Abstract

As part of a project investigating in the potential greenhouse gas mitigation effect of the increased use and production of mass timber worldwide, a comparative study was carried out to show the potential benefit of mass timber use in buildings in central Europe. After designing a mass timber building functionally equivalent to an existing conventional building, cradle to grave life cycle assessments (LCA) were calculated. The reference is an eight-story building with mixed use in Vienna, originally built in reinforced concrete. Global Warming Potential (GWP) is defined as the central parameter of interest. Calculated life cycle phases are A1–A3 (resource to production), A4 and A5 (transport to site and construction, respectively), B4 (replacement in the use phase), and C1–C4 (End of Life), as well as D (benefits and loads beyond the building life). It can be shown that the total mass of the timber building is 47% lower than of the concrete building. Considering life cycle phases A1 to A5, the timber building shows 18% less embodied carbon. Taking the whole building life cycle and the operational energy use (B6) into account, differences in GWP are much lower, as the heating system, though equipped with high efficiency and clean Austrian electricity grid mix, has much higher impact than the other phases.

1. Introduction

The building sector plays a major role when it comes to greenhouse gas (GHG) production. According to [1], almost 40% of energy-related greenhouse gas emissions are from the building and construction sector. During the life cycle of a building, two major phases for the emission of greenhouse gases have been identified—the energy demand during the use phase and in the production phase of the building products [2]. In Europe, the energy demand of the use phase, and related GHG emissions, already has been optimized during the last decades as building types such as Passive- or Plus-Energy Houses have been developed [3]. Therefore, the GHG emissions from building materials manufacturing became more important and, depending on the building type, dominant as well [4], and account for 11% of GHG emissions from the sector [1].

Several comparative LCA investigations have been carried out and published already [5,6,7,8]; Himes and Busby summarized the peer reviewed and comparable articles in a meta-analysis of mid-rise buildings using mass timber and conventional building materials [9]. They showed that substituting conventional building materials by mass timber leads to a reduction in CO2 emission during construction phase by an average of 69%. Additionally, Hafner concluded possible savings of GHG emissions in [10] between 9% and 48% for the life cycle phases A and C. Dodoo laid his focus in [11] on the implication of energy efficiency and the effect of thermal mass, but also concluded that carbon emissions are much higher for concrete than for the investigated wood frame building.

A good overview on methodological issues is presented by Gustavsson in [12], with emphasis on the material properties of concrete and timber. A different approach to tackle methodological issues is carried out by Frischknecht in [13], with kind of a round robin test of national approaches of building assessments with the goal to identify national discrepancies as a basis for harmonization. Results in [13] show huge deviations between the national approaches, which mainly result from the background data used, the scope of the assessment and the reference study period applied.

This article presents findings of a part of phase one of the research program “Assessing the Climate and Forest Impacts of Building with Mass Timber”. This research program has the aim to assess the climate and forest impacts of building with mass timber. Phase 1 is dealing with comparative LCAs of conventional and mass timber buildings worldwide. In this context, results of this investigations deliver input data, which is representative for the regions of central and western Europe.

A pair of model buildings are designed for the central Europe region according to local building codes in Vienna, Austria. An existing new conventional building was selected which fulfills the requirements of eight stories (two with offices and commercial zones and six for residential use). A mass timber building with similar thermal properties is modelled for functional equivalent comparisons with the conventional building (e.g., equivalent height, interior floor space, interior divisions, and intended uses). Focus of the comparative LCA is on embodied carbon and primary energy. The whole life cycle is considered, as well as the additional module D (benefits and loads outside the investigated system) according to ISO 21930, EN 15978, and EN15804 [14,15,16]. Finally, an analysis of the results is carried out, serving as a basis for further steps in the subsequent phases of the mentioned research program.

2. Materials and Methods

In this study, the results of life cycle analyses of the same building, made of different materials, are compared. Therefore, several steps had to be carried out before starting the comparative LCA. This includes the search for an appropriate reference building and the analysis regarding thermal and building acoustic properties, as well as its structural system. Then, a similar building, made of mass timber, is modelled in a way that the thermal performance of the two buildings is exactly the same. This property is proofed by the energy performance certificates. Considering statics, as well as legal acoustic requirements on the real site and fire safety requirements, resulted in a model building that can be regarded as a wooden functional twin of the reference building made of reinforced concrete.

2.1. Architectural Building Designs and Assumptions

The selected reference construction is a multi-story building with up to eight stories in Vienna, Austria. The lower two stories are for commercial use (offices and a dancing studio) and the rest of the building are residential dwellings. It is a conventional building, built of reinforced concrete with flat roofs, partly used as private or shared-use terraces. An idea of the building is given in Figure 1, with a picture and the floor plan. The complete documentation, including building permit plans, are available for this building.

Figure 1.

Selected reference building during construction (a) and (representative) floor plan of the first floor (b).

2.1.1. Building Model Assumptions

In general, building components which are the same in both buildings (conventional and mass timber) are not part of the LCA. This methodological approach was determined for all building LCA calculating partners in the mass timber research project as a basic assumption. This can include large functional equivalent elements, such as cladding panels or underground garages. It is assumed that they are not affected by the change in the load bearing material. Similarly, flooring, interior decorations, and bathroom facilities are also not modelled.

The mass timber building model follows current building codes in Austria (and local regulations in Vienna) as developed to a preliminary design level. Modifications to fulfil the required sound insulation and the improved thermal insulation caused by the replacement of concrete for mass timber (mainly cross laminated timber—CLT) have been considered. Additionally, an appropriate wall board planking is considered for fire protection reasons. Nevertheless, fire protection follows an overall concept, and not only properties of building elements. Staircases and, of course, elevators are not changed and kept in concrete for fire safety reasons and, hence, are not part of the LCA calculation.

2.1.2. Architectural Building Designs

A functional equivalence approach is taken for the building modeling, which does not model elements that are the same in both timber and concrete buildings. This includes elements such as exterior façade materials, windows, and underground garages. Other areas, such as bathroom fixtures, furniture, kitchen appliances, countertops, mechanical soffits, and interior floor coverings, such as hardwood floors or carpets, etc. are also not modeled, as these areas would be the same for both the mass timber and concrete buildings.

However, wall and floor assemblies that are materially impacted, such as the acoustical ratings (both sound and impact) between floors and common walls, or exterior insulation on exterior walls, given the higher thermal performance of mass timber, are modelled. Additional consideration is given to the fire (and life safety) performance of the mass timber construction, and all mass timber assemblies following the requisite code performances as required in the national Austrian building code concerning fire protection [17] provisions for buildings. Gypsum wall board (GWB) is assumed as the required non-combustible protection, as designed to fulfil the fire resistance ratings of the wall/floor assemblies. GWB protection is required only for the mass timber assemblies, but not modeled for the equivalent non-combustible concrete assemblies. For fire protection, mass timber building components are designed to fulfil F60. This has been proven by comparing the measures with the components shown in the dataholz database [18], which the author also contributed to.

