Using Rice Bran Hydrogel Beads to Remove Dye from Aqueous Solutions

Abstract

1. Introduction

2. Materials and Methods

2.1. Rice Bran Hydrogel Beads

2.2. Hydrogel Beads Adsorption Experiments

2.3. Adsorbent Regeneration

3. Results and Discussion

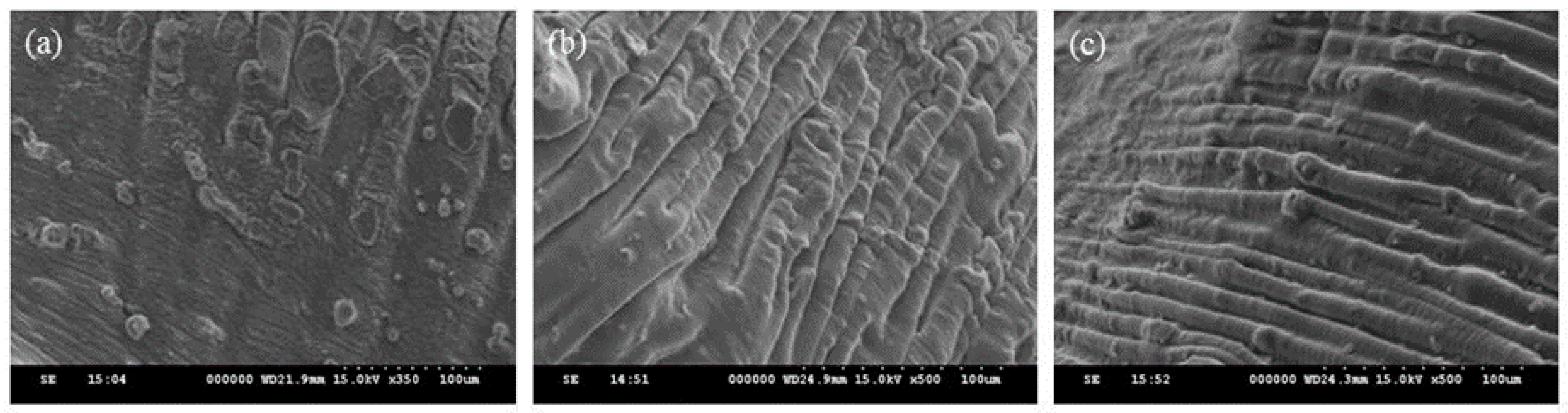

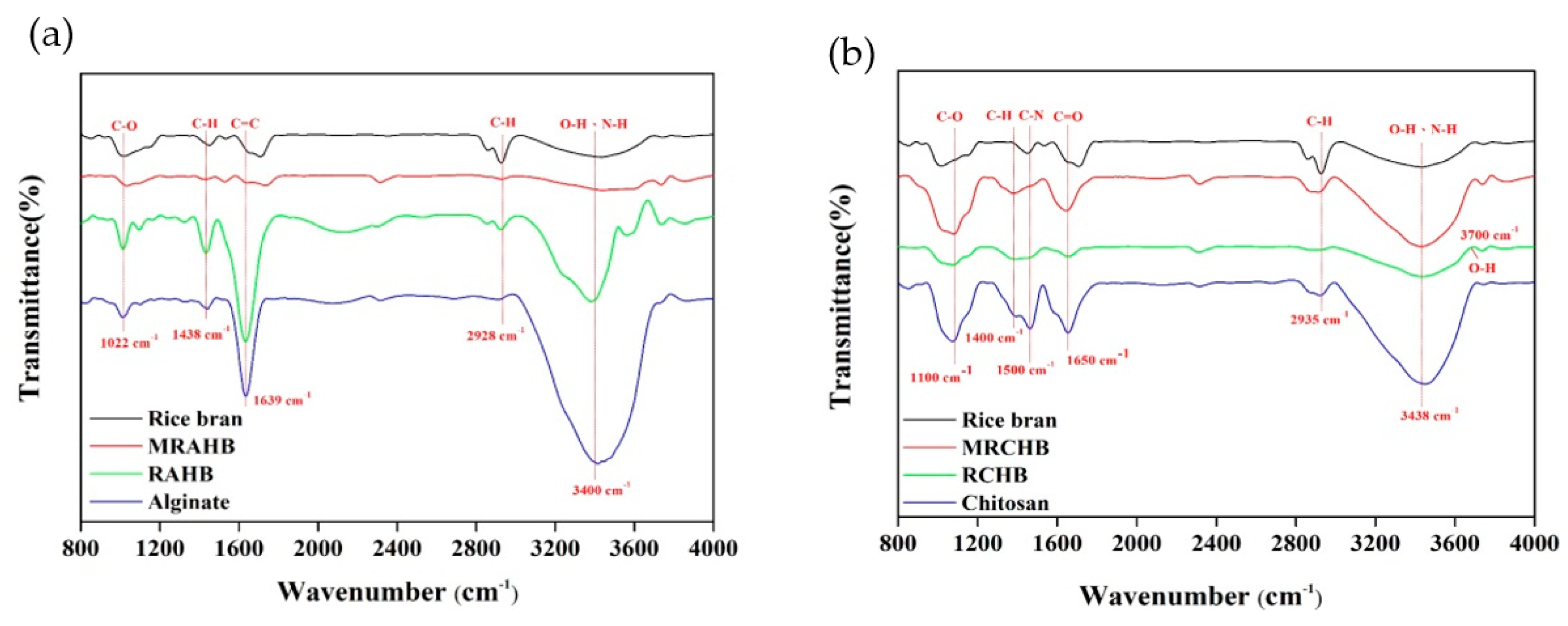

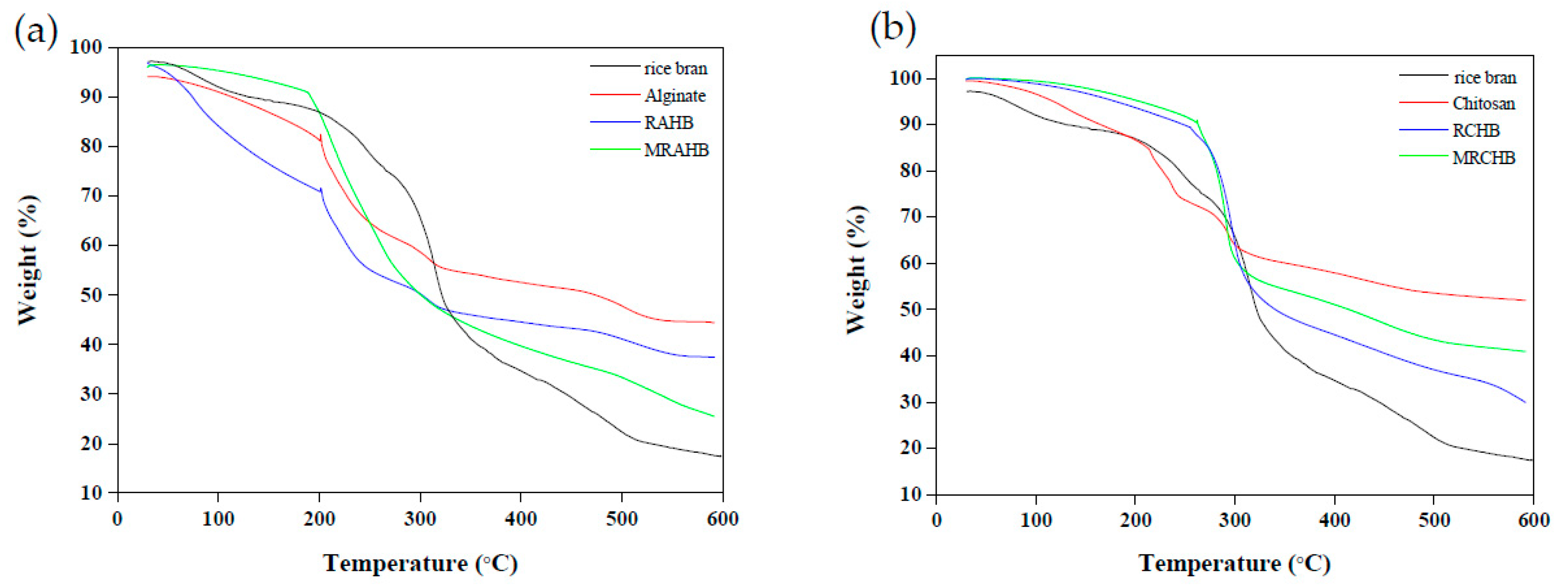

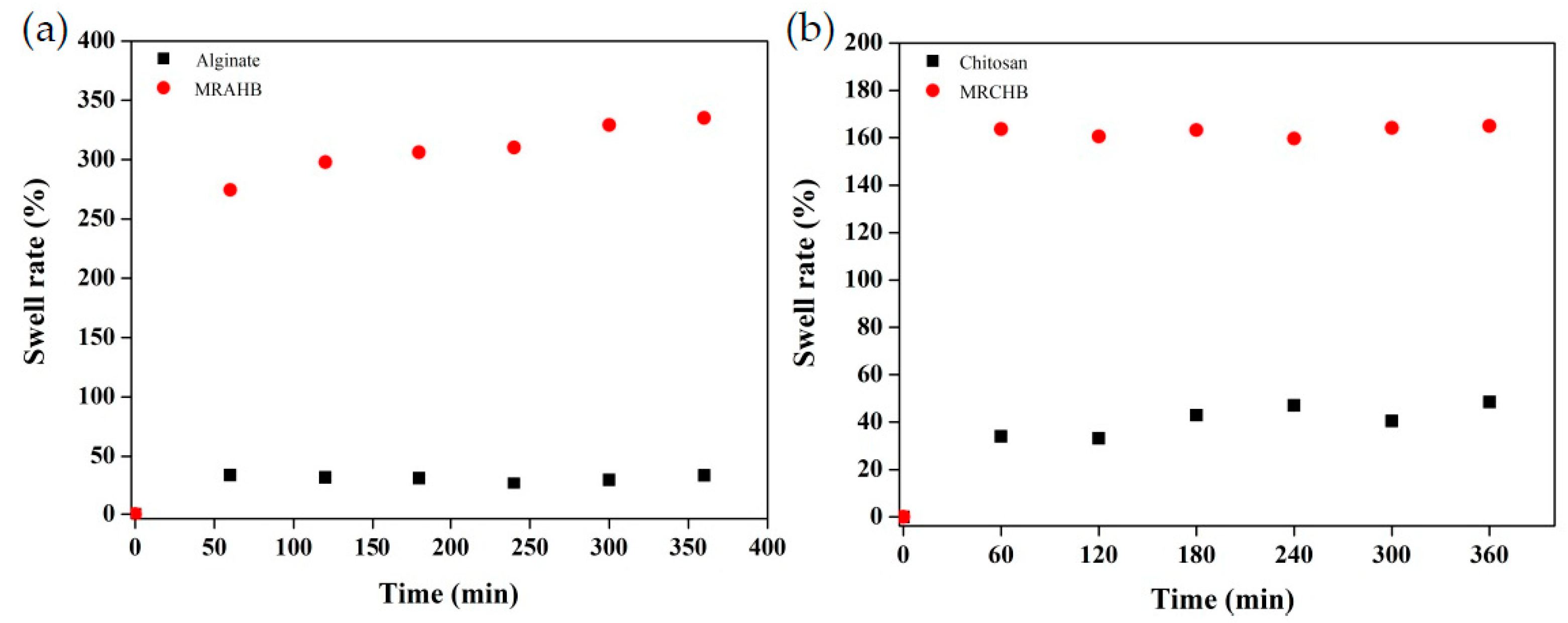

3.1. Hydrogel Beads Material Surface Morphology Analysis

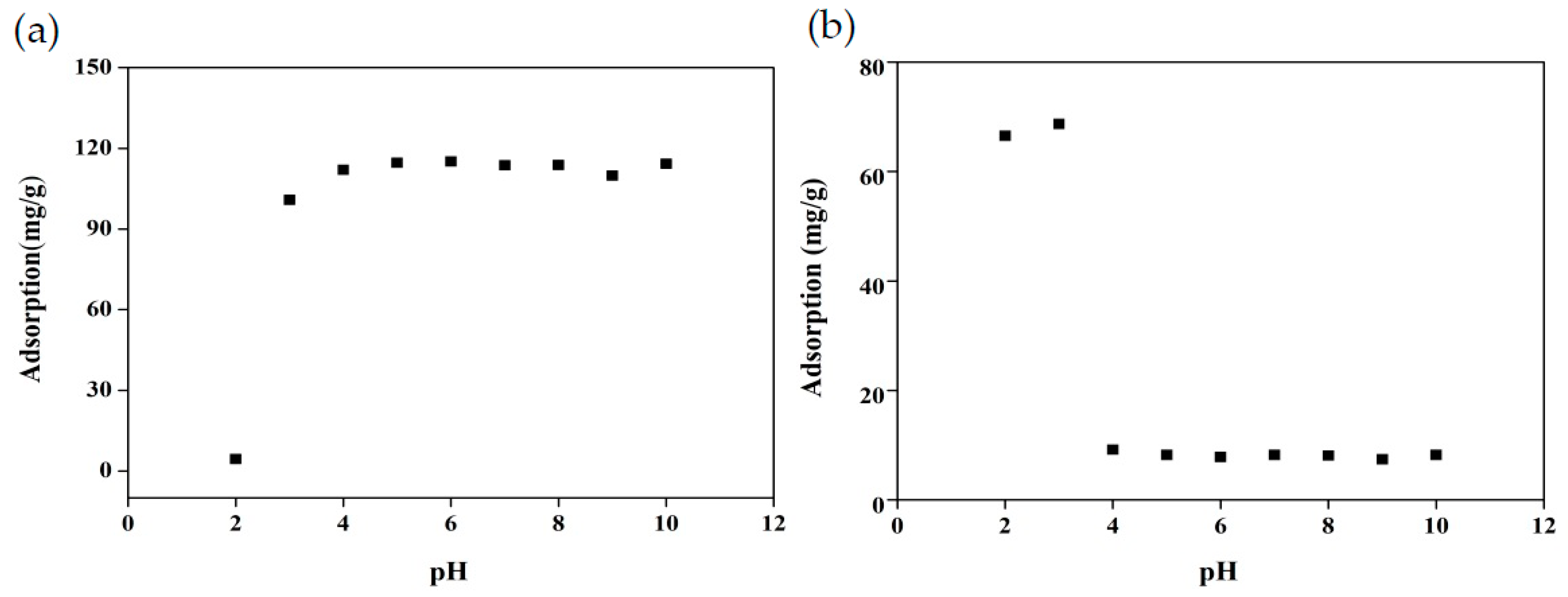

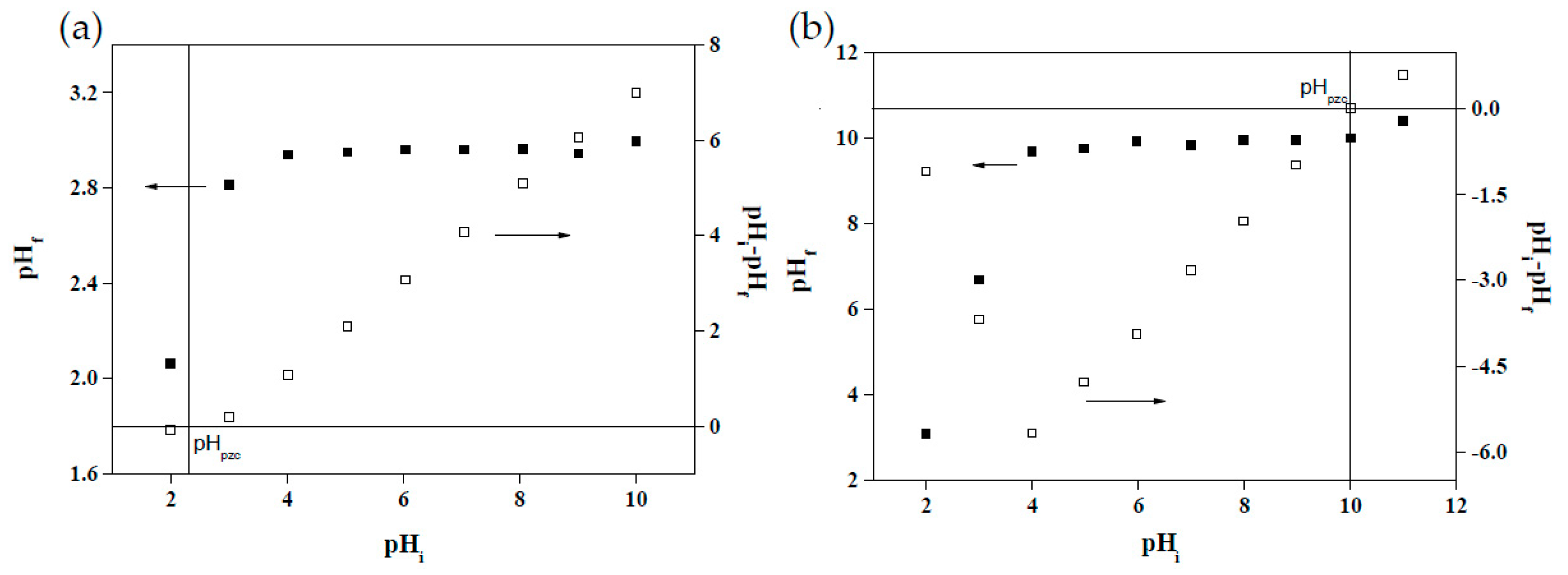

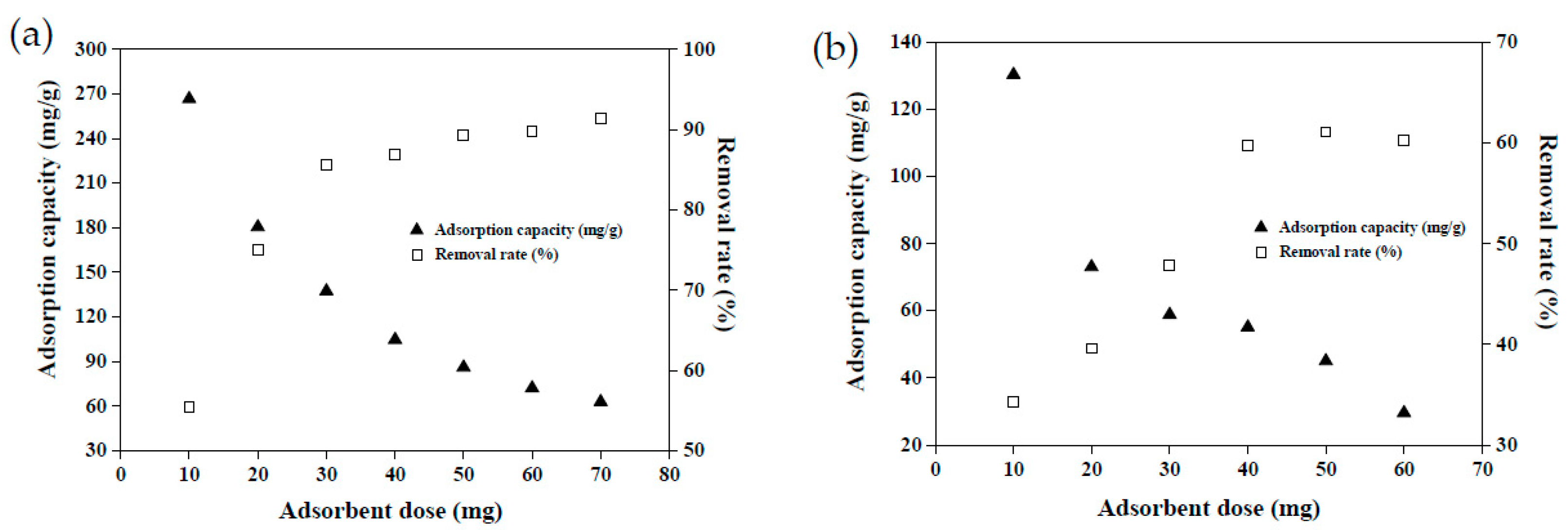

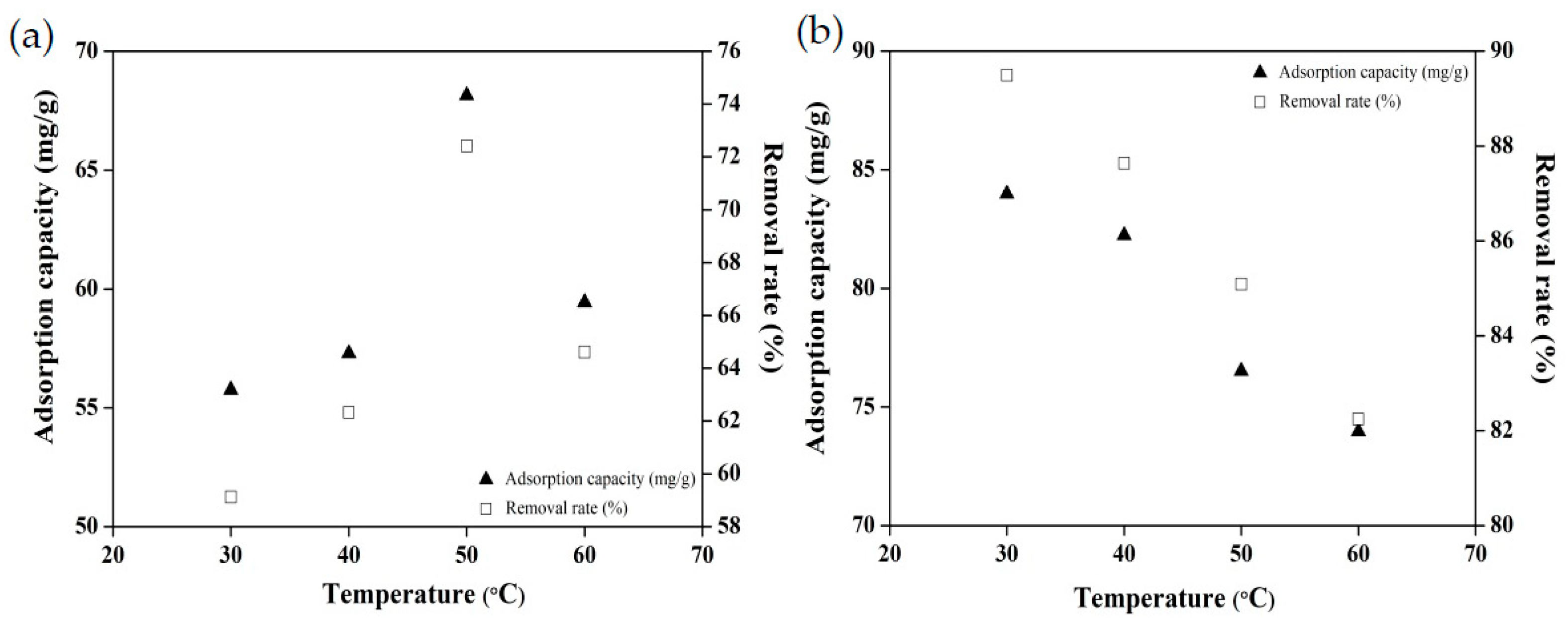

3.2. The Effects of Control Variables

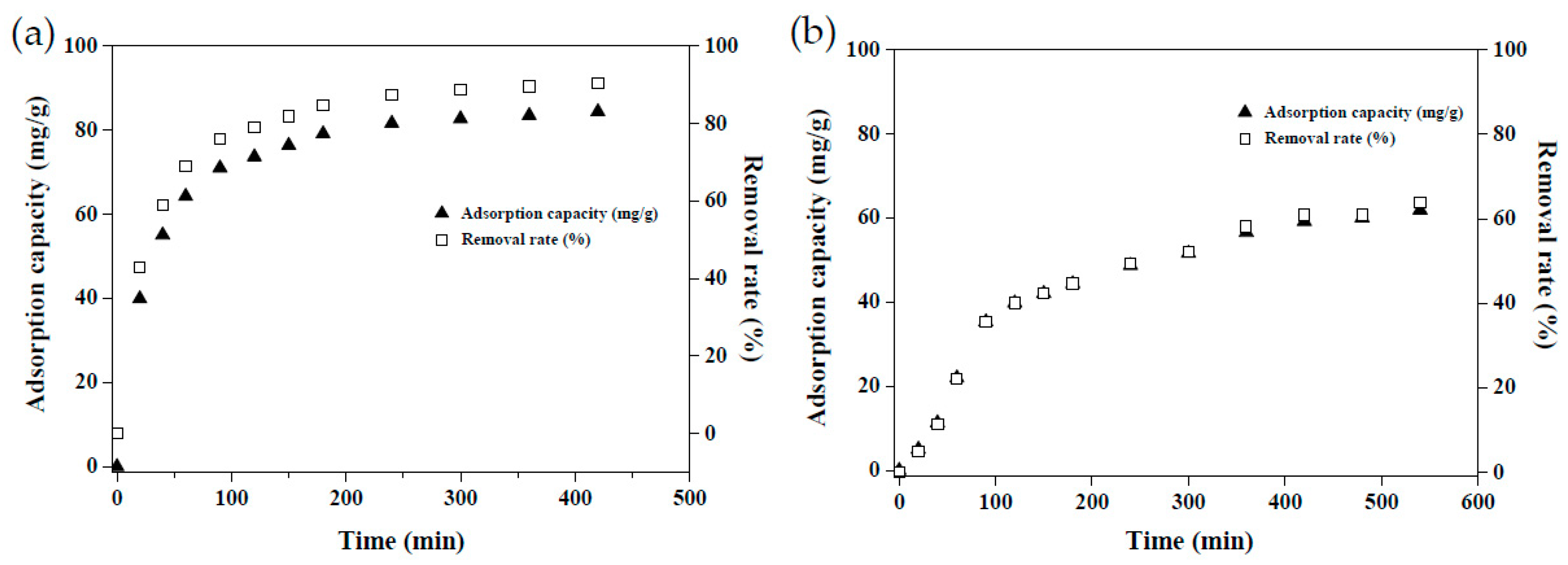

3.3. Kinetics and Isotherm Adsorption

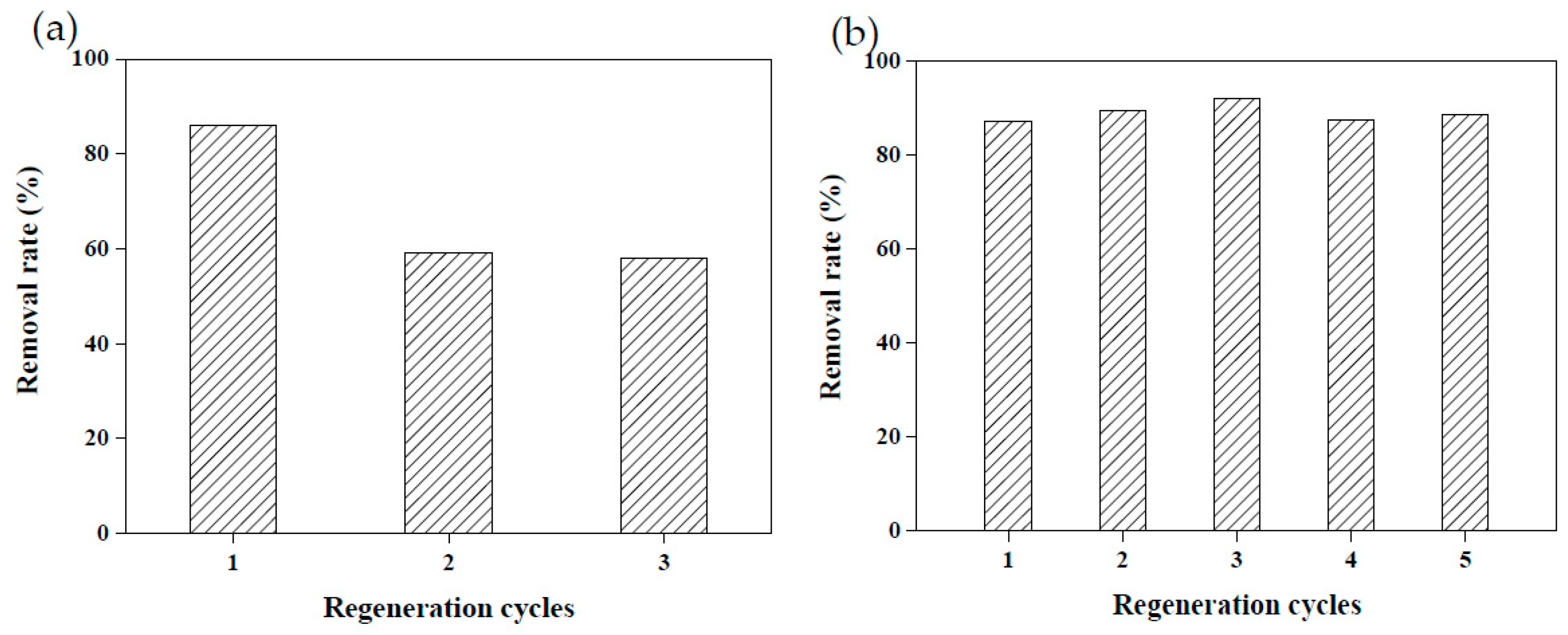

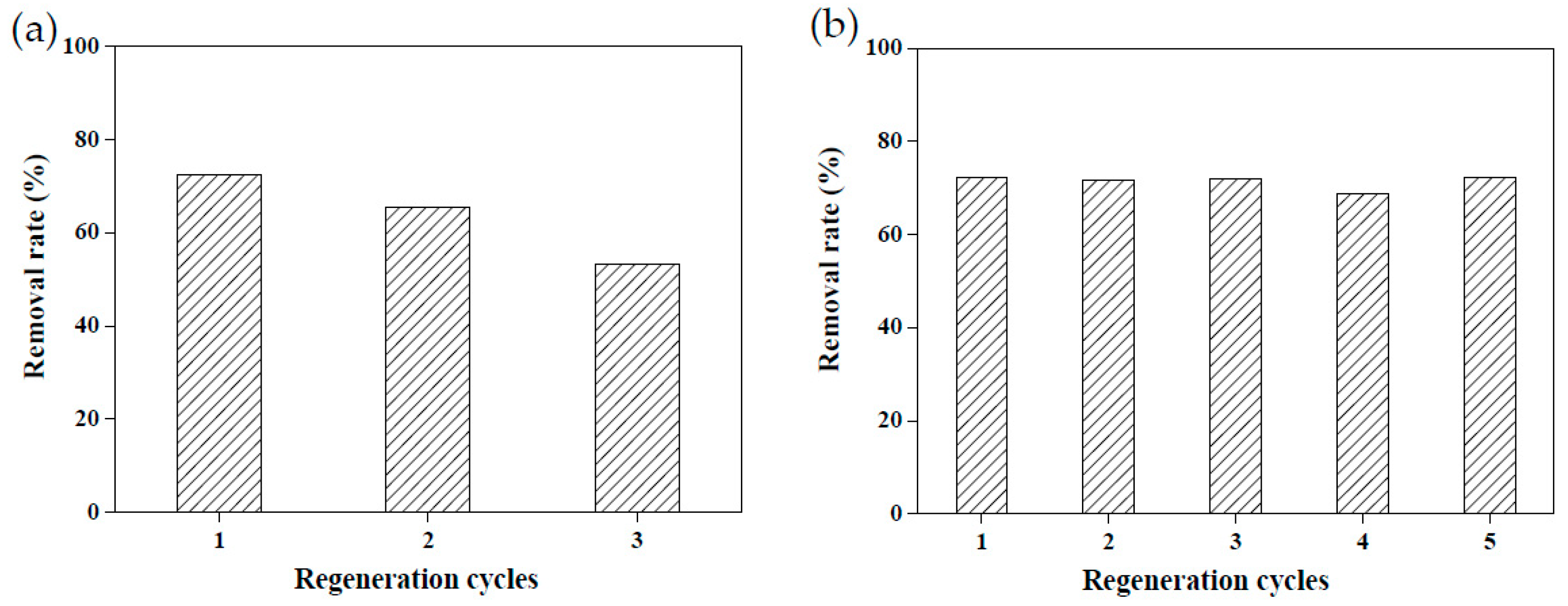

3.4. Adsorbent Regeneration

