Sustainability Assessment of Product–Service Systems Using Flows between Systems Approach

Abstract

:1. Introduction

- -

- Product-oriented services: the consumer will be the owner of the product so that the business model is still mainly geared towards selling products. Nevertheless, some additional services are provided by the company (e.g., insurance or maintenance).

- -

- Use-oriented services: service provider owns the product, selling only the function to customer. Thus, a change in product availability is produced. Product can be sometimes shared by a number of users (e.g., car rental).

- -

- Result-oriented services: the profit centre is result delivered, which client and provider firstly agree on (e.g., activity management-outsourcing such as catering services). There is no predetermined product involved. All materials products and consumables used to deliver the result now become cost factors, creating an incentive to minimize their use.

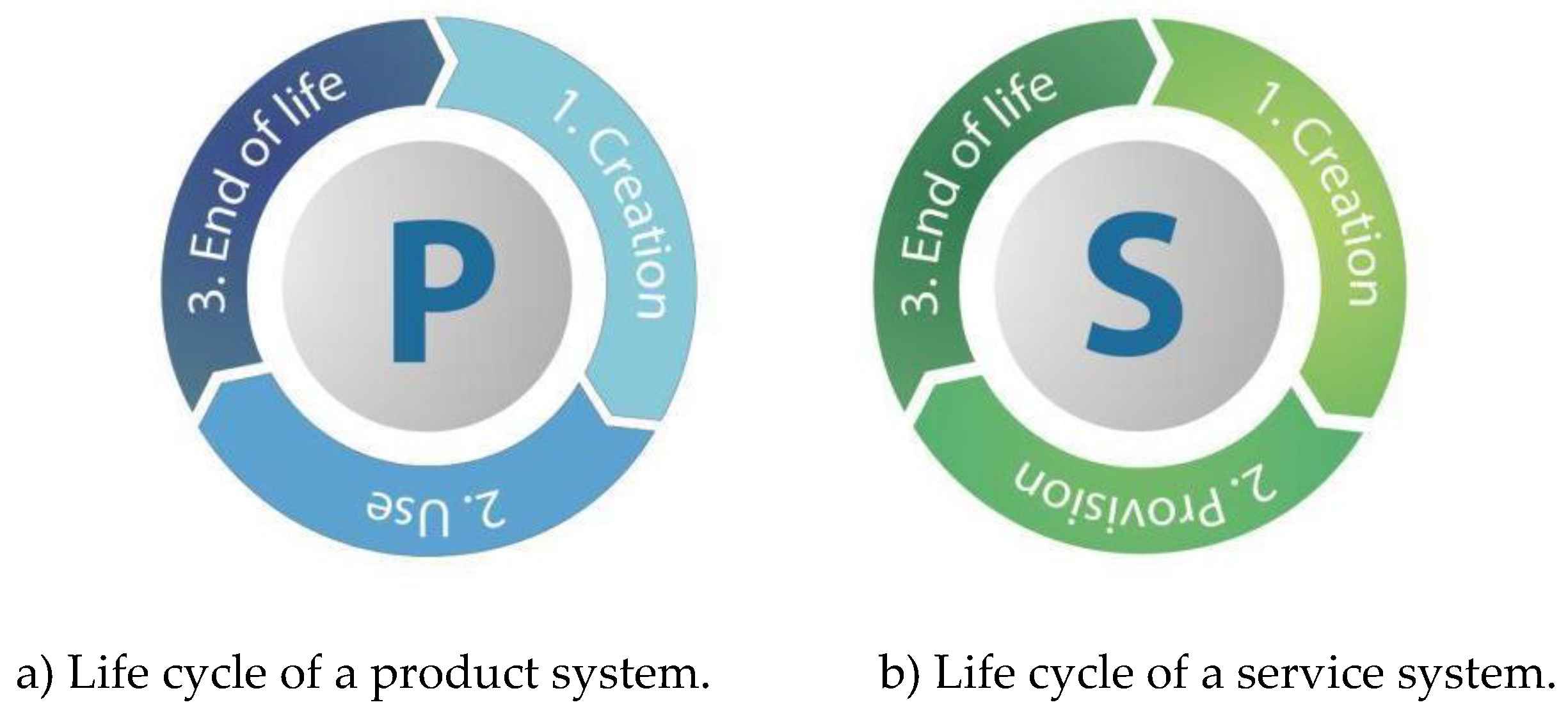

2. LCSA Applied in Product and Service Systems

- (i)

- Goal and scope definition. FU is identified and the system boundaries are established according to the depth and breadth of the study.

- (ii)

- Life cycle sustainability inventory (LCSI). Inputs and outputs of the system are collected to obtain a detailed data inventory.

- (iii)

- Life cycle sustainability impact assessment (LCSIA). Impacts of each sustainability dimension are evaluated using a set of suitable indicators. Quantitative indicators are preferred, although qualitative indicators are also used to value social aspects.

- (iv)

- Interpretation of results. Results are analysed and recommendations for decision making process can be proposed.

