Abstract

The recent technological inclusions in supply chains are encouraging practitioners to continuously rethink and redesign these supply chains. Organizations are trying to implement sustainable manufacturing and supply chain practices to utilize their resources to the full extent in order to gain a competitive advantage. Circular supply chain management acts as the main pathway to achieve optimal circular business models; however, research in this area is still in its infancy and there is a need to study and analyze how the benefits of technology can be leveraged in conventional models to impact circular supply chains and build smart, sustainable, circular business models. To gain better familiarity with the future research paradigms, a detailed systematic literature review was conducted on this topic to identify the dynamics of this field and domains deserving further academic attention. A holistic and unique review technique was used by the authors to capture maximal insights. A total of 96 publications from 2010 to 2021 were selected from the Web of Science core collection database through strict keyword search codes and exclusion criteria, with neat integration of systematic and bibliometric analyses. The findings of this study highlight the knowledge gaps and future research directions, which are presented at the end of this paper.

1. Introduction

The circular economy (CE) approach is a strategy used for sustainable development. The 3R principles of CE are content elimination, reuse, and recycling based on a circular system in which all products are recycled and reused [1]. The new economic business model for sustainable industrial growth is based on the principle of circularity, which refers to the productive application and reuse of energy, resources, and products. This contrasts with the current linear economic model, which is related to the acquisition, production, and disposal of materials within the business model [2]. The European Commission and other EU agencies, as well as a rising number of cities and countries within the European Union, are firmly backing CE-based business models in order to manage environmental degradation. The term “circular economy” was first formally used in [3], while the idea of closed systems was introduced in [4], the author of which envisaged a future economy that would work by reproducing the limited stock inputs and recovering waste outputs.

The CE approach is based on the first and second thermodynamic laws, drawing on the idea that “everything is an input to everything else”. Items and manufacturing processes are designed in such a way that waste is reduced completely and resources are kept in use continuously by ensuring that unavoidable waste is recycled or recovered [5]. The CE approach consists of a technological cycle in which goods, components, or materials are designed and sold to reduce waste. Circular solutions are necessary to tackle depleting capital and emerging environmental issues. Circularity-based product planning, zero waste management, service-based maintenance, refurbishing, and remanufacturing strategies are needed in developing countries to save energy, materials, and resources [6]. However, the circular supply chain (CSC) approach requires a theoretical framework to understand how businesses benefit. It is important to introduce the CE protocols and norms in the production supply chain, with which managers and companies can achieve supply chain alignment [7]. The CSC approach also requires sophisticated technology to capture the supply chain footprints and measure sustainability performance indices in the reverse chain due to increases in complexity [8,9]. Return management methods typically lack visibility and mobility. Businesses can implement advanced strategies by following dedicated technologies to optimize speed and visibility [10].

Nonetheless, the effects of networks and the market structure indicate the possible downsides and costs that firms anticipate as new strategic networks are built around the circular economy. According to [11,12], the circular business model approach has several drivers, such as resource limitations, development of technology, socio-economic pathways, price and supply uncertainty, reduced manufacturing costs, and newer revenue streams and opportunities; however, the environmental, institutional, and social costs are not incorporated into the company expenses when making economic decisions. Moreover, raw material prices are volatile and it is difficult for secondary or recycled resources to meet high-quality standards [6,7]. Several business models have evolved for different purposes with various implementation barriers [13], including circular-economy-based business models as one among them, which are more difficult to develop as most models rely on linearity. Nevertheless, innovation in business models focusing on the concept of circularity is increasingly becoming a priority for governments, industry, and academia to sustain a competitive advantage in the market [14]. Companies have been trying to cope with unprecedented levels of technological development, serious environmental issues, and even more stringent national and foreign regulations for many years. Unconventional business models (BMs) and market approaches are needed to meet the current benchmarks of sustainability [15].

This study aimed to review the literature to study how technologies have been applied in conventional supply chain settings, and how and where such technologies could best fit in the CSC scenario to move forward towards building a circular business model (CBM). This study starts with the definition of the following questions to guide our literature study:

What are the current technological advancements in the circular supply chain?

What are the major challenges and barriers in implementing a circular supply chain to build circular business models?

What are the technological inclusions in the CSC currently needed for the effective design and implementation of CBMs?

Later, with the help of in-depth structured systematic and bibliometric analyses, we outline the important descriptive statistics, impactful research findings, and inferences for technological applications in CSC and the pathway to building CBMs. This article involves an introduction and literature review section discussing the need for research and the current trends in this field, followed by the methodology, results, discussion, future research paradigms, and conclusion sections.

2. Literature Review

2.1. The Circular Economy and Supply Chain

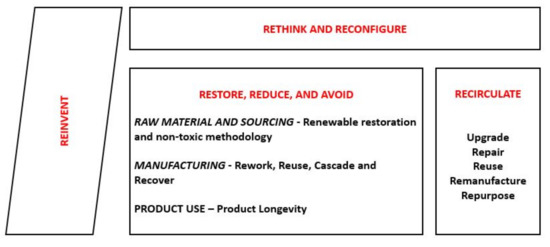

Natural resources are collected as raw materials, processed into products, and discarded as waste in a linear economy-based model. On the other hand, a circular economy-based business model tries to bridge the gap between production and natural ecosystems. A circular economy is an industrial system that is restorative or regenerative. It seeks to eliminate waste by responsibly designing materials, products, techniques, and business models, replacing the concept of end-of-life with sustainable product restoration and reuse [15,16,17].

