1. Introduction

Mineral resources are the essential material basis to maintain the operation of modern society. However, the extensive exploitation of different mineral resources around the globe is leading to the gradual depletion of shallow mines and necessitates deeper excavations in order to satisfy an increasing demand of mineral resources [

1,

2]. There are some metal mines exploiting a depth of over 4500 m; for instance, the Mponeng Gold Mine in South Africa has already reached a depth of 4800 m [

3,

4]. In the early 1980s, coal resources in such countries as Germany, France, Japan, Poland, the former Soviet Union, and the United Kingdom were mined at depths exceeding 1000 m [

5]. In fact, a similar advance to more considerable depths has been observed in China: thirty-two metal mines and forty-seven coal mines have been developed at mining depths over 1000 m [

6], such as the Hongtoushan Copper Mine in Fushun and the Suncun Coal Mine in Xinwen having mining depths of 1600 and 1500 m, respectively. However, it is clear that the high-efficiency development and utilization of deep mineral resources will face more significant problems in safety, environmental impact, and economy, as well as require more advanced technologies [

7,

8,

9,

10,

11,

12], wherein the thermal damage induced by high-temperatures in deep mines, which exceed 303.15−313.15 K at a depth of 1000 m, has become a great challenge for production [

13,

14,

15,

16,

17,

18]. For example, in the Sanhejian Coal Mine (with a mining depth of 1300 m) in Xuzhou, China, the working face temperature is as high as 329.15 K [

19].

From another point of view, the mine heat damage is essentially a kind of thermal energy that belongs to the category of geothermal energy. However, most mines rich in geothermal resources have a large burial depth and traditional ventilation and cooling measures are often unable to reduce the working face temperature. According to the 2016 revision of the “Coal Mine Safety Regulations” promulgated by the State Administration of Work Safety, when the air temperature of the working face exceeds 299.15 K and the temperature of the mechanical and electrical equipment chamber exceeds 303.15 K, the working time of the staff in the overheated location must be shortened and the treatment of high-temperature health care must be given [

20]. When the air temperature of the working face exceeds 303.15 K and the chamber exceeds 307.15 K, the production of the working face must be stopped. This is greatly damaging to the coal mine’s profits. In addition, it is difficult and costly to utilize geothermal energy in deep mines, as it may not meet the requirements of mine production temperature. Although using artificial cooling technology to reduce the temperature of the working face will increase the production cost, it will create more benefits for coal mines. Therefore, most coal mines choose artificial cooling instead of utilizing geothermal energy.

The rising temperature of underground rock strata is one of the crucial reasons for the deterioration of working conditions in deep mines, and a continued high-temperature environment of the mine deteriorates the physiological functions of miners by increasing the heart rate, invoking sweat, nausea, dizziness, and other adverse reactions, which dramatically endanger their safety [

21,

22]. Additionally, it affects the psychological state of workers, causing distraction or even inability to work [

23], which severely affects the labor productivity and can trigger serious accidents. Besides, the high-temperature environment in the mine will further accelerate the wear and tear of mining equipment [

24], reduce the working performance of equipment, and increase its failure rate, thus significantly decreasing the working efficiency. Therefore, the adequate cooling of deep mines is instrumental in the improvement of mining conditions and efficiency, as well as in the minimization of potential accidents. At present, two main categories of mine cooling technologies are used worldwide [

25,

26]: non-artificial and artificial cooling technologies. The former involves traditional cooling methods, which have been implemented at shallow mines before entering the deep mining stage [

27,

28,

29,

30]: mine ventilation, heat source isolation, filling mining implementation, usage of individual protective work suits by miners, etc. Thus, the small cooling capacity and the reduced cooling effect of this approach can be sufficient for shallow mines, but it generally fails to meet the growing cooling requirements of deeper ones. The second category covers the artificial cooling technologies based on the advanced refrigeration principles, which solve the increasingly severe problem of thermal damage by using or combining centralized air conditioning, air pressurization, ice cooling, thermo-electric cooling with ethylene glycol, and high-temperature exchange machinery systems (HEMSs) [

31,

32,

33,

34,

35,

36,

37]. The latter category of technologies have significantly reduced the high-temperature-induced thermal damage in some particular deep mines and resolved their cooling problems. However, since the investment in these artificial cooling methods is much higher than that of non-artificial cooling technologies and the construction time is long, their implementation should be based on an in-depth analysis of the actual situation in specific mines.

