Hysteretic Behavior of Reinforced Concrete Coupling Beams According to Volume Fraction of Steel Fiber

Abstract

:1. Introduction

2. Experimental Program

2.1. Test Plan and Specimen Design

2.2. Material Properties

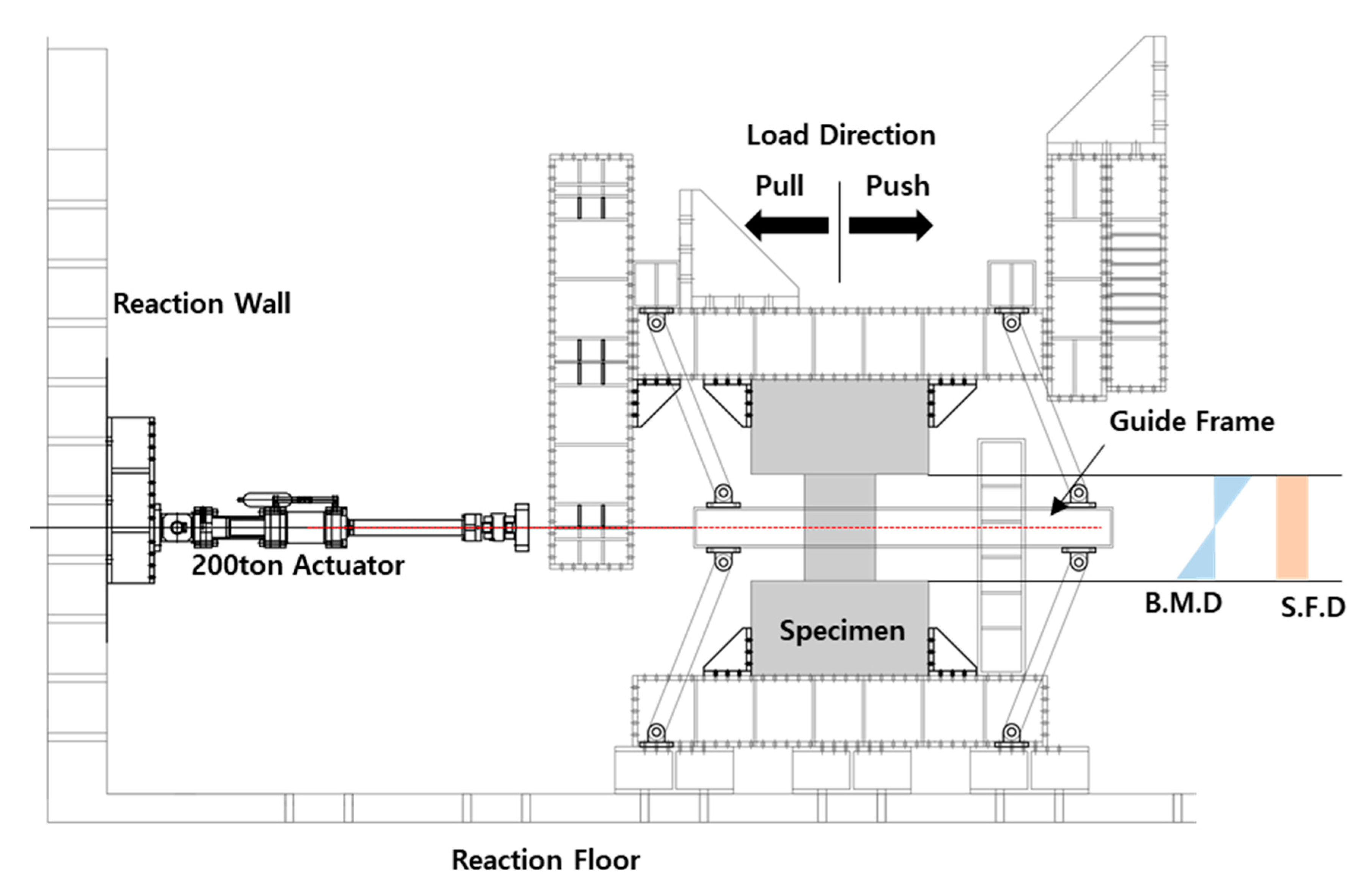

2.3. Test Setup and Loading History

3. Test Results

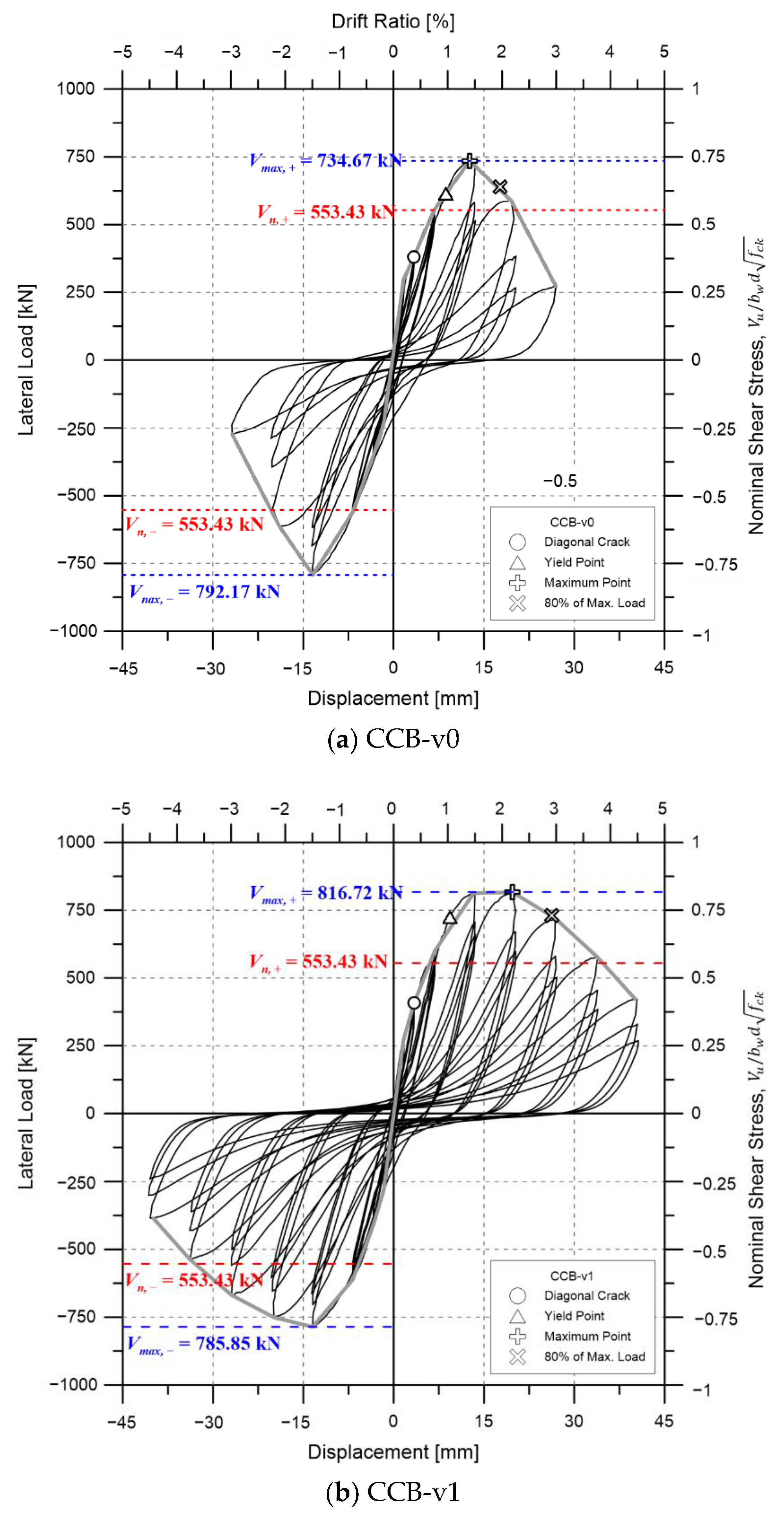

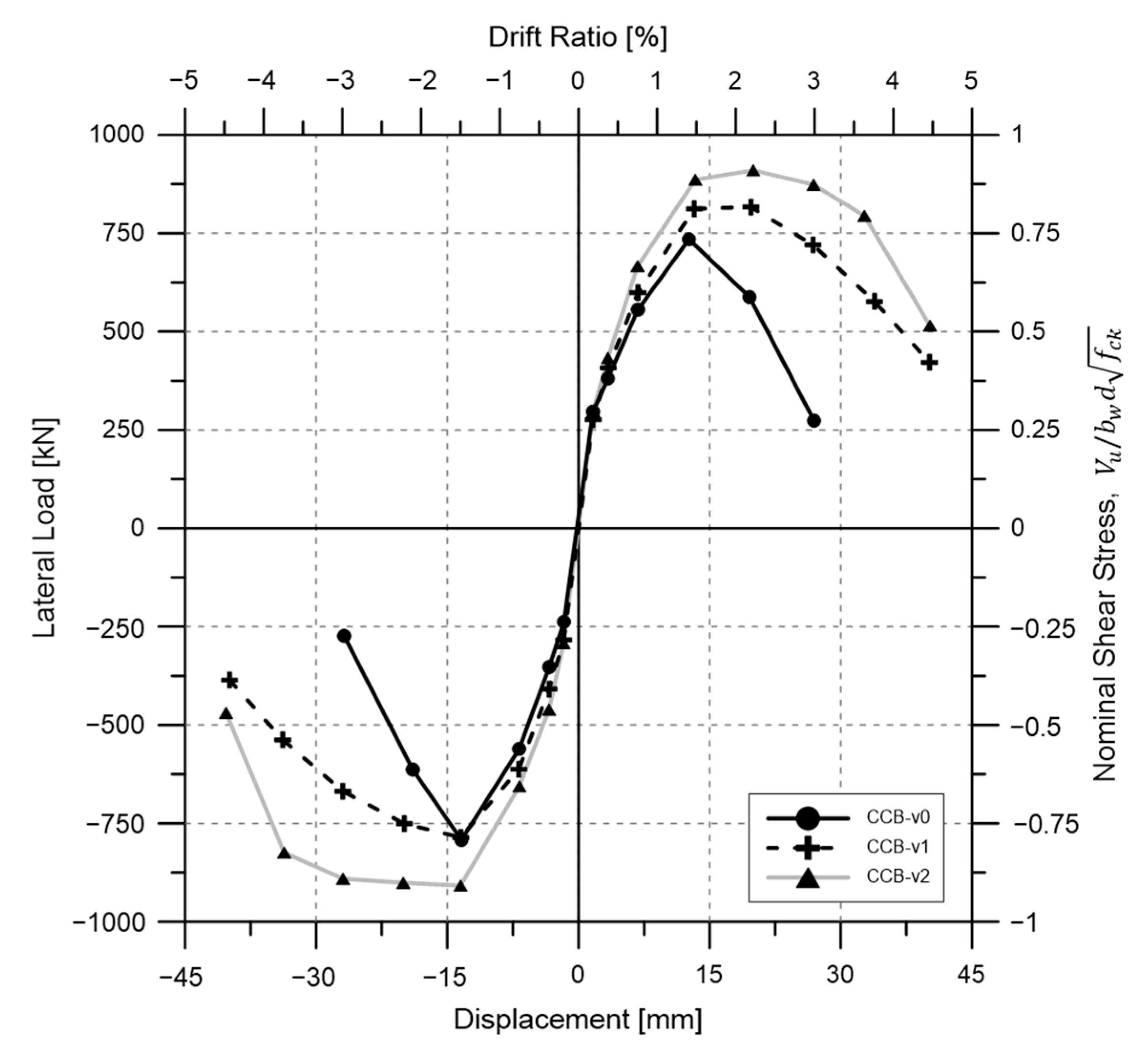

3.1. Load-Displacement Relationship

3.2. Global Behavior of Test Specimens

3.3. Energy Dissipation and Stiffness of SFRC Coupling Beams

4. Deformation Contributions

4.1. Elements Contributing to Deformation

4.2. Contribution of SFRC Coupling Beams to Deformation

5. Conclusions

- (1)