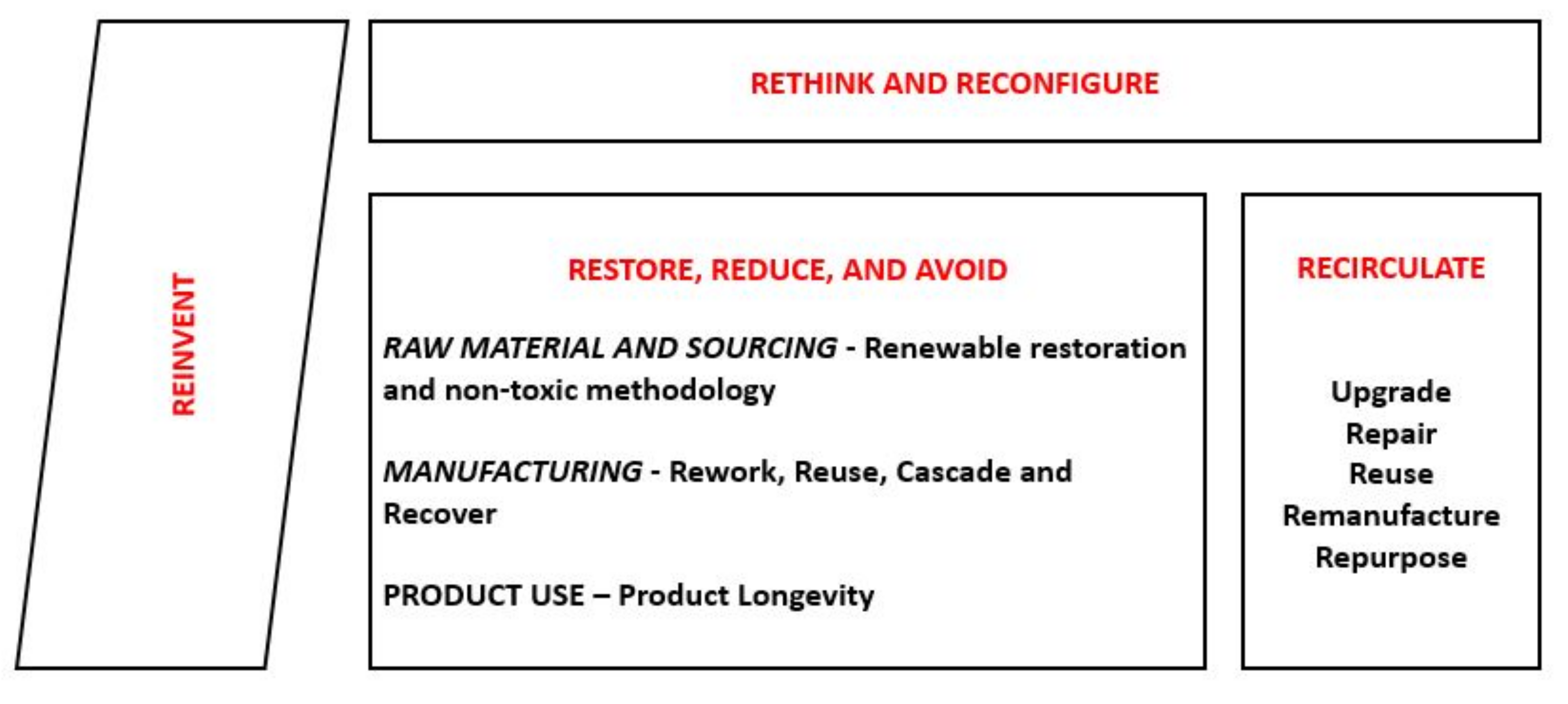

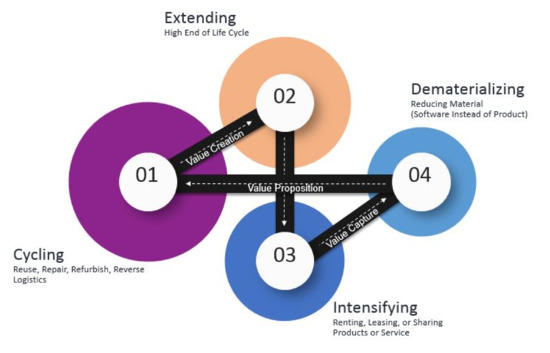

Therefore, it is important to understand the concepts of these strategic models as per the value proposition, which allows businesses to prepare and build new CE-based models [16,17,18]. Although previous research has indicated the impact of culture and regulatory policy on a firm’s willingness to address broader environmental issues and reform their ways of doing business, several manufacturing sectors face a lack of theoretical guidance that explains how these model transitions could be pursued in practice [5]. To get a better understanding, Figure 1 is adapted from [19] and shows the circular supply chain strategy in detail.

Figure 1.

Circular model strategy—adapted from [19].

Circular supply chain management (CSCM) promotes sustainability by ensuring proper collaboration, trust, and transparency to achieve long-term benefits within supply chain networks [20,21,22]. Therefore, in order to set benchmarks for CBMs, it is essential to measure the CSC performance. However, there is currently a lack of research on how to scrutinize the procedures and performance objectives that need to be implemented within a supply chain from a technological perspective in order to design stronger CBMs [23].

2.2. The “Digital Twins” to Understand Supply Chain Dynamics

The supply chain design of circular commodities is a huge challenge in a closed-loop production method. Although it is obvious that all three of these entities, namely reuse, remanufacturing, and recycling, are critical for loop completeness, they each require unique solutions based on different contexts. Hence, good decision-making support tools are needed [24,25]. Before implementing the reverse supply chain in CSC, it must be dynamically viewed via simulation modeling techniques to realistically duplicate a logistics scenario that depicts the revered logistics model’s future states [26].

Simulation blocks can connect and coordinate operations using a standardized approach to visualize the reusability of CSC’s product, process, and factory-related protocols, since dynamic and fast-changing complex scenarios need real-time visualization platforms [25,27]. The usage of simulation models can operate as a medium to facilitate alternative solutions for real-time scenarios in industrial supply chain processes in particular [28,29,30]. Moreover, the dynamic visualization also assists in determining product life cycle features, decision-making on materials and production, inventory mitigation measures, procurement strategies, and economic benefits in CSC [31,32,33].

2.3. IoT Integration Capturing Supply Chain Footprints

IoT provides continuous updates on industrial scenarios and develops and accesses operationalized data on a consumer’s perspective on products, providing implications and insights for reverse supply chains [34,35]. Moreover, an IoT-powered smart supply chain model setup can directly contribute to the increase in the performance and sustainability features of the circular supply chain [36]. However, there are few businesses that use the Internet of Things (IoT) on a large scale [34].

In today’s environment, as the world moves toward a circular economy and sustainability, IoT-integrated data-driven technology makes a smart decision by recording all random undetectable queues and delays in the logistic system in real-time. The Internet of Things enables the collection of data to gain a better knowledge of both actual and predicted infrastructure conditions, as well as automate industrial processes. Industries are always experimenting with novel data collection methods to improve decision-making benchmarks while maintaining long-term viability [33,37,38].

IoT-backed data-driven simulation can automatically visualize complicated processes due to its capacity to record data on queues and delays [33,39,40]. Fluctuating unpredictable environments demand dynamic data-driven application systems. Furthermore, IoT-assisted simulations can provide flexible and highly parallelizable dynamic prescriptive decision support systems [41,42].

2.4. Artificial Intelligence and Machine Learning in Supply Chain for Predictive Analysis

Machine learning algorithms can capture the dynamic behavior of multi-agents to store, save, and retrieve data relating to those activities, allowing them to react autonomously to unpredictable situations [43]. Moreover, operational delays can also be checked in a timely fashion using an optimal ML-based prescriptive algorithm [44,45,46]. It also helps to achieve this objective by feeding real-time data to the machine learning platform [47]. The dynamics of the global supply chain necessitate meticulous logistical planning. Machine learning can help retrieve generic knowledge of those processes to forecast future events and react to each feedback loop in a predictive logistic setting [44]. Automated decision making in logistics systems and optimized vehicle routing are feasible due to ML [48,49]. Furthermore, ML-powered artificial intelligence can assist in building smart flexible process control mechanisms for supply chain 4.0 [50].

2.5. Role of Big Data, Internet of Things, and Cloud Computing Technologies in Supply Chain Information Sharing

In supply chain management, effective data synchronization has become a challenge [51]. Supply chain partners are continuously willing to integrate, coordinate, and create resources, business processes, and organizations to accomplish business goals [52]. However, there have always been issues with information sharing in the supply chain, such as information distortion, information loss, and information delay.

“Big Data” is a data-gathering mechanism capable of capturing a vast amount of data every second. Despite the fact that it is feasible to collect all information, the workers’ ineffectiveness, information unavailability, rubrics of the integration model, and less advanced digital processing software products do not allow for the rapid processing of such a large data set [53]. Industry 4.0 requires digitalization in logistics operations, such as transportation, warehousing, inventory planning, sourcing, and in return can provide firms with high levels of flexibility and efficiency that are key to competitiveness in the era of Industry 4.0. Big Data analytics help in efficient data gathering, integration, interpretation, and reporting to various degrees [54].

2.6. Cyber-Physical Systems in Supply Chain

In logistics, Cyber-Physical Systems (CPS) create the possibilities for transitioning from a traditional logistics system to a smart logistics network built on actors and sensors, allowing real-time data analysis and increased knowledge management using cutting-edge learning methodologies. CPS can be used to improve the quality of production and logistics processes, which directly impacts performance efficiency [55]. Furthermore, CPS would enable greater connectivity, better digitalization, superior computational capabilities, increased flexibility, versatility, and reusability of systems and their components. It can build optimized smart warehouses and create sound location tracking systems and holistic fault diagnostic methods. Furthermore, artificial intelligence, backed by digital twins and cyber-physical systems, is making significant strides in generating new value in the industry [56].

2.7. Blockchain-Powered Supply Chain Smart Contract

Blockchain technology adopts a decentralized distributed ledger to save paperwork and cost, and to solve data monitoring and information security-related problems using predefined timestamps [57]. Its security protocol can address the major flaws in present Internet of Things technology that help standardize the current market order, enhance and generate confidence, and modify the mode of interpersonal cooperation and commercial relationships. We can achieve the goal of reducing supply chain management time, increase quality, and meet demand by establishing application platforms built on blockchain, such as blockchain credit financing, blockchain procurement financing, and so on. A benchmark roadmap for performance improvements and platform architectural design for the transaction system is provided within the supply chain using blockchain [58].

