Defects Impact on PV System GHG Mitigation Potential and Climate Change

Abstract

:1. Introduction

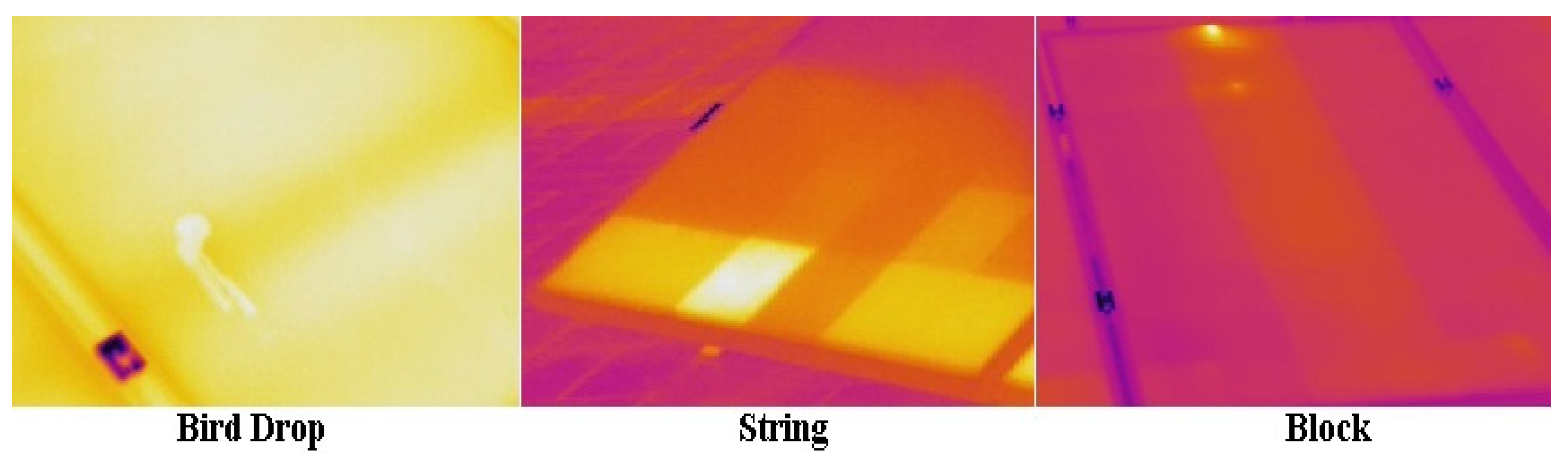

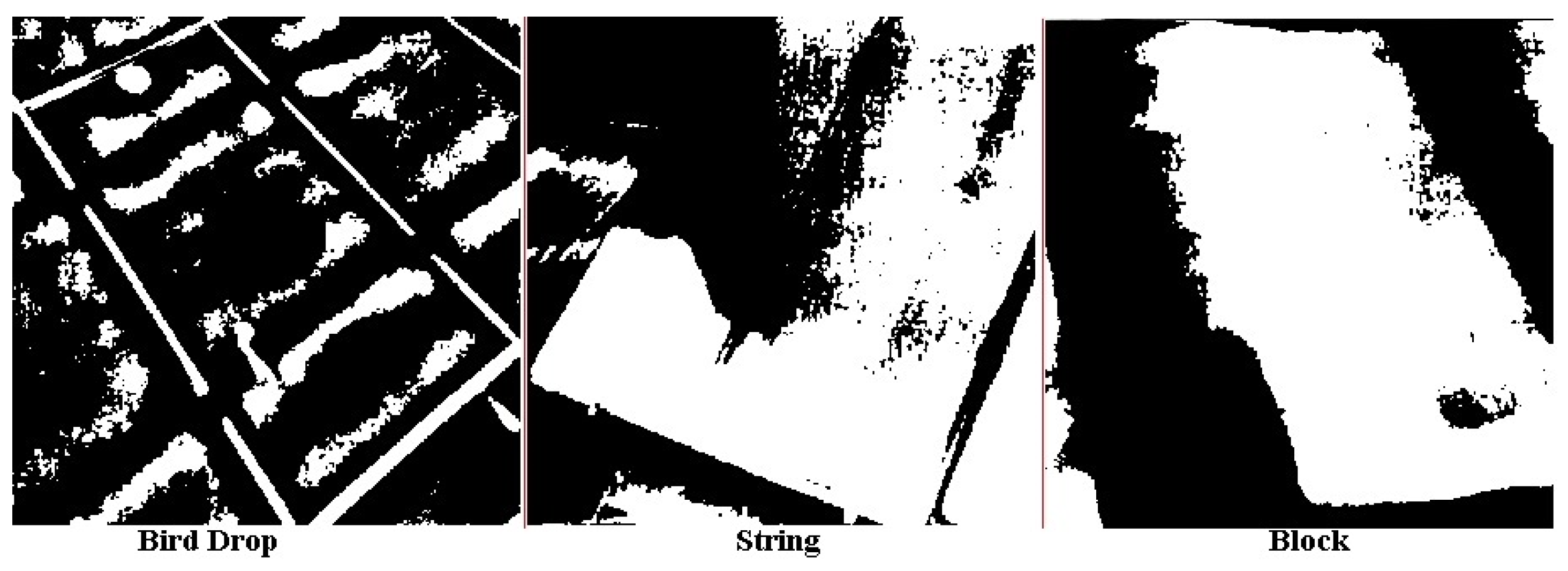

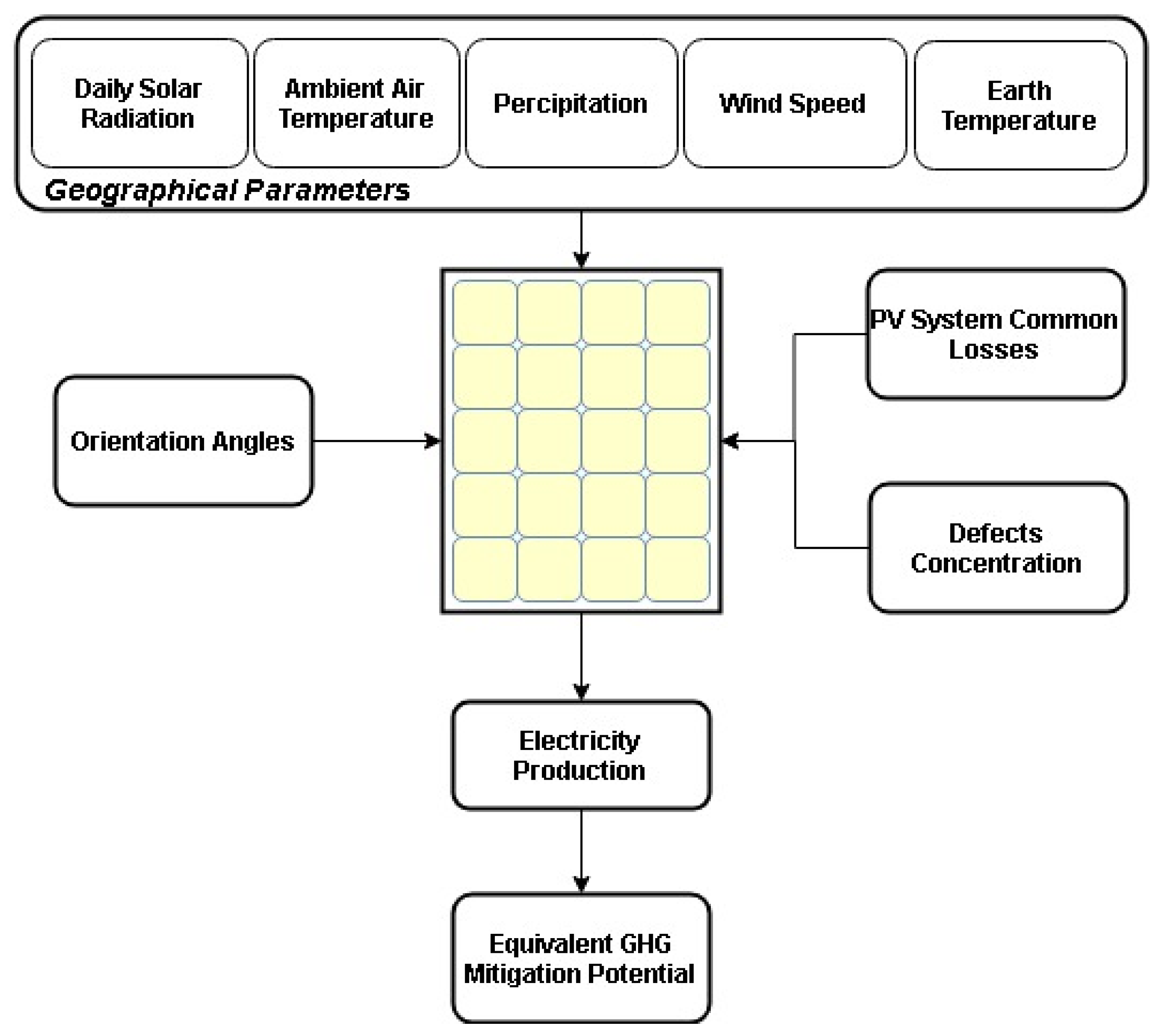

2. Defects Concentration on PV Panel Surface

3. Research Approach

3.1. Location

3.2. PV System

3.3. PV System Losses

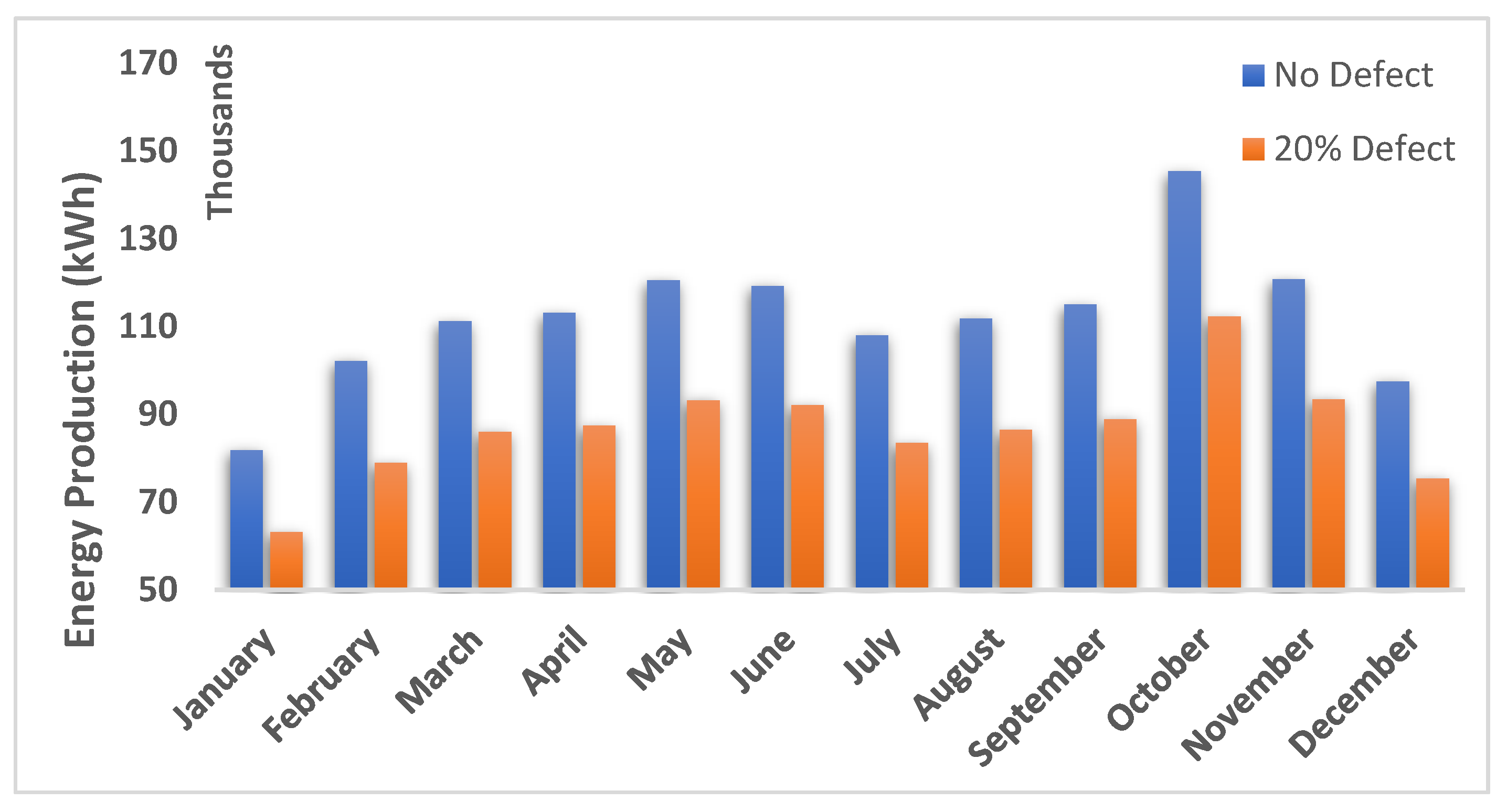

4. Results

5. Research Significance

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ahmed, W.; Sheikh, J.A.; Ahmad, S.; Farjana, S.H.; Mahmud, M.P. Impact of PV System Orientation Angle Accuracy on Greenhouse Gases Mitigation. Case Stud. Therm. Eng. 2021. [Google Scholar] [CrossRef]

- Ahmed, W.; Sheikh, J.A.; Kouzani, A.Z.; Mahmud, M.A. The Role of Single End-Users and Producers on GHG Mitigation in Pakistan—A Case Study. Sustainability 2020, 12, 8351. [Google Scholar] [CrossRef]

