Abstract

Global construction industry has a huge influence on world primary energy consumption, spending, and greenhouse gas (GHGs) emissions. To better understand these factors for mass timber construction, this work quantified the life cycle environmental and economic performances of a high-rise mass timber building in U.S. Pacific Northwest region through the use of life-cycle assessment (LCA) and life-cycle cost analysis (LCCA). Using the TRACI impact category method, the cradle-to-grave LCA results showed better environmental performances for the mass timber building relative to conventional concrete building, with 3153 kg CO2-eq per m2 floor area compared to 3203 CO2-eq per m2 floor area, respectively. Over 90% of GHGs emissions occur at the operational stage with a 60-year study period. The end-of-life recycling of mass timber could provide carbon offset of 364 kg CO2-eq per m2 floor that lowers the GHG emissions of the mass timber building to a total 12% lower GHGs emissions than concrete building. The LCCA results showed that mass timber building had total life cycle cost of $3976 per m2 floor area that was 9.6% higher than concrete building, driven mainly by upfront construction costs related to the mass timber material. Uncertainty analysis of mass timber product pricing provided a pathway for builders to make mass timber buildings cost competitive. The integration of LCA and LCCA on mass timber building study can contribute more information to the decision makers such as building developers and policymakers.

1. Introduction

The buildings and buildings construction sectors together account for over one-third of global primary energy consumption and almost 40% of total CO2 emissions, direct and indirect. Increasing energy demand from buildings and buildings construction is partially driven by surge in global buildings floor area and population [1]. Natural climate solutions have been proposed as one way to mitigate these impacts along with a drive for environmental and economic sustainability [2,3]. The nature of the building construction requires multi-criteria decision-making support and optimization of many aspects including environmental and economic costs [4]. New construction using wood from sustainably-harvest forest is a natural climate solution by both reducing greenhouse gas (GHG) emissions and by storing carbon while providing economic incentives for keeping forests as forest and even afforestation [2,3]. Mass timber construction (MTC), an emerging technology has become an available option to concrete and steel construction which are the primary construction materials for mid- to high-rise nonresidential buildings globally [5,6]. MTC is a category of framing styles using large solid wood panels such as glued, nailed or dowel connected cross laminated timber, known as CLT, NLT and DLT, respectively, and also glue laminated timber (glulam) and mass plywood panels. These are used in walls, floors, columns and roof construction [7,8]. CLT and other mass timber family products exhibit a reduced carbon footprint that are less energy intense relative to concrete and steel [9,10]. Using mass timber allows buildings to be built approximately 20% faster with less noise pollution than a similar project using concrete because of easier material handling and high level of prefabrication at the factory [11]. Well-designed mass timber building may also exhibit better earthquake performance and fire durability [12]. As with any emerging technology, economics drive the adoption of whether it will be accepted as a viable replacement.

All these advantages allow mass timber to replace concrete and steel in selected buildings. CLT was incorporated into the International Building Code (IBC) in 2015 [13], and the following revised 2021 IBC permits mass timber structures up to 18 stories for business and residential buildings [14,15]. Across the United States, 1060 mass timber projects have been evaluated and are in different stages of development and construction [16]. In particular, there has been great interest in mass timber buildings in the Pacific Northwest, due in large part to the cost savings and regional economic benefits associated with local production of the mass timber products. Scouse and others [17] showed the local or regional economic benefits of mass timber over a comparable traditional concrete include direct and indirect jobs and economic growth, when CLT is locally sourced from regional manufacturers. Drivers for increasing MTC include both environmental life-cycle assessment (LCA) and life-cycle cost analysis (LCCA) benefits [18,19,20]. Linking LCA and LCCA together can greatly contribute to creation of a sustainable built environment [21].

Whole building LCA (WBLCA) is a method to analyze building environmental impacts that can include the raw materials extraction, product manufacture, transport, construction, operation over the building lifetime and end of life impacts [22]. LCA is an important tool for guiding the selection of building materials and operating systems and their specific environmental impacts and has been used by the building sector since 1990s [23]. There are several worldwide LCA studies on mass timber buildings [24,25,26,27], and all the results showed mass timber buildings have lower embodied carbon and other environmental impacts than alternative conventional buildings. WBLCA studies of mass timber buildings in the United States are limited [28,29], and some only focused on the cradle-to-site analysis, and the building operations and end of life stages were excluded [10,19]. Nevertheless, there is a consensus that MTC can be an effective means for the mid-term (60–100 years) storage of biogenic carbon [30].

Building LCCA uses a set of financial criteria to evaluate the cost of a building across its entire service life [31]. LCCA is an effective tool to determine the cost effectiveness of different building designs and explore trade-offs between initial costs and long-term cost savings using a discounted accounting approach.

Liang et al. [32] applied this methodology to a hypothetical case study of a high-rise mass timber building compared to a concrete baseline building, and concluded that the total life-cycle cost (TLCC) was dominated by the construction cost, and were also sensitive to variations of study period and discount rate. Several recent studies explored the inclusion of LCA and LCCA on mass timber and other buildings [21,33,34,35], but more efforts are necessary to fully understand the environmental and economic impacts of U.S. mass timber buildings.

As part of a larger project centered on a pioneering high-rise mass timber building named Framework Kelley and Bergman [36], a first of its kind cradle-to-grave LCA and LCCA of a 12-story mass timber building in U.S. Pacific Northwest was performed. This work aims to investigate the environmental implications and economic contributions of CLT mass timber building. Research from this case study can be used to support developers and owners as they strive to reach environmental and economic goals, as well as help policy makers contribute to the development and management of the future sustainable built environment.

2. Case Study

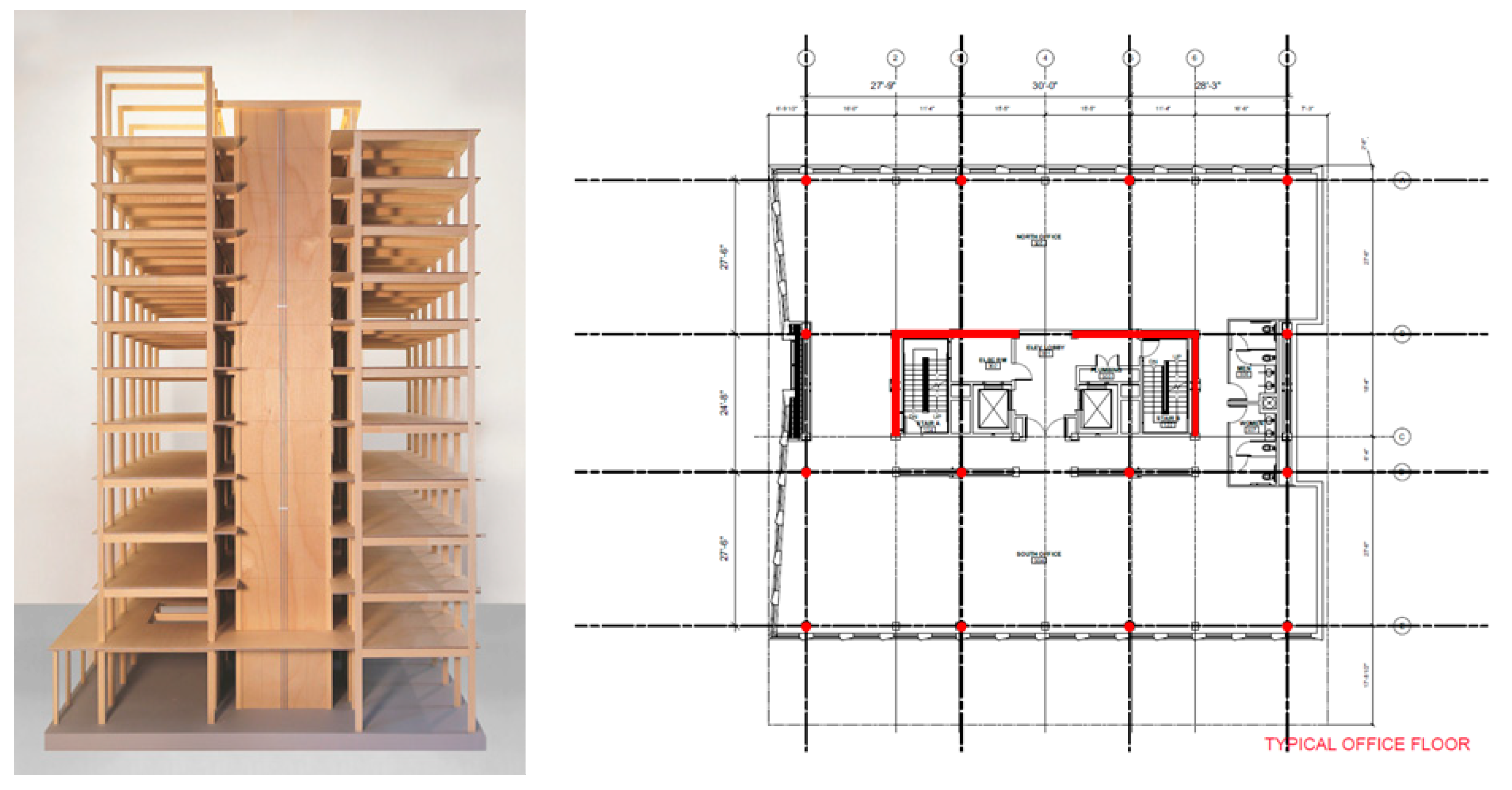

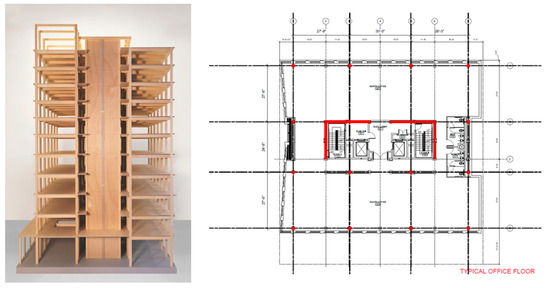

The case study used in this work was a 12-story mixed-use commercial and residential building designed by LEVER Architecture (Portland, OR, USA) and intended to be built in Portland, OR. As illustrated in Figure 1, CLT and glulam are the main construction materials used in the building assemblies of walls, floors and columns and beams. This mass timber building has total floor area of 8360 m2, and the dimension is 30.5 m in length, 25.9 m in width and 45.1 m in height.

