Abstract

The complex and networked nature of sustainable procurement is evoked through confronting two conceptual models, the triple bottom line-inspired parallel-type “interlocking circles model” with the more systems-oriented series-type “concentric circles model”. This endeavor is integrated with a developed application of contingency theory rooted in network thinking. Two subcase narratives from Ghana, one in the upstream portion of the supply chain associated with exploration and platform-based production, and the other an oil refinery in the downstream part are provided. Interaction, interdependency, and integration, all associated with value, conceptually ground the analyses. A developed empirically grounded conceptual model depicts sustainability as systemically intertwined with value and networked in an immediate business, network, and wider noncontextual natural and social environment. Sustainable procurement is networked, a value creating managerial process rather than, as the triple bottom line posits, a norm “out there” directing managerial action. Sustainability is inherently complex. Rather than guiding action through deterministic ethical norms, it emerges as emergent practices primarily through purposeful interaction within the supply network that instead may be interpreted and developed in a long-term sense through using the two discussed conceptual models on sustainable production.

1. Introduction

This study discusses the use of conceptual models on the topic of sustainable procurement in an inherently dynamic supply network to enrich the understanding of what constitutes “sustainable procurement”. A combined contingency and network perspective is taken. This means focusing on the environmentally embedded nature of the purchasing function in its structure and its organizational networked context [1]. In our approach, procurement concerns the networked initiative of firms to ensure resources to sustain their production through transacting on the market. It permeates all activities within Supply chain management (SCM) and, thereby, procurement has the capability to make supply networks sustainable.

Businesses normally focus on gaining a positive rate of return to its shareholders. The expense of the environment and the interest of people and local communities have been, however, ignored in most practices. According to Walker and Phillips [2], sustainable procurement strives to achieve the sustainable development goals through supply and procurement processes reflecting balancing economic, environmental, and social perspectives, and includes an overarching purpose to achieve economic efficiency. The benefits generated do not accrue only to organizations, but also to society, while remaining within the capacity of long-term societal concerns of the environment. Recent literature reviews have shown a special focus of previous research on socially and environmentally responsible procurement within the supply chain networks [3,4,5,6,7,8,9]. Most of this research has, however, lacked theoretical anchoring and/or has been simply rooted in general sustainability literature [10]. It seems that the current knowledge on SCM and sustainable procurement has been either nontheoretical or developed on building models lacking grounding in theory [11]. Addressing business concerns regarding the sustainability of procurement is in this paper, treated as a widening of “procurement” as a business activity to also encompass societal goals regarding the environment from a long-term perspective.

The three important aspects of sustainability are the environmental, economic, and social aspects. These three facets of sustainability are highly interrelated and have been represented by different conceptual models, such as the “interlocking circles model” (ICM) and the “concentric circles model” (CCM) [12,13]. Lozano [13] pointed out how these models have helped to bring into focus for the general public much awareness about issues bothering on sustainability. He also pointed out that “they all suffer from being highly anthropocentric, compartmentalized, and lacking completeness and continuity” ([13], p. 1836). Conceptual models do contribute to better understanding through simplifying reality. Such models are many on equivalent research problems, and understanding what, for example, constitutes “sustainable purchasing” may demand refining the existent models in the area and better adapting them to the specific research issue in question. The first, and by far most widespread approach, views sustainability from a snapshot perspective in time, while the second view, attaining sustainable production more as a hierarchically sequentially organized set of subsystems. This study encompasses search for such an alternative understanding and use of the CCM and ICM models. This implies, in this research, focusing on both the issue of sustainability and procurement as a network-contingent process.

This approach is rooted in Thompson’s [14] writings on production contingencies and interdependencies in networks. This approach also implies further investigation of the networking aspect of using these two models in a business setting, to more explicitly explore applying the Industrial Marketing and Purchasing Group (IMP) network approach on how embeddedness of actors, resources, and activities contribute to the development of sustainable procurement in value-based networks. Hoejmose et al. [11] developed reasoning to apply the IMP approach to study socially and environmentally responsible procurement. Fundamentally, they pointed out how the IMP approach focuses on integration and long-term orientation in business relationships to create sustainable production. Furthermore, these relationships are embedded in a network of multiple relationships, increasing the complexity of managing, for example, procurement. The IMP perspective includes a stream of literature that encompasses a wider societal array of institutions [15,16]. In this stream of studies, Janusz et al. [1] suggested viewing value-based societal networks through three dimensions: interaction, interdependencies, and integration.

The purpose of this investigation is through the provided empirical findings in the form of narratives describing two comparable cases to elaborate on the nature of sustainability in relation to the business function of procurement. The two cases are one case in the upstream segment and one case in the downstream segment of the Ghana oil industry. The choice of the cases was due to convenience and because they provide grounds for discussing the two conceptual models. Following a pragmatic line of investigation, the appropriateness and use of these alternative conceptual models of sustainable production are scrutinized based on the analytical framework developed through the following literature review. This study provides, accordingly, a discussion of sustainable procurement using the two applied models of sustainability. This provides a rich case-specific discussion. Limitations of this approach are that application of the findings to other cases of procurement, in other types of industries must be used with caution through treatment of conceptual findings. This study provides, accordingly, basis for discussion and does not provide grounds for generalized findings.

2. Literature Review

2.1. Two Alternative Conceptual Models of Sustainable Production

Mental models may guide human action. Furthermore, conceptual models founded on research may decisively impact on how business act. How “sustainability” is perceived and treated in business activities, including procurement, is of interest from a research point of view. “Sustainable production” architypes have progressed towards a triadic structure of solutions, grounded in the three dimensions of sustainability: economy, ecology, and equity. This perspective, referred to as the triple bottom line (TBL), provides a new framework to manage large and complex manufacturing projects [17]. These conceptual models on sustainable production [12,13] represent the interrelationship between the environmental, economic, and social aspects of sustainability. The interdependence between nature, society, and the environment is complex [18,19,20]. Following Singh et al. [21], society and business therein need to develop and use models as simplifications of reality to understand how to understand procurement as being sustainable. The reasoning behind this sustainability assessment is to provide decision-makers in organizations with a systems perspective that encompasses three aspects of sustainability: nature, society, and economy [20,21]. This study presents and discusses two alternative approaches to conceptualizing “sustainable production”. This study approaches procurement as a subsystem in the overall production system. The following section briefly describes and discusses two alternative approaches to understanding sustainable production: the interlocking circles model (ICM) and concentric circles model (CCM). Such models of sustainability are beneficial by simplifying the complexity of sustainable production.

