Abstract

Reclaimed asphalt pavement (RAP) has received much attention recently due to its increased use in hot mix asphalt (HMA) pavements to enhance pavement sustainability. The use of aged asphalt in RAP, which is highly oxidised and has lost its properties due to exposure to traffic loads and climatic conditions throughout its lifespan, can cause asphalt mixtures to stiffen and embrittle, thus negatively affecting the behaviour of asphalt mixtures. This issue may be resolved by including rejuvenating agents that can restore both physical and rheological properties of aged asphalt by increasing maltene fractions and decreasing asphaltene. However, the high restoration capacity of any kind of rejuvenating agent does not assure the durability of restored aged asphalt. This study explored the performance and durability of rejuvenated asphalt mixtures embedded with several types of rejuvenators identified from the extensive literature review. The study serves as a significant reference to predict future challenges in rejuvenating aged asphalt.

1. Introduction

The tremendous development witnessed in the Malaysian national infrastructure network since the past decade has led to an increase in road construction [1], where flexible pavement dominates the overall surfacing types across more than 87,626 km. Although the life of asphalt pavement generally lasts for 10–15 years, many asphalt pavements need heavy maintenance within 10 years of construction [2]. This means that the huge amounts of aggregate and asphalt consumed during road construction not only cause economic issues but also increase the misuse of non-renewable resources. With the increasing awareness of environmental protection and sustainable development, the use of recycled materials in pavements (reclaimed asphalt pavement (RAP)) is deployed in many countries [3]. Recycling of road asphalt materials has a crucial role in the sustainable development of road construction [4,5]. RAP is composed of valuable constituents of asphalt binder and aggregates [6]; Kandhal et al. [7] used 20–50% of RAP for constructing flexible pavement, which can save 14–34% of construction costs [8]. Nonetheless, the main drawback for using RAP in constructing pavements refers to its deteriorated performance [9]. Evidently, the use of more than 20% RAP can adversely affect the constructed pavement from withstanding thermal and fatigue cracking, one of the main shortcomings noted in using RAP [10]. The reason is ascribed to the ageing of RAP as a result of exposure to the atmosphere throughout its lifespan. The aromatic compounds in asphalt binders become oxidised and more polar carbonyl compounds are created; thus increasing both elastic modulus and viscosity, as well as stiffening the binder [11]. The fractions of saturates, aromatics, resins, and asphaltenes (SARA) are modified when aromatics decrease and asphaltenes increase over time [12]. Upon being exposed to water, heat, and ultraviolet (UV) rays during its lifespan, the asphalt succumbs to ageing that affects its pavement performance [13]. In fact, asphalt ageing is generally divided into short-term ageing (STA) and long-term ageing (LTA); the STA process includes transporting, mixing, paving, and rolling of asphalt. Asphalt becomes aged and hardened when its light components turn volatile due to high temperature [13]. Asphalt ageing leads to poor workability, cohesiveness, fatigue resistance, as well as fatigue and thermal cracking. Hence, it is vital to restore and enhance the viscoelastic and engineering performance of aged asphalt [14].

The addition of rejuvenating agents may address issues that arise due to use of RAP at high dosages [15]. Most of the existing rejuvenators have been vastly explored for the past two decades for their sustainability. Typically, rejuvenators have high maltene content that can balance the composition in aged binder [16]. A rejuvenator is applied to increase the maltene content in aged asphalt, which deteriorates as a result of oxidation from LTA. Low maltene in RAP binder (aged asphalt) can cause asphaltene to flocculate, which leads to high cracking potential. When maltene is added via rejuvenators, the free-moving asphaltenes can enhance the flow property in the RAP binder [16]. The best rejuvenation denotes low-level saturates (saturates are incompatible with asphalt and promote ageing) and high-level aromatics [17,18]. Many studies have proposed rejuvenating and softening agents to restore crucial RAP properties, such as commercial, waste-derived, plant, and refinery-based oils [19]. Softening agents or fluxing (e.g., slurry oil, flux oil, and lube stock) may decrease the viscosity in RAP binder [20,21], whereas rejuvenating agents can re-balance the composition in aged asphalt due to the presence of sufficient maltene components that restore the inner structure of aged asphalt [21]. In any case, rejuvenating agents should satisfy both short- and long-term criteria. Short-term criteria denote the ability to diffuse quickly into the RAP and cause asphalt mobilisation [22]. An instance of long-term criteria is the modification of asphalt rheology to hinder thermal and fatigue cracking (no rutting or softening issue) [22,23], whereas an example of short-term criteria refers to rapid diffusion into RAP to promote asphalt mobilisation [22].

The homogeneity of asphalt with rejuvenators is crucial to meet these conditions [4]: (1) mechanical mixing uniformity, (2) better compatibility, (3) better diffusion of rejuvenator into RAP—this being the key condition for the entire process. The rate of diffusion is affected by rejuvenator-asphalt composition and layer thickness, as well as temperature. Failing to diffuse into RAP in timely manner, a rejuvenator is only useful as a lubricator [4]. However, the durability of rejuvenated asphalt cannot be guaranteed by a rejuvenating agent with high-level restoration capacity. For instance, rejuvenated asphalt ages again and its durability may not be similar to that of virgin asphalt (VA). Moreover, a rejuvenator may perform better at the early stage of its application, but may not necessarily perform better in the long run [24]. Based on their chemical composition, a rejuvenating agent can impart undesired features that deteriorate the performance of rejuvenated asphalt. Although numerous rejuvenators can restore the original rheological and physicochemical properties in RAP binder, they may affect mixture durability in terms of resistance towards ageing and moisture damage [25]. The latter resistance is ascribed to rejuvenators with a highly polarisable water-soluble element. The durability of asphalt mixtures relies on environmental factors, including UV radiation, temperature, and moisture. In temperate climates, along with poor aggregates and asphalt binder quality, pavement failure is attributed to fatigue cracking, excessive traffic loading, permanent deformation, and ravelling. Under aggressive climatic conditions, the distresses are exacerbated by climate-related loads, such as water damage [26]. Meanwhile, some rejuvenating agents are susceptible to oxidation. In order to achieve high RAP mixture with durability similar to that of new pavement material, rejuvenated asphalt should not age faster than VA [27].

Comprehending the durability of rejuvenated asphalt is crucial to hinder the use of unsuitable rejuvenating agents that could affect the performance of pavement. Despite the vast studies on the benefits of rejuvenating agents, only a handful of scholars have investigated the adverse impact of rejuvenators on pavement durability. Notably, rejuvenators should be assessed for both their rheological restoration capability and durability, particularly ageing and moisture damage resistance. Therefore, the present study explored the role of different types of rejuvenators in restoring the properties of aged asphalt and evaluated their effect on the performance of rejuvenated asphalt mixtures. Several recommendations are listed to choose the type of rejuvenator based on past studies in light of physical, mechanical, and durability characteristics.

2. Classification of Rejuvenators

Rejuvenating agents are materials with certain physical and chemical attributes that may be incorporated into mixtures with high oxidisation level or high RAP content [28]. Studies pertaining to rejuvenators can be traced as far as in the late 1970s. The ASTM D4552 was initiated based on the six grades of rejuvenating agents measured based on viscosity at 60 °C, so as to facilitate the selection of rejuvenators in ensuring good performance in the long run [29]. Martin et al. [16] divided rejuvenators into five general categories, namely: Paraffinic oils, Aromatic extracts, Naphthenic oils, Triglycerides & Fatty Acids, and Tall oils. Based on the chemical composition of asphalt and rejuvenators, Tabatabaee and Kurth [30] classified the latter into three classes; insoluble and soluble softeners, as well as compatibilisers. Insoluble softeners have desirable effects on the rheological attributes of aged asphalt but portray durability and instability issues in the long run. Next, soluble softeners display better compatibility with naphthenic aromatic asphalt that has low polarity. Meanwhile, compatibilisers share some similarities with other numerous fractions found in asphalt.

Luc et al. [31] grouped rejuvenators into six categories to analyse their success and risk factors (Table 1). The emissions were assessed based on their impact on the health of those working with the products and those present in the surrounding area, while concurrently identifying their effect on the natural and built environment. Health, safety, and environment aspects on the use of rejuvenators for asphalt recycling are crucial in evaluating asphalt recycling within the broader sustainable development framework.

Table 1.

Categorising of rejuvenating agents [31].

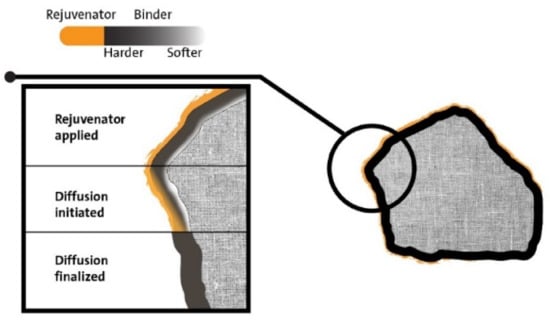

The rejuvenators must increase mobility of molecules and maltene content, enhance the dispersion power in continuous maltene phase, and minimise the size of asphaltene clusters [29,32] in order to reduce stiffness and enhance ductility in aged asphalt [33]. Rejuvenating agents can surround the aged asphalt layer, then penetrate into asphaltene agglomeration that disperses asphaltene in maltene, and decrease the viscosity of the blend [34]. This can improve the adhesion and cohesion properties of aged asphalt, as well as its flexibility [35]. Tran et al. [18] and Kaseer et al. [29] listed three factors that dictate the rejuvenation mechanism: (1) dispersion of RAP, VA, and rejuvenator in the mixture, (2) diffusion of rejuvenator in aged asphalt, and (3) compatibility among aged asphalt, VA, and rejuvenator (see Figure 1). Other manufacturing variables, including production equipment and rejuvenator-VA-aged asphalt blending method, are equally crucial for effective rejuvenation process.

Figure 1.

Rejuvenating agent diffusion into aged asphalt film [22,38].

Various types of softening and rejuvenating agents can lead to various physical and rheological changes [36]. For instance, castor oil causes asphaltene to dissolve in aged asphalt, whilst coke oven gas condensate increases the content of maltene and dilutes aged asphalt [37]. Certain agents (e.g., plant oils) affect the performance grade (PG) or the viscosity of rejuvenated asphalt identical to that of other agents (e.g., petroleum rejuvenators) but at a markedly lower dosage [38]. Loss of recycling agent efficacy with ageing has been observed in rejuvenated binder blends and asphalt mixtures, wherein the extent of such loss relies on the type and the dose of the recycling agent [29].