- The maximum strength of the standard specimen CCB-v0 (0% volume fraction of steel fibers) was 734.67 kN. When 1% steel fiber was introduced, this increased by about 11%, and when 2% steel fiber was introduced the maximum strength was improved by 24%. The displacement ductility ratio was 2.25 when the volume fraction of steel fiber was 0%, but increased by about 43% to 3.22 at the time of 1% containing, and 64% to about 3.68 at the time of 2% containing. All the specimens exceeded the current design standard for diagonal reinforcement coupling beams.

- (2)

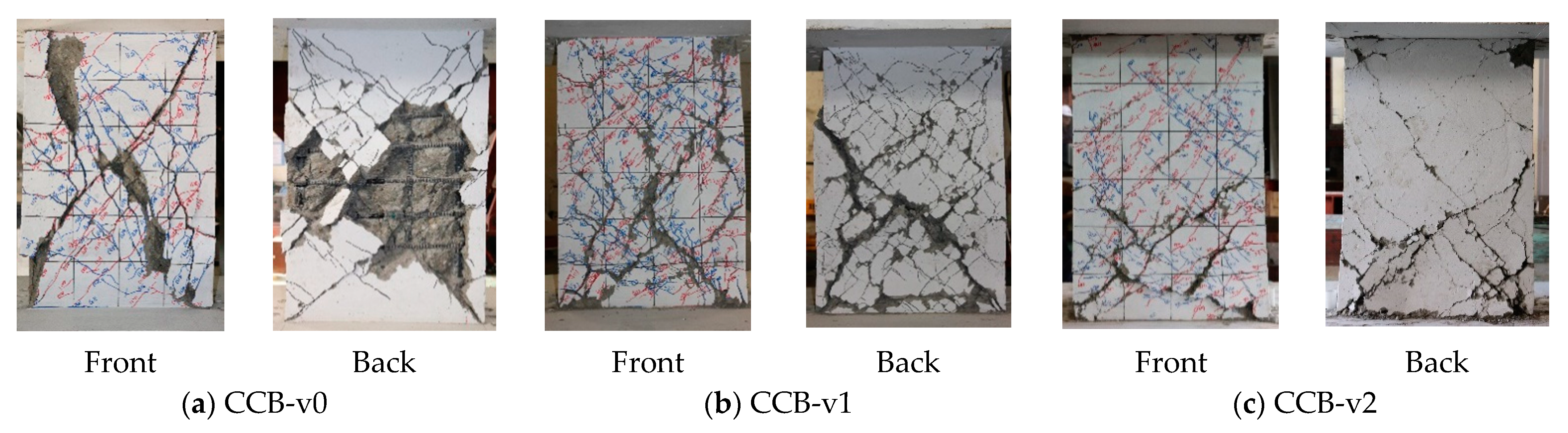

- As the steel fibers were introduced, diagonal cracks occurred late. A large number of microcracks occurred and the angle of the diagonal crack was gradually increased. We believe that this occurred because the increase in crack width was suppressed due to the bridging effect of the steel fibers. In future studies, it is necessary to quantitatively analyze the effect of the crack angle due to steel fiber and its effect on the strength of the coupling beams.

