 86.1 ≤ P < 128.2 | 88.7 ≤ P < 136.3 | 93.2 ≤ P < 143.3 | 107.5 ≤ P < 160.1 | 19.3 ≤ E < 28.7 | 20.0 ≤ E < 30.7 | 21.1 ≤ E < 32.4 | 24.0 ≤ E < 35.7 |

| E | 128.2 ≤ P < 271.9 | 136.3 ≤ P < 284.7 | 143.3 ≤ P < 298.1 | 160.1 ≤ P < 358.8 | 28.7 ≤ E < 59.9 | 30.7 ≤ E < 63.0 | 32.4 ≤ E < 66.3 | 35.7 ≤ E < 82.9 |

| F | 271.9 ≤ P < 318.1 | 284.7 ≤ P < 333.1 | 298.1 ≤ P < 336.8 | 358.8 ≤ P < 419.8 | 59.9 ≤ E < 71.8 | 63.0 ≤ E < 73.7 | 66.3 ≤ E < 79.6 | 82.9 ≤ E < 97.0 |

| G | 318.1 ≤ P | 333.1 ≤ P | 336.8 ≤ P | 419.8 ≤ P | 71.8 ≤ E | 73.7 ≤ E | 79.6 ≤ E | 97.0 ≤ E |

| January Climate Zone W | January Climate Zone X | January Climate Zone Y | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| System | Insulation Material | Optimization Criterion | Walls | Roof | FFF | C | ECS | PP | Walls | Roof | FFF | C | ECS | PP | Walls | Roof | FFF | C | ECS | PP |

| 1 | EPS | Heat | 0.109 | 0.104 | 0.113 | 54.12 | 10.87 | 4.98 | 0.107 | 0.100 | 0.104 | 53.07 | 8.98 | 5.91 | 0.104 | 0.090 | 0.100 | 51.89 | 6.43 | 8.07 |

| Heat + Cool | 0.112 | 0.107 | 0.115 | 54.78 | 11.36 | 4.82 | 0.110 | 0.103 | 0.107 | 53.73 | 9.39 | 5.72 | 0.107 | 0.093 | 0.103 | 52.55 | 6.73 | 7.80 | ||

| MW | Heat | 0.136 | 0.130 | 0.139 | 50.20 | 11.13 | 4.51 | 0.133 | 0.126 | 0.130 | 49.48 | 9.24 | 5.36 | 0.130 | 0.117 | 0.126 | 48.66 | 6.69 | 7.28 | |

| Heat + Cool | 0.139 | 0.134 | 0.142 | 50.75 | 11.62 | 4.37 | 0.137 | 0.129 | 0.134 | 50.03 | 9.65 | 5.18 | 0.134 | 0.120 | 0.129 | 49.21 | 7.00 | 7.03 | ||

| PUR | Heat | 0.089 | 0.085 | 0.091 | 52.28 | 10.99 | 4.76 | 0.087 | 0.082 | 0.085 | 51.39 | 9.10 | 5.65 | 0.085 | 0.075 | 0.082 | 50.39 | 6.56 | 7.69 | |

| Heat + Cool | 0.091 | 0.087 | 0.093 | 52.88 | 11.48 | 4.60 | 0.089 | 0.084 | 0.087 | 52.00 | 9.52 | 5.47 | 0.087 | 0.077 | 0.084 | 51.00 | 6.86 | 7.43 | ||

| XPS | Heat | 0.109 | 0.103 | 0.112 | 54.25 | 10.86 | 5.00 | 0.106 | 0.099 | 0.103 | 53.20 | 8.97 | 5.93 | 0.103 | 0.090 | 0.099 | 52.00 | 6.42 | 8.10 | |

| Heat + Cool | 0.111 | 0.106 | 0.114 | 54.92 | 11.35 | 4.84 | 0.109 | 0.102 | 0.106 | 53.86 | 9.38 | 5.74 | 0.106 | 0.092 | 0.102 | 52.66 | 6.72 | 7.83 | ||

| 2 | EPS | Heat | 0.109 | 0.104 | 0.112 | 54.08 | 10.84 | 4.99 | 0.107 | 0.100 | 0.104 | 53.04 | 8.96 | 5.92 | 0.104 | 0.090 | 0.100 | 51.85 | 6.42 | 8.08 |

| Heat + Cool | 0.112 | 0.106 | 0.115 | 54.74 | 11.33 | 4.83 | 0.110 | 0.102 | 0.106 | 53.70 | 9.37 | 5.73 | 0.106 | 0.093 | 0.102 | 52.51 | 6.72 | 7.82 | ||

| MW | Heat | 0.136 | 0.130 | 0.139 | 50.17 | 11.10 | 4.52 | 0.133 | 0.126 | 0.130 | 49.45 | 9.22 | 5.37 | 0.130 | 0.117 | 0.126 | 48.64 | 6.67 | 7.29 | |

| Heat + Cool | 0.139 | 0.133 | 0.142 | 50.72 | 11.59 | 4.37 | 0.136 | 0.129 | 0.133 | 50.00 | 9.63 | 5.19 | 0.133 | 0.120 | 0.129 | 49.18 | 6.98 | 7.05 | ||

| PUR | Heat | 0.089 | 0.085 | 0.091 | 52.24 | 10.97 | 4.76 | 0.087 | 0.082 | 0.085 | 51.36 | 9.08 | 5.66 | 0.085 | 0.075 | 0.082 | 50.36 | 6.54 | 7.70 | |

| Heat + Cool | 0.091 | 0.087 | 0.093 | 52.85 | 11.46 | 4.61 | 0.089 | 0.084 | 0.087 | 51.97 | 9.49 | 5.47 | 0.087 | 0.077 | 0.084 | 50.97 | 6.84 | 7.45 | ||

| XPS | Heat | 0.108 | 0.103 | 0.112 | 54.22 | 10.84 | 5.00 | 0.106 | 0.099 | 0.103 | 53.16 | 8.95 | 5.94 | 0.103 | 0.090 | 0.099 | 51.96 | 6.41 | 8.11 | |

| Heat + Cool | 0.111 | 0.106 | 0.114 | 54.88 | 11.32 | 4.85 | 0.109 | 0.102 | 0.106 | 53.83 | 9.36 | 5.75 | 0.106 | 0.092 | 0.102 | 52.63 | 6.71 | 7.84 | ||

| 3 | EPS | Heat | 0.084 | 0.079 | 0.088 | 47.92 | 6.81 | 7.04 | 0.082 | 0.075 | 0.079 | 46.87 | 5.58 | 8.40 | 0.079 | 0.065 | 0.075 | 45.69 | 3.93 | 11.62 |

| Heat + Cool | 0.088 | 0.082 | 0.091 | 48.73 | 7.29 | 6.69 | 0.085 | 0.078 | 0.082 | 47.69 | 5.98 | 7.97 | 0.082 | 0.069 | 0.078 | 46.50 | 4.23 | 11.00 | ||

| MW | Heat | 0.106 | 0.100 | 0.109 | 45.06 | 7.01 | 6.42 | 0.103 | 0.096 | 0.100 | 44.34 | 5.79 | 7.66 | 0.100 | 0.087 | 0.096 | 43.52 | 4.14 | 10.52 | |

| Heat + Cool | 0.110 | 0.104 | 0.113 | 45.73 | 7.50 | 6.10 | 0.107 | 0.100 | 0.104 | 45.01 | 6.20 | 7.26 | 0.104 | 0.091 | 0.100 | 44.20 | 4.44 | 9.96 | ||

| PUR | Heat | 0.069 | 0.065 | 0.071 | 46.58 | 6.91 | 6.74 | 0.067 | 0.062 | 0.065 | 45.70 | 5.68 | 8.04 | 0.065 | 0.055 | 0.062 | 44.70 | 4.03 | 11.09 | |

| Heat + Cool | 0.071 | 0.067 | 0.074 | 47.33 | 7.39 | 6.40 | 0.070 | 0.064 | 0.067 | 46.45 | 6.09 | 7.63 | 0.067 | 0.058 | 0.064 | 45.45 | 4.33 | 10.50 | ||

| XPS | Heat | 0.084 | 0.078 | 0.087 | 48.02 | 6.80 | 7.06 | 0.081 | 0.074 | 0.078 | 46.96 | 5.58 | 8.42 | 0.078 | 0.065 | 0.074 | 45.76 | 3.92 | 11.66 | |

| Heat + Cool | 0.087 | 0.082 | 0.090 | 48.84 | 7.28 | 6.71 | 0.085 | 0.078 | 0.082 | 47.78 | 5.98 | 7.99 | 0.082 | 0.068 | 0.078 | 46.58 | 4.22 | 11.04 | ||

| 4 | EPS | Heat | 0.108 | 0.102 | 0.111 | 53.70 | 10.57 | 5.08 | 0.105 | 0.098 | 0.102 | 52.65 | 8.73 | 6.03 | 0.102 | 0.089 | 0.098 | 51.47 | 6.24 | 8.24 |

| Heat + Cool | 0.109 | 0.104 | 0.112 | 54.08 | 10.84 | 4.99 | 0.107 | 0.100 | 0.104 | 53.03 | 8.95 | 5.92 | 0.104 | 0.090 | 0.100 | 51.84 | 6.41 | 8.08 | ||

| MW | Heat | 0.134 | 0.128 | 0.137 | 49.85 | 10.82 | 4.61 | 0.131 | 0.124 | 0.128 | 49.13 | 8.98 | 5.47 | 0.128 | 0.115 | 0.124 | 48.32 | 6.50 | 7.44 | |

| Heat + Cool | 0.136 | 0.130 | 0.139 | 50.16 | 11.09 | 4.52 | 0.133 | 0.126 | 0.130 | 49.44 | 9.21 | 5.37 | 0.130 | 0.117 | 0.126 | 48.63 | 6.67 | 7.29 | ||

| PUR | Heat | 0.087 | 0.083 | 0.090 | 51.89 | 10.69 | 4.86 | 0.086 | 0.081 | 0.083 | 51.01 | 8.85 | 5.77 | 0.083 | 0.074 | 0.081 | 50.01 | 6.37 | 7.86 | |

| Heat + Cool | 0.089 | 0.085 | 0.091 | 52.24 | 10.96 | 4.77 | 0.087 | 0.082 | 0.085 | 51.35 | 9.08 | 5.66 | 0.085 | 0.075 | 0.082 | 50.35 | 6.54 | 7.70 | ||