3. Methodology

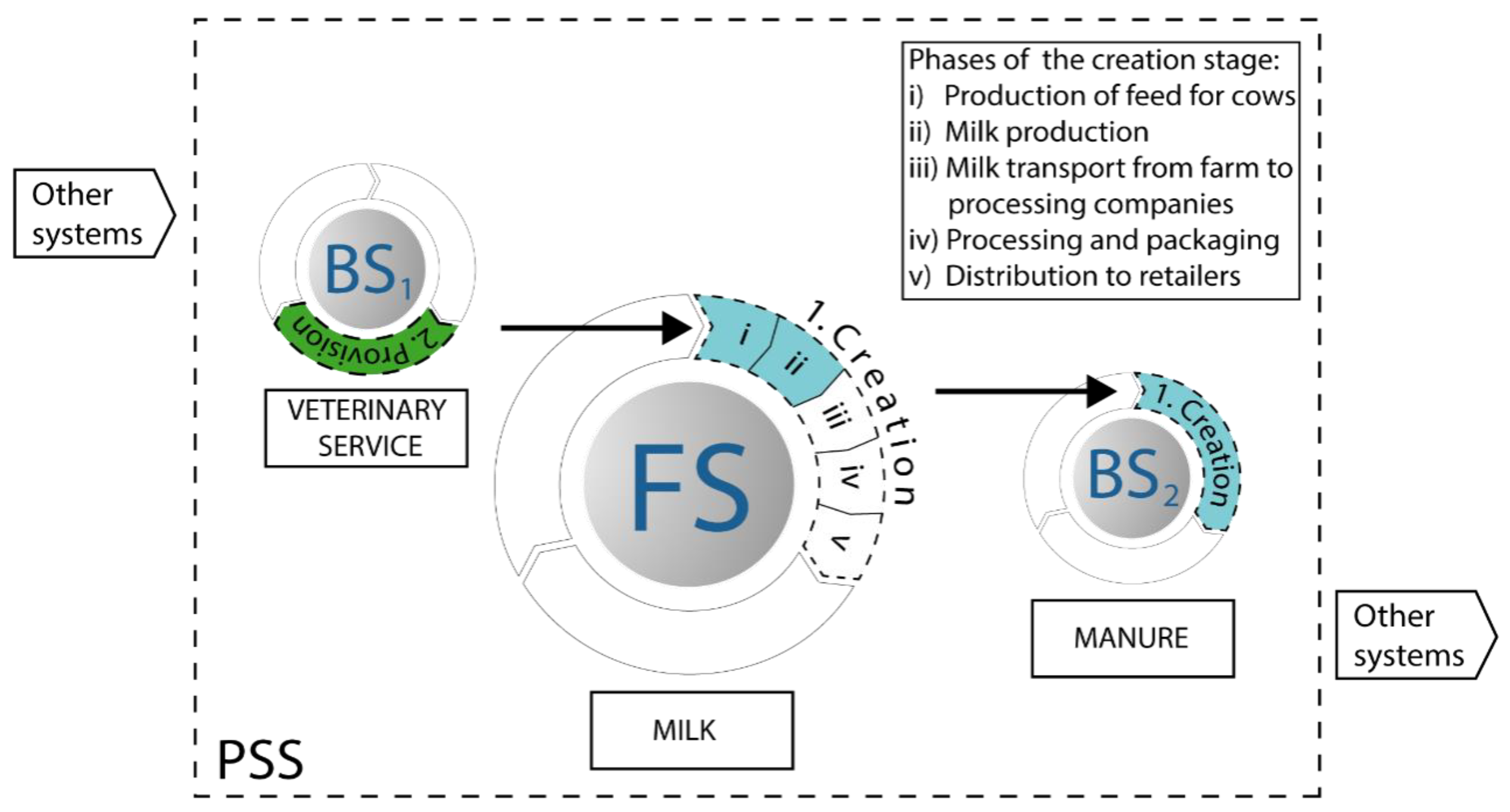

3.1. Flows between Systems Approach

- (i)

- Goal and scope definition. Identification of the FS and BSs involved in PSS and detection of links between systems. FU definition so that it is referred to both products and services, to describe and compare the sustainability of the PSS.

- (ii)

- Life cycle sustainability inventory for each system included in the PSS. Inventory data can be expressed in accordance to the reference unit that quantifies each process or activity.

- (iii)

- Life cycle sustainability impact assessment in PSS. Sustainability results of the PSS should be expressed in accordance to the FU defined. Allocation could be applied in systems that generate coproducts.

- (iv)

- Interpretation of results. Analysis of PSS sustainability results. Relative impact of different systems and recommendations for decision-making process.