Figure 1.

Image model of high-rise mass timber (Framework) building and main office floor plan.

Table 1 provides the bill (list) of material for this mass timber building along with its concrete alternative. The comparable conventional concrete building with same floor area and envelope design was also modeled by LEVER Architecture. Both buildings complied with same Type I-B fire-resistant construction code. This 8360 m2 mixed-use building used a total of 2339 m3 of mass timber products, including 1782 m3 of CLT and 557 m3 of glulam, that equals to 0.27 m3 mass timber per m2 building floor area. Specifically, the walls use 502 m3 of 7-and 9-ply CLT, the floors use 1279 m3 of 5-ply CLT and the post beams use 557 m3 of glulam for columns and beams. Additionally, the mass timber building also consumed 36% more gypsum board, and 16% more structural steel than the concrete alternative. Conversely the mass timber building used 72% less rebar and 58% less concrete than the concrete building. Still about 1104 cubic meters of concrete were used in the mass timber building design for foundation and concrete layer on top of CLT floor for vibration control. Details of material used in each building assembly can be found in previous papers from this study [18,19].

Table 1.

Bill of Building materials and data assumptions.

3. Methodology

3.1. Goal, Scope and Functional Unit

The primary goal of this case study, the first of its kind, is to analyze both the LCA and TLCC of a high-rise mass timber building with a comparison to a functionally equivalent concrete building. The LCA and LCCA approaches used in this research were based on EN 15978 [22] and ASTM E917 [31], respectively. For the baseline analysis in this study, both buildings were assumed to be demolished after 60 years’ service life. The scope of LCA was a cradle-to-grave analysis of materials effects, operation energy and water use over a 60-year period, where the equivalent aspects of the two buildings such as windows, doors, plumbing, electrical, and heating, ventilation and air conditioning (HVAC) systems were excluded from the analysis. The LCCA covered building construction cost, operation cost, maintenance and repair (M & R) cost, and demolish cost and/or salvage value at the end of study period, while the land acquisition, planning and externalities such as management and insurance were excluded from the analysis. The functional unit for this case study is defined as “1 m2 of living/working floor area in a mixed-use commercial/residential building in the Pacific Northwestern United States for 60 years”.

3.2. System Boundary and Life Cycle Stage

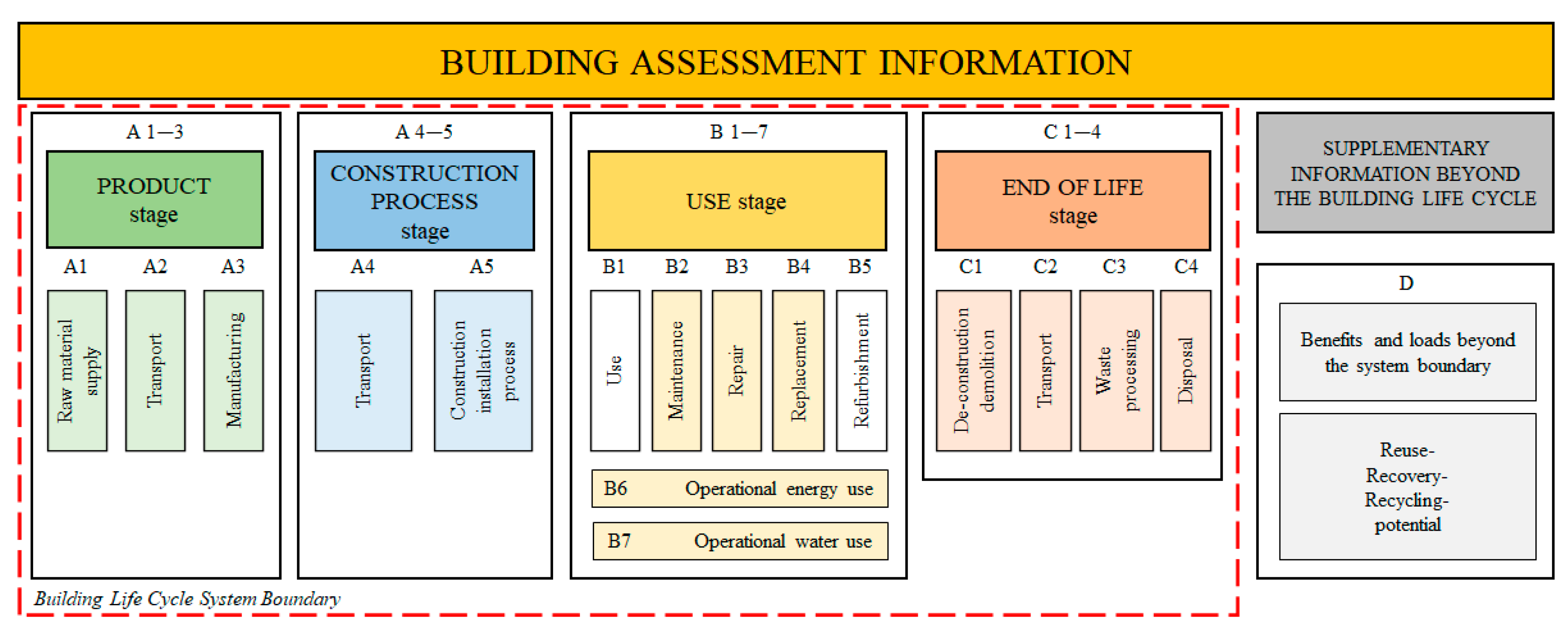

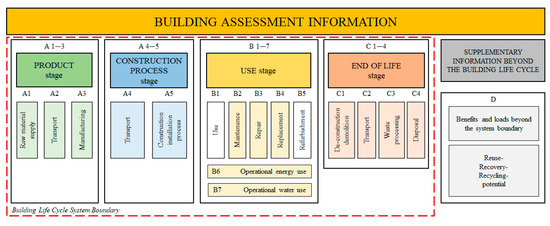

The system boundary defines the life cycle activities to be included in the analysis. Figure 2 illustrates the temporal flow of the building life cycle according to EN 15978 [22]. The building cradle-to-grave LCA includes module A to C minus a few submodules (B1, B5, C1 and C3) and module D (beyond building life cycle). The building LCCA in this case study includes all these modules. Detailed life cycle stages and data assumption were described in the following sections.

Figure 2.

Building life cycle stages and modules.

3.2.1. Product and Construction Stage (Module A)

The product stage (A1–A3) includes raw materials supply (A1, primary resource harvesting and mining), transport (A2, transport up to manufacturing plant gate) and manufacturing (A3, manufacture of raw materials into products). The construction stage (A4–5) includes transport (A4, transport of materials to site) and construction installation process (A5, construction equipment energy use). The A4 transport was based on diesel truck and the estimated transportation distances for the building materials, listed in Table 1. Transportation distances were estimated based on the location of the construction and building materials’ suppliers. The A5 equipment energy inputs were estimated from diesel use in Athena Construction Energy Database described by Bowick [37]. The life cycle inventory (LCI) of building materials and energy were sourced from DATASMART (Long Trail Sustainability, Huntington VT, USA) and Athena Impact Estimator (AIE) databases (Athena Sustainable Materials Institute, Ottawa, ON, Canada) for Pacific Northwest forest resources. The LCI of CLT was provided by the University of Washington [38]. The whole building construction cost was estimated with individual material cost, onsite labor/equipment cost and overhead cost from the RSMeans database [39]. For instance, the estimated construction cost to use 1 m3 glulam consists of $1440 of material cost, $219 of onsite labor/equipment cost and $260 of overhead. In this study, the cost of glulam in mass timber building was used as a proxy for CLT cost since the CLT industry average cost market data are not currently available. This proxy is on the high end of the CLT price range, which made the whole building LCC result more conservative. With the demands increase and more CLT manufacturers emerge, the price for mass timber products will become competitive within building materials. Scenario and uncertainty analysis were conducted to show the potential cost reduction for CLT as the MTC industry matures.

