Exploring the Potential in LID Technologies for Remediating Heavy Metals in Carwash Wastewater

Abstract

:1. Introduction

2. Carwash Wastewater: A Global Perspective

2.1. Wastewater Volumes Generated at Carwash Facilities

2.2. CWW Contaminant Characteristics

2.2.1. Pollutants Other than Heavy Metals

| Parameter | Concentrations | EPA | WHO | EQA |

|---|---|---|---|---|

| pH | 6.51–8.74 [40] 6.96 [14] | 6–9 | 6.5–8 [42] | 6–9 |

| BOD5 (mg/L) | 10.5–11.5 [40] 27–650 [14] | 20 | <5 [42] | |

| COD (mg/L) | 75–738 [40] 220 [14] | 50 | N/A | <50 |

| Turbidity (NTU) | 34.7–86 [40] 275.1 [14] 109–4000 [14] | <1 [43] | <5 | |

| Electrical conductivity (EC) (µS/cm) | 150.7–260.7 [40] 62.5 [14] | 400 [44] | ||

| Total dissolved solids (TDS) (mg/L) | 89.2–151.8 [40] 362–686 [14] | 300 [45] | ||

| Dissolved oxygen (DO) (mg/L) | 2.55 [14] 0.1 [14] | >7 | ||

| Surfactants (mg/L) | 9.20 [41] | |||

| Total phosphorus (TP) (mg/L) | 0.17 [41] | 0.1 * | ||

| Total suspended solids (TSS) (mg/L) | 114.67 [41] | 40 * | ||

| Oils and grease (mg/L) Petroleum, hydrocarbons, gasoline mg/L | 12–43 [14] 5–24 [14] | |||