3. Research Methodology

This research adopted content analysis to locate, analyze, and interpret insights from existing literature in a systematic, explicit, and replicable way. This study critically examined previous research publications on the topic of interest, as projected in the introduction section, to uncover systematic patterns, synthesize knowledge, and address research gaps [59,60]. The authors were interested in looking at CSC’s latest technology adoption, breakthroughs, and challenges, and how they can be leveraged to build efficient CBMs. On that note, the rubrics of technological applications in a conventional supply chain scenario were first reviewed to get an idea about the drivers, barriers, purposes, and benefits of those applications.

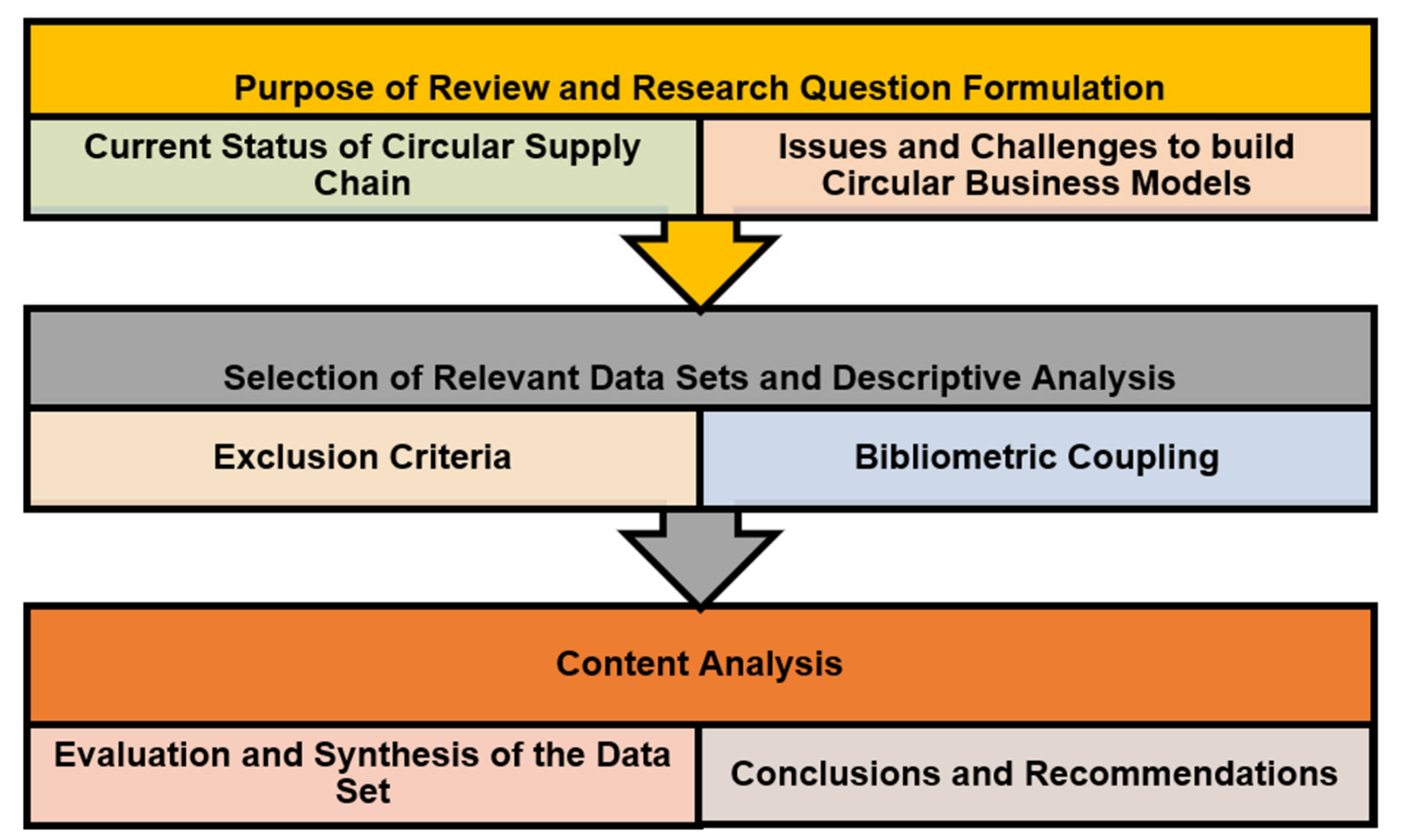

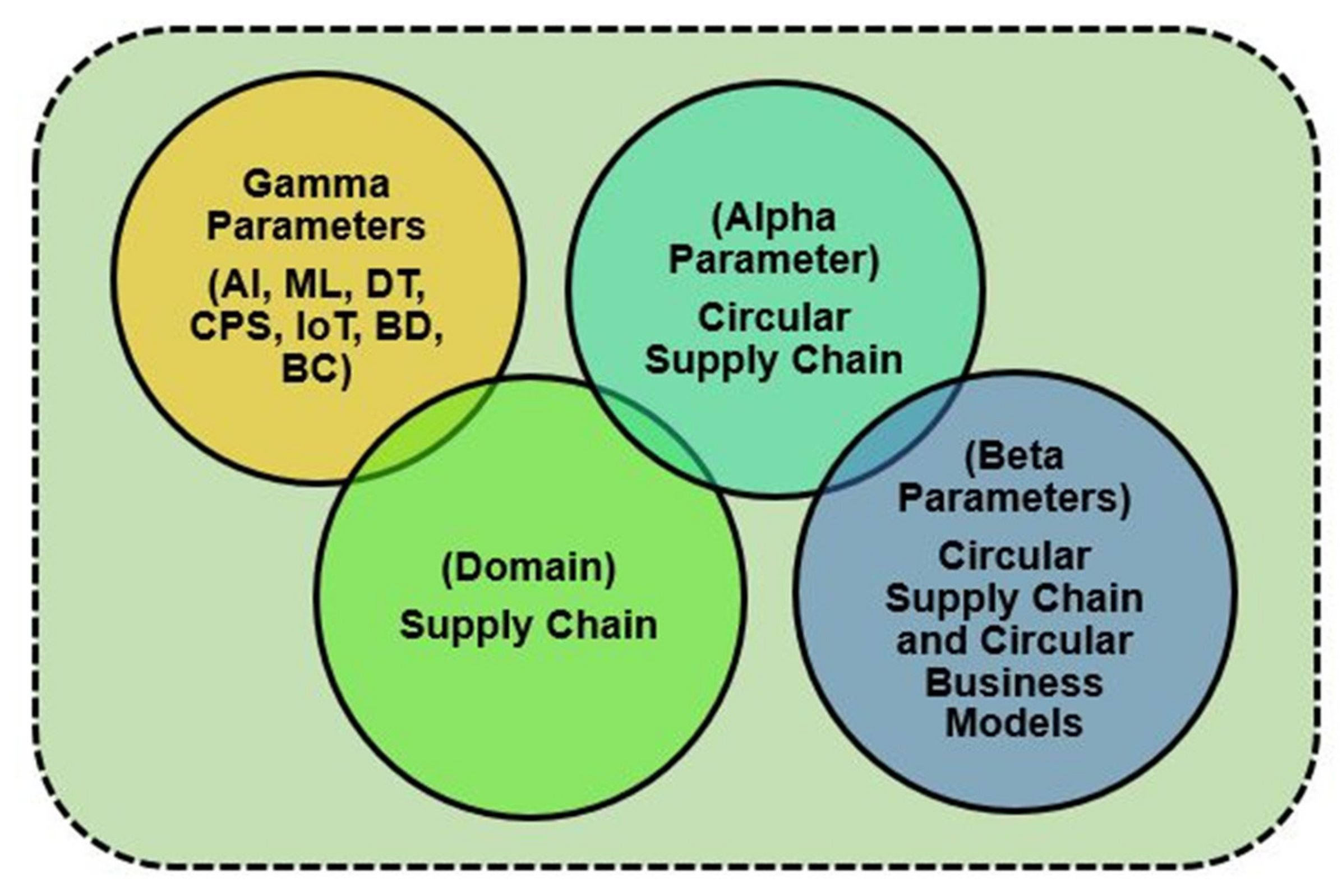

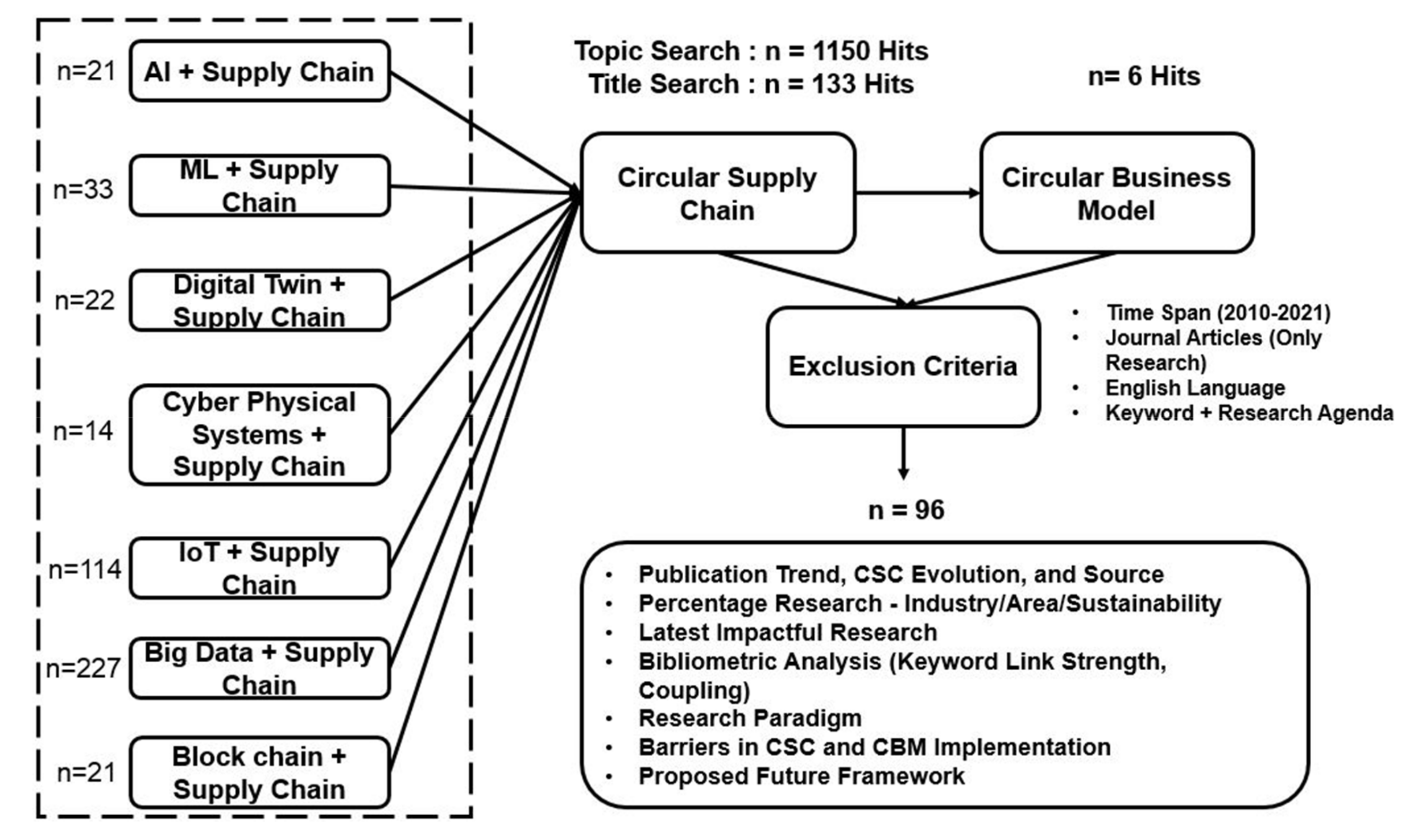

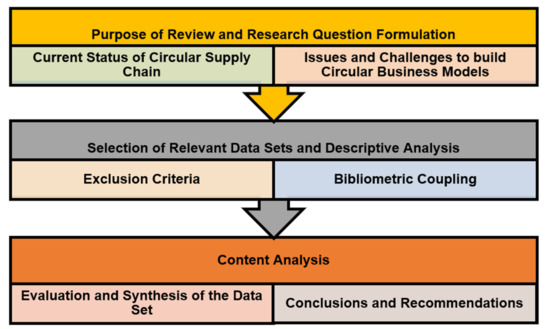

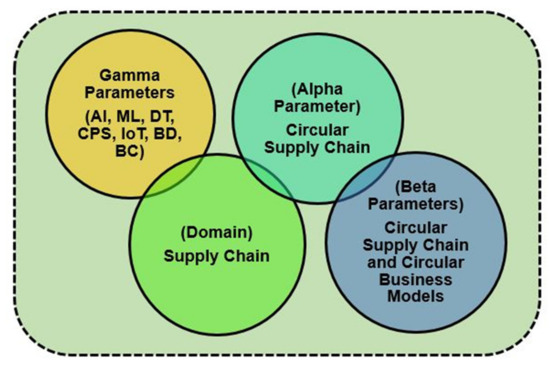

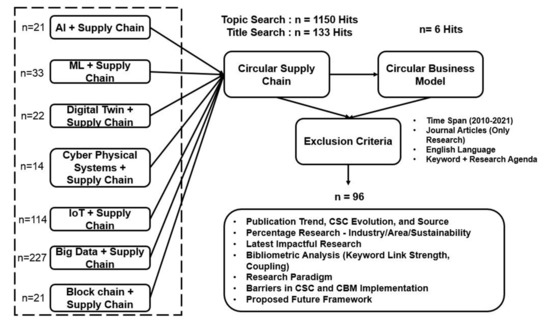

This preliminary research served as the foundation for the conceptual framework proposed at the end of the paper. During our literature search, we observed that using broad search keywords generated a large number of results. Rather, we used a novel approach to find the relevant content to CSC as shown in Figure 2 and Figure 3 and Table 1. Figure 4 shows the content analysis procedure. The review was carried out using the idea illustrated in Figure 2, with the first level analyzing the manifest content and the second level excavating the hidden material [61,62]. At first, the papers were collected and later subjected to delimiting criteria. Then, the descriptive picture of the content was retrieved along with the structural attributes, which were subsequently analyzed to find relevant research work in the literature.

Figure 2.

Review Protocol.

Figure 3.

Search protocol and Venn relationship.

Table 1.

Search code Gamma (Secondary 1).

Figure 4.

The search strategy flow chart.

The WoS core collection database was used for this review because the researchers were solely interested in looking at papers that have met the Web of Science Core Collection indexing criteria through their novelty and research rigor [63,64]. They also stayed consistently relevant to the objective of our study.

The search code was divided into three sections—Primary 1 and 2 and secondary 1 (Alpha, Beta, and Gamma). The authors wanted to first review the literature on the technological applications in a conventional supply chain context. The Gamma keyword search codes selected are shown in Table 1. The Alpha search code primarily focused on the “circular supply chain”, and the Beta search code checked the role of the supply chain in the circular business model. Overall, this type of search strategy is unique, holistic, and the first of its kind that follows the Venn phenomenon, as shown in Figure 3. Figure 3 was added to snowball the insights, derive clear understandings about the research topic from Gamma towards Alpha, and finally answer the proposed research questions.