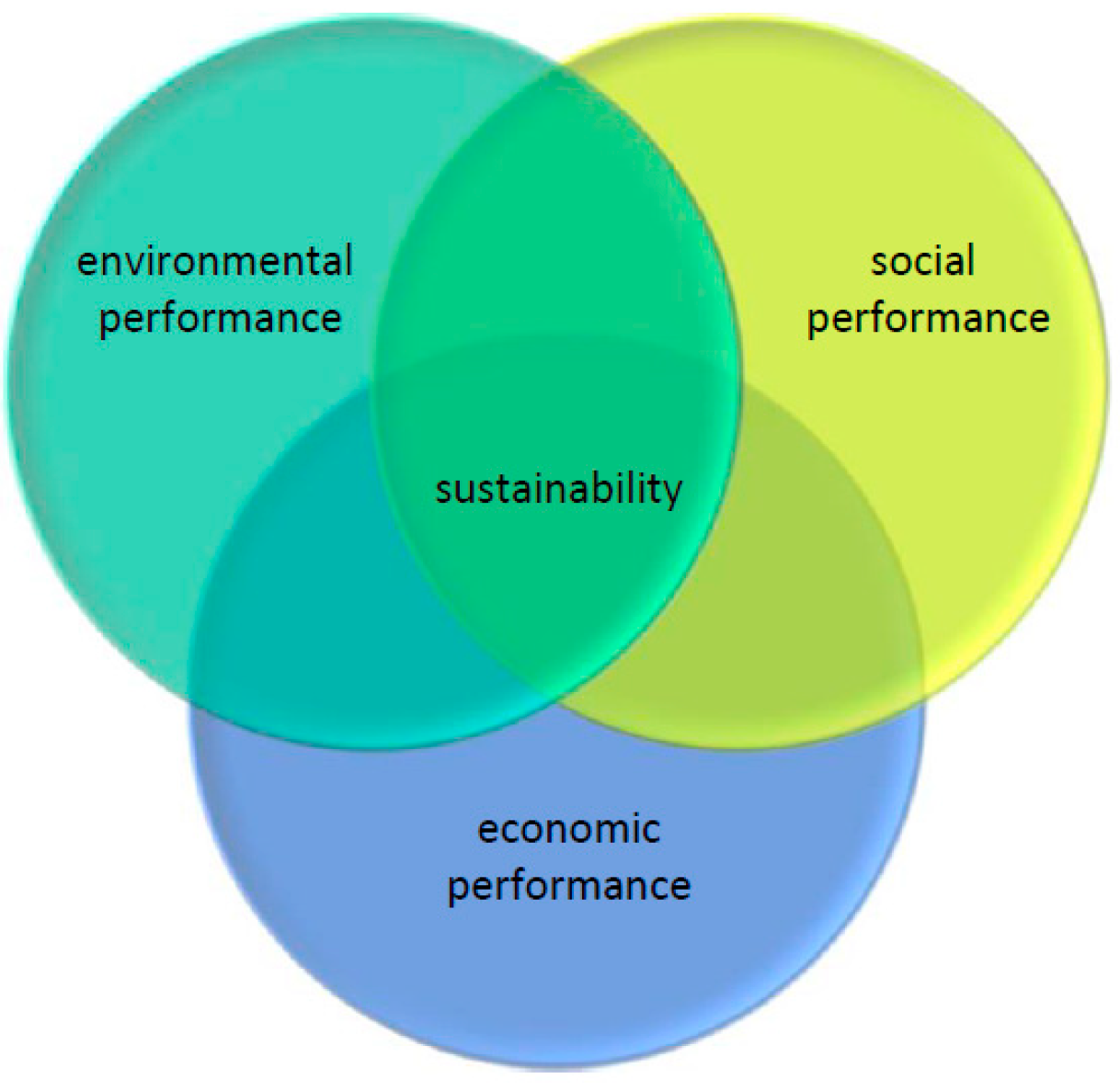

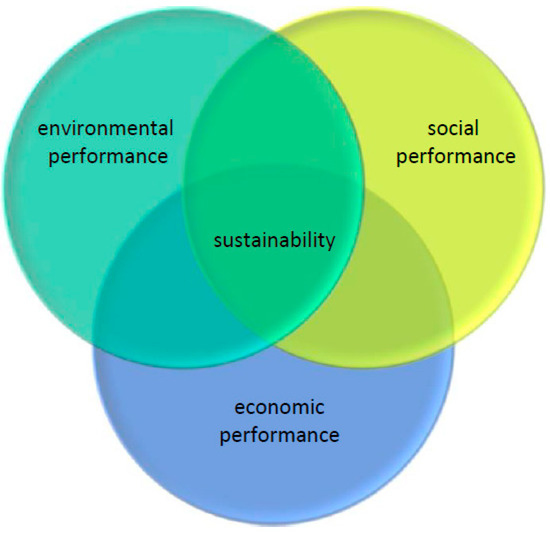

Following Barron and Gauntlett’s [12] empirical findings, in the Western Australian Council of Social Service (WACOSS) Housing and Sustainable Communities Indicators Project, the CCM model was, at an initial phase, argued as most feasible from a business practice perspective. ICM is the most widespread model of sustainability that pictures the three spheres of influence as equals, thereby also simultaneous in their impact on production. Elkington [22] coined this model associated with the triple bottom line (TBL) understanding of sustainable production. This model highlights the importance for organizations to assess sustainability in all three areas of economic, social, and environmental sustainability on equal terms [20]. More organizations are increasingly using business models that seek to include environmental aspects of performance in line with the TBL concept [23]. TBL involves a fundamental assumption of balanced equality in the interdependency between the three involved dimensions of sustainable production. More precisely, in ICM, “sustainability” is the core value. In essence, this means sustainable industrial (including services) production. Figure 1 depicts the ICM:

Figure 1.

Interlocking circles model of sustainability [10].

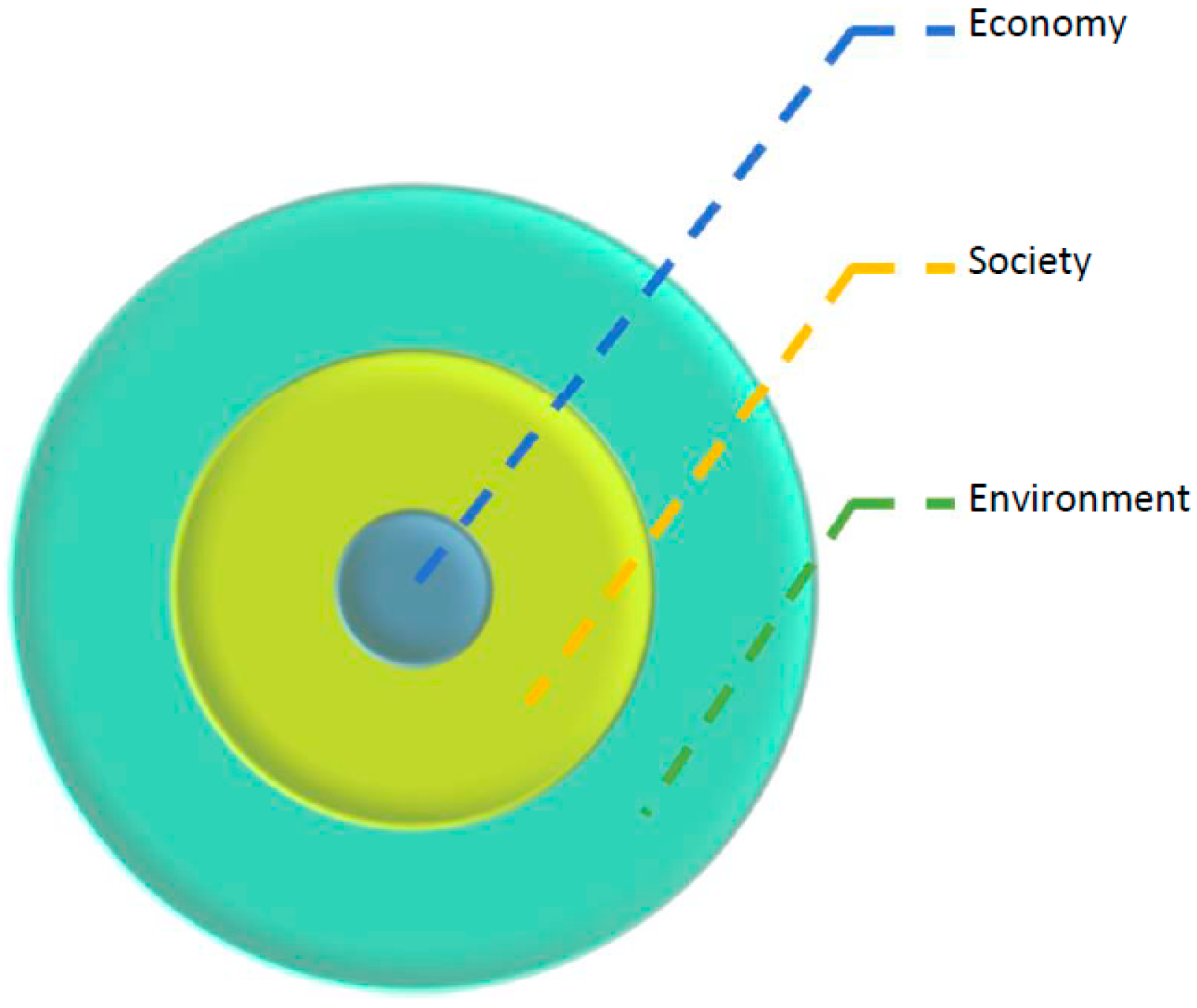

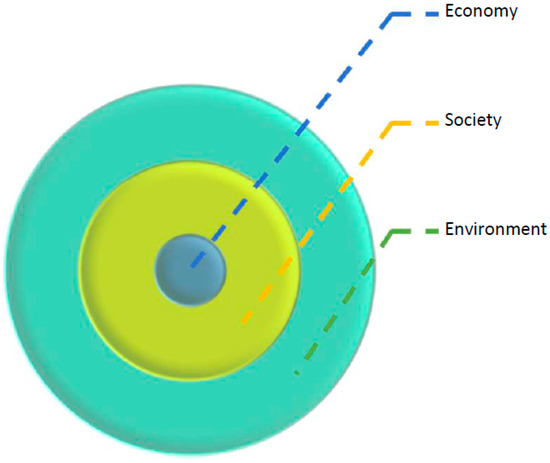

The alternative conceptual model on sustainable production is characterized in parallel by three concentric spheres; the ‘economic’ and ‘social’ spheres conceptually understood as subsystems. These graphical spheres depict “economy” as reliant on the ‘healthiness’ of the environmental sphere. This implies a systems-founded transitional route to sustainability; the different spheres in the CCM are interdependent as a hierarchy, or possibly more precisely a form of sequential interdependency. Green et al. [24] suggested such a transitional process toward sustainability by focusing on the environmental aspects of the supply chain over time through networked interaction. Veleva et al. [25] stated that empirical research from the pharmaceutical industry supports this approach. These authors [24,25] have suggested that an emphasis on the environmental component of sustainability is not limited to ethical considerations. Sustainable production commonly provides financial savings, which has the additional benefit of contributing to economic viability. Figure 2 illustrates this more series-type model:

Figure 2.

Concentric circles model of sustainability [10].

According to Thatcher [26], the ICM and CCM have in common what they consider nature, society, and economy as conceptually interconnected. They also both have in common that neither takes into consideration the time dimension [23]. This also implies that interaction, a typical feature of the time-dependent process, is not considered. The most widespread model of sustainability, the ICM, pictures that the three spheres of influence as equal and thereby also simultaneous in their impact on production. In the current social setting, the TBL has emerged as a seemingly unchallenged paradigm for sustainable development. It involves an approach where meeting the needs of the present and future generations are categorized under three dimensions: environmental, social, and economic [27], and that the business models used by many organizations increasingly seek to include environmental aspects of performance in line with the TBL concept [24,28]. However, this model is more than a classification; it also has fundamental assumptions regarding the interdependency between the three involved dimensions of sustainable production.

