A Research Methodology for Mitigating Climate Change in the Restoration of Buildings: Rehabilitation Strategies and Low-Impact Prefabrication in the “El Rodezno” Water Mill

Abstract

:1. Introduction

2. Methodology: Discussion and Rationale

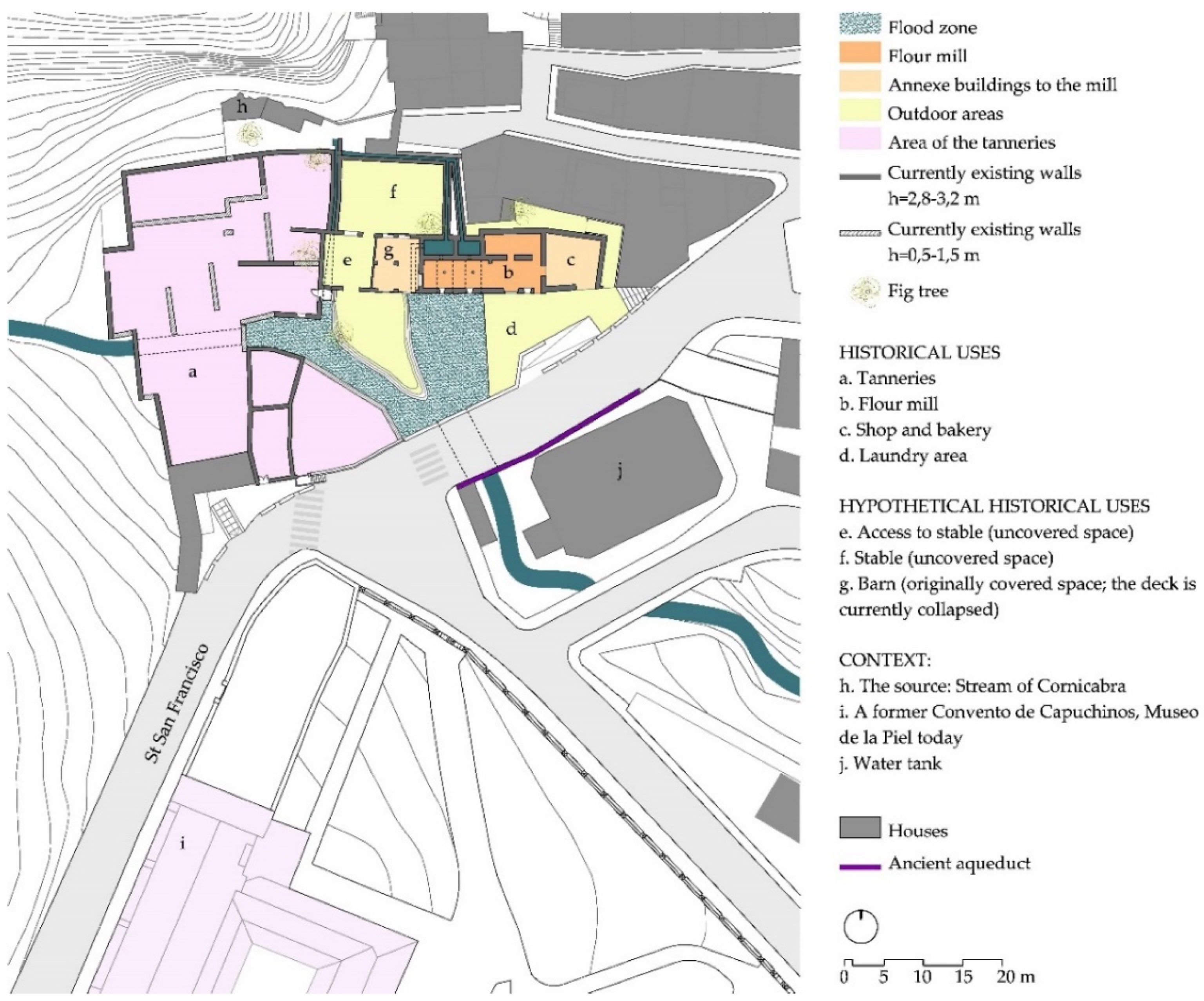

3. Scientific Observation

3.1. Previous Architecture in Light Prefabrication: Values Applicable to the Proposed Intervention Strategies

3.2. Prefabrication and the Construction Industry: Products and Systems Applicable to the Proposed Interventions

- -

- A greater presence of architects was needed in the production teams of companies involved in new materials and construction technologies.

- -

- There was a lack of university education in the design of new technologies.

- -

- There was a big difference in size and weight of the prefabricated products used in construction in comparison, for example, with what was happening in the automotive industry.

- -

- The lifespan of a home was, at the time, approximately 65 years (today perhaps longer), comfortably exceeding the lifespan of a car or of any domestic appliance.

- -

- A change in mentality was needed, both in the sectors and actors that participated in house building and in the people that were going to live in them.

- -

- Products were needed that would be financially profitable and that could hold their own in the market for long enough to create companies and production plants engaged in prefabricated construction.

- ▪

- The use of recycled materials or those that, after use, can be recycled.

- ▪

- Considering the criteria for industrialised prefabrication, the number of different materials to be used must not be high.

- ▪

- The commitment to an open system facilitates the substitution of elements and the adaptation of the construction for new uses.

- ▪

- Implementing a circular economy in the construction process that returns to the environment near the project, using products, industries, and the workforce that are nearby.

- ▪

- Encouraging the restoration and reactivation of pre-existing buildings as an engine for development, alternative to the global economic model.

- ▪

- Based on these premises, the possibilities for using three prefabricated products are explored briefly. Due to their composite and environmental characteristics, as well as their modular nature and weight limitations, they would be suitable for our intervention strategies.