3.1. Search Code Alpha (Primary 1)

In the beginning, the applied WoS keyword search was “Circular Supply Chain—Topic” which gave 1150 hits, so the search code was confined to title search as shown below.

Circular Supply chain: Title—133 Hits, Timespan: 2010–2021. Indexes: SCI- EXPANDED, SSCI, A&HCI, CPCI-S, CPCI-SSH, BKCI-S, BKCI-SSH, ESCI.

3.2. Search Code Beta (Primary 2)

TITLE: (Circular Business Model) AND TITLE: (Supply Chain) Timespan: 2010–2021. Indexes: SCI-EXPANDED, SSCI, A&HCI, CPCI-S, CPCI-SSH, BKCI-S, BKCI-SSH, ESCI. Six hits were achieved.

Targeting the keyword “Supply chain” with the TITLE search tab with other keyword combinations gave the following results as shown in Table 1 below.

The primary data set (Alpha—CSC) and the secondary data set (Beta (CSC + CBM)) were carefully examined. A total of 96 papers were finalized for this study after reading the title, abstract, and full text (only where available). Results from the Gamma search were used only to retrieve insights from the technological inclusion in the supply chain in general. The exclusion criteria were strictly confined to articles published only in journals in the English language. Conference papers were excluded since the research rigor, data analysis, and scope of research were limited. The timespan for this review was fixed from the year 2010 to 2021. The method of data extraction and content analysis is mentioned in Figure 2, Figure 3, and Figure 4, and Table 1, this helped to retrieve, tabulate, arrange, and systematize insights and build a conceptual framework for the business practitioners who are trying to understand and overcome the barriers in the technological adoption in the circular supply chain and the building of circular business models.

4. Results

The publication trend retrieved from the final data set is tabulated in Table 2. After a close look at the trend, from 2010 to 2017, it is understood that the concept of CSC and CBMs was not given much importance due to the lack of need and awareness. However, it suddenly saw a steep rise in 2018. Moreover, the authors conclude that the increase in sustainability norms in the production supply chain was the main reason behind the rise. The technological inclusions in CSC were also evident. Table 3 displays the journal sources where the Journal of Cleaner Production tops the list with 18 publications, followed by Resources Conservation and Recycling, Sustainability, International Journal of Production Research, Production Planning and Control, Business Strategy and the Environment, International Journal of Logistics—Research and Applications, and International Journal of Logistics Management.

Table 2.

Publication trend and CSC evolution (ES: Environmental Sustainability, CE: Circular Economy, WTE: Waste-to-Energy, PaaS: Product as a Service, SaaS: Software as a Service, CBM: Circular Business Model, IR 4.0: Industry 4.0, RL: Reverse Logistics, CSC: Circular Supply Chain).

Table 3.

Publication source.