3.2.2. Operation Stage (Module B)

The M & R stage (B2–B4) includes the production of building materials used for maintaining (B2), repairing (B3) and replacing (B4) building components during operation stage. The material use and M & R frequency assumption were based on literature (Gu and Bergman, 2018) and listed in Table 1. The utility stage (B6–B7) includes the operational energy use (B6, energy production and use) and operation water use (B7, water supply and wastewater treatment) were the same for the two buildings. Table 2 shows the annual utility use and estimated cost for both buildings. The electricity and natural gas consumption were simulated by IES Virtual Environment software (Integrated Environmental Solutions, Glasgow, Scotland, UK), and the water use was estimated based on the plumbing system design. The unit utility prices were obtained from government sources and listed in previous study [19]. The use (B1) and refurbishment (B5) stages were excluded from this case study due to information unavailable for the mass timber buildings.

Table 2.

Annual utility estimation for mass timber and concrete buildings.

3.2.3. End of Life Stage (Module C)

The end-of-life stage (module C) in LCA study includes transport (C2, transport of building waste from site to disposal facilities, and transport of recyclable materials to recycling facilities) and disposal (C4, landfill of building waste), while the deconstruction/demolish (C1) and waste processing (C3) stages were excluded due to lack of data. The distances of 24 km to landfill site and 100 km to recycle facilities were assumed, and the landfill rates of building materials were listed in Table 1. For the LCCA, all modules were included, and the building demolition cost (including de-construction and dump charges) was estimated using RSMeans database for concrete- and wood-framed buildings.

3.2.4. System Expansion (Module D)

Per EN 15978 [22], module D quantifies the potential environmental and economic benefits from the reuse, recovery and recycling of materials and energy from the building and existing system. These outputs are assumed to substitute for materials or energy production from existing technologies. For example, recycled metals substitute for metal scraps, recycled concrete substitute for aggregate and reclaimed wood products substitute for virgin materials and/or are used for energy production. Specifically, this work assumes 30% of CLT and glulam would be landfilled after building demolishment, where for the rest of un-landfilled mass timber, 75% would be reclaimed to substitute virgin CLT/glulam and remaining 25% un-landfilled (with lower heating value of 20.9 MJ/kg) [40,41] would be combusted in wood boilers, with efficiency of 77%, to replace natural gas, with lower heating value of 37.5 MJ/m3 STP and efficiency of 80%. For the concrete material, landfill rate was assumed as 45% (Table 1), and the other 55% would be recycled as aggregates. The demolition costs and salvage values were estimated using RSMeans database [39] and assumed the reused CLT/glulam would be sold at a 50% of virgin price. Sensitivity analysis of different mass timber reclaim ratios and resale prices were also evaluated to address the uncertainties of these assumptions.

3.2.5. Carbon Sequestration and Storage

Wood and concrete can sequester and store carbon at different life-cycle stages which varies depending on various assumptions. For wood, after its original service, the reclaimed CLT/glulam were assumed to keep their structural integrity as well as the carbon stored in wood for additional 60 years beyond the building’s original lifetime thereby doubling its original useful life. Landfilling wood products release GHGs as the wood decays but also store carbon permanently. Michaels and Skog [42] estimated 1.5% of carbon content in wood products was released to the atmosphere and the following literature by Skog [43] increased the number to 23%. According to the IPCC guidelines, wood carbon decayed in landfill maybe as high as 50–60%. However, according to the US EPA, wood decomposition rates vary from 5–16% [44]. The GHG emissions in this study were calculated through DATASMART database within SimaPro LCA modeling software (PRé Sustainability, Amersfoort, Netherlands) based on US EPA [44], with the landfill gas recovery system included. For concrete, concrete carbonation included carbonation during the 60-year building use phase, carbonation of waste fraction in landfill, and carbonation of recycled concrete waste as aggregate. The module A to C concrete carbonation was calculated based on reference [45] with exposed concrete surface area of 764 and 41,718 m2 for CLT and concrete buildings, respectively. The concrete carbon dioxide absorption increases dramatically in 10 years after demolishing building and slows down afterwards to approximately 70% of carbonation limit at 100 years [46]. These assumptions were used to estimate carbon sequestration and storage for modules A to D.

3.3. Life Cycle Impact Assessment

The life cycle inventory data of each building stage was quantified, and the impacts were modeled using SimaPro 9.0 software following the ISO 14040 [47] and ISO 14044 [48] environmental management standards. WBLCA analysis followed EN 15978 [22] and ISO 21930 [49]. Global warming (GW), ozone depletion (ODP), smog formation (SFP), acidification potential (AP) and eutrophication potential (EP) were reported using the embedded TRACI 2.1 impact method [50]. The primary energy consumption which included fossil, nuclear and renewable energy were calculated using the cumulative energy demand (CED) v1.10 method.3.1.

3.4. Life Cycle Costing

The LCCA calculation integrates cost data of each building stage following the ASTM E917 [31] standard and method developed previously [32]. Real term discount and escalation rates were incorporated, and interest payments and taxes were excluded from the analysis. All future costs were discounted to the base-year monetary values, called present value. The building’s TLCC was calculated by the summation of all present values of construction cost, operation cost, M & R cost, demolish cost and salvage value at the end of 60-year study period. The building service life is the span of time in which a building is in use. The study period appropriate to the LCC analysis may or may not reflect the building’s service life span.

4. Results

Table 3 presents the cradle-to-grave LCA and LCCA results of mass timber building and its difference with concrete building. When including the operational stage which was dominant, the mass timber building outperformed the concrete building slightly on most of environmental impacts (0.3–1.6% reduction) except for AP and renewable energy consumption. The AP and renewable energy consumption were mainly derived from the wood products manufacturing processes. In both buildings, operation was the largest contributor to all environmental impacts except for ODP, where the ODP mainly stemmed from the insulation material polystyrene at the M & R stage (module B2–B4). The use of grid electricity and natural gas caused more than 90% of all environmental impacts at the utility stage (module B6). In this initial case study, the building utility included electricity, natural gas and water consumption for 60 years, and assumed both buildings had same utility consumption (Table 2). Excluding the operational utility demands, the environmental impacts of mass timber building over concrete building showed 0.5–40% lower values (e.g., 17% lower GW impact). Details of the comparison excluding the operational energy and water use were published in a previous paper [19]. This is a substantial reduction that can be attributed to the selection of the MTC over concrete construction. As expected for building types, within the product and construction stage (module A) the choice of building material contributes 80–90% of most environmental impacts, followed by material transportation (A4) and on-site construction (A5).

Table 3.

Life cycle impacts and costs of 1 m2 floor area of mass timber building with 60-year study period and difference with alternative concrete building.