3. Characterisation of Rejuvenators with Recycled Asphalt

Overall, rejuvenators increase the flexibility, penetration grade, ductility, phase angle, and m-value; whilst concurrently reducing optimum asphalt content, rutting parameter, softening point, activation energy, viscosity, stiffness, shear complex modulus, and crossover temperature (transition temperature from elastic (glassy) to viscous state); as well as enhancing fatigue life, elasticity, colloidal stability, thixotropy, and temperature susceptibility [37]. Past studies reported that rejuvenated asphalt binders are usually more susceptible to ageing than VA binder [39,40]. Yin et al. [41] explored the efficacy of rejuvenators (tall oil and aromatic extract) with LTA. As a result, the rejuvenators were effective in partially decreasing stiffness and restoring the properties of aged asphalt, but their rejuvenating efficacy diminished with ageing. This proves that many rejuvenators are promising in restoring the physical and rheological properties of aged asphalt, but may exert an adverse effect on mixture durability, where not all rejuvenators have the same effect of the pavement. The following subsections display the rejuvenation of recycled asphalt using various types of recycling agents.

3.1. Rejuvenation of Recycled Asphalt Using Plant-Oils

The chemical characteristics of plant oils have a vital role when blending with aged asphalt. For example, a recent study reported that the addition of waste cooking oil (WCO) restored the flexibility, penetration value, ductility, and softening point of the targeted VA grade [8,42]. Higher dosage of WCO was required for rejuvenation when the aged asphalt was highly oxidised. Zargar et al. [43] assessed the potential of WCO as a rejuvenator. The outcomes of comparing virgin, aged, and rejuvenated asphalts are as follows: aged asphalt was stiffer than VA due to oxidisation, whereas penetration, softening point, and dynamic shear rheometer (DSR) were restored in VA with 3–4% WCO. Meanwhile, Zahoor et al. [8] reported that the efficiency of rejuvenation process was heavily influenced by acidity, WCO quality, and water content. Low WCO quality gradually increased water content and acidity, thus minimising the rejuvenation effect. Yaseen and Hafeez [24] claimed that WCO had some drawbacks, such as weak low-temperature fluid characteristics, oxidative degradation, and vulnerability to hydrolysis in acidic medium; thus limiting its applications.

El-Shorbagy et al. [44] examined the feasibility of using WCO as a rejuvenator and found that 3–4% of WCO had improved the moisture damage resistance of the rejuvenated mixes in comparison to the use of 100% RAP. Similarly, Zaumanis et al. [45] reported that 100% RAP rejuvenated asphalt containing 12% WCO had increased susceptibility to moisture damage and failed the minimum TSR requirement. Hence, one may infer that excessive dosage of WCO can result in loss of adhesion and cohesion, thus leading to moisture damage [8]. Conversely, Ziari et al. [6] studied the impact of rejuvenators on the ageing resistance of recycled mixtures, and concluded that the rejuvenated asphalt mixtures containing WCO were very sensitive to moisture after ageing. Furthermore, the WCO-rejuvenated mixtures exhibited poor resistance against ageing in terms of cracking and fatigue resistance.

The impact of waste edible vegetable oil on RAP binder rejuvenation has been vastly assessed in light of rheological, physical, and chemical properties [2]. Apparently, the rejuvenator could effectively soften aged asphalt. Both the rheological and physical properties of aged asphalts may be enhanced with optimum waste edible vegetable oil dosage. Additionally, the rejuvenator improved the elastic recovery performance, besides enhancing rutting and ageing resistance. The rejuvenated asphalt displayed lower asphaltenes content, as well as decreased sulfoxide (S=O) and carbonyl (C=O) intensity. More importantly, low thermos-stability, temperature flexibility, and elasticity of aged asphalts with waste edible vegetable oil demand further investigation. Another study found that the inclusion of vegetable oil in RAP binders reduced sulfoxide and carbonyl indices [46]. Certain rejuvenating agents (e.g., seed oil) with sulfoxide and carbonyl groups can further enhance those indices. Xinxin et al. [10] found that the use of frying vegetable oil as rejuvenator had improved fatigue and low-temperature anti-cracking properties in aged asphalt, whilst restoring the penetration of aged asphalt but decreasing high-temperature rutting resistance.

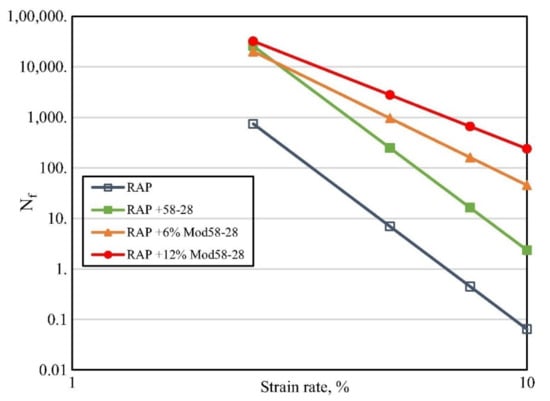

Upon using soybean-derived rejuvenator to restore the properties of aged asphalt [47]. it was found that both low- and high-temperature attributes of the rejuvenated asphalt mixture had been affected. Inclusion of rejuvenators at normal temperature substantially enhanced the linear amplitude sweep (LAS) in fatigue performance of Pressure Ageing Vessel (PAV)-aged asphalt (see Figure 2). Increment in phase angle and persistent decrease in stiffness, as signified by asphalt master curves, had been due to the softening impact of soybean on the aged asphalt. Upon using frying soybean oil as the rejuvenator, Chen et al. [2,48] also utilised plants oils to rejuvenate aged asphalt, and found substantial improvement in fatigue and low-temperature anti-cracking properties, but poor ductility and performance (at high temperature) with higher dosages of rejuvenator.

Figure 2.

LTA Cycles to failure at 25 °C [47].

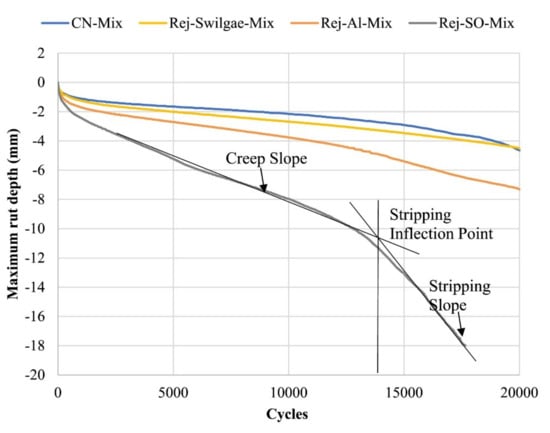

Rajib et al. [25] examined the durability of plant extract and soybean oil-rejuvenated asphalt mixtures containing 25% of RAP in terms of ageing and moisture susceptibility. The SARA fractions for plant extract and soybean oil are as follows: (Saturates: 0.44%, Aromatics: 7m2.49%, Resin: 26.26%, and Asphaltene: 0.71%) and (Saturates: 1.45%, Aromatics: 89.16%, Resin: 8.57%, and Asphaltene: 0.82%), respectively. The results showed that the high restoration capacity of a rejuvenating agent did not assure the durability of the rejuvenated asphalt. The rheological properties of aged asphalt were restored by all the assessed rejuvenating agents. The DSR test revealed that plant extract displayed better performance, stress relaxation, and stiffness than soybean oil. However, the plant extract displayed significant changes during shear-thinning moisture-induced evaluation, particularly at 24 h conditioning in water. As for soybean oil, it was highly susceptible to moisture damage and terribly stripped during the Hamburg Wheel-Track Test (HWTT) (see Figure 3). These outcomes were attributable to the capacity of restoration dictated by the ability of the rejuvenators in penetrating and peptising aged asphalt, whilst the polarizability of the rejuvenators was linked to durability. Highly polarised molecules displayed better interaction with environmental elements (e.g., water and air), thus accelerating moisture damage and ageing.

Figure 3.

HWTT test results for all samples [25].

Rancidity is another factor for the poor performance of rejuvenators. Rancidity is the oxidation of oils in the presence of temperature, light (photo-oxidation), air, and moisture [49,50]. The double bonds of unsaturated fatty acid are decomposed by free-radical reactions with molecular oxygen, which release highly volatile aldehydes and ketones [50,51]. Triglycerides are hydrolysed and free fatty acids are released, in which an oil–water reaction demands a catalyst to form glycerol and fatty acids [52]. The oil breaks down into smaller compounds over time, thus causing a deterioration in the properties of oil-derived rejuvenators, and adversely affecting the mechanical performance of the rejuvenated asphalt mixture.

Mirhosseini et al. [53] assessed the performance of asphalt mixtures containing 20–40% of RAP and 5–10% of date seed oil (DSO) rejuvenator. As a result, the addition of DSO improved the fatigue life of the samples containing 20% and 30% RAP. However, the rutting performance of the mixtures deteriorated, mainly because the addition of DSO to the blend softened the aged asphalt and decreased its viscosity. In the case of adding 40% of RAP, other options than DSO could be considered.

Based on the discussion above, one may infer that the addition of plant oils to binder can increase the flexibility of aged asphalt, as well as offer physical and rheological enhancement, thus increasing non-recoverable creep compliance and decreasing permanent deformation resistance. Rutting resistance should be given attention as this aspect enhances with high plant oil dosages. Rejuvenated asphalt durability is dictated by the quality and type of the plant oil rejuvenator. Plant oil quality is determined by acid value, in which water content and free acids concentration are used to identify presence of water in WCO [8]. Azahar et al. [54] discovered that WCO-rejuvenated asphalt displayed poor chemical, physical, and rheological properties at higher water content and acid value. However, the opposite was noted for lower water content and acid value as the three properties were maintained as similar to as those of VA binder. Hence, acid value best indicates the efficiency and efficacy of rejuvenated plant oil. Preliminary chemical treatment can minimise water and free fatty acid contents [8]. Table 2 summarised the effect of adding plant oils on the characteristics of recycled asphalt.

Table 2.

Effect of adding plant oil as rejuvenator.