3.2.1. Laminated and Cross-Laminated Timber Panels

3.2.2. Industrialised Structural Steel

3.2.3. Light Steel. Light Steel Framing

4. Construction Period

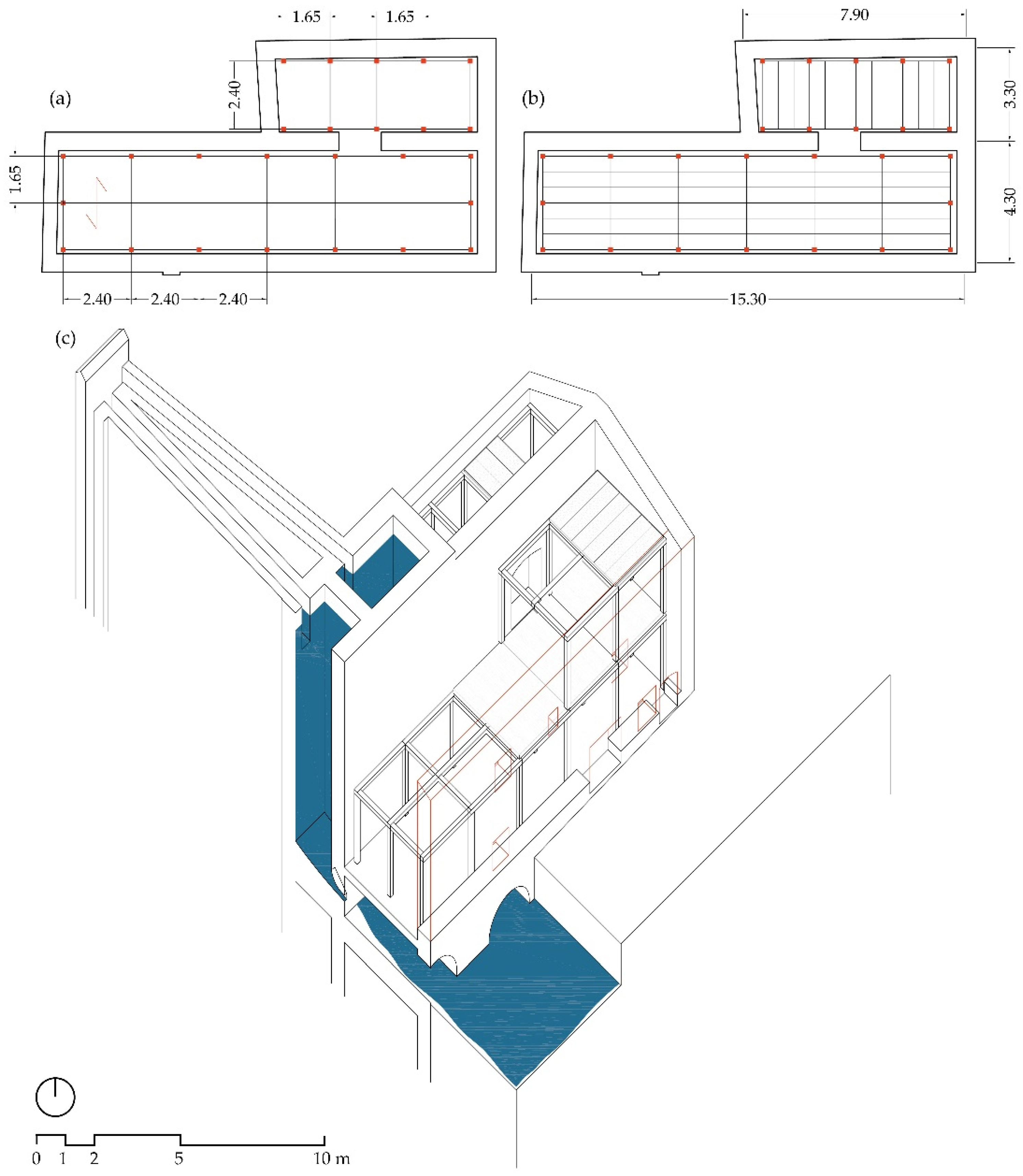

4.1. Intervention Strategies in the El Rodezno Watermill

- ▪

- Open systems, compatible with traditional construction.

- ▪

- Frequently used products that guarantee availability in warehouses or rapid relocation.

- ▪

- Products that correspond to production processes such as that of nearly zero energy schemes.

- ▪

- Preference for local industrial production.

- ▪

- Reduced number of materials.

- ▪

- Dry assembly that enables the optimisation of implementation times, producing minimal or zero waste during the work.

- ▪

- Systems that fabricate modular elements with small dimensions or that are easy to adapt to the construction site.

- ▪

- Weight of prefabricated products limited to handling by two or three operators.

- ▪

- Systems that enable the disassembly, reuse, and recycling of the prefabricated elements.

- ▪

- Laminated wood panels: Thermochip type. Dimensions: 550 mm × 2400 mm.

- ▪

- Cross-laminated wood panels: EGO_CLT and EGO_CLT MIX panel type (with insulation). Usual dimensions (transport limit): 2400 × 10,000 mm.

