Sustainable Additive Manufacturing: Mechanical Response of Acrylonitrile-Butadiene-Styrene over Multiple Recycling Processes

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

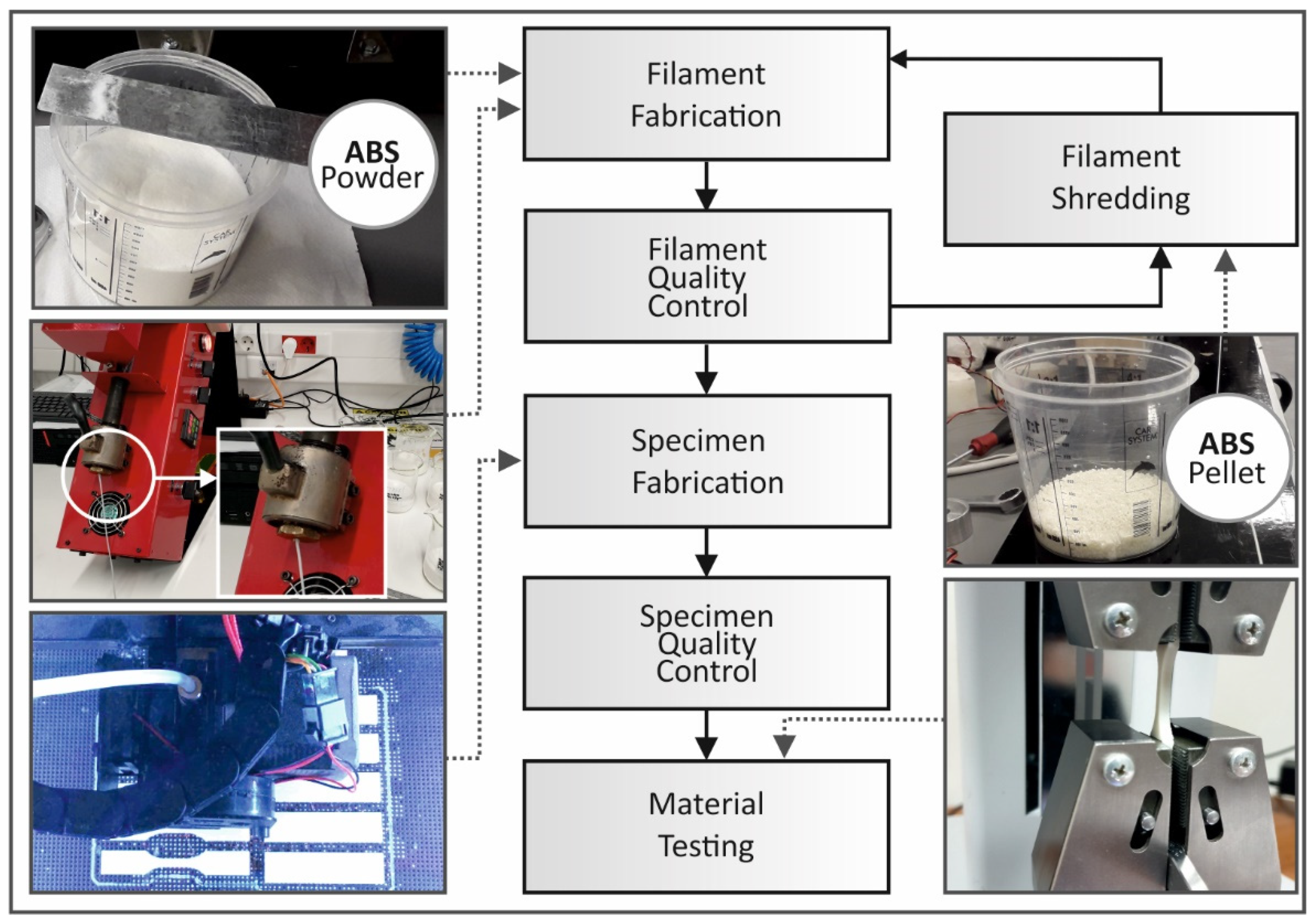

2.2.1. Recycling Simulation and Experimental Course

2.2.2. Tensile Specimens’ Fabrication and Testing

2.2.3. Compression Specimens’ Fabrication and Testing

2.2.4. Flexion Specimens’ Fabrication and Testing

2.2.5. Impact Specimens’ Fabrication and Testing

2.2.6. Micro-Hardness Measurements

2.2.7. Morphological Characterization