| Ammonium (mg/L) | 0.4–75 [14] | |||

| Heterotrophic bacteria (CFU/100 mL) | 2800–4600 [14] |

2.2.2. Heavy Metal Pollutants

2.3. Conventional Treatment Methods for CWW

3. LID Technologies for Heavy Metal Remediation

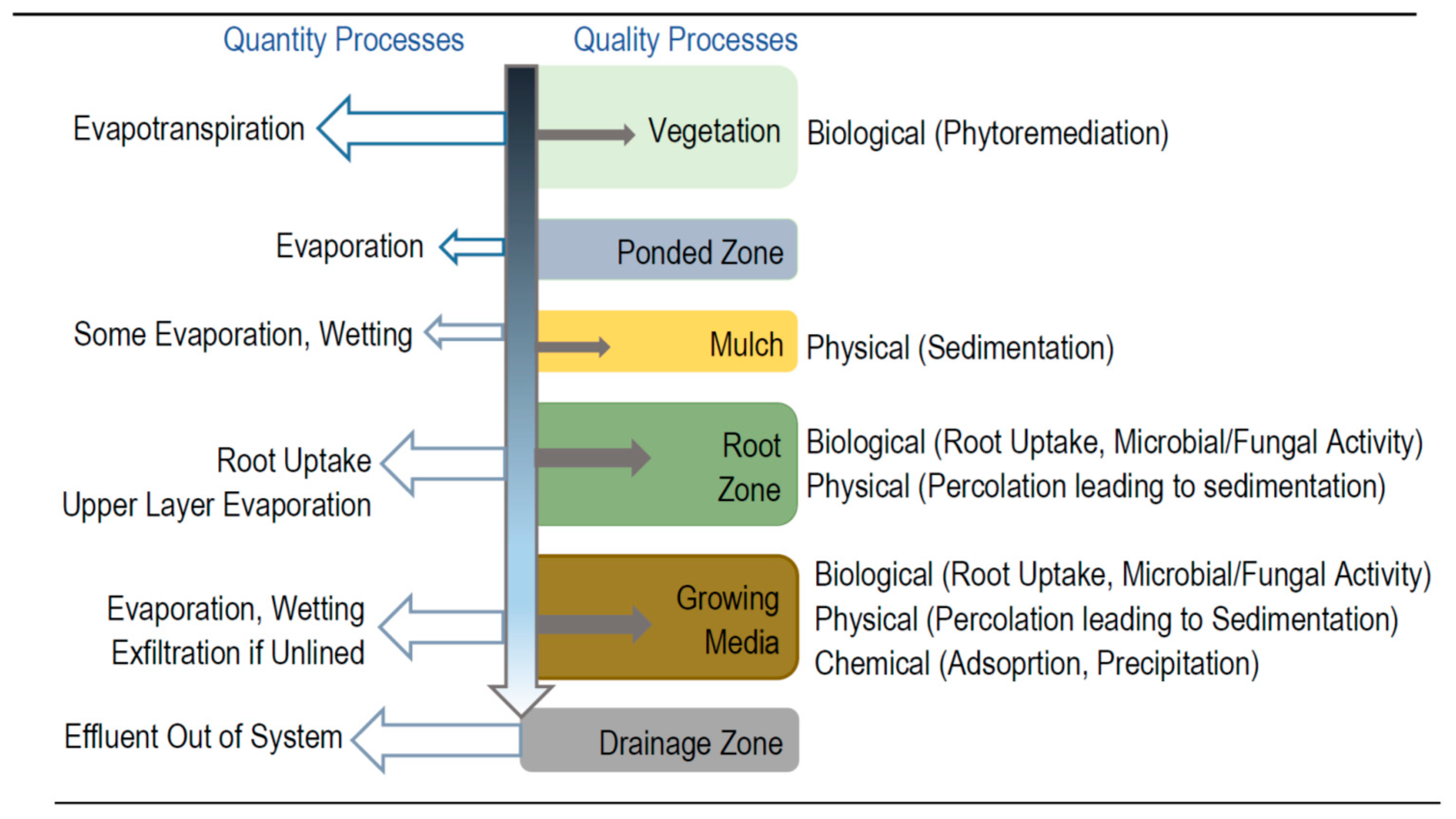

3.1. Vegetated LIDs

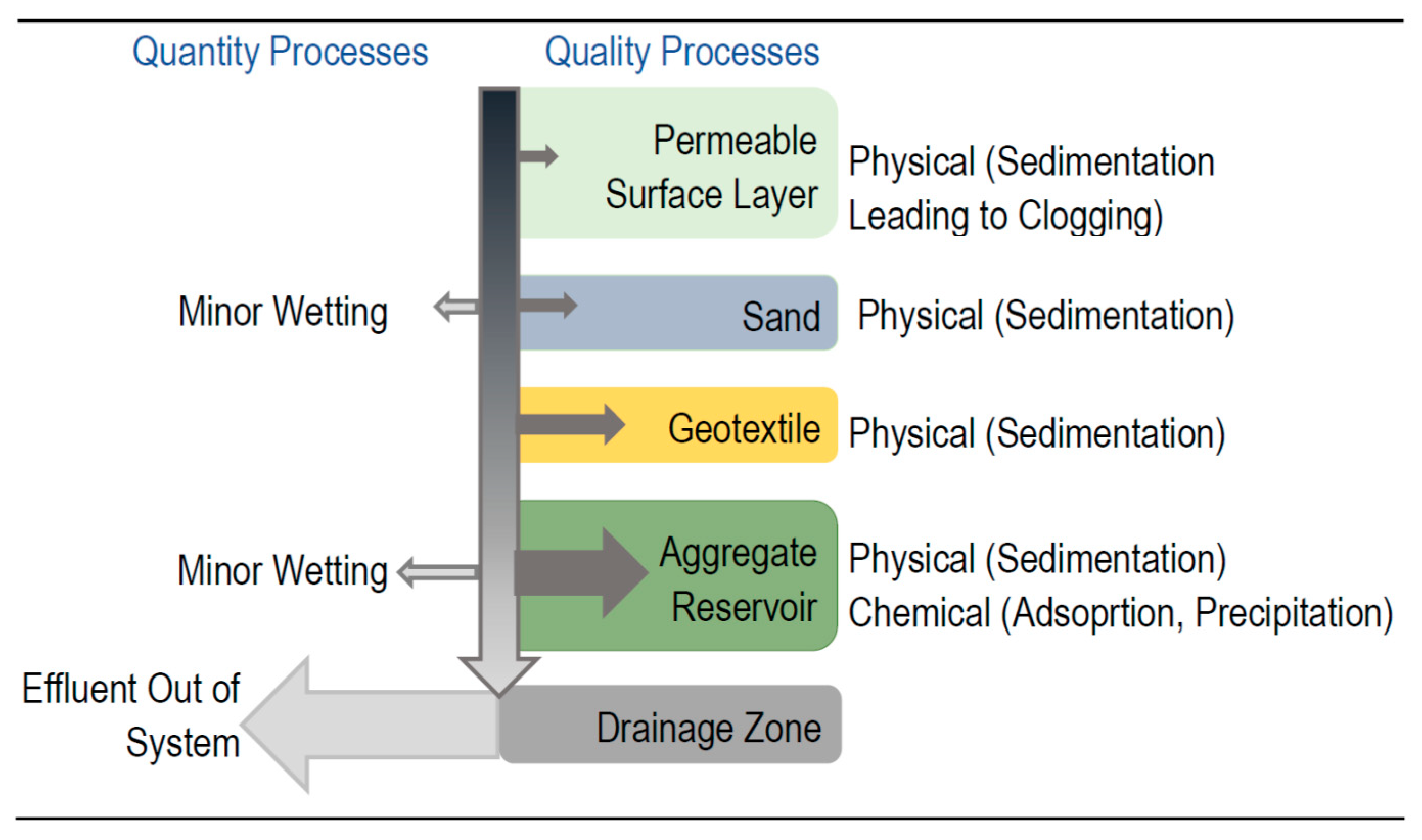

3.2. Unvegetated LIDs

4. Discussion of LID Potential for Use in CWW Treatment

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Correction Statement

References

- Abagale, F.; Sarpong, D.; Ojediran, O.; Osei, R.; Abdul-Ganiyu, S.; Birteeb, P. Heavy metal concentration in wastewater from car washing bays used for agriculture in the tamale metropolis, Ghana. Int. J. Curr. Res. 2013, 5, 1571–1576. [Google Scholar]

- Talebzadeh, F.; Sobhanardakani, S.; Zandipak, R. Effective adsorption of As(V) and V(V) ions from water samples using 2,4-dinitrophenylhydrazine functionalized sodium dodecyl sulfate-coated magnetite nanoparticles. Sep. Sci. Technol. 2017, 52, 622–633. [Google Scholar] [CrossRef]

- Tchounwou, P.B.; Yedjou, C.Y.; Platlolla, A.K.; Sutton, D.J. Heavy metals, toxicity and the environment. Exp. Suppl. 2012, 101, 133–164. [Google Scholar] [CrossRef]

- Al-Odwani, A.; Ahmed, M.; Bou-Hamad, S. Carwash water reclamation in Kuwait. Desalination 2007, 206, 17–28. [Google Scholar] [CrossRef]

- Bhatti, Z.A.; Mahmood, Q.; Raja, I.A.; Malik, A.H.; Khan, M.S.; Wu, D. Chemical oxidation of carwash industry wastewater as an effort to decrease water pollution. Phys. Chem. Earth Parts A/B/C 2011, 36, 465–469. [Google Scholar] [CrossRef]