- (3)

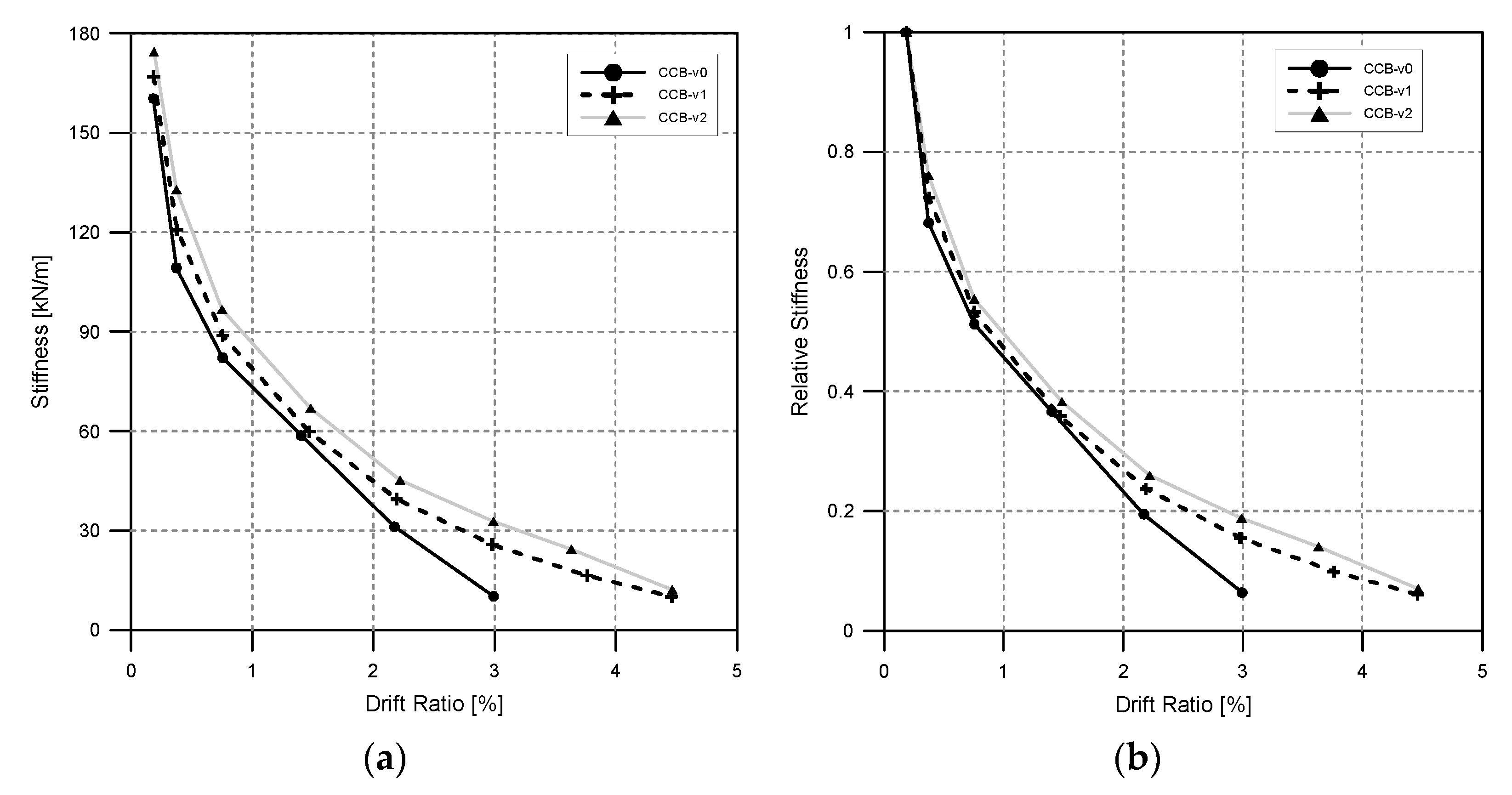

- As the steel fibers were introduced, the stiffness increased; also, the degradation of the relative stiffness decreased as the volume fraction of steel fibers increased. In the standard specimen CCB-v0 which had no steel fibers, the stiffness decreased sharply after the maximum strength was reached, but in the specimen CCB-v02 with 2% steel fibers, this rapid decrease in stiffness did not occur. The energy dissipation capacity increased as the steel fibers were introduced, and of particular note was that the energy dissipation increased rapidly when the longitudinal reinforcing bar yielded. There was no significant difference in the yield point of the longitudinal reinforcing bars according to the steel fibers, but the cumulative energy dissipation capacity increased as the steel fibers were contained.