2.2.8. Differential Scanning Calorimetry (DSC) Analysis

3. Results

3.1. Tension Results

3.2. Compression Results

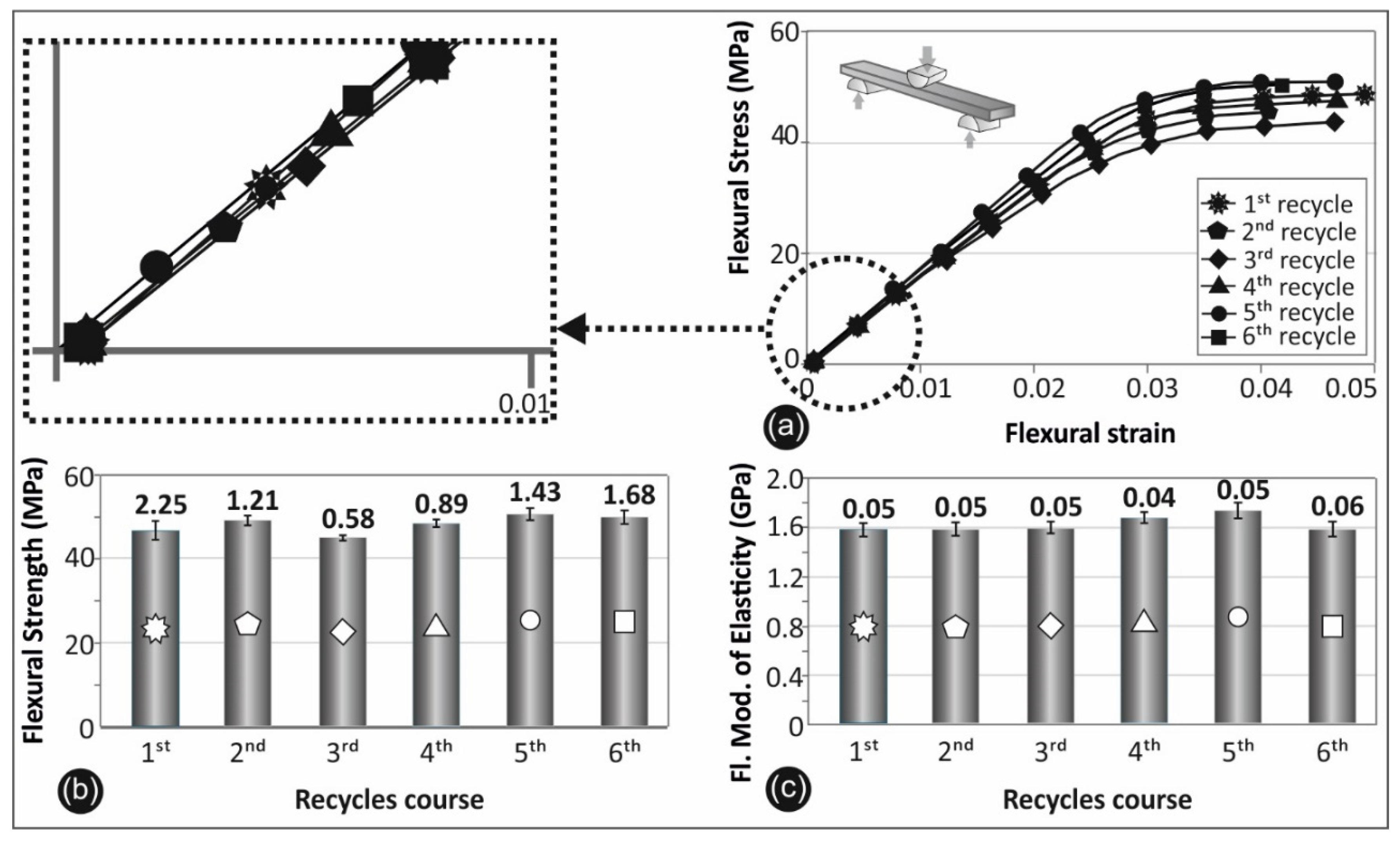

3.3. Flexion Results

3.4. Impact and Micro-Hardness Results

3.5. Morphological Characterization

3.6. DSC Analysis Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Cruz Sanchez, F.A.; Boudaoud, H.; Hoppe, S.; Camargo, M. Polymer recycling in an open-source additive manufacturing context: Mechanical issues. Addit. Manuf. 2017, 17, 87–105. [Google Scholar] [CrossRef]