| XPS | Heat | 0.107 | 0.102 | 0.110 | 53.83 | 10.56 | 5.10 | 0.105 | 0.097 | 0.102 | 52.77 | 8.72 | 6.05 | 0.102 | 0.088 | 0.097 | 51.57 | 6.23 | 8.27 | |

| Heat + Cool | 0.108 | 0.103 | 0.112 | 54.21 | 10.83 | 5.01 | 0.106 | 0.099 | 0.103 | 53.15 | 8.94 | 5.94 | 0.103 | 0.090 | 0.099 | 51.95 | 6.40 | 8.11 | ||

| January Climate Zone X | January Climate Zone Y | January Climate Zone Z | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| System | Insulation Material | Optimization Criterion | Walls | Roof | FFF | C | ECS | PP | Walls | Roof | FFF | C | ECS | PP | Walls | Roof | FFF | C | ECS | PP |

| 1 | EPS | Heat | 0.104 | 0.097 | 0.101 | 52.29 | 8.50 | 6.15 | 0.101 | 0.087 | 0.097 | 51.10 | 6.08 | 8.40 | 0.101 | 0.077 | 0.097 | 50.47 | 5.83 | 8.66 |

| Heat + Cool | 0.111 | 0.103 | 0.107 | 53.95 | 9.52 | 5.66 | 0.107 | 0.094 | 0.103 | 52.76 | 6.83 | 7.72 | 0.107 | 0.083 | 0.103 | 52.13 | 6.55 | 7.96 | ||

| MW | Heat | 0.130 | 0.122 | 0.126 | 48.83 | 8.76 | 5.58 | 0.126 | 0.113 | 0.122 | 48.01 | 6.33 | 7.58 | 0.126 | 0.102 | 0.122 | 47.58 | 6.08 | 7.83 | |

| Heat + Cool | 0.138 | 0.131 | 0.135 | 50.21 | 9.79 | 5.13 | 0.135 | 0.121 | 0.131 | 49.39 | 7.10 | 6.96 | 0.135 | 0.110 | 0.131 | 48.95 | 6.81 | 7.18 | ||

| PUR | Heat | 0.085 | 0.079 | 0.082 | 50.67 | 8.63 | 5.87 | 0.082 | 0.072 | 0.079 | 49.67 | 6.20 | 8.01 | 0.082 | 0.064 | 0.079 | 49.14 | 5.95 | 8.26 | |

| Heat + Cool | 0.090 | 0.085 | 0.088 | 52.20 | 9.65 | 5.41 | 0.088 | 0.078 | 0.085 | 51.20 | 6.96 | 7.36 | 0.088 | 0.070 | 0.085 | 50.66 | 6.68 | 7.59 | ||

| XPS | Heat | 0.103 | 0.096 | 0.100 | 52.40 | 8.50 | 6.17 | 0.100 | 0.087 | 0.096 | 51.20 | 6.07 | 8.43 | 0.100 | 0.076 | 0.096 | 50.56 | 5.82 | 8.69 | |

| Heat + Cool | 0.110 | 0.103 | 0.107 | 54.08 | 9.51 | 5.68 | 0.107 | 0.093 | 0.103 | 52.87 | 6.82 | 7.75 | 0.107 | 0.082 | 0.103 | 52.24 | 6.54 | 7.99 | ||

| 2 | EPS | Heat | 0.104 | 0.097 | 0.101 | 52.25 | 8.48 | 6.16 | 0.101 | 0.087 | 0.097 | 51.07 | 6.07 | 8.42 | 0.101 | 0.076 | 0.097 | 50.43 | 5.81 | 8.68 |

| Heat + Cool | 0.110 | 0.103 | 0.107 | 53.92 | 9.50 | 5.67 | 0.107 | 0.094 | 0.103 | 52.73 | 6.82 | 7.73 | 0.107 | 0.083 | 0.103 | 52.10 | 6.54 | 7.97 | ||

| MW | Heat | 0.129 | 0.122 | 0.126 | 48.80 | 8.73 | 5.59 | 0.126 | 0.113 | 0.122 | 47.98 | 6.32 | 7.60 | 0.126 | 0.102 | 0.122 | 47.55 | 6.06 | 7.84 | |

| Heat + Cool | 0.137 | 0.130 | 0.134 | 50.18 | 9.77 | 5.14 | 0.134 | 0.121 | 0.130 | 49.36 | 7.08 | 6.97 | 0.134 | 0.110 | 0.130 | 48.93 | 6.80 | 7.20 | ||

| PUR | Heat | 0.084 | 0.079 | 0.082 | 50.64 | 8.60 | 5.89 | 0.082 | 0.072 | 0.079 | 49.64 | 6.19 | 8.02 | 0.082 | 0.064 | 0.079 | 49.11 | 5.93 | 8.28 | |

| Heat + Cool | 0.090 | 0.085 | 0.088 | 52.17 | 9.63 | 5.42 | 0.088 | 0.078 | 0.085 | 51.17 | 6.94 | 7.37 | 0.088 | 0.070 | 0.085 | 50.63 | 6.66 | 7.60 | ||

| XPS | Heat | 0.103 | 0.096 | 0.100 | 52.37 | 8.48 | 6.18 | 0.100 | 0.086 | 0.096 | 51.17 | 6.06 | 8.45 | 0.100 | 0.076 | 0.096 | 50.53 | 5.80 | 8.71 | |

| Heat + Cool | 0.110 | 0.103 | 0.107 | 54.04 | 9.49 | 5.69 | 0.107 | 0.093 | 0.103 | 52.84 | 6.81 | 7.76 | 0.107 | 0.082 | 0.103 | 52.20 | 6.53 | 8.00 | ||

| 3 | EPS | Heat | 0.079 | 0.072 | 0.076 | 46.24 | 5.28 | 8.76 | 0.076 | 0.063 | 0.072 | 45.05 | 3.71 | 12.14 | 0.076 | 0.052 | 0.072 | 44.42 | 3.54 | 12.53 |

| Heat + Cool | 0.088 | 0.081 | 0.085 | 48.28 | 6.28 | 7.69 | 0.085 | 0.071 | 0.081 | 47.09 | 4.44 | 10.60 | 0.085 | 0.060 | 0.081 | 46.46 | 4.25 | 10.93 | ||

| MW | Heat | 0.100 | 0.093 | 0.097 | 43.81 | 5.48 | 7.99 | 0.097 | 0.084 | 0.093 | 43.00 | 3.91 | 10.99 | 0.097 | 0.073 | 0.093 | 42.56 | 3.75 | 11.36 | |

| Heat + Cool | 0.110 | 0.103 | 0.107 | 45.50 | 6.50 | 7.00 | 0.107 | 0.093 | 0.103 | 44.68 | 4.66 | 9.58 | 0.107 | 0.083 | 0.103 | 44.25 | 4.47 | 9.90 | ||

| PUR | Heat | 0.065 | 0.060 | 0.063 | 45.12 | 5.38 | 8.39 | 0.063 | 0.053 | 0.060 | 44.12 | 3.81 | 11.59 | 0.063 | 0.045 | 0.060 | 43.59 | 3.64 | 11.97 | |

| Heat + Cool | 0.072 | 0.066 | 0.069 | 46.99 | 6.39 | 7.36 | 0.069 | 0.059 | 0.066 | 45.99 | 4.55 | 10.11 | 0.069 | 0.051 | 0.066 | 45.45 | 4.35 | 10.44 | ||

| XPS | Heat | 0.079 | 0.072 | 0.076 | 46.32 | 5.27 | 8.78 | 0.076 | 0.062 | 0.072 | 45.12 | 3.70 | 12.19 | 0.076 | 0.052 | 0.072 | 44.48 | 3.54 | 12.58 | |

| Heat + Cool | 0.087 | 0.080 | 0.084 | 48.37 | 6.27 | 7.71 | 0.084 | 0.070 | 0.080 | 47.17 | 4.44 | 10.63 | 0.084 | 0.060 | 0.080 | 46.53 | 4.24 | 10.97 | ||

| 4 | EPS | Heat | 0.102 | 0.095 | 0.099 | 51.88 | 8.26 | 6.28 | 0.099 | 0.086 | 0.095 | 50.69 | 5.90 | 8.59 | 0.099 | 0.075 | 0.095 | 50.06 | 5.65 | 8.85 |

| Heat + Cool | 0.106 | 0.099 | 0.103 | 52.83 | 8.83 | 5.98 | 0.103 | 0.089 | 0.099 | 51.64 | 6.32 | 8.17 | 0.103 | 0.079 | 0.099 | 51.01 | 6.06 | 8.42 | ||

| MW | Heat | 0.128 | 0.120 | 0.125 | 48.49 | 8.51 | 5.70 | 0.125 | 0.111 | 0.120 | 47.67 | 6.15 | 7.75 | 0.125 | 0.100 | 0.120 | 47.24 | 5.90 | 8.00 | |

| Heat + Cool | 0.132 | 0.125 | 0.129 | 49.28 | 9.09 | 5.42 | 0.129 | 0.116 | 0.125 | 48.46 | 6.58 | 7.37 | 0.129 | 0.105 | 0.125 | 48.03 | 6.31 | 7.61 | ||

| PUR | Heat | 0.083 | 0.078 | 0.081 | 50.30 | 8.38 | 6.00 | 0.081 | 0.071 | 0.078 | 49.30 | 6.02 | 8.19 | 0.081 | 0.063 | 0.078 | 48.76 | 5.77 | 8.45 | |

| Heat + Cool | 0.086 | 0.081 | 0.084 | 51.17 | 8.95 | 5.71 | 0.084 | 0.074 | 0.081 | 50.17 | 6.44 | 7.78 | 0.084 | 0.066 | 0.081 | 49.64 | 6.18 | 8.03 | ||

| XPS | Heat | 0.101 | 0.094 | 0.098 | 51.99 | 8.25 | 6.30 | 0.098 | 0.085 | 0.094 | 50.79 | 5.89 | 8.62 | 0.098 | 0.074 | 0.094 | 50.15 | 5.64 | 8.88 | |

| Heat + Cool | 0.105 | 0.098 | 0.102 | 52.95 | 8.82 | 6.00 | 0.102 | 0.089 | 0.098 | 51.75 | 6.31 | 8.20 | 0.102 | 0.078 | 0.098 | 51.11 | 6.05 | 8.45 | ||

| January Climate Zone X | January Climate Zone Y | January Climate Zone Z | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| System | Insulation Material | Optimization Criterion | Walls | Roof | FFF | C | ECS | PP | Walls | Roof | FFF | C | ECS | PP | Walls | Roof | FFF | C | ECS | PP |