2.1.3. Energy Performance and HVAC

For thermal insulation, sound insulation, and fire protection, the building permission certificates of the conventional building are used. Mass timber components have been designed in a way that thermal insulation is, as far as possible, the same (thermal transmission coefficient). Exceptions are made when sound insulation requires more or additional insulation material to fulfil requirements of Austrian building code [19]. This leads to the fact that thermal insulation of the mass timber building is slightly better than the one from the conventional building. Nevertheless, as this is for sound insulation reasons, energy demand and related GWP emissions are calculated with the same energy demand as the conventional building.

The energy performance certificate is the basis for the LCA of the use phase. The building is heated by two sole-water heat pumps with monovalent operation mode with depth probe. For the energy supply, the current Austrian electricity grid mix is assumed, based on ecoinvent [20] v3.5 database. In total, an end energy demand of 254,720 kWh/a (electricity) for power supply of the whole building is required (including heating energy with heat pumps mentioned, with total operating factors—3.34 and 2.6 according to the energy performance certificate of the conventional building).

2.2. Structural Assumptions for the Virtual Mass Timber Building

Usually, change to a lighter material entails changes in the required foundation. In this special case, due to the poor ground quality, gravel pile foundation is required, and a concrete slab is used. The so called “Rüttelstopfverfahren” has been applied for compacting the soil. In this technique, gravel is filled into the shaking column and pressed laterally into the adjacent ground. As this method is quite expensive to improve the given ground, reduction in gravel piles to half of the amount, and a corresponding increase in thickness of the concrete foundation slab, is common practice to get a cheaper construction (a more practical, but less ecological approach). In addition, detailed structural assumptions are:

Exterior walls: Mass timber (CLT) design with increasing thickness towards the lower stories and the same thermal insulation as the reference building, as well as an appropriate sound insulation for the situation of the building near the railway track. In case of External Thermal Insulation Composite System (ETICS), the plaster is considered, as this is a substantial part of the system. Additionally, fire protection issues are considered.

Balconies: CLT instead of concrete, with additional moisture protection.

Separating floors between dwellings: Designed according to the typical LCA floor structure in Austria. Consideration is given to airborne and impact sound insulation requirements for multifamily dwellings and offices (which are the same in Austria), as well as fire protection issues.

Separating walls between dwellings (lightweight): As they are built from metal studs and gypsum wall board planking (usual assembly in Austria), they are not changed and not considered.

Separating walls between dwellings and staircase/elevator (reinforced concrete): For fire safety reasons, separating walls to staircases are kept in concrete and therefore they are not changed or considered in the calculations.

Internal walls (not load bearing): These are not considered, as they are always lightweight and made of gypsum wall board with metal studs. This is the same construction type as it would be realized in CLT buildings as well (usual assembly in Austria).

Floor between cellar and first floor: This is not changed and not considered.

Roofs and terraces: Conventional structures changed to CLT structures by considering thermal insulation, and requirements of sound insulation and fire protection.

Installation shaft F90 (lightweight): Three layers of gypsum wall board—not changed and not considered.

Building components or materials which are replaced within the service life of the building are considered in the calculation of the whole life cycle A to D in the life cycle phase B4. Guidelines are provided in [21], with a list of service lives of materials, or rather building components or parts of building components, as service life always depends on application and combination with other materials or building parts.

2.3. LCA Approach

As defined by the International Organization for Standardization in ISO 14040 and ISO 14044 [22,23], LCA is a multiphase process consisting of several interconnected steps, and their outcomes are based on goals and purposes of a particular study. The methodology for Life Cycle Assessments for building products and buildings is provided in EN 15978. Calculation is carried out with software Eco2soft—methodological assumptions are provided in IBO [24], and are based on ecoinvent v2.2 for materials and ecoinvent v3.5 for energy datasets.

2.3.1. General Assumptions for the LCA

Functional equivalent: This study follows closely EN 15978 and ISO 21930, which require identification of a functional equivalent for the building to enable a valid basis for future comparisons to other buildings. According to EN 15978, a functional equivalent is “the quantified functional requirements and/or technical requirements for a building or an assembled system (part of works) for use as a basis for comparison.” In other words, the functional equivalent is a set of design criteria that both buildings must have in common to ensure a serious comparison. The functional equivalent is described above in Section 2.1 Architectural Building Designs and Assumptions.

System boundary: The system boundary defines which life cycle activities are included in the analysis. The various processes that occur at each stage are classified and grouped in “modules”, labeled in alpha-numeric design A1–C4. This modular structure provides a consistent and transparent reporting format for building assessments. The system boundary for this assessment is the whole life cycle from A to C and includes module D (potential benefits and loads outside the boundaries of the product system). From the use phase (B), only B4 (replacement) and B6 (operational energy of the building) is calculated, as the other phases in B usually have a negligible impact on the results of a LCA. Crucial for the results of phase B4 are basic assumptions of the service life of building components and their related rate of replacement during the service life of the building. Applied service lives of the most important materials are given in [21], taking their application and combination with other materials in the building component into account.

Indicators for assessment: According to the goal of phase 1 of the given research project, emphasis was placed on a selected set of indicators, including GWP (Global Warming Potenial) (divided into GWPfossil and GWPmaterial) and indicators showing use of primary energy resources RPRE, NRPRE, RPRM, and NRPRM ( Renewable PRimary energy carrier used as Energy, Non-Renewable PRimary energy carrier used as Energy, Renewable PRimary energy in Material, and Non-Renewable PRimary energy in Material).

2.3.2. Specific Methodological Assumptions

Transport (A4) is calculated in tkm, assuming default trucks in Eco2Soft building LCA software based on ecoinvent database v2.2. All 100% of materials (all the ones calculated in the LCA) are considered in this phase.

The construction and installation phase, referred to as the A5 phase in the life cycle assessment, considers all the ground and onsite works for building erection, heating/cooling and ventilation provided, and onsite water and waste management, etc. For this phase, an equation for the average energy consumption of a crane on the construction site from Athena Institute [25] is considered. Floor area averaged height (8.73 m) is calculated, as well as the associated diesel fuel consumption from the material masses. The ecoinvent process “Diesel burned in building machine (market)” gives a value for GWP per MJ, which is transformed into liter (taking the net calorific heating value of diesel into account). Moreover, emissions resulting from the energy consumption of the machine carrying out the Rüttelstopfverfahren (foundation with compacted gravel piles) are considered. Such data are available in IBO internal databases for foundation works.

Carbonation (CO2 uptake of concrete) is calculated according to [26]. A constant uptake is assumed (other than in reality, as it is a non-linear diffusion process) during use phase, but only of the inner surface, as the outer one is covered with ETICS which prevents the CO2 diffusion process in the use phase B. The usual way of End of Life of concrete in Austria is the use as crushed stones for roadbeds. It is assumed that no carbonation is taking place in this application with an unlimited time horizon, as the concrete is covered, and no data is available for this application.

Specific material issues are considered for mass timber (CLT). For the necessary mounting devices of this product, the ecoinvent process for galvanized steel was used. This process assumes that the 6% contribution of zinc (as use-surface) is not recycled, but the steel is recycled completely (1 kg Steel, electric, un- and low-alloyed, at plant/RER S).