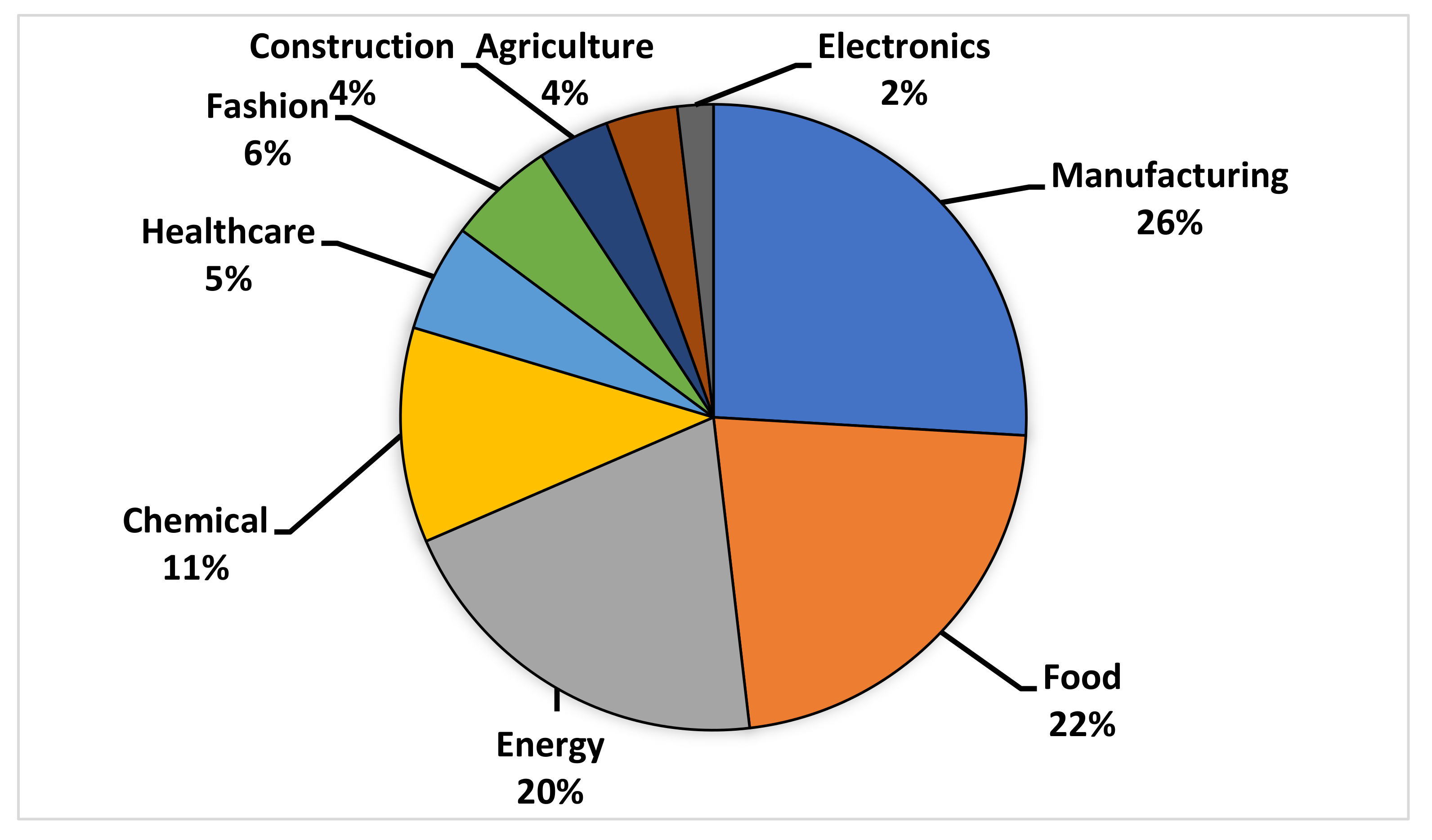

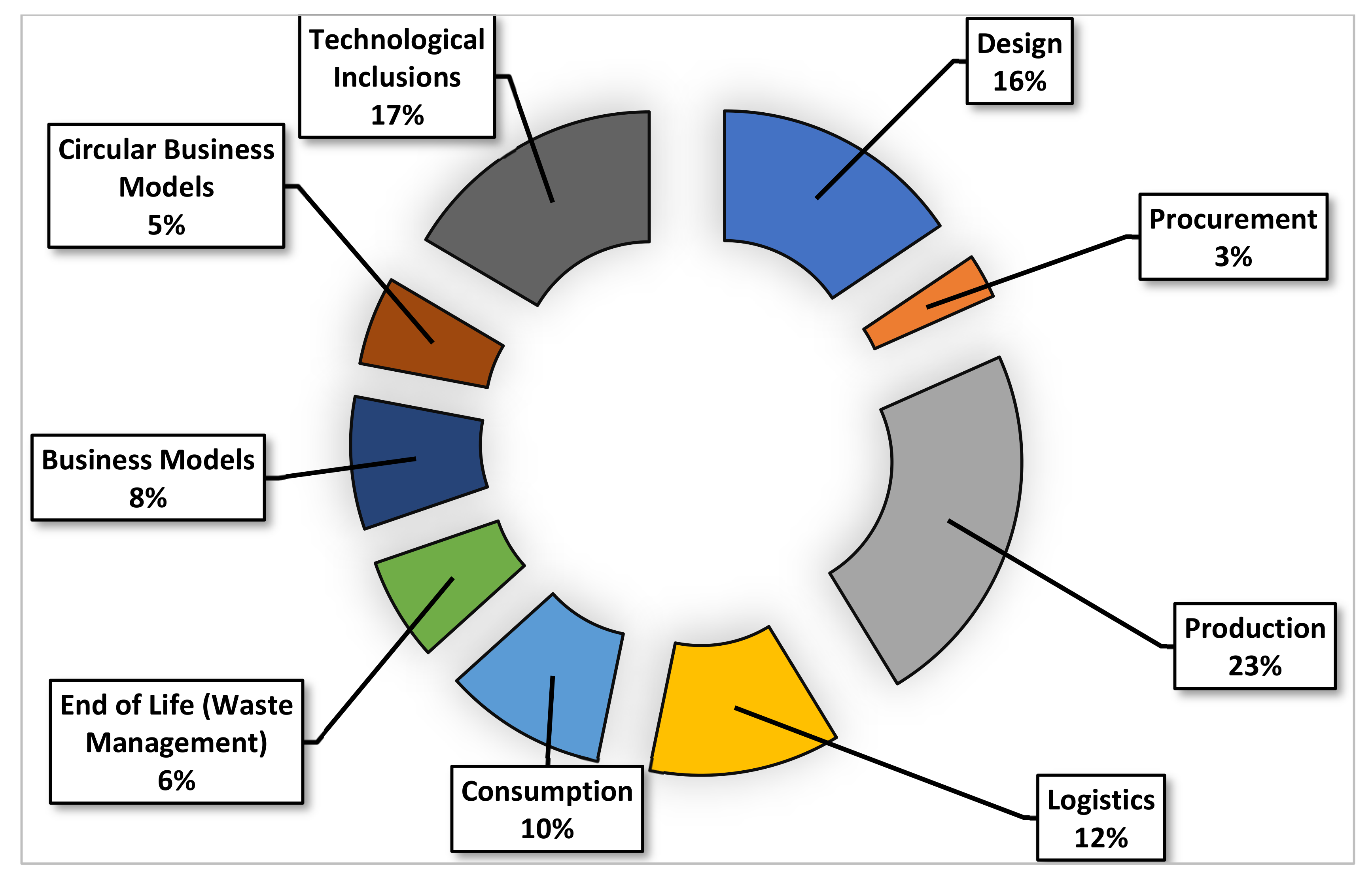

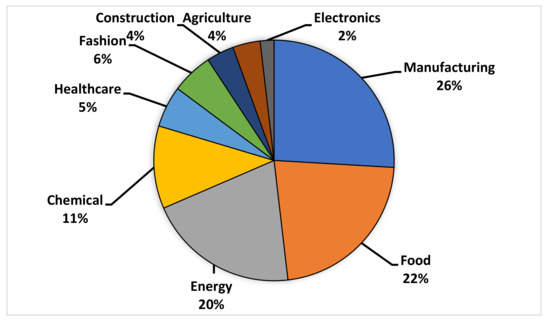

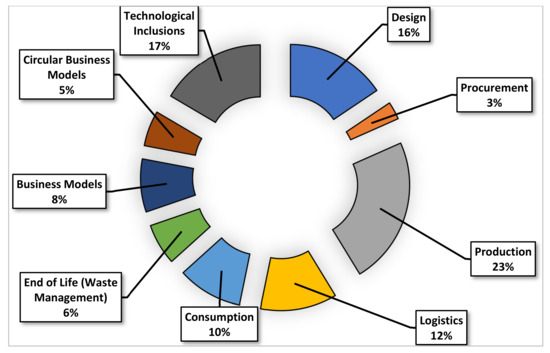

Authors thoroughly read the title and abstract of all the papers in the final data set and scrutinized the research done according to sectors and research areas in order to acquire Figure 5 and Figure 6, respectively. Figure 5 displays the percentage of research contribution according to the sector. A considerable amount of research has been done in the food, energy, manufacturing, and chemical sectors, and more focus has to be diverted towards healthcare, fashion, agriculture, and electronics. Figure 6 portrays the research contribution according to the production cycle, starting from design to technological inclusions. Circular business models have received very little attention. End-of-life management, procurement, resource consumption, and logistics also need considerable attention.

Figure 5.

Percentage research contribution based on industry.

Figure 6.

Classification according to research area.