- Singh, N.; Hui, D.; Singh, R.; Ahuja, I.P.S.; Feo, L.; Fraternali, F. Recycling of plastic solid waste: A state of art review and future applications. Compos. Part B Eng. 2017, 115, 409–422. [Google Scholar] [CrossRef]

- Association of Plastics Manufacturers, Plastics—The Facts 2019. Available online: https://www.plasticseurope.org (accessed on 20 April 2020).

- Peeters, B.; Kiratli, N.; Semeijn, J. A barrier analysis for distributed recycling of 3D printing waste: Taking the maker movement perspective. J. Clean. Prod. 2019, 241, 118313. [Google Scholar] [CrossRef]

- Zhong, S.; Pearce, J.M. Tightening the loop on the circular economy: Coupled distributed recycling and manufacturing with recyclebot and RepRap 3-D printing. Resour. Conserv. Recycl. 2018, 128, 48–58. [Google Scholar] [CrossRef] [Green Version]

- Santander, P.; Cruz Sanchez, F.A.; Boudaoud, H.; Camargo, M. Closed loop supply chain network for local and distributed plastic recycling for 3D printing: A MILP-based optimization approach. Resour. Conserv. Recycl. 2020, 154, 104531. [Google Scholar] [CrossRef] [Green Version]

- Zander, N.E.; Gillan, M.; Lambeth, R.H. Recycled polyethylene terephthalate as a new FFF feedstock material. Addit. Manuf. 2018, 21, 174–182. [Google Scholar] [CrossRef]

- Rahimi, M.; Esfahanian, M.; Moradi, M. Effect of reprocessing on shrinkage and mechanical properties of ABS and investigating the proper blend of virgin and recycled ABS in injection molding. J. Mater. Process. Technol. 2014, 214, 2359–2365. [Google Scholar] [CrossRef]

- Mao, N.D.; Thanh, T.D.; Thuong, N.T.; Grillet, A.C.; Kim, N.H.; Lee, J.H. Enhanced mechanical and thermal properties of recycled ABS/nitrile rubber/nanofil N15 nanocomposites. Compos. Part B Eng. 2016, 93, 280–288. [Google Scholar] [CrossRef]

- Scaffaro, R.; Botta, L.; Di Benedetto, G. Physical properties of virgin-recycled ABS blends: Effect of post-consumer content and of reprocessing cycles. Eur. Polym. J. 2012, 48, 637–648. [Google Scholar] [CrossRef]

- García, M.D.G.T.; Schlatter, M.; Cabrera, F.M.; Manzanares, J.T.; Hanafi, I. Recycling of Acrylonitrile-butadiene-styrene Using Injection Moulding Machine. Procedia Technol. 2016, 22, 399–406. [Google Scholar]

- Manisha, M.; Gurjara, D.; Sharmaa, S.; Akasha, A.; Sarkara, M. A Review on testing methods of recycled Acrylonitrile Butadiene-Styrene. Mater. Today Proc. 2018, 5, 28296–28304. [Google Scholar] [CrossRef]

- Matias, Á.A.; Lima, M.S.; Pereira, J.; Pereira, P.; Barros, R.; Coelho, J.F.J.; Serra, A.C. Use of recycled polypropylene/poly(ethylene terephthalate) blends to manufacture water pipes: An industrial scale study. Waste Manag. 2020, 101, 250–258. [Google Scholar] [CrossRef] [PubMed]

- Singh, N.; Singh, R.; Ahuja, I.P.S.; Farina, I.; Fraternali, F. Metal matrix composite from recycled materials by using additive manufacturing assisted investment casting. Compos. Struct. 2019, 207, 129–135. [Google Scholar] [CrossRef]