End of Life, phase C, is calculated based on Eco2soft data, and therefore End of Life (EoL) processes from ecoinvent v2.2. The assumptions for waste processing follow the usual practices in Austria:

- Mineral materials (concrete)—disposal or comparable downcycling.

- Metals—recycling.

- Wood (from building sites) and plastics (carbon containing materials)—incineration with energy recovery.

- Thermal treatment of plastics and wood: According to Austrian legal regulation for disposal of building products [27], plastics and wood are not allowed to be landfilled, but must be recycled or burned in waste incineration plants (MVA) due to their carbon and energy content;

- Currently wood residues from building sites are always burned in MVAs, as recycling requires expensive chemical analysis of the wood product to ensure absence of hazardous substances. These types of analyses are currently not in operation in Austria for wooden construction site residues [28];

- For energy recovery of (mass) timber and plastic residues, the following scenario is assumed as the most relevant in Austria (and used in environmental product declarations (EPD) as well): Energy recovery is divided into 1/3 electricity, with an efficiency of 17%, and 2/3 heat, with an efficiency of 75% [29];

- Mass timber (CLT) consists of wood and glue (mainly MDI—a polyurethane-based adhesive). The following heating values have been considered when CLT is incinerated: Lower heating value (u = 10%) is 17.25 MJ/kg for softwood, and lower heating value of the adhesive is 27.61 MJ/kg (ecoinvent).

Relevant processes for life cycle phase D (net benefits and loads beyond the system boundary) are:

- Steel for reinforcing concrete: According to the EPD of an Austrian producer of reinforcing steel, only recycling steel is used. This leads to the fact, that no benefits in phase D can be applied. Nevertheless, 63% of primary steel is assumed in average reinforcing steel in Austria, which seems to be a reasonable assumption;

- Ecoinvent process for secondary steel used: 1 kg Steel, electric, un- and low-alloyed, at plant/RER S,

- Aluminum consists of 68% primary material. Ecoinvent process used for secondary aluminum is: 1 kg aluminum, secondary, from old scrap, at plant/RER S;

- Incineration of wood and plastics considering individual heating values.

3. Results

Given results are always related to the functional unit, which is defined as 1 m2 net floor area. The whole building offers a net floor area of 3528.65 m2.