| 1 | EPS | Heat | 0.101 | 0.094 | 0.098 | 51.66 | 8.14 | 6.35 | 0.098 | 0.085 | 0.094 | 50.48 | 5.81 | 8.69 | 0.098 | 0.074 | 0.094 | 49.84 | 5.56 | 8.96 |

| Heat + Cool | 0.114 | 0.107 | 0.111 | 54.86 | 10.11 | 5.43 | 0.111 | 0.098 | 0.107 | 53.68 | 7.27 | 7.39 | 0.111 | 0.087 | 0.107 | 53.04 | 6.97 | 7.61 | ||

| MW | Heat | 0.126 | 0.119 | 0.123 | 48.31 | 8.38 | 5.76 | 0.123 | 0.110 | 0.119 | 47.49 | 6.06 | 7.84 | 0.123 | 0.099 | 0.119 | 47.06 | 5.81 | 8.10 | |

| Heat + Cool | 0.142 | 0.135 | 0.139 | 50.96 | 10.38 | 4.91 | 0.139 | 0.126 | 0.135 | 50.15 | 7.54 | 6.65 | 0.139 | 0.115 | 0.135 | 49.71 | 7.24 | 6.87 | ||

| PUR | Heat | 0.083 | 0.077 | 0.080 | 50.10 | 8.25 | 6.07 | 0.080 | 0.070 | 0.077 | 49.10 | 5.93 | 8.28 | 0.080 | 0.062 | 0.077 | 48.56 | 5.68 | 8.55 | |

| Heat + Cool | 0.093 | 0.088 | 0.091 | 53.04 | 10.24 | 5.18 | 0.091 | 0.081 | 0.088 | 52.04 | 7.40 | 7.04 | 0.091 | 0.073 | 0.088 | 51.50 | 7.10 | 7.26 | ||

| XPS | Heat | 0.101 | 0.093 | 0.098 | 51.78 | 8.13 | 6.37 | 0.098 | 0.084 | 0.093 | 50.58 | 5.80 | 8.72 | 0.098 | 0.073 | 0.093 | 49.94 | 5.56 | 8.99 | |

| Heat + Cool | 0.113 | 0.106 | 0.110 | 55.00 | 10.10 | 5.45 | 0.110 | 0.097 | 0.106 | 53.79 | 7.26 | 7.41 | 0.110 | 0.086 | 0.106 | 53.16 | 6.96 | 7.64 | ||

| 2 | EPS | Heat | 0.101 | 0.094 | 0.098 | 51.63 | 8.12 | 6.36 | 0.098 | 0.085 | 0.094 | 50.44 | 5.80 | 8.70 | 0.098 | 0.074 | 0.094 | 49.81 | 5.55 | 8.97 |

| Heat + Cool | 0.114 | 0.107 | 0.111 | 54.83 | 10.09 | 5.43 | 0.111 | 0.098 | 0.107 | 53.65 | 7.25 | 7.40 | 0.111 | 0.087 | 0.107 | 53.01 | 6.95 | 7.63 | ||

| MW | Heat | 0.126 | 0.119 | 0.123 | 48.28 | 8.36 | 5.77 | 0.123 | 0.110 | 0.119 | 47.47 | 6.04 | 7.86 | 0.123 | 0.099 | 0.119 | 47.03 | 5.80 | 8.11 | |

| Heat + Cool | 0.142 | 0.135 | 0.139 | 50.94 | 10.36 | 4.92 | 0.139 | 0.125 | 0.135 | 50.12 | 7.52 | 6.66 | 0.139 | 0.115 | 0.135 | 49.69 | 7.22 | 6.88 | ||

| PUR | Heat | 0.082 | 0.077 | 0.080 | 50.07 | 8.23 | 6.08 | 0.080 | 0.070 | 0.077 | 49.07 | 5.91 | 8.30 | 0.080 | 0.062 | 0.077 | 48.53 | 5.67 | 8.56 | |

| Heat + Cool | 0.093 | 0.088 | 0.091 | 53.01 | 10.22 | 5.19 | 0.091 | 0.081 | 0.088 | 52.01 | 7.38 | 7.05 | 0.091 | 0.073 | 0.088 | 51.48 | 7.08 | 7.27 | ||

| XPS | Heat | 0.100 | 0.093 | 0.097 | 51.74 | 8.11 | 6.38 | 0.097 | 0.084 | 0.093 | 50.54 | 5.79 | 8.73 | 0.097 | 0.073 | 0.093 | 49.90 | 5.54 | 9.00 | |

| Heat + Cool | 0.113 | 0.106 | 0.110 | 54.96 | 10.08 | 5.45 | 0.110 | 0.097 | 0.106 | 53.76 | 7.24 | 7.42 | 0.110 | 0.086 | 0.106 | 53.12 | 6.94 | 7.65 | ||

| 3 | EPS | Heat | 0.077 | 0.070 | 0.074 | 45.74 | 5.05 | 9.06 | 0.074 | 0.061 | 0.070 | 44.55 | 3.54 | 12.59 | 0.074 | 0.050 | 0.070 | 43.92 | 3.38 | 13.00 |

| Heat + Cool | 0.093 | 0.086 | 0.090 | 49.61 | 6.99 | 7.10 | 0.090 | 0.077 | 0.086 | 48.43 | 4.96 | 9.76 | 0.090 | 0.066 | 0.086 | 47.80 | 4.75 | 10.06 | ||

| MW | Heat | 0.098 | 0.091 | 0.095 | 43.39 | 5.24 | 8.28 | 0.095 | 0.081 | 0.091 | 42.58 | 3.74 | 11.40 | 0.095 | 0.070 | 0.091 | 42.14 | 3.58 | 11.78 | |

| Heat + Cool | 0.117 | 0.109 | 0.114 | 46.61 | 7.22 | 6.46 | 0.114 | 0.100 | 0.109 | 45.79 | 5.19 | 8.82 | 0.114 | 0.089 | 0.109 | 45.36 | 4.98 | 9.11 | ||

| PUR | Heat | 0.063 | 0.058 | 0.061 | 44.66 | 5.14 | 8.69 | 0.061 | 0.051 | 0.058 | 43.66 | 3.63 | 12.02 | 0.061 | 0.043 | 0.058 | 43.12 | 3.47 | 12.41 | |

| Heat + Cool | 0.076 | 0.071 | 0.074 | 48.22 | 7.10 | 6.79 | 0.074 | 0.064 | 0.071 | 47.22 | 5.07 | 9.31 | 0.074 | 0.056 | 0.071 | 46.68 | 4.86 | 9.61 | ||

| XPS | Heat | 0.077 | 0.070 | 0.074 | 45.81 | 5.04 | 9.09 | 0.074 | 0.060 | 0.070 | 44.61 | 3.53 | 12.63 | 0.074 | 0.049 | 0.070 | 43.97 | 3.37 | 13.04 | |

| Heat + Cool | 0.092 | 0.085 | 0.089 | 49.72 | 6.98 | 7.12 | 0.089 | 0.076 | 0.085 | 48.52 | 4.95 | 9.79 | 0.089 | 0.065 | 0.085 | 47.88 | 4.74 | 10.10 | ||

| 4 | EPS | Heat | 0.100 | 0.093 | 0.097 | 51.26 | 7.90 | 6.49 | 0.097 | 0.083 | 0.093 | 50.07 | 5.64 | 8.88 | 0.097 | 0.072 | 0.093 | 49.44 | 5.40 | 9.16 |

| Heat + Cool | 0.107 | 0.100 | 0.104 | 53.12 | 9.01 | 5.90 | 0.104 | 0.091 | 0.100 | 51.93 | 6.45 | 8.05 | 0.104 | 0.080 | 0.100 | 51.30 | 6.18 | 8.30 | ||

| MW | Heat | 0.125 | 0.117 | 0.122 | 47.98 | 8.15 | 5.89 | 0.122 | 0.108 | 0.117 | 47.16 | 5.88 | 8.02 | 0.122 | 0.097 | 0.117 | 46.73 | 5.64 | 8.28 | |

| Heat + Cool | 0.134 | 0.126 | 0.131 | 49.52 | 9.26 | 5.35 | 0.131 | 0.117 | 0.126 | 48.70 | 6.71 | 7.26 | 0.131 | 0.106 | 0.126 | 48.26 | 6.44 | 7.50 | ||

| PUR | Heat | 0.081 | 0.076 | 0.079 | 49.73 | 8.02 | 6.20 | 0.079 | 0.069 | 0.076 | 48.73 | 5.75 | 8.47 | 0.079 | 0.061 | 0.076 | 48.20 | 5.52 | 8.74 | |

| Heat + Cool | 0.087 | 0.082 | 0.085 | 51.43 | 9.13 | 5.63 | 0.085 | 0.075 | 0.082 | 50.43 | 6.57 | 7.67 | 0.085 | 0.067 | 0.082 | 49.90 | 6.31 | 7.91 | ||

| XPS | Heat | 0.099 | 0.092 | 0.096 | 51.37 | 7.90 | 6.51 | 0.096 | 0.082 | 0.092 | 50.17 | 5.63 | 8.91 | 0.096 | 0.072 | 0.092 | 49.53 | 5.39 | 9.19 | |

| Heat + Cool | 0.106 | 0.099 | 0.103 | 53.24 | 9.00 | 5.92 | 0.103 | 0.090 | 0.099 | 52.04 | 6.44 | 8.08 | 0.103 | 0.079 | 0.099 | 51.40 | 6.17 | 8.33 | ||

| System | Insulation Material | Optimization Criterion | Walls | Roof | FFF | C | ECS | PP |