- Singh, R.; Kumar, R.; Singh, P. Prospect of 3D Printing for Recycling of Plastic Product to Minimize Environmental Pollution; Elsevier Ltd.: Amsterdam, The Netherlands, 2018; ISBN 9780128035818. [Google Scholar]

- Ortega, Z.; Monzón, M.; Paz, R.; Suárez, L. Banana Fiber Processing for the Production of Technical. Sustain. Des. Manuf. 2017. Smart Innov. Syst. Technol. 2017, 3, 11. [Google Scholar]

- Sauerwein, M.; Doubrovski, E.L. Local and recyclable materials for additive manufacturing: 3D printing with mussel shells. Mater. Today Commun. 2018, 15, 214–217. [Google Scholar] [CrossRef]

- Gu, H.; Bashir, Z.; Yang, L. The re-usability of heat-exposed poly (ethylene terephthalate) powder for laser sintering. Addit. Manuf. 2019, 28, 194–204. [Google Scholar] [CrossRef]

- Feng, L.; Wang, Y.; Wei, Q. PA12 powder recycled from SLS for FDM. Polymers (Basel) 2019, 11, 727. [Google Scholar] [CrossRef] [Green Version]

- Azuaje, J.; Tubío, C.R.; Escalante, L.; Gómez, M.; Guitián, F.; Coelho, A.; Caamaño, O.; Gil, A.; Sotelo, E. An efficient and recyclable 3D printed α-Al2O3 catalyst for the multicomponent assembly of bioactive heterocycles. Appl. Catal. A Gen. 2017, 530, 203–210. [Google Scholar] [CrossRef]

- Asgari, H.; Baxter, C.; Hosseinkhani, K.; Mohammadi, M. On microstructure and mechanical properties of additively manufactured AlSi10Mg_200C using recycled powder. Mater. Sci. Eng. A 2017, 707, 148–158. [Google Scholar] [CrossRef]

- Melugiri-Shankaramurthy, B.; Sargam, Y.; Zhang, X.; Sun, W.; Wang, K.; Qin, H. Evaluation of cement paste containing recycled stainless steel powder for sustainable additive manufacturing. Constr. Build. Mater. 2019, 227, 116696. [Google Scholar] [CrossRef]

- Gorji, N.E.; O’Connor, R.; Mussatto, A.; Snelgrove, M.; González, P.G.M.; Brabazon, D. Recyclability of stainless steel (316 L) powder within the additive manufacturing process. Materialia 2019, 8, 100489. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, R. Prospect of Recycling of Plastic Product to Minimize Environmental Pollution; Elsevier Ltd.: Houston, TX, USA, 2020; ISBN 9780128035818. [Google Scholar]

- Hart, K.R.; Frketic, J.B.; Brown, J.R. Recycling meal-ready-to-eat (MRE) pouches into polymer filament for material extrusion additive manufacturing. Addit. Manuf. 2018, 21, 536–543. [Google Scholar] [CrossRef]

- Suárez, L.; Domínguez, M. Sustainability and environmental impact of fused deposition modelling (FDM) technologies. Int. J. Adv. Manuf. Technol. 2020, 106, 1267–1279. [Google Scholar]

- Zander, N.E.; Gillan, M.; Burckhard, Z.; Gardea, F. Recycled polypropylene blends as novel 3D printing materials. Addit. Manuf. 2019, 25, 122–130. [Google Scholar] [CrossRef]

- Schirmeister, C.G.; Hees, T.; Licht, E.H.; Mülhaupt, R. 3D printing of high density polyethylene by fused filament fabrication. Addit. Manuf. 2019, 28, 152–159. [Google Scholar] [CrossRef]

- Chong, S.; Pan, G.T.; Khalid, M.; Yang, T.C.K.; Hung, S.T.; Huang, C.M. Physical Characterization and Pre-assessment of Recycled High-Density Polyethylene as 3D Printing Material. J. Polym. Environ. 2017, 25, 136–145. [Google Scholar] [CrossRef]

- Chong, S.; Yang, T.C.K.; Lee, K.C.; Chen, Y.F.; Juan, J.C.; Tiong, T.J.; Huang, C.M.; Pan, G.T. Evaluation of the physico-mechanical properties of activated-carbon enhanced recycled polyethylene/polypropylene 3D printing filament. Sadhana Acad. Proc. Eng. Sci. 2020, 45, 10–15. [Google Scholar] [CrossRef]