3.2. Sustainability Indicators

4. Case Studies

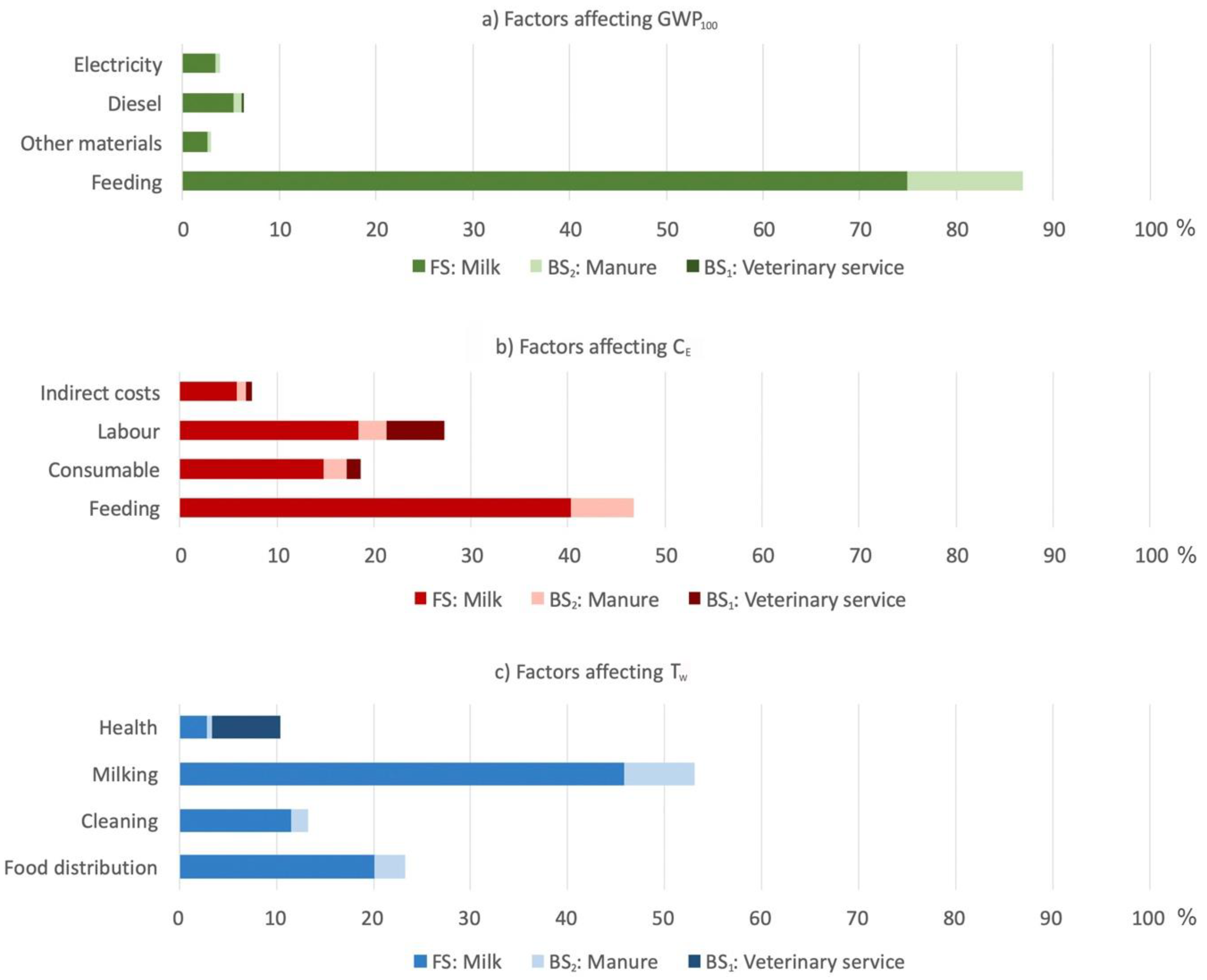

4.1. Case 1: Milk Production

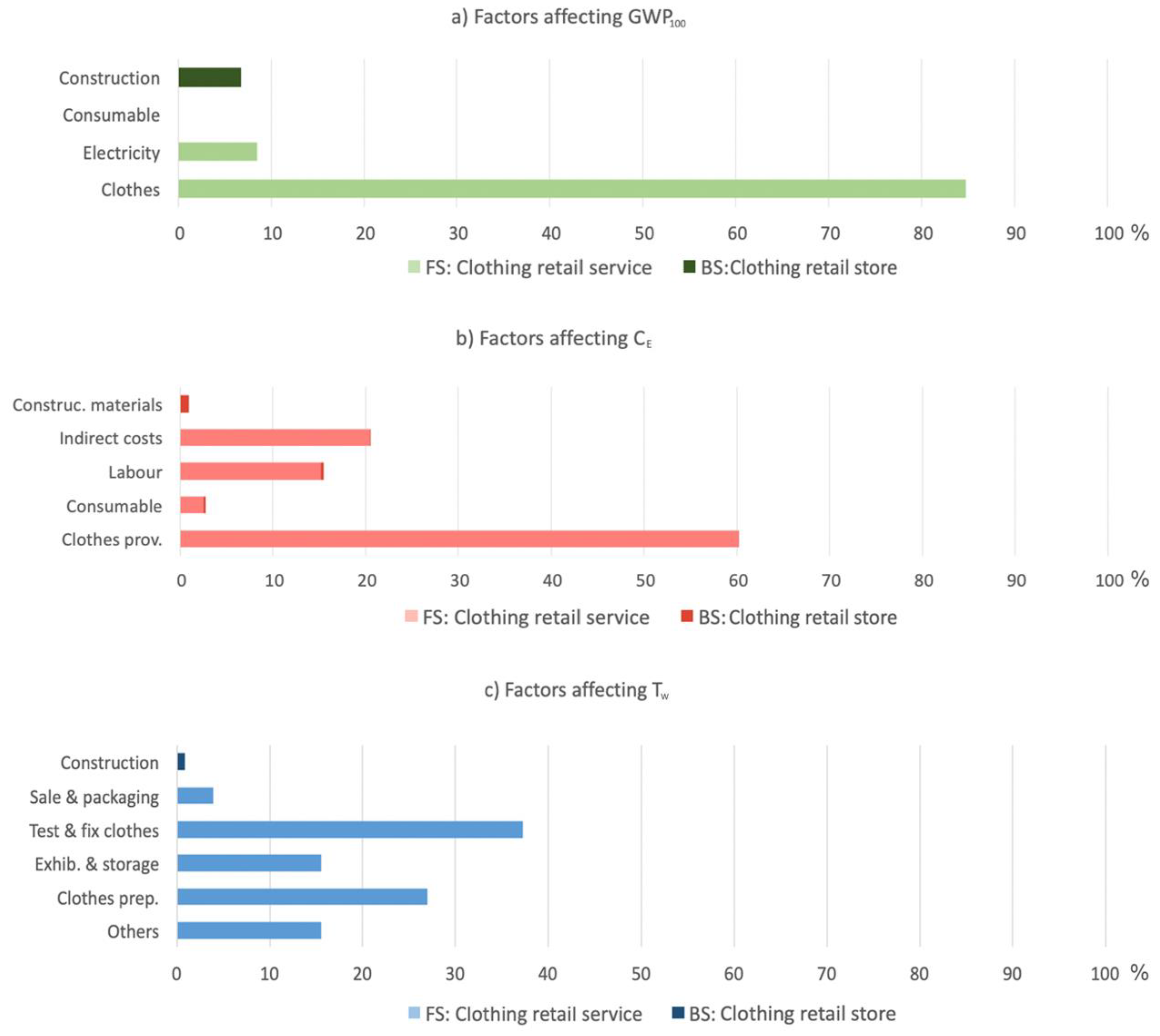

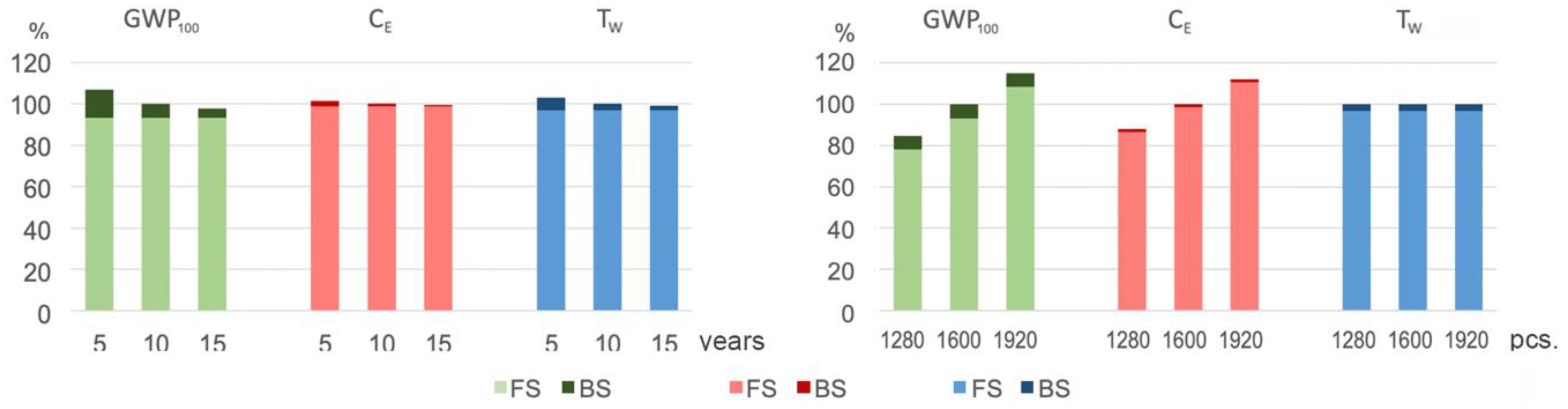

4.2. Case 2: Clothing Retail Service

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Pigosso, D.C.A.; McAloone, T.C. Maturity-based approach for the development of environmentally sustainable product/service-systems. CIRP J. Manuf. Sci. Technol. 2016, 15, 33–41. [Google Scholar] [CrossRef] [Green Version]

- Morelli, N. Developing new product service systems (PSS): methodologies and operational tools. J. Clean. Prod. 2006, 14, 1495–1501. [Google Scholar] [CrossRef]

- Tukker, A.; Tischner, U. Product-services as a research field: past, present and future. Reflections from a decade of research. J. Clean. Prod. 2006, 14, 1552–1556. [Google Scholar] [CrossRef]

- United Nations Environment Programme (UNEP). 2015. Using Product-Service Systems to Enhance Sustainable Public Procurement. Available online: http://www.unep.org/10yfp/Portals/50150/10YFP%20SPP/3A_Technical%20report.pdf (accessed on 15 August 2015).

- Tukker, A. Product services for a resource-efficient and circular economy – a review. J. Clean. Prod. 2015, 97, 76–91. [Google Scholar] [CrossRef]

- Ashford, N.; Hall, R. The Importance of Regulation-Induced Innovation for Sustainable Development. Sustainability 2011, 3, 270–292. [Google Scholar] [CrossRef] [Green Version]

- Boehm, M.; Thomas, O. Looking beyond the rim of one’s teacup: a multidisciplinary literature review of Product-Service Systems in Information Systems, Business Management, and Engineering & Design. J. Clean. Prod. 2013, 51, 245–260. [Google Scholar] [CrossRef]

