Perspective Biomethane Potential and Its Utilization in the Transport Sector in the Current Situation of Latvia

Abstract

:1. Introduction

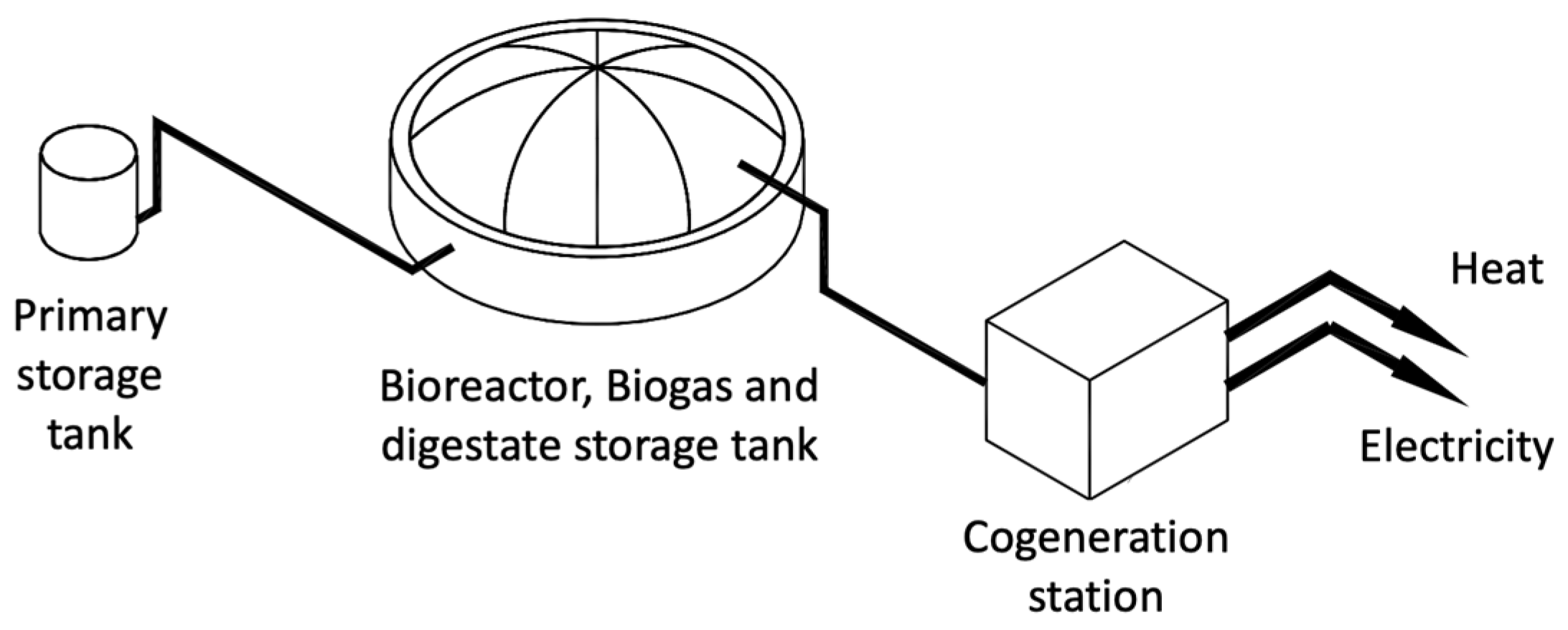

1.1. Production Process

1.1.1. Biogas and Its Properties

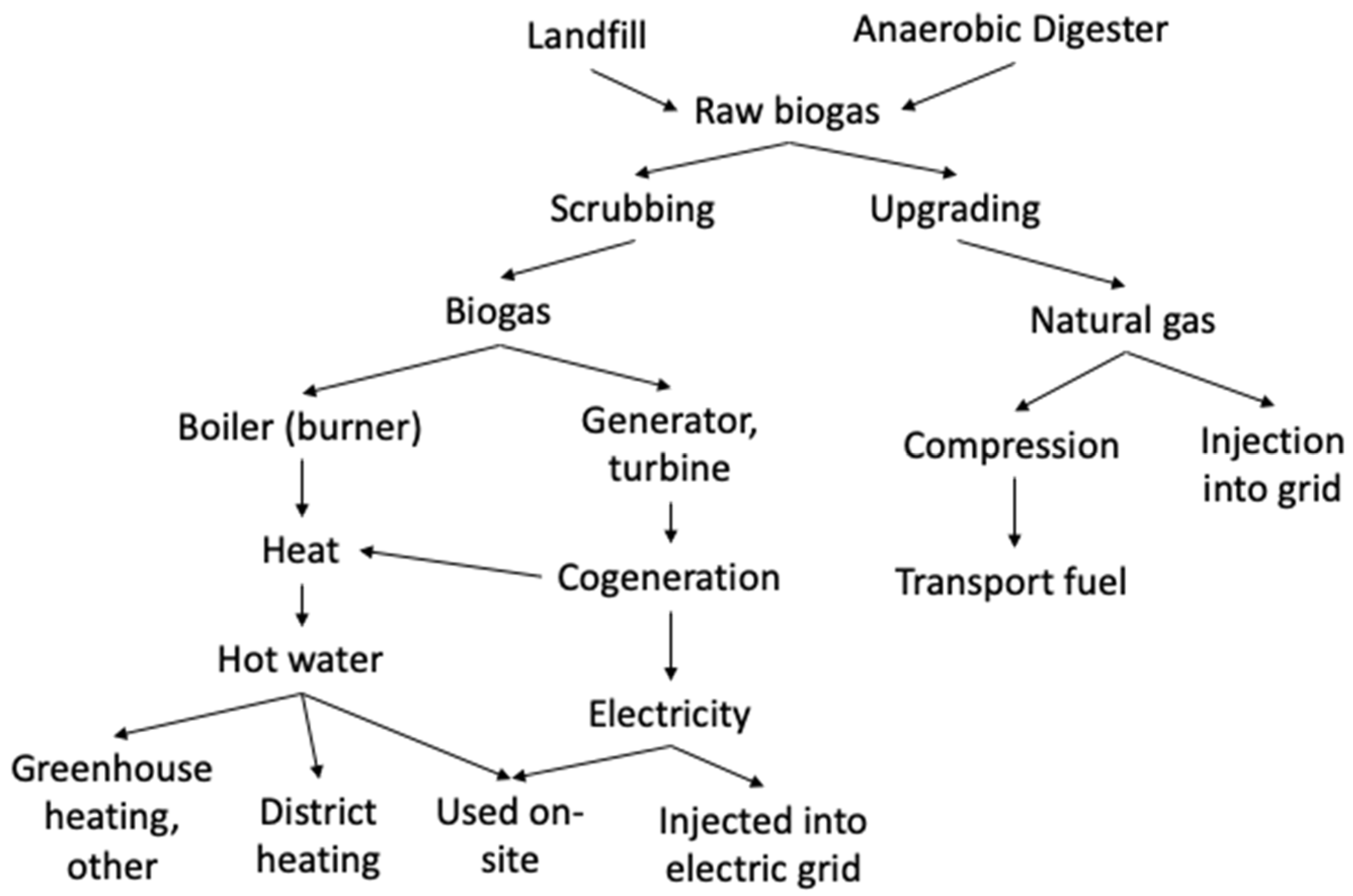

1.1.2. Biogas Utilization

1.2. Production Costs

- To avoid inconveniences, nuisances, and disputes linked to odors and increased traffic to and from the biogas plant, the site must be located at a suitable distance from populated areas.

- The direction of the prevailing winds must be taken into account to avoid wind-borne odors reaching populated areas.

- The area must have easy access to infrastructure, such as the electricity grid, to facilitate the sale of electricity, and transport routes to facilitate the transportation of raw materials and recycled digestate.

- Before starting construction, the soil of the area must be examined.

- The potential area must not be located in flood-affected areas.

- The area must be relatively close (centrally located) to agricultural raw materials (manure, slurry, energy crops) to reduce the transportation of raw materials distances, time, and costs.

- Due to cost efficiency, the biogas plant should be located as close as possible to the potential heat consumers. Alternatively, other potential heat consumers may be transferred, such as plants, greenhouses, etc., closer to the biogas plant site.

- The size of the site must be sufficient for the activities carried out and the amount of biomass supplied.