3.2. Rejuvenation of Recycled Asphalt Using Refined Crude-Oils

Many studies have explored the effect of crude oil-derived rejuvenators on aged asphalt due to their similarities in molecular structure that enable smooth rejuvenator-crude oil combination. In assessing aged asphalt and maltene (rejuvenator), Hussein et al. [55] investigated the possibility of restoring the physical properties of very old-aged asphalt using maltene-derived asphalt as a rejuvenating agent. The characteristics of rejuvenated asphalt were examined with penetration, softening point, viscosity, and storage stability. The results indicate that 15% of maltene can be used to restore the properties of aged asphalt. Moreover, Al-Saffar et al. [56] explored the potential application of maltene as a rejuvenator to enhance the properties of asphalt mixtures, including RAP. The outcomes confirmed that 8% and 16% of maltene can restore the physical properties of 30% and 50% of recycled asphalt, respectively. The performance of recycled asphalt at high- and low-temperature was restored approximately to that of VA. The oxygenated indices of RAP binder were reduced by when maltene was added. Meanwhile, TGA exhibited that the thermal stability of rejuvenated asphalts was close to VA. Accordingly, the mechanical features of rejuvenated asphalt mixtures were enhanced compared to the VA mixture.

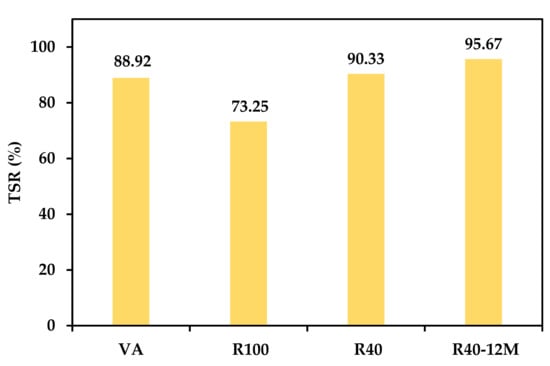

Al-Saffar et al. [57] examined the engineering properties of 40% reclaimed hot mix asphalt (HMA) mixture rejuvenated by 12% maltene-derived asphalt. As a result, the ageing effect of RAP asphalt was effectively mitigated by maltene, whilst substantially enhancing the RAP-maltene blend when compared to VA and RAP without maltene. Both moisture damage and cracking resistance of the rejuvenated RAP after LTA exceeded those of VA; signifying the efficacy of maltene to rejuvenate aged asphalt (see Figure 4).

Figure 4.

TSR results of collected samples after LTA [57].

Zaumanis et al. [58] studied the efficacy of rejuvenators (waste engine oil (WEO), paraffinic-based oil, WEO bottoms, refined tallow, WEO+ Fischer Tropsch wax, aromatic extracts, distilled tall oil, organic blends, and naphthenic flux oil) in generating RAP mixtures (see Table 3). Mixed outcomes were reported as paraffinic-based oil and aromatic extract exhibited the lowest viscosity (18% by weight of total asphalt), whilst WEO bottoms the highest viscosity level, and refined tallow was the most efficient in lowering aged asphalt viscosity (9% by weight of total asphalt). However, the after ageing study was disregarded.

Table 3.

Asphalt test results [58].

Wang et al. [59] reported that increment of aromatic content in aged asphalt due to addition of WEO as the rejuvenator had enhanced the ductility attribute in the sample. Optimum WEO amount depended on the sample attributes (e.g., stiffness), whereas excessive WEO content led to soft pavement and deteriorated performance. The WEO-asphalt adhesion was enhanced with an anti-stripping agent, whilst the blend failed at high temperature. Next, Li et al. [60] reported that WCO and WEO enhanced the properties (ductility, penetration, and softening point) of aged asphalt. Nonetheless, lower amount of WCO demonstrated a similar rejuvenation impact displayed by WEO; signifying WCO as the better rejuvenator than WEO. Liu et al. [61] also revealed that 4–8% WEO increased δ values, but substantially lowered viscosity and G* of aged asphalt. The WEO exerts positive and negative effects on fatigue behaviour and asphalt rutting resistance, respectively [61]. Apart from the low rutting resistance, Lin et al. [62] found that WEO lowered cohesive strength at a high temperature.

Farooq et al. [63] evaluated the effect of adding used motor engine oil (UMEO) on indirect tensile strength (ITS) and moisture damage properties. Increased rejuvenator dose caused the ITS for both unconditioned and conditioned cases to reduce, whilst the TSR increased due to low fatigue resistance and adhesion level of RAP. Wang and Fang [59] found that WEO was conducive as a rejuvenator to asphalt performance at low temperatures. However, anti-stripping agent was needed as WEO affected the aggregate-asphalt adhesion.

Some rejuvenating agents could cause rutting damage when incorporated into pavements [45,64]. For instance, WEO and certain petroleum-based products are beneficial solely for boosting asphalt performance at low temperature, but unsuitable at high temperature due to extreme softening of oil and ineffective aggregates-asphalt binding [59,65,66]. Other factors responsible for rutting damage are low stiffness of micro-layer surface of RAP, as well as incompatible and ineffective blending between rejuvenator and RAP binder (aged asphalt) [67]. The durability of rejuvenators is another issue, as the presence of volatile compounds in some softening agents can lower asphalt stiffness to enable the eventual compaction and further improvement [47]. The rejuvenator-asphalt chemical interaction is another vital factor as some rejuvenating agents accelerate ageing, thus making asphalt unusable [47]. For example, heavy fuel oils can easily volatilise at high recycling temperature, thus limiting the content of RAP in the asphalt mixture to be less than 30% [68]. Upon incorporation, the same rejuvenators can act differently in other asphalts. For instance, an aromatic extract from crude oil displayed higher efficiency when used with asphalt (PG58-10) than with asphalt (PG58-28) [69].

Yin et al. [41] studied the efficacy of rejuvenating agents (tall oil and aromatic extract) with LTA. Although the rejuvenating agents were effective in partially reducing the stiffness and restoring the properties of aged asphalt, their efficacy deteriorated with ageing. In a comparative study, plant oils (soybean or corn oil) as rejuvenators were more effective in reducing the hardness of aged asphalt binders than did fuel oil (petroleum)-based rejuvenators [68,70]. Organic rejuvenators require lower dose than petroleum-based rejuvenators to yield similar effects on the rheological properties [37]. Upon comparing the efficacy between WCO and WEO, the former restored the original rheological properties more effectively than the latter [60].

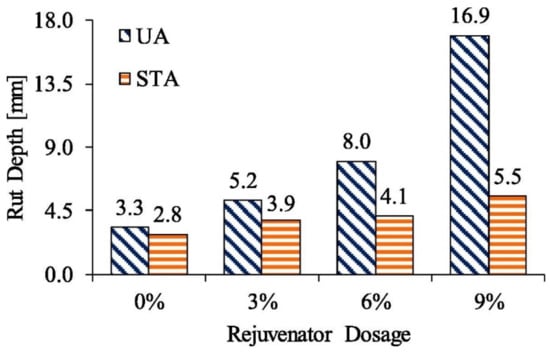

Another research assessed the effect of aromatic oil on the rutting resistance of un-aged (UA) and STA mixtures using HWTT [71]. The asphalt mixture was blended with aromatic oil dosages ranging at 0–9%, and the samples were tested at UA and STA conditions to determine the change of the rejuvenating agent impact over time. As a result, increasing aromatic oil content increased rutting susceptibility. The effect on rutting was very pronounced at a high dosage (see Figure 5). Meanwhile, STA reduced the flexibility and increased the rutting resistance of asphalt mixture.

Figure 5.

Rut depth at 10,000 passes [71].

Al-Saffar et al. [72] reported that low WEO content was an effective rejuvenator, as high amount of WEO can permanently deform asphalt blend. They concluded that, as WEO was susceptible to ageing, WEO-asphalt blend could suffer from ageing due to low fatigue resistance. Such findings question the efficacy of WEO as a rejuvenator in RAP blend for long-term use. Hence, it is prescribed to incorporate WEO with other rejuvenators, including anti-stripping material, polymers, and maltene. Table 4 summarised the effect of adding refined crude-oils as rejuvenator.

Table 4.

Effect of adding refined crude-oils as rejuvenator.

3.3. Rejuvenation of Recycled Asphalt Using Bio-Oil Products

Based on the results of researches, bio-oils which are extracted from two sources: plant-based and animal-based [73], in addition to the bio-crude oil have been vastly explored as rejuvenating agents. Zhang et al. [74] studied the impact of waste wood bio-oil (rejuvenator with 10%, 15% and 20% concentration levels) on PAV-aged asphalt. The use of VA (PG 58-28) had facilitated in preparing the bio-rejuvenated asphalts. The empirical outcomes showed that the blend viscosity lowered with the incorporation of bio-oil due to the presence of light compounds in the bio-oil. Besides increasing the resistance of asphalt towards cracking at low temperature (due to better mixture fluidity), the bio-oil improved both the rutting resistance and fatigue life of the aged asphalt.

Sawdust-derived bio-oil was used to restore the rheological properties of both PAV PG 58-28 and PAV PG 64-22 [75]. Various tests (viscosity, DSR, and Asphalt Binder Cracking Device (ABCD)) were executed to evaluate the properties of bio-rejuvenated and VA samples. As a result, loss of lighter elements and oxidisation further stiffened asphalt, thus dramatically increasing viscosity. Nevertheless, 15% and 20% of the rejuvenator softened and restored the properties of the two samples, respectively. Viscosity, activation energy, and rutting index decreased, whilst improvement was noted for low-temperature cracking resistance in aged asphalts after adding the bio-oil. These changes were ascribed to high aromatic content in the bio-rejuvenator, which balanced the chemical components in the aged asphalt. The bio-rejuvenating agent increased the fracture stress of the aged asphalts, thus the potential to endure high thermal stress due to cooling stemming from the presence of tiny bio-char particles in bio-oil that relaxed thermal stress. FTIR analysis revealed that both sulfoxide (S=O) and aromatic (C=C) indices decreased with the increase in bio-rejuvenating agent content. However, the carbonyl (C=O) index increased with the addition of more than 10% of bio-oil. This was attributed to the presence of ketones, aldehydes, carboxylic acids, esters, and acyls in bio-oil, which promoted polarity.

