Economic Feasibility and Sustainability Assessment of Residual Municipal Solid Waste Management Scenarios in NSW, Australia

Abstract

:1. Introduction

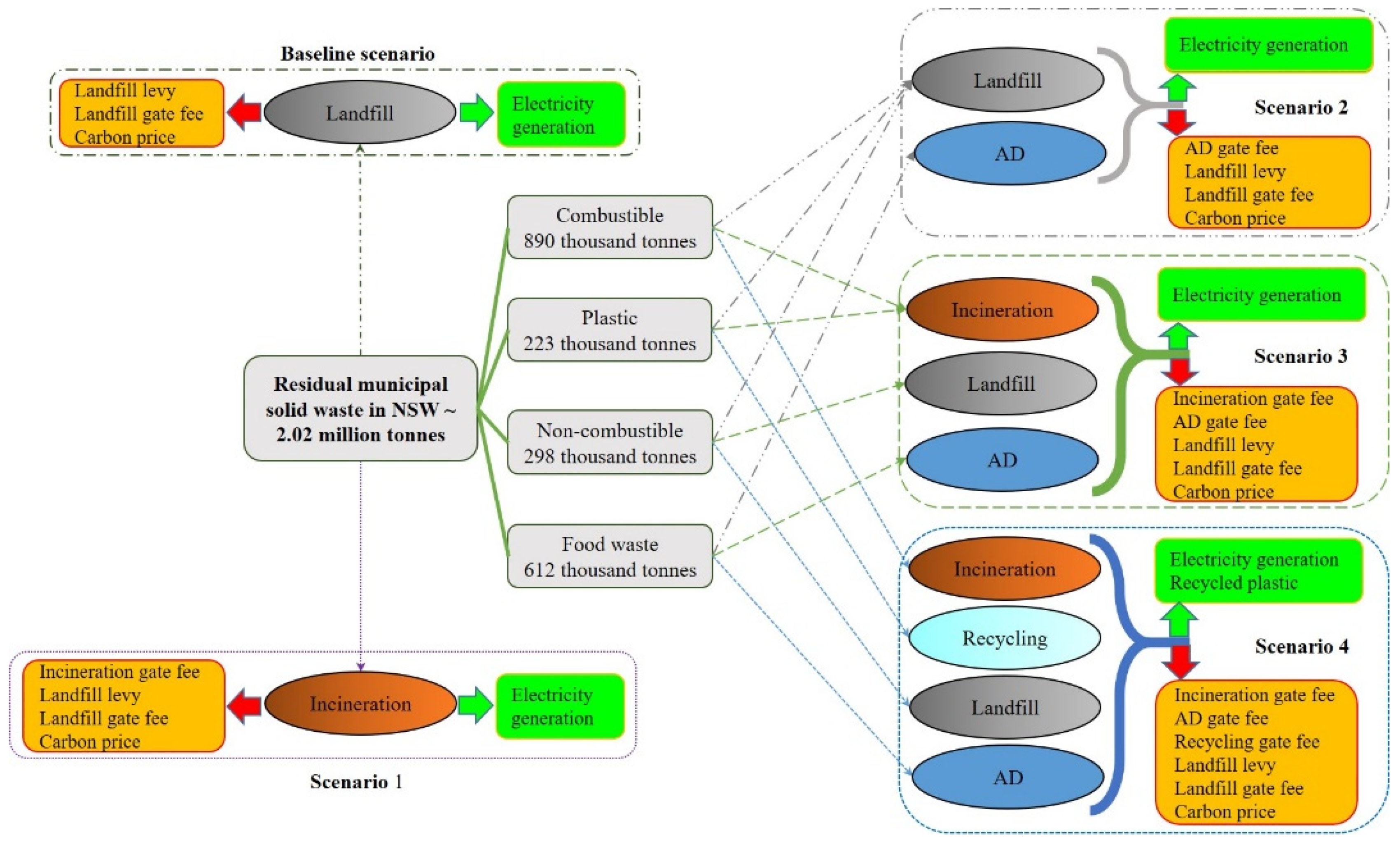

2. Materials and Methods

3. Results and Discussion

3.1. Cost and Benefit of Different Waste Management Scenarios

3.2. Sensitivity Analysis: The Efficiency of Incineration for Electricity Generation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kaza, S.; Yao, L.; Bhada-Tata, P.; Van Woerden, F. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050; World Bank: Washington, DC, USA, 2018; ISBN 1-4648-1347-7. [Google Scholar]