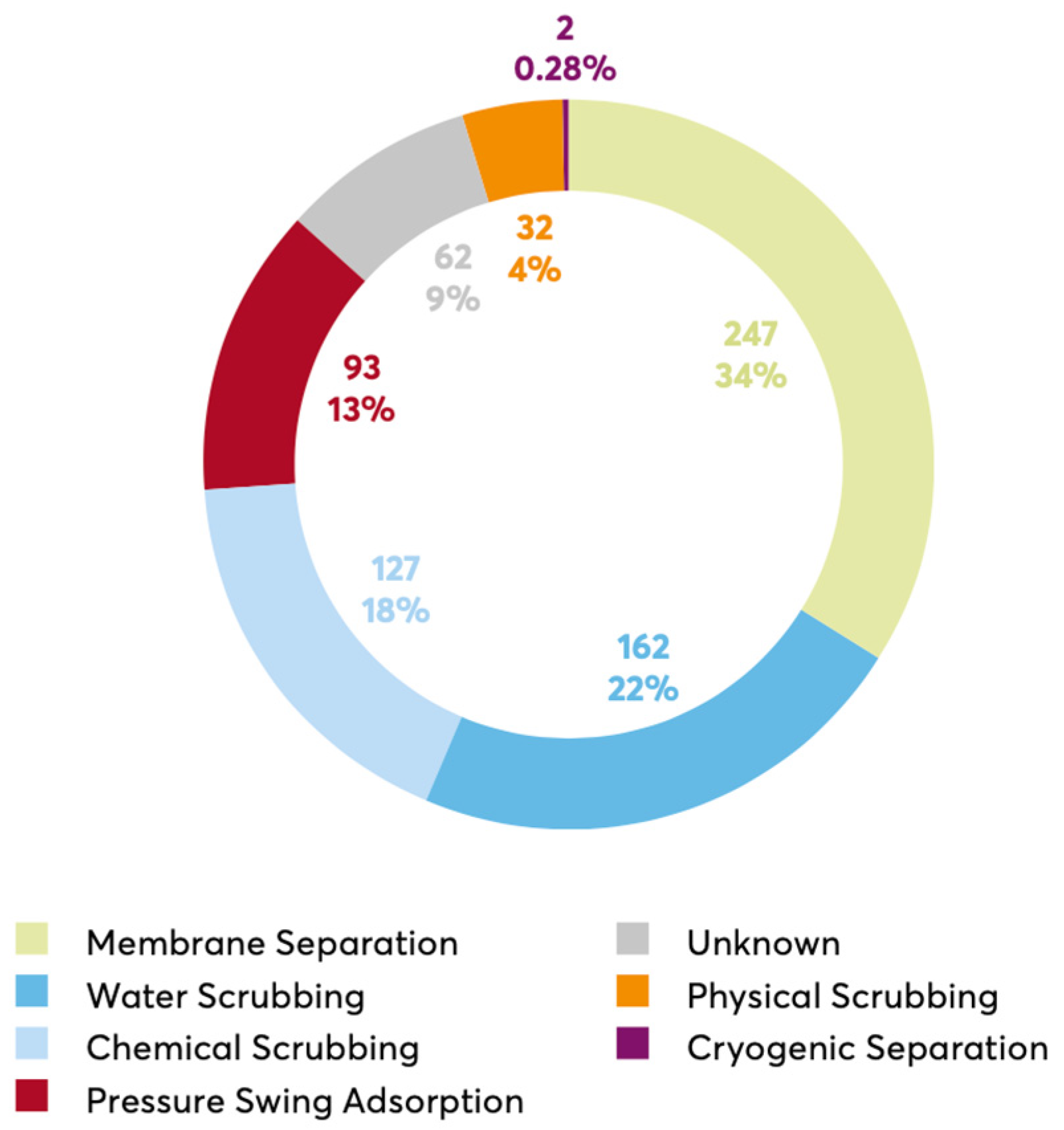

1.3. Biomethane Production

1.3.1. Biomethane as a Transport Fuel

1.3.2. Biomethane Injection in the Natural Gas Grid

2. Materials, Methods, and Assumptions

2.1. Biomethane Potential Calculations and Assumptions

2.1.1. Livestock Manure Potential

2.1.2. Wastewater Sludge Potential

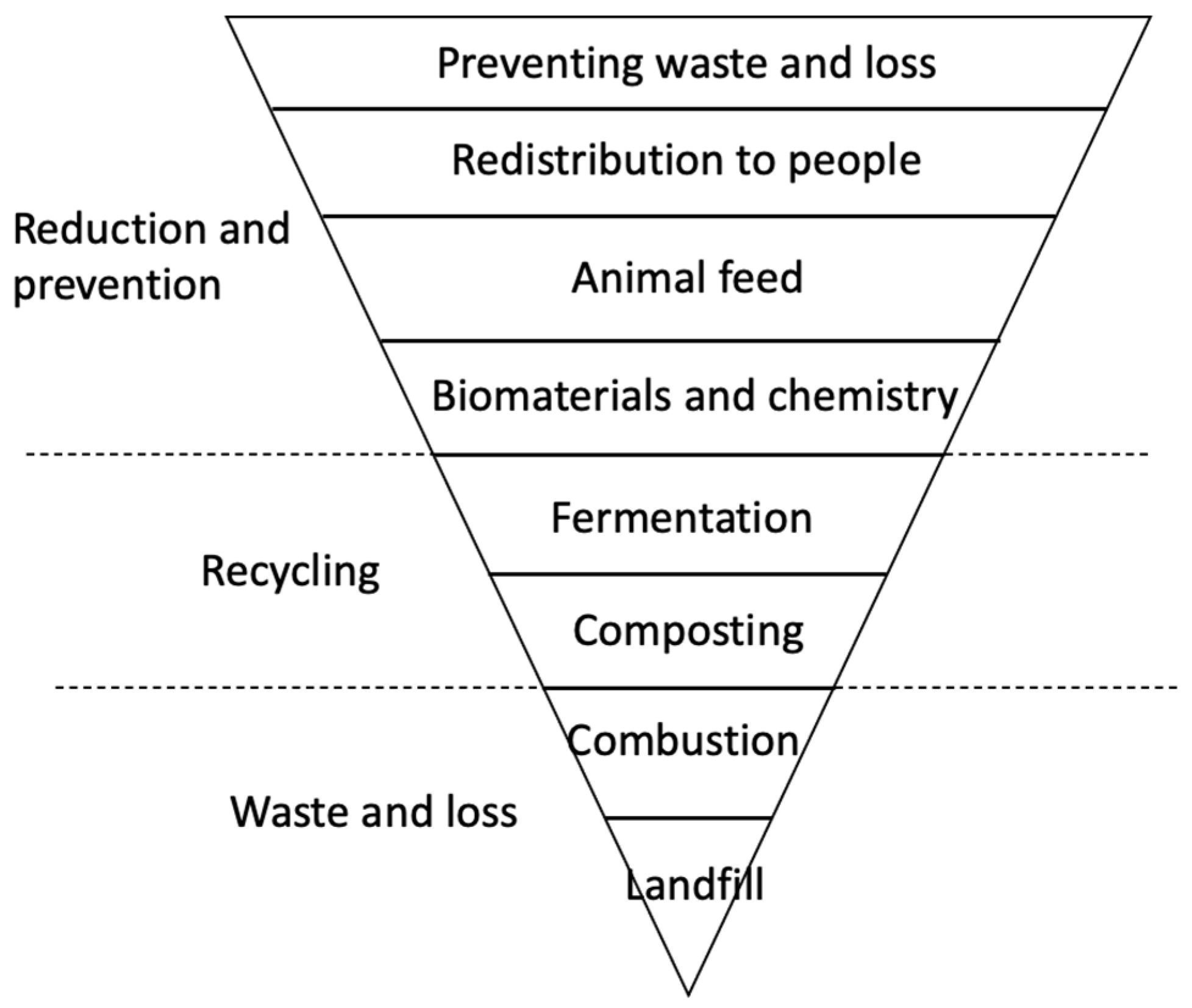

2.1.3. Municipal Organic Food Waste Potential

2.2. Emission Calculations and Assumptions

3. Results and Discussion

3.1. Biomethane Potential

3.1.1. Livestock Manure Potential

3.1.2. Wastewater Sludge Potential

3.1.3. Municipal Organic Food Waste Potential

3.1.4. Overall Biomethane Potential

3.2. Emissions

3.2.1. Livestock Manure Emissions

3.2.2. Wastewater Sludge Emissions

3.2.3. Municipal Organic Food Waste Emissions

3.2.4. Overall Emissions

4. Conclusions

- Total biomethane potential from processing livestock manure, wastewater sludge, and municipal organic food waste in Latvia is 2.21 to 4.28 PJ.

- 91% of biomethane potential comes from processing livestock manure, out of which ~61% share is from processing dairy cow manure. Emission savings from using livestock manure as feedstock for biomethane production is calculated to be 209%.

- If all the biomethane potential would be used in the transport sector, potentially 4.07–7.88% of total energy could be replaced, and total transport emissions would be with renewable biomethane. Total transport emissions would be 8.06–15.43% less.