Kowalski et al. [76] examined the effect of bio-rapeseed oil on the properties of aged asphalt. The addition of 2.5% rapeseed oil decreased the viscosity of the sample changed its properties at low temperature. Nonetheless, the viscosity increased and the properties of the rejuvenated asphalt at high temperatures were enhanced due to the polymerisation process of double unsaturated bonds and cobalt catalyser in the rapeseed methyl esters. Cao et al. [46] assessed the chemical components in W-oil rejuvenated asphalt. W-oil is soybean oil by-product after being treated at high temperature. Since aliphatic ester is the main element in soybean oil, ethers and carbonyl are present in W-oil but no trace of sulfoxide or benzene. The FTIR spectra revealed that adding W-oil reduced the sulfoxide index; ascribed to W-oil physical dilution in asphalt. At 10–15% W-oil, the rejuvenated asphalt had similar S=O with that of VA. High W-oil content increased the carbonyl index, as W-oil mostly contained fatty acid with high carbonyl (C=O) content. A study assessed the impact of a rejuvenator on asphalt subjected to LTA [77]. The study used a bio-binder (cotton oil) as the plasticiser. The peak-area intensity of the oxygenated groups (C=O and S=O) was used to probe the degree of ageing and the rejuvenation of asphalt. The results showed that rejuvenating agent lowered both carbonyl and sulfoxide indices of the PAV-aged asphalt. Although the PG-grade results showed that 5%-bio-rejuvenating agent is recommended to recycle the aged asphalt, it cannot be used to restore the low-temperature properties of the aged asphalt to its original level at −18 °C and −24 °C The results of SARA analysis demonstrated that the rejuvenating agent had lowered the asphaltene content in the PAV-aged asphalts (see Table 5). However, the COI of the extracted asphalt after rejuvenation was lower than that of the VA, meaning that the properties of VA and bio-rejuvenated asphalts are not similar.

Table 5.

SARA analysis of aged and bio-rejuvenated asphalts [77].

Rejuvenated asphalts were reported to be more susceptible to ageing than VA, although most rejuvenators did enhance the physical and rheological aspects in the samples [39,78]. Thus, VA aged slower than rejuvenated asphalt [37]. Cai et al. [39] found that the ageing rate of physical properties in asphalt increased after rejuvenation, whilst Grilli et al. [78] noted that the ageing effect on rejuvenated asphalt was more detrimental than on VA as the former had higher parameter values variation. Despite restoring the viscoelastic behaviour of aged asphalt, rejuvenators cause earlier ageing than VA.

The early ageing attribute is mostly noted for bio-rejuvenators due to the higher oxygen content in bio-oils than petroleum oil. Some studies discovered better ageing resistance in rejuvenated asphalts than VA [37]. The early ageing of bio-binders is linked with higher mass loss than VA as a result of weight compounds volatilisation [79]. Bio-binders may experience mass loss because of water loss [79] as biomass has plenty of moisture. The advantages of rejuvenating agents are lost due to ageing [80], although rejuvenated asphalt may display better improvement than binder recycled without rejuvenator.

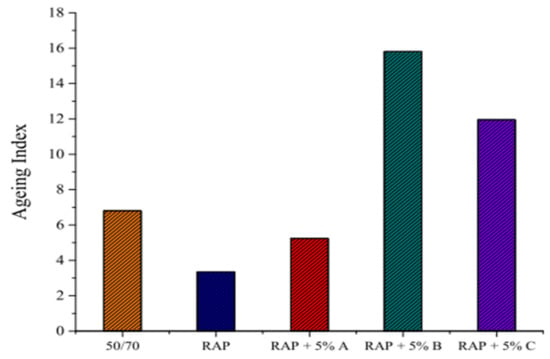

Cavalli et al. [81] assessed the effects of ageing on the rheological properties of aged asphalt modified with three commercial bio-rejuvenators: natural seed oil (A), cashew nut shell oil (B), and tall oil (C), with a dose of 5% by weight of the aged asphalt. Prior to ageing, rejuvenators B and C demonstrated higher potential of softening the aged asphalt than A. Upon being subjected to ageing, the rheological characteristics of the rejuvenated samples were affected the most. Cavalli et al. [81] also portrays that the ageing indices of (RAP + B) and (RAP + C) were higher than those of virgin and aged asphalts; signifying that the rheological properties of the samples were highly affected by ageing (Figure 6).

Figure 6.

Variation of the ageing index for the different samples [81].

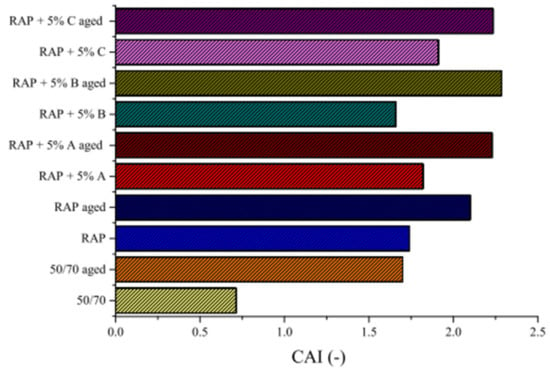

The study also assessed the impacts of the rejuvenators on the chemical properties of the samples. The results showed that ageing affected the characteristics of the rejuvenated asphalts. Increment in chemical ageing index (CAI) revealed the presence of oxidation at a functional group level despite rejuvenation (see Figure 7). Both RAP+C and RAP+A exhibited higher absorbance at wavenumber linked to carbonyl index than aged asphalt because A and C have C=O carboxylic groups. Similarly, Nayak and Sahoo [82] reported the presence of ketone in Pongamia oil derived from Pongamia pinnata plant seeds. Incorporation of rejuvenating agents, thus, softened the aged asphalt without breaking the chemical bonds at the molecular level.

Figure 7.

CAI of asphalt samples before and after ageing [81].

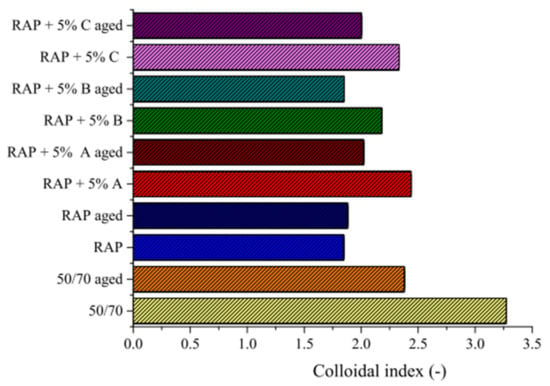

The fractions of asphalt change due to ageing. Referring to SARA outcomes, COI was determined by dividing the ratio of resins and aromatics to asphaltene and saturates. The COI revealed gel or sol structures in asphalt; whereby low COI signified higher gel structure. Figure 8 illustrates a new agglomeration between non-polar and polar fractions generated by the rejuvenating agents as the COI values of virgin and aged asphalts were near similar. However, the COI values of the rejuvenated asphalt samples after ageing were lower than those before ageing; signifying that 50/70 aged asphalt and 50/70 VA were less susceptible to ageing than rejuvenated asphalts.

Figure 8.

COI for asphalt samples before and after ageing [81].

Use of bio-oils can enhance the moisture susceptibility in binders as a result of hydrophilic groups dissolution from bio-oil [83,84]. Due to failed cohesion and adhesion, moisture damages the asphalt blend; thus, adding rejuvenators with water-soluble and hydrophilic components into asphalt can address moisture damage issue [25]. For example, although WCO-rejuvenated asphalt had its rheological properties restored [85], it displayed moisture damage [86]. A study on RAP containing bio-rejuvenator based on plant extract revealed enhanced resistance towards moisture damage due to increased loss-modulus and storage-modulus ratios of moisture-conditioned samples [87]. In short, the ageing issue has been associated with the different types of bio-rejuvenating agents; this is attributable to the high oxygen content in bio-oil than in asphalt. The ageing of bio-rejuvenating agents is related to higher loss of mass than in VA because of water loss (biomass has plenty of moisture) and volatilisation of weight compounds [79,88]. Therefore, the benefit of incorporating rejuvenating agents are compromised due to ageing [37,89]. Moisture can severely damage asphalt mixtures by failing both cohesion and adhesion [25]. Hence, although WCO bio-rejuvenating agent (as an example) effectively restore the rheological properties of aged asphalt, it accelerates moisture damage [25]. Table 6 summarised the effect of adding bio-oil as rejuvenator.

Table 6.

Effect of adding bio-oil as rejuvenator.

3.4. Rejuvenation of Recycled Asphalt Using Hybrid Rejuvenator

The use of hybrid rejuvenators was introduced recently to decrease the adverse effects of some softening and rejuvenating agents [90]. For example, Rajib et al. [25] tested the durability of rejuvenated asphalt mixtures containing 25% RAP and hybrid rejuvenator in light of ageing and moisture susceptibility. The hybrid rejuvenator refers to Rej-Swilgae (co-liquefied 1:1 ratio of swine manure to algae bio-oil) that contained Saturates: 0.85%, Aromatics: 0.25%, Resin: 72.7%, and Asphaltene: 26.25%. The hybrid rejuvenator showed high resistance towards ageing and moisture damage, whilst concurrently efficient in restoring the rheological properties in aged asphalt. Pahlavan et al. [91] assessed the merits of using a hybrid bio-oil rejuvenator derived from algae and swine manure to rejuvenate aged asphalt by restoring the properties of the sample. The proposed rejuvenator indicated more noticeable restoration, along with better de-agglomeration of oxidised asphaltenes.

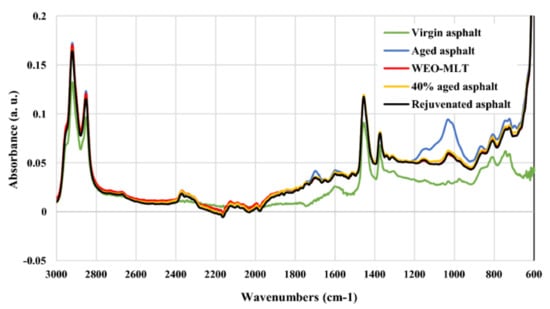

Bai et al. [92] examined the physical and rheological attributes of aged asphalt using three rejuvenators: (A) treated WEO, (B) treated WEO+ furfural extraction oil, and (C) B+epoxy resin. The samples were subjected to FTIR, penetration, bending beam rheometer (BBR), softening point, DSR, and ductility measurements. As a result, Rejuvenator C displayed dominance, whilst WEO enhanced asphalt subjected to STA with appropriate additive modification.