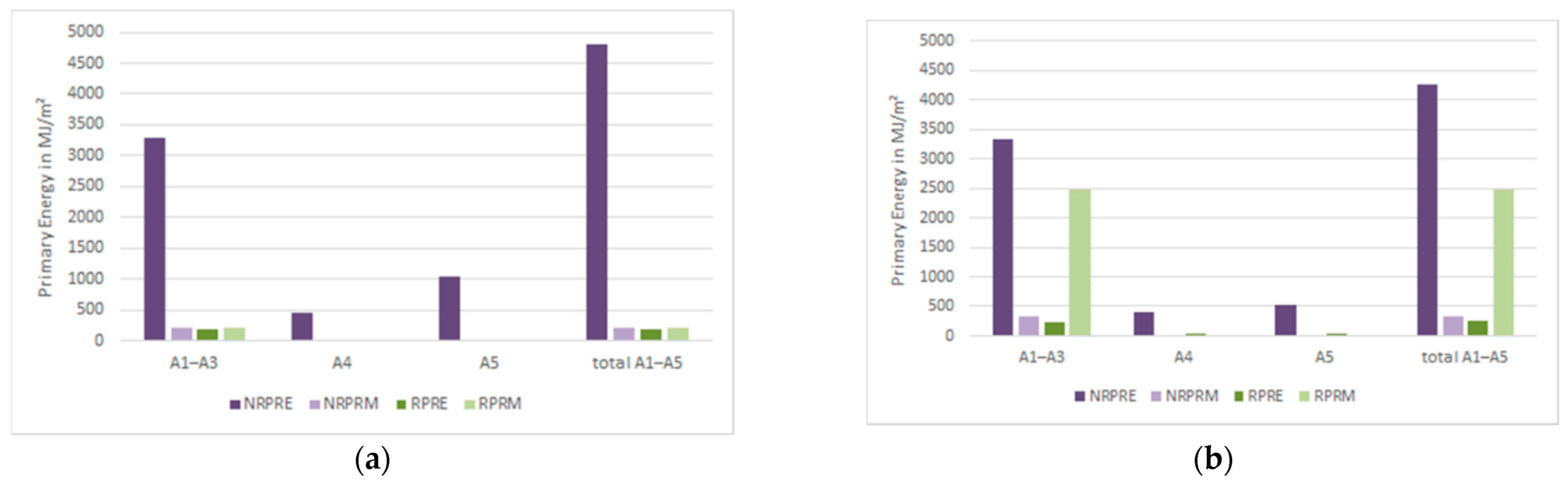

3.1. Building Mass

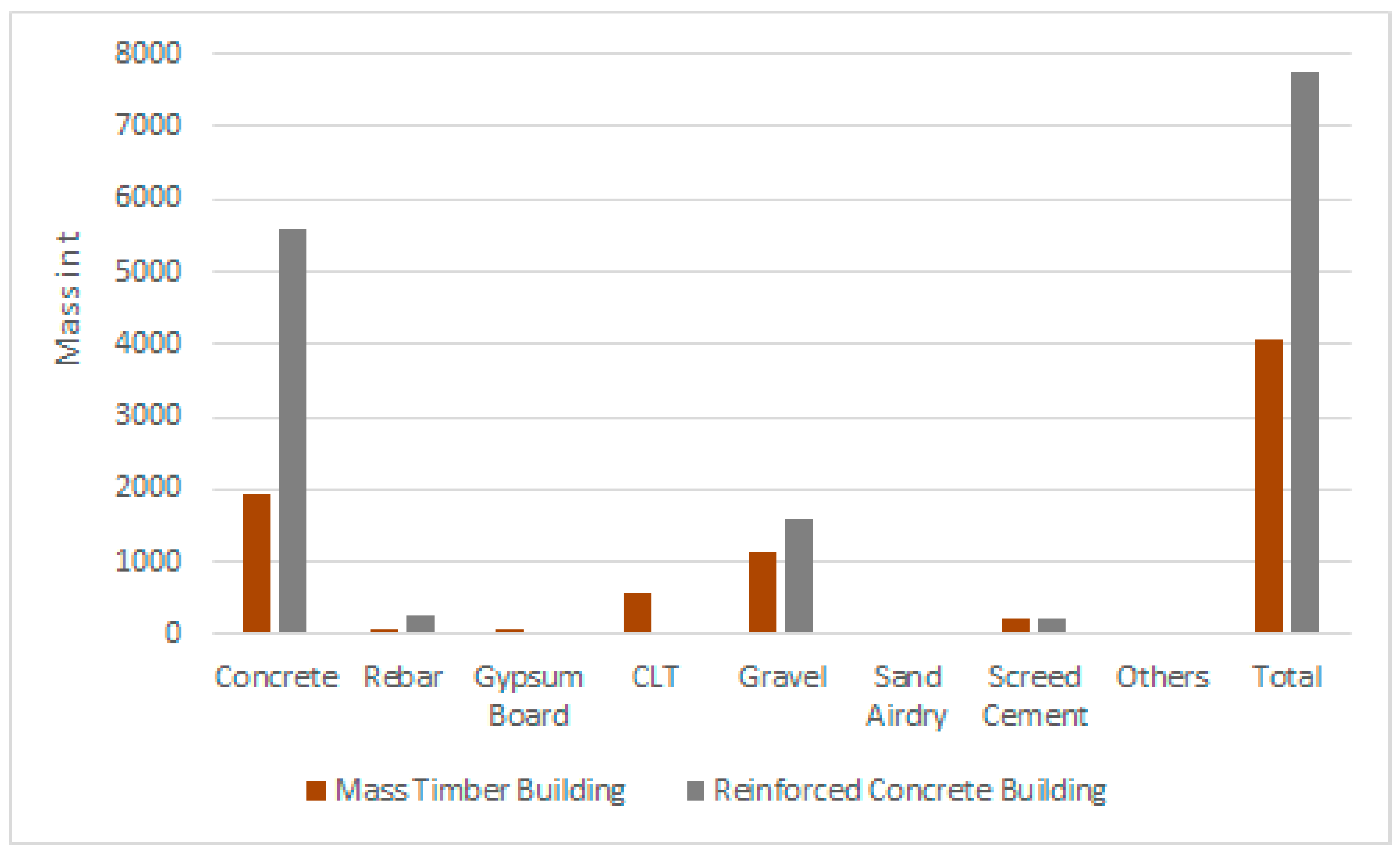

For all building designs, concrete represents the largest contribution by mass (Figure 2). As the foundation is based on compressed gravel piles, gravel takes a large share of the mass as well. For timber buildings, the density of the wood (usually spruce in the Austrian case) is assumed with 475 kg/m3, which is given by the producer of the CLT. Detailed figures of the building mass by material are shown in Appendix A, Table A1.

Figure 2.

Material contribution by mass for eight-story concrete and mass timber building designs in the central Europe region (CE).