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dietrich, A.M.; Burlingame, G.A. Critical review and rethinking of USEPA secondary standards for maintaining organoleptic quality of drinking water. Environ. Sci. Technol. 2015, 49, 708–720. [Google Scholar] [CrossRef] [PubMed]

- Moreira, F.C.; Boaventura, R.A.R.; Brillas, E.; Vilar, V.J.P. Electrochemical advanced oxidation processes: A review on their application to synthetic and real wastewaters. Appl. Catal. B 2017, 202, 217–261. [Google Scholar] [CrossRef]

- Zhou, Y.; Lu, J.; Zhou, Y.; Liu, Y. Recent advances for dyes removal using novel adsorbents: A review. Environ. Pollut. 2019, 252, 352–365. [Google Scholar] [CrossRef] [PubMed]

- Robinson, T.; McMullan, G.; Marchant, R.; Nigam, P. Remediation of dyes in textile effluent: A critical review on current treatment technologies with a proposed alternative. Bioresour. Technol. 2001, 77, 247–255. [Google Scholar] [CrossRef]

- Hynes, N.R.J.; Kumar, J.K.; Kamyab, H.; Sujana, J.A.J.; Al-Khashman, O.A.; Kuslu, Y.; Ene, A.; Kumar, B.S. Modern enabling techniques and adsorbents based dye removal with sustainability concerns in textile industrial sector—A comprehensive review. J. Clean. Prod. 2020, 272, 122636. [Google Scholar] [CrossRef]

- Yaseen, D.A.; Scholz, M. Textile dye wastewater characteristics and constituents of synthetic effluents: A critical review. Int. J. Environ. Sci. Technol. 2018, 16, 1193–1226. [Google Scholar] [CrossRef]

- Fernandes, F.H.; Bustos-Obregon, E.; Salvadori, D.M.F. Disperse Red 1 (textile dye) induces cytotoxic and genotoxic effects in mouse germ cells. Reprod. Toxicol. 2015, 53, 75–81. [Google Scholar] [CrossRef]