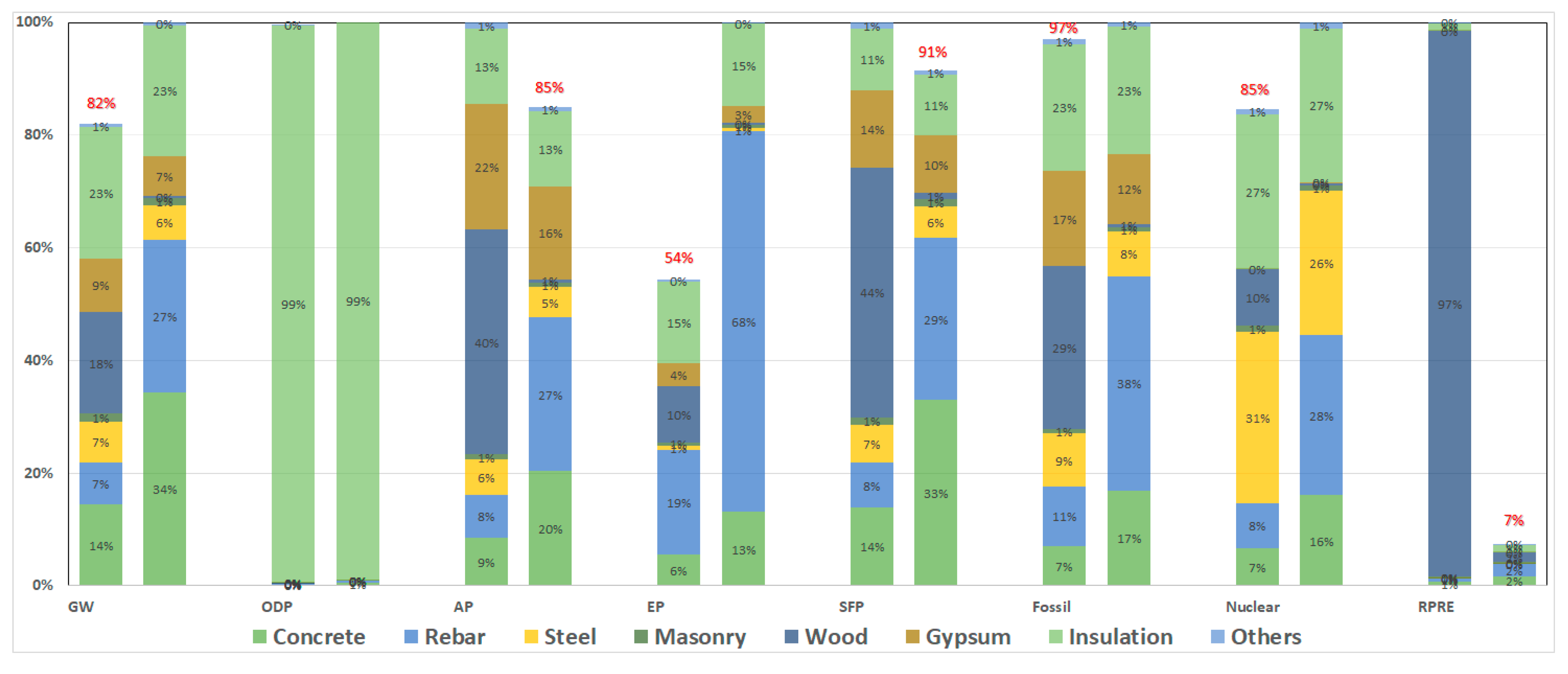

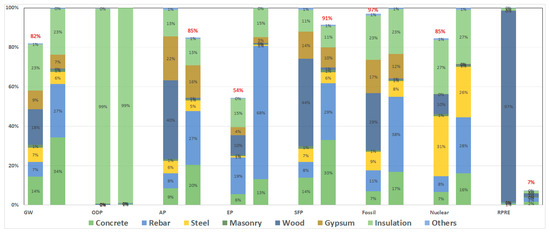

Figure 3 shows the relative environmental impacts contribution of material type to material use life-cycle impact assessment results at product and M & R stages (modules A1–A3, B2–B4). For concrete building, concrete (35%), rebar (27%) and insulation (23%) materials were the largest contributors to GW impact, while insulation (28%), wood (22%) and concrete (18%) were the largest contributors to GW impact for mass timber building due to the substitution of concrete and rebar by CLT and glulam as well as the extra gypsum board use. The extra gypsum board was used to meet the building fire code requirements, which required almost all exposed wood surfaces to be covered for a building of this height (ICC 2019; Breneman and Richardson 2019). Similar trends were also found for other environmental impacts except for ODP and renewable energy consumption. As expected, wood was the dominant contributor (97%) to renewable energy consumption in the mass timber building because wood product manufacturing facilities burned wood residue onsite for steam or electricity production for processing.

Figure 3.

Material type contributions to material use life-cycle impact assessment results for high-rise mass timber (left column) and concrete (right column) buildings.

In contrast to the LCA results, the mass timber building had 9.6% higher TLCC than concrete building. Building construction cost was the largest contributor to the TLCC, accounting 57% and 50% for mass timber and concrete buildings, respectively. As shown in Table 3, the mass timber building had an estimated construction (A1–A5) cost of $2281 per m2 floor area, which was 26% higher than concrete building. Additionally, the mass timber building had an estimated end of life (or recycled) value of $30 per m2 floor area versus end-of-life cost of $94 per m2 floor area for concrete building. It is worth noting that while the mass timber building had higher initial costs, these buildings are also expected to be a ‘premium product’ and command higher rents, and thus be more profitable [51,52].

5. Discussion

5.1. Operational Energy Consumption

Operational energy tends to dominate the overall environmental life-cycle impacts the longer the building lasts. For example, the operational energy frequently has the greatest environmental impacts and accounted for over 90% of building cradle-to-grave GW with study period ranges from 50 to 100 years [37,45]. The consumption of electricity is site-specific, influenced by climate zone, building type and energy efficiency. In this case study, the electricity use during the occupation in buildings were mainly for heating and cooling, vent fans, plug loads and lights. For this analysis, both buildings were designed by LEVER to have the same, superior energy performance. When compared to a standard, typical code-compliance concrete building in Portland area, the mass timber building design in this study could save 70% annual energy use (according to LEVER architects), or 68% reduction in total cradle-to-grave GW. This energy saving is equivalent to avoiding 882 tonnes of fossil CO2 emission annually. The same effect would occur for a high-performance concrete building over a code-compliant mass timber building. Although the operational energy contributed 90% of cradle-to-grave GW it only contributed 7% of TLCC for both buildings because energy is relatively cheap in the United States. If the more energy-efficient design was incorporated into the mass timber building, this could reduce the TLCC by 4.9% from the typical code-compliance concrete building as shown in the previous study [32]. As buildings continue to improve in operating energy usage, the embodied carbon emissions of the structure will become more prominent.

Although this study was based on the assumption of same operational energy and water use during the building use stage for both buildings, there is still potential that mass timber products will provide better thermal performance to save building’s heating/cooling energy in reality since wood has lower thermal conductivity comparing to steel and concrete, so it contributes to energy efficiency with exceptional air tightness and thermal insulation during building service life [53]. A simulation study by Khavari et al. [54] compared a 10-story multi-unit residential building model constructed using CLT versus light-frame metal with same floor plan, and concluded that the CLT envelope has significant improvements for heating energy and for varied energy performance efficiency at different climate zones. Energy-efficiency buildings have long-term environmental and economic benefits [55,56], and it is highly possible that MTC in green building could become part of normal construction and business practices.

5.2. Cross Laminated Timber

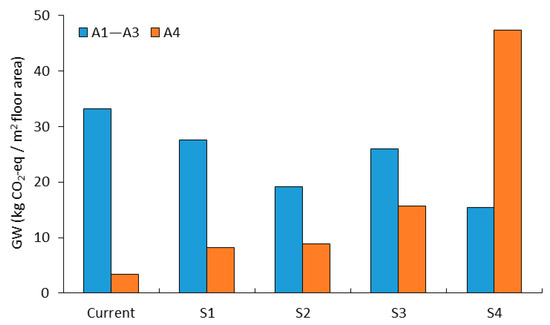

The environmental impacts of CLT are mainly from upstream lumber production, electricity consumption during manufacturing, resin use and feedstock transportation. The lumber production and electricity consumption together contributed over 70% of total GW [38]. The wood species and electricity grid composition at various US regions are different, as shown in Table 4, therefore the GW impacts from lumber (47–81 kg CO2-eq/m3) and electricity (0.3–0.8 kg CO2-eq/kWh) varied greatly (DATASMART, 2019) between regions, too. Therefore, CLT produced from different regions have different environmental impacts. In this case study, the GW from lumber was estimated to be 59 kg CO2-eq/m3, and thus the CLT in the mass timber building contributed 33 kg CO2-eq GW per m2 floor area, or 18% of total GW at product stage (module A1–A3). For module A4, the transport of CLT from manufacturer to building site (320 km via truck) contributed 3.4 kg CO2-eq GW per m2 floor area, or 39% of total GW at transport stage.

Table 4.

Global warming impacts of lumber and electricity for cross-laminated timber production for different US regions.