- (4)

- To confirm the flexural and shear stiffness of the coupling beams according to their steel fiber content, the deformation distribution of the coupling beams was evaluated. The results showed that as the steel fibers were introduced, the deformation contribution of shear decreased, but the deformation contribution of rocking increased. The deformation contribution due to bending did not comparatively increase, which we attribute to the steel fibers improving the tensile strength of the concrete and greatly improving the resistance to shear.

- (5)

- This study confirmed that each deformation element (flexure, shear, and rocking) changes due to the steel fiber content, and this trend was the same in previous studies. Therefore, the effective stiffness of coupling beams according to the volume fraction ratio of steel fibers should be further quantitatively evaluated based on the results of previous studies and this study.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Paulay, T.; Park, R. Reinforced Concrete Structures; John Wiley: New York, NY, USA, 1975. [Google Scholar]

- Paulay, T.; Priestley, M.J.N. Seismic Design of Reinforced Concrete and Masonry Buildings; John Wiley: New York, NY, USA, 1992. [Google Scholar]

- Paulay, T. The Coupling of Shear Walls. Ph.D. Thesis, University of Canterbury, Christchurch, New Zealand, 1969. [Google Scholar]

- Paulay, T.; Binney, J.R. Diagonally reinforced coupling beams of shear walls. In Shear in Reinforced Concrete; SP-42, American Concrete Institute: Farmington Hills, MI, USA, 1974; Volume 42, pp. 579–598. [Google Scholar]

- Tassios, T.P.; Moretti, M.; Bezas, A. On the behavior and ductility of reinforced concrete coupling beams of shear walls. ACI Struct. J. 1996, 93, 711–720. [Google Scholar]

- Galano, L.; Vignoli, A. Seismic behavior of short coupling beams with different reinforcement layouts. ACI Struct. J. 2000, 97, 876–885. [Google Scholar]

- Seo, S.Y.; Yun, H.D.; Chun, Y.S. Hysteretic Behavior of Conventionally Reinforced Concrete Coupling Beams in Reinforced Concrete Coupled Shear Wall. Int. J. Concr. Struct. Mater. 2017, 11, 599–616. [Google Scholar] [CrossRef] [Green Version]

- Kwon, H.-W.; Jeon, Y.-R.; Lee, K.-H.; Shin, M.-S.; Han, S.-W. Cyclic Behavior of High-Performance Fiber-Reinforced Cement Composite Coupling Beam Having Diagonal Reinforcement. J. Korea Concr. Inst. 2013, 25, 649–656. [Google Scholar] [CrossRef]

- Park, W.S.; Kang, T.H.; Kim, S.; Yun, H.D. Seismic Performance of Moderately Short Concrete Coupling Beams with Various Reinforcements. ACI Struct. J. 2020, 117, 141–154. [Google Scholar] [CrossRef]

- Cai, G.; Zhao, J.; Degée, H.; Vandoren, B. Shear capacity of steel fibre reinforced concrete coupling beams using conventional reinforcements. Eng. Struct. 2016, 128, 428–440. [Google Scholar] [CrossRef]

- Lequensne, R.D.; Parra-Montesino, G.; Wight, J.K. Seismic response of fiber reinforced concrete coupled walls. ACI Struct. J. 2016, 113, 435–445. [Google Scholar]

- ACI 318-19. Building Code Requirement for Structural Concrete and Commentary; ACI Committee: Farmington Hill, MI, USA, 2019. [Google Scholar]

- Moehle, J.P.; Ghodsi, T.; Hooper, J.D.; Fields, D.C.; Gedhada, R. Seismic Design of Cast-in-Place Concrete Special Structural Walls and Coupling Beams: A Guide for practicing engineer. In NEHRP Seismic Design Technical Brief, No. 6; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2011. [Google Scholar]

- ACI 544.4R-88. Design Considerations for Steel Fiber Reinforced Concrete; ACI Committee: Farmington Hill, MI, USA, 2017. [Google Scholar]