Al-Saffar et al. [90] reported hindrance of stiffness increment, reduced softening point, as well as better ductility and penetration, when hybrid rejuvenator (WEO+ maltene) was added at 7.5% concentration to enhance aged asphalt samples. Apart from significantly enhancing the chemical and rheological properties of the samples at high and low temperatures, the hybrid rejuvenator maintained the viscosity of the samples to VA level. The FTIR analysis, however, showed slightly escalated ageing in the samples due to the carboxyl group (C=O) present in the hybrid rejuvenator (Figure 9). Meanwhile, the thermogravimetric (TG) analysis and the stripping resistance test revealed that the initial decomposition and the efficiency of the rejuvenated asphalt were near similar to VA, respectively. Li et al. [93] examined if inclusion of WEO (rejuvenator) and additives (as auxiliary components, e.g., organic polymer & rubber powder) restored the attributes in aged asphalt samples. As a result, the properties of the samples did improve when 3–4% of the rejuvenator was added. The substantially enhanced physical and rheological (based on DSR) properties in the asphalt samples indicated the suitability of the proposed hybrid rejuvenator in recycling asphalt pavement.

Figure 9.

FTIR spectra for asphalt samples [90].

Upon assessing the mechanical performance of HMA with 30%, 40%, and 100% of aged asphalt, Jahanbakhsh et al. [94] concluded that the high stiffness of aged asphalt degraded the mechanical efficacy of the asphalt blend. However, the addition of crumb rubber modified (CRM) and WEO softened the asphalt blend and cause the mechanical performance to be equal or even better than the conventional blend. Besides, 4.0% and 7.5% of high-density polyethylene (HDPE) and used motor oil (UMO), respectively, effectively functioned as rejuvenators in retaining the mechanical attributes of HMA+ 50% RAP [95]. Fernandes et al. [96] developed stone mastic asphalt (SMA) mixtures containing 50% aged asphalt with high proportions of EO products and polymers. As a result, the EO elements restored the penetration attribute (physical property), whereas the softening point and viscosity of the rejuvenated samples displayed lower scores than the ages asphalts. Most importantly, dosage of EO with polymers should be at the optimum level. As for rheological property, the rejuvenated asphalts were not as susceptible to temperature fluctuation (high and low G* at high and low temperatures, respectively) as virgin and aged asphalts; reflecting higher resistance towards permanent deformation with rejuvenator. The rejuvenated blends displayed exceptional water sensitivity as they resulted in TSR scores above 80%. Hence, EO displayed a positive effect on fatigue cracking resistance in recycled SMA blends.

Deef-Allah et al. [97] reported both engineering and environmental concerns on the usage of WEO to rejuvenate aged asphalt using four CRM asphalt binder samples: two each with and without WEO. In light of the engineering aspect, WEO+CR balanced high- and low-temperature properties of asphalt binders. The environmental impacts were assessed via gas chromatography to determine air emissions for benzene, toluene, ethyl-benzene, and xylenes (BTEX). Toxic elements that may leach from modified HMA were identified using the US Environmental Protection Agency (EPA) Toxicity Characteristic Leaching Protocol (TCLP). For asphalt binders modified with CRM-WEO, the CRM lowered the release rate of BTEX by absorbing WEO. All leachate elements were below EPA limit and WEO blends revealed a certain fraction of sulphur, in comparison to blends without WEO. The study prescribed use of UMO below 3% and WEO only after testing samples gathered from multiple sources to assure compliance of leachate and air emission rates.

3.5. Rejuvenation of Recycled Asphalt Using Commercial Rejuvenators

Mohammadafzali et al. [27] examined the long-term performance of two commercial rejuvenating agents on rheological properties of aged asphalt. The rejuvenators were heavy paraffinic oil with high aromatic content (R1) and a re-refined product, which is a semi-solid substance (R2). The findings showed that the impact of rejuvenators on the long-term performance of asphalt relied on the type and the dosage of the rejuvenators. As R1 displayed high softening power, a small amount was sufficient to restore the properties of asphalt. On the contrary, a large amount of R2 was required to soften the aged asphalt since the material is semi-solid. Notably, higher percentage of rejuvenators exerted greater effect on the ageing aspect of the asphalt samples. Another study used Cyclogen and Rapiol as the rejuvenating agents to restore the performance of asphalt mixtures with 0%, 25%, 50%, 75%, and 100% RAP materials [98]. It was found that the mixtures with RAP material had higher resistance against rutting and moisture damage. Although the values decreased with the addition of rejuvenators, they were still higher than those of the VA mixture. Fatigue and intermediate-temperature crack resistance of asphalt mixtures were impaired by RAP material. Apparently, the rejuvenators decreased the stiffness of mixtures, thus enhancing fatigue life in aged asphalt blends. Rapiol performed better than Cyclogen for fatigue at low RAP content and low-stress level. Recently, Cyclogen, Rapiol, and WCO were used as rejuvenators to assess their effects on moisture resistance of 50% RAP mixtures [99]. As a result, asphalt with RAP demonstrated more resistance against water than rejuvenated and virgin HMA. The results were ascribed to strong bonding between aged asphalt and RAP aggregate. The rejuvenated mixtures, however, did not achieve the TSR requirements (≥80%) as stipulated in AASHTO T283. This means that the rejuvenating agents exerted an adverse effect on the resistance of moisture damage in asphalt. It is important to mention that the Rapiol rejuvenating agent exemplified the best performance, followed by WCO and Cyclogen.

Ziari et al. [6] assessed the impact of ageing on moisture damage resistance in asphalt with 50% RAP, along with three rejuvenators (Rapiol, Cyclogen, and WCO). The TSR values displayed better resistance against moisture damage in UA RAP mixtures than virgin HMA. The outcome was ascribed to the strong bonding between aggregate and aged asphalt interior layers in RAP that hindered moisture damage. The ageing had slightly reduced moisture resistance in the mixtures. This is because ageing forms more interconnected voids in the mixtures, as the flow of moisture can cause severe damage. The moisture resistance in WCO-rejuvenated mixtures reduced for STA, whilst RAP mixtures with WCO lost their adhesion capacity upon ageing. As such, ageing resistance in RAP mixtures was strongly influenced by the type of rejuvenator. The RAP mixtures rejuvenated by WCO (organic) accelerated ageing more than Rapiol and Cyclogen (oil based). Dhasmana et al. [100] assessed the performance of asphalt binder blends with aged asphalt and rejuvenators. Virgin PG 64-22 binder was aged using RTFO and PAV and was further mixed with three rejuvenators: Hydrolene 90T (R1), Kendex@ME (R2), and Hydrogreen S (R3) at 3%, 6%, and 9% by weight of the total binder. Next, the asphalt samples were aged for 5, 10, 15, 20, 40, and 60 h in PAV. A comparative analysis was executed to identify the impact of increased ageing and rejuvenator addition in varying amounts on the performance of asphalt blends. It was reported that all three rejuvenating agents did restore the rheological properties of the samples. Notably, the modifier type dictated the effect of rejuvenation at high, intermediate, and low temperatures. The R1-rejuvenated asphalt was softer, whilst R2 at 3% showed almost negligible effect on PAV ageing, especially for ageing ≤ 15 h at low and intermediate temperatures. Meanwhile, a substantial increase in G* values was noted for PAV ageing > 15 h. Ageing susceptibility of the asphalt samples increased with increment in rejuvenator. The stiffness in binder lowered as the rejuvenator was increased from 3 to 6%. However, rejuvenation with R1 and R3 demonstrated the opposite—a slight drop was observed. R3 enhanced ageing susceptibility despite yielding the softest binder when compared to R1 and R2. The effect of increased rejuvenator from 3 to 9% was insignificant when compared to the impact of PAV ageing. The modulus seemed to increase with rejuvenation for asphalt samples aged for 5 h in PAV. Asphalt aged for 60 h had more stiffness from 3 to 6% rejuvenation and softened after adding 9% of R1. Next, 3% modified binder aged for 15 h and unmodified binder aged for 10 h demonstrated similar performance. Unmodified binders aged slower than rejuvenated binders; signifying better long-term performance with VA. Im et al. [35] evaluated three different commercial rejuvenators (R1, R2 and R3) and their impact on the performance properties of asphalt mixtures containing RAP. R1 and R2 were directly added to the virgin asphalt (wet process), whilst R3 was added to the RAP (dry process). The rejuvenated mixtures revealed an improvement in cracking resistance, moisture susceptibility and rutting resistance. However, the performance of the rejuvenators highly depended on the degree of blending between the rejuvenator and asphalt, different source of the aggregates, and the rejuvenator dosage.

Ishaq and Giustozzi [101] investigated the effect of moisture and freeze/thaw cycles on asphalt mixtures containing 20% RAP. Outcomes highlighted how the use of the rejuvenator can contribute to reduce the deterioration of RAP mixtures as well as decreasing the moisture and freeze/thaw damage effects on the durability of pavement.

4. Selection of Rejuvenator

Although proper use of rejuvenators can improve the properties, the performance, and the longevity of aged asphalt mixtures, the treatment details of rejuvenators (type and dosage, blending and curing, properties affected, and performance characteristics) are scarce [102]. For example, using a faster ageing rejuvenator (e.g., semi-solid re-refined product) decreases the life of rejuvenated asphalt to less than one-half. On the contrary, the life of rejuvenated asphalt can be increased up to 30% when a slow ageing rejuvenator (e.g., heavy paraffinic oil) is applied [27]. Afzali et al. [27] evaluated the long-term performance of two commercial rejuvenating agents based on the rheological properties of aged asphalt. The rejuvenating agents included heavy paraffinic oil with high aromatic content (R1) and a re-refined product that is a semi-solid substance (R2). The finding reported that the impact of rejuvenating agents on the long-term performance of asphalt depends on the type and the dosage of rejuvenating agent. The reason for this is that R1 has a high softening power; thus, a small amount was sufficient to restore the properties of asphalt. In contrast, a large quantity of R2 was required to soften the aged asphalt, since the material is semi-solid. However, the higher the percentage of a rejuvenating agent, the greater its effect on the ageing of asphalt. The reason is correlated with light components’ presence in the rejuvenating agents, which may be oxidised during asphalt mixture production.

Conversely, if the type of rejuvenator is inappropriate in terms of compatibility with asphalt, the diffusion and the homogeneity of the rejuvenator with aged asphalt would not be adequately achieved. Cong et al. [103] investigated the diffusion possibility of a rejuvenating agent in aged asphalt and concluded that diffusion in asphalt is complex. The reason behind the complexity is that the diffusion of rejuvenating agents in aged asphalt remains a challenge to recognize, anticipate and control; it greatly depends on the asphaltene’s concentration and the degree of swelling. It also relies on the viscosity of aged asphalt, in addition to the time and temperature of mixing.