- If diesel fuel would be replaced with renewable biomethane, potentially 6.30–12.19% of diesel could be replaced, and emissions would be reduced by 12.47 to 23.86%.

- If all the biomethane potential would be used in the transport sector replacing fossil fuel, 0.4–0.8 million tonnes of CO2-eq emissions could be avoided, and if the current total biogas station energy would be used combined with the total biomethane potential, 1.0–1.4 million tonnes of CO2-eq emissions could be avoided.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Shanmugam, K.; Baroth, A.; Nande, S.; Yacout, D.M.M.; Tysklind, M.; Upadhyayula, V.K.K. Social cost benefit analysis of operating compressed biomethane (CBM) transit buses in cities of developing nations: A case study. Sustainability 2019, 11, 4190. [Google Scholar] [CrossRef] [Green Version]

- Rasi, S.; Timonen, K.; Joensuu, K.; Regina, K.; Virkajärvi, P.; Heusala, H.; Tampio, E.; Luostarinen, S. Sustainability of vehicle fuel biomethane produced from grass silage in Finland. Sustainability 2020, 12, 3994. [Google Scholar] [CrossRef]

- Pääkkönen, A.; Aro, K.; Aalto, P.; Konttinen, J.; Kojo, M. The potential of biomethane in replacing fossil fuels in heavy transport-a case study on Finland. Sustainability 2019, 11, 4750. [Google Scholar] [CrossRef] [Green Version]

- Dubrovskis, V. Biogas from Landfills in Latvia; 6th International Conference on Renewable Energy Gas Technology: Malmö, Sweden, 2018; pp. 1–2. Available online: https://lfg-baltic.beic.nu/Resources/P89_Vilis_Dubrovskis.pdf (accessed on 1 March 2021).