- Vezzoli, C.; Kohtala, C.; Srinivasan, A. Product-Service System Design for Sustainability; Greenleaf Publishing: Sheffield, UK, 2014. [Google Scholar]

- Chen, C.-W. Guidance on the Conceptual Design of Sustainable Product–Service Systems. Sustainability 2018, 10, 2452. [Google Scholar] [CrossRef] [Green Version]

- Nasiri, M.; Rantala, T.; Saunila, M.; Ukko, J.; Rantanen, H. Transition towards Sustainable Solutions: Product, Service, Technology, and Business Model. Sustainability 2018, 10, 358. [Google Scholar] [CrossRef] [Green Version]

- Sousa-Zomer, T.; Cauchick-Miguel, P.A. Sustainable business models as an innovation strategy in the water sector: An empirical investigation of a sustainable product-service system. J. Clean. Prod. 2018, 171, S119–S129. [Google Scholar] [CrossRef]

- Kloepffer, W. Life-cycle based sustainability assessments as part of LCM. In Proceedings of the 3rd LCM Conference, Zurich, Switzerland, 27–29 August 2007. [Google Scholar]

- Finkbeiner, M.; Schau, E.; Lehmann, A.; Traverso, M. Towards Life Cycle Sustainability Assessment. Sustainability 2010, 2, 3309–3322. [Google Scholar] [CrossRef] [Green Version]

- Lacasa, E.; Santolaya, J.; Biedermann, A. Obtaining sustainable production from the product design analysis. J. Clean. Prod. 2016, 139, 706–716. [Google Scholar] [CrossRef]

- Fauzi, R.T.; Lavoie, P.; Sorelli, L.; Heidari, M.D.; Amor, B. Exploring the Current Challenges and Opportunities of Life Cycle Sustainability Assessment. Sustainability 2019, 11, 636. [Google Scholar] [CrossRef] [Green Version]

- Tan, A.R.; McAloone, T.C.; Andreasen, M.M. What happens to integrated product development models with product/service-system approaches? In Proceedings of the 6th Workshop on Integrated Product Development, Magdeburg, Germany, 18–20 September 2006. [Google Scholar]