The first step in this approach to implementing sustainable procurement is to identify and assess the various “components of sustainability” [29]. Literature has acknowledged the elements of the triple bottom line [19]. According to Carter and Rogers [30], components include economic performance, environmental stewardship, and social equity. Economic performance focuses on the financial consideration of business and shareholder value creation. Environmental stewardship emphasizes the preservation of the natural environment and natural resources, waste minimization, and reduced emission. The social equity aspect relates to a firm’s purchasing social responsibility (such as human rights, local community and people development, cultural diversity, fairness, and safety). The effective management of the TBL is generally believed to be an important issue in improving efficiency and profitability over the long term [31]. Fiorino [32] stated that this broader perspective on production, with sustainability as an approach, aligns economic considerations with sociopolitical systems and environmental needs. Many organizations are now including environmental aspects of performance in their business models, in line with the triple bottom line concept [23]. The TBL approach suggests that besides economic and shareholder value creation, organizations need to, at an equal level, engage in activities that ensure environmental preservation and social development. By adopting the triple bottom line approach, an organization takes a responsible position on economic prosperity, environmental quality, and social justice [33].

The alternative conceptual model on sustainable production highlights three concentric spheres, the ‘economic’ and ‘social’ spheres placed in context of the environmental sphere. Rather than the three partially connected circles depicted by ICM, the economy lies here graphically at the center of the figure. This shows an alternative picture of a sustainable community as the circle within circles. This ‘three-nested-dependencies model’ reflects a co-dependent reality. It shows that human society is a wholly owned subordinate of the environment—dependent on food, clean water, fresh air, fertile soil, and other natural resources. This also implies a transitional route to sustainability; the different spheres in the CCM are interdependent as a hierarchy, or possibly more precisely, sequentially organized regarding perceptions of what comes first. The concentric circles model is similar to the egg of wellbeing model, except that there are multiple levels of subsystems; the largest circle is the natural environment, which encapsulates the subsystem of human society, which in turn encapsulates the subsystem of the economy. Green et al. [24] suggested such a transitional route, with the environment as the driver. Veleva et al. [25] stated that empirical research from the pharmaceutical industry supports this approach. These authors [25] suggested that a focus on the environmental dimension of sustainability is not limited to ethical considerations.

CCM suggests that enhancing shareholder value is the fundamental goal of any business. This is, however, contingent on the environment. Today’s business perspective of the environment requires, thus, a broader perspective of value considerations from the business communities. Policymakers, consumers, and the general business stakeholder are increasingly considering the environmental and social impact of the products and services and demanding organizations be accountable in these regards. Challenges of creating new, environmentally sustainable products and services and socially responsive initiatives now face both domestic and multinational organizations. At the same time, they have concerns about remaining profitable and enhancing shareholder value in the globalized market economy. Concerning procurement, this implies that sustainability is part of the central economic sphere, which affects the outer layers of the social sphere, which again affects the environmental sphere. This concerns, as mentioned in the introduction, how sustainable the purchasing process themselves are, as well as the outcome of the purchase in supporting sustainable production operations.

2.2. Towards a Model of Sustainable Procurement

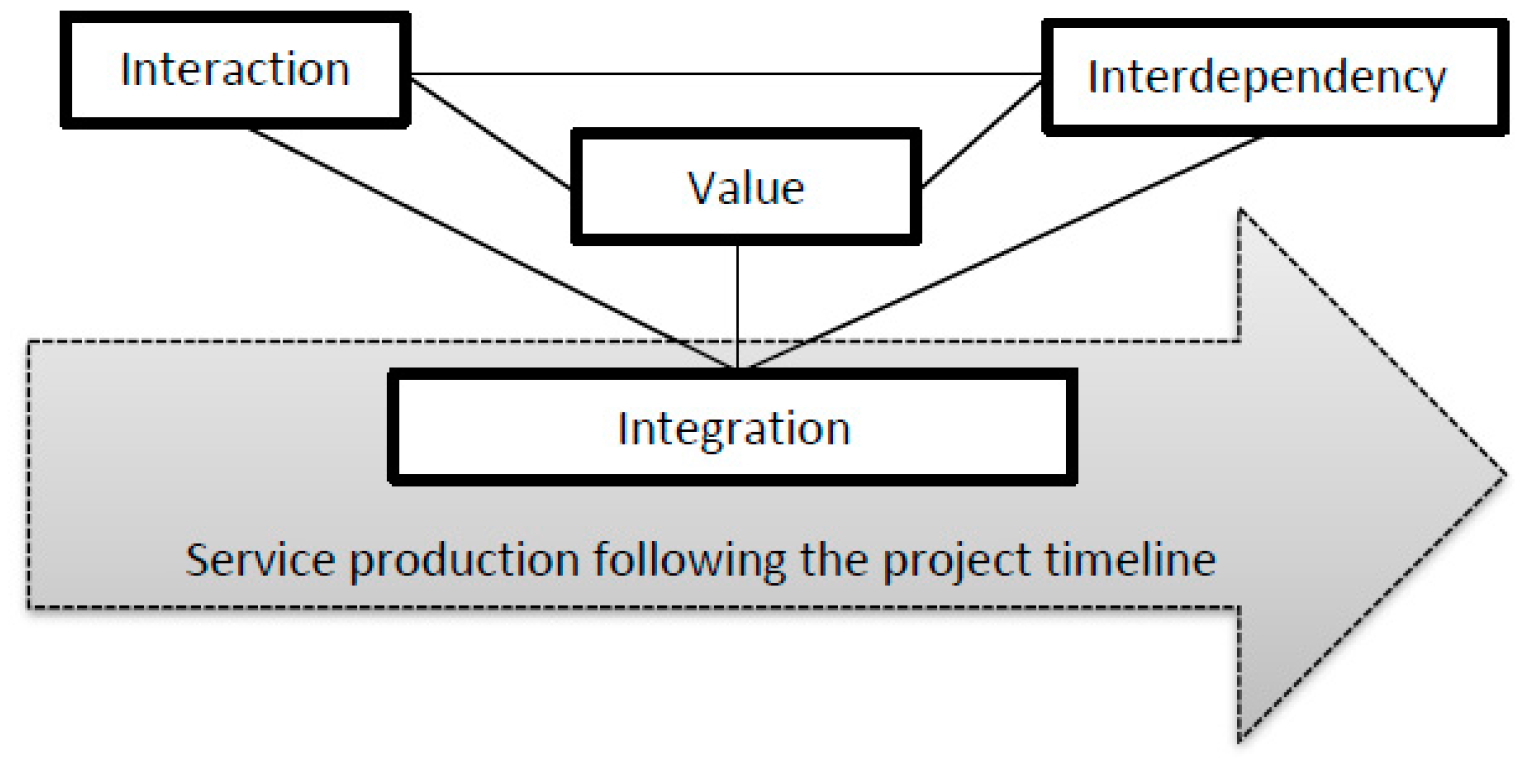

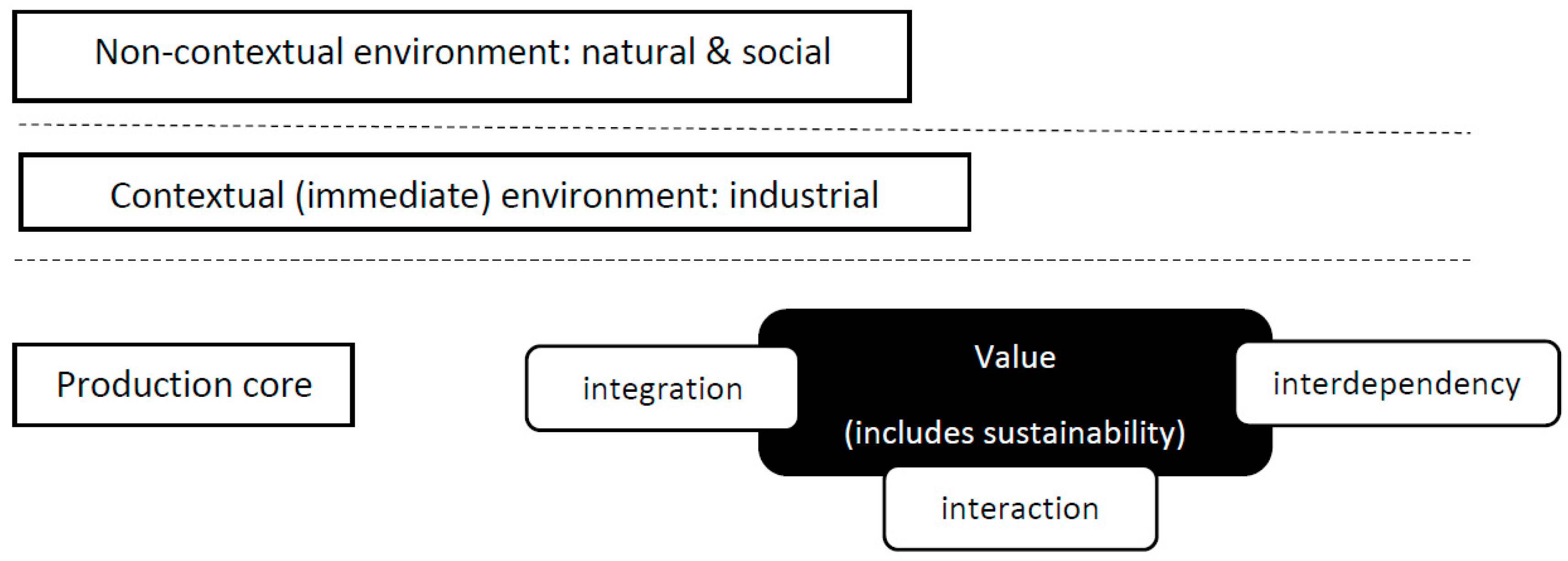

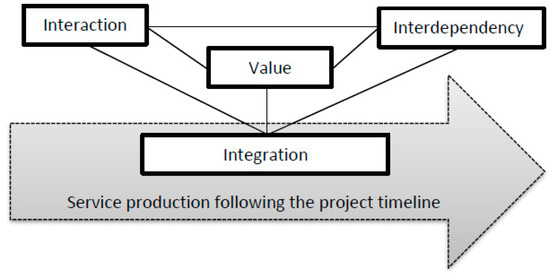

We now turn to consider using CCM and ICM to analyze sustainable procurement from an IMP networking approach. Purchasing is an interorganizational activity. It takes place in the organizational context of the supply chain, in complex industrial networks. Organizational contingency is therefore decisive to purchasing. An important consideration of contingency theory is about how organizations cope with environmental uncertainty [14]. Network actors actualize production through interaction. In Janusz et al.’s [1] network view, the following are modelled as conceptually interdependent in regards to creating and sustaining customer value in the industrial network: (1) interaction, (2) interdependency, and (3) integration. Interaction concerns action, interdependency, “the reasoning” for and “the result” of interaction in a network structure, and integration helps characterize the nature of activity links and resource ties in the network (see Figure 3):

Figure 3.