- Spoerk, M.; Arbeiter, F.; Raguž, I.; Holzer, C.; Gonzalez-Gutierrez, J. Mechanical recyclability of polypropylene composites produced by material extrusion-based additive manufacturing. Polymers (Basel) 2019, 11, 1318. [Google Scholar] [CrossRef] [Green Version]

- Boparai, K.S.; Singh, R.; Fabbrocino, F.; Fraternali, F. Thermal characterization of recycled polymer for additive manufacturing applications. Compos. Part B Eng. 2016, 106, 42–47. [Google Scholar] [CrossRef]

- Farina, I.; Singh, N.; Colangelo, F.; Luciano, R.; Bonazzi, G.; Fraternali, F. High-Performance Nylon-6 Sustainable Filaments for Additive Manufacturing. Materials (Basel) 2019, 12, 3955. [Google Scholar] [CrossRef] [Green Version]

- Domingues, J.; Marques, T.; Mateus, A.; Carreira, P.; Malça, C. An Additive Manufacturing Solution to Produce Big Green Parts from Tires and Recycled Plastics. Procedia Manuf. 2017, 12, 242–248. [Google Scholar]

- Lanzotti, A.; Martorelli, M.; Maietta, S.; Gerbino, S.; Penta, F.; Gloria, A. A comparison between mechanical properties of specimens 3D printed with virgin and recycled PLA. Procedia CIRP 2019, 79, 143–146. [Google Scholar]

- Cisneros-López, E.O.; Pal, A.K.; Rodriguez, A.U.; Wu, F.; Misra, M.; Mielewski, D.F.; Kiziltas, A.; Mohanty, A.K. Recycled poly(lactic acid)–based 3D printed sustainable biocomposites: A comparative study with injection molding. Mater. Today Sustain. 2020, 8, 1–12. [Google Scholar]

- Zhao, X.G.; Hwang, K.J.; Lee, D.; Kim, T.; Kim, N. Enhanced mechanical properties of self-polymerized polydopamine-coated recycled PLA filament used in 3D printing. Appl. Surf. Sci. 2018, 441, 381–387. [Google Scholar]

- Tian, X.; Liu, T.; Wang, Q.; Dilmurat, A.; Li, D.; Ziegmann, G. Recycling and remanufacturing of 3D printed continuous carbon fiber reinforced PLA composites. J. Clean. Prod. 2017, 142, 1609–1618. [Google Scholar]

- Rahimizadeh, A.; Kalman, J.; Henri, R.; Fayazbakhsh, K.; Lessard, L. Recycled glass fiber composites fromwind turbine waste for 3D printing feedstock: Effects of fiber content and interface on mechanical performance. Materials (Basel) 2019, 12, 3929. [Google Scholar]

- Mohammed, M.I.; Wilson, D.; Gomez-Kervin, E.; Tang, B.; Wang, J. Investigation of Closed-Loop Manufacturing with Acrylonitrile Butadiene Styrene over Multiple Generations Using Additive Manufacturing. ACS Sustain. Chem. Eng. 2019, 7, 13955–13969. [Google Scholar]

- Goutham, R.; Veena, T.R.; Babagowda; Prasad, K.R.S. Study on mechanical properties of recycled Acrylonitrile Butadiene Styrene (ABS) blended with virgin Acrylonitrile Butadiene Styrene (ABS) using Taguchi method. Mater. Today Proc. 2018, 5, 24836–24845. [Google Scholar]

- Mohammed, M.I.; Das, A.; Gomez-kervin, E.; Wilson, D.; Gibson, I. EcoPrinting: Investigating the use of 100% recycled Acrylonitrile Butadiene Styrene (ABS) for Additive Manufacturing. In Proceedings of the 28th Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 7–9 August 2017; pp. 532–542. [Google Scholar]

- Woern, A.L.; Byard, D.J.; Oakley, R.B.; Fiedler, M.J.; Snabes, S.L.; Pearce, J.M. Fused particle fabrication 3-D printing: Recycled materials’ optimization and mechanical properties. Materials (Basel) 2018, 11, 1413. [Google Scholar]