- Rajaeifar, M.A.; Ghanavati, H.; Dashti, B.B.; Heijungs, R.; Aghbashlo, M.; Tabatabaei, M. Electricity Generation and GHG Emission Reduction Potentials through Different Municipal Solid Waste Management Technologies: A Comparative Review. Renew. Sustain. Energy Rev. 2017, 79, 414–439. [Google Scholar] [CrossRef]

- Iqbal, A.; Liu, X.; Chen, G.-H. Municipal Solid Waste: Review of Best Practices in Application of Life Cycle Assessment and Sustainable Management Techniques. Sci. Total Environ. 2020, 729, 138622. [Google Scholar] [CrossRef]

- Laurent, A.; Bakas, I.; Clavreul, J.; Bernstad, A.; Niero, M.; Gentil, E.; Hauschild, M.Z.; Christensen, T.H. Review of LCA Studies of Solid Waste Management Systems—Part I: Lessons Learned and Perspectives. Waste Manag. 2014, 34, 573–588. [Google Scholar] [CrossRef]

- Istrate, I.-R.; Iribarren, D.; Gálvez-Martos, J.-L.; Dufour, J. Review of Life-Cycle Environmental Consequences of Waste-to-Energy Solutions on the Municipal Solid Waste Management System. Resour. Conserv. Recycl. 2020, 157, 104778. [Google Scholar] [CrossRef]

- Turk, J.; Cotič, Z.; Mladenovič, A.; Šajna, A. Environmental Evaluation of Green Concretes versus Conventional Concrete by Means of LCA. Waste Manag. 2015, 45, 194–205. [Google Scholar] [CrossRef]

- Gibassier, D. From Écobilan to LCA: The Elite’s Institutional Work in the Creation of an Environmental Management Accounting Tool. Crit. Perspect. Account. 2017, 42, 36–58. [Google Scholar] [CrossRef]

- Dastjerdi, B.; Strezov, V.; Kumar, R.; He, J.; Behnia, M. Comparative Life Cycle Assessment of System Solution Scenarios for Residual Municipal Solid Waste Management in NSW, Australia. Sci. Total Environ. 2021, 767, 144355. [Google Scholar] [CrossRef]

- Fruergaard, T.; Astrup, T. Optimal Utilization of Waste-to-Energy in an LCA Perspective. Waste Manag. 2011, 31, 572–582. [Google Scholar] [CrossRef]

- Jensen, M.B.; Møller, J.; Scheutz, C. Comparison of the Organic Waste Management Systems in the Danish–German Border Region Using Life Cycle Assessment (LCA). Waste Manag. 2016, 49, 491–504. [Google Scholar] [CrossRef]

- Perez, J.; Manuel de Andres, J.; Lumbreras, J.; Rodriguez, E. Evaluating Carbon Footprint of Municipal Solid Waste Treatment: Methodological Proposal and Application to a Case Study. J. Clean. Prod. 2018, 205, 419–431. [Google Scholar] [CrossRef]

- Tong, H.; Shen, Y.; Zhang, J.; Wang, C.-H.; Ge, T.S.; Tong, Y.W. A Comparative Life Cycle Assessment on Four Waste-to-Energy Scenarios for Food Waste Generated in Eateries. Appl. Energy 2018, 225, 1143–1157. [Google Scholar] [CrossRef]