The conceptual framework [1].

These factors show value creation as a product of interaction, integration, and interdependency; it is a complex phenomenon. The position of “value” in the model depicts a belief that this is the principle that importantly guides production. While Janusz et al. [1] considered this view of networked value creation in a longitudinal study of a project organization, this study applies the same framework to examine the sustainability of operations in the Ghana oil industry reflected upon using the ICM and CCM. The following discusses the key constructs in Figure 1.

Håkansson and Johanson ([34], p. 43) stated that, largely due to interaction, “networks are, by their very nature, in imbalance”. Interaction activates fragmented and passive resources, and as such, interaction is the trigger and activator and the value generator (here referring to actor level interaction), where changes in resource combinations or value created is the outcome of interaction. Producing value in this regard means facilitating and managing actor-level interaction in a purposeful manner. In line with this consideration, Cantu et al. [35] stated that “solutions (i.e., resource combinations) always emerge as a consequence of interaction among actors. This interaction makes the actual combination dependent on the web of actors involved and, therefore, difficult to predict” ([35], p. 148). Production is therefore networked and emergent; it is complex. Following Cantu et al. [35], this complexity is rooted in the facts that (1) solutions (the outcome of production) can be interpreted differently by different actors in the network; (2) actors usually have dual roles, as resource providers and also users; and (3) the dual perspectives of actors as resource users and providers are confronted in business relationships through interaction.

Developing sustainable production is an environmentally contingent process. Pettigrew [33] proposed a working definition of a process as: “A sequence of individual and collective events, actions and activities unfolding over time in a context”. Processes, both purchasing and production, are in their fundamental nature unfolding through synchronised sequentially interdependent decision-making events in a network interconnected by mutual interactions that unfold over time in specific contexts [36,37,38]. Thompson ([14], pp. 101–102) stated that: “…human action emerges from the interaction of (1) the individual, who brings aspirations, standards, and knowledge or beliefs about causation; and (2) the situation, which presents opportunities and constraints”. Interaction to purchase is, according to contingency theory, embedded in its environment. Although they, in time, seem linear in form, this unfolding of meaning, sensemaking, usually involves many interacting processes and many interacting people, as well as artefacts. “There is, therefore, no stop in interaction, events unfold following a timeline, and this continuity impacts on how actors perceive one-another in the industrial network in an ever-changing manner” ([1], p. 463).

“Interdependency” concerns another aspect of production; why networked actors interact to produce [11]. Heterogeneity is a core reasoning as to why firms network and gradually integrate. Interdependence is also an expression of network-founded power [39]. An explanation as to “why networked actors interact” is out of necessity; no firm controls all the needed resources to solve their “problems”. Resources have a provision and, likewise, a use side [40]. Perceptions of a potential or actual complementary link between provision and use fuels interaction in business relationships. Supported by this exchange, the activity linkage grows in strength. In networks, there is an abundance of such ties, and each business is a node in its network [41]. This manifold interdependence characterizes the supply network’s structure. In this structure, actors combine and value production resources. This perceived value is emergent.

Interaction affects the perception of value [42]. Value is a networked phenomenon. Likewise, perceptions of interdependence may change given changing perceptions of value. In the supply network, “customer value is a moving target for marketers. Interdependency is accordingly a perception by actors of reasoning why they may want to interact with other actors in a network” ([1], p. 464). Producing value therefore requires access to resources controlled elsewhere. The problem-driven nature of networked actors therefore motivates relationship building to facilitate effective interaction. In the oil industry, which ultimately produces a form of goods through a series of chemical fabrications, interdependency is predominately sequential.

Parsons [43] classified organizations as having three distinct levels of responsibility and control: technical, managerial, and institutional. Interdependence is a reasoning for production accomplishments, rather than a foundation for coercive behavior. Since a network consists of many business relationships, following IMP network thinking: “The manager becomes someone who must operate within multiple dependencies” ([44], p. 31). In the network, each firm manages, following Håkansson and Persson [41], a set of supplier and customer relationships. Interdependency is a feature of network structure. This changes more slowly; it is the experienced context of an interaction. “The institutional aspect of networks is key to understanding its interdependencies; it is perceived, and interdependency is an important perception held by various actors in a more or less collective network organisational structure” ([1], p. 464).

The CCM and ICM are, based on the preceding discussion, considered as part of this institutional layer. These models provide meaning as to how should sustainable procurement be achieved. In a network, the perception of the environmental friendliness of a supplier will influence the reasoning of the network system. Following the ICM, agents would seek to understand sustainability, a value intertwined with societal, environmental, and economic concerns. It is an issue guiding the supplier. Following the CCM, perceptions of suppliers as embedded agents impact perceptions of interdependence. This includes their degree of sustainability, a result of continuous processes in the economic subsystem. This view would also invite the purchaser to see the sustainability of a supplier’s production as workings of a system, rather than, following the ICM model, as a detachable ideology. Next, we turn to the feasibility of interaction given the purchaser’s perceptions of supplier interdependency. This brings up the topic of supplier relationship integration. How well does the purchaser know the supplier.