- Chahinez, H.O.; Abdelkader, O.; Leila, Y.; Tran, H.N. One-stage preparation of palm petiole-derived biochar: Characterization and application for adsorption of crystal violet dye in water. Environ. Technol. Innov. 2020, 19, 100872. [Google Scholar] [CrossRef]

- Hong, G.B.; Wang, Y.K. Synthesis of low-cost adsorbent from rice bran for the removal of reactive dye based on the response surface methodology. Appl. Surf. Sci. 2017, 423, 800–809. [Google Scholar] [CrossRef]

- Bhatti, H.N.; Jabeen, A.; Iqbal, M.; Noreen, S.; Naseem, Z. Adsorptive behavior of rice bran-based composites for malachite green dye: Isotherm, kinetic and thermodynamic studies. J. Mol. Liq. 2017, 237, 322–333. [Google Scholar] [CrossRef]

- Cinar, S.; Kaynar, U.H.; Aydemir, T.; Kaynar, S.C.; Ayvacikli, M. An efficient removal of RB5 from aqueous solution by adsorption onto nano-ZnO/chitosan composite beads. Int. J. Biol. Macromol. 2017, 96, 459–465. [Google Scholar] [CrossRef]

- Li, Y.; Li, Y.; Zang, H.; Chen, L.; Meng, Z.; Li, H.; Ci, L. ZnCl2-activated carbon from soybean dregs as a high efficiency adsorbent for cationic dye removal: Isotherm, kinetic, and thermodynamic studies. Environ. Technol. 2018, 30, 1–24. [Google Scholar] [CrossRef] [PubMed]

- Jawad, A.H.; Kadhum, A.M.; Ngoh, Y.S. Applicability of dragon fruit (Hylocereus 77 polyrhizus) peels as low-cost biosorbent for adsorption of methylene blue from aqueous solution: Kinetics, equilibrium and thermodynamics studies. Desalin. Water Treat. 2018, 109, 231–240. [Google Scholar] [CrossRef]

- Karthik, R.; Muthezhilan, R.; Hussain, A.J.; Ramalingam, K.; Rekha, V. Effective removal of methylene blue dye from water using three different low-cost adsorbents. Desalin. Water Treat. 2016, 57, 10626–10631. [Google Scholar] [CrossRef]

- Ma, C.M.; Hong, G.B.; Wang, Y.K. Performance Evaluation and Optimization of Dyes Removal using Rice Bran-Based Magnetic Composite Adsorbent. Materials 2020, 13, 2764. [Google Scholar] [CrossRef]

- Qian, W.C.; Luo, X.P.; Wang, X.; Guo, M.; Li, B. Removal of methylene blue from aqueous solution by modified bamboo hydrochar. Ecotoxicol. Environ. Saf. 2018, 157, 300–306. [Google Scholar] [CrossRef]

- Kyzas, G.Z.; Kostoglou, M. Green adsorbents for wastewaters: A critical review. Materials 2014, 7, 333–364. [Google Scholar] [CrossRef]

- Shakoor, S.; Nasar, A. Utilization of punica granatum peel as an eco-friendly biosorbent for the removal of methylene blue dye from aqueous solution. J. Appl. Biotechnol. Bioeng. 2018, 5, 242–249. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhang, L.; Cheng, Z. Removal of organic pollutants from aqueous solution using agricultural wastes: A review. J. Mol. Liq. 2015, 212, 739–762. [Google Scholar] [CrossRef]