- Dzene, I.; Barisa, A.; Rosa, M.; Dobraja, K. A Conceptual Methodology for Waste-to-biomethane Assessment in an Urban Environment. Energy Procedia 2016, 95, 3–10. [Google Scholar] [CrossRef] [Green Version]

- Svenskt Gastekniskt Center AB. Basic Data on Biogas; Serviceförvaltningen i Lunds kommun: Lund, Sweden, 2012; ISBN 9789185207107. [Google Scholar]

- Al-Wahaibi, A.; Osman, A.I.; Al-Muhtaseb, A.H.; Alqaisi, O.; Baawain, M.; Fawzy, S.; Rooney, D.W. Techno-economic evaluation of biogas production from food waste via anaerobic digestion. Sci. Rep. 2020, 10. [Google Scholar] [CrossRef] [PubMed]

- Kapoor, R.; Ghosh, P.; Kumar, M.; Vijay, V.K. Evaluation of biogas upgrading technologies and future perspectives: A review. Environ. Sci. Pollut. Res. 2019. [Google Scholar] [CrossRef]

- Navaratnasamy, M.; Koberstein, B.; Partington, B. Anaerobic Digesters. Available online: https://www.thepigsite.com/articles/anaerobic-digesters (accessed on 25 May 2021).

- Latvijas Biogāzes Asociācija. Priekšizpēte Par Biometāna Ražošanas un Uzglabāšanas Iespējām Latvijā; Latvijas Biogāzes Asociācija: Riga, Latvia, 2019. [Google Scholar]

- Blumberga, D.; Dzene, I.; Al Sedi, A.I.; Rucs, D.; Prasls, H.; Ketners, M.; Finstervalders, T.; Folka, S.; Jansens, R. Biogāze: Rokasgrāmata [Biogas: Handbook]; Big>East, Germany, 2009; ISBN 9789934805806. Available online: https://ortus.rtu.lv/science/en/publications/5847 (accessed on 1 March 2021).

- How Much Energy in Biogas Inoplex. Available online: https://www.inoplex.com.au/information/how-much-energy-is-in-biogas (accessed on 25 May 2021).

- Grab-rogaliński, K. Selected combustion parameters of biogas at elevated pressure—Temperature conditions. Siln. Spalinowe 2012, 51, 40–47. [Google Scholar]

- Sara, T. Fact Sheet—Biogas: Converting Waste to Energy. Available online: https://www.eesi.org/papers/view/fact-sheet-biogasconverting-waste-to-energy (accessed on 21 May 2021).

- Priekulis, J.; Aplocina, E.; Laurs, A. Chemical composition of digestate. Eng. Rural Dev. 2016, 2016, 381–386. [Google Scholar]

- Schmidt, A.M. 2014 UNL Manure Demonstration Day Manure vs. Commercial Fertilizer: Can soil and Crops Tell the Difference? University of Nebraska: Nebraska, NE, USA, 2014. [Google Scholar]

- European Biogas Association. Digestate Factsheet: The value of organic fertilisers for Europe’s economy, society and environment. Dig. Factsheet 2015, 9, 1–4. [Google Scholar]

- Mieldažys, R.; Jotautienė, E.; Jasinskas, A.; Pekarskas, J.; Zinkevičienė, R. Investigation of physical-mechanical properties and impact on soil of granulated manure compost fertilizers. J. Environ. Eng. Landsc. Manag. 2019, 27, 153–162. [Google Scholar] [CrossRef] [Green Version]

- Mieldazys, R.; Jotautiene, E.; Jasinskas, A.; Aboltins, A. Evaluation of physical mechanical properties of experimental granulated cattle manure compost fertilizer. Eng. Rural Dev. 2017, 16, 575–580. [Google Scholar] [CrossRef]

- Latvijas Biogāzes Asociācija. Biogāzes Attīstība Latvijā; Latvijas Biogāzes Asociācija: Riga, Latvia, 2020. [Google Scholar]

- Latvijas Valsts Ministru Kabinets Prasības Biometāna un Gāzveida Stāvoklī Pārvērstas Sašķidrinātās Dabasgāzes Ievadīšanai un Transportēšanai Dabasgāzes Pārvades un Sadales Sistēmā. Available online: https://likumi.lv/ta/id/285189-prasibas-biometana-un-gazveida-stavokli-parverstas-saskidrinatas-dabasgazes-ievadisanai-un-transportesanai-dabasgazes-parvades (accessed on 23 May 2021).

- Hoyer, K.; Hulteberg, C.; Svensson, M.; Jernberg, J. Energiforsk Technical Repport: Biogas Upgrading—Technical Review; Energiforsk: Stockholm, Sweden, 2016; ISBN 978-1-4673-6773-8. [Google Scholar]

- Repele, M.; Paturska, A.; Valters, K.; Bazbauers, G. Life cycle assessment of bio-methane supply system based on natural gas infrastructure. Agron. Res. 2014, 12, 999–1006. [Google Scholar]

- Bernacchi, S.; Weissgram, M.; Wukovits, W.; Herwig, C. Process efficiency simulation for key process parameters in biological methanogenesis. AIMS Bioeng. 2014, 1, 53–71. [Google Scholar] [CrossRef]

- Götz, M.; Lefebvre, J.; Mörs, F.; McDaniel Koch, A.; Graf, F.; Bajohr, S.; Reimert, R.; Kolb, T. Renewable Power-to-Gas: A technological and economic review. Renew. Energy 2016, 85, 1371–1390. [Google Scholar] [CrossRef] [Green Version]

- Bioenergy Europe Statistical Report 2020-Biomass Supply. 2020. Available online: https://bioenergyeurope.org/index.php?option=com_content&view=article&id=270 (accessed on 15 May 2021).