- Talebzadeh, F.; Valeo, C.; Gupta, R. Cadmium Water Pollution Associated with Motor Vehicle Brake Parts. IOP Conf. Ser. Earth Environ. Sci. 2021, 691, 012001. [Google Scholar] [CrossRef]

- Boussu, K.; Kindts, C.; Vandecasteele, C.; Van der Bruggen, B. Applicability of nanofiltration in the carwash industry. Sep. Purif. Technol. 2007, 54, 139–146. [Google Scholar] [CrossRef]

- Gupta, R.; Sharma, N.; Valeo, C.; Garg, M.; Sharma, A.; Aneja, S.; Prasher, S.; Constabel, C. Novel Integration of Geopolymer Pavers, Silva Cells and Poplar Trees for In-Situ Treatment of Car-Wash Wastewater. Sustainability 2020, 12, 8472. [Google Scholar] [CrossRef]

- Nadzirah, Z.; Haslina, H.N.; Rafidah, H. Removal of Important Parameter from Car Wash Wastewater—A Review. Appl. Mech. Mater. 2015, 773–774, 1153–1157. [Google Scholar] [CrossRef]

- Duncan, R.N. Electroless nickel and the end-of-life vehicle directive. J. Clean. Prod. 2006, 11, 1–15. [Google Scholar]

- Zaneti, R.; Etchepare, R.; Rubio, J. More environmentally friendly vehicle washes: Water reclamation. J. Clean. Prod. 2012, 37, 115–124. [Google Scholar] [CrossRef]

- Oknich, J. The Perceived Environmental Impact of Car Washing. Jen Oknich Ramsey-Washington Metro Watershed District. Ramsey-Washington Metro Watershed District. 2002, p. 9. Available online: https://docplayer.net/7410053-The-perceived-environmental-impact-of-car-washing-jen-oknich-ramsey-washington-metro-watershed-district-9-04-02.html (accessed on 12 January 2021).