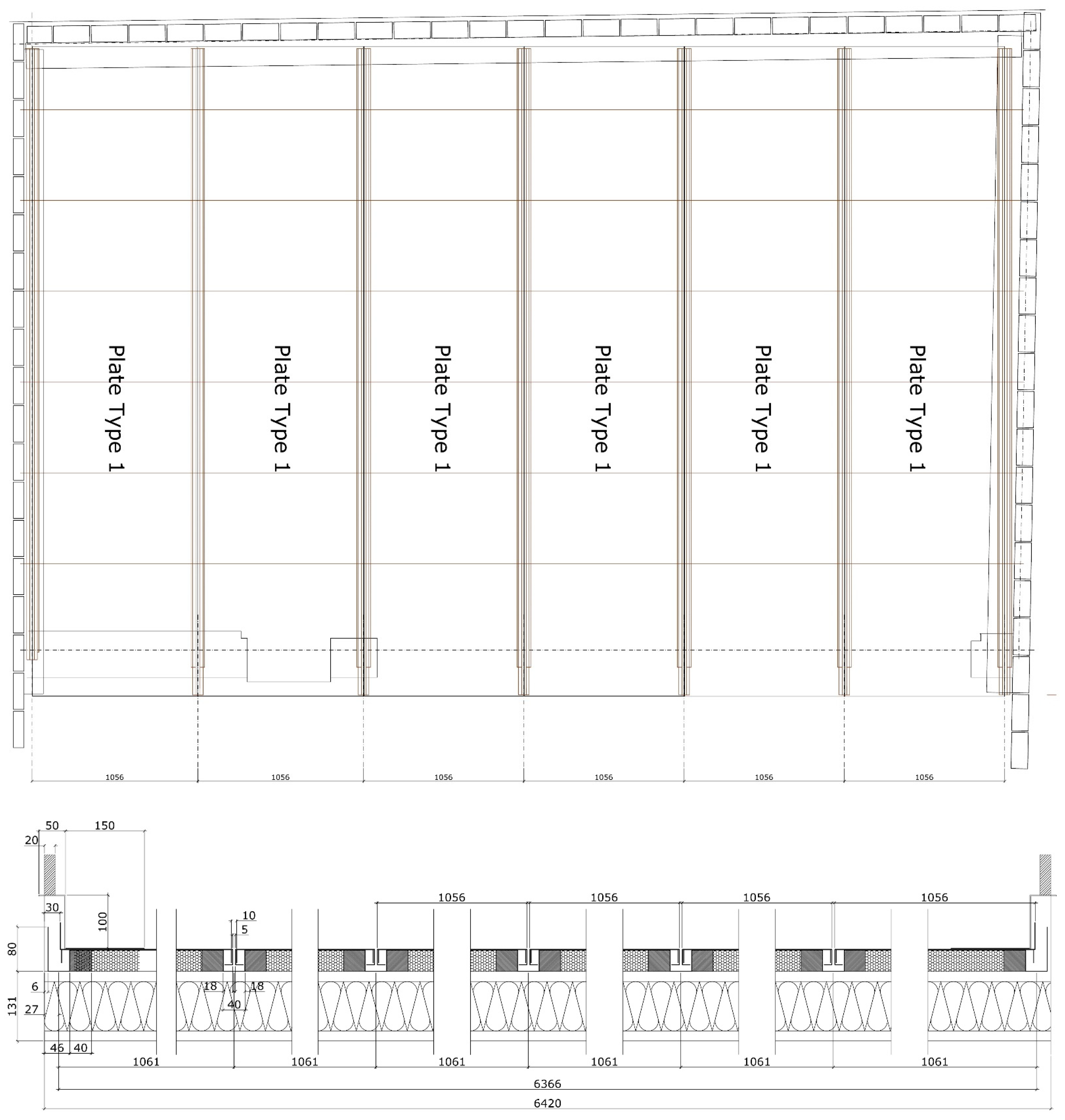

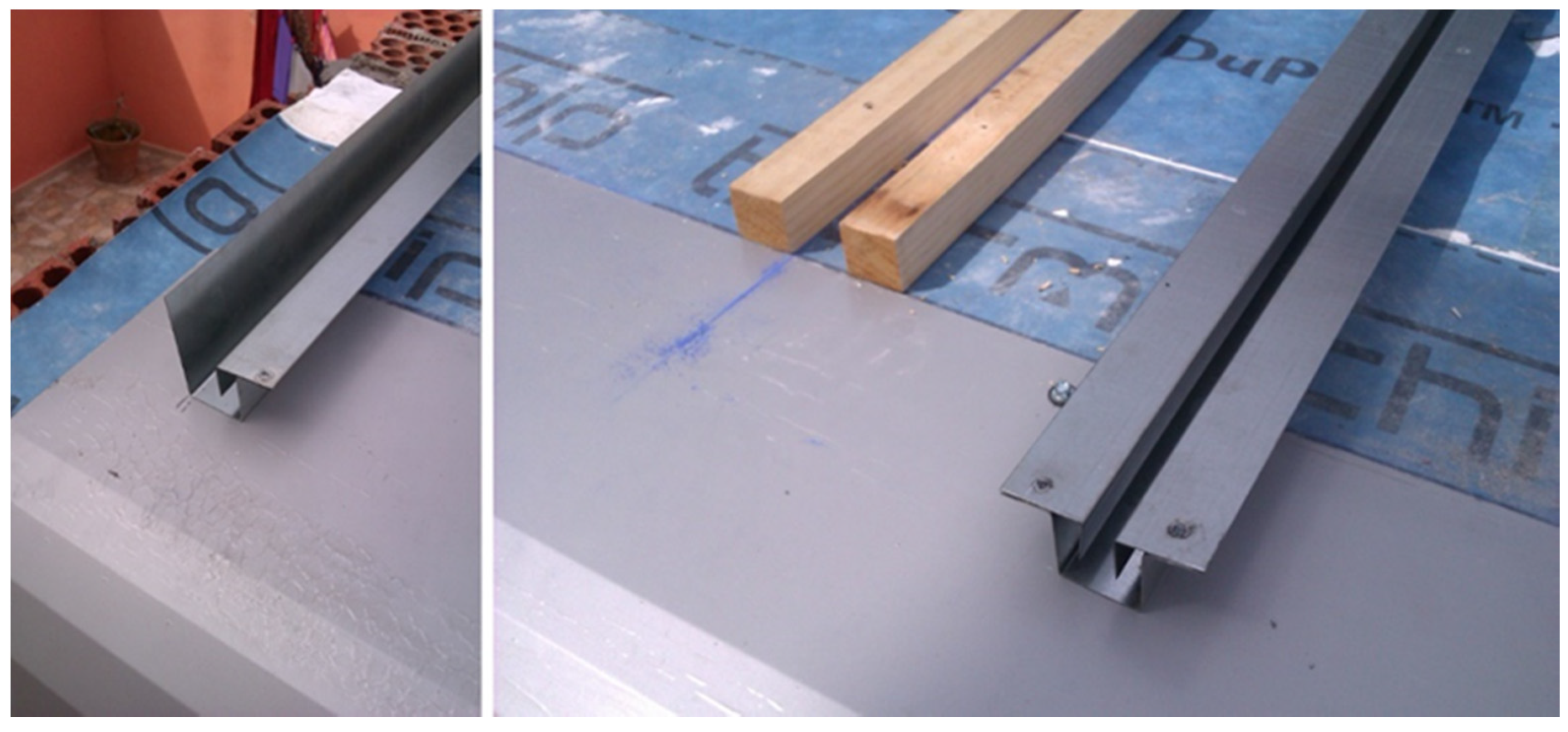

4.2. Construction of the Roof

5. Discussion of Results

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Olmedo Granados, F. La arquitectura agraria en Andalucía. In Cortijos, Haciendas y Lagares en Andalucía De Cádiz, 3rd ed.; Gil Pérez, M.D., Ed.; Junta de Andalucía, Consejería de Obras Públicas y Vivienda: Seville, Spain, 2007; pp. 13–19. [Google Scholar]

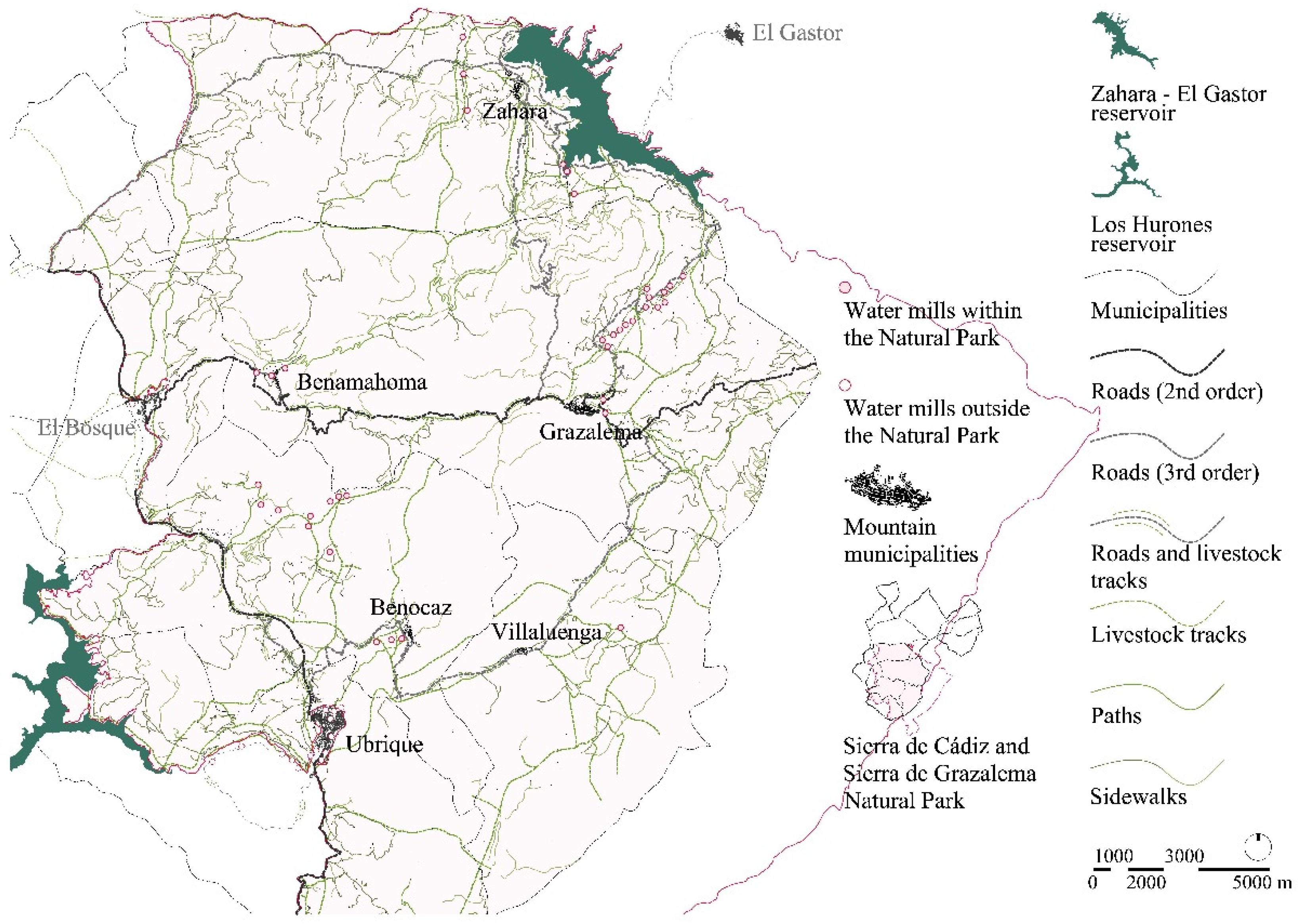

- Rivero-Lamela, G. La Arquitectura de un Territorio Productivo: Los Molinos Hidráulicos de la Sierra De Cádiz. Ph.D. Thesis, Universidad de Sevilla, Sevilla, Spain, 2021. [Google Scholar]

- Rivero-Lamela, G.; Ramos-Carranza, A. The Watermills of the Sierra de Cádiz (Spain). A Traditional Open Water Re-circulation System. SPOOL 2021, 7, 39–58. [Google Scholar] [CrossRef]

- Anasagasti, T.de. Discursos Leídos ante la Real Academia de Bellas Artes de San Fernando, en la Recepción Pública de Don Teodoro de Anasagasti. 1929. Available online: https://bibliotecadigital.jcyl.es/es/consulta/registro.cmd?id=1744 (accessed on 13 February 2021).