- Kjaer, L.L.; Pagoropoulos, A.; Schmidt, J.; McAloone, T.C.; Kjær, L.L. Challenges when evaluating Product/Service-Systems through Life Cycle Assessment. J. Clean. Prod. 2016, 120, 95–104. [Google Scholar] [CrossRef] [Green Version]

- ISO, 2006a. ISO 14040 International Standard. In Environmental Management - Life Cycle Assessment - Principles and Framework; International Organisation: Geneva, Switzerland, 2006. [Google Scholar]

- ISO, 2006b. ISO 14040 International Standard. In Environmental Management - Life Cycle Assessment - Requirements and Guidelines; International Organisation: Geneva, Switzerland, 2006. [Google Scholar]

- Goedkoop, M.; Spriensma, R. The Eco-indicator 99. A damage oriented method for Life Cycle Impact Assessment; Methodology Report; PRé Consultants B.V.: Amersfoort, The Netherlands, 2001. [Google Scholar]

- Guinée, J.; Gorrée, M.; Heijungs, R.; Huppes, G.; Kleijn, R.; de Koning, A.; van Oers, L.; Sleeswijk, A.; Suh, S.; Udo de Haes, H. Life Cycle Assessment - an Operational Guide to the ISO Standards. Centre of Environmental Sciences (CML), Leiden University, 2001. Available online: https://pdfs.semanticscholar.org/83a8/8111da022a55b5045da17e5480ddaa754b26.pdf (accessed on 9 April 2020).

- WCED (World Commission on Environment and Development). Our Common Future; Oxford University Press: Oxford, UK, 1987. [Google Scholar]

- UNCED, Agenda 21. In Proceedings of the United Nations Conference on Environment and Development, Rio de Janeiro, Brazil, 3–14 June 1992.

- UNEP/SETAC. Guidelines for Social Life Cycle Assessment of Products; United Nations Environment Programme: Paris, France, 2009. [Google Scholar]

- Kloepffer, W. Life cycle sustainability assessment of products (with comments by Helias A. Udo de Haes, p. 95). Int. J. Life Cycle Assess. 2008, 13, 89–95. [Google Scholar] [CrossRef]

- Hannouf, M.; Assefa, G. A Life Cycle Sustainability Assessment-Based Decision-Analysis Framework. Sustainability 2018, 10, 3863. [Google Scholar] [CrossRef] [Green Version]

- Traverso, M.; Asdrubali, F.; Francia, A.; Finkbeiner, M. Towards life cycle sustainability assessment: an implementation to photovoltaic modules. Int. J. Life Cycle Assess. 2012, 17, 1068–1079. [Google Scholar] [CrossRef]

- Bernier, E.; Wang, L.; Samson, R. Life cycle optimization of energy-intensive processes using eco-costs. Int. J. Life Cycle Assess. 2013, 18, 1747–1761. [Google Scholar] [CrossRef] [Green Version]

- Valdivia, S.M.; Ugaya, C.M.L.; Hildenbrand, J.; Traverso, M.; Mazijn, B.; Sonnemann, G. A UNEP/SETAC approach towards a life cycle sustainability assessment—our contribution to Rio+20. Int. J. Life Cycle Assess. 2012, 18, 1673–1685. [Google Scholar] [CrossRef]

- Santolaya, J.L.; Lacasa, E.; Biedermann, A.M.; Muñoz, N. A practical methodology to project the design of more sustainable products in the production stage. Res. Eng. Des. 2019, 30, 539–558. [Google Scholar] [CrossRef]

- Capitano, C.; Traverso, M.; Rizzo, G.; Finkbeiner, M. Life cycle sustainability assessment: an implementation to marble products. In Proceedings of the LCM Conference, Berlin, Germany, 28–31 August 2011. [Google Scholar]

- Foolmaun, R.K.; Ramjeawon, T. Life cycle sustainability assessments (LCSA) of four disposal scenarios for used polyethylene terephthalate (PET) bottles in Mauritius. Environ. Dev. Sustain. 2012, 15, 783–806. [Google Scholar] [CrossRef]

- Chen, W.-T.; Hsu, C.-I. Greenhouse gas emission estimation for temperature-controlled food distribution systems. J. Clean. Prod. 2015, 104, 139–147. [Google Scholar] [CrossRef]

- Bartolozzi, I.; Baldereschi, E.; Daddi, T.; Iraldo, F. The application of life cycle assessment (LCA) in municipal solid waste management: A comparative study on street sweeping services. J. Clean. Prod. 2018, 182, 455–465. [Google Scholar] [CrossRef]

- Asadi, S.; Babaizadeh, H.; Foster, N.; Broun, R. Environmental and economic life cycle assessment of PEX and copper plumbing systems: A case study. J. Clean. Prod. 2016, 137, 1228–1236. [Google Scholar] [CrossRef]

- Hossain, U.; Poon, C.S. Comparative LCA of wood waste management strategies generated from building construction activities. J. Clean. Prod. 2018, 177, 387–397. [Google Scholar] [CrossRef]

- Ren, J.; Manzardo, A.; Mazzi, A.; Zuliani, F.; Scipioni, A. Prioritiation of bioethanol production pathways in China based on life cycle sustainability assessment and multicriteria decision-making. Int. J. Life Cycle Assess. 2015, 20, 842–853. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Y.; Sun, Y.; Tingley, D.D.; Zhang, Y. Life cycle sustainability assessment of fly ash concrete structures. Renew. Sustain. Energy Rev. 2017, 80, 1162–1174. [Google Scholar] [CrossRef]

- Rabbitt, N.; Ghosh, B. Economic and environmental impacts of organised Car Sharing Services: A case study of Ireland. Res. Transp. Econ. 2016, 57, 3–12. [Google Scholar] [CrossRef]