- Partzsch, L. Smart regulation for water innovation—The case of decentralized rainwater technology. J. Clean. Prod. 2009, 17, 985–991. [Google Scholar] [CrossRef]

- Al-Gheethi, A.A.; Mohamed, R.M.S.R.; Rahman, M.A.A.; Johari, M.R.; Kassim, A.H.M. Treatment of Wastewater from Car Washes Using Natural Coagulation and Filtration System. IOP Conf. Ser. Mater. Sci. Eng. 2016, 136, 012046. [Google Scholar] [CrossRef]

- Tekere, M.; Sibanda, T.; Maphangwa, K.W. An assessment of the physicochemical properties and toxicity potential of carwash effluents from professional carwash outlets in Gauteng Province, South Africa. Environ. Sci. Pollut. Res. 2016, 23, 11876–11884. [Google Scholar] [CrossRef]

- Pishgar, R.; Lee, J.; Dominic, J.A.; Hosseini, S.; Tay, J.H.; Chu, A. Augmentation of Biogranules for Enhanced Performance of Full-Scale Lagoon-Based Municipal Wastewater Treatment Plants. Appl. Biochem. Biotechnol. 2020, 191, 426–443. [Google Scholar] [CrossRef]

- Valeo, C.; Gupta, R. Hybrid absorbable landscapes: Treatment trains for urban stormwater management, monitoring, modeling, design, and implementation. In Proceedings of the Canadian Society of Civil Engineering Annual Conference, Vancouver, BC, Canada, 31 May–3 June 2017; Volume 733, p. 10. [Google Scholar]

- Xu, Z.; Valeo, C.; Chu, A.; Zhao, Y. The Efficacy of Whole Oyster Shells for Removing Copper, Zinc, Chromium, and Cadmium Heavy Metal Ions from Stormwater. Sustainability 2021, 13, 4184. [Google Scholar] [CrossRef]

- Nkansah, M.A.; Donkoh, M.; Akoto, O.; Ephraim, J.H. Preliminary Studies on the Use of Sawdust and Peanut Shell Powder as Adsorbents for Phosphorus Removal from Water. Emerg. Sci. J. 2019, 3, 33. [Google Scholar] [CrossRef]

- Kaykhosravi, S.; Khan, U.T.; Jadidi, M.A. The Effect of Climate Change and Urbanization on the Demand for Low Impact Development for Three Canadian Cities. Water 2020, 12, 1280. [Google Scholar] [CrossRef]

- Huang, J.; Valeo, C.; He, J.; Chu, A. Winter Performance of Inter-Locking Pavers—Stormwater Quantity and Quality. Water 2012, 4, 995. [Google Scholar] [CrossRef]

- Allafchi, F.; Valeo, C.; Chu, A.; He, J.; Lee, W.; Oshkai, P.; Neumann, N. A velocity meter for quantifying advection velocity vectors in large water bodies. Sensors 2020, 20, 7204. [Google Scholar] [CrossRef] [PubMed]

- Spraakman, S.; Rodgers, T.; Monri-Fung, H.; Nowicki, A.; Diamond, M.; Passeport, E.; Thuna, M.; Drake, J. A Need for Standardized Reporting: A Scoping Review of Bioretention Research 2000–2019. Water 2020, 12, 3122. [Google Scholar] [CrossRef]

- Valeo, C.; He, J.; Amell, B.; Chu, A. A Look into the Barriers to Widespread Use of Rain Gardens in Our Communities; Municipal World: Sparta, ON, Canada, 2019; Volume 129, p. 5. [Google Scholar]

- Spraakman, S. Bioretention Systems for Stormwater Management: Assessment, Performance and Changes over Time. Ph.D. Thesis, Civil and Mineral Engineering, University of Toronto, Toronto, ON, Canada, 2021; p. 299. [Google Scholar]

- Khan, U.; Valeo, C.; Chu, A.; Van Duin, B. Bioretention cell efficacy in cold climates: Part 1—hydrologic performance. Can. J. Civ. Eng. 2012, 39, 1210–1221. [Google Scholar] [CrossRef]

- PennState Extension. Rain Gardens (BioRetention Cells)—A Stormwater BMP. Available online: https://extension.psu.edu/rain-gardens-bioretention-cells-a-stormwater-bmp (accessed on 28 July 2021).