|---|---|---|---|---|---|---|---|---|

| 1 | EPS | Heat | 0.115 | 0.091 | 0.111 | 54.02 | 7.42 | 7.28 |

| Heat + Cool | 0.117 | 0.093 | 0.113 | 54.58 | 7.70 | 7.09 | ||

| MW | Heat | 0.144 | 0.119 | 0.140 | 50.52 | 7.70 | 6.56 | |

| Heat + Cool | 0.147 | 0.122 | 0.142 | 50.99 | 7.98 | 6.39 | ||

| PUR | Heat | 0.094 | 0.076 | 0.091 | 52.40 | 7.56 | 6.93 | |

| Heat + Cool | 0.096 | 0.078 | 0.093 | 52.92 | 7.83 | 6.76 | ||

| XPS | Heat | 0.114 | 0.090 | 0.110 | 54.13 | 7.41 | 7.30 | |

| Heat + Cool | 0.117 | 0.092 | 0.112 | 54.70 | 7.68 | 7.12 | ||

| 2 | EPS | Heat | 0.115 | 0.091 | 0.111 | 53.98 | 7.40 | 7.29 |

| Heat + Cool | 0.117 | 0.093 | 0.113 | 54.54 | 7.68 | 7.11 | ||

| MW | Heat | 0.144 | 0.119 | 0.140 | 50.49 | 7.68 | 6.57 | |

| Heat + Cool | 0.146 | 0.122 | 0.142 | 50.96 | 7.96 | 6.40 | ||

| PUR | Heat | 0.094 | 0.076 | 0.091 | 52.36 | 7.54 | 6.95 | |

| Heat + Cool | 0.095 | 0.078 | 0.092 | 52.88 | 7.81 | 6.77 | ||

| XPS | Heat | 0.114 | 0.090 | 0.110 | 54.09 | 7.39 | 7.32 | |

| Heat + Cool | 0.116 | 0.092 | 0.112 | 54.66 | 7.67 | 7.13 | ||

| 3 | EPS | Heat | 0.088 | 0.064 | 0.084 | 47.28 | 4.55 | 10.39 |

| Heat + Cool | 0.091 | 0.066 | 0.087 | 47.98 | 4.82 | 9.96 | ||

| MW | Heat | 0.111 | 0.087 | 0.107 | 44.93 | 4.78 | 9.41 | |

| Heat + Cool | 0.114 | 0.090 | 0.110 | 45.51 | 5.05 | 9.01 | ||

| PUR | Heat | 0.072 | 0.054 | 0.069 | 46.21 | 4.66 | 9.92 | |

| Heat + Cool | 0.074 | 0.056 | 0.071 | 46.85 | 4.93 | 9.50 | ||

| XPS | Heat | 0.087 | 0.063 | 0.083 | 47.35 | 4.54 | 10.42 | |

| Heat + Cool | 0.090 | 0.066 | 0.086 | 48.06 | 4.81 | 9.99 | ||

| 4 | EPS | Heat | 0.113 | 0.089 | 0.109 | 53.56 | 7.21 | 7.43 |

| Heat + Cool | 0.115 | 0.090 | 0.111 | 53.88 | 7.36 | 7.32 | ||

| MW | Heat | 0.142 | 0.117 | 0.137 | 50.14 | 7.48 | 6.70 | |

| Heat + Cool | 0.143 | 0.119 | 0.139 | 50.41 | 7.64 | 6.60 | ||

| PUR | Heat | 0.092 | 0.074 | 0.089 | 51.98 | 7.34 | 7.08 | |

| Heat + Cool | 0.093 | 0.075 | 0.090 | 52.27 | 7.49 | 6.98 | ||

| XPS | Heat | 0.112 | 0.088 | 0.108 | 53.67 | 7.20 | 7.46 | |

| Heat + Cool | 0.114 | 0.089 | 0.110 | 54.00 | 7.35 | 7.35 |

| CZ | JCZ | System | HED | CED | FEC | TPEC | NRPEC | EM | RNRPEC | REM | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| D1 | W | 1 | 2.15 | 160.84 | 4.66 | 207.09 | 247.54 | 245.96 | 64.45 | E | F |

| 2 | 2.15 | 160.84 | 4.66 | 191.51 | 231.58 | 229.67 | 48.44 | E | E | ||

| 3 | 2.15 | 160.84 | 4.66 | 207.09 | 233.41 | 21.96 | 4.46 | A | A | ||

| 4* | 2.15 | 160.84 | 4.66 | 71.95 | 170.37 | 140.58 | 23.81 | E | D | ||

| 4 | 2.15 | 160.84 | 4.66 | 71.17 | 168.53 | 139.07 | 23.56 | E | D | ||

| X | 1 | 1.85 | 138.32 | 4.01 | 180.50 | 215.72 | 214.36 | 56.17 | E | E | |

| 2 | 1.85 | 138.32 | 4.01 | 166.91 | 201.81 | 200.16 | 42.22 | E | E | ||

| 3 | 1.85 | 138.32 | 4.01 | 180.50 | 203.40 | 19.09 | 3.88 | A | A | ||

| 4* | 1.85 | 138.32 | 4.01 | 62.69 | 148.45 | 122.50 | 20.75 | D | D | ||

| 4 | 1.85 | 138.32 | 4.01 | 62.02 | 146.87 | 121.19 | 20.53 | D | D | ||

| Y | 1 | 1.45 | 107.94 | 3.13 | 144.35 | 172.47 | 171.40 | 44.92 | E | E | |

| 2 | 1.45 | 107.94 | 3.13 | 133.48 | 161.35 | 160.04 | 33.76 | E | E | ||

| 3 | 1.45 | 107.94 | 3.13 | 144.35 | 162.62 | 15.19 | 3.09 | A | A | ||

| 4* | 1.45 | 107.94 | 3.13 | 50.11 | 118.66 | 97.91 | 16.59 | D | C | ||

| 4 | 1.45 | 107.94 | 3.13 | 49.59 | 117.43 | 96.90 | 16.41 | D | C | ||

| D2 | X | 1 | 1.85 | 131.55 | 9.99 | 175.14 | 212.94 | 210.36 | 54.57 | E | E |

| 2 | 1.85 | 131.55 | 9.99 | 162.19 | 199.68 | 196.82 | 41.27 | E | E | ||

| 3 | 1.85 | 131.55 | 9.99 | 175.14 | 201.20 | 24.22 | 4.72 | A | A | ||

| 4* | 1.85 | 131.55 | 9.99 | 62.84 | 148.81 | 122.80 | 20.80 | D | D | ||

| 4 | 1.85 | 131.55 | 9.99 | 61.18 | 144.87 | 119.54 | 20.25 | D | D | ||

| Y | 1 | 1.45 | 102.66 | 7.80 | 140.23 | 170.38 | 168.36 | 43.69 | E | E | |

| 2 | 1.45 | 102.66 | 7.80 | 129.86 | 159.76 | 157.51 | 33.03 | E | E | ||

| 3 | 1.45 | 102.66 | 7.80 | 140.23 | 160.97 | 19.21 | 3.74 | A | A | ||

| 4* | 1.45 | 102.66 | 7.80 | 50.25 | 119.00 | 98.19 | 16.63 | D | C | ||

| 4 | 1.45 | 102.66 | 7.80 | 48.95 | 115.92 | 95.65 | 16.20 | D | C | ||

| Z | 1 | 1.40 | 99.61 | 7.57 | 136.80 | 166.18 | 164.22 | 42.62 | E | E | |

| 2 | 1.40 | 99.61 | 7.57 | 126.68 | 155.82 | 153.64 | 32.22 | E | E | ||

| 3 | 1.40 | 99.61 | 7.57 | 136.80 | 157.00 | 18.70 | 3.65 | A | A | ||

| 4* | 1.40 | 99.61 | 7.57 | 49.01 | 116.05 | 95.76 | 16.22 | D | C | ||

| 4 | 1.40 | 99.61 | 7.57 | 47.75 | 113.06 | 93.30 | 15.80 | D | C | ||

| D3 | X | 1 | 1.85 | 126.30 | 19.34 | 173.44 | 216.47 | 211.97 | 54.13 | E | E |

| 2 | 1.85 | 126.30 | 19.34 | 160.97 | 203.71 | 198.95 | 41.33 | E | E | ||

| 3 | 1.85 | 126.30 | 19.34 | 173.44 | 205.17 | 32.81 | 6.15 | A | A | ||

| 4* | 1.85 | 126.30 | 19.34 | 65.35 | 154.75 | 127.69 | 21.63 | D | D | ||

| 4 | 1.85 | 126.30 | 19.34 | 62.13 | 147.12 | 121.40 | 20.56 | D | C | ||

| Y | 1 | 1.45 | 98.56 | 15.09 | 138.83 | 173.04 | 169.52 | 43.33 | E | E | |

| 2 | 1.45 | 98.56 | 15.09 | 128.84 | 162.81 | 159.08 | 33.06 | E | E | ||

| 3 | 1.45 | 98.56 | 15.09 | 138.83 | 163.98 | 25.90 | 4.86 | A | A | ||

| 4* | 1.45 | 98.56 | 15.09 | 52.18 | 123.57 | 101.96 | 17.27 | D | C | ||

| 4 | 1.45 | 98.56 | 15.09 | 49.67 | 117.61 | 97.05 | 16.44 | D | C | ||

| Z | 1 | 1.40 | 95.64 | 14.64 | 135.25 | 168.55 | 165.13 | 42.21 | E | E | |

| 2 | 1.40 | 95.64 | 14.64 | 125.51 | 158.58 | 154.96 | 32.21 | E | D | ||

| 3 | 1.40 | 95.64 | 14.64 | 135.25 | 159.72 | 25.18 | 4.73 | A | A | ||

| 4* | 1.40 | 95.64 | 14.64 | 50.82 | 120.33 | 99.30 | 16.82 | D | C | ||

| 4 | 1.40 | 95.64 | 14.64 | 48.38 | 114.55 | 94.53 | 16.01 | D | C | ||

| E1 | Z | 1 | 1.40 | 123.70 | 2.82 | 163.06 | 194.42 | 193.35 | 50.74 | E | E |

| 2 | 1.40 | 123.70 | 2.82 | 150.76 | 181.82 | 180.49 | 38.10 | E | E | ||

| 3 | 1.40 | 123.70 | 2.82 | 163.06 | 183.26 | 16.50 | 3.38 | A | A | ||

| 4* | 1.40 | 123.70 | 2.82 | 56.37 | 133.49 | 110.15 | 18.66 | D | C | ||

| 4 | 1.40 | 123.70 | 2.82 | 55.90 | 132.38 | 109.23 | 18.50 | D | C |

| January Climate Zone W | January Climate Zone X | January Climate Zone Y | |||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| System | Insulation Material | Optimization Criterion | HED | CED | FEC | TPEC | NRPEC | EM | RNRPEC | REM | HED | CED | FEC | TPEC | NRPEC | EM | RNRPEC | REM | HED | CED | FEC | TPEC | NRPEC | EM | RNRPEC | REM | |||

| 1 | EPS | Heat | 0.42 | 31.25 | 0.91 | 53.37 | 63.62 | 63.28 | 16.61 | C | C | 0.42 | 31.25 | 0.91 | 53.64 | 63.94 | 63.60 | 16.69 | C | C | 0.42 | 31.25 | 0.91 | 53.68 | 63.99 | 63.64 | 16.70 | C | C |