This issue was covered in our analysis of a particular case study, namely the Longgu Coal Mine (LCM) of Shandong province, China. Due to the influence of ground temperature, water inflow in the mine, and seasonal temperature changes, the problem of high-temperature-induced thermal damage in this mine is severe. For example, the temperature of underground working faces exceed 303.15 K (with a maximum temperature of 312.35 K), which has severely affected the health of miners and even caused the cease of operations in the working faces. Additionally, as the mine continues to be developed deeper and the amount of water inflow in the well increases, the temperature of the underground working face has an unfavorable trend of further growth. Since the high-temperature underground working environment failed to be further improved by traditional ventilation and single artificial cooling, the whole mine must adopt comprehensive artificial cooling measures. Therefore, we considered the mining geological conditions of the LCM as the engineering background, analyzed its high-temperature heat sources and factors, and proposed a single cooling method for the working face and an overall cooling method for each underground working place, which were different from other mines, and finally formed a set of comprehensive measures for the control and reduction of high-temperature-induced thermal damage (taking each mining face, tunneling face, pumping room and mine chamber as examples). This set of integrated cooling modes can comprehensively reduce the temperature of all working places in the mine, and consist the largest mine cooling system to be created and established in China, compared with single cooling methods of other high-temperature mines, such as chiller refrigeration cooling, air compression refrigeration, cold and heat electricity co-production air conditioning systems, and ice slurry transportation air conditioning systems. In brief, this study should not only solve the thermal damage problem of the LCM on the premise of ensuring technical and economic benefits, but also provide an example for the treatment of thermal damage in mines and a new idea for the comprehensive control of thermal damage in large deep mines.

2. Overview of Mining and Geological Conditions in the Study Area

The LCM is located in the south-central part of the Juye coalfield in the Shandong province of China. This mine is a national critical oversize mine with a designed coal production capacity of six million tons per year. It adopts four vertical shafts (i.e., two main shafts, one auxiliary shaft, and one air shaft) as the development mode, with two development levels of −810 and −950 m, respectively. At the early stage of mining, the parallel exhaust ventilation in the central part of the mine was adopted simultaneously using the separate ventilation technique, with an auxiliary shaft inlet, a small amount of air input in the main shafts and air return in the air shaft.

There are six minable layers of coal seams in the coal-bearing strata of the mine, which are mainly composed of fat coals and 1/3 coking coals. The #3 coal seam is the primary minable and first-mined coal seam of the mine. The buried depth of the coal seam is about 900 m, and the thickness of the roof bedrocks generally ranges from 100 to 200 m, while the thickness of the alluvium overlying the bedrock exceeds 600 m. The thickness of the coal seam is 5.66 to 11.36 m, with an average value of 8.82 m. The coal seam has tilt angles ranging from 2° to 9°, with an average angle of 5.5°. The coal seam is stable in occurrence, relatively simple in structure, and locally contains up to three layers of dirt bands. The average geothermal gradient of the study area is 2.8 K/hm, whereas those of the non-coal and coal-bearing strata are 2.52 and 3.23 K/hm, respectively. Temperatures of the #3 coal seam floor of the primary minable mine have the average value of 314.53 K, thus falling into the primary or secondary high-temperature zones and invoking significant challenges to the underground coal seam mining.

3. Analysis of High-Temperature Heat Sources and Factors in the LCM

The geothermal temperature of the initial mined block in the LCM ranges from 312.15 to 314.15 K. The maximum temperature of the rock mass at the bottom of the vertical shaft is 317.85 K, while that at the end of the #1301 working face in the northern wing of the mine is 317.05 K. To identify the high-temperature heat sources [

38], field temperature measurements have been performed, which revealed that the high-temperature thermal damage in the LCM is dominated by the following factors:

(1) Exothermic heat from surrounding rock of the underground roadway:

The highest temperature of the surrounding rock with a level of −810 m in the mine is 317.95 K (with no ventilation system), which is in the secondary thermal damage zone. The highest temperature of this surrounding rock with a level of −810 m in the mine reaches 312.65 K after the formation of the ventilation system. As a result, the primary heat source of airflow in the mine is exothermic heat from the surrounding rock of underground roadway.

(2) Exothermic heat from the inflow of high-temperature water:

At the initial stage of mine construction (April 2007), the total water inflow in the mine was about 1600 m3/h, while the current total water inflow in the mine ranges from 1000 to 1500 m3/h. The temperature of the water inflow at the level of −810 m is up to 321.15−324.15 K, which is 4−6.3 K higher than that of the rock surrounding the roadway at the same level in the mine. Therefore, the continuous underground inflow of high-temperature water has become an essential characteristic of high-temperature-induced thermal damage in mine.