- Minnesota Pollution Control Agency. Bioretention Device Cost Estimate Worksheet. Available online: https://stormwater.pca.state.mn.us/index.php/Bioretention_device_cost_estimate_worksheet (accessed on 28 July 2021).

- Spraakman, S.; Van Seters, T.; Drake, J.; Passeport, E. How has it changed? A comparative field evaluation of bioretention infiltration and treatment performance post-construction and at maturity. Ecol. Eng. 2020, 158, 106036. [Google Scholar] [CrossRef]

- Roy, A.H.; Wenger, S.J.; Fletcher, T.D.; Walsh, C.J.; Ladson, A.; Shuster, W.; Thurston, H.W.; Brown, R. Impediments and Solutions to Sustainable, Watershed-Scale Urban Stormwater Management: Lessons from Australia and the United States. Environ. Manag. 2008, 42, 344–359. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.; Valeo, C.; He, J.; Chu, A. Three Types of Permeable Pavements in Cold Climates: Hydraulic and Environmental Performance. J. Environ. Eng. 2016, 142, 401–417. [Google Scholar] [CrossRef]

- Valeo, C.; Gupta, R. Determining Surface Infiltration Rate of Permeable Pavements with Digital Imaging. Water 2018, 10, 133. [Google Scholar] [CrossRef]

- Lake Superior Duluth, Streams.org. Bioretention Basins. Available online: www.lakesuperiorstreams.org/stormwater/toolkit/bioretention.html (accessed on 28 July 2021).

- Minnesota Stormwater Steering Committee. The Minnesota Stormwater Manual; Minnesota Pollution Control Agency: St. Paul, MN, USA, 2005; Version 1; p. 718. Available online: www.pca.state.mn.us/water/stormwater/stormwater-manual.html (accessed on 28 July 2021).

- Low Impact Development Center, Inc. Low Impact Development (LID) Urban Design Tools Website. Available online: www.lid-stormwater.net/bio_costs.htm (accessed on 28 July 2021).

- Home Advisor. How Much Does Permeable Pavement Cost? Available online: www.homeadvisor.com/cost/garages/permeable-pavement/ (accessed on 28 July 2021).

- Boluarte, I.A.R.; Andersen, M.; Pramanik, B.; Chang, C.-Y.; Bagshaw, S.; Farago, L.; Jegatheesan, V.; Shu, L. Reuse of car wash wastewater by chemical coagulation and membrane bioreactor treatment processes. Int. Biodeterior. Biodegrad. 2016, 113, 44–48. [Google Scholar] [CrossRef]

- Hashim, N.H.; Zayadi, N. Pollutants Characterization of Car Wash Wastewater. MATEC Web Conf. 2016, 47, 5008. [Google Scholar] [CrossRef]

- Brown, C.; Consulting, C.B. Water Use, Evaporation and Carryout; Chris Brown Consulting: San Marcos, CA, USA, 2018; pp. 36–45. [Google Scholar]

- Lau, W.; Ismail, A.F.; Firdaus, S. Car wash industry in Malaysia: Treatment of car wash effluent using ultrafiltration and nanofiltration membranes. Sep. Purif. Technol. 2013, 104, 26–31. [Google Scholar] [CrossRef]

- Bakacs, M.E.; Yergeau, S.E.; Obropta, C.C. Assessment of Car Wash Runoff Treatment Using Bioretention Mesocosms. J. Environ. Eng. 2013, 139, 1132–1136. [Google Scholar] [CrossRef]

- Rickwood, C.; Carr, G.M. Global Drinking Water Quality Index: Development and Sensitivity Analysis; UNEP GEMS Water Programme Office: Koblenz, Germany, 2007; p. 60. ISBN 92-95039-14-9. [Google Scholar]

- World Health Organization. Water Quality and Health—Review of Turbidity: Information for Regulators and Water Suppliers. 2017, p. 10. Available online: https://www.who.int/water_sanitation_health/publications/turbidity-information-200217.pdf (accessed on 10 January 2021).