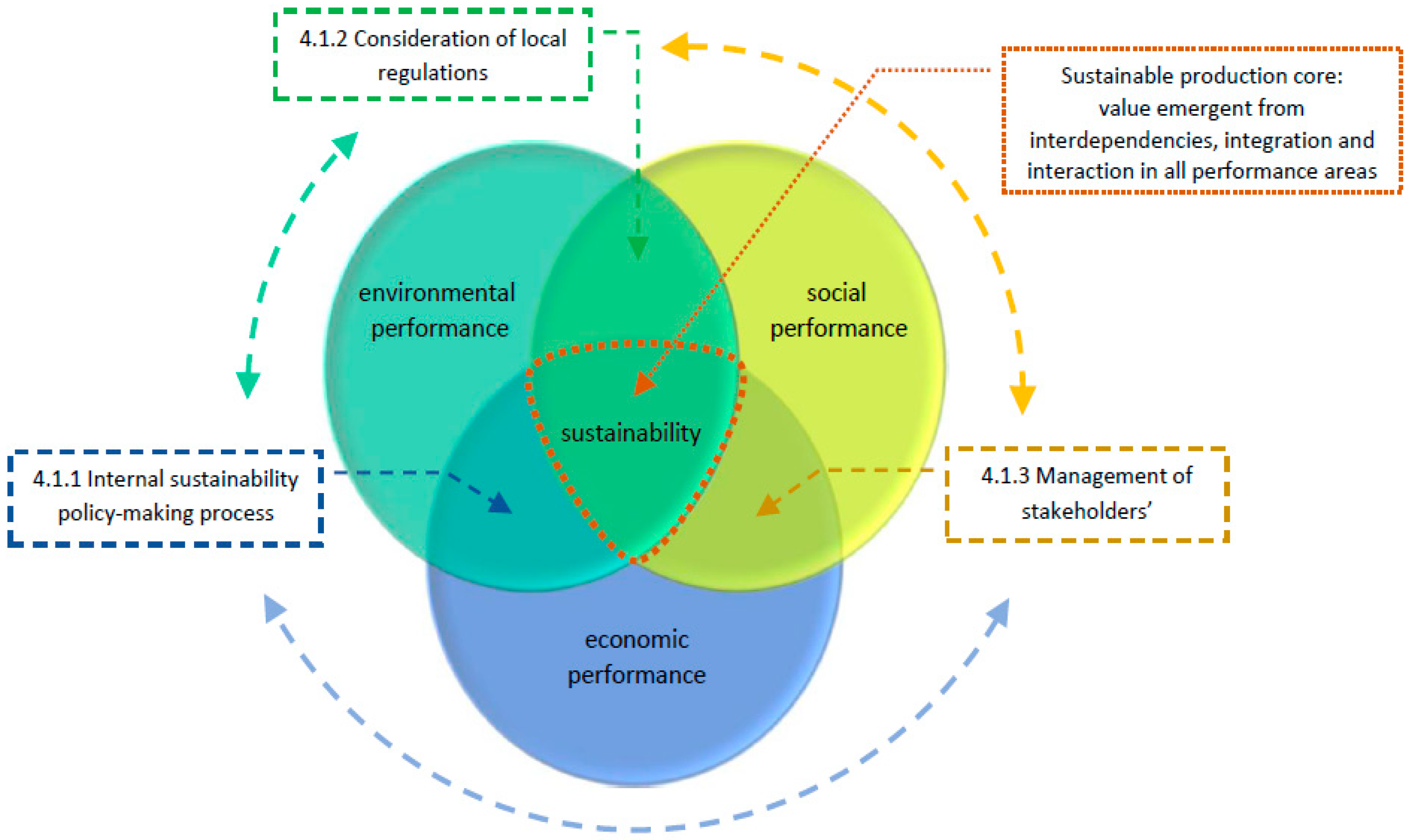

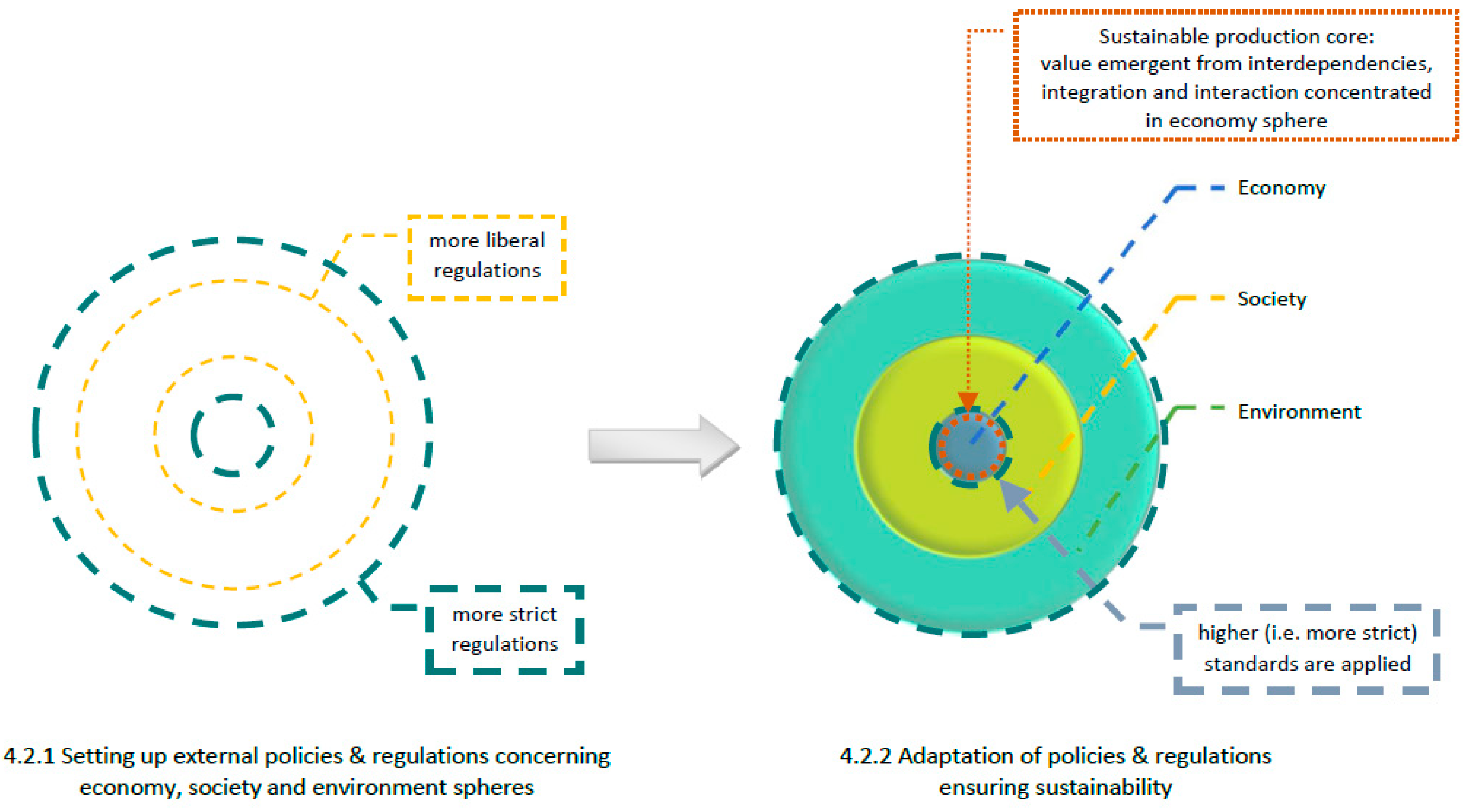

“Integration” is a key SCM concept [45], a norm and value of interaction in the “supply chain”. The IMP wording points more to “relationship ties”. Integration is conceptually wider than ties. A supply network is composed of more or less heterogeneous actors that do business with each other or compete with each other based on perceptions of degrees of complementarity [46]. In this network, the strength of integration may change affecting the state of interdependency. “This state is fragmented since integration is measured in business relationships, that the importance of these may change as interdependencies fluctuate, or are simply chosen by managers to alter the characteristics” ([1], p. 465). Organizations involved in the production are heterogeneous entities, harnessing the economies of complementarities through integration. Interaction, interdependence, and integration concerns all the relationships, and these features are different when comparing a purchaser’s different supplier relationships. This is also a reason why the strengthening of relationships ties is never clear-cut. They may grow, weaken, or remain much the same based on a perceived change of the value of the relationships. This value perception is in motion, and it is network contingent. “This description provides thus the foundation for considering reasons for how interaction changes based both on changes in the contextual factors interdependency and integration” ([1], p. 465). Figure 4 provides an understanding of ICM model applying our approach.

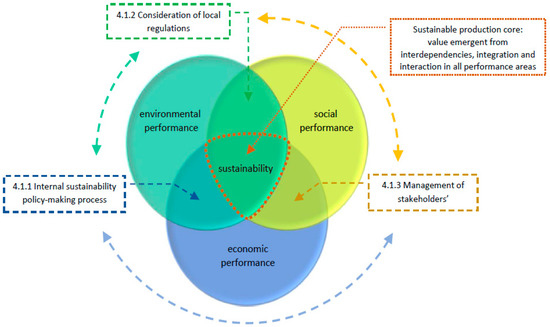

Figure 4.

An interlocking circles model (ICM)-based conceptual model of sustainable production.

Sustainable production is viewed in this model as value emergent from interdependencies, integration, and interaction in all performance areas in its complex network context.

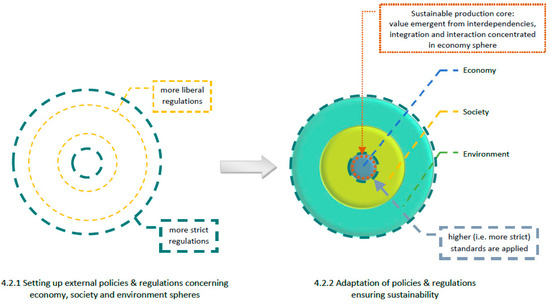

Likewise CCM is pictured using our approach in Figure 5.

Figure 5.

A concentric circles model (CCM)-based conceptual model of sustainable production.

Here, we regard sustainability as emergent, though complex, production in the context of a likewise complex, though slower changing, network. In attaining sustainable purchases, knowing the supplier and becoming ever-more integrated, involving, in practice, a range of pooled resources including the physical ones and knowledge, facilitates purchasing quality. The “quality” concept here importantly covers the degree of sustainability achieved through purchasing in a business relationship. Following ICM, this model would provide norms to guide networking behavior. It is not clear how these norms may contribute to integration or whether integration somehow supports the achievement of sustainable purchasing. CCM, however, with its view of the economic subsystem that is production reflects a degree of sustainability. Integration is a feature of this subsystem. Integration varies and it is the degree supply chain integration that is achieved that is a facilitator of sustainable procurement. We now seek to reflect upon these two models of sustainable production with empirical findings regarding sustainable procurement in two different cases of oil production in Ghana. This provides mainly a conceptual challenge regarding the usefulness of these two models from business practice seen as network-embedded activity.

3. Research Method

This study applied a comparative case study research design. Case studies focus on an inquiry with a phenomenon in its real-life organizational settings. In this approach, we sought to elucidate the unique features of the phenomenon. Voss C. et al. [47] indicated that case study research, aside from investigating the “why” and “how” questions, is also particularly suitable for developing new theory and ideas and may also be applied for testing and refining existing theories and therefore must be encouraged. Following Bryman and Bell [48], this two-case study focused on collecting data on the focal research problem regarding how sustainable production is understood and practiced in their two unique contexts. Analyzing the data, we applied the alternative TBL and CCM approaches.

These two cases encompassed interviewing two companies. Petrol Explore Ghana (PEG), representing the upstream segment, and Ghana Oil Refinery (GOR), representing the downstream sector of the industry. The names are fictive. The reasons for this choice was judgmental. This means that a step-by-step procedure often termed “snowballing” in qualitative research was applied. Key initial informants provided a set of other informants, as well as the sequencing of the research timeline that one informant directed, in many cases, to the next. Being a judgmental approach meant that the researcher had to make choices while underway in the research process. Several factors were involved in such choices. These included a variation on placement in the value chain, differences in the type of production within the petroleum industry, and that one is a multinational company and the other is domestically owned. The similarity is that they mainly, in principle, may be part of the same supply chain, and are part of the same industrial sector. Both the interviewed companies are large organizations carrying out relatively advanced and environmentally challenging technical operations. The organizations under study both operate in the Ghana oil and gas industry. The two organizations present some unique features that justify their selection in order to expound the phenomena under study. The two organizations operate within different sectors of the industry (upstream, PEG, and downstream, GOR) and have different ownership structures (public-owned GOR and privately owned PEG), as well as geographical coverage (national GOR and multinational PEG). The research, therefore, answers the research questions with a focus on the unique context of each organization. Interviewing government regulators and suppliers of these two companies provided an adequate understanding of the business context of these companies regarding sustainability concerns. They addressed the inter-organizational character of sustainable production. The degree of sustainability in procurement affects the viability of production. This was an underlying assumption driving this study. Therefore, industrial context matters. This also provided the foundation to gain a more holistic perspective of sustainability matters in the Ghana petroleum industry.