- Latvijas Standarts. Dabasgāze un Biometāns Lietošanai Transportā un Biometāns Ievadei Dabasgāzes Tīklā. 2. Daļa: Automobiļu Degvielas Specifikācija; LVS: Riga, Latvia, 2020. [Google Scholar]

- IRENA. Biogas for Road Vehicles Technology Brief. Available online: https://www.irena.org/publications/2017/Mar/Biogas-for-road-vehicles-Technology-brief (accessed on 26 May 2021).

- Dena, M.E.; Rubial, D.; Nedgia, F.; Focroul, D.; Ergar, A.K.; Agcs, S.K.; Elering, O.; Agcs, A.W.; Cib, L.M.; Eba, D.; et al. D3. 1 Guidelines for Establishing National Biomethane Registries Registries. Available online: https://www.regatrace.eu/wp-content/uploads/2019/11/REGATRACE-D3.1.pdf (accessed on 26 May 2021).

- Latvijas Republikas Zemkopības Ministrija. Kūtsmēslu Ieguve un Apsaimniekošana; Latvijas Republikas Zemkopības Ministrija: Riga, Latvia, 2008. [Google Scholar]

- Prussi, M.; Yugo, M.; De Prada, L.; Padella, M.; Edwards, M. JEC Well-To-Wheels Report v5; EUR 30284 EN; Publications Office of the European Union: Luxembourg, 2020; ISBN 978-92-76-20109-0. [Google Scholar]

- Lauksaimniecības Datu Centrs LDC. Publiskā Datu Bāze. Available online: http://pub.ldc.gov.lv/pub_stat.php?lang=lv (accessed on 15 May 2021).

- Latvijas Republikas Ministru Kabinets. Prasības Ūdens, Augsnes un Gaisa Aizsardzībai no Lauksaimnieciskās Darbības Izraisīta Piesārņojuma. In Minist. Kabineta Noteikumi Nr.834. Available online: https://likumi.lv/doc.php?id=271376 (accessed on 16 May 2021).

- Vides Aizsardzības un Reģionālās Attīstības Ministrija. Komunālo Notekūdeņu un Notekūdeņu Dūņu Apsaimniekošana Latvijā; Vides Aizsardzības un Reģionālās Attīstības Ministrija: Riga, Latvia, 2018. [Google Scholar]

- Eurostat Municipal Waste by Waste Management Operations. Available online: https://ec.europa.eu/eurostat/databrowser/view/env_wasmun/default/table?lang=en (accessed on 12 May 2021).

- EUROSTAT. Statistics Explained Municipal Waste Statistics—Statistics Explained; 2020; ISSN 2443-8219. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php/Municipal_waste_statistics#Municipal_waste_generation (accessed on 13 May 2021).

- Simon, J.M. A Zero Waste Hierarchy for Europe. Zero Waste Europe. Available online: https://zerowasteeurope.eu/2019/05/a-zero-waste-hierarchy-for-europe/ (accessed on 17 May 2021).

- Andriukaitis, V.; Billingham, C.; Borzan, B.; Cioci, G.; Depouillon, J.; Hartikainen, H.; Joensuu, K.; Kavasa, D.; Kruopienė, J.; Markey, E.; et al. (Food) Waste Not. Want Not. Why Food Waste Is a Big Deal and How to Scale-Up Preventive Action; ISBN 9789934864735. Available online: https://www.feps-europe.eu/attachments/publications/food_web.pdf (accessed on 18 May 2021).

- Stenmarck, Å.; Jensen, C.; Quested, T.; Moates, G.; Cseh, B.; Juul, S.; Parry, A.; Politano, A.; Redlingshofer, B.; Scherhaufer, S.; et al. FUSIONS Estimates of European Food Waste Levels; 2016; ISBN 9789188319012. Available online: https://www.eu-fusions.org/phocadownload/Publications/Estimates%20of%20European%20food%20waste%20levels.pdf (accessed on 17 May 2021).

- Bharathiraja, B.; Sudharsana, T.; Jayamuthunagai, J.; Praveenkumar, R.; Chozhavendhan, S.; Iyyappan, J. Retraction notice to “Biogas production—A review on composition, fuel properties, feed stock and principles of anaerobic digestion” (Renewable and Sustainable Energy Reviews (2018) 90 (570–582)). Renew. Sustain. Energy Rev. 2018, 94, 1229. [Google Scholar] [CrossRef]

- Kythreotou, N.; Tassou, S.A.; Florides, G. An assessment of the biomass potential of Cyprus for energy production. Energy 2012, 47, 253–261. [Google Scholar] [CrossRef]

- WorldData.info. Energy Consumption in Latvia. Available online: https://www.worlddata.info/europe/ireland/energy-consumption.php (accessed on 17 May 2021).