(3) Exothermic heat from seasonal temperature rise:

The LCM shaft is mainly heated by high seasonal temperatures all year round, especially from May to September. During this time, temperatures at the top and bottom of the mine shaft are the same, and temperature at the bottom of the shaft is only about 1 K higher than that of the ground, which is fundamentally different from the cooling of other mine shafts in summer. This is to say, the seasonal temperature variation (especially during the high-temperature period in summer) is the primary cause of the high-temperature-induced thermal damage in the mine during summer.

(4) Exothermic heat from electromechanical equipment operation:

The mine is a large modernized mine with high mechanized production. The mechanical and electrical equipment, which has a large installed capacity, such as mining, excavation, and transportation in the mine, exerts a significant effect on the thermal environment of the mine. For example, in the main pumping chamber at the level of −810 m, which is equipped with five 1800 kW drainage pumps, when three units are in normal operation, the temperature of the airflow jumps from 299.15 to 308.15 K, with a temperature difference of up to 9 K.

(5) Exothermic heat from airflow compression in the mine:

Airflow is a compressible gas, and its enthalpy value varies due to compression when it flows along the shaft (or roadway). For instance, when the airflow is sent to the tunneling face through the high-pressure compression of the local ventilator, its temperature in the air duct raises 4–6 K compared to the forward airflow in the local ventilator. This implies that exothermic heat from airflow compression in the mine also has a specific effect on the cooling of the tunneling face.

4. Four Kinds of Artificial Cooling Measures

On the basis of the normal ventilation cooling of the mine, according to the geological characteristics of the LCM and the advantages and disadvantages of various cooling modes, the underground cooling system in the LCM has integrated and optimized the following types of artificial cooling modes, including cooling through mobile refrigeration units, water source heat pump refrigeration units, a ground centralized ice-cooling radiation system, and the WAT underground centralized cooling system. This set of comprehensive cooling measures was designed by us to reduce the temperature of each mining face, tunneling face, pumping room, and mine chamber. To mitigate the severe problem of thermal damage in the mine, this combination effectively realized the objective of overall mine cooling.

4.1. Cooling via Mobile Refrigeration Units

With the continuous extension of mine development, the distance of the underground roadway will gradually increase. The mobile refrigeration unit can move forward flexibly along with the advance of the tunneling face; compared with other cooling methods, it has better flexibility, a better cooling effect and a lower cost, and is more suitable for the cooling of long-distance driving faces.

(1) The working principle of the mobile refrigeration unit:

The mobile refrigeration unit is mainly composed of a compressor, a condenser, a chiller, and an evaporator. The specific working principle is as follows (

Figure 1): first, the gaseous refrigerant (Freon) is compressed by the compressor, and the refrigerant of a higher temperature and larger pressure difference is condensed by water cooling in a heat exchanger (condenser) with a heat release, which is carried away by water; next, the heat-absorbing water is cooled by the evaporative chiller, and the cold water is returned to the condenser again for heat exchange; then, the liquid refrigerant in the condenser passes through the drying filter, expands in the expansion valve, and is sprayed into the evaporator, where it absorbs heat from the air and evaporates, returns into a gaseous state and is compressed again by the compressor. The above cycle is continuously repeated to provide the overall cooling.

(2) The cooling effect of the mobile refrigeration unit:

The design length of the entry on the #1301 working face of the LCM is about 1100 m. During the long-distance tunneling process, a counter-rotating axial flow local ventilator (FBD6.3, Zibo Fan Factory Co., Ltd., Zibo, China) with a power of 60 kW, and a mobile refrigeration unit (EAV300, Shandong Xinxue Mine Cooling Technology Co., Ltd., Taian, China) (

Figure 2) with a cooling capacity of 144 kW were operated in combination for air cooling. The specific process can be described as follows: (i) drilling the chamber at 200 m at the entry opening of the #1301 working face as a workshop of mobile refrigeration units; (ii) additionally installing an air cooler (MK-300, Shandong Xinxue Mine Cooling Technology Co., Ltd., Taian, China) at the air duct near the refrigeration unit, with the cooler end being used as the air inlet and the hotter end as the air outlet; (iii) connecting the refrigeration unit to the air cooler with a high-pressure hose and supplying the underground dust-prevention water to the refrigeration unit for cooling; (iv) supplying the airflow that exchanges heat with the low-temperature water in the air cooler to the head-on side of the tunneling face; (v) returning the high-temperature water after the heat exchange to the refrigeration unit for cooling and re-circulation. In the process of the roadway excavation for the #1301 working face, before the mobile refrigeration unit was installed, the average temperature of the head-on air was about 306.75 K (up to 308.15 K). After using the mobile refrigeration unit, this temperature was effectively reduced to 300.55 K (not exceeding 301.15 K), with the temperature dropped by 6.2−6.6 K in the head-on side of the tunneling face of the long-distance coal roadway.