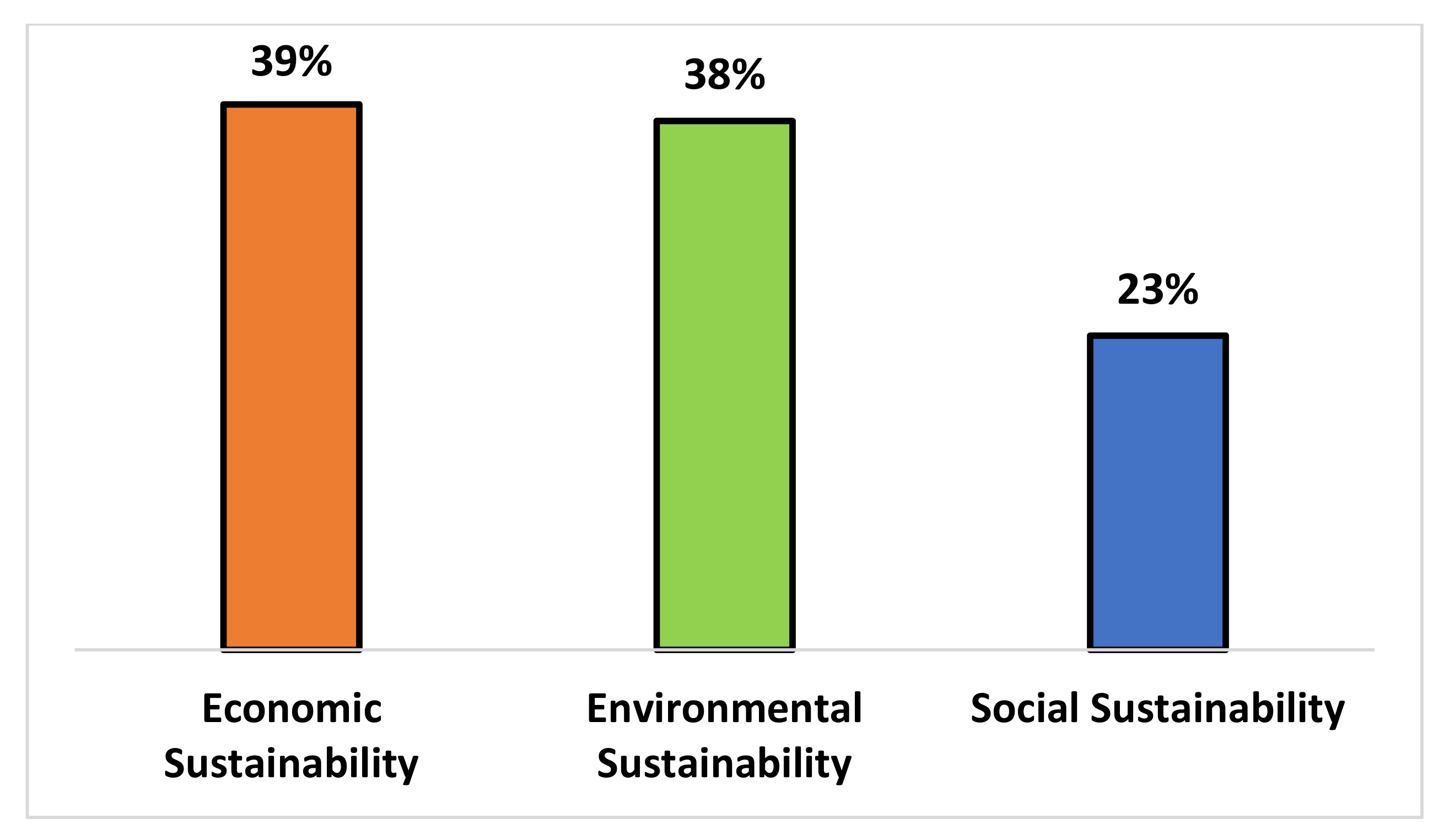

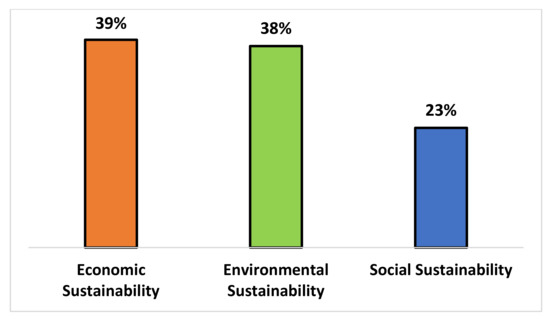

The authors were also interested to review the data and learn how much research was done in economic, social, and environmental sustainability. After a thorough reading of the abstract and title of each article of the data set, inferences for Figure 7 were obtained. Figure 7 concluded that environmental aspects were given the utmost importance along with economic (profit or performance-oriented) business solutions. More research is needed to integrate all these types of sustainability, as shown in Figure 7.

Figure 7.

Research work on type of sustainability.

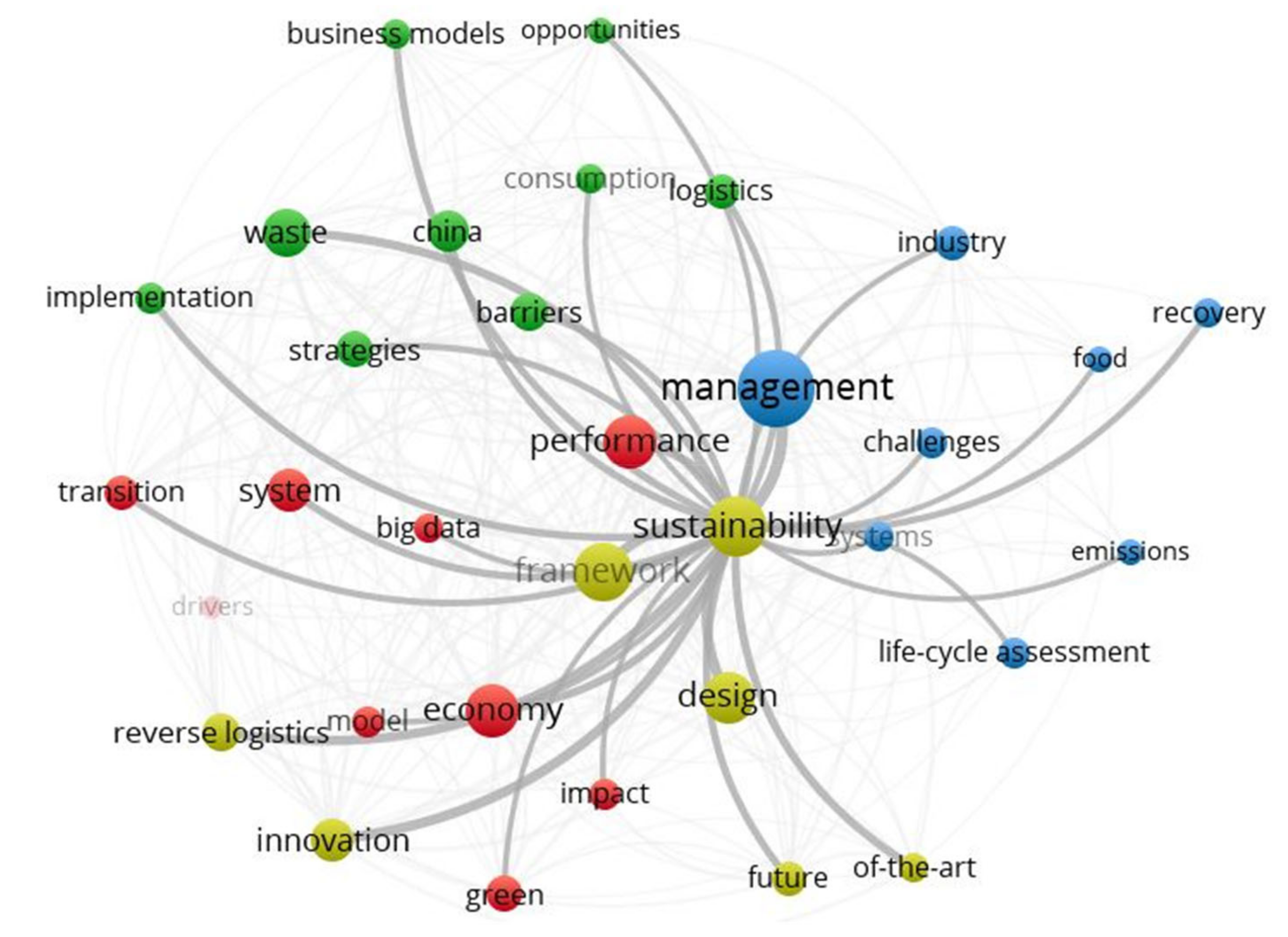

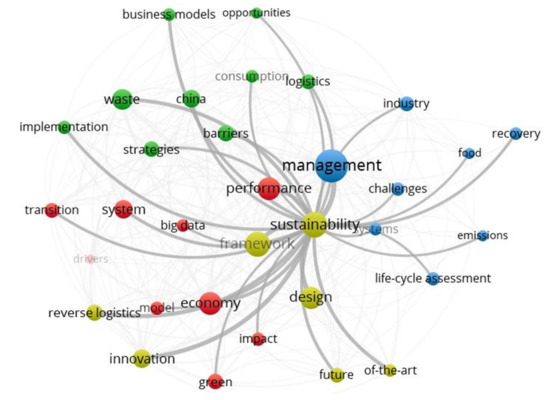

Table 4 shows a selected set of the latest research on the integration of technological tools in the conventional supply chain. Table 5 portrays the research link strength (keyword coupling) derived from the Vosviewer software to determine the research relevance between these technological applications in the supply chain scenario. The items that are italicized denote areas with less research work.

Table 4.

Latest commendable work and findings. (AI: artificial intelligence, ML: machine learning, DT: digital twin, IoT: Internet of Things, BD: Big Data, CPS: cyber-physical systems, BC: blockchain).

Table 5.

Keyword link strength of AI, ML, DT, IoT, CBS, BD, BC. (AI: artificial intelligence, ML: machine learning, DT: digital twin, IoT: Internet of Things, BD: Big Data, CPS: cyber-physical systems, BC: blockchain).

Bibliometric Analysis of the Alpha and Beta Data Set

Combining a systematic review and bibliometric analysis yields greater insights and facilitates the analysis of research gaps and future research opportunities. Both are a combination of descriptive analysis that can best use the information contained within the data set to better understand the current research and its limitations [33]. The bibliometric coupling on the “All keywords” option for the final 96 data sets was conducted using Vosviewer. As shown in Figure 8, with full counting option criteria (minimum number of occurrences of keywords—3), out of 304 total keywords, 49 met the requirements. The results from the bibliometric keyword coupling (Figure 8) show various insights. There are four major clusters (yellow, red, blue, and green). Table 6 shows the keyword cluster combinations. Based on these results, the research orientations and directions were finalized by the authors that helped design Figure 9. According to [89], the keyword denotes the research topic. The larger nodes indicate that there has been extensive research done in that area, and nodes that are close suggest that the percentage of relevance between them is very strong. Each research area is represented by nodes that are either the least or the most relevant.