- Ayodele, T.R.; Ogunjuyigbe, A.S.O.; Alao, M.A. Economic and Environmental Assessment of Electricity Generation Using Biogas from Organic Fraction of Municipal Solid Waste for the City of Ibadan, Nigeria. J. Clean. Prod. 2018, 203, 718–735. [Google Scholar] [CrossRef]

- Fan, Y.V.; Klemeš, J.J.; Perry, S.; Lee, C.T. Anaerobic Digestion of Lignocellulosic Waste: Environmental Impact and Economic Assessment. J. Environ. Manag. 2019, 231, 352–363. [Google Scholar] [CrossRef]

- Paes, M.X.; de Medeiros, G.A.; Mancini, S.D.; Bortoleto, A.P.; Puppim de Oliveira, J.A.; Kulay, L.A. Municipal Solid Waste Management: Integrated Analysis of Environmental and Economic Indicators Based on Life Cycle Assessment. J. Clean. Prod. 2020, 254, 119848. [Google Scholar] [CrossRef]

- Martinez-Sanchez, V.; Kromann, M.A.; Astrup, T.F. Life Cycle Costing of Waste Management Systems: Overview, Calculation Principles and Case Studies. Waste Manag. 2015, 36, 343–355. [Google Scholar] [CrossRef]

- Luz, F.C.; Rocha, M.H.; Lora, E.E.S.; Venturini, O.J.; Andrade, R.V.; Leme, M.M.V.; del Olmo, O.A. Techno-Economic Analysis of Municipal Solid Waste Gasification for Electricity Generation in Brazil. Energy Convers. Manag. 2015, 103, 321–337. [Google Scholar] [CrossRef]

- Colvero, D.A.; Ramalho, J.; Gomes, A.P.D.; de Matos, M.A.A.; da Cruz Tarelho, L.A. Economic Analysis of a Shared Municipal Solid Waste Management Facility in a Metropolitan Region. Waste Manag. 2020, 102, 823–837. [Google Scholar] [CrossRef]

- Woon, K.S.; Lo, I.M.C. An Integrated Life Cycle Costing and Human Health Impact Analysis of Municipal Solid Waste Management Options in Hong Kong Using Modified Eco-Efficiency Indicator. Resour. Conserv. Recycl. 2016, 107, 104–114. [Google Scholar] [CrossRef]

- EPA-NSW. The Waste Hierarchy. Available online: https://www.epa.nsw.gov.au/your-environment/recycling-and-reuse/warr-strategy/the-waste-hierarchy (accessed on 28 July 2019).

- Randell, P.; Pickin, J.; Grant, B. Waste Generation and Resource Recovery in Australia: Reporting Period 2010/11; Final Report Prepared for DSEWPC; Blue Environment Pty Ltd.: Docklands, Australia, 2014; Volume 128. [Google Scholar]

- Brunner, P.H.; Rechberger, H. Waste to Energy—Key Element for Sustainable Waste Management. Waste Manag. 2015, 37, 3–12. [Google Scholar] [CrossRef]

- Dastjerdi, B.; Strezov, V.; Kumar, R.; Behnia, M. An Evaluation of the Potential of Waste to Energy Technologies for Residual Solid Waste in New South Wales, Australia. Renew. Sustain. Energy Rev. 2019, 115, 109398. [Google Scholar] [CrossRef]

- Gohlke, O. Efficiency of Energy Recovery from Municipal Solid Waste and the Resultant Effect on the Greenhouse Gas Balance. Waste Manag. Res. 2009, 27, 894–906. [Google Scholar] [CrossRef]

- Kourkoumpas, D.-S.; Karellas, S.; Kouloumoundras, S.; Koufodimos, G.; Grammelis, P.; Kakaras, E. Comparison of Waste-to-Energy Processes by Means of Life Cycle Analysis Principles Regarding the Global Warming Potential Impact: Applied Case Studies in Greece, France and Germany. Waste Biomass Valoriz. 2015, 6, 605–621. [Google Scholar] [CrossRef]