- Meride, Y.; Ayenew, B. Drinking water quality assessment and its effects on residents health in Wondo genet campus, Ethiopia. Environ. Syst. Res. 2016, 5, 1. [Google Scholar] [CrossRef]

- Chaitanya, V.S. Minimum TDS Level for Drinking Water (Total Dissolved Solids). Kitchenarena. 2018. Available online: https://www.kitchenarena.in/total-dissolved-solids/ (accessed on 10 January 2021).

- Nguegang, B.; Sibanda, T.; Tekere, M. Cultivable bacterial diversity, physicochemical profiles, and toxicity determination of car wash effluents. Environ. Monit. Assess. 2019, 191, 478. [Google Scholar] [CrossRef]

- Kinuthia, G.K.; Ngure, V.; Beti, D.; Lugalia, R.; Wangila, A.; Kamau, L. Levels of heavy metals in wastewater and soil samples from open drainage channels in Nairobi, Kenya: Community health implication. Sci. Rep. 2020, 10, 8434. [Google Scholar] [CrossRef]

- Bilos, C.; Colombo, J.C.; Skorupka, C.N.; Presa, M.J.R. Sources, distribution and variability of airborne trace metals in La Plata City area, Argentina. Environ. Pollut. 2001, 111, 149–158. [Google Scholar] [CrossRef]

- Manno, E.; Varrica, D.; Dongarrà, G. Metal distribution in road dust samples collected in an urban area close to a petro-chemical plant at Gela, Sicily. Atmos. Environ. 2006, 40, 5929–5941. [Google Scholar] [CrossRef]

- Lu, X.; Wang, L.; Li, L.Y.; Lei, K.; Huang, L.; Kang, D. Multivariate statistical analysis of heavy metals in street dust of Baoji, NW China. J. Hazard. Mater. 2010, 173, 744–749. [Google Scholar] [CrossRef] [PubMed]

- Grigoratos, T. Regulation on brake/tire composition. In Non-Exhaust Emissions; Elsevier BV: Amsterdam, The Netherlands, 2018; pp. 89–100. [Google Scholar]

- Saha, J.K.; Panwar, N.R.; Singh, M.V. Determination of lead and cadmium concentration limits in agricultural soil and municipal solid waste compost through an approach of zero tolerance to food contamination. Environ. Monit. Assess. 2010, 168, 397–406. [Google Scholar] [CrossRef]

- Huang, Y.; He, C.; Shen, C.; Guo, J.; Mubeen, S.; Yuan, J.; Yang, Z. Toxicity of cadmium and its health risks from leafy vegetable consumption. Food Funct. 2017, 46, 231–242. [Google Scholar] [CrossRef]

- Wang, W. Interactions of trace metals and different marine food chains. Mar. Ecol. Prog. Ser. 2002, 243, 295–309. [Google Scholar] [CrossRef]

- Fthenakis, V.M. Life cycle impact analysis of cadmium in CdTe PV production. Renew. Sustain. Energy Rev. 2004, 8, 303–334. [Google Scholar] [CrossRef]

- Barakat, M. New trends in removing heavy metals from industrial wastewater. Arab. J. Chem. 2011, 4, 361–377. [Google Scholar] [CrossRef]

- Vakalis, S.; Moustakas, K.; Malamis, D.; Sotiropoulos, A.; Malamis, S. Assessing the removal of heavy metals in industrial wastewater by means of chemical exergy. Desalination Water Treat. 2017, 91, 146–151. [Google Scholar] [CrossRef]

- Ida, S.; Eva, T. Removal of heavy metals during primary treatment of municipal wastewater and possibilities of enhanced removal: A review. Water 2021, 13, 1121. [Google Scholar] [CrossRef]

- Zhao, G.; Meng, D.Z. Research Progress of Low Impact Development Technology. IOP Conf. Ser. Earth Environ. Sci. 2020, 474, 520–533. [Google Scholar] [CrossRef]

- Dekker, I.; Sharifyazd, S.; Batung, E.; Dubrawski, K. Maximizing Benefits to Nature and Society in Techno-Ecological Innovation for Water. Sustainability 2021, 13, 6400. [Google Scholar] [CrossRef]