Kuang et al. [104] highlighted the issues of applying rejuvenated asphalt, including lower high-temperature rutting properties than expected. Apparently, a rejuvenating agent functions as lubricating oil when diffusion is absent between asphalt and rejuvenator. If the rejuvenator is not diffused into the aged asphalt, the high-temperature properties of the rejuvenated asphalt pavement will be affected. This indicates the significance of diffusing rejuvenators into aged asphalt to retain the RAP properties [4]. In contrast, Kuang et al. [104] reported that lightweight oil can effectively restore the properties of slightly aged asphalt due to higher aromatics and lower asphaltenes in the aged asphalt. Nevertheless, the lightweight oil failed to restore properties in aged asphalt containing high asphaltene content that forms an interspace-network structure as a result of the strong force among the asphaltene molecules. The lightweight oil does not effectively dissolve the asphaltenes in severely aged asphalt, thus limiting the impact of any rejuvenating agent on restoring the properties in severely aged asphalt [104].

Furthermore, the selection of a rejuvenating agent relies on the degree to which it can enhance the properties of aged asphalt, while concurrently reversing the effect of ageing process in asphalt. The asphalt ageing phenomenon must be understood to assure the long-term performance of asphalt pavement [12]. Asphalt ageing takes place during asphalt production (in refinery), storage, transportation, asphalt mixing, asphalt mixture transportation and compaction, as well as from the environmental impact on the pavement service life [12]. For proper field usage of rejuvenating agent, it is of high priority to balance the cracking and rutting performance of recycled asphalt mixture [19]. The rejuvenator should reduce fatigue and low-temperature cracking potential whilst maintaining stability to rutting [105]. Therefore, it is necessary to obtain a comprehensive understanding of the engineering properties for rejuvenated asphalt mixture. Moreover, there is also a need for sufficient understanding of the dynamic characteristics of recycled hot mix asphalt [19]. Arámbula-Mercado et al. [106] assessed three rejuvenator dosage selection methods for high RAP content in asphalt mixtures. Excessive rejuvenator dosages had significantly softened both virgin and aged asphalt in mixtures, thus adversely affecting their rutting resistance. On the contrary, very low dosages of rejuvenating agent, although had decreased the brittleness in aged asphalt, failed to promote cracking resistance.

In short, rejuvenators should be stable and non-hazardous at any temperature, from production to application. They should display neither evaporation nor exudation to ascertain exceptional performance in asphalt pavement based on the regulated specification [21]. A rejuvenator should satisfy the conditions listed below [72]:

- Restore viscosity, penetration, ductility, and softening point attributes.

- Improve cracking resistance without adversely affecting high-temperature performance.

- Maintain cohesion and adhesion properties close to those of VA.

- Possess acceptable resistance to ageing (close to that of VA).

- Possess adequate flow, stability, ITS, and resistance to moisture damage before and after ageing.

- Achieve a balance between stiffness and rutting resistance in the rejuvenated asphalt.

5. Conclusions

This study has presented an overview regarding the performance and durability of rejuvenating agents and assessed if the proposed rejuvenators are indeed viable for building pavements. The main outcomes in terms of performance are summarised as follows:

- Most rejuvenators can restore the physical properties of aged asphalt. However, high restoration capacity of these rejuvenating agents does not assure the durability of restored aged asphalt.

- In addition, some rejuvenators can be used in cold regions, but unsuitable in hot regions. Certain rejuvenators have poor resistance to moisture damage.

- In attaining a viable solution from technical and practical stances, some rejuvenating agents are not preferred due to their potential rutting damage, poor practicality, and low durability for their medium- to long-term usage.

- The negative impact of rejuvenating agents can be minimised by including additives, such as polymers, fibers, and CRM.

- The rejuvenators should possess a series of fundamental requirements in terms of performance, availability, and logistics. More importantly, these rejuvenators should have homogeneity in composition.

- Early ageing due to certain rejuvenators demands further exploration, particularly for LTA. Thus, it is compulsory to study the ageing effect on the rejuvenators before introducing them to the industry.

Author Contributions

Conceptualization, writing—original draft, methodology, investigation, formal analysis, Z.H.A.-S.; supervision, reviewing, resources, funding acquisition, H.Y.; supervision, reviewing, funding acquisition, H.Y.K.; supervision and reviewing, M.K.I.M.S.; reviewing, editing, and data curation, M.B.; reviewing and editing, R.P.J., A.S.E.; writing—reviewing and editing, H.R.R. All authors have read and agreed to the published version of the manuscript.

Funding

This work was funded by Ministry of Education Malaysia through the Fundamental Research Grant Scheme [Grant Number R.J130000.7851.5F019] and Universiti Tenaga Nasional Internal Research Grant OPEX (J5100D4103-BOLDREFRESH2025-CENTRE OF EXCELLENCE).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data used in this research can be provided upon request.

Acknowledgments

The authors express their gratitude to the Universiti Tenaga Nasional for supporting this article via Internal Research Grant OPEX (J5100D4103-BOLDREFRESH2025-CENTRE OF EXCELLENCE).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ahmad, J.; Yusoff, N.I.M.; Hainin, M.R.; Abd Rahman, M.Y.; Hossain, M. Investigation into hot-mix asphalt moisture-induced damage under tropical climatic conditions. Constr. Build. Mater. 2014, 50, 567–576. [Google Scholar] [CrossRef]

- Chen, M.; Leng, B.; Wu, S.; Sang, Y. Physical, chemical and rheological properties of waste edible vegetable oil rejuvenated asphalt binders. Constr. Build. Mater. 2014, 66, 286–298. [Google Scholar] [CrossRef]

- Zhang, J.; Sun, C.; Li, P.; Jiang, H.; Liang, M.; Yao, Z.; Zhang, X.; Airey, G. Effect of different viscous rejuvenators on chemical and mechanical behavior of aged and recovered bitumen from RAP. Constr. Build. Mater. 2020, 239, 117755. [Google Scholar] [CrossRef]

- Xu, M.; Zhang, Y. Study of rejuvenators dynamic diffusion behavior into aged asphalt and its effects. Constr. Build. Mater. 2020, 261, 120673. [Google Scholar] [CrossRef]

- Bilema, M.; Aman, M.Y.; Hassan, N.A.; Memon, Z.A.; Omar, H.A.; Yusoff, N.I.M.; Milad, A. Mechanical Performance of Reclaimed Asphalt Pavement Modified with Waste Frying Oil and Crumb Rubber. Materials 2021, 14, 2781. [Google Scholar]

- Ziari, H.; Moniri, A.; Bahri, P.; Saghafi, Y. The effect of rejuvenators on the aging resistance of recycled asphalt mixtures. Constr. Build. Mater. 2019, 224, 89–98. [Google Scholar] [CrossRef]

- Kandhal, P.; Mallick, R. Pavement Recycling Guidelines for State And Local Governments—Participant’s Handbook; U.S. Department of Transportation: Washington, DC, USA, 1997.

- Zahoor, M.; Nizamuddin, S.; Madapusi, S.; Giustozzi, F. Sustainable asphalt rejuvenation using waste cooking oil: A comprehensive review. J. Clean. Prod. 2020, 278, 123304. [Google Scholar] [CrossRef]

- Copeland, A. Reclaimed Asphalt Pavement in Asphalt Mixtures: State of the Practice (Publication No. FHWA-HRT-11-021); Turner-Fairbank Highway Research Center, Federal Highway Administration: McLean, VA, USA, 2011. [Google Scholar]

- Xinxin, C.; Xuejuan, C.; Boming, T.; Yuanyuan, W.; Xiaolong, L. Investigation on possibility of waste vegetable oil rejuvenating aged asphalt. Appl. Sci. 2018, 8, 765. [Google Scholar] [CrossRef] [Green Version]

- Sreedhar, S.; Coleri, E. The effect of long-term aging on fatigue cracking resistance of asphalt mixtures. Int. J. Pavement Eng. 2020, 1–13. [Google Scholar] [CrossRef]

- Kleizienė, R.; Panasenkienė, M.; Vaitkus, A. Effect of Aging on Chemical Composition and Rheological Properties of Neat and Modified Bitumen. Materials 2019, 12, 4066. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Z.; Han, S.; Han, X.; Dong, S.; Yao, T. Performance changes of hot recycled asphalt mixture in different layers under coupling of multiple aging factors. Constr. Build. Mater. 2020, 269, 121343. [Google Scholar] [CrossRef]

- Ren, S.; Liu, X.; Wang, H.; Fan, W.; Erkens, S. Evaluation of rheological behaviors and anti-aging properties of recycled asphalts using low-viscosity asphalt and polymers. J. Clean. Prod. 2020, 253, 120048. [Google Scholar] [CrossRef]

- Ahmad, K.A.; Abdullah, M.E.; Hassan, N.A.; Usman, N.; Hassan, M.R.M.; Bilema, M.A.; Saeed, S.M.; Batari, A. Effect of Bio Based Rejuvenator on Mix Design, Energy Consumption and GHG Emission of High RAP Mixture. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2018; p. 012086. [Google Scholar]

- Xie, Z.; Rizvi, H.; Purdy, C.; Ali, A.; Mehta, Y. Effect of rejuvenator types and mixing procedures on volumetric properties of asphalt mixtures with 50% RAP. Constr. Build. Mater. 2019, 218, 457–464. [Google Scholar] [CrossRef]

- Yu, X.; Zaumanis, M.; Dos Santos, S.; Poulikakos, L.D. Rheological, microscopic, and chemical characterization of the rejuvenating effect on asphalt binders. Fuel 2014, 135, 162–171. [Google Scholar] [CrossRef]

- Tran, N.H.; Taylor, A.; Willis, R. Effect of Rejuvenator on Performance Properties of HMA Mixtures with High RAP and RAS Contents; NCAT Report No. 12-05; National Center for Asphalt Technology, Auburn University: Auburn, AL, USA, 2012. [Google Scholar]

- Pan, P.; Kuang, Y.; Hu, X.; Zhang, X. A comprehensive evaluation of rejuvenator on mechanical properties, durability, and dynamic characteristics of artificially aged asphalt mixture. Materials 2018, 11, 1554. [Google Scholar] [CrossRef] [Green Version]

- Roberts, F.L.; Kandhal, P.S.; Brown, E.R.; Lee, D.-Y.; Kennedy, T.W. Hot Mix Asphalt Materials, Mixture Design and Construction; National Asphalt Pavement Association Research and Education Foundation: Lanham, MD, USA, 1991. [Google Scholar]