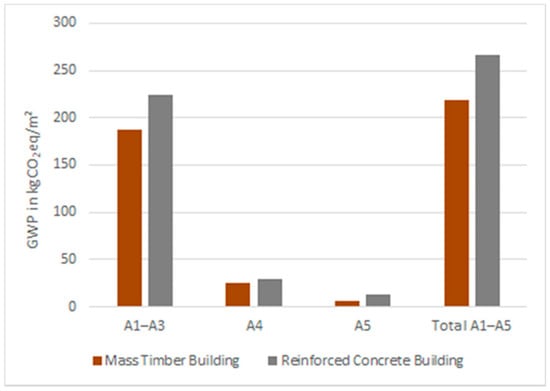

3.2. Embodied Carbon—GWP

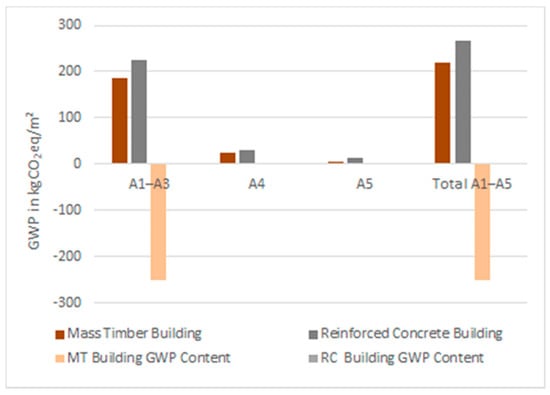

3.2.1. GWP in the Production and Construction Phases (A1–A5)

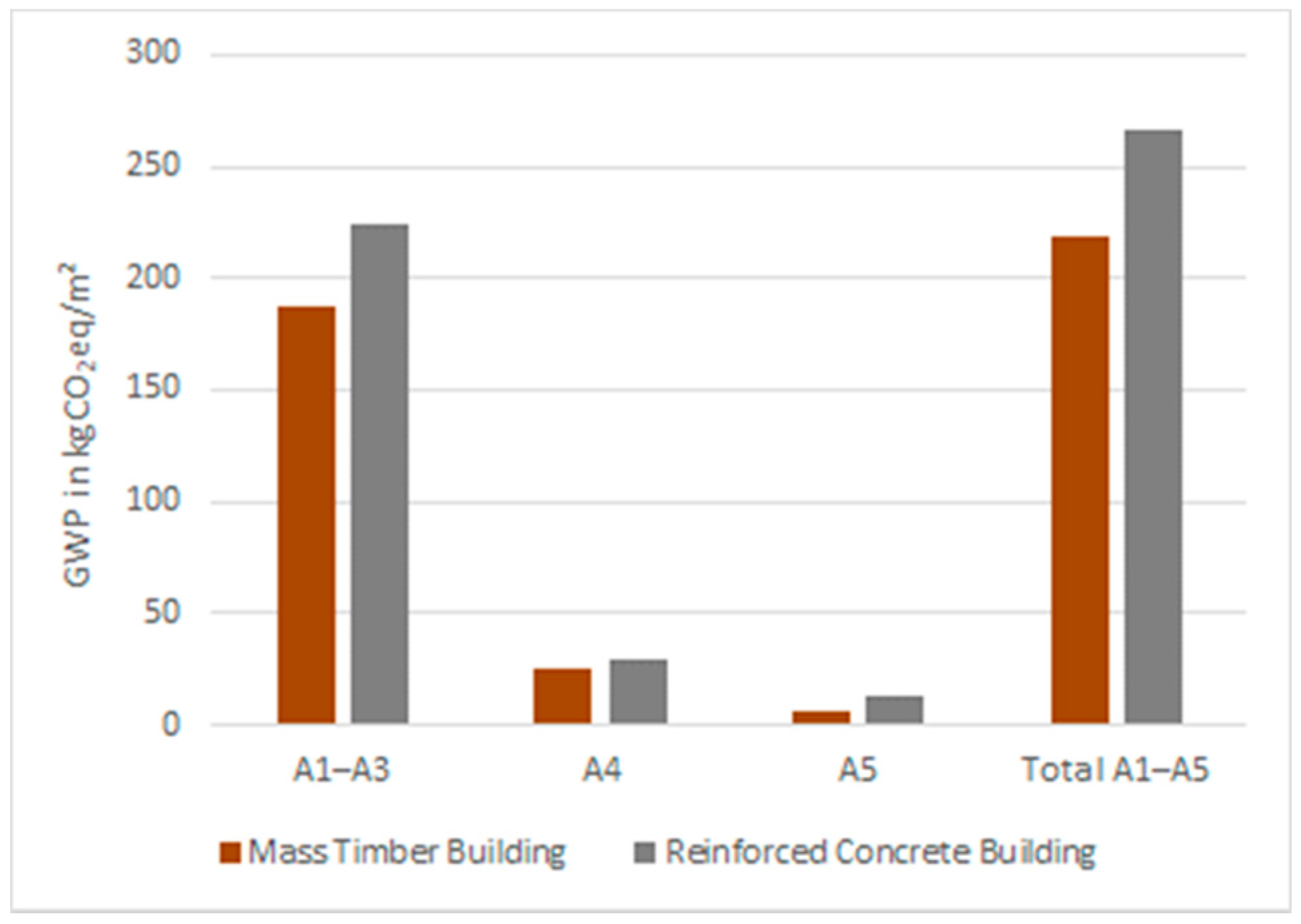

The building embodied carbon is the total global warming potential (GWP) associated with carbon emissions from cradle to gate of all the manufacturing of materials, transportation, and installation of construction materials. Embodied carbon, expressed as kg of CO2eq (equivalents of carbon dioxide), includes greenhouse gas (GHG) emissions released due to the manufacture of all materials, transportation, and installation of construction materials. The expression is used to encompass the building life cycle assessment stage A1–A5 within the system boundary. The total embodied carbon or GWP of the central European timber and concrete building designs shown in Figure 3 are not divided into GWPfossil and GWPbiogenic, as the used software Eco2soft only allows the differentiation between GWPfossil and GWPbiogenicMATERIAL, which is the GWP of the stored carbon in timber.

Figure 3.

Total embodied carbon as measure by kg of CO2eq (GWP) for mass timber and concrete building designs, CE.

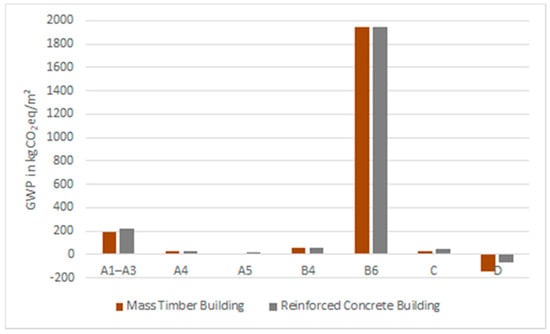

3.2.2. GWP—Whole Life Cycle (A–D)

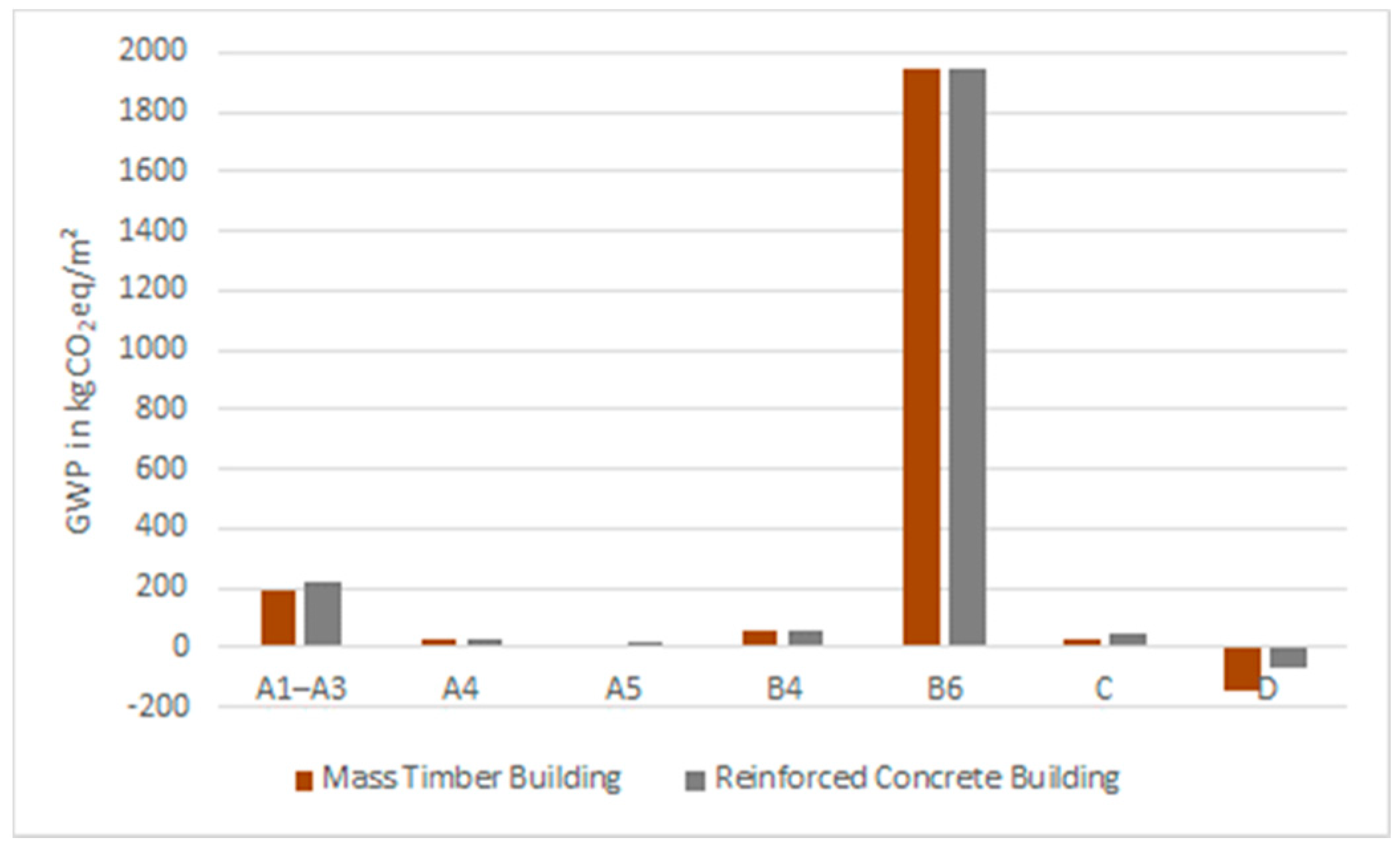

Examining the results for the whole life cycle, including D (benefits and loads beyond the life cycle), the dominant GWP impact is the energy use during the 100-year service life of the building. Although an efficient heat pump is used, both buildings are well insulated, and the Austrian grid mix provides relatively low-carbon electricity (large share of hydroelectric power plants), the building’s energy consumption over 100 years accounts for the most important contribution (1944 kgCO2eq/m2) to the life cycle’s GWP (Figure 4). The negative GWP of the concrete building mainly results from the recycling of the steel reinforcement of the concrete.

Figure 4.

Comparison of GWPfossil of eight-story timber and concrete buildings, whole life cycle, including D per m2, 100-year service life, CE.