- Rose, S.; Peters, N.E. Effects of urbanization on streamflow in the Atlanta area (Georgia, USA): A comparative hydrological approach. Hydrol. Process. 2001, 15, 1441–1457. [Google Scholar] [CrossRef]

- Damodaram, C.; Giacomoni, M.; Parkash, C.; Holmes, H.; Ryan, A.; Saour, W.; Zechman, E.M. Simulation of Combined Best Management Practices and Low Impact Development for Sustainable Stormwater Management. J. Am. Water Resour. Assoc. 2010, 46, 907–918. [Google Scholar] [CrossRef]

- Lucke, T.; Nichols, P.W.B. The pollution removal and stormwater reduction performance of street-side bioretention basins after ten years in operation. Sci. Total Environ. 2015, 536, 784–792. [Google Scholar] [CrossRef]

- Goh, H.W.; Lem, K.S.; Azizan, N.A.; Chang, C.K.; Talei, A.; Leow, C.S.; Zakaria, N.A. A review of bioretention components and nutrient removal under different climates—Future directions for tropics. Environ. Sci. Pollut. Res. 2019, 26, 14904–14919. [Google Scholar] [CrossRef]

- Ali, W.; Takaijudin, H.; Yusof, K.W. The Role of Bioretention Plant on Nutrient Removal of Stormwater Runoff. IOP Conf. Ser. Earth Environ. Sci. 2021, 721, 012015. [Google Scholar] [CrossRef]

- Lefèvre, V.; Ravi-Chandar, K.; Lopez-Pamies, O. Cavitation in rubber: An elastic instability or a fracture phenomenon? Int. J. Fract. 2014, 192, 1–23. [Google Scholar] [CrossRef]

- Wan, Z.; Li, T.; Shi, Z. A layered bioretention system for inhibiting nitrate and organic matters leaching. Ecol. Eng. 2017, 107, 233–238. [Google Scholar] [CrossRef]

- Noh, M.N.M. The stormwater management manual for Malaysia. In Proceedings of the Seminar on Water Resources and Environment: Application of Nuclear and Related Technologies, Malaysian Institute for Nuclear Technology Research, Bukit Merah, Malaysia, 3–5 April 2006; pp. 81–91. Available online: http://inis.iaea.org/Search/search.aspx?orig_q=RN:39065547 (accessed on 28 May 2021).

- You, H. Impact of urbanization on pollution-related agricultural input intensity in Hubei, China. Ecol. Indic. 2016, 62, 249–258. [Google Scholar] [CrossRef] [PubMed]

- Dagenais, D.; Brisson, J.; Fletcher, T.D. The role of plants in bioretention systems; does the science underpin current guidance? Ecol. Eng. 2018, 120, 532–545. [Google Scholar] [CrossRef]

- Rycewicz-Borecki, M.; McLean, J.E.; Dupont, R.R. Nitrogen and phosphorus mass balance, retention and uptake in six plant species grown in stormwater bioretention microcosms. Ecol. Eng. 2017, 99, 409–416. [Google Scholar] [CrossRef]

- Pereira, B.; David, L.M.; Galvão, A. Green Infrastructures in Stormwater Control and Treatment Strategies. Proceedings 2019, 48, 7. [Google Scholar] [CrossRef]

- Hermawan, A.A.; Talei, A.; Leong, J.Y.C.; Jayatharan, M.; Goh, H.W.; Alaghmand, S. Performance Assessment of a Laboratory Scale Prototype Biofiltration System in Tropical Region. Sustainability 2019, 11, 1947. [Google Scholar] [CrossRef]

- Gülbaz, S.; Kazezyılmaz-Alhan, C.M.; Copty, N.K. Evaluation of Heavy Metal Removal Capacity of Bioretention Systems. Water Air Soil Pollut. 2015, 226, 376–389. [Google Scholar] [CrossRef]

- Wang, X.; Tian, Y.; Zhao, X. The influence of dual-substrate-layer extensive green roofs on rainwater runoff quantity and quality. Sci. Total Environ. 2017, 592, 465–476. [Google Scholar] [CrossRef]

- Whittinghill, L.J.; Hsueh, D.; Culligan, P.; Plunz, R. Stormwater performance of a full scale rooftop farm: Runoff water quality. Ecol. Eng. 2016, 91, 195–206. [Google Scholar] [CrossRef]