- Vilches, A.; Garcia-Martinez, A.; Sanchez-Montañes, B. Life cycle assessment (LCA) of building refurbishment: A literature review. Energy Build. 2017, 135, 286–301. [Google Scholar] [CrossRef]

- Baldini, C.; Gardoni, D.; Guarino, M. A critical review of the recent evolution of Life Cycle Assessment applied to milk production. J. Clean. Prod. 2017, 140, 421–435. [Google Scholar] [CrossRef]

- Millán, I.; Lacasa, E.; Sánchez, A.; Diago, L.; Santolaya, J.L. Methodology for a sustainable design of Product-Service Systems. In Advances on Mechanics, Design Engineering and Manufacturing II; Springer Nature: Basel, Switzerland, 2019; pp. 13–22. [Google Scholar]

- Vinyes, E.; Oliver-Solà, J.; Ugaya, C.; Rieradevall, J.; Gasol, C.M. Application of LCSA to used cooking oil waste management. Int. J. Life Cycle Assess. 2012, 18, 445–455. [Google Scholar] [CrossRef]

- Ciroth, A.; Franze, J. LCA of an Ecolabeled Notebook. Consideration of Social and Environmental Impacts along the Entire Life Cycle; GreenDeltaTC GmbH: Berlin, Germany, 2011. [Google Scholar]

- Chang, Y.-J.; Sproesser, G.; Neugebauer, S.; Wolf, K.; Scheumann, R.; Pittner, A.; Rethmeier, M.; Finkbeiner, M. Environmental and Social Life Cycle Assessment of Welding Technologies. Procedia CIRP 2015, 26, 293–298. [Google Scholar] [CrossRef] [Green Version]

- Ferrari, A.; Volpi, L.; Pini, M.; Siligardi, C.; García-Muiña, F.E.; Settembre-Blundo, D. Building a Sustainability Benchmarking Framework of Ceramic Tiles Based on Life Cycle Sustainability Assessment (LCSA). Resources 2019, 8, 11. [Google Scholar] [CrossRef] [Green Version]

- Iriarte, A.; Gabarrell, X.; Rieradevall, J.; Durany, X.G. LCA of selective waste collection systems in dense urban areas. Waste Manag. 2009, 29, 903–914. [Google Scholar] [CrossRef] [PubMed]

- Li, P.; Bai, W.; Ma, K. Life cycle assessment based carbon footprint calculation and analysis of Accommodation services — A case of four-star hotels in Kunming city of China. In Proceedings of the International Conference on Management and Engineering (CME), Shanghai, China, 24–25 May 2014; pp. 1400–1418. [Google Scholar]

- Sanjuan-Delmás, D.; Petit-Boix, A.; Martínez-Blanco, J.; Rieradevall, J. Environmental metabolism of educational services. Case study of nursery schools in the city of Barcelona. Energy Effic. 2015, 9, 981–992. [Google Scholar] [CrossRef] [Green Version]

- Chun, Y.-Y.; Lee, K.M. Environmental impacts of the rental business model compared to the conventional business model: a Korean case of water purifier for home use. Int. J. Life Cycle Assess. 2016, 22, 1096–1108. [Google Scholar] [CrossRef]

- Cerutti, A.; Ardente, F.; Contu, S.; Donno, D.; Beccaro, G.L. Modelling, assessing, and ranking public procurement options for a climate-friendly catering service. Int. J. Life Cycle Assess. 2017, 23, 95–115. [Google Scholar] [CrossRef] [Green Version]

- Wulf, C.; Werker, J.; Ball, C.; Zapp, P.; Kuckshinrichs, W. Review of Sustainability Assessment Approaches Based on Life Cycles. Sustainability 2019, 11, 5717. [Google Scholar] [CrossRef] [Green Version]

- Doualle, B.; Medini, K.; Boucher, X.; Laforest, V. Investigating Sustainability Assessment Methods of Product-service Systems. Procedia CIRP 2015, 30, 161–166. [Google Scholar] [CrossRef]

- Weidema, B.P. Avoiding Co- Product Allocation in Life Cycle. J. Ind. Ecol. 2000, 4, 11–34. [Google Scholar] [CrossRef]

- Boër, C.R.; Pedrazzoli, P.; Bettoni, A.; Sorlini, M. Mass Customization and Sustainability. An Assessment Framework and Industrial Implementation; Springer: London, UK, 2013. [Google Scholar]

- Durlinger, B.; Koukouna, E.; Broekema, R.; van Paassen, M.; Scholten, J. Agri-footprint 3.0; Blonk consultants: Gouda, The Netherlands, 2017. [Google Scholar]

- Probas Database. German Environmental Protection Agency. Umweltbundesamt (UBA). Available online: https://www.probas.umweltbundesamt.de/php/index.php (accessed on 13 April 2017).

- EPD Database, 2020. Available online: www.environdec.com/EPD-Search/ (accessed on 4 February 2020).

- Mapama, 2018. Spain Government. Available online: www.miteco.gob.es/ca/cambio-climatico/temas/mitigacion-politicas-y-medidas/factores_emision_tcm34-446710.pdf (accessed on 23 January 2018).