- Bés, K.; Brisola, M.C.; Crecencio, R.B.; Bitner, D.S.; Frigo, A.; Rampazzo, L.; Faria, G.A.; Araujo, D.N.; da Silva, A.S.; Stefani, L.M. Evaluation of a novel anaerobic co-digestion system for disposal of dead swine and manure: An important tool in animal production. Int. J. Recycl. Org. Waste Agric. 2020, 9, 229–236. [Google Scholar] [CrossRef]

- Chiapetta, H.; Harrison, J.; Gay, J.; McClanahan, R.; Whitefield, E.; Evermann, J.; Nennich, T.; Gamroth, M. Reduction of Pathogens in Bovine Manure in Three Full-scale Commercial Anaerobic Digesters. Water. Air. Soil Pollut. 2019, 230. [Google Scholar] [CrossRef]

- Rajagopal, R.; Ghosh, D.; Ashraf, S.; Goyette, B.; Zhao, X. Effects of low-temperature dry anaerobic digestion on methane production and pathogen reduction in dairy cow manure. Int. J. Environ. Sci. Technol. 2019, 16, 4803–4810. [Google Scholar] [CrossRef]

- Jun, P.; Gibbs, M.; Gaffney, K. CH4 and N2O emissions from livestock manure. Backgr. Pap. Good Pract. Guid. Uncertain. Manag. Natl. Greenh. Gas. Invent. 2000, 2, 321–338. [Google Scholar]

- Skrebele, A.; Štelce, V.; Lupkina, L.; Rubene, L.; Cakars, I.; Siņics, L.; Bārdule, A. Latvia’s Informative Inventory Report. Available online: https://www.meteo.lv/fs/CKFinderJava/userfiles/files/Vide/Gaiss/Piesarnojums/New/IIR_2020_NECD.pdf (accessed on 18 May 2021).

- Latvijas Republikas Zemkopības Ministrija. Gaisa Kvalitātes Aizsardzība. Available online: https://www.zm.gov.lv/lauksaimnieciba/statiskas-lapas/vides-aizsardzibas-prasibas-lauksaimnieciskai-darbibai/gaisa-kvalitates-aizsardziba?nid=2751 (accessed on 10 May 2021).

- Frolova, O.; Priekulis, J.; Berzina, L.; Aboltins, A. Trend of ammonia emissions from livestock sector in Latvia. Eng. Rural Dev. 2020, 19, 598–602. [Google Scholar] [CrossRef]

- Rotz, C.A. Modeling greenhouse gas emissions from dairy farms. J. Dairy Sci. 2018, 101, 6675–6690. [Google Scholar] [CrossRef] [PubMed]

- Worldometer Latvia CO2 Emissions. 2016. Available online: https://www.worldometers.info/co2-emissions/latvia-co2-emissions/ (accessed on 12 May 2021).

- CSDD. Statistics of Registered Vehicle. 2021. Available online: https://www.csdd.lv/vehicles/statistics-of-registered-vehicle (accessed on 13 May 2021).

- Statista Latvia. Annual Greenhouse Gas Emissions of the Transport Sector 2017|Statista; Statista Latvia. Available online: https://www.statista.com/statistics/411863/annual-greenhouse-gas-emissions-of-the-transport-sector-in-germany/ (accessed on 13 May 2021).

- EEA. Greenhouse Gas Emissions from Transport in Europe—European Environment Agency. Europe Environment Agency. 2018. Available online: https://www.eea.europa.eu/data-and-maps/indicators/transport-emissions-of-greenhouse-gases-7/assessment%0Ahttps://www.eea.europa.eu/data-and-maps/indicators/transport-emissions-of-greenhouse-gases-7/assessment%0Ahttps://www.eea.europa.eu/data-and-maps/ind (accessed on 14 May 2021).

| Lower Heating Value | Higher Heating Value | |||

|---|---|---|---|---|

| Biogas CH4 Content, % | MJ/m3 | kWh/m3 | MJ/m3 | kWh/m3 |

| 45 | 16.1 | 4.47 | 17.9 | 4.97 |

| 50 | 17.9 | 4.97 | 19.9 | 5.53 |

| 55 | 19.7 | 5.47 | 19.9 | 6.08 |

| 60 | 21.5 | 5.96 | 23.9 | 6.63 |

| 65 | 23.3 | 6.46 | 25.9 | 7.18 |

| 70 | 25.1 | 6.96 | 27.9 | 7.74 |

| Upgraded Biogas | ||||

| 95 | 34.0 | 9.44 | 37.8 | 10.50 |

| 96 | 34.4 | 9.54 | 38.2 | 10.61 |

| 97 | 34.7 | 9.64 | 38.6 | 10.72 |

| 98 | 35.1 | 9.74 | 39.0 | 10.83 |

| 99 | 35.4 | 9.84 | 39.4 | 10.94 |

| Manure Type | Cattle Manure | Pig Liquid Manure | Poultry Manure |

|---|---|---|---|

| Dry matter, % | 7.28 | 6.26 | 8.85 |

| Total amount of N, % DM | 3.51 | 7.61 | 6.35 |

| Ammonium N, % DM | 2.82 | 5.03 | 6.00 |

| Phosphorus P2O5, % DM | 2.68 | 3.57 | 6.20 |

| Potassium K2O, % DM | 5.15 | 5.03 | 6.15 |

| Biomass | Biogas Production, m3/kg |

|---|---|

| Pig manure | 0.34–0.68 |

| Beef manure | 0.2–0.4 |

| Poultry manure | 0.37–0.64 |

| Wastewater sludge | 0.2–0.6 |

| Organic household food waste | 0.11 |

| Biogas Yield, m3 (60% CH4) | Biomethane Yield, m3 (97% CH4) | Biomethane Potential, GWh | Biomethane Potential, PJ | |||||