| Heat + Cool | 0.41 | 30.89 | 0.89 | 52.94 | 63.10 | 62.76 | 16.47 | C | C | 0.41 | 30.89 | 0.89 | 53.21 | 63.42 | 63.08 | 16.56 | C | C | 0.41 | 30.89 | 0.89 | 53.25 | 63.47 | 63.13 | 16.57 | C | C | ||

| MW | Heat | 0.38 | 28.19 | 0.82 | 49.72 | 59.26 | 58.94 | 15.47 | C | C | 0.38 | 28.19 | 0.82 | 50.00 | 59.58 | 59.26 | 15.56 | C | C | 0.38 | 28.19 | 0.82 | 50.04 | 59.63 | 59.31 | 15.57 | C | C | |

| Heat + Cool | 0.37 | 27.89 | 0.81 | 49.36 | 58.83 | 58.51 | 15.36 | C | C | 0.37 | 27.89 | 0.81 | 49.63 | 59.15 | 58.83 | 15.44 | C | C | 0.37 | 27.89 | 0.81 | 49.68 | 59.20 | 58.88 | 15.46 | C | C | ||

| PUR | Heat | 0.40 | 29.79 | 0.86 | 51.62 | 61.53 | 61.20 | 16.06 | C | C | 0.40 | 29.79 | 0.86 | 51.89 | 61.85 | 61.52 | 16.15 | C | C | 0.40 | 29.79 | 0.86 | 51.94 | 61.90 | 61.57 | 16.16 | C | C | |

| Heat + Cool | 0.39 | 29.45 | 0.85 | 51.22 | 61.05 | 60.72 | 15.94 | C | C | 0.39 | 29.45 | 0.85 | 51.50 | 61.37 | 61.04 | 16.02 | C | C | 0.39 | 29.45 | 0.85 | 51.54 | 61.42 | 61.09 | 16.04 | C | C | ||

| XPS | Heat | 0.42 | 31.36 | 0.91 | 53.50 | 63.78 | 63.43 | 16.65 | C | C | 0.42 | 31.36 | 0.91 | 53.77 | 64.10 | 63.75 | 16.73 | C | C | 0.42 | 31.36 | 0.91 | 53.81 | 64.15 | 63.80 | 16.75 | C | C | |

| Heat + Cool | 0.42 | 31.00 | 0.90 | 53.06 | 63.25 | 62.91 | 16.51 | C | C | 0.42 | 31.00 | 0.90 | 53.34 | 63.57 | 63.23 | 16.60 | C | C | 0.42 | 31.00 | 0.90 | 53.38 | 63.62 | 63.28 | 16.61 | C | C | ||

| 2 | EPS | Heat | 0.42 | 31.27 | 0.91 | 49.37 | 59.52 | 59.09 | 12.48 | C | B | 0.42 | 31.27 | 0.91 | 49.62 | 59.82 | 59.39 | 12.54 | C | B | 0.42 | 31.27 | 0.91 | 49.66 | 59.87 | 59.44 | 12.55 | C | B |

| Heat + Cool | 0.41 | 30.91 | 0.90 | 48.96 | 59.04 | 58.61 | 12.37 | C | B | 0.41 | 30.91 | 0.90 | 49.21 | 59.34 | 58.91 | 12.44 | C | B | 0.41 | 30.91 | 0.90 | 49.25 | 59.38 | 58.95 | 12.45 | C | B | ||

| MW | Heat | 0.38 | 28.21 | 0.82 | 45.99 | 55.44 | 55.04 | 11.62 | B | B | 0.38 | 28.21 | 0.82 | 46.24 | 55.74 | 55.34 | 11.68 | B | B | 0.38 | 28.21 | 0.82 | 46.28 | 55.78 | 55.38 | 11.69 | B | B | |

| Heat + Cool | 0.37 | 27.90 | 0.81 | 45.65 | 55.03 | 54.64 | 11.54 | B | B | 0.37 | 27.90 | 0.81 | 45.91 | 55.33 | 54.94 | 11.60 | B | B | 0.37 | 27.90 | 0.81 | 45.94 | 55.38 | 54.98 | 11.61 | B | B | ||

| PUR | Heat | 0.40 | 29.80 | 0.86 | 47.75 | 57.57 | 57.15 | 12.07 | B | B | 0.40 | 29.80 | 0.86 | 48.00 | 57.87 | 57.45 | 12.13 | B | B | 0.40 | 29.80 | 0.86 | 48.04 | 57.91 | 57.49 | 12.14 | B | B | |

| Heat + Cool | 0.39 | 29.47 | 0.85 | 47.38 | 57.12 | 56.71 | 11.97 | B | B | 0.39 | 29.47 | 0.85 | 47.63 | 57.42 | 57.00 | 12.04 | B | B | 0.39 | 29.47 | 0.85 | 47.67 | 57.46 | 57.05 | 12.05 | B | B | ||

| XPS | Heat | 0.42 | 31.38 | 0.91 | 49.49 | 59.67 | 59.24 | 12.51 | C | B | 0.42 | 31.38 | 0.91 | 49.74 | 59.97 | 59.54 | 12.57 | C | B | 0.42 | 31.38 | 0.91 | 49.78 | 60.02 | 59.58 | 12.58 | C | B | |

| Heat + Cool | 0.42 | 31.01 | 0.90 | 49.08 | 59.18 | 58.75 | 12.40 | C | B | 0.42 | 31.01 | 0.90 | 49.33 | 59.48 | 59.05 | 12.47 | C | B | 0.42 | 31.01 | 0.90 | 49.37 | 59.52 | 59.09 | 12.48 | C | B | ||

| 3 | EPS | Heat | 0.48 | 35.61 | 1.03 | 58.55 | 65.82 | 5.94 | 1.22 | A | A | 0.48 | 35.61 | 1.03 | 58.83 | 66.12 | 5.96 | 1.22 | A | A | 0.48 | 35.61 | 1.03 | 58.87 | 66.17 | 5.97 | 1.22 | A | A |

| Heat + Cool | 0.47 | 34.92 | 1.01 | 57.73 | 64.89 | 5.85 | 1.20 | A | A | 0.47 | 34.92 | 1.01 | 58.01 | 65.19 | 5.88 | 1.20 | A | A | 0.47 | 34.92 | 1.01 | 58.05 | 65.24 | 5.88 | 1.20 | A | A | ||

| MW | Heat | 0.43 | 31.80 | 0.92 | 54.02 | 60.71 | 5.45 | 1.12 | A | A | 0.43 | 31.80 | 0.92 | 54.29 | 61.01 | 5.48 | 1.12 | A | A | 0.43 | 31.80 | 0.92 | 54.34 | 61.05 | 5.48 | 1.12 | A | A | |

| Heat + Cool | 0.42 | 31.23 | 0.90 | 53.34 | 59.94 | 5.38 | 1.10 | A | A | 0.42 | 31.23 | 0.90 | 53.61 | 60.24 | 5.40 | 1.11 | A | A | 0.42 | 31.23 | 0.90 | 53.66 | 60.29 | 5.41 | 1.11 | A | A | ||

| PUR | Heat | 0.45 | 33.78 | 0.98 | 56.38 | 63.37 | 5.71 | 1.17 | A | A | 0.45 | 33.78 | 0.98 | 56.65 | 63.67 | 5.73 | 1.17 | A | A | 0.45 | 33.78 | 0.98 | 56.70 | 63.72 | 5.73 | 1.17 | A | A | |

| Heat + Cool | 0.44 | 33.15 | 0.96 | 55.63 | 62.52 | 5.63 | 1.15 | A | A | 0.44 | 33.15 | 0.96 | 55.90 | 62.82 | 5.65 | 1.16 | A | A | 0.44 | 33.15 | 0.96 | 55.94 | 62.87 | 5.65 | 1.16 | A | A | ||

| XPS | Heat | 0.48 | 35.74 | 1.04 | 58.72 | 66.00 | 5.96 | 1.22 | A | A | 0.48 | 35.74 | 1.04 | 58.99 | 66.30 | 5.98 | 1.22 | A | A | 0.48 | 35.74 | 1.04 | 59.03 | 66.35 | 5.98 | 1.22 | A | A | |

| Heat + Cool | 0.47 | 35.05 | 1.02 | 57.89 | 65.07 | 5.87 | 1.20 | A | A | 0.47 | 35.05 | 1.02 | 58.16 | 65.37 | 5.89 | 1.21 | A | A | 0.47 | 35.05 | 1.02 | 58.20 | 65.42 | 5.90 | 1.21 | A | A | ||

| 4 | EPS | Heat | 0.42 | 31.49 | 0.91 | 18.54 | 43.91 | 36.24 | 6.14 | A | A | 0.42 | 31.49 | 0.91 | 18.64 | 44.13 | 36.42 | 6.17 | A | A | 0.42 | 31.49 | 0.91 | 18.65 | 44.17 | 36.44 | 6.17 | A | A |

| Heat + Cool | 0.42 | 31.28 | 0.91 | 18.30 | 43.34 | 35.77 | 6.06 | A | A | 0.42 | 31.28 | 0.91 | 18.40 | 43.56 | 35.95 | 6.09 | A | A | 0.42 | 31.28 | 0.91 | 18.41 | 43.60 | 35.97 | 6.09 | A | A | ||

| MW | Heat | 0.38 | 28.39 | 0.82 | 17.26 | 40.87 | 33.72 | 5.71 | A | A | 0.38 | 28.39 | 0.82 | 17.35 | 41.09 | 33.90 | 5.74 | A | A | 0.38 | 28.39 | 0.82 | 17.36 | 41.12 | 33.93 | 5.75 | A | A | |

| Heat + Cool | 0.38 | 28.21 | 0.82 | 17.05 | 40.37 | 33.31 | 5.64 | A | A | 0.38 | 28.21 | 0.82 | 17.14 | 40.59 | 33.49 | 5.67 | A | A | 0.38 | 28.21 | 0.82 | 17.15 | 40.62 | 33.52 | 5.68 | A | A | ||

| PUR | Heat | 0.40 | 30.01 | 0.87 | 17.93 | 42.45 | 35.03 | 5.93 | A | A | 0.40 | 30.01 | 0.87 | 18.02 | 42.67 | 35.21 | 5.96 | A | A | 0.40 | 30.01 | 0.87 | 18.03 | 42.71 | 35.24 | 5.97 | A | A | |