4.2. Cooling via Water Source Heat Pump Refrigeration Units

A water source heat pump is a kind of high-efficiency energy-saving air conditioning system that can provide the heat refrigeration by making use of underground shallow geothermal resources [

39], which is especially suitable for mines with large-inflow and high-temperature water. It is also essentially an energy-boosting device that consumes a portion of the energy itself to transfer heat from a low-temperature zone to a high-temperature one. Compared with the ice-making process, the water source heat pump refrigerating unit system is lower-cost, simpler, and more reliable. The electricity consumption of preparing 280.15 K chilled water is 20% lower than that of preparing 277.15 K glycol solution with the ice machine. The geothermal water gushing in the mine is fully utilized, the mine water is directly used as the carrier for condensing waste heat, and the mine’s own drainage system is fully utilized without additional drainage costs. Therefore, the water source heat pump refrigeration unit was selected as the cooling mode of the LCM.

(1) The working principle of water source heat pump refrigeration units:

The water source heat pump refrigeration unit usually consists of a compressor, an evaporator, a condenser, and an expansion valve. The specific working principle is as follows (

Figure 3): the low-temperature gaseous refrigerant (R22) is pressurized to the saturated state by the compressor, and then pressed into the condenser to condense and release heat. The condensed liquid refrigerant loses moisture and impurities after flowing through the liquid storage tank and filter. After the thermal expansion valve throttling and depressurization, it enters the evaporator to absorb the heat in the water medium and then continuously evaporates, becoming low-temperature low-pressure superheated dry steam and returning to the compressor again. Meanwhile, the cooling water medium (chilled water) is used for refrigeration, thereby forming a complete refrigeration process.

(2) The cooling effect of water source heat pump refrigeration unit:

A water source heat pump (GSG870DDA, Shandong Tongfang Energy Engineering Technology Co., Ltd., China) (

Figure 4) with a cooling capacity of 840 kW was used in the cooling chamber of the #2 auxiliary roadway in the LCM, to ensure the cooling of the underground #1 and #2 auxiliary tunneling faces. The chilled water with a temperature ranging from 280.15 to 285.15 K prepared by the water source heat pump flowed through the refrigeration pipeline to the air cooler at the head-on side of the tunneling face, where cold air was delivered via the local air ventilator after the heat exchange. The warmed water (284.15−293.15 K) that absorbed the ambient heat flowed back to the evaporator to continue the circulation. At the same time, the underground water inflow in the mine with temperatures ranging from 318.15 to 321.15 K, was used as cooling water in the condenser; it was warmed by the heat absorption to a temperature of about 327.15 K, transferred to the underground water sump, and then drained through the pump house to the ground. Before adopting a water source heat pump refrigeration unit in the head-on side of underground auxiliary tunneling faces (#1 and #2) in the LCM, average temperatures of the airflow in the two tunneling faces were 302.15 and 305.15 K, respectively. After applying the above cooling measures, these temperatures declined to 294.25 and 298.15 K, respectively, and temperature differences reached 8 or 7 K, which strongly indicates that the working conditions of the head-on side were significantly improved.

4.3. Cooling via the Ground Centralized Ice-Cooling Radiation System

As the infrastructure construction work of the LCM has been gradually completed and became ready for production (one fully mechanized working face, one spare working face, and eight tunneling faces), the mine’s required cooling capacity increased significantly. For example, the temperature of the return airflow in the first-mined working face was up to 308.15 K, which means that only adopting partial cooling measures cannot meet the needs of normal production. Since ice has the advantages of large cold storage capacity and strong applicability, as well as that ice-cooling low-temperature radiation cooling can solve the problem of treatment in a high-temperature water inflow in the mine, the ground centralized system was installed on the ground and thus is easy to operate and maintain, and the system has high reliability. In addition, we have experience in ice-cooling radiation systems, thus the ground centralized ice-cooling radiation system was selected. The ground centralized ice-cooling radiation system was built to satisfy the cooling needs of underground production in the early stages of mine operation.