- Loise, V.; Caputo, P.; Porto, M.; Calandra, P.; Angelico, R.; Oliviero Rossi, C. A review on Bitumen Rejuvenation: Mechanisms, materials, methods and perspectives. Appl. Sci. 2019, 9, 4316. [Google Scholar] [CrossRef] [Green Version]

- Zaumanis, M.; Mallick, R.B.; Frank, R. 100% recycled hot mix asphalt: A review and analysis. Resour. Conserv. Recycl. 2014, 92, 230–245. [Google Scholar] [CrossRef]

- Moghaddam, T.B.; Baaj, H. The use of rejuvenating agents in production of recycled hot mix asphalt: A systematic review. Constr. Build. Mater. 2016, 114, 805–816. [Google Scholar] [CrossRef]

- Yaseen, G.; Hafeez, I. Effect of Cereclor as Rejuvenator to Enhance the Aging Resistance of Reclaimed Asphalt Pavement Binder. Materials 2020, 13, 1582. [Google Scholar] [CrossRef] [Green Version]

- Rajib, A.I.; Pahlavan, F.; Fini, E.H. Investigating Molecular-Level Factors That Affect the Durability of Restored Aged Asphalt Binder. J. Clean. Prod. 2020, 270, 122501. [Google Scholar] [CrossRef]

- Bilema, M.; Aman, M.Y.; Hassan, N.A.; Al-Saffar, Z.; Mashaan, N.S.; Memon, Z.A.; Milad, A.; Yusoff, N.I.M. Effects of Waste Frying Oil and Crumb Rubber on the Characteristics of a Reclaimed Asphalt Pavement Binder. Materials 2021, 14, 3482. [Google Scholar]

- Mohammadafzali, M.; Ali, H.; Musselman, J.A.; Sholar, G.A.; Rilko, W.A. Aging of rejuvenated asphalt binders. Adv. Mater. Sci. Eng. 2017. [Google Scholar] [CrossRef] [Green Version]

- Shen, J.; Amirkhanian, S.; Tang, B. Effects of rejuvenator on performance-based properties of rejuvenated asphalt binder and mixtures. Constr. Build. Mater. 2007, 21, 958–964. [Google Scholar] [CrossRef]

- Kaseer, F.; Martin, A.E.; Arámbula-Mercado, E. Use of recycling agents in asphalt mixtures with high recycled materials contents in the United States: A literature review. Constr. Build. Mater. 2019, 211, 974–987. [Google Scholar] [CrossRef]

- Tabatabaee, H.A.; Kurth, T.L. Analytical investigation of the impact of a novel bio-based recycling agent on the colloidal stability of aged bitumen. Road Mater. Pavement Des. 2017, 18, 131–140. [Google Scholar] [CrossRef]

- De Bock, L.; Vansteenkiste, S.; Vanelstraete, A. Categorisation and Analysis of Rejuvenators for Asphalt Recycling; Belgian Road Research Centre: Brussels, Belgium, 2020. [Google Scholar]

- Zadshir, M.; Oldham, D.J.; Hosseinnezhad, S.; Fini, E.H. Investigating bio-rejuvenation mechanisms in asphalt binder via laboratory experiments and molecular dynamics simulation. Constr. Build. Mater. 2018, 190, 392–402. [Google Scholar] [CrossRef]

- Ali, A.W.; Mehta, Y.A.; Nolan, A.; Purdy, C.; Bennert, T. Investigation of the impacts of aging and RAP percentages on effectiveness of asphalt binder rejuvenators. Constr. Build. Mater. 2016, 110, 211–217. [Google Scholar] [CrossRef]

- Elseifi, M.A.; Mohammad, L.N.; Cooper, S.B. III. Laboratory evaluation of asphalt mixtures containing sustainable technologies. Asph. Paving Technol. 2011, 227–244. [Google Scholar]

- Im, S.; Zhou, F.; Lee, R.; Scullion, T. Impacts of rejuvenators on performance and engineering properties of asphalt mixtures containing recycled materials. Constr. Build. Mater. 2014, 53, 596–603. [Google Scholar] [CrossRef]

- Kaseer, F.; Cucalon, L.G.; Arámbula-Mercado, E.; Martin, A.E.; Epps, J. Practical tools for optimizing recycled materials content and recycling agent dosage for improved short-and long-term performance of rejuvenated binder blends and mixtures. J. Assoc. Asph. Paving Technol. 2018, 87, 513–550. [Google Scholar] [CrossRef]

- Behnood, A. Application of rejuvenators to improve the rheological and mechanical properties of asphalt binders and mixtures: A review. J. Clean. Prod. 2019, 231, 171–182. [Google Scholar] [CrossRef]

- Al-Saffar, Z.H.; Yaacob, H.; Satar, M.K.I.M.; Saleem, M.K.; Lai, J.C.; Putra Jaya, R. A review on rejuvenating materials used with reclaimed hot mix asphalt. Can. J. Civ. Eng. 2021, 48, 233–249. [Google Scholar] [CrossRef]

- Cai, X.; Zhang, J.; Xu, G.; Gong, M.; Chen, X.; Yang, J. Internal aging indexes to characterize the aging behavior of two bio-rejuvenated asphalts. J. Clean. Prod. 2019, 220, 1231–1238. [Google Scholar] [CrossRef]

- Yang, X.; Mills-Beale, J.; You, Z. Chemical characterization and oxidative aging of bio-asphalt and its compatibility with petroleum asphalt. J. Clean. Prod. 2017, 142, 1837–1847. [Google Scholar] [CrossRef]

- Yin, F.; Kaseer, F.; Arámbula-Mercado, E.; Epps Martin, A. Characterising the long-term rejuvenating effectiveness of recycling agents on asphalt blends and mixtures with high RAP and RAS contents. Road Mater. Pavement Des. 2017, 18, 273–292. [Google Scholar] [CrossRef]

- Bilema, M.; Aman, M.; Hassan, N.; Abdullah, N. Investigation on Rheology and Physical Properties of Asphalt Binder Blended with Waste Cooking Oil. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; p. 012045. [Google Scholar]

- Zargar, M.; Ahmadinia, E.; Asli, H.; Karim, M.R. Investigation of the possibility of using waste cooking oil as a rejuvenating agent for aged bitumen. J. Hazard. Mater. 2012, 233, 254–258. [Google Scholar] [CrossRef] [PubMed]

- El-Shorbagy, A.M.; El-Badawy, S.M.; Gabr, A.R. Investigation of waste oils as rejuvenators of aged bitumen for sustainable pavement. Constr. Build. Mater. 2019, 220, 228–237. [Google Scholar] [CrossRef]

- Zaumanis, M.; Mallick, R.B.; Poulikakos, L.; Frank, R. Influence of six rejuvenators on the performance properties of Reclaimed Asphalt Pavement (RAP) binder and 100% recycled asphalt mixtures. Constr. Build. Mater. 2014, 71, 538–550. [Google Scholar] [CrossRef]

- Cao, X.; Wang, H.; Cao, X.; Sun, W.; Zhu, H.; Tang, B. Investigation of rheological and chemical properties asphalt binder rejuvenated with waste vegetable oil. Constr. Build. Mater. 2018, 180, 455–463. [Google Scholar] [CrossRef]

- Elkashef, M.; Williams, R.C. Improving fatigue and low temperature performance of 100% RAP mixtures using a soybean-derived rejuvenator. Constr. Build. Mater. 2017, 151, 345–352. [Google Scholar] [CrossRef]

- Chen, M.; Xiao, F.; Putman, B.; Leng, B.; Wu, S. High temperature properties of rejuvenating recovered binder with rejuvenator, waste cooking and cotton seed oils. Constr. Build. Mater. 2014, 59, 10–16. [Google Scholar] [CrossRef]

- Featherstone, S. A Complete Course in Canning and Related Processes: Volume 3 Processing Procedures for Canned Food Products; Woodhead Publishing: Sawston, UK, 2015. [Google Scholar]

- Embuscado, M.E. Herbs and Spices as Antioxidants for Food Preservation. In Handbook of Antioxidants for Food Preservation; Elsevier: Amsterdam, The Netherlands, 2015; pp. 251–283. [Google Scholar]

- Murphy, B.; Horner, G.; Tarcy, D.; Bylikin, S. Oxford IB Diploma Programme: Chemistry Course Companion; Oxford University Press-Children: Oxford, UK, 2014. [Google Scholar]

- Gibson, M. Food Science and the Culinary Arts; Academic Press: Cambridge, MA, USA, 2018. [Google Scholar]

- Mirhosseini, A.F.; Tahami, S.A.; Hoff, I.; Dessouky, S.; Ho, C.-H. Performance evaluation of asphalt mixtures containing high-RAP binder content and bio-oil rejuvenator. Constr. Build. Mater. 2019, 227, 116465. [Google Scholar]

- Wan Azahar, W.N.A.; Bujang, M.; Jaya, R.P.; Hainin, M.R.; Ngadi, N.; Al Bakri, M.M.A. Performance of Waste Cooking Oil in Asphalt Binder Modification. In Key Engineering Materials; Trans Tech Publications: Freienbach, Switzerland, 2016; pp. 216–226. [Google Scholar]

- Hussein, Z.; Yaacob, H.; Idham, M.; Hassan, N.; Choy, L.; Jaya, R. Restoration of Aged Bitumen Properties Using Maltenes. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; p. 012014. [Google Scholar]

- Al-Saffar, Z.H.; Yaacob, H.; Satar, M.K.I.M.; Saleem, M.K.; Jaya, R.P.; Basar, N.; Radeef, H.R.; Hassan, N.A. Effects of maltene on the attributes of reclaimed asphalt pavement: Performance optimisation. Constr. Build. Mater. 2021, 302, 124210. [Google Scholar] [CrossRef]

- Al-Saffar, Z.H.; Yaacob, H.; Mohd Satar, M.K.I.; Putra Jaya, R. The tailored traits of reclaimed asphalt pavement incorporating maltene: Performance analyses. Int. J. Pavement Eng. 2020, 1–14. [Google Scholar] [CrossRef]

- Zaumanis, M.; Mallick, R.B.; Frank, R. Evaluation of rejuvenator’s effectiveness with conventional mix testing for 100% reclaimed Asphalt pavement mixtures. Transp. Res. Rec. 2013, 2370, 17–25. [Google Scholar] [CrossRef] [Green Version]

- Wang, F.; Fang, Y.; Chen, Z.; Wei, H. Effect of Waste Engine Oil on Asphalt Reclaimed Properties. In AIP Conference Proceedings; AIP Publishing: College Park, MD, USA, 2018; p. 020012. [Google Scholar]