| Heat + Cool | 0.40 | 29.81 | 0.86 | 17.70 | 41.92 | 34.59 | 5.86 | A | A | 0.40 | 29.81 | 0.86 | 17.79 | 42.14 | 34.77 | 5.89 | A | A | 0.40 | 29.81 | 0.86 | 17.81 | 42.17 | 34.80 | 5.89 | A | A | ||

| XPS | Heat | 0.42 | 31.60 | 0.92 | 18.59 | 44.02 | 36.33 | 6.15 | A | A | 0.42 | 31.60 | 0.92 | 18.68 | 44.24 | 36.51 | 6.18 | A | A | 0.42 | 31.60 | 0.92 | 18.70 | 44.27 | 36.53 | 6.19 | A | A | |

| Heat + Cool | 0.42 | 31.39 | 0.91 | 18.35 | 43.45 | 35.85 | 6.07 | A | A | 0.42 | 31.39 | 0.91 | 18.44 | 43.67 | 36.03 | 6.10 | A | A | 0.42 | 31.39 | 0.91 | 18.46 | 43.70 | 36.06 | 6.11 | A | A | ||

| January Climate Zone X | January Climate Zone Y | January Climate Zone Z | |||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| System | Insulation Material | Optimization Criterion | HED | CED | FEC | TPEC | NRPEC | EM | RNRPEC | REM | HED | CED | FEC | TPEC | NRPEC | EM | RNRPEC | REM | HED | CED | FEC | TPEC | NRPEC | EM | RNRPEC | REM | |||

| 1 | EPS | Heat | 0.42 | 30.16 | 2.29 | 51.05 | 61.70 | 61.08 | 15.90 | C | C | 0.42 | 30.16 | 2.29 | 51.30 | 61.99 | 61.37 | 15.98 | C | C | 0.42 | 30.16 | 2.29 | 50.72 | 61.31 | 60.69 | 15.80 | C | C |

| Heat + Cool | 0.41 | 29.27 | 2.22 | 49.97 | 60.38 | 59.77 | 15.56 | C | C | 0.41 | 29.27 | 2.22 | 50.21 | 60.67 | 60.06 | 15.64 | C | C | 0.41 | 29.27 | 2.22 | 49.64 | 59.99 | 59.39 | 15.46 | C | C | ||

| MW | Heat | 0.38 | 27.17 | 2.06 | 47.42 | 57.28 | 56.71 | 14.77 | B | C | 0.38 | 27.17 | 2.06 | 47.67 | 57.57 | 57.00 | 14.85 | B | C | 0.38 | 27.17 | 2.06 | 47.10 | 56.89 | 56.32 | 14.67 | B | C | |

| Heat + Cool | 0.37 | 26.43 | 2.01 | 46.53 | 56.18 | 55.63 | 14.49 | B | C | 0.37 | 26.43 | 2.01 | 46.77 | 56.47 | 55.92 | 14.57 | B | C | 0.37 | 26.43 | 2.01 | 46.20 | 55.80 | 55.25 | 14.39 | B | C | ||

| PUR | Heat | 0.40 | 28.73 | 2.18 | 49.31 | 59.58 | 58.98 | 15.36 | C | C | 0.40 | 28.73 | 2.18 | 49.56 | 59.87 | 59.27 | 15.43 | C | C | 0.40 | 28.73 | 2.18 | 48.98 | 59.19 | 58.60 | 15.26 | C | C | |

| Heat + Cool | 0.39 | 27.91 | 2.12 | 48.32 | 58.37 | 57.79 | 15.05 | C | C | 0.39 | 27.91 | 2.12 | 48.56 | 58.66 | 58.08 | 15.12 | C | C | 0.39 | 27.91 | 2.12 | 47.99 | 57.98 | 57.40 | 14.95 | C | C | ||

| XPS | Heat | 0.43 | 30.26 | 2.30 | 51.18 | 61.86 | 61.23 | 15.94 | C | C | 0.43 | 30.26 | 2.30 | 51.43 | 62.15 | 61.52 | 16.02 | C | C | 0.43 | 30.26 | 2.30 | 50.85 | 61.47 | 60.84 | 15.84 | C | C | |

| Heat + Cool | 0.41 | 29.37 | 2.23 | 50.09 | 60.53 | 59.92 | 15.60 | C | C | 0.41 | 29.37 | 2.23 | 50.34 | 60.82 | 60.21 | 15.68 | C | C | 0.41 | 29.37 | 2.23 | 49.76 | 60.14 | 59.54 | 15.50 | C | C | ||

| 2 | EPS | Heat | 0.42 | 30.18 | 2.29 | 47.27 | 57.84 | 57.13 | 12.00 | B | B | 0.42 | 30.18 | 2.29 | 47.50 | 58.11 | 57.40 | 12.06 | C | B | 0.42 | 30.18 | 2.29 | 46.97 | 57.48 | 56.77 | 11.93 | B | B |

| Heat + Cool | 0.41 | 29.28 | 2.22 | 46.27 | 56.60 | 55.91 | 11.75 | B | B | 0.41 | 29.28 | 2.22 | 46.50 | 56.87 | 56.18 | 11.81 | B | B | 0.41 | 29.28 | 2.22 | 45.97 | 56.23 | 55.55 | 11.67 | B | B | ||

| MW | Heat | 0.38 | 27.19 | 2.07 | 43.91 | 53.69 | 53.04 | 11.15 | B | B | 0.38 | 27.19 | 2.07 | 44.14 | 53.96 | 53.31 | 11.20 | B | B | 0.38 | 27.19 | 2.07 | 43.61 | 53.32 | 52.68 | 11.07 | B | B | |

| Heat + Cool | 0.37 | 26.45 | 2.01 | 43.08 | 52.66 | 52.03 | 10.93 | B | B | 0.37 | 26.45 | 2.01 | 43.30 | 52.93 | 52.30 | 10.99 | B | B | 0.37 | 26.45 | 2.01 | 42.77 | 52.29 | 51.67 | 10.86 | B | B | ||

| PUR | Heat | 0.40 | 28.74 | 2.18 | 45.66 | 55.85 | 55.17 | 11.59 | B | B | 0.40 | 28.74 | 2.18 | 45.89 | 56.12 | 55.44 | 11.65 | B | B | 0.40 | 28.74 | 2.18 | 45.36 | 55.49 | 54.81 | 11.52 | B | B | |

| Heat + Cool | 0.39 | 27.92 | 2.12 | 44.74 | 54.71 | 54.05 | 11.36 | B | B | 0.39 | 27.92 | 2.12 | 44.97 | 54.98 | 54.32 | 11.42 | B | B | 0.39 | 27.92 | 2.12 | 44.44 | 54.35 | 53.69 | 11.28 | B | B | ||

| XPS | Heat | 0.43 | 30.28 | 2.30 | 47.39 | 57.99 | 57.28 | 12.03 | C | B | 0.43 | 30.28 | 2.30 | 47.62 | 58.26 | 57.55 | 12.09 | C | B | 0.43 | 30.28 | 2.30 | 47.09 | 57.62 | 56.92 | 11.96 | B | B | |

| Heat + Cool | 0.41 | 29.39 | 2.23 | 46.38 | 56.74 | 56.05 | 11.78 | C | B | 0.41 | 29.39 | 2.23 | 46.61 | 57.01 | 56.32 | 11.83 | B | B | 0.41 | 29.39 | 2.23 | 46.08 | 56.38 | 55.69 | 11.70 | B | B | ||

| 3 | EPS | Heat | 0.48 | 34.40 | 2.61 | 56.20 | 64.20 | 7.22 | 1.42 | A | A | 0.48 | 34.40 | 2.61 | 56.45 | 64.47 | 7.24 | 1.43 | A | A | 0.48 | 34.40 | 2.61 | 55.88 | 63.83 | 7.19 | 1.41 | A | A |

| Heat + Cool | 0.46 | 32.76 | 2.49 | 54.21 | 61.90 | 6.93 | 1.37 | A | A | 0.46 | 32.76 | 2.49 | 54.46 | 62.17 | 6.95 | 1.37 | A | A | 0.46 | 32.76 | 2.49 | 53.88 | 61.53 | 6.91 | 1.36 | A | A | ||

| MW | Heat | 0.43 | 30.69 | 2.33 | 51.70 | 59.00 | 6.57 | 1.30 | A | A | 0.43 | 30.69 | 2.33 | 51.94 | 59.28 | 6.59 | 1.30 | A | A | 0.43 | 30.69 | 2.33 | 51.37 | 58.64 | 6.54 | 1.29 | A | A | |

| Heat + Cool | 0.41 | 29.33 | 2.23 | 50.05 | 57.10 | 6.34 | 1.25 | A | A | 0.41 | 29.33 | 2.23 | 50.29 | 57.37 | 6.36 | 1.25 | A | A | 0.41 | 29.33 | 2.23 | 49.72 | 56.73 | 6.31 | 1.24 | A | A | ||

| PUR | Heat | 0.46 | 32.62 | 2.48 | 54.04 | 61.71 | 6.91 | 1.36 | A | A | 0.46 | 32.62 | 2.48 | 54.29 | 61.98 | 6.93 | 1.37 | A | A | 0.46 | 32.62 | 2.48 | 53.72 | 61.34 | 6.88 | 1.35 | A | A | |

| Heat + Cool | 0.44 | 31.12 | 2.36 | 52.21 | 59.60 | 6.65 | 1.31 | A | A | 0.44 | 31.12 | 2.36 | 52.46 | 59.87 | 6.67 | 1.31 | A | A | 0.44 | 31.12 | 2.36 | 51.89 | 59.23 | 6.62 | 1.30 | A | A | ||

| XPS | Heat | 0.49 | 34.53 | 2.62 | 56.37 | 64.38 | 7.24 | 1.43 | A | A | 0.49 | 34.53 | 2.62 | 56.61 | 64.65 | 7.26 | 1.43 | A | A | 0.49 | 34.53 | 2.62 | 56.04 | 64.02 | 7.21 | 1.42 | A | A | |

| Heat + Cool | 0.46 | 32.88 | 2.50 | 54.36 | 62.07 | 6.95 | 1.37 | A | A | 0.46 | 32.88 | 2.50 | 54.61 | 62.34 | 6.98 | 1.37 | A | A | 0.46 | 32.88 | 2.50 | 54.03 | 61.70 | 6.93 | 1.36 | A | A | ||

| 4 | EPS | Heat | 0.43 | 30.39 | 2.31 | 18.22 | 43.13 | 35.59 | 6.03 | B | A | 0.43 | 30.39 | 2.31 | 18.30 | 43.33 | 35.76 | 6.06 | B | A | 0.43 | 30.39 | 2.31 | 18.10 | 42.87 | 35.38 | 5.99 | B | A |