- Hirayama, D.; Saron, C. Morphologic and mechanical properties of blends from recycled acrylonitrile-butadiene-styrene and high-impact polystyrene. Polymer (Guildf) 2018, 135, 271–278. [Google Scholar]

- Rahimizadeh, A.; Kalman, J.; Fayazbakhsh, K.; Lessard, L. Recycling of fiberglass wind turbine blades into reinforced filaments for use in Additive Manufacturing. Compos. Part B Eng. 2019, 175, 107101. [Google Scholar] [CrossRef]

- Vidakis, N.; Vairis, A.; Petousis, M.; Savvakis, K.; Κechagias, J. Fused Deposition Modelling Parts Tensile Strength Characterisation. Acad. J. Manuf. Eng. 2016, 14, 87–94. [Google Scholar]

- Vidakis, N.; Maniadi, A.; Petousis, M.; Koudoumas, E.; Kenanakis, G. Mechanical and Electrical Properties Investigation of 3D-Printed Acrylonitrile-butadiene-styrene Graphene and Carbon Nanocomposites. J. Mater. Eng. Perform. 2020. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Vairis, A.; Savvakis, K.; Maniadi, A. A parametric determination of bending and Charpy’s impact strength of ABS and ABS-plus fused deposition modeling specimens. Prog. Addit. Manuf. 2019, 4, 323–330. [Google Scholar] [CrossRef]

- Chacón, J.M.; Caminero, M.A.; Núñez, P.J.; García-Plaza, E.; García-Moreno, I.; Reverte, J.M. Additive manufacturing of continuous fibre reinforced thermoplastic composites using fused deposition modelling: Effect of process parameters on mechanical properties. Compos. Sci. Technol. 2019, 181, 107688. [Google Scholar] [CrossRef]

- Zhao, P.; Rao, C.; Gu, F.; Sharmin, N.; Fu, J. Close-looped recycling of polylactic acid used in 3D printing: An experimental investigation and life cycle assessment. J. Clean. Prod. 2018, 197, 1046–1055. [Google Scholar] [CrossRef]

- Hamming, L.M.; Qiao, R.; Messersmith, P.B.; Brinson, L.C. Effects of dispersion and interfacial modification on the macroscale properties of TiO(2) polymer matrix nanocomposites. Compos. Sci. Technol. 2009, 69, 1880–1886. [Google Scholar] [CrossRef] [Green Version]

- Gnanasekaran, K.; Heijmansa, T.; Bennekom, S.; Woldhuis, H.; Wijniab, S.; Witha, G.; Friedrich, H. 3D printing of CNT- and graphene-based conductive polymer nanocomposites by fused deposition modelling. Appl. Mater. Today 2017, 9, 21–28. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vidakis, N.; Petousis, M.; Maniadi, A.; Koudoumas, E.; Vairis, A.; Kechagias, J. Sustainable Additive Manufacturing: Mechanical Response of Acrylonitrile-Butadiene-Styrene over Multiple Recycling Processes. Sustainability 2020, 12, 3568. https://doi.org/10.3390/su12093568

Vidakis N, Petousis M, Maniadi A, Koudoumas E, Vairis A, Kechagias J. Sustainable Additive Manufacturing: Mechanical Response of Acrylonitrile-Butadiene-Styrene over Multiple Recycling Processes. Sustainability. 2020; 12(9):3568. https://doi.org/10.3390/su12093568

Chicago/Turabian StyleVidakis, Nectarios, Markos Petousis, Athena Maniadi, Emmanuel Koudoumas, Achilles Vairis, and John Kechagias. 2020. "Sustainable Additive Manufacturing: Mechanical Response of Acrylonitrile-Butadiene-Styrene over Multiple Recycling Processes" Sustainability 12, no. 9: 3568. https://doi.org/10.3390/su12093568

APA StyleVidakis, N., Petousis, M., Maniadi, A., Koudoumas, E., Vairis, A., & Kechagias, J. (2020). Sustainable Additive Manufacturing: Mechanical Response of Acrylonitrile-Butadiene-Styrene over Multiple Recycling Processes. Sustainability, 12(9), 3568. https://doi.org/10.3390/su12093568

_Kechagias.jpg)