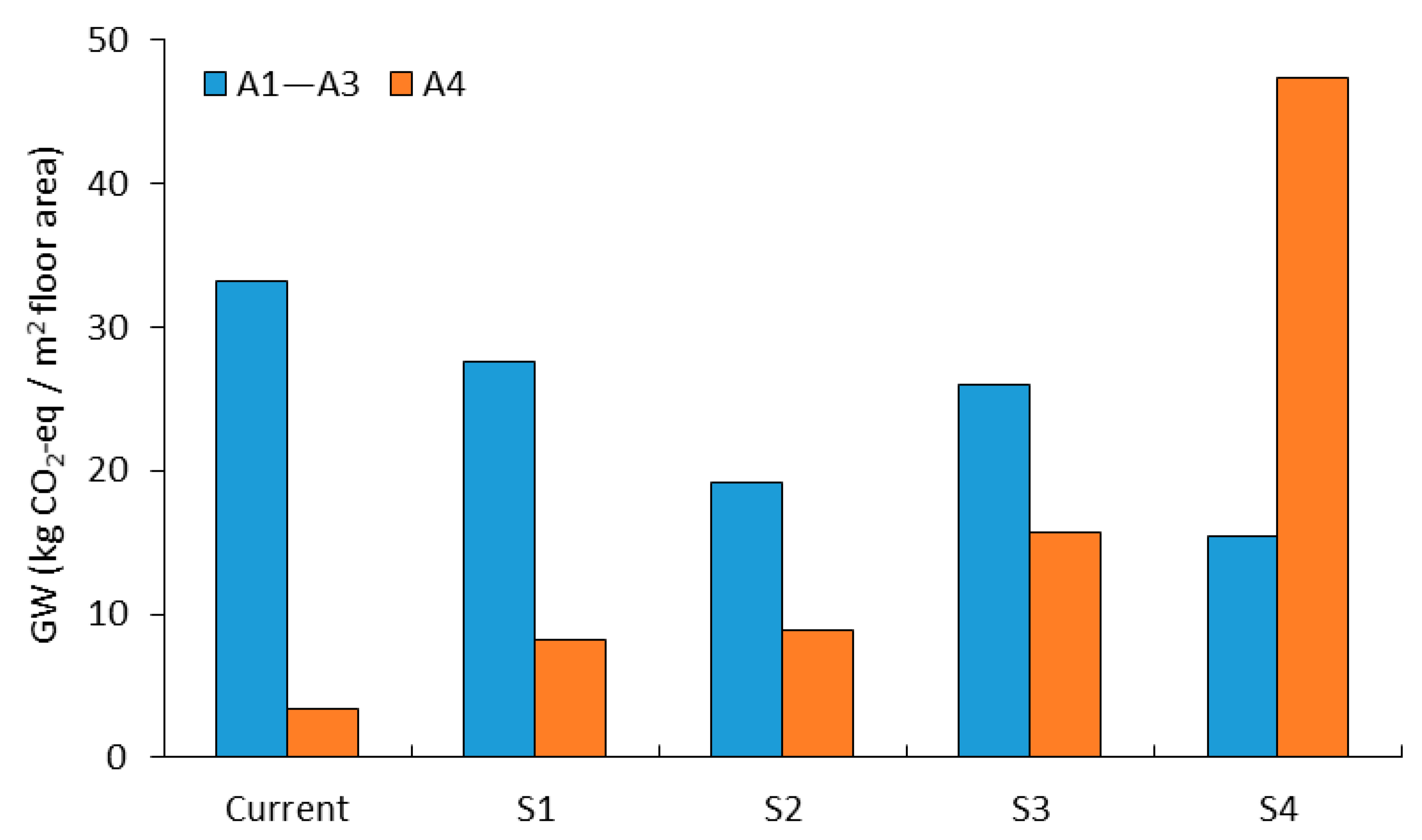

Figure 4 shows the comparison results of mass timber building GW impacts caused by CLT material (module A1–A3) and its transportation to site (module A4) under different scenarios (S1 sources from Inland Northwest, S2 sources from BC, Canada; S3 sources from QB, Canada; and S4 sources from Austria, Europe). These additional four scenarios were analyzed and assumed the CLT was sourced from different North American and European manufacturers [24,57,58]. The GW impact of mass timber building CLT at product stage (module A1–A3) varied from 15 to 34 kg CO2-eq per m2 floor area under different scenarios, which was largely due to the wood species and regional electricity composition differences as mentioned above. Sensitivity analysis shows that ±50% changes of CLT’s embodied carbon emissions, would cause only ±0.5% variation in the total cradle-to-grave GW emissions over the 60 years lifetime of the building. While the GW of mass timber building CLT at transport stage (module A4) varied from 3.4 to 47 kg CO2-eq per m2 floor area, and obviously longer CLT transport distances create greater financial and environment costs. It is highly possible that CLT’s embodied carbon emissions from its transport will be reduced as more local, technologically advanced production infrastructure is developed.

Figure 4.

Global warming impact of cross-laminated timber material (module A1–A3) and transportation to construction site (module A4) for mass timber building under different scenarios (S1 sources from Inland Northwest, S2 sources from BC, Canada; S3 sources from QB, Canada; and S4 sources from Austria, Europe).

The use of CLT in mass timber building costs $409 per m2 floor area (0.21 m3 of CLT per m2 floor area), accounting 18% of total building construction cost. It is worth noting that the price range of CLT is relatively wide due to its early adoption status and nature as specialized product in building sector [17]. This current work modeled the LCCA using the glulam prices in RSMeans database [39] as a proxy for CLT, (e.g., $1440 per m3 of CLT, construction labor/equipment cost of $219 per m3, and overhead of $260 per m3), which is on the high end for CLT price. Other work [59] has suggest that the price of CLT could range from $600–750 per m3, or as high as $1500 per m3.

To evaluate the wide range of potential prices, a Monte Carlo simulation was conducted to test the impacts of combined uncertainties of CLT price (triangular, mode = $1440 per m3, min = $600 per m3, max = $1500 per m3), labor/equipment charge (normal, μ = $219 per m3, σ = $44 per m3), and overhead (normal, μ = $260 per m3, σ = $52 per m3) on the overall CLT construction cost. The results are shown in Table 5. The simulated total cost of CLT used in the study’s mass timber building was $354 ± 2.8 per m2 floor area (95% confidence interval), and there was a 97.5% likelihood that the total cost of CLT mass timber building would be less than $427 per m2 floor area. Additionally, sensitivity analysis result showed that ±50% change in CLT price would affect ±6.7% of mass timber building construction cost and ±2.8% of mass timber building TLCC and would result in a TLCC that is 6.5–12.8% higher for mass timber building relative to the concrete building with same operational energy and water use for 60 years.

Table 5.

Monte Carlo simulation results of total cost of cross-laminated timber use in mass timber building.

Building life span has a significant impact on the TLCC. In this study, both buildings were assumed to be demolished after 60 years. A survey of building longevity conducted by Athena Sustainable Materials Institute (Ottawa, Ontario, Canada) found that more than 65% of demolished wood buildings were older than 75 years, while 60–80% of concrete and steel buildings were demolished at less than 50 years old. Architects from Lever Architecture believe the mass timber buildings are more likely to survive for more than 100 years (personal communication). Using projected building longevity of 100 and 75 years for mass timber and concrete buildings, respectively, under the same study period of 60 years, the mass timber building would have 2.5% lower TLCC than the functionally equivalent concrete building.

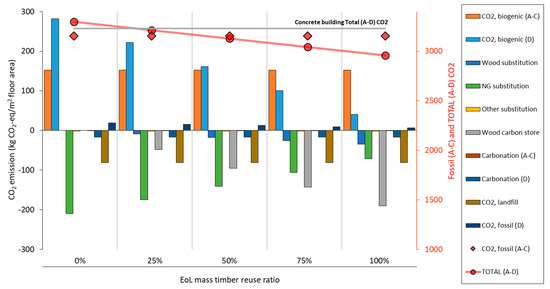

5.3. End of Life Management and Carbon Analysis

After buildings are demolished, some materials can be recycled to substitute for new materials required for construction of the next building, and in the case of wood products burned for energy to avoid fossil fuel consumption. The environmental and economic consequences of these end-of-life decisions can be significant at the building level and could represent up to 50% of the building total life cycle impacts [60]. In this work, the mass timber building stored 364 kg CO2-eq per m2 floor area due to the recycling of the mass timber in module D. In contrast, recycling at the end of life for the concrete building only stored 46 kg CO2-eq per m2 floor area, which mainly derived from concrete carbonation. Therefore, including module D for carbon credit, the mass timber building had a total GW of 2789 kg CO2-eq per m2 floor area that is 12% lower than concrete building (3157 kg CO2-eq per m2 floor area).

In landfills, solid wood decomposes very slowly, but nevertheless releases biogenic methane while sequestering the majority of carbon. In this work, the base case assumption was that 30% of the CLT was landfilled and 70% were recycled and reused. If this landfill rate was increased to 100%, the total carbon credit at module D would be reduced from 364 kg CO2-eq per m2 floor area to 287 kg CO2-eq per m2 floor area. While this the carbon credit is still large, landfill should be avoided, and recycle and reuse should be the first principle in waste management.