| Heat + Cool | 0.42 | 29.86 | 2.27 | 17.60 | 41.68 | 34.40 | 5.83 | A | A | 0.42 | 29.86 | 2.27 | 17.69 | 41.88 | 34.56 | 5.85 | A | A | 0.42 | 29.86 | 2.27 | 17.49 | 41.42 | 34.18 | 5.79 | A | A | ||

| MW | Heat | 0.39 | 27.37 | 2.08 | 16.89 | 40.00 | 33.00 | 5.59 | A | A | 0.39 | 27.37 | 2.08 | 16.97 | 40.19 | 33.17 | 5.62 | A | A | 0.39 | 27.37 | 2.08 | 16.78 | 39.73 | 32.79 | 5.55 | A | A | |

| Heat + Cool | 0.38 | 26.92 | 2.04 | 16.35 | 38.73 | 31.96 | 5.41 | A | A | 0.38 | 26.92 | 2.04 | 16.44 | 38.93 | 32.12 | 5.44 | A | A | 0.38 | 26.92 | 2.04 | 16.24 | 38.46 | 31.74 | 5.38 | A | A | ||

| PUR | Heat | 0.41 | 28.94 | 2.20 | 17.58 | 41.63 | 34.35 | 5.82 | A | A | 0.41 | 28.94 | 2.20 | 17.66 | 41.83 | 34.52 | 5.85 | A | A | 0.41 | 28.94 | 2.20 | 17.47 | 41.37 | 34.13 | 5.78 | A | A | |

| Heat + Cool | 0.40 | 28.45 | 2.16 | 17.00 | 40.27 | 33.23 | 5.63 | A | A | 0.40 | 28.45 | 2.16 | 17.09 | 40.46 | 33.39 | 5.66 | A | A | 0.40 | 28.45 | 2.16 | 16.89 | 40.00 | 33.01 | 5.59 | A | A | ||

| XPS | Heat | 0.43 | 30.50 | 2.32 | 18.26 | 43.25 | 35.69 | 6.05 | B | A | 0.43 | 30.50 | 2.32 | 18.35 | 43.44 | 35.85 | 6.07 | B | A | 0.43 | 30.50 | 2.32 | 18.15 | 42.98 | 35.47 | 6.01 | B | A | |

| Heat + Cool | 0.42 | 29.96 | 2.28 | 17.65 | 41.79 | 34.48 | 5.84 | A | A | 0.42 | 29.96 | 2.28 | 17.73 | 41.99 | 34.65 | 5.87 | A | A | 0.42 | 29.96 | 2.28 | 17.54 | 41.52 | 34.26 | 5.80 | A | A | ||

| January Climate Zone X | January Climate Zone Y | January Climate Zone Z | |||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| System | Insulation Material | Optimization Criterion | HED | CED | FEC | TPEC | NRPEC | EM | RNRPEC | REM | HED | CED | FEC | TPEC | NRPEC | EM | RNRPEC | REM | HED | CED | FEC | TPEC | NRPEC | EM | RNRPEC | REM | |||

| 1 | EPS | Heat | 0.43 | 29.30 | 4.49 | 47.99 | 59.39 | 58.32 | 14.97 | B | C | 0.43 | 29.30 | 4.49 | 48.66 | 60.18 | 59.11 | 15.18 | B | C | 0.43 | 29.30 | 4.49 | 45.88 | 56.89 | 55.83 | 14.31 | B | C |

| Heat + Cool | 0.41 | 27.67 | 4.24 | 45.94 | 56.81 | 55.81 | 14.33 | B | C | 0.41 | 27.67 | 4.24 | 46.61 | 57.61 | 56.60 | 14.54 | B | C | 0.41 | 27.67 | 4.24 | 43.83 | 54.32 | 53.32 | 13.67 | B | C | ||

| MW | Heat | 0.39 | 26.37 | 4.04 | 44.32 | 54.79 | 53.82 | 13.83 | B | C | 0.39 | 26.37 | 4.04 | 44.99 | 55.58 | 54.61 | 14.03 | B | C | 0.39 | 26.37 | 4.04 | 42.21 | 52.29 | 51.34 | 13.17 | B | B | |

| Heat + Cool | 0.37 | 25.02 | 3.83 | 42.62 | 52.65 | 51.74 | 13.29 | B | B | 0.37 | 25.02 | 3.83 | 43.29 | 53.44 | 52.53 | 13.50 | B | B | 0.37 | 25.02 | 3.83 | 40.51 | 50.16 | 49.25 | 12.64 | B | B | ||

| PUR | Heat | 0.41 | 27.90 | 4.27 | 46.23 | 57.18 | 56.16 | 14.42 | B | C | 0.41 | 27.90 | 4.27 | 46.90 | 57.97 | 56.95 | 14.63 | B | C | 0.41 | 27.90 | 4.27 | 44.12 | 54.69 | 53.68 | 13.77 | B | C | |

| Heat + Cool | 0.39 | 26.40 | 4.04 | 44.35 | 54.82 | 53.86 | 13.83 | B | C | 0.39 | 26.40 | 4.04 | 45.02 | 55.61 | 54.64 | 14.04 | B | C | 0.39 | 26.40 | 4.04 | 42.24 | 52.33 | 51.37 | 13.18 | B | B | ||

| XPS | Heat | 0.43 | 29.41 | 4.50 | 48.12 | 59.55 | 58.48 | 15.01 | B | C | 0.43 | 29.41 | 4.50 | 48.79 | 60.34 | 59.27 | 15.22 | B | C | 0.43 | 29.41 | 4.50 | 46.01 | 57.06 | 55.99 | 14.35 | B | C | |

| Heat + Cool | 0.41 | 27.76 | 4.25 | 46.06 | 56.96 | 55.95 | 14.37 | B | C | 0.41 | 27.76 | 4.25 | 46.73 | 57.75 | 56.74 | 14.58 | B | C | 0.41 | 27.76 | 4.25 | 43.95 | 54.47 | 53.46 | 13.71 | B | C | ||

| 2 | EPS | Heat | 0.43 | 29.32 | 4.49 | 44.53 | 55.85 | 54.71 | 11.40 | B | B | 0.43 | 29.32 | 4.49 | 45.15 | 56.59 | 55.44 | 11.56 | B | B | 0.43 | 29.32 | 4.49 | 42.58 | 53.52 | 52.39 | 10.91 | B | B |

| Heat + Cool | 0.41 | 27.68 | 4.24 | 42.62 | 53.42 | 52.34 | 10.91 | B | B | 0.41 | 27.68 | 4.24 | 43.24 | 54.16 | 53.08 | 11.06 | B | B | 0.41 | 27.68 | 4.24 | 40.67 | 51.09 | 50.02 | 10.42 | B | B | ||

| MW | Heat | 0.39 | 26.39 | 4.04 | 41.12 | 51.51 | 50.48 | 10.52 | B | B | 0.39 | 26.39 | 4.04 | 41.74 | 52.25 | 51.22 | 10.68 | B | B | 0.39 | 26.39 | 4.04 | 39.18 | 49.18 | 48.16 | 10.03 | B | B | |

| Heat + Cool | 0.37 | 25.03 | 3.83 | 39.54 | 49.50 | 48.52 | 10.12 | B | B | 0.37 | 25.03 | 3.83 | 40.16 | 50.24 | 49.25 | 10.27 | B | B | 0.37 | 25.03 | 3.83 | 37.59 | 47.17 | 46.20 | 9.62 | B | B | ||

| PUR | Heat | 0.41 | 27.92 | 4.27 | 42.90 | 53.77 | 52.68 | 10.98 | B | B | 0.41 | 27.92 | 4.27 | 43.52 | 54.51 | 53.42 | 11.14 | B | B | 0.41 | 27.92 | 4.27 | 40.95 | 51.44 | 50.36 | 10.49 | B | B | |

| Heat + Cool | 0.39 | 26.41 | 4.04 | 41.15 | 51.54 | 50.51 | 10.53 | B | B | 0.39 | 26.41 | 4.04 | 41.76 | 52.28 | 51.24 | 10.68 | B | B | 0.39 | 26.41 | 4.04 | 39.20 | 49.21 | 48.19 | 10.04 | B | B | ||

| XPS | Heat | 0.43 | 29.42 | 4.51 | 44.65 | 56.00 | 54.86 | 11.43 | B | B | 0.43 | 29.42 | 4.51 | 45.27 | 56.74 | 55.60 | 11.59 | B | B | 0.43 | 29.42 | 4.51 | 42.71 | 53.68 | 52.54 | 10.94 | B | B | |

| Heat + Cool | 0.41 | 27.77 | 4.25 | 42.73 | 53.56 | 52.48 | 10.94 | B | B | 0.41 | 27.77 | 4.25 | 43.35 | 54.30 | 53.21 | 11.09 | B | B | 0.41 | 27.77 | 4.25 | 40.78 | 51.23 | 50.16 | 10.45 | B | B | ||

| 3 | EPS | Heat | 0.49 | 33.46 | 5.12 | 53.20 | 62.43 | 9.31 | 1.76 | A | A | 0.49 | 33.46 | 5.12 | 53.87 | 63.17 | 9.37 | 1.77 | A | A | 0.49 | 33.46 | 5.12 | 51.09 | 60.08 | 9.13 | 1.72 | A | A |

| Heat + Cool | 0.45 | 30.54 | 4.68 | 49.55 | 58.08 | 8.58 | 1.62 | A | A | 0.45 | 30.54 | 4.68 | 50.21 | 58.82 | 8.64 | 1.64 | A | A | 0.45 | 30.54 | 4.68 | 47.44 | 55.73 | 8.40 | 1.59 | A | A | ||

| MW | Heat | 0.44 | 29.82 | 4.57 | 48.65 | 57.01 | 8.40 | 1.59 | A | A | 0.44 | 29.82 | 4.57 | 49.32 | 57.75 | 8.46 | 1.60 | A | A | 0.44 | 29.82 | 4.57 | 46.54 | 54.66 | 8.22 | 1.55 | A | A | |

| Heat + Cool | 0.40 | 27.40 | 4.20 | 45.61 | 53.40 | 7.80 | 1.48 | A | A | 0.40 | 27.40 | 4.20 | 46.28 | 54.15 | 7.86 | 1.49 | A | A | 0.40 | 27.40 | 4.20 | 43.50 | 51.05 | 7.62 | 1.44 | A | A | ||