- Castellano Pulido, F.J. Bancales habitados: De la reutilización en la arquitectura tradicional al trabajo con el tiempo de César Manrique y Souto de Moura. Proy. Prog. Arquit. 2019, 21, 34–51. [Google Scholar] [CrossRef]

- Vilches, A.; García-Martínez, A.; Sánchez-Montañes, B. Life cycle assessment (LCA) of building refurbishment: A literature review. Energy Build. 2017, 135, 287. [Google Scholar] [CrossRef]

- European Commission. Draft Horizon 2020 Work Programme 2014–2015 in the Area of Secure, Clean and Efficient Energy; European Commission: Strasbourg, France, 2015. [Google Scholar]

- Aalto, A. Una ciudad americana en Finlandia. In Alvar Aalto: De Palabra y Por; Escrito; Schildt, G., Kapanen, E., García Ríos, I., Casabella, N., Eds.; El Croquis: Madrid, Spain, 2000; pp. 173–186. [Google Scholar]

- See Muñoz Jiménez, M.T. Verano de 1948. Buckminster Fuller en Black Mountain College. La Arquitectura como acontecimiento. Proy. Prog. Arquit. 2010, 3, 110–117. [Google Scholar] [CrossRef] [Green Version]

- Benevolo, L.; Melograni, C.; Giura Longo, T. La Proyectación de la Ciudad Moderna; Editorial Gustavo Gili, S.A: Barcelona, Spain, 2000; p. 9. [Google Scholar]

- Archer, B. The Nature of Research. Co-Des. Interdiscip. J. Des. 1995, 6–13. [Google Scholar]

- Frayling, C.H. Research in Art and Design. R. Coll. Art Res. Pap. 1993, 1, 1–5. [Google Scholar]

- Ramos-Carranza, A. De la investigación, la enseñanza y el aprendizaje experimental de la Arquitectura. Proy. Prog. Arquit. 2015, 12, 14–17. [Google Scholar] [CrossRef] [Green Version]

- Torres Cueco, J. El proyecto de arquitectura como investigación académica. Una aproximación crítica. In Colección Investigaciones IdPA_03; RU: Sevilla, Spain, 2017; pp. 13–28. [Google Scholar]

- Baxandall, M. Patterns of Intention: On the Historical Explanation of Pictures; Yale University: New Haven, CT, USA, 1985. [Google Scholar]