- Hamzeh, Y.; Ashori, A.; Azadeh, E.; Abdulkhani, A. Removal of acid orange 7 and remazol black 5 reactive dyes from aqueous solutions using a novel biosorbent. Mater. Sci. Eng. C 2012, 32, 1394–1400. [Google Scholar] [CrossRef]

- Alizadeh, N.; Shariati, S.; Besharati, N. Adsorption of crystal violet and methylene blue on azolla and fig leaves modified with magnetite iron oxide nanoparticles. Int. J. Environ. Res. 2017, 11, 197–206. [Google Scholar] [CrossRef]

- Basu, M.; Guha, A.K.; Ray, L. Adsorption of lead on cucumber peel. J. Clean. Prod. 2017, 151, 603–615. [Google Scholar] [CrossRef]

- Kadhom, M.; Albayati, N.; Alalwan, H.; Al-Furaiji, M. Removal of dyes by agricultural waste. Sustain. Chem. Pharm. 2020, 16, 100259. [Google Scholar] [CrossRef]

- Ma, C.M.; Yang, B.Y.; Hong, G.B. Husk of agarwood fruit-based hydrogel beads for adsorption of cationic and anionic dyes in aqueous solutions. Molecules 2021, 26, 1437. [Google Scholar] [CrossRef] [PubMed]

- Dawood, S.; Sen, T.K.; Phan, C. Performance and dynamic modelling of biochar and kaolin packed bed adsorption column for aqueous phase methylene blue (MB) dye removal. Environ. Technol. 2018, 26, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Quansah, J.O.; Hlaing, T.; Lyonga, F.N.; Kyi, P.P.; Hong, S.H.; Lee, C.G.; Park, S.J. Nascent rice husk as an adsorbent for removing cationic dyes from textile wastewater. Appl. Sci. 2020, 10, 3437. [Google Scholar] [CrossRef]

- Wong, S.; Ghafar, N.A.; Ngadi, N.; Razmi, F.A.; Inuwa, I.M.; Mat, R.; Amin, N.A.S. Effective removal of anionic textile dyes using adsorbent synthesized from coffee waste. Sci. Rep. 2020, 10, 2928. [Google Scholar] [CrossRef] [PubMed]

- Dai, Y.; Sun, Q.; Wang, W.; Lu, L.; Liu, M.; Li, J.; Yang, S.; Sun, Y.; Zhang, K.; Xu, J.; et al. Utilizations of agricultural waste as adsorbent for the removal of contaminants: A review. Chemosphere 2018, 211, 235–253. [Google Scholar] [CrossRef]

- Tan, K.B.; Vakili, M.; Horri, B.A.; Poh, P.E.; Abdullah, A.Z.; Salamatinia, B. Adsorption of dyes by nanomaterials: Recent developments and adsorption mechanisms. Sep. Purif. Technol. 2015, 150, 229–242. [Google Scholar] [CrossRef]

- Gan, L.; Li, H.; Chen, L.; Xu, L.; Liu, J.; Geng, A.; Mei, C.; Shang, S. Graphene oxide incorporated alginate hydrogel beads for the removal of various organic dyes and bisphenol A in water. Colloid Polym. Sci. 2018, 296, 607–615. [Google Scholar] [CrossRef]

- Guo, X.; Wang, Y.; Qin, Y.; Shen, P.; Peng, Q. Structures, properties and application of alginic acid: A review. Int. J. Biol. Macromol. 2020, 162, 618–628. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, A.; Mubarak, N.M.; Jannat, F.T.; Ashfaq, T.; Santulli, C.; Rizwan, M.; Najda, A.; Bin-Jumah, M.; Abdel-Daim, M.M.; Hussain, S.; et al. A critical review on the synthesis of natural sodium alginate based composite materials: An innovative biological polymer for biomedical delivery applications. Processes 2021, 9, 137. [Google Scholar] [CrossRef]

- Hu, Z.H.; Omer, A.M.; Ouyang, X.K.; Yu, D. Fabrication of carboxylated cellulose nanocrystal/sodium alginate hydrogel beads for adsorption of Pb(II) from aqueous solution. Int. J. Biol. Macromol. 2018, 108, 149–157. [Google Scholar] [CrossRef] [PubMed]

- Butter, B.; Santander, P.; Pizarro, G.D.C.; Oyarzun, D.P.; Tasca, F.; Sanchez, J. Electrochemical reduction of Cr(VI) in the presence of sodium alginate and its application in water purification. J. Environ. Sci. 2021, 101, 304–312. [Google Scholar] [CrossRef] [PubMed]

- Shao, Z.J.; Huang, X.L.; Yang, F.; Zhao, W.F.; Zhou, X.Z.; Zhao, C.S. Engineering sodium alginate-based cross-linked beads with high removal ability of toxic metal ions and cationic dyes. Carbohydr. Polym. 2018, 187, 85–93. [Google Scholar] [CrossRef] [PubMed]

- Cho, D.W.; Jeon, B.H.; Chon, C.M.; Schwartz, F.W.; Jeong, Y.; Song, H. Magnetic chitosan composite for adsorption of cationic and anionic dyes in aqueous solution. J. Ind. Eng. Chem. 2015, 28, 60–66. [Google Scholar] [CrossRef]

- Perez-Calderon, J.; Santos, M.V.; Zaritzky, N. Reactive RED 195 dye removal using chitosan coacervated particles as bio-sorbent: Analysis of kinetics, equilibrium and adsorption mechanisms. J. Environ. Chem. Eng. 2018, 6, 6749–6760. [Google Scholar] [CrossRef]

- Croisier, F.; Jerome, C. Chitosan-based biomaterials for tissue engineering. Eur. Polym. J. 2013, 49, 780–792. [Google Scholar] [CrossRef]

- Vakili, M.; Rafatullah, M.; Salamatinia, B.; Abdullah, A.Z.; Ibrahim, M.H.; Tan, K.B.; Gholami, Z.; Amouzgar, P. Application of chitosan and its derivatives as adsorbents for dye removal from water and wastewater: A review. Carbohydr. Polym. 2014, 113, 115–130. [Google Scholar] [CrossRef]