(1) The working principle of the ground centralized ice-cooling radiation system:

The ground centralized ice-cooling radiation system is mainly composed of the ground-cooling, ice-making, ice-transporting and ice-melting subsystems, as well as the cold-air-transporting and cold-air-dissipating subsystems. The specific working principle of this system includes the following steps (

Figure 5): firstly, granular or mud-like ice is prepared in the ice machine chamber on the ground by using the ground-cooling and ice-making subsystems (including the refrigeration compression unit, flake-ice machine, evaporative condenser, etc.). Due to the shape and transportation targets of the prepared ice, the ice is transported to the particular underground ice-melting pool while adopting different transport methods (wind power, water power, gravity, etc.), and after heat exchange with ice, water in the ice-melting pool is cooled. Then, the cold water in the pool is transported to the working face through the pipeline by a cooling pump, and the operation site is cooled and dust-prevented utilizing the air cooler and the spraying of cold water. Finally, some of the remaining cold water delivered to the working site is returned to the ice-melting pool as circulating water, while another part is used as underground auxiliary water.

(2) The cooling effect of the ground centralized ice-cooling radiation system:

At the initial stage of operation of the LCM, the total required cooling capacity was 6215.2 kW (to attain the temperature below 301.15 K after cooling), and the ground centralized ice-cooling radiation system was adopted (

Figure 6). The system comprised seven sets of spiral compressors (CSR1220, Shanghai Fusheng Air Compressor Co., Ltd., China), each having a cooling capacity of 1006 kW. Therefore, the total cooling capacity of the system was 7042 kW. Twenty-one sets of flake-ice machines (X60T, Shandong Xinxue Mine Cooling Technology Co., Ltd., China) were also adopted with a total ice-making capacity of 1260 t/d, each having an ice-making capacity of 60 t/d. Additionally, three sets of en-masse conveyors (XGZ06, Shandong Zhongmei Industrial and Mining Group, China) served as ice-transporting devices on the ground, transporting the prepared flake ice to the ice-transporting pipeline in the auxiliary vertical shaft, and then this ice was delivered to the underground ice-melting pool (with an effective volume 319.7 m

3) by its gravity force. The outlet water and return water of the ice-melting pool had temperatures of about 280.15 and 288.65 K, respectively. The ice-cooling circulating water had a moving rate of about 265 m

3/h and an effective cooling capacity of 5200 kW, which provided cooling for 16 underground air coolers. For example, when the belt roadway in the north area of the LCM was excavated, temperatures of the forward and rear airflows in the air cooler were 30 and 297.15 K, respectively, with a temperature reduction of 6 K. The outlet of the local ventilator connected with the air cooler had a temperature of 299.15 K and an airflow volume of 246 m

3/min. The temperature of the head-on side in the tunneling face dropped by 4.2 K, i.e., from 304.35 to 300.15 K, which guaranteed the normal operation of the tunneling face.

4.4. Cooling via the WAT Underground Centralized Cooling System

After the LCM was officially put into operation, the mining intensity of the mine gradually increased, and the number of underground mining districts steadily rose from two to four. Thus, the number of underground cooling locations was further increased. Besides, the length of the underground refrigeration pipeline for conveying chilled water also rose to the maximum value of 5−6 km, resulting in severe loss of cooling capacity. The estimated value of required cooling capacity in the mine being 9190 kW, about 1838 kW (or 20%) is assumed to be lost, thus increasing the total required cooling capacity in the mine to 11,028 kW. However, the original ground centralized ice-cooling radiation system with an effective cooling capacity of 5200 kW in the mine could no longer fully meet the normal cooling needs of underground high-intensity production. Consequently, after multiple calculations and demonstrations, a cooling system with an effective cooling capacity of 6600 kW needed to be built on the LCM. The centralized cooling system varies according to the layout and combination of the refrigerators, and mainly has two types: a ground centralized cooling system and an underground centralized cooling system. The basic principle is that the refrigeration station prepares frozen water to be transported underground as refrigerant to realize the purpose of cooling. The Forth Mine of Pingdingshan (located in Henan, China) has adopted a ground centralized cooling system and installs underground pressure exchange system (PES) to solve the difference between surface and underground high pressure summed up the following characteristics in the actual cooling work: the cooling capacity is large (above 3000 kW); and condensation heat is easy to exclude. PES, of course, has some shortcomings in its work multiple pressure exchangers are required to be used in series and the resistance is large; the PES usually operates when the high-pressure side flow is greater than the low-pressure side flow, and the cold water produced by the refrigeration station cannot all reach the air cooler, which increases the operating load of the refrigeration station [