| PUR | Heat | 0.47 | 31.72 | 4.86 | 51.02 | 59.83 | 8.87 | 1.68 | A | A | 0.47 | 31.72 | 4.86 | 51.69 | 60.58 | 8.93 | 1.69 | A | A | 0.47 | 31.72 | 4.86 | 48.91 | 57.48 | 8.70 | 1.64 | A | A | |

| Heat + Cool | 0.43 | 29.04 | 4.45 | 47.66 | 55.84 | 8.21 | 1.55 | A | A | 0.43 | 29.04 | 4.45 | 48.33 | 56.58 | 8.26 | 1.57 | A | A | 0.43 | 29.04 | 4.45 | 45.55 | 53.49 | 8.03 | 1.52 | A | A | ||

| XPS | Heat | 0.49 | 33.59 | 5.14 | 53.36 | 62.62 | 9.34 | 1.77 | A | A | 0.49 | 33.59 | 5.14 | 54.03 | 63.37 | 9.40 | 1.78 | A | A | 0.49 | 33.59 | 5.14 | 51.26 | 60.27 | 9.16 | 1.73 | A | A | |

| Heat + Cool | 0.45 | 30.65 | 4.69 | 49.69 | 58.25 | 8.61 | 1.63 | A | A | 0.45 | 30.65 | 4.69 | 50.35 | 58.99 | 8.67 | 1.64 | A | A | 0.45 | 30.65 | 4.69 | 47.58 | 55.90 | 8.43 | 1.59 | A | A | ||

| 4 | EPS | Heat | 0.43 | 29.53 | 4.52 | 17.91 | 42.40 | 34.99 | 5.93 | A | A | 0.43 | 29.53 | 4.52 | 18.13 | 42.94 | 35.43 | 6.00 | A | A | 0.43 | 29.53 | 4.52 | 17.19 | 40.71 | 33.59 | 5.69 | A | A |

| Heat + Cool | 0.42 | 28.52 | 4.37 | 16.70 | 39.54 | 32.62 | 5.53 | A | A | 0.42 | 28.52 | 4.37 | 16.92 | 40.08 | 33.07 | 5.60 | A | A | 0.42 | 28.52 | 4.37 | 15.98 | 37.84 | 31.22 | 5.29 | A | A | ||

| MW | Heat | 0.39 | 26.57 | 4.07 | 16.49 | 39.06 | 32.23 | 5.46 | A | A | 0.39 | 26.57 | 4.07 | 16.72 | 39.60 | 32.67 | 5.53 | A | A | 0.39 | 26.57 | 4.07 | 15.78 | 37.36 | 30.83 | 5.22 | A | A | |

| Heat + Cool | 0.38 | 25.72 | 3.94 | 15.44 | 36.55 | 30.16 | 5.11 | A | A | 0.38 | 25.72 | 3.94 | 15.66 | 37.09 | 30.61 | 5.18 | A | A | 0.38 | 25.72 | 3.94 | 14.72 | 34.86 | 28.76 | 4.87 | A | A | ||

| PUR | Heat | 0.41 | 28.11 | 4.30 | 17.23 | 40.80 | 33.67 | 5.70 | A | A | 0.41 | 28.11 | 4.30 | 17.46 | 41.34 | 34.11 | 5.78 | A | A | 0.41 | 28.11 | 4.30 | 16.51 | 39.10 | 32.27 | 5.47 | A | A | |

| Heat + Cool | 0.40 | 27.18 | 4.16 | 16.09 | 38.11 | 31.44 | 5.33 | A | A | 0.40 | 27.18 | 4.16 | 16.32 | 38.65 | 31.89 | 5.40 | A | A | 0.40 | 27.18 | 4.16 | 15.38 | 36.41 | 30.04 | 5.09 | A | A | ||

| XPS | Heat | 0.43 | 29.64 | 4.54 | 17.96 | 42.52 | 35.09 | 5.94 | A | A | 0.43 | 29.64 | 4.54 | 18.18 | 43.06 | 35.53 | 6.02 | A | A | 0.43 | 29.64 | 4.54 | 17.24 | 40.83 | 33.69 | 5.71 | A | A | |

| Heat + Cool | 0.42 | 28.62 | 4.38 | 16.74 | 39.64 | 32.71 | 5.54 | A | A | 0.42 | 28.62 | 4.38 | 16.97 | 40.18 | 33.16 | 5.62 | A | A | 0.42 | 28.62 | 4.38 | 16.02 | 37.94 | 31.31 | 5.30 | A | A | ||

| System | Insulation Material | Optimization Criterion | HED | CED | FEC | TPEC | NRPEC | EM | RNRPEC | REM | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | EPS | Heat | 0.40 | 35.22 | 0.80 | 56.21 | 66.92 | 66.58 | 17.49 | B | C |

| Heat + Cool | 0.40 | 34.90 | 0.80 | 55.83 | 66.47 | 66.14 | 17.37 | B | C | ||

| MW | Heat | 0.36 | 31.89 | 0.73 | 52.25 | 62.20 | 61.89 | 16.26 | B | C | |

| Heat + Cool | 0.36 | 31.63 | 0.72 | 51.94 | 61.83 | 61.52 | 16.16 | B | C | ||

| PUR | Heat | 0.38 | 33.62 | 0.77 | 54.31 | 64.65 | 64.33 | 16.90 | B | C | |

| Heat + Cool | 0.38 | 33.33 | 0.76 | 53.97 | 64.24 | 63.93 | 16.79 | B | C | ||

| XPS | Heat | 0.40 | 35.34 | 0.81 | 56.35 | 67.08 | 66.75 | 17.53 | B | C | |

| Heat + Cool | 0.40 | 35.02 | 0.80 | 55.97 | 66.63 | 66.30 | 17.42 | B | C | ||

| 2 | EPS | Heat | 0.40 | 35.24 | 0.80 | 51.99 | 62.60 | 62.17 | 13.13 | B | B |

| Heat + Cool | 0.40 | 34.93 | 0.80 | 51.64 | 62.18 | 61.76 | 13.04 | B | B | ||

| MW | Heat | 0.36 | 31.91 | 0.73 | 48.33 | 58.18 | 57.79 | 12.21 | B | B | |

| Heat + Cool | 0.36 | 31.65 | 0.72 | 48.04 | 57.83 | 57.44 | 12.13 | B | B | ||

| PUR | Heat | 0.38 | 33.64 | 0.77 | 50.23 | 60.48 | 60.07 | 12.69 | B | B | |

| Heat + Cool | 0.38 | 33.35 | 0.76 | 49.91 | 60.09 | 59.69 | 12.61 | B | B | ||

| XPS | Heat | 0.40 | 35.36 | 0.81 | 52.12 | 62.75 | 62.33 | 13.17 | B | B | |

| Heat + Cool | 0.40 | 35.04 | 0.80 | 51.77 | 62.33 | 61.91 | 13.08 | B | B | ||

| 3 | EPS | Heat | 0.45 | 39.95 | 0.91 | 61.83 | 69.39 | 6.11 | 1.26 | A | A |

| Heat + Cool | 0.45 | 39.35 | 0.90 | 61.12 | 68.59 | 6.03 | 1.24 | A | A | ||

| MW | Heat | 0.41 | 35.81 | 0.82 | 56.92 | 63.86 | 5.60 | 1.15 | A | A | |

| Heat + Cool | 0.40 | 35.32 | 0.81 | 56.33 | 63.20 | 5.54 | 1.14 | A | A | ||

| PUR | Heat | 0.43 | 37.97 | 0.87 | 59.47 | 66.74 | 5.87 | 1.21 | A | A | |

| Heat + Cool | 0.42 | 37.42 | 0.85 | 58.82 | 66.01 | 5.80 | 1.19 | A | A | ||

| XPS | Heat | 0.45 | 40.10 | 0.92 | 62.00 | 69.58 | 6.13 | 1.26 | A | A | |

| Heat + Cool | 0.45 | 39.50 | 0.90 | 61.29 | 68.78 | 6.05 | 1.24 | A | A | ||

| 4 | EPS | Heat | 0.40 | 35.48 | 0.81 | 19.48 | 46.14 | 38.07 | 6.45 | A | A |

| Heat + Cool | 0.40 | 35.30 | 0.81 | 19.27 | 45.64 | 37.66 | 6.38 | A | A | ||

| MW | Heat | 0.36 | 32.11 | 0.73 | 18.10 | 42.85 | 35.36 | 5.99 | A | A | |

| Heat + Cool | 0.36 | 31.95 | 0.73 | 17.91 | 42.41 | 35.00 | 5.93 | A | A | ||

| PUR | Heat | 0.38 | 33.86 | 0.77 | 18.82 | 44.56 | 36.77 | 6.23 | A | A | |

| Heat + Cool | 0.38 | 33.69 | 0.77 | 18.62 | 44.09 | 36.38 | 6.16 | A | A | ||

| XPS | Heat | 0.40 | 35.60 | 0.81 | 19.53 | 46.25 | 38.17 | 6.47 | A | A | |

| Heat + Cool | 0.40 | 35.41 | 0.81 | 19.32 | 45.75 | 37.75 | 6.40 | A | A |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

López-Ochoa, L.M.; Las-Heras-Casas, J.; López-González, L.M.; García-Lozano, C. Energy Renovation of Residential Buildings in Cold Mediterranean Zones Using Optimized Thermal Envelope Insulation Thicknesses: The Case of Spain. Sustainability 2020, 12, 2287. https://doi.org/10.3390/su12062287

López-Ochoa LM, Las-Heras-Casas J, López-González LM, García-Lozano C. Energy Renovation of Residential Buildings in Cold Mediterranean Zones Using Optimized Thermal Envelope Insulation Thicknesses: The Case of Spain. Sustainability. 2020; 12(6):2287. https://doi.org/10.3390/su12062287

Chicago/Turabian StyleLópez-Ochoa, Luis M., Jesús Las-Heras-Casas, Luis M. López-González, and César García-Lozano. 2020. "Energy Renovation of Residential Buildings in Cold Mediterranean Zones Using Optimized Thermal Envelope Insulation Thicknesses: The Case of Spain" Sustainability 12, no. 6: 2287. https://doi.org/10.3390/su12062287

APA StyleLópez-Ochoa, L. M., Las-Heras-Casas, J., López-González, L. M., & García-Lozano, C. (2020). Energy Renovation of Residential Buildings in Cold Mediterranean Zones Using Optimized Thermal Envelope Insulation Thicknesses: The Case of Spain. Sustainability, 12(6), 2287. https://doi.org/10.3390/su12062287