- Li, H.; Dong, B.; Wang, W.; Zhao, G.; Guo, P.; Ma, Q. Effect of Waste Engine Oil and Waste Cooking Oil on Performance Improvement of Aged Asphalt. Appl. Sci. 2019, 9, 1767. [Google Scholar] [CrossRef] [Green Version]

- Liu, S.; Peng, A.; Wu, J.; Zhou, S.B. Waste engine oil influences on chemical and rheological properties of different asphalt binders. Constr. Build. Mater. 2018, 191, 1210–1220. [Google Scholar] [CrossRef]

- Lin, P.-S.; Wu, T.-L.; Chang, C.-W.; Chou, B.-Y. Effects of recycling agents on aged asphalt binders and reclaimed asphalt concrete. Mater. Struct. 2011, 44, 911–921. [Google Scholar] [CrossRef]

- Farooq, M.A.; Mir, M.S.; Sharma, A. Laboratory study on use of RAP in WMA pavements using rejuvenator. Constr. Build. Mater. 2018, 168, 61–72. [Google Scholar] [CrossRef]

- Bilema, M.; Aman, Y.B.; Hassan, N.A.; Al-Saffar, Z.; Ahmad, K.; Rogo, K. Performance of Aged Asphalt Binder Treated with Various Types of Rejuvenators. Civ. Eng. J. 2021, 7, 502–517. [Google Scholar] [CrossRef]

- Borhan, M.N.; Suja, E.; Ismail, A.; Rahmat, R.A.O. Used Cylinder Oil Modified Cold—Mix Asphalt Concrete. J. Appl. Sci. 2007, 7, 3485–3491. [Google Scholar]

- Jia, X.; Huang, B.; Moore, J.A.; Zhao, S. Influence of waste engine oil on asphalt mixtures containing reclaimed asphalt pavement. J. Mater. Civ. Eng. 2015, 27, 04015042. [Google Scholar] [CrossRef]

- Zaumanis, M.; Mallick, R.B. Review of very high-content reclaimed asphalt use in plant-produced pavements: State of the art. Int. J. Pavement Eng. 2015, 16, 39–55. [Google Scholar] [CrossRef]

- Ji, J.; Yao, H.; Suo, Z.; You, Z.; Li, H.; Xu, S.; Sun, L. Effectiveness of vegetable oils as rejuvenators for aged asphalt binders. J. Mater. Civ. Eng. 2017, 29, D4016003. [Google Scholar] [CrossRef]

- Al-Saffar, Z.H.; Yaacob, H.; Satar, M.K.I.M. Performance of reclaimed asphalt pavement rejuvenated with maltene. Ph.D. Thesis, Universiti Technologi Malaysia, Skudai, Malaysia, 2021. [Google Scholar]

- Zhao, K.; Wang, Y.; Chen, L.; Li, F. Diluting or dissolving? The use of relaxation spectrum to assess rejuvenation effects in asphalt recycling. Constr. Build. Mater. 2018, 188, 143–152. [Google Scholar] [CrossRef]

- Espinoza-Luque, A.F.; Al-Qadi, I.L.; Ozer, H. Optimizing rejuvenator content in asphalt concrete to enhance its durability. Constr. Build. Mater. 2018, 179, 642–648. [Google Scholar] [CrossRef]

- Al-Saffar, Z.H.; Yaacob, H.; Satar, M.K.I.M.; Kamarudin, S.N.N.; Mahmud, M.Z.H.; Ismail, C.R.; Hassan, S.A.; Mashros, N. A review on the usage of waste engine oil with aged asphalt as a rejuvenating agent. Mater. Today Proc. 2021, 42, 2374–2380. [Google Scholar] [CrossRef]

- Wang, H.; Ma, Z.; Chen, X.; Hasan, M.R. Preparation process of bio-oil and bio-asphalt, their performance, and the application of bio-asphalt: A comprehensive review. J. Traffic Transp. Eng. 2020, 7, 137–151. [Google Scholar] [CrossRef]

- Zhang, R.; You, Z.; Wang, H.; Chen, X.; Si, C.; Peng, C. Using bio-based rejuvenator derived from waste wood to recycle old asphalt. Constr. Build. Mater. 2018, 189, 568–575. [Google Scholar] [CrossRef]

- Zhang, R.; You, Z.; Wang, H.; Ye, M.; Yap, Y.K.; Si, C. The impact of bio-oil as rejuvenator for aged asphalt binder. Constr. Build. Mater. 2019, 196, 134–143. [Google Scholar] [CrossRef]

- Kowalski, K.J.; Król, J.B.; Bańkowski, W.; Radziszewski, P.; Sarnowski, M. Thermal and fatigue evaluation of asphalt mixtures containing RAP treated with a bio-agent. Appl. Sci. 2017, 7, 216. [Google Scholar] [CrossRef] [Green Version]

- Zhu, H.; Xu, G.; Gong, M.; Yang, J. Recycling long-term-aged asphalts using bio-binder/plasticizer-based rejuvenator. Constr. Build. Mater. 2017, 147, 117–129. [Google Scholar] [CrossRef]

- Grilli, A.; Gnisci, M.I.; Bocci, M. Effect of ageing process on bitumen and rejuvenated bitumen. Constr. Build. Mater. 2017, 136, 474–481. [Google Scholar] [CrossRef]

- Peralta, J.; Williams, R.C.; Silva, H.M.; Machado, A.V.A. Recombination of Asphalt with Bio-Asphalt: Binder Formulation and Asphalt Mixes Application; Iowa State University: Ames, IA, USA, 2014. [Google Scholar]

- Tran, N.; Taylor, A.; Turner, P.; Holmes, C.; Porot, L. Effect of rejuvenator on performance characteristics of high RAP mixture. Road Mater. Pavement Des. 2017, 18, 183–208. [Google Scholar] [CrossRef]

- Cavalli, M.C.; Zaumanis, M.; Mazza, E.; Partl, M.N.; Poulikakos, L.D. Effect of ageing on the mechanical and chemical properties of binder from RAP treated with bio-based rejuvenators. Compos. Part B Eng. 2018, 141, 174–181. [Google Scholar] [CrossRef]

- Nayak, P.; Sahoo, U.C. Rheological, chemical and thermal investigations on an aged binder rejuvenated with two non-edible oils. Road Mater. Pavement Des. 2017, 18, 612–629. [Google Scholar] [CrossRef]

- Gong, M.; Yang, J.; Zhang, J.; Zhu, H.; Tong, T. Physical–chemical properties of aged asphalt rejuvenated by bio-oil derived from biodiesel residue. Constr. Build. Mater. 2016, 105, 35–45. [Google Scholar] [CrossRef]

- Mogawer, W.S.; Booshehrian, A.; Vahidi, S.; Austerman, A.J. Evaluating the effect of rejuvenators on the degree of blending and performance of high RAP, RAS, and RAP/RAS mixtures. Road Mater. Pavement Des. 2013, 14, 193–213. [Google Scholar] [CrossRef]

- Ahmed, R.B.; Hossain, K. Waste cooking oil as an asphalt rejuvenator: A state-of-the-art review. Constr. Build. Mater. 2020, 230, 116985. [Google Scholar] [CrossRef]

- Hosseinnezhad, S.; Shakiba, S.; Mousavi, M.; Louie, S.M.; Karnati, S.R.; Fini, E.H. Multiscale Evaluation of Moisture Susceptibility of Biomodified Bitumen. ACS Appl. Bio Mater. 2019, 2, 5779–5789. [Google Scholar] [CrossRef]

- Hajj, E.Y.; Souliman, M.I.; Alavi, M.Z.; Salazar, L.G.L. Influence of hydrogreen bioasphalt on viscoelastic properties of reclaimed asphalt mixtures. Transp. Res. Rec. 2013, 2371, 13–22. [Google Scholar] [CrossRef]

- Ingrassia, L.P.; Lu, X.; Ferrotti, G.; Canestrari, F. Renewable materials in bituminous binders and mixtures: Speculative pretext or reliable opportunity? Resour. Conserv. Recycl. 2019, 144, 209–222. [Google Scholar] [CrossRef]

- Menapace, I.; Cucalon, L.G.; Kaseer, F.; Arámbula-Mercado, E.; Martin, A.E.; Masad, E.; King, G. Effect of recycling agents in recycled asphalt binders observed with microstructural and rheological tests. Constr. Build. Mater. 2018, 158, 61–74. [Google Scholar] [CrossRef]

- Al-Saffar, Z.H.; Yaacob, H.; Mohd Satar, M.K.I.; Saleem, M.K.; Jaya, R.P.; Lai, C.J.; Shaffie, E. Evaluating the Chemical and Rheological Attributes of Aged Asphalt: Synergistic Effects of Maltene and Waste Engine Oil Rejuvenators. Arab. J. Sci. Eng. 2020, 45, 8685–8697. [Google Scholar] [CrossRef]

- Pahlavan, F.; Samieadel, A.; Deng, S.; Fini, E. Exploiting Synergistic Effects of Intermolecular Interactions To Synthesize Hybrid Rejuvenators To Revitalize Aged Asphalt. ACS Sustain. Chem. Eng. 2019, 7, 15514–15525. [Google Scholar] [CrossRef]

- Bai, T.; Hu, Z.-A.; Hu, X.; Liu, Y.; Fuentes, L.; Walubita, L.F. Rejuvenation of short-term aged asphalt-binder using waste engine oil. Can. J. Civ. Eng. 2019, 999, 1–11. [Google Scholar] [CrossRef]

- Li, H.; Liu, G.; Dong, B.; Zhao, G.; Guo, P.; Huang, J.; Sheng, Y. Research on the development and regeneration performance of asphalt rejuvenator based on the mixed waste engine oil and waste cooking oil. Int. J. Pavement Res. Technol. 2019, 12, 336–346. [Google Scholar] [CrossRef]

- Jahanbakhsh, H.; Karimi, M.M.; Naseri, H.; Nejad, F.M. Sustainable asphalt concrete containing high reclaimed asphalt pavements and recycling agents: Performance assessment, cost analysis, and environmental impact. J. Clean. Prod. 2020, 244, 118837. [Google Scholar] [CrossRef]

- Abreu, L.P.; Oliveira, J.R.; Silva, H.M.; Fonseca, P.V. Recycled asphalt mixtures produced with high percentage of different waste materials. Constr. Build. Mater. 2015, 84, 230–238. [Google Scholar] [CrossRef] [Green Version]