40]. The WAT underground centralized cooling system can freely choose the installation location of underground cooling units, so that the underground cooling units are always in the load center, which greatly reduces the loss of chilled water in the process of conveying. The underground centralized cooling system adopts an underground cooling and surface heat removal mode. A high efficiency chiller can be selected as the refrigerating machine, which has a higher cooling efficiency and lower operating cost. The water outlet temperature of the chiller is 276.15 K, because the distance of chilled water conveying is short, the loss of chilled water is minimal, the water supply temperature of the end air cooler is low, the cooling effect is good, and the operating cost is effectively saved. Therefore, the WAT underground centralized cooling system is selected to ensure a combined operation of ground and underground centralized cooling systems with a total effective cooling capacity of 11,800 kW, which could satisfy cooling requirements of the underground high-intensity production.

(1) The working principle of the WAT underground centralized cooling system:

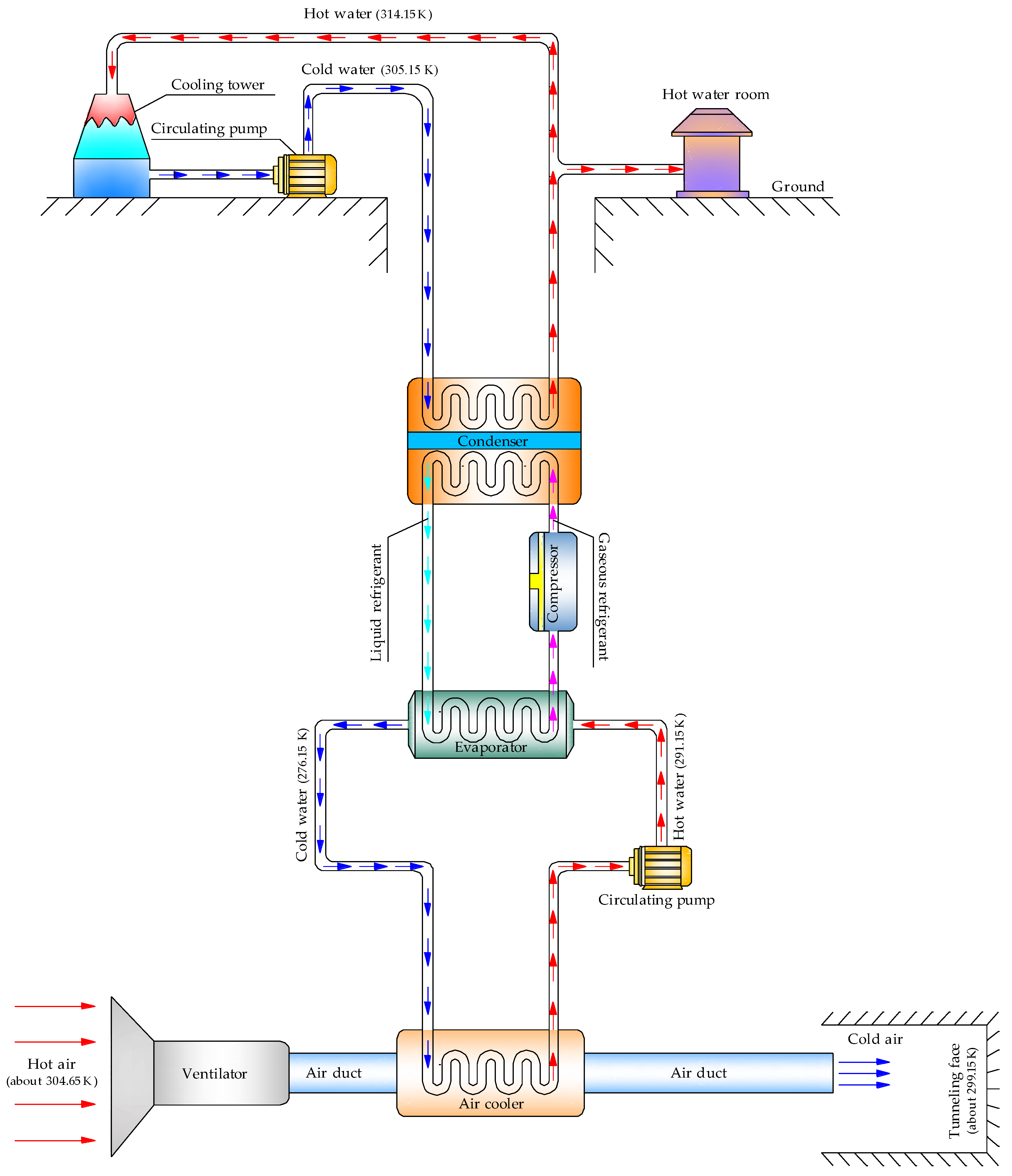

The main equipment of the underground centralized cooling system in the LCM was provided by WAT GmbH, Hamminkeln, Germany. The system mainly included a chilled water circulation subsystem, a cooling water circulation subsystem, a cold-air-dissipating subsystem and corresponding supporting equipment. The specific working principle is as follows (