- Ali, M.U.; Khan, H.F.; Masud, M.; Kallu, K.D.; Zafar, A. A machine learning framework to identify the hotspot in photovoltaic module using infrared thermography. Sol. Energy 2020, 208, 643–651. [Google Scholar] [CrossRef]

- Energy Resources of Pakistan. Available online: http://ntdc.gov.pk/energy (accessed on 12 July 2021).

- Bdour, M.; Dalala, Z.; Al-Addous, M.; Radaideh, A.; Al-Sadi, A. A Comprehensive Evaluation on Types of Microcracks and Possible Effects on Power Degradation in Photovoltaic Solar Panels. Sustainability 2020, 12, 6416. [Google Scholar] [CrossRef]

- Ahmed, W.; Masood, M.T.; Ali, M.U. Influence of load-shedding and night on SiR insulator environmental aging under AC test voltages. SN Appl. Sci. 2021, 3, 190. [Google Scholar] [CrossRef]

- Madeti, S.R.; Singh, S.N. A comprehensive study on different types of faults and detection techniques for solar photovoltaic system. Sol. Energy 2017, 158, 161–185. [Google Scholar] [CrossRef]

- Niazi, K.; Khan, H.A.; Amir, F. Hot-spot reduction and shade loss minimization in crystalline-silicon solar panels. J. Renew. Sustain. Energy 2018, 10, 033506. [Google Scholar] [CrossRef]

- Bharadwaj, P.; Karnataki, K.; John, V. Formation of hotspots on healthy PV modules and their effect on output performance. In Proceedings of the 2018 IEEE 7th World Conference on Photovoltaic Energy Conversion (WCPEC) (A joint conference of 45th IEEE PVSC, 28th PVSEC & 34th EU PVSEC), Waikoloa, HI, USA, 10–15 June 2018; pp. 0676–0680. [Google Scholar]

- Ahsan, S.; Niazi, K.A.K.; Khan, H.A.; Yang, Y. Hotspots and performance evaluation of crystalline-silicon and thin-film photovoltaic modules. Microelectron. Reliab. 2018, 88, 1014–1018. [Google Scholar] [CrossRef]

- Olalla, C.; Hasan, M.; Deline, C.; Maksimović, D. Mitigation of hot-spots in photovoltaic systems using distributed power electronics. Energies 2018, 11, 726. [Google Scholar] [CrossRef] [Green Version]

- Dunderdale, C.; Brettenny, W.; Clohessy, C.; van Dyk, E.E. Photovoltaic defect classification through thermal infrared imaging using a machine learning approach. Prog. Photovolt. Res. Appl. 2020, 28, 177–188. [Google Scholar] [CrossRef]

- Jadin, M.S.; Zamridin, K.A.B.; Shah, A.S.M. Development of PV Module Hotspot Detector. In InECCE2019; Springer: Singapore, 2020; pp. 875–884. [Google Scholar]

- Dhimish, M.; Holmes, V.; Mather, P.; Sibley, M. Novel hot spot mitigation technique to enhance photovoltaic solar panels output power performance. Sol. Energy Mater. Sol. Cells 2018, 179, 72–79. [Google Scholar] [CrossRef] [Green Version]