- Deely, J.; Hynes, S.; Barquín, J.; Burgess, D.; Finney, G.; Silió, A.; Álvarez-Martínez, J.M.; Bailly, D.; Ballé-Béganton, J. Barrier identification framework for the implementation of blue and green infrastructures. Land Use Policy 2020, 99, 105–118. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhou, S.; Zhao, C.; Valeo, C. The Influence of Geotextile Type and Position in a Porous Asphalt Pavement System on Pb(II) Removal from Stormwater. Water 2018, 10, 1205. [Google Scholar] [CrossRef]

- Brown, R.A.; Line, D.E.; Hunt, W.F. LID Treatment Train: Pervious Concrete with Subsurface Storage in Series with Bioretention and Care with Seasonal High Water Tables. J. Environ. Eng. 2012, 138, 689–697. [Google Scholar] [CrossRef]

- Xian, B.C.C.; Kang, C.W.; Ab Wahab, M.; Zainol, M.R.R.M.A.; Baharudin, F. Evaluation of low impact development and best management practices on peak flow reduction using SWMM. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Guilin, China, 13–15 November 2020; IOP Publishing: Bristol, UK, 2021; Volume 646, p. 012045. [Google Scholar]

- Garg, M.; Valeo, C.; Gupta, R.; Prasher, S.; Sharma, N.R.; Constabel, P. Integrating natural and engineered remediation strategies for water quality management within a low-impact development (LID) approach. Environ. Sci. Pollut. Res. 2018, 25, 29304–29313. [Google Scholar] [CrossRef] [PubMed]

| Location | Used Water (L/car) |

|---|---|

| India | 35–40, 40–50 [8] |

| Pakistan | 100 [5] |

| Malaysia | 40–120 [38] |

| USA | 170 [39] |

| Australia | 200 [37] |

| Kuwait | 200–400 [4] |

| Heavy Metal | Concentration | WHO (mg/L) [47] | EPA (mg/L) [42] |

|---|---|---|---|

| Lead | <1 mg/L [46] 0.28 mg/L [1] | 0.01 | 0.05 |

| Copper | 0.94–3.8 mg/L [46] 0.06 mg/L [1] | 2.0 | 0.1 |

| Zinc | 1.15–3 mg/L [46] 0.18 mg/L [1] | 3.0 | 1.0 |

| Iron | 4.97 mg/L [1] | 0.3 | - |

| Cadmium | <0.002 mg/L [1] | 0.003 | 0.005 |

| Chromium | 0.42 mg/L [1] | ||

| Cobalt | <1 mg/L [46] |

| Component | Water Quality Mitigation Role |

|---|---|

| Ponded layer | Retention of incoming water, pooling of water leading to infiltration [26] |

| Mulch layer | Prevents clogging, moisture management with some water holding capacity [64] |

| Vegetation, root zone | Infiltration, contaminant and nutrient uptake [65] |

| Growing media | Sorption, denitrification, nitrification [66]; adsorption, moisture management [67]; metals removal through chemical processes |

| Drainage zone | Collects and conveys treated water to the outlet pipe, and prevents washout of soil media [68] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Talebzadeh, M.; Valeo, C.; Gupta, R.; Constabel, C.P. Exploring the Potential in LID Technologies for Remediating Heavy Metals in Carwash Wastewater. Sustainability 2021, 13, 8727. https://doi.org/10.3390/su13168727

Talebzadeh M, Valeo C, Gupta R, Constabel CP. Exploring the Potential in LID Technologies for Remediating Heavy Metals in Carwash Wastewater. Sustainability. 2021; 13(16):8727. https://doi.org/10.3390/su13168727

Chicago/Turabian StyleTalebzadeh, Mahta, Caterina Valeo, Rishi Gupta, and C. Peter Constabel. 2021. "Exploring the Potential in LID Technologies for Remediating Heavy Metals in Carwash Wastewater" Sustainability 13, no. 16: 8727. https://doi.org/10.3390/su13168727

APA StyleTalebzadeh, M., Valeo, C., Gupta, R., & Constabel, C. P. (2021). Exploring the Potential in LID Technologies for Remediating Heavy Metals in Carwash Wastewater. Sustainability, 13(16), 8727. https://doi.org/10.3390/su13168727