Primary data for this research included15 interviews. The informants were busy people who could not spare too much of their time for the research interview. Therefore interviews where kept as short as possible. Further interviews were scheduled with some of the respondents for clarification where the needed. Other interview respondents included first-tier locally owned and local–foreign partnership suppliers of GOR and PEG. Table 1 shows a summary of the interviews conducted during the field research.

Table 1.

Summary of the interviews conducted during the field research.

We applied narative analysis as the primary qualitative data analysis approach. Narrative analysis is useful in exploring the relationships and linkages, as well as socially constructed explanations that naturally occur within narrative accounts. Narrative analysis is particularly useful where the fragmentation of the data into categories and themes would therefore be unnecessary. In recent years, stories and storytelling have become more frequently used in organisational research, although they are still in their infancy [49]. Stories have been defined as narratives that have both plots and characters and generate emotion in the storyteller and their audience using elaboration and poetic licence [50]. Qualitative data can be collected as stories through, for example, semi-structured or unstructured interviews. Here, the requirements for accuracy are often less important than the points that are made and what these points symbolise. This analytic approach is useful in bringing to light phenomena of much interest to the researcher, such as organisational culture, politics, and change [49]. Consequently, whilst such narratives may not always present facts, they provide meaning to the facts. We did not seek to build a theory around the core or central theme that emerged from the qualitative data as the fundamental premise of “grounded theory” demands. Rather we sought to adapt the analytic approach to the narratives as the principal means of analysing our qualitative data. Aided by the semi-stuctured interview design and our analytic approach, we tell the “story” of suitability and sustainable procurement in the Ghana oil and gas industry.

4. Case Presentation

4.1. PEG: The Upstream Supply Chain

Several factors (key drivers of sustainable procurement) can be identified from the case analysis. One of such key drivers is the procurement policy formulation of the upstream supply chain regarding the law on local content and local supply participation. The local content law set thresholds and targets the industry had to meet concerning the involvement of local suppliers in the upstream operations. As emphasized by a senior manager of a supplier:

“According to the current legislation, oil companies have to involve local suppliers in their operations. Depending on the capacity availability of locally procured services it is required 10%, 20% or 30%, even up to 100% local participation. The legislation on the promotion of local participation contributes to ensuring the direct benefit of oil resources by the local communities and citizens in Ghana. There was no cause to apply sanctions for the non-compliance with the local content law because major companies partnered the government in the achievement of the benefit”.

Internal commitment of PEG to the legal requirement to involve local suppliers in the upstream operations was one of the main drivers for satisfying the social aspect of sustainable procurement. As emphasized by a senior manager of PEG:

“We seek to benefit the local communities where we develop our operations by investing in local suppliers, their skills and by creating opportunities within the oil and gas industry. Compliance with the Law of local content is not only a legislative norm for us. We do it because we would like to take this social responsibility that creates in turn positive social and economic effects. It also makes good business sense because collaboration with local companies can reduce our project time and costs”.

The Ghanaian government constantly monitored and engaged the local actors in the upstream sector to seek for the further improvement in the participation of local suppliers within the supply chain. After conducting a “value chain assessment exercise” in 2017, the regulatory authorities mandated the reserve of provision of certain goods and services solely to the Ghanaian supplier. The Ghanaian suppliers were involved in many services sectors, where they had full or partial capacity, particularly in the low handling of goods and general supplies. These sectors included catering, supply of fuel, petroleum products and lubricants, supply of low voltage cable, minor fabrication works, supply of industrial and drinking water, etc. Further, the Environmental Protection Agency has constantly monitored the oil and gas industry’s activities to assess their influence on the environment and ensure adherence to all environmental practices. PEG in turn aimed at engaging the best environmental practices and benchmarked its environmental performance measurements in the industry against some of the highest global standards to make procurement practice more sustainable.

Being a global organization in the oil and gas industry, PEG aimed at elaborating its own internal policies to develop and promote sustainable procurement within the petroleum industry. As noted by a senior manager of PEG:

“When formulating internal procurement policies, we have to take into consideration local regulations and laws. At the same time, many different actors like the government, local communities, environmental activists, suppliers, etc. are involved in oil discovery and exploration processes. These actors produce various so-called social expectations that are able to affect the oil exploration activities and making it more sustainable. We try to manage them by using different procurement tools, including corporate social responsibility as the most reliable way for us”.

PEG’s management viewed sustainable procurement as an opportunity not only to use procurement activities for ensuring cost minimization and profitability, but also for enhancing the well-being of local people and local communities, as well as protecting the natural environment. The approach to sustainability lay in the commitment to managing risks and mitigating the impacts of oil exploration operations. This was reflected just partly in the code of ethics. The main driver was, however, economic concern. As emphasized a senior manager of PEG:

“We are a private organization that aims at ensuring profitability and returns on stakeholder investments. We also have to be compliant with the laws, regulations, social expectations and ethical norms. Once we achieve these major concerns, our company can be sure of gaining a positive corporate image and reputation, ensuring environmental and community preservation, operation continuity and ultimately being accountable to all stakeholder interests”.

Thus, PEG took a holistic approach to sustainable procurement. The company’s profit-orientation and cost minimization allowed them to enhance the economic support of the local community and to protect the natural environment. This made it possible to be compliant with social expectations and foster long-term sustainable development. The focus in developing sustainable procurement was to encourage and support local suppliers because technical competence and cost efficiency from suppliers’ products and services matter particularly. At the same time, PEG’s initiatives on the development of sustainable procurement faced several challenges, like cost minimization (whole life cost), eco-designed products, diversity, supply security, quality assurance, health and safety, environmental management, and community development, as well as human and labor rights. PEG took proactive action at ensuring local participation in the supply chain by reserving some procured items and services for only local suppliers. As emphasized by a senior manager of PEG:

“We seek to eliminate any barriers that may hinder the participation of local suppliers. It is common when small-scale suppliers have a potential and technical capacity to meet the requirement but need support in the form of employee training programs on “how to do business with the organization”.

Thus, the internal drivers to sustainable procurement were not only cost minimization but also the competence of suppliers. As noted by a senior manager of PEG:

“We pay particular attention to the selection of suppliers based on their competence and key performance indicators that show how effectively suppliers achieve their key business objectives. How much our suppliers are specialized and professional affects product cost, product efficiency, environmental impact, etc. So we require from suppliers international certifications like SA 800 (social), ISO 14,001 (environment), ISO 9001 (quality)”.

Almost all local suppliers received preferential treatment from PEG as a purchasing organization by providing their services like recruitment of local employees for rigs, warehouse facilities for oil-producing companies, catering/hospitality services, and provision of offshore supply vessels. Further, PEG provided support to local suppliers in the form of training and seminars on the issues of procurement and supply, as well as more specifically bidding and doing business with oil companies. As noted by a senior manager of a local supplier:

“All we need to do is to be the most competitive in the local market to win contracts. Now it is easier for local suppliers in comparison with foreign service-providers. Catering and hospitality have been solely reserved for the local supplier market in Ghana. The preference for other services has to be deserved based on the level of competence and service quality of local suppliers”.

4.2. GOR: The Downstream Supply Chain

The regulatory authorities had a function to specify just acceptable minimum engineering specifications in the downstream sector and to monitor compliance of oil companies with all environmental specifications for the safety of the environment and citizens. One of the examples was the regulations on sulfur content levels in diesel and petrol products of the downstream sector. At the same time, the environmental aspect of sustainability was paid attention in the procurement activities and policies of the downstream petroleum sector, though not as much as the economic aspect. The Public Procurement Act was a key guiding principle in the procurement activities of organizations. It determined cost and value for money, including effectiveness for purpose and efficiency, as key considerations among other procurement issues. As noted by a senior manager of GOR:

“Our company has been always guided by legislation to protect the public purse. Actually, the dominance of value for money, supported by laws, has been a driver towards sustainable procurement. There are no specific norms and regulations to support the social aspect of sustainable procurement and the participation issues of local suppliers, unlike the upstream sector. This is only the internal responsibility of our PEGs a purchasing organization. The issue of local community development is therefore driven by purchasing organizations’ internal organizational culture and top management orientation”.

GOR did not develop explicit policy statements on sustainable procurement or specific procurement policies on the three aspects of sustainability. As emphasized by a senior manager of GOR:

“We do not discriminate suppliers by their location of ownership. We do not, therefore, develop an explicit policy on local supplier engagement in our procurement activities. Local supply is only prioritized when delivery time is of the essence”.

At the same time, the procurement activities of the downstream sector supported the promotion of the environmental aspect of sustainability in the form of natural resource conservation and environmental protection. As emphasized by a senior manager of GOR:

“We have to take into the environmental effects of our purchases. The procurement of technical and complicated products is fulfilled by a project team with the support of other departments like the user department and the engineering department. This allows ensuring product purchasing based not only on achieving value for money but also on meeting environmental standards”.

So, value for money is the main driver in the procurement process and the selection of a supplier. As noted by a senior manager of GOR:

“We view value for money as a product that is fit for the purpose (effective), efficient (provide better and improved service) and economical lowest whole life cost). The terms of supply should be favourable as well”.

The priority of value for money derived from the general procurement practice established by the laws of Ghana that determined open national competitive tendering procedure for all purchasing companies in the downstream sector. The suppliers had to participate in these competitive tenders as well to win their supply and services contracts from the refinery organization. The critical point was that the engagement of local suppliers in the procurement activities of the public-owned organizations was entirely at the discretion of the procurement originator (in our case, the oil refinery company) rather than being imposed by the law—e.g., quota or preserved procurement products and services for the local supplier, unlike in the upstream sector. Thus, the public-owned downstream refinery organization (in our case GOR) decided whether to activate the National Competitive Tendering process for any particular procurement need or not.