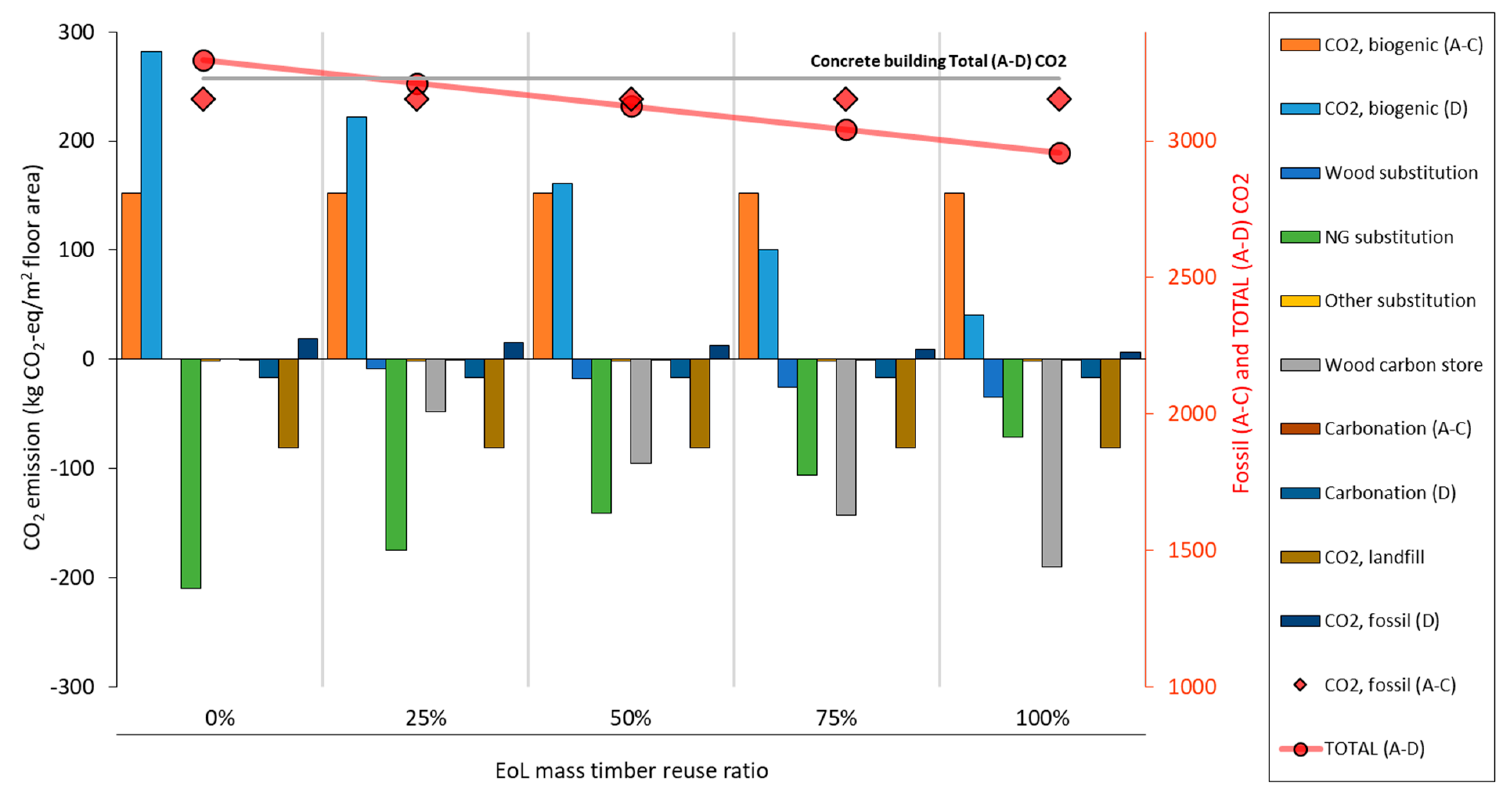

This research further assumed that 52.5% of building mass timber (75% of the 70% non-landfilled) could be reclaimed for reuse in MTC, and the remaining 17.5% of building mass timber (25% of the 70% non-landfilled) would be combusted in boiler to substitute natural gas for heat and electricity. This assumption could be conservative when considering the nature of mass timber as building structural components. Studies from USDA Forest Products Laboratory (Madison, WI, USA) found reclaimed glulam after 75 years’ building life had showed no degradation in structural integrity and exhibited good mechanical performance [61,62]. In the case of CLT, the reuse rate is less likely to be related to the strength of wood, but more likely driven by the match of the specific dimension of the CLT coming out of service. To evaluate this issue, different mass timber reuse ratios for the CLT between 0 to 100% were applied. This range in the reclaim ratio led to a variation of 9–12% lower total GW (module A–D) for the mass timber building relative to the concrete building. Sensitivity analysis result shows that ±25% changes in mass timber reuse rate would affect ±9% of carbon credit at module D, or ±1% of total GW for module A–D. Carbon impact of each source at different mass timber reuse rates were calculated and illustrated in Figure 5. The absolute values of fossil and biogenic carbon dioxide emission as well as natural gas substitution decreased, and wood carbon storage increased with the increase of mass timber reclaim/reuse rate. Biogenic carbon dioxide emissions are considered carbon neutral from the climate change prospective based off the IPCC’s 100-year timeline, however some debates exist on global warming carbon accounting with biogenic and fossil carbon dioxide [63]. The total carbon dioxide (including the biogenic carbon) emission of mass timber building decreased with the increase of mass timber reuse rate except for the scenario where all the non-landfilled mass timber was combusted for energy. Combusting all mass timber at end of life generated 2% higher total carbon dioxide emission, while in other scenarios the mass timber building had 1–8% lower total carbon dioxide emission than the concrete building (Figure 5).

Figure 5.

Full carbon accounting of mass timber building at different end-of-life mass timber reuse rates with respect to a functionally equivalent concrete building.

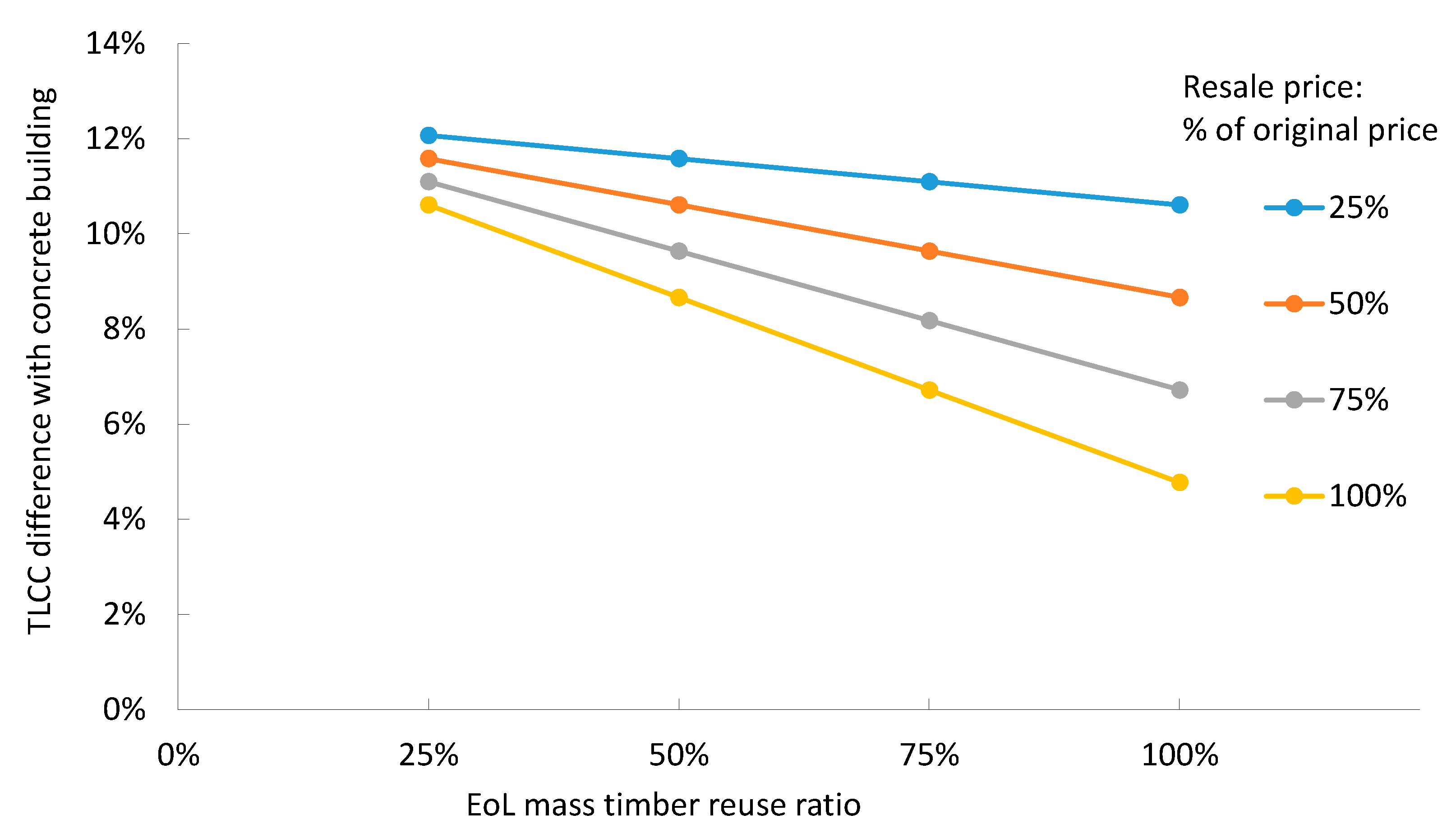

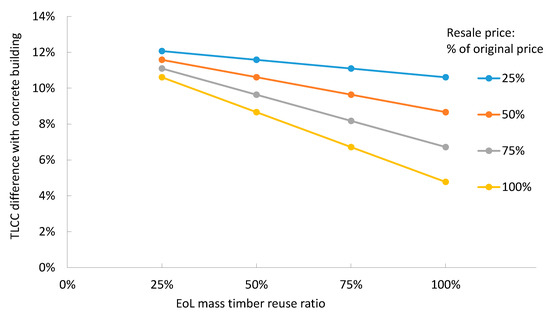

The reclaimed mass timber has financial value. It was assumed that the reclaimed mass timber could be re-sold as 50% of its virgin price, and under such assumption, the end-of-life salvage value of mass timber building was approximately $123 per m2 floor area, accounting 3% of TLCC. As expected, the salvage value was impacted by both the value and volume of recovered mass timber, and there were large uncertainties in these assumptions. To better understand these effects, different reclaiming rates (25–100%) and resale prices (25–100% of the original price) were evaluated and shown in Figure 6. Without considering the end-of-life costs, the TLCC costs of the mass timber building was about 13% higher than the concrete building. With considering the end of life where 25% of the mass timber was recovered and valued at 25% of its original value, the TLCC costs for the mass timber building were about 12% higher than the concrete building. When assuming the best-hope scenario for the reclaiming rate of 100% and the original value being maintained, the mass timber building’s TLCC would be only 4.8% higher than the concrete building. Although this assumption maybe considered unrealistic from the current view, it implies, anyhow, that the mass timber buildings ought to be designed and then deconstructed/demolished with outmost care to maintain the value of the CLT and glulam.