- Murer, M.J.; Spliethoff, H.; De Waal, C.M.W.D.; Wilpshaar, S.; Berkhout, B.; Van Berlo, M.A.J.V.; Gohlke, O.; Martin, J.J.E. High Efficient Waste-to-Energy in Amsterdam: Getting Ready for the next Steps. Waste Manag. Res. 2011, 29, 20–29. [Google Scholar] [CrossRef]

- EPA-NSW. Levy Regulated Area and Levy Rates. Available online: https://www.epa.nsw.gov.au/your-environment/waste/waste-levy/levy-regulated-area-and-levy-rates (accessed on 11 April 2021).

- Bulk Energy Australian Electricity Prices & the Cost of Electricity in Australia per KWh. Bulk Energy. 2018. Available online: https://gobulk.com.au/australian-electricity-prices/ (accessed on 11 April 2021).

- Clean Energy Regulator Carbon Pricing Mechanism. Available online: http://www.cleanenergyregulator.gov.au/Infohub/CPM/About-the-mechanism (accessed on 11 April 2021).

- Ritchie, M. State of Waste. Available online: https://www.eianz.org/document/item/4661 (accessed on 11 April 2021).

- Pickin, J.; Wardle, C.; O’Farrell, K.; Nyunt, P.; Donovan, S. National Waste Report 2020. Available online: https://www.environment.gov.au/protection/waste/national-waste-reports/2020 (accessed on 21 March 2021).

- EcoGeneration EarthPower, the Biogas Plant That Bubbled Back from the Brink. Available online: https://www.ecogeneration.com.au/earthpower-the-biogas-plant-that-bubbled-back-from-the-brink/ (accessed on 11 April 2021).

- Stammbach, M. Submission to the NSW Parliamentary Inquiry into EfW Technology. Available online: https://www.parliament.nsw.gov.au/lcdocs/submissions/58101/0179%20HZIA%20Australia.pdf (accessed on 11 April 2021).

- DAWE. The Full Cost of Landfill Disposal in Australia. Available online: http://www.environment.gov.au/protection/waste/publications/full-cost-landfill-disposal-australia#:~:text=Estimated%20costs%20of%20the%20disposal,management%20controls%20and%20prevailing%20climate (accessed on 11 April 2021).

- Maghmoumi, A.; Marashi, F.; Houshfar, E. Environmental and Economic Assessment of Sustainable Municipal Solid Waste Management Strategies in Iran. Sustain. Cities Soc. 2020, 59, 102161. [Google Scholar] [CrossRef]

- Escamilla-García, P.E.; Camarillo-López, R.H.; Carrasco-Hernández, R.; Fernández-Rodríguez, E.; Legal-Hernández, J.M. Technical and Economic Analysis of Energy Generation from Waste Incineration in Mexico. Energy Strategy Rev. 2020, 31, 100542. [Google Scholar] [CrossRef]

- Alzate, S.; Restrepo-Cuestas, B.; Jaramillo-Duque, A. Municipal Solid Waste as a Source of Electric Power Generation in Colombia: A Techno-Economic Evaluation under Different Scenarios. Resources 2019, 8, 51. [Google Scholar] [CrossRef] [Green Version]

- Dos Santos, R.E.; dos Santos, I.F.S.; Barros, R.M.; Bernal, A.P.; Tiago Filho, G.L.; da Silva, F.d.G.B. Generating Electrical Energy through Urban Solid Waste in Brazil: An Economic and Energy Comparative Analysis. J. Environ. Manag. 2019, 231, 198–206. [Google Scholar] [CrossRef] [PubMed]

| Scenarios | Class (Treatment) | Treated Waste (kt/year) | Landfilled Waste (kt/year) | Electricity Generation (GWh/year) | GHG Emissions (kt CO2 eq Emission/year) |