5. Analysis and Discussion

Firms are expected by their stakeholders to fulfil environmental and social responsibilities [51]. One key challenge is how to apply sustainability as an overall strategy throughout the whole supply chain (upstream and downstream) to involve all partners and processes (including procurement). Our overall findings suggest that the organizations’ understandings of sustainable procurement, to a large extent, were found to influence the origination’s policy directions towards individual elements of sustainable procurement (economic, social, and environmental). The case studies illustrated varying applicability of the two different sustainability models to the different cases. Their explanatory strengths varied thereof in relation to features of the empirical phenomenon investigated. Sustainability is a norm “out there” in procurement, indicating the fitness of the ICM approach to explain the role of sustainability in procurement in the PEG case. The reason for this is that in the upstream portion of the petroleum industry supply chain, economic concerns are taken for granted, given the existent comfortable profit margins in this type of industry. In contrast, our findings show that the downstream sector is less ‘driven’ by stakeholder influence and organizational culture. Thus, while stakeholder influence and organizational culture are major driving forces in the upstream sector, these were found to have a rather low influence in driving the sustainable procurement policies and activities of the downstream public-owned oil refinery organization. Findings are grouped in Table 2 to provide an overview of factors potentially affecting sustainable production in upstream and downstream spheres of the Ghanaian oil industry.

Table 2.

Factors potentially affecting sustainable production in upstream and downstream spheres of Ghanaian oil industry.

The findings on the procurement policies of PEG mainly support this assertion of compliance with the local content laws and the support for sustainable social procurement by the operating organization. The research findings indicate that the organization adopted some form of partnership and collaborative procurement policies (such as long term supply contracts, single procurement, and the use of fewer dedicated suppliers) in dealing with its vital strategic suppliers and supplies. This was indicated by the interviewee of PEG who stated that the organization does not always engage in an open competitive “as some products and suppliers call for a more strategic and collaborative approach to procurement”. The study on how the procurement policies impact on sustainability in the upstream Ghana oil and gas industry produced results that largely reflect the varying influences of the various driving forces of sustainable procurement within the sector and the organization.

The findings point to a strategic procurement policy aimed at a holistic and balanced achievement of the three aspects of sustainability and sustainable procurement, namely, sustainable economic procurement, sustainable sociopolitical procurement, and sustainable environmental procurement. Here also, the ICM approach provided the best explanation to the role of sustainability as the norm rather than process. Interaction is networked and guided by norms of sustainability. Sustainability is therefore enacted rather than a norm out there. Sustainability is learned through interaction in an integrated and interdependent network even though a norm out there is perceivable.

The analysis revealed that the issue of networked influence in driving the sustainability agenda in the downstream sector may not be as vital as in the upstream sector. As such, matters of public accountability and its associated corporate reputation, on the issue of sustainability, which is mostly determined by public opinion on corporate policies and behavior, may also not be regarded as a significant driving force of sustainability and sustainable procurement in the downstream sector of the oil industry in Ghana. Sustainable procurement in the downstream oil refinery sector of the Ghana oil and gas industry was found to be driven, by varying degrees of influence, laws and regulations and economic goals. Both of these concerns were found to be primary drivers on equal terms in the upstream sector, were also found to be significant drivers of sustainable procurement in the downstream industry.

Despite the advocacy of environmental and social sustainability by the objective of the procurement law, the economic goal seemed more paramount within the downstream public-owned organization. The dominance of economic concerns in driving the sustainable procurement agenda and policies of the downstream was demonstrated in response to the question on the prioritization of the various drivers of sustainable procurement in the procurement activities by the refinery organizations. This implies that sustainable procurement can best be explained in the GOR case using the CCM approach. Value is a focal aim, and this is to secure the well-being of the business. Thus, the evidence reveals heightened awareness of the economic subsystem as focal and intertwined with sustainability as an outer systemic influence. Likewise, as in the preceding case, but with an opposite value, economic concerns are real in this case, and therefore sustainability is considered intertwined as a process in its overall production system. Learning sustainability is in this case more intertwined with value concerns.

Environmentally contingent learning creates sustainable production. Learning step-by-step through networking in its context increases the sustainability of its purchasing processes. Interaction is guided by sensemaking [51], and these models of sustainable production propose two somewhat opposing views regarding how to interact to attain, in this case, sustainable procurement. ICM suggests an ideology and norms whereby interaction should on equal terms consider the impact of environmental, social, and economic performance on the sustainability of procurement. CCM views, on the other hand, show how economic considerations are embedded in layers of society first, then the environment. This seems much in line with contingency theory. More specifically, networked agents perceive the sustainability of their economic activities and their production as impressions of the environment filtered through the societal context. For businesses, this context is the organizational network of interacting firms. This highlights the importance of interdependency in attaining sustainable procurement.

6. Conclusions

The main findings reveal that the appropriateness of using the two models of sustainability on the business function of sustainable procurement varied between the two cases. The preceding discussion highlighted how these cases are different. This indicates an overall contribution regarding conceptual modelling and its applicability to various empirical settings may vary. Sustainability is a norm out there, indicating the fitness of the ICM approach to explain the role of sustainability in procurement in the PEG case.

One reasoning for this is that in the upstream portion of the petroleum industry supply chain, economic concerns are taken for granted given the existent comfortable profit margins in this type of industry. On the contrary, stakeholder influence and organizational culture, featured as the other major driving forces within the upstream sector, were found to have a rather low influence in driving the sustainable procurement policies and activities of the downstream public owned oil refinery organization (GOR case). This indicates that mental models, as well as research-grounded conceptual models, may vary in fitness when comparing divergent cases of purchasing. PEG is global and a part of a global economy where local economic considerations are weakly felt by the local operator. This is contrary to the GOR case.

The impact on network interdependencies of the environment in these two cases also reveals a heightened economic concern in the GOR case also, implying increased importance of integration and SCM. The GOR case reveals sustainability embedded in the economic workings of the firm, not as a prioritized external norm. In the PEG case, sustainability in procurement is something out there. The environment is, following the applied approach to “sustainable purchasing”, layered as, first, the contextual economic network, and outside this the noncontextual social and environmental network. Being sustainable is an aspect of institutionalized economic behaviors.

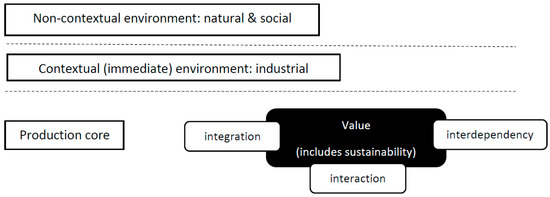

Figure 6 illustrates this view of sustainability as intertwined with value perception in a layered contextual (perceivable and thus influencing) environment:

Figure 6.

A conceptual research-directing model of sustainable production.

Sustainability is, following this model, not limited to a single network actor since it is something done through business interaction. The reasoning for sustainability is rooted in knowing this value through learning through the network. Why sustainability? The collective of actors enacts sustainability as value according to our suggested view. It is not a directive, a result of coercive actions from, for example, governments or market pressures alone. These are merely pieces in the network puzzle that shape sustainable procurement activities, and this is a continuous process. It is a complex system. This implies that developing sustainable procurement implies incremental and continuous change. The ethical guidelines of environmental friendliness in purchasing is limited to being a contextual pressure. It is a learning process.

Limitations include that in this case study empirical findings generated through this study cannot, other than as conceptual knowledge, be generalized. Figure 6 is a model that may accordingly help the transferability of our results to other industrial cases. Furthermore, this indicates a need for more research to refine the suggested network-based approach to sustainable production. In this case, the empirical focus was on procurement. Other studies may include other aspects of sustainable production including construction, human resource management, services, and manufacturing.

Author Contributions

Data collection and initial analysis was carried out by E.N. under the supervision of P.E. who also initiated and saw thruogh transforming this student work into an academic paper. R.G.-G. and A.J. contributed to enhancing the analysis and refining figures and tables. All authors have read and agreed to the published version of the manuscript.

Funding

APC was funded by Univerity of Tromsø.

Data Availability Statement

This article is in line with MDPI Research Data Policies.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Janusz, A.; Bednarek, A.; Komarowski, L.; Boniecki, P.; Engelseth, P. Networked interdependencies and interaction in a biotechnology research project. IMP J. 2018, 12, 460–482. [Google Scholar] [CrossRef]

- Walker, H.; Phillips, W. Sustainable procurement: Emerging issues. Int. J. Procure. Manag. 2009, 2, 41. [Google Scholar] [CrossRef]

- Seuring, S.; Müller, P.D.M. From a literature review to a conceptual framework for sustainable supply chain management. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Gold, S.; Seuring, S.; Beske, P. Sustainable supply chain management and inter-organizational recources: A literature review. Corp. Soc. Responsib. Environ. Manag. 2010, 17, 230–245. [Google Scholar]

- Walker, H.; Miemczyk, J.; Johnsen, T.; Spencer, R. Sustainable procurement: Past, present and future. J. Purch. Supply Manag. 2012, 18, 201–206. [Google Scholar] [CrossRef]

- Hoejmose, S.U.; Adrien-Kirby, A.J. Socially and environmentally responsible procurement: A literature review and future research agenda of a managerial issue in the 21st century. J. Purch. Supply Manag. 2012, 18, 232–242. [Google Scholar] [CrossRef]

- Cheng, W.; Appolloni, A.; D’Amato, A.; Zhu, Q. Green Public Procurement, Missing Concepts and Future Trends—A Critical Review. J. Clean. Prod. 2018, 176, 770–784. [Google Scholar] [CrossRef]

- Appolloni, A.; D’Amato, A.; Cheng, W. Is Public Procurement Going Green? Experiences and Open Issues. In The Applied Law and Economics of Public Procurement. The Economics of Legal Relationships; Piga, G., Treumer, S., Eds.; Routledge: London UK, 2012; ISBN 978-0-415-62216-5. [Google Scholar]

- Ma, Y.; Liu, Y.; Appolloni, A.; Liu, J. Does green public procurement encourage firm’s environmental certification practice? The mediation role of top management support. Corp. Soc. Responsib. Environ. Manag. 2020. Early cite. Available online: https://onlinelibrary.wiley.com/doi/abs/10.1002/csr.2101 (accessed on 24 December 2020).