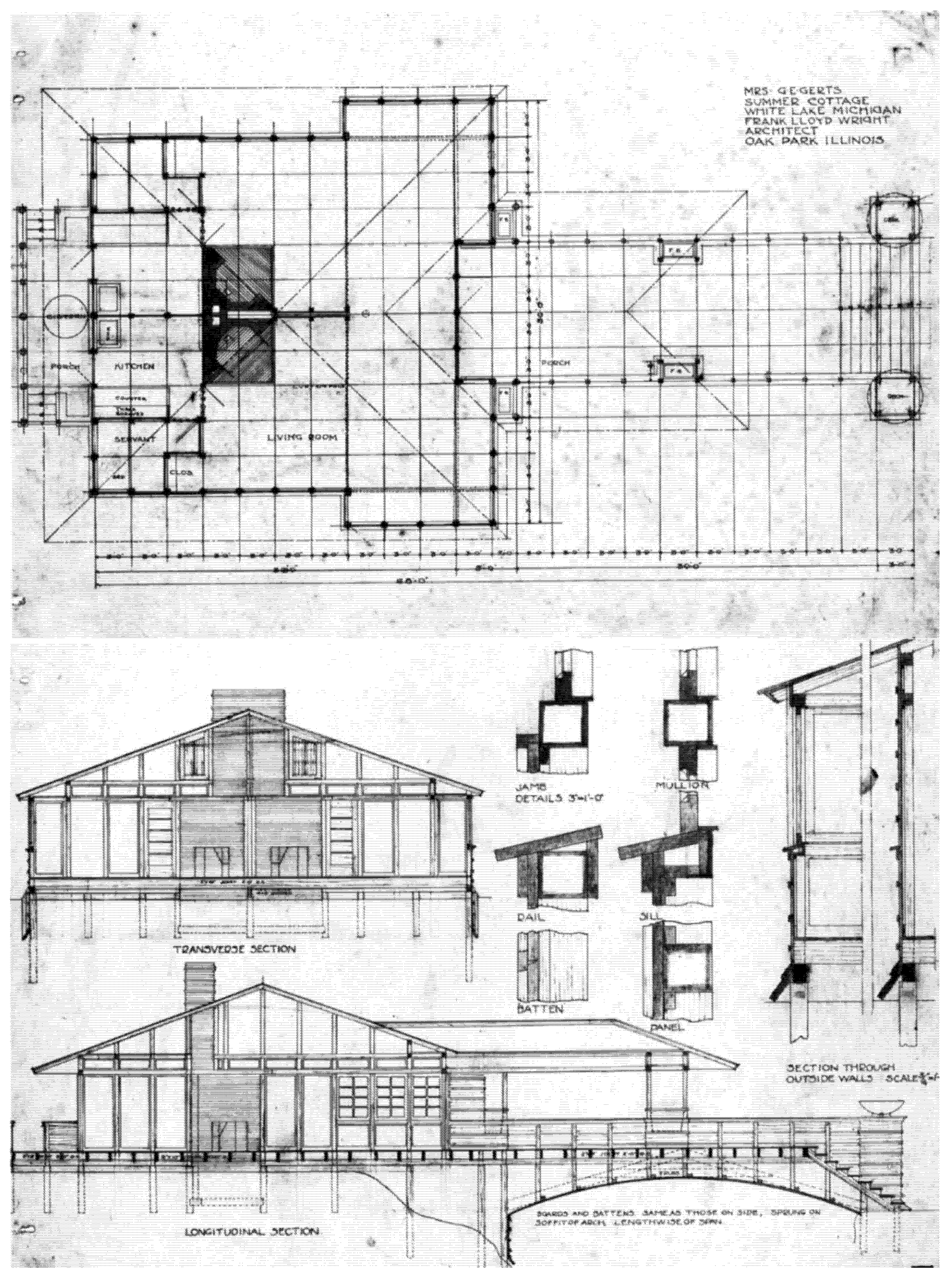

- Futagawa, Y. (Ed.) Brooks Pfeiffer, B. (tex). Frank Lloyd Wright. Monograph 1902–1906; A.D.A. Edita: Tokyo, Japan, 1987; p. 42. [Google Scholar]

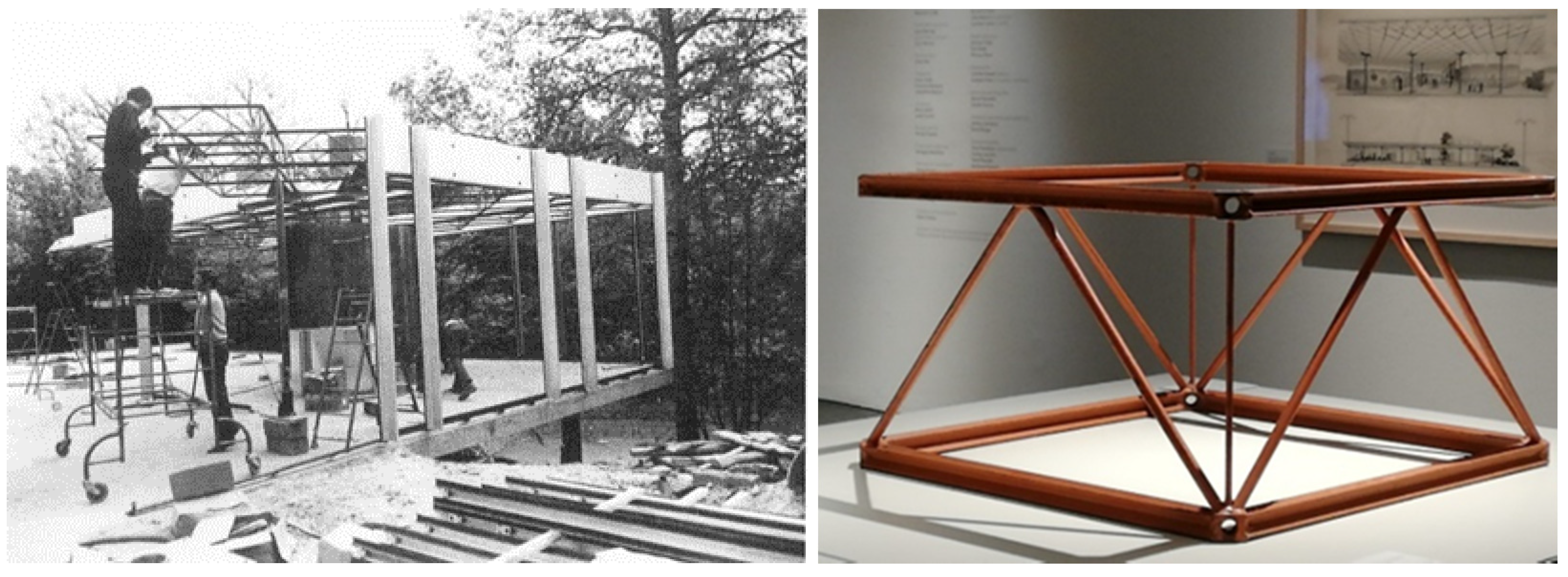

- Ramos-Carranza, A.; Bueno-Pozo, V. Design methodology for a school prototype: JeanProuvé’s Jules Ferry School Group in Dieulouard, France, 1952–1953. J. Archit. 2019, 24, 385–407. [Google Scholar] [CrossRef]

- Sulzer, P. Jean Prouvé: Oeuvre Complète = Complete Works. 4,s 1954–1984; Birkhäuser: Basel, Switzerland, 2005. [Google Scholar]

- Cinqualbre, O.; Occeli, M.; Billé, R.; Archieri, J.-F. El Universo De Jean Prouvé. Arquitectura/Industria/Mobiliario; Fundación “la Caixa”: Barcelona, Spain, 2021. [Google Scholar]