- Kim, C.-G.; Park, H.-G.; Hong, G.-H.; Kang, S.-M. Evaluation on Shear Contribution of Steel Fiber Reinforced Concrete in Place of Minimum Shear Reinforcement. J. Korea Concr. Inst. 2014, 27, 603–613. [Google Scholar] [CrossRef]

- MacGregor, J.G.; Wight, J.K.; Teng, S.; Irawan, P. Reinforced Concrete: Mechanics and Design, 5th ed.; Prentice Hall: Upper Saddle River, NJ, USA, 1997. [Google Scholar]

- KS F 2403. Standard Test Method for Making and Curing Concrete Specimens; Korean Agency for Technology and Standards: Seoul, Korea, 2014; pp. 1–14.

- KS F 2405. Standard Test Method for Compressive Strength of Concrete; Korean Agency for Technology and Standards: Seoul, Korea, 2014; pp. 1–16.

- Bae, B.I.; Chung, J.H.; Choi, H.K.; Jung, H.S.; Choi, C.S. Experimental study on the cyclic behavior of steel fiber reinforced high strength concrete columns and evaluation of shear strength. Eng. Struct. 2018, 157, 250–267. [Google Scholar] [CrossRef]

- KS F 2423. Method of Test for Splitting Tensile Strength of Concrete; Korean Agency for Technology and Standards: Seoul, Korea, 2016; pp. 1–12.

- KS F 2408. Method of Test for Flexural Strength of Concrete; Korean Agency for Technology and Standards: Seoul, Korea, 2016; pp. 1–16.

- KS B 0802. Method of Tensile Test for Metallic Materials; Korean Agency for Technology and Standards: Seoul, Korea, 2013; pp. 1–7.

- ACI 374.2R-13. Guide for Testing Reinforced Concrete Structural Elements under Slowly Applied Simulated Seismic Load; ACI Committee 374: Farmington Hill, MI, USA, 2013. [Google Scholar]

- Hognestad, E. Inelastic behavior in tests of eccentrically loaded short reinforced concrete columns. J. Proc. 1952, 49, 117–139. [Google Scholar]

- Vu, N.S.; Li, B.; Beyer, K. Effective stiffness of reinforced concrete coupling beams. Eng. Struct. 2014, 76, 371–382. [Google Scholar]

- Priestley, M.J.N.; Park, R. Strength and ductility of concrete bridge columns under seismic loading. Struct. J. 1987, 84, 61–76. [Google Scholar]

- Paulay, T.; Santhakumar, A.R. Ductile behavior of coupled shear walls. J. Struct. Div. 1976, 102, 93–108. [Google Scholar]

- American Society of Civil Engineers. ASCE 41-17: Seismic Evaluation and Retrofit Rehabilitation of Existing Buildings; American Society of Civil Engineers: Reston, Virginia, 2017. [Google Scholar]

- Lequesne, R.D. Behavior and Design of High-Performance Fiber-Reinforced Concrete Coupling Beams and Coupled-Wall Systems. Ph.D. Thesis, University of Michigan, Ann Arbor, MI, USA, 2011. [Google Scholar]

- Setkit, M. Seismic Behavior of Slender Coupling Beams Constructed with High-Performance Fiber-Reinforced Concrete. Ph.D. Thesis, University of Michigan, Ann Arbor, MI, USA, 2012. [Google Scholar]

- Kowalsky, M.J.; Priestley, M.J.; Seible, F. Shear Behavior of Lightweight Concrete Columns under Seismic Conditions; Report SSRP-95/10, Structures Division; University of California: San Diego, CA, USA, 1995. [Google Scholar]