- Pramana, P.A.A.; Dalimi, R. Hotspot Detection Method in Large Capacity Photovoltaic (PV) Farm. In IOP Conference Series: Materials Science and Engineering; No. 1; IOP Publishing: Purbalingga, Indonesia, 2020; p. 012019. [Google Scholar]

- Gallardo-Saavedra, S.; Hernández-Callejo, L.; Alonso-García, M.D.C.; Muñoz-Cruzado-Alba, J.; Ballestín-Fuertes, J. Infrared Thermography for the Detection and Characterization of Photovoltaic Defects: Comparison between Illumination and Dark Conditions. Sensors 2020, 20, 4395. [Google Scholar] [CrossRef]

- Niazi, K.A.K.; Akhtar, W.; Khan, H.A.; Yang, Y.; Athar, S. Hotspot diagnosis for solar photovoltaic modules using a Naive Bayes classifier. Sol. Energy 2019, 190, 34–43. [Google Scholar] [CrossRef]

- Tang, W.; Yang, Q.; Xiong, K.; Yan, W. Deep learning based automatic defect identification of photovoltaic module using electroluminescence images. Sol. Energy 2020, 201, 453–460. [Google Scholar] [CrossRef]

- Itako, K.; Hossam, B.; Kudoh, T.; Huang, Q. Development of real time hotspot detection system using scan-method for PV generation system. In Proceedings of the IECON 2015-41st Annual Conference of the IEEE Industrial Electronics Society, Yokohama, Japan, 9–12 November 2015; pp. 001032–001036. [Google Scholar]

- Review of Failures of Photovoltaic Modules. Available online: https://iea-pvps.org/wp-content/uploads/2020/01/IEA-PVPS_T13-01_2014_Review_of_Failures_of_Photovoltaic_Modules_Final.pdf (accessed on 12 July 2021).

- The Impacts of Climate Change on Human Health in the United States: A Scientific Assessment. Available online: https://health2016.globalchange.gov/ (accessed on 12 July 2021).

- Climate Impacts on Society. Available online: https://19january2017snapshot.epa.gov/climate-impacts/climate-impacts-society_.html#Overview (accessed on 12 July 2021).

- Otsu, N. A threshold selection method from gray-level histograms. IEEE Trans. Syst. Man Cybern. 1979, 9, 62–66. [Google Scholar] [CrossRef] [Green Version]

- RETScreen International. RETScreen Software Online User Manual; CANMET Energy Technology Centre: Varennes, QC, Canada, 2005; Available online: http://www.nrcan.gc.ca/energy/software-tools/7465 (accessed on 12 July 2021).

- Solar Panel Datasheet. Available online: https://www.canadiansolar.com/au/wp-content/uploads/sites/2/2020/05/Canadian_Solar-Datasheet-KuBlack_CS3K-MS_IEC1500V_v5.61_AU-1.pdf (accessed on 12 July 2021).

- Electric Power Transmission and Distribution Losses (% of output)—Pakistan. Available online: https://data.worldbank.org/indicator/EG.ELC.LOSS.ZS?end=2014&locations=PK&start=1971 (accessed on 12 July 2021).

| Latitude | 33.62 N |

| Longitude | 73.1 E |

| Air temperature | 21.6 Celsius |

| Relative humidity | 62.0% |

| Precipitation | 30.52 inches |

| Annual average daily solar radiations | 4.02 kWh/m2/d |

| Atmospheric pressure | 91.1 kPa |

| Wind speed (10 m height) | 2.4 m/s |

| Earth temperature | 20.1 Celsius |

| PV Panel (Pmax) | 300 Wp |

| Module efficiency | 18.05% |

| Operating voltages | 32.5 V |

| Operating current | 9.24 A |

| Output | 25 years, linear |

| PV System | 12 kWp |

| Inverter | 12 kW |

| Inverter efficiency | 99% |

| Location | 33.62 N, 73.1 E | ||||

| Orientation angles | −34 tilt, 180 azimuths | ||||

| Ambient air temperature per annum average | 21.6 Celsius | ||||

| Defect/hotspot Concentration | |||||

| PV output per month average (kWh) | Daily Solar Radiations (kWh/m2/d) | Healthy | 0.5% | 1% | 20% |