- Safie, N.N.; Zahrim, A.Y. Recovery of nutrients from sewage using zeolite-chitosan-biochar adsorbent: Current practices and perspectives. J. Water Process. Eng. 2021, 40, 101845. [Google Scholar] [CrossRef]

- Qi, J.; Li, Y.; Majeed, H.; Goff, H.D.; Rahman, M.R.T.; Fang Zhong, F. Adsorption mechanism modeling using lead (Pb) sorption data on modified rice bran-insoluble fiber as universal approach to assess other metals toxicity. Int. J. Food Prop. 2019, 22, 1397–1410. [Google Scholar] [CrossRef]

- Patel, M.; Naik, N. Gamma-oryzanol from rice bran oil-a review. J. Sci. Ind. Res. 2004, 63, 569–578. [Google Scholar]

- Kong, Y.; Zhuang, Y.; Han, Z.; Yu, J.; Shi, B.; Han, K.; Hao, H. Dye removal by eco-friendly physically cross-linked double network polymer hydrogel beads and their functionalized composites. J. Environ. Sci. 2019, 78, 81–91. [Google Scholar] [CrossRef] [PubMed]

- Chatterjee, S.; Lee, M.W.; Woo, S.H. Adsorption of congo red by chitosan hydrogel beads impregnated with carbon nanotubes. Bioresour. Technol. 2010, 101, 1800–1806. [Google Scholar] [CrossRef] [PubMed]

- Mohammadi, A.; Doctorsafaei, A.H.; Zia, K.M. Alginate/calix[4] arenes modified graphene oxide nanocomposite beads: Preparation, characterization, and dye adsorption studies. Int. J. Biol. Macromol. 2018, 120, 1353–1361. [Google Scholar] [CrossRef] [PubMed]

- Shi, Q.X.; Li, Y.; Wang, L.; Wang, J.; Cao, Y.L. Preparation of supported chitosan adsorbent with high adsorption capacity for Titan Yellow removal. Int. J. Biol. Macromol. 2020, 152, 449–455. [Google Scholar] [CrossRef]

- Elwakeel, K.Z. Removal of reactive black 5 from aqueous solutions using magnetic chitosan resins. J. Hazard. Mater. 2009, 167, 383–392. [Google Scholar] [CrossRef]

- Wu, M.; Chen, W.; Mao, Q.; Bai, Y.; Ma, H. Facile synthesis of chitosan/gelatin filled with graphene bead adsorbent for orange II removal. Chem. Eng. Res. Des. 2019, 144, 35–46. [Google Scholar] [CrossRef]

- Kang, S.; Qin, L.; Zhao, Y.; Wang, W.; Zhang, T.; Yang, L.; Rao, F.; Song, S. Enhanced removal of methyl orange on exfoliated montmorillonite/chitosan gel in presence of methylene blue. Chemosphere 2020, 238, 124693. [Google Scholar] [CrossRef]

- Chowdhury, S.; Saha, P. Sea shell powder as a new adsorbent to remove basic green 4 (malachite green) from aqueous solutions: Equilibrium, kinetic and thermodynamic studies. Chem. Eng. J. 2010, 164, 168–177. [Google Scholar] [CrossRef]

- Ong, S.T.; Lee, C.K.; Zainal, Z. Removal of basic and reactive dyes using ethylenediamine modified rice hull. Bioresour. Technol. 2007, 98, 2792–2799. [Google Scholar] [CrossRef] [PubMed]

| CV onto MRAHB | RB4 onto MRCHB | |

|---|---|---|

| qexp (mg/g) | 96.29 | 74.71 |

| PFOM | ||

| k1 (1/min) | 0.0043 | 0.0032 |

| qe (mg/g) | 49.18 | 64.83 |

| R2 | 0.801 | 0.940 |

| PSOM | ||

| k2 (g/mg·g) | 5.69 × 10−4 | 8.11 × 10−5 |

| qe (mg/g) | 88.49 | 80.00 |

| R2 | 0.997 | 0.869 |

| IPDM (stage 1) | ||

| kid (g/mg·min0.5) | 7.54 | 3.53 |

| C | 3.666 | −5.064 |

| R2 | 0.977 | 0.764 |

| IPDM (stage 2) | ||

| kid (g/mg·min0.5) | 3.03 | 1.95 |

| C | 38.845 | 18.099 |

| R2 | 0.987 | 0.988 |

| CV onto MRAHB | RB4 onto MRCHB | ||||||

|---|---|---|---|---|---|---|---|

| Temperature (°C) | 30 | 40 | 50 | 60 | 30 | 40 | 50 |

| Langmuir | |||||||

| qm (mg/g) | 454.55 | 400.00 | 384.62 | 357.14 | 133.33 | 192.31 | 212.77 |

| KL (L/mg) | 0.011 | 0.006 | 0.005 | 0.004 | 0.014 | 0.011 | 0.015 |

| R2 | 0.955 | 0.976 | 0.966 | 0.964 | 0.993 | 0.985 | 0.994 |

| Freundlich | |||||||

| KF (mg/g)(L/mg)1/n | 10.33 | 1.26 | 1.60 | 2.16 | 26.80 | 21.67 | 32.04 |

| N | 1.46 | 0.72 | 0.74 | 0.73 | 4.10 | 2.97 | 3.45 |

| R2 | 0.969 | 0.999 | 0.999 | 0.999 | 0.776 | 0.669 | 0.451 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hong, G.-B.; Yu, T.-J.; Lee, H.-C.; Ma, C.-M. Using Rice Bran Hydrogel Beads to Remove Dye from Aqueous Solutions. Sustainability 2021, 13, 5640. https://doi.org/10.3390/su13105640

Hong G-B, Yu T-J, Lee H-C, Ma C-M. Using Rice Bran Hydrogel Beads to Remove Dye from Aqueous Solutions. Sustainability. 2021; 13(10):5640. https://doi.org/10.3390/su13105640

Chicago/Turabian StyleHong, Gui-Bing, Tzu-Jui Yu, Hsueh-Chia Lee, and Chih-Ming Ma. 2021. "Using Rice Bran Hydrogel Beads to Remove Dye from Aqueous Solutions" Sustainability 13, no. 10: 5640. https://doi.org/10.3390/su13105640

APA StyleHong, G.-B., Yu, T.-J., Lee, H.-C., & Ma, C.-M. (2021). Using Rice Bran Hydrogel Beads to Remove Dye from Aqueous Solutions. Sustainability, 13(10), 5640. https://doi.org/10.3390/su13105640