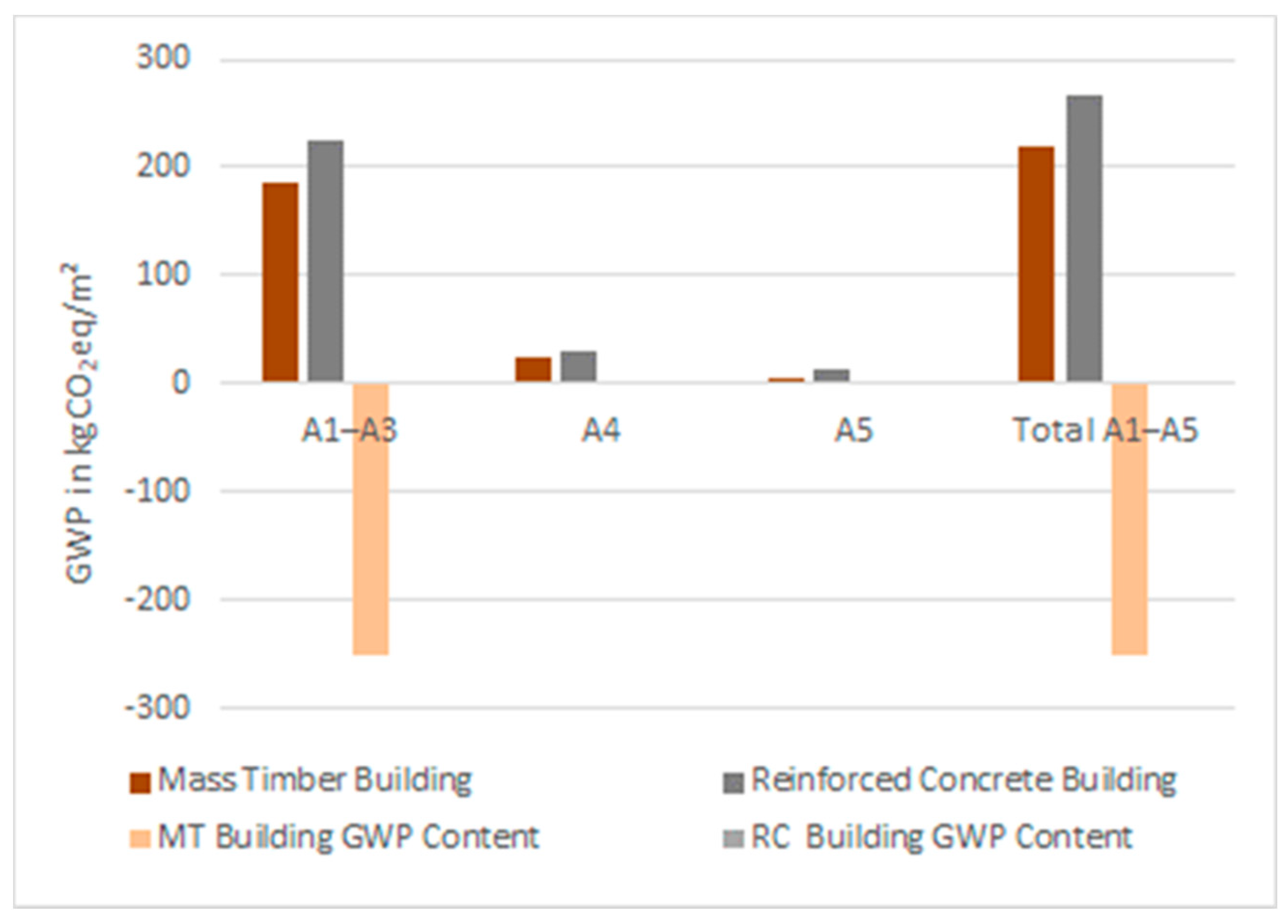

3.3. GWP—Carbon Storage and Sequestered CO2

Each building using wood products stores carbon. The CO2 stored in the form of carbon in the timber itself (around 50%), according to [30], leads to a net negative GWP, shown in Figure 5. The total carbon (carbon content) in tons of the timber building is 239 t (877 t CO2eq), and 6 t of the reinforced concrete building. In the central Europe building design, more carbon is stored in the mass timber building than is released (fossil and biogenic based) during production (A1–A5).

Figure 5.

Total embodied carbon and carbon content (light) in kg of CO2eq (GWP) for eight-story mass timber (MT) and reinforced concrete (RC) building designs, CE.

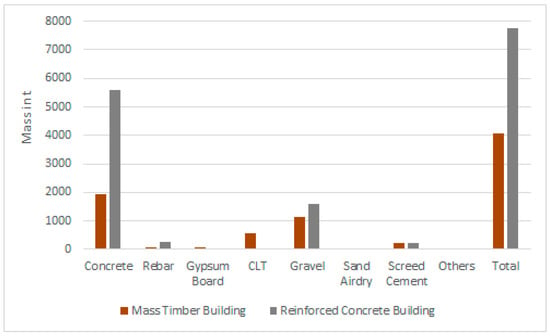

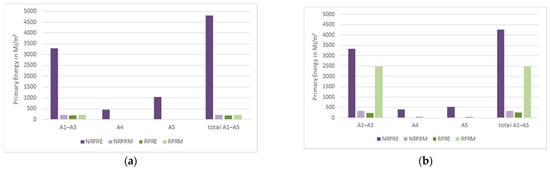

3.4. Energy Use—Primary Energy

Both renewable and non-renewable energy are used in the production of the materials used in the building designs. Embodied energy is the sum of all energy consumed by all of the processes associated with the construction of a building and production of building materials, from the mining and processing of natural resources, to manufacturing, transport, and product delivery. Total (A1–A5) non-renewable energy (fossil and nuclear) was lower in the mass timber building than concrete.

Renewable energy is used almost exclusively for the production of softwood lumber feedstock (A1–A3) used to produce CLT and glulam. For mass timber, most of the renewable energy is generated by combustion of biomass (sawdust, chips, and other waste from the milling processes) at the mill site. The total renewable energy used in the mass timber building represented 37% of the total energy, while non-renewable energy represented 93% of the energy used in the concrete building design. In general, total embodied energy was higher in the mass timber building (7334 MJ/m2) compared to the concrete building (5415 MJ/m2). A detailed compilation for the results of the different primary energy types can be found in Figure 6.

Figure 6.

Comparison of primary energy (PE) of the eight-story reinforced concrete (a) and mass timber (b) building, CE.

4. Discussion

A comparative LCA study of an existing concrete building and a functionally equivalent mass timber building was carried out with focus on the life cycle phases A1 to A5. Special emphasis was on the environmental indicator GWP (global warming potential) and the parameter describing resource use PE (primary energy). In both parameters, the mass timber building outperformed the concrete building. Nevertheless, when results of the Austrian study are compared to US results, a significantly lower difference between the two building types can be shown. Whilst US partners found differences in GWP of 40 to 50%, the Austrian study only resulted in an 18% lower fossil GWP of the mass timber building. The rather low difference results on one hand from the economic decision for a reduction in the foundation gravel piles, with implicit increasing thickness of the concrete slab of the mass timber building. On the other hand, the environmentally worst process for mass timber in the baubook database [31] was selected. Both issues led to a rather unfavorable result for the mass timber building, and an actually significantly higher GWP reduction potential of mass timber application. Compared to the 12-story high rise comparative study of [7], with a resulting 20.6% reduction in the mass timber building, our results seem to be quite close, although, according to [10], the GHG reduction potential decreases with the height of the building. Nevertheless, taking European studies, such as Hafner [10], into account, where results of GWP for phases A and C are compared, the Austrian result (20% regarding A and C) is quite good in the range of the results of several multi-story buildings (between 9 and 40% lower GHG emissions of the wood buildings) examined in the German investigation.