- Ohtaki, T.; Benzoni, G.; Priestley, M.J.N. Seismic Performance of a Full Scale Bridge Column-as Built and as Repaired; Report SSRP-97/02, Structures Division; University of California: San Diego, CA, USA, 1997. [Google Scholar]

| Specimens | b | d | h | /h | Longitudinal Rebar | Transverse Rebar | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Rebar | Rebar | ||||||||||

| [mm] | [MPa] | [MPa] | [%] | ||||||||

| CCB-v0 | 300 | 544 | 600 | 1.5 | 6-D25 | 0.017 | 400 | D10 @300 | 0.008 | 400 | 0 |

| CCB-v1 | 1 | ||||||||||

| CCB-v2 | 2 | ||||||||||

(%) | W/B (%) | S/A (%) | Unit Weight (kg/m3) | |||||

|---|---|---|---|---|---|---|---|---|

| C | W | S | G | AD | SF | |||

| 0 | 33.8 | 45.7 | 325 | 157 | 764 | 913 | 3.72 | 0 |

| 1 | 78.5 | |||||||

| 2 | 157 | |||||||

(%) | (MPa) | (MPa) | (MPa) | (MPa) |

|---|---|---|---|---|

| 0 | 51.02 | 4.23 | 4.2 | 42,901 |

| 1 | 40.72 | 5.13 | 4.64 | 40,691 |

| 2 | 35.37 | 5.56 | 6.85 | 46,315 |

| Rebar | (MPa) | (MPa) | (mm/mm) | (MPa) |

|---|---|---|---|---|

| D13 | 400 | 483.5 | 0.0024 | 589.4 |

| D25 | 400 | 493.9 | 0.0025 | 624.1 |

| Performance Points | Properties | Specimens | |||||

|---|---|---|---|---|---|---|---|

| CCB-v0 | CCB-v1 | CCB-v2 | |||||

| Positive | Negative | Positive | Negative | Positive | Negative | ||

| Yield displacement | Drift ratio (%) | 0.97 | 1.14 | 1.04 | 0.89 | 1.04 | 1.06 |

(kN) | 613.83 | 712.26 | 723.35 | 640.90 | 790.00 | 783.80 | |

(mm) | 8.69 | 10.27 | 9.35 | 8.01 | 9.36 | 9.55 | |

(kN/mm) | 70.64 | 69.35 | 77.36 | 80.01 | 84.40 | 82.07 | |

| Maximum load | Drift ratio (%) | 1.40 | 1.49 | 2.19 | 1.50 | 2.22 | 1.50 |

(kN) | 734.67 | 792.17 | 816.72 | 785.85 | 910.27 | 907.93 | |

(mm) | 12.63 | 13.39 | 19.72 | 13.46 | 19.98 | 13.49 | |

| Ultimate Load ( | Drift ratio (%) | 2.17 | 2.03 | 3.34 | 3.23 | 3.83 | 3.94 |

(kN) | 587.74 | 633.74 | 653.38 | 628.68 | 728.22 | 726.34 | |

(mm) | 19.56 | 18.31 | 30.10 | 29.03 | 34.47 | 35.49 | |

| 2.25 | 1.78 | 3.22 | 3.62 | 3.68 | 3.72 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chung, J.-H.; Son, D.-H.; Kim, S.-Y.; Bae, B.-I.; Choi, C.-S. Hysteretic Behavior of Reinforced Concrete Coupling Beams According to Volume Fraction of Steel Fiber. Sustainability 2021, 13, 182. https://doi.org/10.3390/su13010182

Chung J-H, Son D-H, Kim S-Y, Bae B-I, Choi C-S. Hysteretic Behavior of Reinforced Concrete Coupling Beams According to Volume Fraction of Steel Fiber. Sustainability. 2021; 13(1):182. https://doi.org/10.3390/su13010182

Chicago/Turabian StyleChung, Joo-Hong, Dong-Hee Son, Su-Yong Kim, Baek-Il Bae, and Chang-Sik Choi. 2021. "Hysteretic Behavior of Reinforced Concrete Coupling Beams According to Volume Fraction of Steel Fiber" Sustainability 13, no. 1: 182. https://doi.org/10.3390/su13010182

APA StyleChung, J.-H., Son, D.-H., Kim, S.-Y., Bae, B.-I., & Choi, C.-S. (2021). Hysteretic Behavior of Reinforced Concrete Coupling Beams According to Volume Fraction of Steel Fiber. Sustainability, 13(1), 182. https://doi.org/10.3390/su13010182