- Ng, R.; Yeo, Z.; Low, J.S.C.; Song, B. A method for relative eco-efficiency analysis and improvement: case study of bonding technologies. J. Clean. Prod. 2015, 99, 320–332. [Google Scholar] [CrossRef]

- Lacasa, E. Approach and Implementation of a Methodology to Project the Development of Sustainable Products. Ph.D. Thesis, University of Zaragoza, Zaragoza, Spain, 2018. [Google Scholar]

- De Vries, M.; De Boer, I.J.M. Comparing environmental impacts for livestock products: A review of life cycle assessments. Livest. Sci. 2010, 128, 1–11. [Google Scholar] [CrossRef]

- Fantin, V.; Buttol, P.; Pergreffi, R.; Masoni, P. Life cycle assessment of Italian high quality milk production. A comparison with an EPD study. J. Clean. Prod. 2012, 28, 150–159. [Google Scholar] [CrossRef]

- EN 15804:2012+A2:2019. Sustainability of Construction Works - Environmental Product Declarations - Core rules for the Product Category of Construction Products; CEN/TC: Brussels, Belgium, 2019. [Google Scholar]

- Muñoz, N.; Santolaya, J.L.; Biedermann, A.; Molina, J. Sustainability assessment in the implementation phase of a retail space. Adv. Des. Eng. 2020, 31–39. [Google Scholar] [CrossRef]

| Authors | System | Objective | Scope | Assessment Method | Results | |

|---|---|---|---|---|---|---|

| Product sustainability studies | Ciroth and Franze [44] (2011) | Notebook for office use | Detection of main impacts in environment and social dimensions | Entire life cycle | E-LCA; S-LCA; Single indicators; FU: 1 notebook | The development of a more sustainable product (environmental and social) is possible |

| Capitano et al., (2011) | Marble products | Evaluation and comparison of two production industrial plants | Stages of extraction, production and distribution | LCSA; Single indicators; FU: 1 m3 | The identification of hot spots in the two production processes | |

| Traverso et al., (2012) | Photovoltaic module | Study of three different scenarios of production | Production stage (assembly process) | LCSA; LCSD; Aggregated index; FU: 1 m2 | The best sustainability performance is detected by an aggregated index | |

| Foolmaun and Ramjeawon (2012) | PET bottles | Comparative analysis of four scenarios for used bottles | Final disposition stage | LCSA; Multi-criteria; AHP; Single indicators; FU: 1 t | A scenario that combines flake production and landfilling causes less impact. | |

| Chang et al. [45], (2015) | Welding technology | Study of four different welding processes | Production stage | LCA; SLCA; Single indicators; FU: 1 m weld seam | The technology with the higher impact and higher health risk for welders is identified | |

| Ren et al., (2015) | Bioethanol | Comparing three production alternatives | Crop and bioethanol production stages | LCSA; MCDM; AHP; Single indicators; FU: 1 t | The selection of an alternative is carried out by the decision-makers. | |

| Asadi et al., (2016) | Plumbing system | Effects of the use of two materials in piping | Entire life cycle | LCA; LCC; Single indicators; FU: 1000 m | PEX piping reduce the effect of environmental impacts and reduce the total cost | |

| Wang et al., (2017) | Structures of concrete | Study of different substitution percentage of fly ash | Material acquisition and production | LCSA; Sustainable Value; Aggregated index; FU: 1 m3 | Impacts are considerably reduced if cement is replaced by fly ash | |

| Hossain and Poon (2018) | Wood waste from construction activities | To evaluate the potential of four different management systems | Entire life cycle | LCA; Single indicators; Sensitivity analysis; FU: 1 t | The use of wood waste instead of virgin wood is preferable in production of particleboard | |

| Ferrari et al. [46], (2019) | Ceramic tiles | Construction of a reference benchmarking in this ambit | Entire life cycle including internal production costs | LCA; LCC and S-LCA: FU: 1 m2 porcelain stoneware | The logistics system presents critical issues and opportunities for improvement | |

| Service sustainability studies | Iriarte et al. [47], (2009) | Collection of municipal solid waste | To compare three selective collection services | Waste storage, urban and inter-city transport | LCA; Single indicators;F U: 1500 t in 1 month | The multi-container system has the least impact. Inter-city transport is a critical stage in all cases |

| Vinyes et al., (2013) | Collection of domestic used cooking oil | To compare three systems of collection in a big city | Collection and transport to the plant by tanker | LCSA; Aggregated index; FU: 10000 hab in 1 year | A multi-waste collection service is preferred. The transport stage has a high influence | |

| Li et al. [48], (2014) | Hotel accommodation | Emissions assessment due to service provision in six hotels | Construction, operation and post-operation | LCA; CFT model; FU: 1 room and 1 night | Operation phase has high impact due mainly to the energy consumption | |

| Chen and Hsu, (2015) | Refrigerated food distribution | Analysis of two temperature control techniques | Transport from terminal to retailers | Numerical model; Single indicators; FU: 1 kg in 1 day | A multi-temperature joint distribution system reduces emissions by lowering fuel consumption | |

| Rabbitt and Ghosh, (2016) | Organized car sharing service | Study of potential impacts of switching to car sharing | Service operation within an area | Statistical data; Surveys; Single indicators; FU: geographic area in 1 year | Significant savings in travel costs and CO2 emissions could be obtained Introducing car sharing service | |

| Sanjuán et al. [49], (2016) | Early education of children | Environmental profile of 12 public nursery schools | Travel to the nursery school and child-care | E-LCA; Surveys; Single indicators; FU: 1 m2 in 1 year | Energy consumption in facilities and car use in transport show high potential for improvement | |

| Chun and Lee [50] (2017) | Home water purifier rental | To compare rental model with a product-oriented model | Operation and maintenance | LCA; Single indicators; FU: 10 l/day for 15 years | Rental model shows high potential for the improvement if consumers are educated | |

| Bartolozzi et al., (2018) | Municipal service of street sweeping | To compare manual and mechanical street sweeping | Activities directly related in operational phase | LCA; PEF; Single indicators; FU: 1 h and one worker | Fuel consumption is the largest contributor in all environmental impact categories | |

| Cerutti et al. [51], (2018) | Public restoration—school catering | To assess and rank the effect of different strategies | From production of food to waste management | LCA; Single indicators; FU: average meal for 1 year | The production of food is the dominant stage. A change in diet is the most effective strategy |