|---|---|---|---|---|---|

| Baseline Scenario | All (Landfill) | 2024 | 2024 | 75.5 | 1469.6 |

| Scenario 1 | All (Incineration) | 2024 | 630 | 1502.9 | −330.4 |

| Scenario 2 | Food (AD) | 612 | - | 182.0 | −113.9 |

| Combustible and non-combustible (Landfill) | 1412 | 1412 | 39.5 | 1037 | |

| Subtotal | 2024 | 1412 | 221.5 | 923.1 | |

| Scenario 3 | Combustible (Incineration) | 1114 | 287 | 1389.0 | −721.6 |

| Food (AD) | 612 | - | 182.0 | −113.9 | |

| Non-combustible (Landfill) | 298 | 298 | 0.0 | 1.6 | |

| Subtotal | 2024 | 585 | 1594.2 | −833.9 | |

| scenario 4 | Combustible (Incineration) | 890 | 223 | 671.1 | −156 |

| Plastic (Recycling) | 223 | 19 | −3.7 | −516 | |

| Food (AD) | 612 | - | 182.0 | −113.9 | |

| Non-combustible (Landfill) | 298 | 298 | 0.0 | 1.6 | |

| Subtotal | 2024 | 540 | 849.4 | −784.3 |

| Economic Variable | Unit | Value | References |

|---|---|---|---|

| Electricity generation | AUD/MWh | 88.06 | [28] |

| Landfill levy | AUD/t waste | 146 | [27] |

| Carbon price | AUD/t CO2 eq | 24.15 | [29] |

| Plastic recycling * | AUD/t waste | 400 | [30] |

| Recycled plastic | AUD/t plastic | 47 | [31] |

| Anaerobic digestion gate fees | AUD/t waste | 200 | [32] |

| Incineration gate fees | AUD/t waste | 130 | [33] |

| Landfill gate fee | AUD/t waste | 75 | [34] |

| Economic Factors | Bsc | Sc1 | Sc2 | Sc3 | Sc4 |

|---|---|---|---|---|---|

| Generated electricity (mAUD/year) | −6.6 | −132.3 | −19.5 | −138.3 | −74.8 |

| Recycled plastic (mAUD/year) | 0 | 0 | 0 | 0 | −9.6 |

| Landfill levy (mAUD/year) | 295.5 | 91.9 | 206.1 | 85.5 | 78.8 |

| Carbon price (mAUD/year) | 35.5 | −8 | 22.3 | −20.1 | −18.9 |

| Landfill gate fee (mAUD/year) | 151.8 | 47.2 | 105.9 | 43.9 | 40.5 |

| MRFs gate fee (99.5% quality separation) (mAUD/year) | 0 | 0 | 0 | 0 | 89.4 |

| Anaerobic digestion gate fees (mAUD/year) | 0 | 0 | 122.4 | 122.4 | 122.4 |

| Incineration gate fees (mAUD/year) | 0 | 263.1 | 0 | 144.8 | 115.7 |

| Total cost and benefit (mAUD/year) | 476.1 | 261.9 | 437.2 | 238.1 | 343.6 |

| Category | Bsc | Sc1 * | Sc2 | Sc3 * | Sc4 * | Unit |

|---|---|---|---|---|---|---|

| Economic cost | 476.1 | 261.9 | 437.2 | 238.1 | 343.6 | m AUD/year |

| Damage to ecosystems | 4.8 | −3.2 | 2.8 | −5.0 | −3.9 | species·yr/year |

| Damage to human health | 5719.1 | 389.9 | 3730.2 | −1241.8 | −914.1 | DALY/year |