Figure 6.

Total life cycle cost difference between mass timber and concrete buildings at different mass timber reuse rates and salvage prices.

6. Conclusions

A high-rise mass timber building in Pacific Northwest was assessed using LCA and LCCA approaches to evaluate the life-cycle environmental and economic performances and compared these results to a concrete building of same design. Operating over 60 years, the cradle-to-grave (module A–C) LCA results show the mass timber building had better performance in respect to GW (1.6% lower) and other environmental impacts than concrete building. As expected, the operating energy dominated the buildings’ GHG emissions, accounting for over 90% of the emissions from the mass timber building. Simply comparing the GW impacts of the materials, the mass timber building had 17% lower emissions. These greater carbon benefits in the materials of construction, will have enlarged benefits when the timing of the emissions is considered [64,65]. The GW advantages of mass timber building become more significant when considering the end-of-life management activities tracked in module D (potential benefits beyond building life) are included, which highlights the need for architects and designers to consider deconstruction instead of demolishing at end of life and potential mass timber reuse in the original building design phase. The mass timber building had 9.6% higher TLCC than concrete building for a 60-year service life analysis. The cost was mainly driven by front end construction cost, especially mass timber cost, which is a relatively unknown parameter. Uncertainty analysis showed that the building’s service life span and a design that allowed for recycling of the mass timber could significantly lower the TLCC of mass timber building.

Author Contributions

Conceptualization, S.L., H.G and R.B.; methodology, S.L. and H.G.; software, S.L.; validation, H.G.; formal analysis, S.L.; investigation, S.L. and H.G.; data curation, S.L.; writing—original draft preparation, S.L.; writing—review and editing, H.G. and R.B.; supervision, H.G.; project administration, R.B.; funding acquisition, R.B. All authors have read and agreed to the published version of the manuscript.

Funding

This project was financially supported by a joint venture agreement between the USDA Forest Service, Forest Products Laboratory, and the U.S. Endowment for Forestry & Communities, Inc., Endowment Green Building Partnership—Phase 1, No. 16-JV-11111137-094.

Institutional Review Board Statement

The study was conducted according to the guidelines of the USDA Forest Service scientific research process, and approved by the Institutional Quality Act Peer Review process at the Forest Products Laboratory.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

This research was supported [in part] by the U.S. Department of Agriculture, Forest Service. The findings and conclusions in this report are those of the author(s) and should not be construed to represent any official USDA or U.S. Government determination or policy.

References

- Buildings a Source of Enormous Untapped Efficiency Potential. Available online: https://www.iea.org/topics/buildings (accessed on 16 May 2021).

- Amiri, A.; Ottelin, J.; Sorvari, J.; Junnila, S. Cities as carbon sinks-classification of wooden buildings. Environ. Res. Lett. 2020, 15, 094076. [Google Scholar] [CrossRef]

- Himes, A.; Busby, G. Wood buildings as a climate solution. Dev. Built Environ. 2020, 4, 100030. [Google Scholar] [CrossRef]

- Schneider-Marin, P.; Lang, W. Environmental costs of buildings: Monetary valuation of ecological indicators for the building industry. Int. J. Life Cycle Assess. 2020, 25, 1637–1659. [Google Scholar] [CrossRef]

- Anderson, R.; Atkins, D.; Beck, B.; Dawson, E.; Gale, C.B. 2020 State of the Industry: North American Mass Timber. 2020, p. 156. Available online: http://www.lfpdc.lsu.edu/publications/bits/2020/20200609-2020%20North-American-Mass-Timber-State-of-the-industry-report-is-available-for-free%20.pdf (accessed on 16 May 2021).

- D’Amico, B.; Pomponi, F.; Hart, J. Global potential for material substitution in building construction: The case of cross laminated timber. J. Clean. Prod. 2021, 279, 123487. [Google Scholar] [CrossRef]

- Harte, A.M. Mass timber—The emergence of a modern construction material. J. Struct. Integr. Maint. 2017, 2, 121–132. [Google Scholar] [CrossRef]

- Zhou, J.; Chui, Y.H.; Gong, M.; Hu, L. Elastic properties of full-size mass timber panels: Characterization using modal testing and comparison with model predictions. Compos. Part B Eng. 2017, 112, 203–212. [Google Scholar] [CrossRef]

- Kremer, P.D.; Symmons, M.A. Mass timber construction as an alternative to concrete and steel in the Australia building industry: A PESTEL evaluation of the potential. Int. Wood Prod. J. 2015, 6, 138–147. [Google Scholar] [CrossRef]

- Pierobon, F.; Huang, M.; Simonen, K.; Ganguly, I. Environmental benefits of using hybrid CLT structure in midrise non-residential construction: An LCA based comparative case study in the US PNW. J. Build Eng. 2019, 26, 100862. [Google Scholar] [CrossRef]

- Mass Timber Market Analysis (Completed for: Council of Western State Foresters). Available online: https://www.oregon.gov/ODF/Documents/ForestBenefits/Beck-mass-timber-market-analysis-report.pdf (accessed on 16 May 2021).

- Van de Lindt, J.W.; Furley, J.; Amini, M.O.; Pei, S.; Tamagnone, G.; Barbosa, A.R.; Rammer, D.; Line, P.; Fragiacomo, M.; Popovski, M. Experimental seismic behavior of a two-story CLT platform building. Eng. Struct. 2019, 183, 408–422. [Google Scholar] [CrossRef]

- Cross-Laminated Timber in the 2015 IBC and NDS (MAT242). Available online: https://www.awc.org/pdf/education/mat/AWC-MAT242-CLT-2015NDS-2hr-150825.pdf (accessed on 16 May 2021).

- Tall Wood Buildings and the 2021 IBC: Up to 18 Stories of Mass Timber. Available online: https://www.awc.org/pdf/education/des/AWC-DES607A-TallWood2021IBC-190619-color.pdf (accessed on 16 May 2021).

- Fiscal Monitor, October 2019: How to Mitigate Climate Change. Available online: https://www.imf.org/en/Publications/FM/Issues/2019/10/16/Fiscal-Monitor-October-2019-How-to-Mitigate-Climate-Change-47027 (accessed on 16 May 2021).

- Building Trends: Mass Timber. Available online: https://www.woodworks.org/publications-media/building-trends-mass-timber/ (accessed on 16 May 2021).

- Scouse, A.; Kelley, S.S.; Liang, S.; Bergman, R. Regional and net economic impacts of high-rise mass timber construction in Oregon. Sustain. Cities Soc. 2020, 61, 102154. [Google Scholar] [CrossRef]

- Gu, H.; Liang, S.; Bergman, R. Comparison of building construction and life-cycle cost for a high-rise mass timber building with its concrete alternative. For. Prod. J. 2020, 70, 482–492. [Google Scholar]

- Liang, S.; Gu, H.; Bergman, R.; Kelley, S. Comparative life-cycle assessment of a mass timber building and concrete alternative. Wood Fiber Sci. 2020, 52, 217–229. [Google Scholar] [CrossRef]

- Zelinka, S.L.; Williamson, T.; Martinson, K.L.; Ritter, M.A. Research needs assessment for the mass timber industry: Proceedings of the 2nd North American mass timber research needs workshop. In General Technical Report FPL-GTR-273; Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2019; pp. 1–41. [Google Scholar]

- Santos, R.; Costa, A.A.; Silvestre, J.D.; Vandenbergh, T.; Pyl, L. BIM-based life cycle assessment and life cycle costing of an office building in Western Europe. Build. Environ. 2020, 169, 106568. [Google Scholar] [CrossRef]

- EN 15978. 2011 Sustainability of construction works—Assessment of environmental performance of buildings—Calculation method. In European Committee for Standardization; CEN European Committee for Standardization, Management Centre: Brussels, Belgium, 2011; pp. 1–60. [Google Scholar]

- Ortiz, O.; Castells, F.; Sonnemann, G. Sustainability in the construction industry: A review of recent developments based on LCA. Constr. Build. Mater. 2009, 23, 28–39. [Google Scholar] [CrossRef]

- Durlinger, B.; Crossin, E.; Wong, J. Life Cycle Assessment of a Cross Laminated Timber Building; Forest & Wood Products Australia Limited: Melbourne, Australia, 2013; pp. 1–110. [Google Scholar]

- Jayalath, A.; Naravatnam, S.; Ngo, T.; Mendis, P.; Hewson, N.; Aye, L. Life cycle performance of cross Laminated Timber mid-rise residential buildings in Australia. Energy Build. 2020, 223, 110091. [Google Scholar] [CrossRef]

- CLT Buildings: A WBLCA Case Study Series—Five Whole Building Life Cycle Assessment Case Studies. Available online: http://tallwoodinstitute.org/sites/twi/files/Case_Studies_Final_2.pdf (accessed on 16 May 2021).