| January | 2.90 | 981.310 | 975.735 | 970.159 | 758.285 |

| February | 4.11 | 1225.732 | 1218.768 | 1211.803 | 947.157 |

| March | 4.17 | 1334.896 | 1327.311 | 1319.727 | 1031.510 |

| April | 4.55 | 1357.484 | 1349.711 | 1342.058 | 1048.965 |

| May | 4.85 | 1447.077 | 1438.855 | 1430.633 | 1118.196 |

| June | 5.04 | 1430.101 | 1421.976 | 1413.850 | 1105.078 |

| July | 4.35 | 1295.885 | 1288.522 | 1281.159 | 1001.366 |

| August | 4.46 | 1342.288 | 1334.661 | 1327.035 | 1037.222 |

| September | 4.66 | 1380.110 | 1372.269 | 1364.427 | 1066.449 |

| October | 5.52 | 1743.688 | 1733.780 | 1723.873 | 1347.395 |

| November | 4.55 | 1449.648 | 1441.411 | 1433.174 | 1120.182 |

| December | 3.47 | 1169.652 | 1163.006 | 1156.361 | 903.822 |

| PV output per annum average (kWh) | 4.38 | 16,157.871 | 16,066.065 | 15,974.259 | 12,485.6278 |

| System efficiency (%) | - | 100 | 99.43 | 98.86 | 77.27 |

| Energy Loss (%) | - | 0 | 0.57 | 1.14 | 22.73 |

| Common Loss | Aging and very small layer of inert pollution | ||||

| Equivalent Cases | GHG Reduction Potential (per Annum) | |||

|---|---|---|---|---|

| Healthy | 0.5% Loss | 1% Loss | 20% Loss | |

| Annual GHG emissions reduction | 7.9774 t CO2 | 7.932 t CO2 | 7.8867 t CO2 | 6.1643 t CO2 |

| Cars and light trucks not used | 1.4611 | 1.4528 | 1.4445 | 1.129 |

| Litres of gasoline not consumed | 3427.6479 | 3408.1726 | 3388.6974 | 2648.637 |

| Barrels of crude oil not consumed | 18.552 | 18.4466 | 18.3412 | 14.3356 |

| People reducing energy use by 20% | 7.9774 | 7.932 | 7.8867 | 6.1643 |

| Acres of forest absorbing carbon | 1.813 | 1.8027 | 1.7924 | 1.401 |

| Hectares of forest absorbing carbon | 0.7337 | 0.7295 | 0.7254 | 0.567 |

| Tons of waste recycled | 2.7508 | 2.7352 | 2.7196 | 2.1256 |

| Equivalent Cases | GHG Reduction Potential (per Annum) | ||

|---|---|---|---|

| No Defect | 20% Defective | Difference | |

| Annual GHG emissions reduction | 664.9126 t CO2 | 513.7961 t CO2 | 151.1165 t CO2 |

| Cars and light trucks not used | 121.7789 | 94.1019 | 27.677 |

| Litres of gasoline not consumed | 285,694.4523 | 220,763.895 | 64,930.5573 |

| Barrels of crude oil not consumed | 1546.3085 | 1194.8747 | 351.4338 |

| People reducing energy use by 20% | 664.9126 | 513.7961 | 151.1165 |

| Acres of forest absorbing carbon | 151.1165 | 116.7718 | 34.3447 |

| Hectares of forest absorbing carbon | 61.1547 | 47.2559 | 13.8988 |

| Tons of waste recycled | 229.2802 | 177.1711 | 52.1091 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmed, W.; Sheikh, J.A.; Farjana, S.H.; Mahmud, M.A.P. Defects Impact on PV System GHG Mitigation Potential and Climate Change. Sustainability 2021, 13, 7793. https://doi.org/10.3390/su13147793

Ahmed W, Sheikh JA, Farjana SH, Mahmud MAP. Defects Impact on PV System GHG Mitigation Potential and Climate Change. Sustainability. 2021; 13(14):7793. https://doi.org/10.3390/su13147793

Chicago/Turabian StyleAhmed, Waqas, Jamil Ahmed Sheikh, Shahjadi Hisan Farjana, and M. A. Parvez Mahmud. 2021. "Defects Impact on PV System GHG Mitigation Potential and Climate Change" Sustainability 13, no. 14: 7793. https://doi.org/10.3390/su13147793

APA StyleAhmed, W., Sheikh, J. A., Farjana, S. H., & Mahmud, M. A. P. (2021). Defects Impact on PV System GHG Mitigation Potential and Climate Change. Sustainability, 13(14), 7793. https://doi.org/10.3390/su13147793