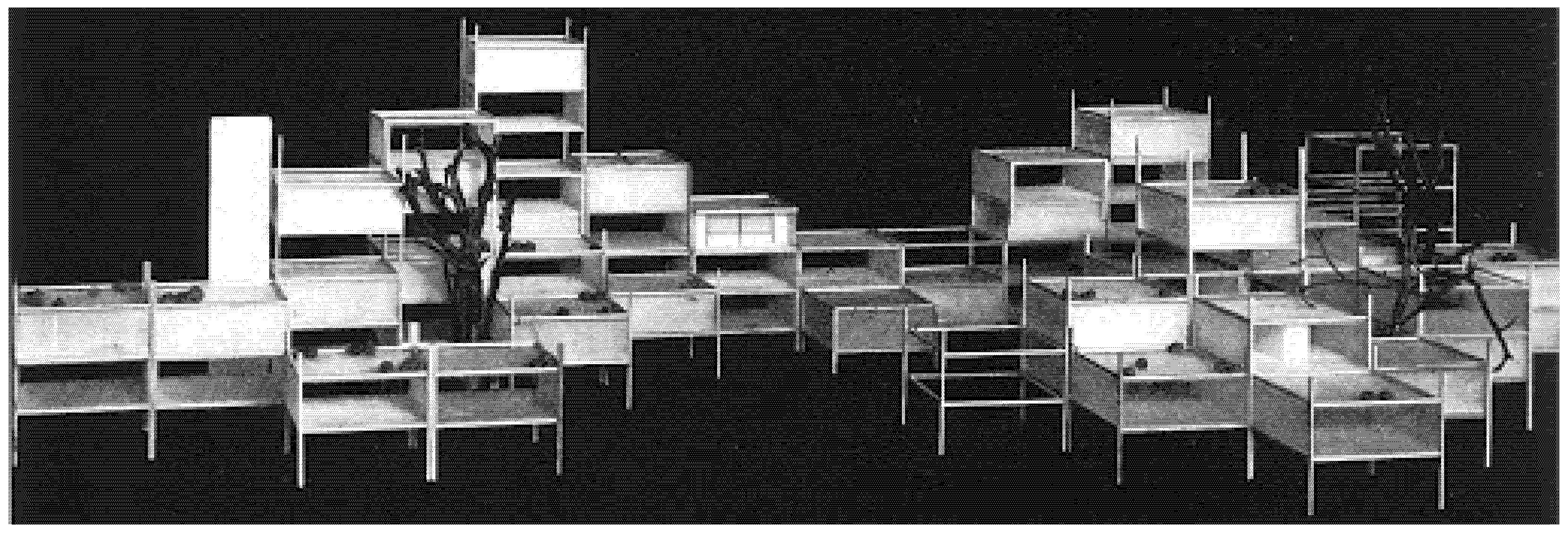

- Schulze-Fielitz, E. Metasprache Des Raums = Metalanguage of Space; Springer: Wien, Austria, 2010. [Google Scholar]

- Bezos Alonso, J.L. Dispositivos Abiertos: Habitares Open Sources. Ph.D. Thesis, University of Seville, Sevilla, Spain, 2017. [Google Scholar]

- Stadtbausysteme. Disponible en. Available online: http://www.nrw-architekturdatenbank.tu-dortmund.de/objekte_gross.php?gid=2222 (accessed on 1 June 2021).

- Mac Quaid, M. Shigeru Ban; Phaidon: New York, NY, USA, 2003; pp. 202–207. [Google Scholar]

- Salas, J. De los sistemas de prefabricación cerrada a la industrialización sutil de la edificación: Algunas claves del cambio tecnológico. Inf. Constr. 2008, 60, 19–34. [Google Scholar] [CrossRef] [Green Version]

- Staib, G.; Dörrhöfer, A.; Rosenthal, M. Components and Systems: Modular Construction: Design Structure New Technologies; Detail: Basel, Switzerland, 2008. [Google Scholar]

- Wadel, G.; Avellaneda, J.; Cuchí, A. La sostenibilidad en la arquitectura industrializada: Cerrando el ciclo de los materiales. Inf. Constr. 2010, 62, 37–51. [Google Scholar] [CrossRef] [Green Version]

- Ruiz-Larrea, C.; Prieto, E.; Gómez, A. Arquitectura, Industria y Sostenibilidad. Inf. Constr. 2008, 60, 35–45. [Google Scholar] [CrossRef] [Green Version]

- Llewelyn–Davies, R.; Weeks, J. Endless Architecture. Archit. Assoc. J. 1951, 106–112. [Google Scholar]

- Pike, A. Deficiencias de la construcción industrializada aplicada a los problemas de la vivienda. Cuad. Summa Nueva–Visión 1968, 13, 3–7. [Google Scholar]

- Collinge, W.O.; Landis, A.E.; Jones, A.K.; Schaefer, L.A.; Bilec, M.M. Dynamic lifecycle assessment: Framework and application to an institutional building. Int. J. Life Cycle Assess. 2013, 18, 538–552. [Google Scholar] [CrossRef]

- Tavares, V.; Soares, N.; Raposo, N.; Marques, P.; Freire, F. Prefabricated versus conventional construction: Comparing life-cycle impacts of alternative structural materials. J. Build. Eng. 2021, 41, 2. [Google Scholar] [CrossRef]

- Cervantes Torre-Marín, G. Ecología industrial: Innovación y desarrollo sostenible en sistemas industriales. Rev. Int. Sostenibilidad Tecnol. Humanismo 2011, 6, 59–78. [Google Scholar]

- According to the Catalogue of Construction Elements of the CTE (Technical Building Code—Spain), the Thermal Conductivity of a Light Conifer is λ = 0.13 W/mK with a Thermal Transmittance of the Order of 1.58 < 0.59 W/m2K for Thicknesses from 60 to 200 mm. Available online: http://cte-web.iccl.es/materiales.php (accessed on 24 April 2020).