Figure 7): low-temperature chilled water prepared by using underground cooling units is transported through a cold-air-transporting pipeline to each spot that needs to be cooled for the heat exchange, and then is returned to underground cooling units to be chilled again. Therefore, the chilled water circulation subsystem is developed. Low-temperature chilled water from the ground-cooling tower is conveyed through the water supply pipe in the surface borehole by a circulating pump to the inlet of the condenser in the underground cooling unit. After absorbing the condensation heat of the refrigerant, chilled water gets warmed and then returns to the ground-cooling tower through the reverse pipe in the surface borehole and is cooled again, thus forming a cooling water circulation subsystem. After being transported to the underground tunneling face, using air cooler as a cold-air-dissipating terminal, and being connected with an air duct at the tunneling face, chilled water provides the effective cooling of the tunneling face.

(2) The cooling effect of WAT underground centralized cooling system:

The WAT underground centralized refrigeration system of the LCM adopted a cooling unit with a cooling capacity of 3300 kW (KM3000, WAT GmbH, Hamminkeln, Germany) (

Figure 8), and the designed temperatures of the outlet and inlet water were 3 and 1281.15 K, respectively, with a temperature difference of 288.15 K. Combined with the layout position of the ground-cooling machine room of the mine (

Figure 9), an ultra-low noise square cross-flow tower (CDW-875ASSY, Ebara Machinery Co., Ltd., Beijing, China) was used as a cooling tower (

Figure 10), and the designed temperatures of inlet and outlet water were 314.15 and 305.15 K, respectively, with a temperature difference of 282.15 K. The circulating cooling water had a designed flowing rate of 484.6 m

3/h, which could withstand a maximum water pressure of 16 MPa. By drilling two vertical boreholes in the ground (

Figure 11) and laying cooling water pipes (each having a diameter of 480 mm) in the boreholes, the ground-cooling tower was connected to the underground WAT cooling unit to realize the discharge of the condensation heat of the underground cooling unit through the ground-cooling tower. According to the different cooling capacities required by underground mining faces, the respective numbers of air coolers (RWX-450, WAT GmbH, Ltd., Hamminkeln, Germany) were applied to the terminal cold-air dissipation.

Taking the underground centralized cooling in the second mining area of the south wing of the LCM as an example, three sets of KM3000 cooling units (two for use and one for standby) were selected to be installed in the cooling chamber of the second mining area in the south wing, with a total cooling capacity of 6600 kW. To cool and discharge the condensation heat for them, three sets of CDW-875ASSY cooling towers and corresponding supporting equipment were arranged on the ground. In addition, twelve RWX-450 air coolers were installed underground to perform the terminal cooling for the #2302 mining face in the second mining area where ten sets were installed, and for two tunneling faces where two sets were installed. As a result of the joint combined operation of the ground ice-cooling radiation system and the WAT underground cooling system, the temperature of the fully mechanized caving face in the second mining area of the south wing dropped from 305.55 to 293.15 K, i.e., by 11.281.15 K, while that of the head-on side of the tunneling face dropped from 304.65 to 299.15 K, i.e., by 278.65 K. These cooling measures ensured a safe and efficient mining production in the second mining area of the south wing.

(3) Optimization and improvement of WAT underground centralized cooling system:

At present, the centralized cooling mode of mines in accordance with the different layout locations of cooling units can be subdivided into two types: (i) centralized ground-cooling and (ii) centralized underground cooling. The latter mode has some unique advantages over the former one but also has certain deficiencies. For example, the position of refrigeration units after their installation is relatively fixed, and as the scale of underground production continues to expand and the length of the embedded cooling pipeline increases, the cooling capacity in the cold-air-transporting pipeline and the terminal cooling effect sharply deteriorate. Therefore, the original WAT underground centralized cooling system has been improved, according to the actual situation of underground production, and we further proposed a “step-by-step” implementation of the underground centralized cooling mode. In this mode, the underground cooling unit is installed near the center of the underground load constantly, by simultaneously moving the underground cooling unit and the ground-cooling machine chamber; in addition, these two systems are connected by drilling, which can not only continuously ensure high efficiency and low loss of cooling capacity of the underground centralized cooling system, but also enhance the terminal cooling effect.