- Liu, Y.; Guo, H.; Sun, C.; Chang, W.S. Assessing Cross Laminated Timber (CLT) as an alternative material for mid-rise residential buildings in cold regions in China—A life-cycle assessment approach. Sustainability 2016, 8, 1047. [Google Scholar] [CrossRef] [Green Version]

- Gu, H.; Bergman, R. Life cycle assessment and environmental building declaration for the design building at the University of Massachusetts. In General Technical Report FPL-GTR-255; U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2018; pp. 1–71. [Google Scholar]

- Chen, Z.; Gu, H.; Bergman, R.; Liang, S. Comparative Life cycle assessment of a high-rise mass timber building with an equivalent reinforced concrete alternative using the Athena Impact Estimator for Buildings. Sustainability 2020, 12, 4708. [Google Scholar] [CrossRef]

- Churkina, G.; Organschi, A.; Reyer, C.P.O.; Ruff, A.; Vinke, K.; Liu, Z.; Reck, B.K.; Graedel, T.E.; Schellnhuber, H.J. Buildings as a global carbon sink. Nat. Sustain. 2020, 3, 269–276. [Google Scholar] [CrossRef]

- ASTM E917-17. Standard Practice for Measuring Life-Cycle Costs of Buildings and Building Systems; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Liang, S.; Gu, H.; Bilek, T.; Bergman, R. Life-cycle cost analysis of a mass-timber building: Methodology and hypothetical case study. In Research Paper FPL-RP-702; U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2019; pp. 1–11. [Google Scholar]

- Dara, C.; Hachem-Vermette, C.; Assefa, G. Life cycle assessment and life cycle costing of container-based single-family housing in Canada: A case study. Build. Environ. 2019, 163, 106332. [Google Scholar] [CrossRef]

- Lu, H.R.; Hanandeh, A.E.; Gilbert, B.P. A comparative life cycle study of alternative materials for Australian multi-storey apartment building frame constructions: Environmental and economic perspective. J. Clean. Prod. 2017, 166, 458–473. [Google Scholar] [CrossRef]

- Teshnizi, Z.; Pilon, A.; Storey, S.; Lopez, D.; Froese, T.M. Lessons Learned from Life Cycle Assessment and Life Cycle Costing of Two Residential Towers at the University of British Columbia. Procedia CIRP 2018, 69, 172–177. [Google Scholar] [CrossRef]

- Potential for Tall Wood Buildings to Sequester Carbon, Support Forest Communities, and Create New Options for Forest Management. Available online: https://www.fpl.fs.fed.us/documnts/rips/fplrip-4851-018-NCSU-TallBldgs-Bergman-Kelley.pdf (accessed on 16 May 2021).

- Bowick, M. Wood Innovation and Design Centre Prince George, BC: An Environmental Building Declaration According to EN 15978 Standard; Athena Sustainable Materials Institute: Ottawa, ON, Canada, 2015; pp. 1–55. [Google Scholar]

- Chen, C.X.; Pierobon, F.; Ganguly, I. Life cycle assessment (LCA) of cross-laminated timber (CLT) produced in western Washington: The role of logistics and wood species mix. Sustainability 2019, 11, 1278. [Google Scholar] [CrossRef] [Green Version]

- RSMeans Online. Available online: https://www.rsmeansonline.com/ (accessed on 2 February 2019).

- Puettmann, M.; Milota, M. Life-Cycle Assessment for Wood-Fired Boilers Used in the Wood Products Industry. For. Prod. J. 2017, 67, 381–389. [Google Scholar] [CrossRef]

- Tabakaev, R.; Shanenkov, I.; Kazakov, A.; Zavorin, A. Thermal processing of biomass into high-calorific solid composite fuel. J. Anal. Appl. Pyrolysis 2017, 124, 94–102. [Google Scholar] [CrossRef]

- Michaels, J.A.; Skog, K.E. The decomposition of forest products in landfills. Int. Biodeterior. Biodegrad. 1997, 39, 145–158. [Google Scholar]

- Skog, K.E. Sequestration of carbon in harvested wood products for the United States. For. Prod. J. 2008, 58, 56–72. [Google Scholar]

- Documentation for Greenhouse Gas Emission and Energy Factors Used in the Waste Reduction Model (WARM). Available online: https://www.epa.gov/sites/production/files/2019-10/documents/warm_v15_management_practices_updated_10-08-2019.pdf (accessed on 16 May 2021).

- Bowick, M. Athena Brock Commons Tallwood House, University of British Columbia: An Environmental Building Declaration According to EN 15978 Standard; Athena Sustainable Materials Institute: Ottawa, ON, Canada, 2018; pp. 1–55. [Google Scholar]

- Grann, B. A Comparative Life Cycle Assessment of Two Multistory Residential Buildings: Cross-Laminated Timber vs. Concrete Slab and Column with Light Gauge Steel Walls; FPInnovations: Pointe-Claire, QC, Canada, 2013; p. 142. [Google Scholar]

- ISO 14040. Environmental Management—Life Cycle Assessment—Principles and Framework; International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- ISO 14044. Environmental Management—Life Cycle Assessment—Requirement and Guidelines; International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- ISO 21930. Sustainability in buildings and civil engineering works. In Core Rules for Environmental Product Declarations of Construction Products and Services; International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- Bare, J. TRACI 2.0: The tool for the reduction and assessment of chemical and other environmental impacts 2.0. Clean Technol. Environ. Policy 2011, 13, 687–696. [Google Scholar] [CrossRef]

- Cover, J. Mass timber: The new sustainable choice for tall buildings. Int. J. High-Rise Build. 2020, 9, 87–93. [Google Scholar]

- Thigpen, A. Sustainable Value Creation through Mass Timber Development in North America. Master’s Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2020. [Google Scholar]

- Energy Efficiency. Available online: https://www.woodworks.org/why-wood/energy-efficiency/ (accessed on 16 May 2021).

- Khavari, A.M.; Pei, S.; Tabares-Velasco, P.C. Energy consumption analysis of multistory cross-laminated timber residential buildings: A comparative study. J. Archit. Eng. 2016, 22, 04016002. [Google Scholar] [CrossRef]

- Kneifel, J. Life-cycle carbon and cost analysis of energy efficiency measures in new commercial buildings. Energy Build. 2010, 42, 333–340. [Google Scholar] [CrossRef]

- Marszal, A.J.; Heiselberg, P.; Bourrelle, J.S.; Musall, E.; Voss, K.; Sartori, I.; Napolitano, A. Zero Energy Building—A review of definitions and calculation methodologies. Energy Build. 2011, 43, 971–979. [Google Scholar] [CrossRef]

- Huang, M.; Chen, C.X.; Pierobon, F.; Ganguly, I.; Simonen, K. Life Cycle Assessment of Katerra’s Cross-Laminated Limber (CLT) and Catalyst Building: Final Report; University of Washington: Seattle, WA, USA, 2019; pp. 1–63. [Google Scholar]

- Puettmann, M.; Sinha, A.; Ganguly, I. CORRIM REPORT—Life Cycle Assessment of Cross Laminated Timbers Produced in Oregon; Consortium for Research on Renewable Industrial Materials: Corvallis, OR, USA, 2018; pp. 1–36. [Google Scholar]

- Brandt, K.; Wilson, A.; Bender, D.; Dolan, J.D.; Wolcott, M.P. Techno-economic analysis for manufacturing cross-laminated timber. BioResources 2019, 14, 7790–7804. [Google Scholar] [CrossRef]

- Delem, L.; Wastiels, L. Module D in the Building Life Cycle: Significance Based on a Case Study Analysis. IOP Conf. Ser. Earth Environ. Sci. 2019, 290, 012042. [Google Scholar] [CrossRef]

- Rammer, D.R.; de Melo Moura, J.; Ross, R.J. Structural performance of the second oldest glued-laminated structure in the United States. In Proceedings of the Structures Congress; American Society of Civil Engineers: Boston, MA, USA, 2014; pp. 1233–1243. [Google Scholar]

- Teder, M.; Wang, X. Nondestructive evaluation of a 75-year old glulam arch. In Proceedings of the 18th International Nondestructive Testing and Evaluation of Wood Symposium; Southern Research Station US Forest Service: Madison, WI, USA, 2013; pp. 624–632. [Google Scholar]

- Gunn, J.S.; Ganz, D.J.; Keeton, W.S. Biogenic vs. geologic carbon emissions and forest biomass energy production. GCB Bioenergy 2012, 4, 239–242. [Google Scholar] [CrossRef]

- Bergman, R.D. The Effect on Climate Change Impacts for Building Products When Including the Timing of Greenhouse Gas Emissions. Ph.D. Thesis, University of Wisconsin, Madison, WI, USA, 2012. [Google Scholar]

- Salazar, J.; Bergman, R. Temporal Considerations of Carbon Sequestration in LCA. In Proceedings from the LCA XIII International Conference; American Center for Life Cycle Assessment: Orlando, FL, USA, 2013; pp. 136–142. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).