|---|---|---|---|---|---|---|---|---|

| Min | Max | Min | Max | Min | Max | Min | Max | |

| Dairy cow | 56,563,353 | 113,126,706 | 34,987,641 | 69,975,282 | 337 | 675 | 1.213 | 2.430 |

| Poultry | 21,384,180 | 36,988,852 | 13,227,328 | 22,879,702 | 128 | 221 | 0.461 | 0.796 |

| Pig | 15,809,154 | 31,618,308 | 9,778,858 | 19,557,716 | 94 | 189 | 0.338 | 0.680 |

| Total | 93,756,687 | 181,733,866 | 57,993,827 | 112,412,700 | 559 | 1 084 | 2.012 | 3.902 |

| Average | 137,745,277 | 85,203,264 | 822 | 2.958 | ||||

| Biogas Yield, m3 (60% CH4) | Biomethane Yield, m3 (97% CH4) | Biomethane Potential, GWh | Biomethane Potential, PJ | |||||

|---|---|---|---|---|---|---|---|---|

| Min | Max | Min | Max | Min | Max | Min | Max | |

| Wastewater sludge | 3,822,190 | 11,466,569 | 2,285,433 | 6,856,299 | 22.04 | 73.49 | 0.079 | 0.265 |

| Average | 7,644,379 | 4,570,866 | 47.76 | 0.172 | ||||

| Biogas Yield, m3 (60% CH4) | Biomethane Yield, m3 (97% CH4) | Biomethane Potential | ||

|---|---|---|---|---|

| GWh | PJ | |||

| Municipal organic food waste | 5,274,876 | 3,262,810 | 31.46 | 0.133 |

| Biogas Yield, m3 (60% CH4) | Biomethane Yield, m3 (97% CH4) | Biomethane Potential, GWh | Biomethane Potential, PJ | |||||

|---|---|---|---|---|---|---|---|---|

| Min | Max | Min | Max | Min | Max | Min | Max | |

| Livestock manure | 93,756,687 | 181,733,866 | 57,993,827 | 112,412,700 | 559 | 1,084 | 2.013 | 3.902 |

| Wastewater sludge | 3,822,190 | 11,466,569 | 2,285,433 | 6,856,299 | 22.04 | 73.49 | 0.079 | 0.265 |

| Municipal organic food waste | 5,274,876 | 3,262,810 | 31.46 | 0.113 | ||||

| Total | 102,853,753 | 193,200,435 | 63,542,070 | 119,268,999 | 613 | 1.189 | 2.211 | 4.280 |

| Average | 148,027,094 | 91,405,535 | 901 | 3.243 | ||||

| Biomethane Potential, PJ | Emissions If Diesel, Tonnes CO2-eq | Potential Emissions, Tonnes CO2-eq | Avoidable Emissions, Tonnes CO2-eq | |||||

|---|---|---|---|---|---|---|---|---|

| Min | Max | Min | Max | Min | Max | Min | Max | |

| Livestock manure | 2.013 | 3.902 | 189,222 | 366,788 | −207,138 | −401,516 | −396,360 | −768,304 |

| Wastewater sludge | 0.079 | 0.265 | 7426 | 24,910 | 1762 | 5910 | −5664 | −19,001 |

| Municipal organic food waste | 0.113 | 10 650 | 1 076 | -9 574 | ||||

| Total | 2.211 | 4.280 | 207,298 | 391,698 | −204,300 | −395,606 | −411,598 | −787,304 |

| Average | 3.243 | 299,498 | −299,953 | −599,451 | ||||

| Current biogas stations | 3.072 | 288,731 | −316,068 | −604,799 | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Argalis, P.P.; Vegere, K. Perspective Biomethane Potential and Its Utilization in the Transport Sector in the Current Situation of Latvia. Sustainability 2021, 13, 7827. https://doi.org/10.3390/su13147827

Argalis PP, Vegere K. Perspective Biomethane Potential and Its Utilization in the Transport Sector in the Current Situation of Latvia. Sustainability. 2021; 13(14):7827. https://doi.org/10.3390/su13147827

Chicago/Turabian StyleArgalis, Pauls P., and Kristine Vegere. 2021. "Perspective Biomethane Potential and Its Utilization in the Transport Sector in the Current Situation of Latvia" Sustainability 13, no. 14: 7827. https://doi.org/10.3390/su13147827