5. Analysis of Technical and Economic Benefits

According to the geological conditions and thermal damage in the LCM, a set of comprehensive cooling measures was used for the first time and realized the cooling of the entire mine. A method of complete set of equipment selection and installation location selection was designed, and large-scale refrigeration equipment was operated jointly for the first time, which effectively solved the needs of large amounts of cold air, proved the advancement and feasibility of the cooling measures, and made full use of the waste heat of the mine. This included the successful application of a ground centralized ice-cooling radiation system and a WAT underground centralized cooling system, reaching the advanced level of similar coal mines in terms of cooling systems in China. Eventually, the average temperature of the main operation sites in the LCM was reduced by about 8 K, and the cooling of the whole mine was finally realized (the average temperature of the underground working face was maintained within 299.15 K), which effectively solved the problem of high-temperature-induced thermal damage, improved the underground working environment, ensured the production progress of the underground mining face, and achieved good technical and economic benefits; it also provides a precedent for domestic and foreign mines to use comprehensive cooling measures to solve severe thermal damage.

As the Outline of the 13th Five-Year Plan (2016−2020) for the National Economic and Social Development of the People’s Republic of China points out “... build a green, efficient, safe and sustainable modern energy system...”, the presented comprehensive artificial cooling measures in this study not only effectively avoids a single artificial cooling system from meeting the requirement of production, but also provides a new idea for treating thermal damage from deep resource development in the future. Therefore, the topic of this study is in line with the national energy development strategy. But it must be pointed out that the input cost of these artificial cooling methods is high and the construction time is long, which determines that this technology cannot be directly adopted by small- and medium-sized mines. Each mine should consider how to improve the technology after fully weighing its own geological and economic conditions. Taking the LCM as an example, before implementing comprehensive cooling measures, the working faces had to stop during the high-temperature period (May to September), which caused severe losses to the production of the mine. After implementing the comprehensive cooling measures, the working efficiency of underground workers increased by about 40% (calculated according to 30 days/month work schedule), increasing annual coal production by about 350,000 tons. The damage rate of mechanical and electrical equipment was markedly reduced, saving the annual maintenance cost by about 2.286 million USD per year. The economic benefits of comprehensive cooling measures in the recent three years (2016−2018) are shown in

Table 1. From the following economic data, the total three-year increase in revenue and savings is about 76.3 million USD, and the achieved technical and economic benefits are quite significant.

6. Conclusions

(1) The LCM is a typical deep high-temperature mine, of which the primary minable coal seam (#3 coal seam) is in the primary or secondary high-temperature zones. The main factors causing the high-temperature thermal damage in the LCM include exothermic heat from surrounding rock of the underground roadway, the inflow of high-temperature water, seasonal temperature rise, mechanical and electrical equipment operation, and airflow compression in the mine. In addition, the temperature of mine water is 277.15−279.15 K higher than the temperature of the surrounding rock. In summer, the shaft of the LCM tends to heat up and maintain its heat for the entire year, which is fundamentally different from the cooling trend of other mine shafts in summer.

(2) To alleviate the high-temperature-induced thermal damage in the LCM, using its particular geological conditions and the available system of the normal ventilation cooling in this mine, a comprehensive cooling mode was creatively proposed in this study, which included cooling via mobile refrigeration units, water source heat pump refrigeration units, a ground centralized ice-cooling radiation system, and the WAT underground centralized cooling system. Due to the application of the proposed cooling mode, temperatures at main operation sites were reduced by 281.15 K on average, and the temperature of the underground working face was maintained within 299.15 K on average, so that the problem of high-temperature-induced thermal damage in the mine was effectively solved.

(3) Given certain deficiencies of the WAT underground centralized cooling system, a “step-by-step” implementation of the underground centralized cooling mode was further proposed. It dealt with several problems, including losses of cooling capacity in the embedded cold-air-transporting pipeline, realizing flexible positioning of the underground cooling units and of the ground-cooling tower. Thus, the terminal cooling effect was significantly enhanced.

(4) After the overall treatment of high-temperature-induced thermal damage in the LCM, the temperature and humidity of the underground tunneling face were reduced, the work conditions for miners and the operational efficiencies of underground mechanical and electrical equipment were enhanced, and the production progress of the underground working face was ensured. Good technical and economic benefits were obviously achieved, with the total three-year increase in revenue and savings being estimated at 76.3 million USD.