- Johnsen, T.E.; Miemczyk, J.; Howard, M. A systematic literature review of sustainable purchasing and supply research: Theoretical perspectives and opportunities for IMP-based research. Ind. Mark. Manag. 2017, 61, 130–143. [Google Scholar] [CrossRef]

- Hoejmose, S.U.; Roehrich, J.K.; Grosvold, J. Is doing more doing better? The relationship between responsible supply chain management and corporate reputation. Ind. Mark. Manag. 2014, 43, 77–90. [Google Scholar] [CrossRef]

- Barron, L.; Gauntlett, E. The Regional Institute Online Publishing 2002. Available online: http://www.regional.org.au/au/soc/2002/4/barron_gauntlett.htm (accessed on 19 July 2017).

- Lozano, F.J. Envisioning sustainability three-dimensionally. J. Clean. Prod. 2008, 16, 1838–1846. [Google Scholar] [CrossRef]

- Thompson, J.D. Organizations in Action; McGraw Hill: New York, NY, USA, 1967. [Google Scholar]

- Harrison, D.; Easton, G. Patterns of actor response to environmental change. J. Bus. Res. 2002, 55, 545–552. [Google Scholar] [CrossRef]

- Öberg, C.; Huge-Brodin, M.; Björklund, M. Applying a network level in environmental impact assessments. J. Bus. Res. 2012, 65, 247–255. [Google Scholar] [CrossRef]

- Álvarez, M.E.P.; Bárcena, M.M.; González, F.A. On the sustainability of machining processes. Proposal for a unified framework through the triple bottom-line from an understanding review. J. Clean. Prod. 2017, 142, 3890–3904. [Google Scholar] [CrossRef]

- Cabezas, H.; Pawlowski, C.W.; Mayer, A.L.; Hoagland, N.T. Sustainability: Ecological, social, economic, technological, and systems perspectives. Clean Technol. Environ. Policy 2003, 5, 167–180. [Google Scholar] [CrossRef]

- Mayer, A.L.; Thurton, H.W.; Pawlowski, C.W. The multidisciplinary influence of common sustainability indices. Front. Ecol. Environ. 2004, 2, 419–426. [Google Scholar] [CrossRef]

- Mayer, A.L. Strengths and weaknesses of common sustainability indices for multidimensional systems. Environ. Int. 2008, 34, 277–291. [Google Scholar] [CrossRef]

- Singh, R.K.; Murty, H.; Gupta, S.; Dikshit, A. An overview of sustainability assessment methodologies. Ecol. Indic. 2009, 9, 189–212. [Google Scholar] [CrossRef]

- Elkington, J. Partnerships from cannibals with forks: The triple bottom line of 21st-century business. Environ. Qual. Manag. 1998, 8, 37–51. [Google Scholar] [CrossRef]

- Birkin, F.; Polesie, T.; Lewis, L. A new business model for sustainable development: An exploratory study using the theory of constraints in Nordic organizations. Bus. Strat. Environ. 2009, 18, 277–290. [Google Scholar] [CrossRef]

- Green, K.; Morton, B.; New, S. Purchasing and environmental management: Interactions, policies and opportunities. Bus. Strat. Environ. 1996, 5, 188–197. [Google Scholar] [CrossRef]

- Veleva, V.; Hart, M.; Greiner, T.; Crumbley, C. Indicators for measuring environmental sustainability: A case study of the pharmaceutical industry. Benchmarking 2003, 10, 107–119. [Google Scholar] [CrossRef]

- Thatcher, A. Theoretical definitions and models of sustainable development that apply to human factors and ergonomics. In Proceedings of the 11th International Symposium on Human Factors in Organisational Design and Management & 46th Annual Nordic Ergonomics Society Conference, Copenhagen, Denmark, 17–20 August 2014; IEA Press: Copenhagen, Denmark, 2014; pp. 747–752. [Google Scholar]

- Dyllick, T.; Hockerts, K. Beyond the business case for corporate sustainability. Bus. Strategy Environ. 2002, 11, 130–141. [Google Scholar] [CrossRef]

- Birkin, F.; Cashman, A.; Koh, S.C.L.; Liu, Z. New sustainable business models in China. Bus. Strat. Environ. 2009, 18, 64–77. [Google Scholar] [CrossRef]

- Krause, D.R.; Vachon, S.; Klassen, R.D. Special topic forum on sustainable supply chain management: Introduction and reflections on the role of purchasing management. J. Supply Chain Manag. 2009, 45, 18–25. [Google Scholar] [CrossRef]

- Carter, C.R.; Rogers, D.S. A framework of sustainable supply chain management: Moving toward new theory. Int. J. Phys. Distrib. Logist. Manag. 2008, 38, 360–387. [Google Scholar] [CrossRef]

- Closs, D.; Speier, C.; Meacham, N. Sustainability to support end-to-end value chains: The role of supply chain management. J. Acad. Mark. Sci. 2011, 39, 101–116. [Google Scholar] [CrossRef]

- Fiorino, D.J. Sustainability as a Conceptual Focus for Public Administration. Public Adm. Rev. 2010, 70, s78–s88. [Google Scholar] [CrossRef]

- Bai, C.; Sarkis, J. Integrating sustainability into supplier selection with grey system and rough set methodologies. Int. J. Prod. Econ. 2010, 124, 252–264. [Google Scholar] [CrossRef]

- Håkansson, H.; Johanson, J. The network governance structure: Interfirm cooperation beyond markets and hierarchy. In The Embedded Firm; Grabher, G., Ed.; Routledge: London, UK, 1993. [Google Scholar]

- Cantu, C.L.; Corsaro, D.; Snehota, I. Roles of actors in combining resources into complex solutions. J. Bus. Res. 2012, 65, 139–150. [Google Scholar] [CrossRef]

- Pettigrew, A.M. What is processual analysis? Scandinavian. J. Manag. 1997, 13, 337–348. [Google Scholar]

- Van De Ven, A.H. Suggestions for studying strategy process: A research note. Strat. Manag. J. 1992, 13, 169–188. [Google Scholar] [CrossRef]

- Halinen, A.; Medlin, C.J.; Törnroos, J.-Å. Time and process in business network research. Ind. Mark. Manag. 2012, 41, 215–223. [Google Scholar] [CrossRef]

- Emerson, R.M. Power-Dependence Relations. Am. Sociol. Rev. 2006, 27, 31. [Google Scholar] [CrossRef]

- Håkansson, H.; Snehota, I. Developing Relationships in Business Networks; Routledge: London, UK, 1995. [Google Scholar]

- Håkansson, H.; Persson, G. Supply Chain Management: The Logic of Supply Chains and Networks. Int. J. Logist. Manag. 2004, 15, 11–26. [Google Scholar] [CrossRef]

- Parsons, T. Structure and Processes in Modern Society; Free Press of Glencoe: New York, NY, USA, 1960. [Google Scholar]

- Ford, D.; Mattson, L.-G.; Snehota, I. Management in the Interactive Business World. In No Business is an Island; Håkansson, H., Snehota, I., Eds.; Emerald Publishing: Bingley, UK, 2017. [Google Scholar]

- Halldorsson, A.; Kotzab, H.; Skjott-Larsen, T. Inter-organizational theories behind Supply Chain Management—Discussion and applications. In Strategy and Organization in Supply Chains; Seuring, S., Müller, M., Goldbach, M., Schneidewind, U., Eds.; Physica Verlag: Berlin, Germany, 2003. [Google Scholar]

- Gadde, L.-E.; Håkansson, H.; Persson, G. Supply Network Strategies; Wiley: Chichester, UK, 2010. [Google Scholar]

- Voss, C.; Tsikriktsis, N.; Frohlich, M. Case research in operations management. Int. J. Oper. Prod. Manag. 2002, 22, 195–219. [Google Scholar] [CrossRef]

- Bryman, A.; Bell, E. Business Research Methods; Oxford University Press: Oxford, UK, 2015. [Google Scholar]

- Gabriel, Y.; Griffiths, D.S. Stories in Organizational Research. In Essential Guide to Qualitative Methods and Analysis in Organizational Researc; Cassell, C., Symon, G., Eds.; Sage: London, UK, 2004. [Google Scholar]

- Gabriel, Y. Storytelling in Organizations: Facts, Fictions Fantasies; Oxford University Press: Oxford, UK, 2000. [Google Scholar]

- Shou, Y.; Shao, J.; Lai, K.; Kang, M.; Park, Y.W. The impact of sustainability and operations orientations on sustainable supply management and the triple bottom line. J. Clean. Prod. 2019, 240, 118280. [Google Scholar] [CrossRef]

- Weick, K.E.; Sutcliffe, K.M.; Obstfeld, D. Organizing and the Process of Sensemaking. Organ. Sci. 2005, 16, 409–421. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).