The given results are also quite similar to the mass timber–concrete comparative LCA for the construction phase (A1–A5) of a multi-story building presented in [12]. GHG emissions of the concrete building are 242, and the emissions of the mass timber building 142 kgCO2-eq per m2, compared to 267 and 219 kgCO2-eq per m2, respectively, in the given investigation.

Taking carbon sequestration into account, results for mass timber show a slightly negative GWP impact for phases A1 to A5. Including phase C as well, this advantage for CLT is gone, as the benefit of temporary carbon storage is not currently respected in relevant standardization, and CO2 always has to be calculated as released at the end of the life cycle, although there are comprehensive methods available for the calculation of temporary carbon sequestration, as summarized in [32].

Finally, it should be pointed out that, although the investigated building is well insulated (good low energy standard in Austria), equipped with an efficient heat pump, and powered with the relatively clean Austrian grid mix (large share of hydro power), the environmental impact of the operational energy use (B6) of the building is about seven times higher than the impact of the building materials over the whole life cycle. However, the outcome of 19.44 kgCO2-eq per m2 per year for B6 seems to be in line with findings in [13], for example, where the variation the national assessment results varied between 7.9 and 45 kg. As the main reason for the differences can be found in the GHG emissions of the electricity mixes used in the different counties, according to [13], the relatively low carbon mix in Austria, despite the fact that the whole energy consumption of the building was considered, leads to a result near the lower threshold. Another important aspect to explain the large differences between construction related emissions (A, B4, and C) and emissions from the energy supply (B6), is the chosen methodologic approach to include only building components, which are affected by the change in the load bearing material and not the whole building. This methodological decision also explains the relatively low GHG results for both buildings (concrete 362.74 and CLT 300.61 kgCO2-eq per m2) compared to national results in [13]. Another reason is the specific kind of concrete used, which allows extra slim concrete building elements (with related lower GHG emissions) and, of course, the CLT with lower GHG emissions during production stage in general.

5. Outlook

The present investigation, as well as several others mentioned and cited in this article, show the tremendous potential of mass timber for the substitution of conventional building materials such as reinforced concrete as a measure to slow down climate change. Evidence for the substitution potential for mass timber, replacing building materials typically applied to multi-story buildings in central Europe region, has been provided. However, this is not the only benefit the application of timber implicates.

Another important issue, also mentioned in this article, is the ability of wood to sequester CO2 from the atmosphere during the growth phase and to store it as carbon. This temporary carbon storage delays CO2 emissions for as long as the wooden building product is in use and not incinerated. However, this aspect still is not respected in the standardized methodologies for life cycle assessments of building products [33]. The inclusion of temporary carbon storage needs further investigation, and a convincing approach, in order to include this material characteristic of timber into the corresponding standards, as it can be regarded as an essential contribution to tackle climate change.

Author Contributions

Conceptualization, F.D.; methodology, F.D. and H.F.; software, I.D.; validation, F.D., M.W. and H.F.; formal analysis, M.W. and I.D.; investigation, F.D.; resources, F.D.; data curation, M.W.; writing—original draft preparation, F.D.; writing—review and editing, F.D., I.D., and M.W.; visualization, F.D.; supervision, H.F.; project administration, F.D.; and funding acquisition, F.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research was financially supported by The Nature Conservancy.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Acknowledgments

The authors acknowledge the valuable support of Niko Kumer, research manager at Stora Enso Wood Products Austria GmbH, in fire safety and structural engineering issues concerning CLT, as well as the assistance of Iztok Šušteršič, research group leader for Sustainable Building with Renewable Materials at InnoRenew CoE, Slovenia, in issues concerning foundation dimensions.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Table A1.

Whole building mass by material.

Table A1.

Whole building mass by material.

| Material | Timber | Timber | Concrete | Concrete |

|---|---|---|---|---|

| t | % | t | % | |

| Gypsum plaster | 3.3 | 0.08 | 8.0 | 0.10 |

| Concrete | 1938.6 | 47.60 | 5602.1 | 72.28 |

| Rebar | 79.3 | 1.95 | 248.2 | 3.20 |

| Gypsum board 12.5 mm | 77.5 | 1.90 | 3.1 | 0.04 |

| CLT—cross laminated timber | 550.8 | 13.53 | 0.0 | 0.0 |

| Glue mineral | 1.5 | 0.04 | 1.5 | 0,02 |

| Mineral wool facade | 11.1 | 0.27 | 14.2 | 0.18 |

| Plastering | 12.2 | 0.30 | 12.2 | 0.16 |

| Gravel | 1145.0 | 28.12 | 1606.9 | 20.73 |

| Extruded polystyrene | 0.7 | 0.02 | 0.9 | 0.01 |

| Bitumen | 3.0 | 0.07 | 2.7 | 0.03 |

| Expanded polystyrene | 0.1 | 0.00 | 0.1 | 0.00 |

| Mineral wool internal | 0.7 | 0.02 | 0.2 | 0.00 |

| Polyethylene | 0.8 | 0.02 | 0.0 | 0.0 |

| Polyethylene vapor barrier | 1.3 | 0.3 | 0.6 | 0.01 |

| Sand air-dry | 27.9 | 0.68 | 27.9 | 0.36 |

| Rubber granulate mat | 0.9 | 0.02 | 0.0 | 0.0 |

| EPDM | 0.7 | 0.02 | 0.0 | 0.0 |

| Steel sheet, zink coated | 3.0 | 0.07 | 0.0 | 0.0 |

| Screed cement | 211.0 | 5.18 | 211.0 | 2.72 |

| Polystyrene impact insulation | 0.5 | 0.01 | 0.5 | 0.01 |

| Wood fibre insulation | 2.5 | 0.06 | 0.0 | 0.0 |

| Polystyrene cement bonded | 0.0 | 0.0 | 10.6 | 0.14 |

References

- IEA. Global Status Report for Buildings and Construction: Towards a Zero-Emission, Efficient and Resilient Buildings and Construction Sector. Available online: https://www.iea.org/reports/global-status-report-for-buildings-and-construction-2019 (accessed on 25 April 2021).