| Environmental Dimension | ||

| GWP100(kgCO2-eq) Ac (gSO2-eq) GE (MJ) | Global Warming Potential. Total emissions of the greenhouse gases calculating the radiative forcing over a time horizon of 100 years. Acidification. It indicates the pH reduction due to emissions of acid gases like the nitrogen oxides (NOx) and sulphur oxides (SOx). Global Energy. Energy consumption considering electricity as well as net calorific value of resources used. | |

| Economic Dimension | ||

| CE (€) EE (€/kg CO2-eq) | Execution cost. It expresses the total cost to develop an activity. Eco-efficiency. Ratio between economic and environmental impacts. CE and GWP100 indicators can be used. | |

| Social Dimension | ||

| Tw (h) Sw (€) | Working time. Time required by the workers to develop an activity. Salary of the workers involved in the development of an activity. | Workers category |

| Material inputs and Outputs | Units | Meas. | |

|---|---|---|---|

| Feeding | Corn silage | kg | 0.786 |

| Feed | kg | 0.357 | |

| Alfalfa | kg | 0.250 | |

| Water | l | 3.496 | |

| Other material inputs | Water | l | 0.282 |

| Detergent | l | 0.0014 | |

| Acid | l | 0.0008 | |

| Protector | l | 0.0007 | |

| Medicines | g | 0.150 | |

| Straw | kg | 0.125 | |

| Diesel | l | 0.009 | |

| Outputs | Milk | l | 1 |

| Manure | kg | 2.44 | |

| Activities within the dairy farm | Energy (MJ) | TW (h)·10−3 | |

| Mixing and distribution of food | 0.343 | 1.65 | |

| Water heating | 0.129 | - | |

| Stables cleaning | 0.171 | 0.94 | |

| Milking | 0.050 | 3.76 | |

| Milk cooling | 0.081 | - | |

| Animal health | - | 0.23 | |

| Money inputs and outputs | (€) | ||

| Revenues | Milk | 0.310 | |

| Manure | 0.049 | ||

| Production costs | Feeding | 0.158 | |

| Consumable | 0.058 | ||

| Labour | 0.072 | ||

| Indirect costs | 0.025 | ||

| Environmental Dimension | Economic Dimension | Social Dimension | ||||

|---|---|---|---|---|---|---|

| System | GWP100 (kg CO2-eq) | Ac (g SO2-eq)·10−3 | CE (€) | EE (€/kg CO2-eq) | Tw (h)·10−3 | Sw (€) |

| (FS) Milk | 0.557 | 10.9 | 0.270 | 0.53 | 5.7 | 0.062 |

| (BS2) Manure | 0.086 | 1.8 | 0.043 | 0.53 | 0.9 | 0.010 |

| (FS+BS2) | 0.643 | 12.7 | 0.313 | 0.53 | 6.6 | 0.072 |

| (BS1) Veterinary | 0.002 | 0.58 | 0.013 | 6.5 | 0.53 | 0.009 |

| PSS (FS+BS1+BS2) | 0.645 | 13.28 | 0.326 | 0.50 | 7.13 | 0.081 |

| Material | Mass (t) | Material | Mass (t) |

|---|---|---|---|

| Wood | 0.33 | Plaster | 2.99 |

| Metal | 0.61 | Concrete | 20.7 |

| Plastic | 0.19 | Ceramic | 1.23 |

| Glass | 0.35 | Others | 0.03 |

| Activities | GE (MJ) | CE (€) | Tw (h) |

| Facades | 219.8 | 50.5 | 0.28 |

| Partitions | 272.6 | 49.3 | 1.53 |

| Facilities | 145.1 | 135.6 | 0.60 |

| Coatings | 251.1 | 97.6 | 2.46 |

| Furniture | 115.3 | 58.2 | 0.24 |

| Others | 239.1 | 36.8 | 0.38 |

| Material inputs | Units | |

| Clothes | 3.6 | |

| Other material inputs | (g) | |

| Packaging | 320 | |

| Management | 9.6 | |

| Sewing | 1.5 | |

| Cleaning products | 29.6 | |

| Activities | Energy(MJ) | Tw(h) |

| Clothes preparation | 24.44 | 3.14 |

| Exhibition and storage | 7.96 | 1.78 |

| Test and fix of clothes | 19.27 | 4.34 |

| Sale and packaging | 1.95 | 0.42 |

| Others | 8.29 | 1.79 |

| Operation costs | (€) | |

| Clothes provision | 404.7 | |

| Labour | 102.1 | |

| Consumable | 16.79 | |

| Indirect costs | 137.8 | |

| Environmental Dimension | Economic Dimension | Social Dimension | ||||

|---|---|---|---|---|---|---|

| System | GWP100 (kg CO2-eq) | GE (MJ) | CE (€) | EE (€/kg CO2-eq) | Tw (h) | Sw (€) |

| (FS) Service | 0.454 | 10.18 | 10.13 | 22.31 | 0.176 | 0.683 |

| (BS) Store | 0.033 | 0.37 | 0.127 | 3.86 | 0.0016 | 0.027 |

| PSS (FS+BS) | 0.487 | 10.55 | 10.25 | 21.04 | 0.177 | 0.71 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Muñoz López, N.; Santolaya Sáenz, J.L.; Biedermann, A.; Serrano Tierz, A. Sustainability Assessment of Product–Service Systems Using Flows between Systems Approach. Sustainability 2020, 12, 3415. https://doi.org/10.3390/su12083415

Muñoz López N, Santolaya Sáenz JL, Biedermann A, Serrano Tierz A. Sustainability Assessment of Product–Service Systems Using Flows between Systems Approach. Sustainability. 2020; 12(8):3415. https://doi.org/10.3390/su12083415

Chicago/Turabian StyleMuñoz López, Natalia, Jose Luis Santolaya Sáenz, Anna Biedermann, and Ana Serrano Tierz. 2020. "Sustainability Assessment of Product–Service Systems Using Flows between Systems Approach" Sustainability 12, no. 8: 3415. https://doi.org/10.3390/su12083415