- Arrizabalaga Echeberría, J.J.; Rodríguez García, J. (Eds.) Investigación Para Interpretar las Claves de los Diferentes Sistemas Constructivos Industrializables y su Posible Aplicación en la Vivienda de Protección Pública en el Ámbito de la CAPV/IDEFABRIK, Equipo de Investigación; Departamento de Arquitectura, Universidad del País Vasco: San Sebastián, Spain, 2012; Available online: http://37.187.25.28/documentos/actualidad/doc_980.pdf (accessed on 13 January 2019).

- Vidal, R.; Sánchez-Pantoja, N.; Martínez, G. Life cycle assessment of a residential building with cross-laminated timber structure in Granada-Spain. Inf. Constr. 2019, 71, e289. [Google Scholar] [CrossRef]

- Notarnicola, B.; Tassielli, G.; Renzulli, P.A. Industrial symbiosis in the Taranto industrial district: Current level, constraints and potential new synergies. J. Clean. Prod. 2016, 122, 133–143. [Google Scholar] [CrossRef]

- Iuorio, O.; Napolano, L.; Fiorino, L.; Landolfo, R. The environmental impacts of an innovative modular lightweight steel system: The Elissa case. J. Clean. Prod. 2019, 238, 1–16. [Google Scholar] [CrossRef]

- Horizonte. 2020. Available online: http://eshorizonte2020.cdti.es/index.asp?MP=87&MS=718&MN=2&TR=C&IDR=2043 (accessed on 18 February 2019).

- Mileto, C.; Vegas López-Manzanares, F.; García-Soriano, L. La restauración de la tapia monumental: Pasado, presente y futuro. Inf. Constr. 2017, 69, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Bruno Quelhas, B.; Cantini, L.; Miranda Guedes, J.; Da Porto, F.; Almeida, C. Characterization and Reinforcement of Stone Masonry Walls. In Structural Rehabilitation of Old Buildings; Springer: Berlin/Heidelberg, Germany, 2013; pp. 131–155. [Google Scholar] [CrossRef]

- Tomaževič, M.; Gams, M.; Berset, T.H. Strengthening of stone masonry walls with composite reinforced coating. Bull. Earthq. Eng. 2015, 13, 2003–2027. [Google Scholar] [CrossRef]

- España, Ley 14/2007, de 26 de noviembre, del Patrimonio Histórico de Andalucía. Boletín Oficial del Estado, núm. 38, de 13 de febrero de 2008. Referencia BOE-A-2008-2494. 2007. Available online: https://www.boe.es/buscar/pdf/2008/BOE-A-2008-2494-consolidado.pdf (accessed on 2 December 2019).

- Terrados, J. Prefabricación Ligera De Viviendas. NUEVAS Premisas; IUACC: Sevilla, Spain, 2012. [Google Scholar]

- Ramos-Carranza, A.; Añón-Abajas, R.M. Patent Title: Light Covering For Construction Roofs. Application Number P201830264, 18 March 2019. Patent title with substantive examination. Publication No.: ES 2 725 129 B2 PCT/ES2019/070177. With Support from the Plan Propio de Investigación de la Universidad de Sevilla. Available online: https://www.sumobrain.com/patents/wipo/Light-covering-construction-roofs/WO2019180289A1.html (accessed on 15 February 2021).

- Capitel, A. La arquitectura como modo de entender el mundo. Notas de un profesor veterano. Proy. Prog. Arquit. 2015, 12, 20. [Google Scholar] [CrossRef] [Green Version]

- Moyano-Mercader, P.; Esquivias, P.M. Decarbonization and Circular Economy in the Sustainable Development and Renovation of Buildings and Neighbourhoods. Sustainability 2020, 12, 7914. [Google Scholar] [CrossRef]

- Nash, G. Do-ít-Yourself. The Complete Handbook; Sterling Publishing: New York, NY, USA, 1995; p. 8. [Google Scholar]

- Herbert, G. The Dream of the Factory-Made House. Walter Gropius and Konrad Wachsman; The MIT Press: Cambridge, MA, USA, 1984; p. 33. [Google Scholar]

- Borrallo-Jiménez, M.; Lopez de Asiain, M.; Herrera-Limones, R.; Lumbreras Arcos, M. Towards a Circular Economy for the City of Seville: The Method for Developing a Guide for a More Sustainable Architecture and Urbanism (GAUS). Sustainability 2020, 12, 7421. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramos-Carranza, A.; Añón-Abajas, R.M.; Rivero-Lamela, G. A Research Methodology for Mitigating Climate Change in the Restoration of Buildings: Rehabilitation Strategies and Low-Impact Prefabrication in the “El Rodezno” Water Mill. Sustainability 2021, 13, 8869. https://doi.org/10.3390/su13168869

Ramos-Carranza A, Añón-Abajas RM, Rivero-Lamela G. A Research Methodology for Mitigating Climate Change in the Restoration of Buildings: Rehabilitation Strategies and Low-Impact Prefabrication in the “El Rodezno” Water Mill. Sustainability. 2021; 13(16):8869. https://doi.org/10.3390/su13168869

Chicago/Turabian StyleRamos-Carranza, Amadeo, Rosa María Añón-Abajas, and Gloria Rivero-Lamela. 2021. "A Research Methodology for Mitigating Climate Change in the Restoration of Buildings: Rehabilitation Strategies and Low-Impact Prefabrication in the “El Rodezno” Water Mill" Sustainability 13, no. 16: 8869. https://doi.org/10.3390/su13168869

APA StyleRamos-Carranza, A., Añón-Abajas, R. M., & Rivero-Lamela, G. (2021). A Research Methodology for Mitigating Climate Change in the Restoration of Buildings: Rehabilitation Strategies and Low-Impact Prefabrication in the “El Rodezno” Water Mill. Sustainability, 13(16), 8869. https://doi.org/10.3390/su13168869