| Electricity generation | 75.5 | 1502.9 | 221.5 | 1594.2 | 849.4 | GWh/year |

| Category | Bsc | Sc1 * | Sc2 | Sc3 * | Sc4 * |

|---|---|---|---|---|---|

| Economic cost | 1.00 | 0.10 | 0.84 | 0.00 | 0.44 |

| Damage to ecosystems | 1.00 | 0.19 | 0.79 | 0.00 | 0.11 |

| Damage to human health | 1.00 | 0.23 | 0.71 | 0.00 | 0.05 |

| Total cost and damage | 3.00 | 0.52 | 2.34 | 0.00 | 0.60 |

| Category | No Incineration | Incineration Efficiency 23% | Incineration Efficiency 25% | Incineration Efficiency 30% | Unit | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bsc | Sc2 | Sc1 | Sc3 | Sc4 | Sc1 | Sc3 | Sc4 | Sc1 | Sc3 | Sc4 | ||

| Economic cost | 476 | 437 | 301 | 272 | 361 | 290 | 262 | 356 | 262 | 238 | 344 | m AUD/year |

| Damage to ecosystems | 4.80 | 2.77 | −1.57 | −3.52 | −3.22 | −2.02 | −3.94 | −3.42 | −3.15 | −5.00 | −3.92 | species·yr/year |

| Damage to human health | 5719 | 3730 | 1094 | −580 | −600 | 893 | −769 | −691 | 390 | −1242 | −914 | DALY/year |

| Electricity generation | 75 | 222 | 1152 | 1265 | 693 | 1252 | 1359 | 737 | 1503 | 1594 | 849 | GWh/year |

| GHG emissions | 1471 | 923 | −7 | −530 | −640 | −99 | −617 | −682 | −330 | −834 | −784 | kt CO2 eq/year |

| Category(Normalized Value) | No Incineration | Incineration Efficiency 23% | Incineration Efficiency 25% | Incineration Efficiency 30% | Correlation with | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bsc | Sc2 | Sc1 | Sc3 | Sc4 | Sc1 | Sc3 | Sc4 | Sc1 | Sc3 | Sc4 | Electricity Generation | GHGEmissions | |

| Economic cost | 1.00 | 0.84 | 0.26 | 0.14 | 0.52 | 0.22 | 0.10 | 0.49 | 0.10 | 0.00 | 0.44 | −0.99 | 0.77 |

| Damage to ecosystems | 1.00 | 0.79 | 0.35 | 0.15 | 0.18 | 0.30 | 0.11 | 0.16 | 0.19 | 0.00 | 0.11 | −0.81 | 0.99 |

| Damage to human health | 1.00 | 0.71 | 0.34 | 0.10 | 0.09 | 0.31 | 0.07 | 0.08 | 0.23 | 0.00 | 0.05 | −0.73 | 1.00 |

| Total cost and damage | 3.00 | 2.34 | 0.95 | 0.39 | 0.79 | 0.83 | 0.28 | 0.74 | 0.52 | 0.00 | 0.60 | −0.88 | 0.96 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dastjerdi, B.H.; Strezov, V.; Kumar, R.; Behnia, M. Economic Feasibility and Sustainability Assessment of Residual Municipal Solid Waste Management Scenarios in NSW, Australia. Sustainability 2021, 13, 8972. https://doi.org/10.3390/su13168972

Dastjerdi BH, Strezov V, Kumar R, Behnia M. Economic Feasibility and Sustainability Assessment of Residual Municipal Solid Waste Management Scenarios in NSW, Australia. Sustainability. 2021; 13(16):8972. https://doi.org/10.3390/su13168972

Chicago/Turabian StyleDastjerdi, Behnam Hosseini, Vladimir Strezov, Ravinder Kumar, and Masud Behnia. 2021. "Economic Feasibility and Sustainability Assessment of Residual Municipal Solid Waste Management Scenarios in NSW, Australia" Sustainability 13, no. 16: 8972. https://doi.org/10.3390/su13168972

APA StyleDastjerdi, B. H., Strezov, V., Kumar, R., & Behnia, M. (2021). Economic Feasibility and Sustainability Assessment of Residual Municipal Solid Waste Management Scenarios in NSW, Australia. Sustainability, 13(16), 8972. https://doi.org/10.3390/su13168972