- Hafner, A. Contribution of timber buildings on sustainability issues. In Proceedings of the World Sustainable Building 2014, Barcelona, Spain, 28–30 October 2014. [Google Scholar]

- Bribián, I.Z.; Capilla, A.V.; Usón, A.A. Life cycle assessment of building materials: Comparative analysis of energy and environmental impacts and evaluation of the eco-effciency improvement potential. Build. Environ. 2011, 46, 1133–1140. [Google Scholar] [CrossRef]

- Penaloza, D.; Eriksson, P.E.; Norén, J. Decreasing the carbon footprint of energy efficient buildings, what comes next? In Proceedings of the Passivhus Norden, Göteborg, Sweden, 15–17 October 2013. [Google Scholar]

- Dodoo, A. Lifecycle impacts of structural frame materials for multistorey building systems. J. Sustain. Architect. Civ. Eng. 2019, 24, 17–28. [Google Scholar] [CrossRef] [Green Version]

- Penaloza, D.; Erlandsson, M.; Falk, A. Exploring the climate impact effects of increased use of bio-based materials in buildings. Construct. Build. Mater. 2019, 125, 219–226. [Google Scholar] [CrossRef] [Green Version]

- Chen, Z.; Gu, H.; Bergman, R.D.; Liang, S. Comparative Life Cycle Assessment of a High-Rise Mass Timber Building with an Equivalent Reinforced Concrete Alternative Using the Athena Impact Estimator for Buildings. Sustainability 2020, 12, 4708. [Google Scholar] [CrossRef]

- Liang, S.; Gu, H.; Bergman, R.; Kelley, S.S. Comparative life-cycle assessment of a mass timber building and concrete alternative. Wood Fiber Sci. 2020, 52, 217–229. [Google Scholar] [CrossRef]

- Himes, A.; Busby, G. Wood buildings as a climate solution. Dev. Built Environ. 2020, 4, 1–7. [Google Scholar] [CrossRef]

- Hafner, A.; Rüter, S.; Ebert, S.; Schäfer, S.; König, H.; Cristofaro, L.; Diederichs, S.; Kleinhenz, M.; Krechel, M. Treibhausgasbilanzierung von Holzgebäuden—Umsetzung Neuer Anforderungen an Ökobilanzen und Ermittlung Empirischer Substitutionsfaktoren (THG-Holzbau). 28W-B-3-054-01 Waldklimafonds. 2017. Available online: https://www.ruhr-uni-bochum.de/reb/mam/content/thg_bericht-final.pdf (accessed on 25 April 2021).

- Dodoo, A. Life Cycle Primary Energy Use and Carbon Emission of Residential Buildings. Ph.D. Thesis, Mid Sweden University, Östersund, Sweden, 2011. [Google Scholar]

- Gustavsson, L.; Dodoo, A.; Sathre, R. Climate change effects over the lifecycle of a building. In Report on Methodological Issues in Determining the Climate Change Effects over the Lifecycle of a Building; Final report for Boverket; Linnaeus University: Växjö, Sweden, 2015. [Google Scholar]

- Frischknecht, R.; Ramseier, L.; Yang, W.; Birgisdottir, H.; Chae, C.U.; Lützkendorf, T.; Passer, A.; Balouktsi, M.; Berg, B.; Bragança, L.; et al. Comparison of greenhouse gas emissions of a high-rise residential building assessed with different national LCA approaches—IEA EBC Annex 72. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2020; Volume 588, p. 022029. [Google Scholar]

- ISO 21930:2017. Sustainability in Buildings and Civil Engineering Works. Core Rules for Environmental Product Declarations of Construction Products and Services; ISO: Geneva, Switzerland, 2017. [Google Scholar]

- EN 15978:2011. Sustainability of Construction Works—Assessment of Environmental Performance of Buildings—Calculation Method; CEN: Brussels, Belgium, 2011. [Google Scholar]

- EN 15804:2012+A1. Sustainability of Construction Works—Environmental Product Declarations—Core Rules for the Product Category of Construction Products; CEN: Brussels, Belgium, 2012. [Google Scholar]

- OIB: Richtlinie 2 Brandschutz. Available online: https://www.oib.or.at/sites/default/files/richtlinie_2_26.03.15.pdf (accessed on 25 April 2021).

- dataholz.eu. Available online: https://www.dataholz.eu/en.htm (accessed on 25 April 2021).

- OIB Richtlinie 5 Schallschutz. Available online: https://www.oib.or.at/sites/default/files/richtlinie_5_26.03.15.pdf (accessed on 25 April 2021).

- Ecoinvent. Available online: https://www.ecoinvent.org/ (accessed on 25 April 2021).

- IBO. Available online: https://www.ibo.at/fileadmin/ibo/materialoekologie/EI10_Berechnungsleitfaden_V2.01_2020.pdf (accessed on 25 April 2021).

- ISO 14040:2006. Environmental Management. Life Cycle Assessment. Principles and Framework; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- ISO 14044:2006. Environmental Management. Life Cycle Assessment. Requirements and Guidelines; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- Boogman, P.; Figl, H.; Wurm, M. IBO-Richtwerte für Baumaterialien. Wesentliche methodische Annahmen für die IBO-Richtwerte. Available online: https://www.ibo.at/fileadmin/ibo/materialoekologie/IBO-Richtwerte-2017_Methode_v32_2020-12-28.pdf (accessed on 25 April 2021).

- Athena. A cradle-to-Gate Life Cycle Assessment of Ready-Mix Concrete Manufactured by NRMCA Members. Version 3.0. Available online: https://calculatelca.com/wp-content/themes/athenasmisoftware/images/LCA%20Reports/Maintenance_Repair_And_Replacement.pdf (accessed on 25 April 2021).

- EN 16757:2017. Sustainability of Construction Works—Environmental Product Declarations—Product Category Rules for Concrete and Concrete Elements; CEN: Brussels, Belgium, 2017. [Google Scholar]

- Verordnung des Bundesministers für Land- und Forstwirtschaft, Umwelt und Wasserwirtschaft über Deponien (Deponieverordnung). Available online: https://www.ris.bka.gv.at/GeltendeFassung.wxe?Abfrage=Bundesnormen&Gesetzesnummer=20005653 (accessed on 25 April 2021).

- Figl, H.; Thurner, C.; Dolezal, F.; Schneider-Marin, P.; Nemeth, I. A new Evaluation Method for the End-of-life Phase of Buildings. Earth Environ. Sci. 2019, 225, 12024. [Google Scholar] [CrossRef]

- UBA. Abfallverbrennung in Österreich, Statusbericht 2006. Available online: https://www.umweltbundesamt.at/fileadmin/site/publikationen/REP0113.pdf (accessed on 25 April 2021).

- EN 16449:2014. Wood and Wood-Based Products—Calculation of the Biogenc Carbon Content of Wood and Conversion to Carbon Dioxide; CEN: Brussels, Belgium, 2014. [Google Scholar]

- Baubook. Available online: https://www.baubook.at (accessed on 25 April 2021).

- Brandao, M.; Levasseur, A.; Kirschbaum, M.U.F.; Weidema, B.P. Key issues and options in accounting for carbon sequestration and temporary storage in life cycle assessment and carbon footprinting. Int. J. Life Cycle Assess 2013, 18, 230–240. [Google Scholar] [CrossRef]

- Churkina, G.; Organschi, A.; Reyer, C.P.O.; Ruff, A.; Vinke, K.; Liu, Z.; Reck, B.K.; Graedel, T.E.; Schellnhuber, H. Buildings as a global carbon sink. Nat. Sustain. 2020, 3, 269–276. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).