Figure 8.

Keyword coupling.

Table 6.

Keyword cluster of final data set.

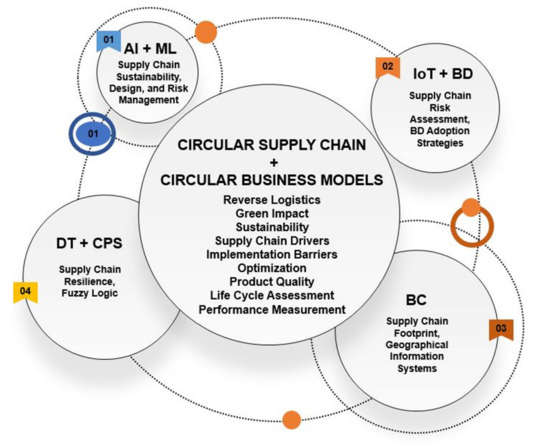

Figure 9.

Identified research paradigm.

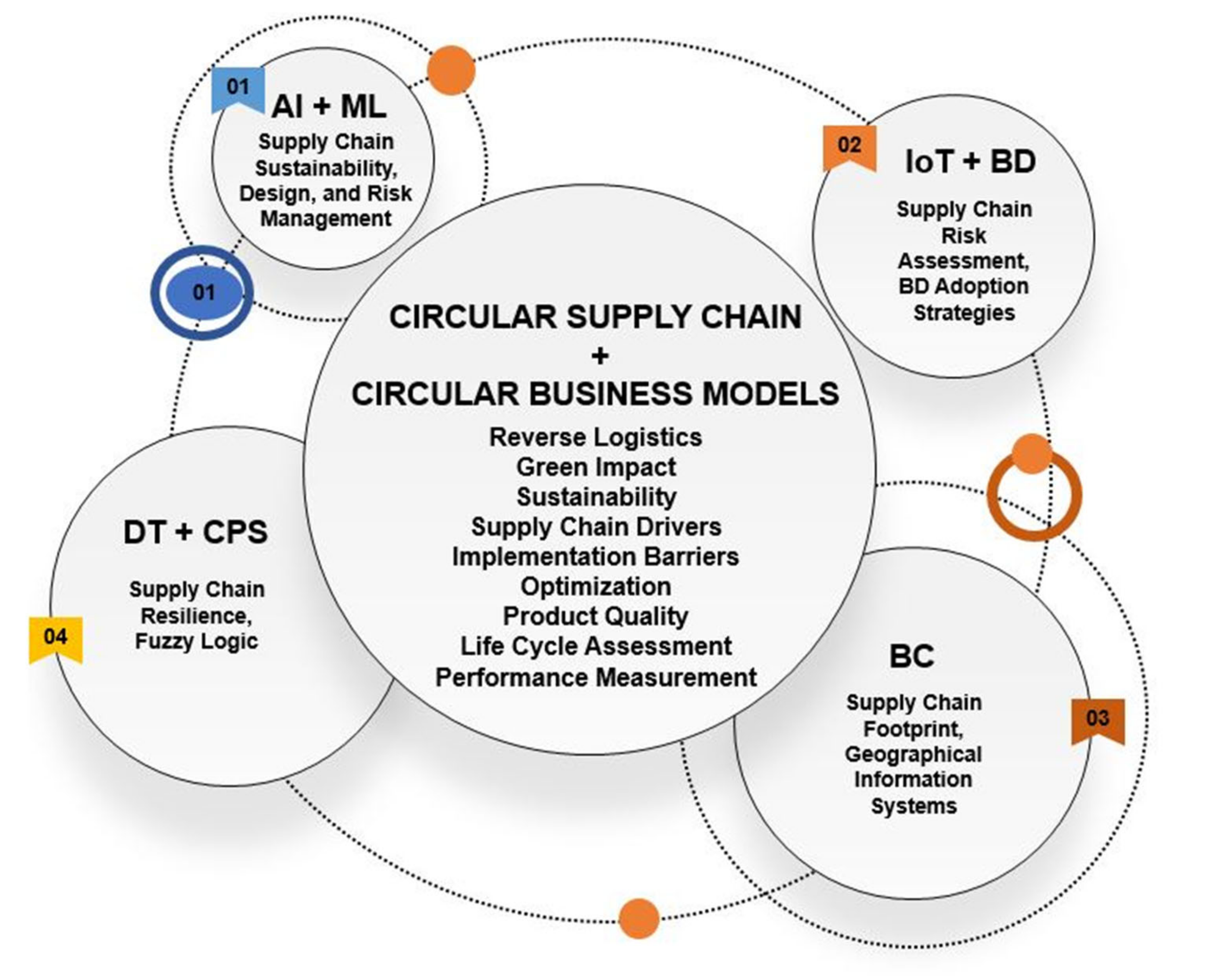

The findings of this analysis demonstrate that in the context of the circular supply chain, innovations in business models have not yet been given much attention since the nodes are farther apart and least relevant. The only technological tool that has been widely used is Big Data. Research on green impact, life cycle assessment, implementation barriers and challenges, and potential for transitioning to a circular business model requires further attention. In Table 6, the cluster analysis is neatly tabulated and presented to get a clear picture of the research clusters (keywords) and their relevance. Cluster 5 in the last column is the least significant column, and it ascends in significance up to column 1. Researchers need to focus on research areas in columns 5, 4, and 3, and integrate research topics between the clusters [33].

5. Future Research Directions of (AI, ML, DT, IoT, CPS, BD, and BC) in Supply Chain (Derived from Tables 5 and 6 and Figure 8)

The data sets from the Gamma search code results were analyzed with the Vosviewer software. The keyword link strength showed the research intensity and connections between the different research directions [33]. The keywords or research topics with low link strength (bold and italic) corresponding to each technological tool are written inside the green rows in Table 5. The combined insights acquired from Table 5 and Table 6 and Figure 8 give various conclusions in terms of research gaps and future research agendas as shown in Figure 9. The keyword combinations were analyzed to retrieve the link or usage strength of the keywords mentioned in the articles. According to the results obtained, AI + ML needs to be applied more to improve the sustainability aspect of the supply chain. IoT + BD should focus on SC risk assessment and adoption strategies. BC needs to assist in managing effective SC footprints with proper geographical information systems. DT and CPS should focus on SC resilience and increased application of fuzzy-based approaches for better results.

6. Discussion

6.1. Circular Supply Chain—Developments and Barriers in Technological Adoption

CSCM (circular supply chain management) has proven to be a valuable contributor to sustainable development [90]. Circular thinking is a promising answer for sustainable development and reducing the economic model, which minimizes resource input, waste, emissions, and energy leaks, without compromising growth and profitability. At the same time, the sustainability performance of the CBM and the circular supply chains must be measured. The CBMs range in complexity and the circular supply chain’s value proposition can help achieve sustainability objectives [91]. Industry 4.0-assisted circular economy models and solutions have been created to turn products at the end of their lifecycle into new products with diverse uses. The adoption of digitalization techniques in the circular economy can enable circular supply chain management. Managers and policymakers, however, require more empirical measurable evidence at this time [92]. The lack of government backing, subsidies, policies, and protocols are major barriers to the implementation of CBMs [93]. With increasing globalization and digitalization, organizations have started changing their business processes to be more sophisticated, customer-centric, and sustainable [93,94,95]. Lack of market governance and weak collaboration of supply chain actors (stakeholders) seem to be the most prominent barriers towards the implementation of CSC and CBMs [96]. The authors have projected a set of barriers in CSC to attain CBMs in Table 7. Based on the framework portrayed in Figure 1, Table 7 was formulated. Columns three and four in Table 7 show the CSC-related barriers and area of research, respectively.

Table 7.

Challenges and barriers in CSC and CBM implementation.

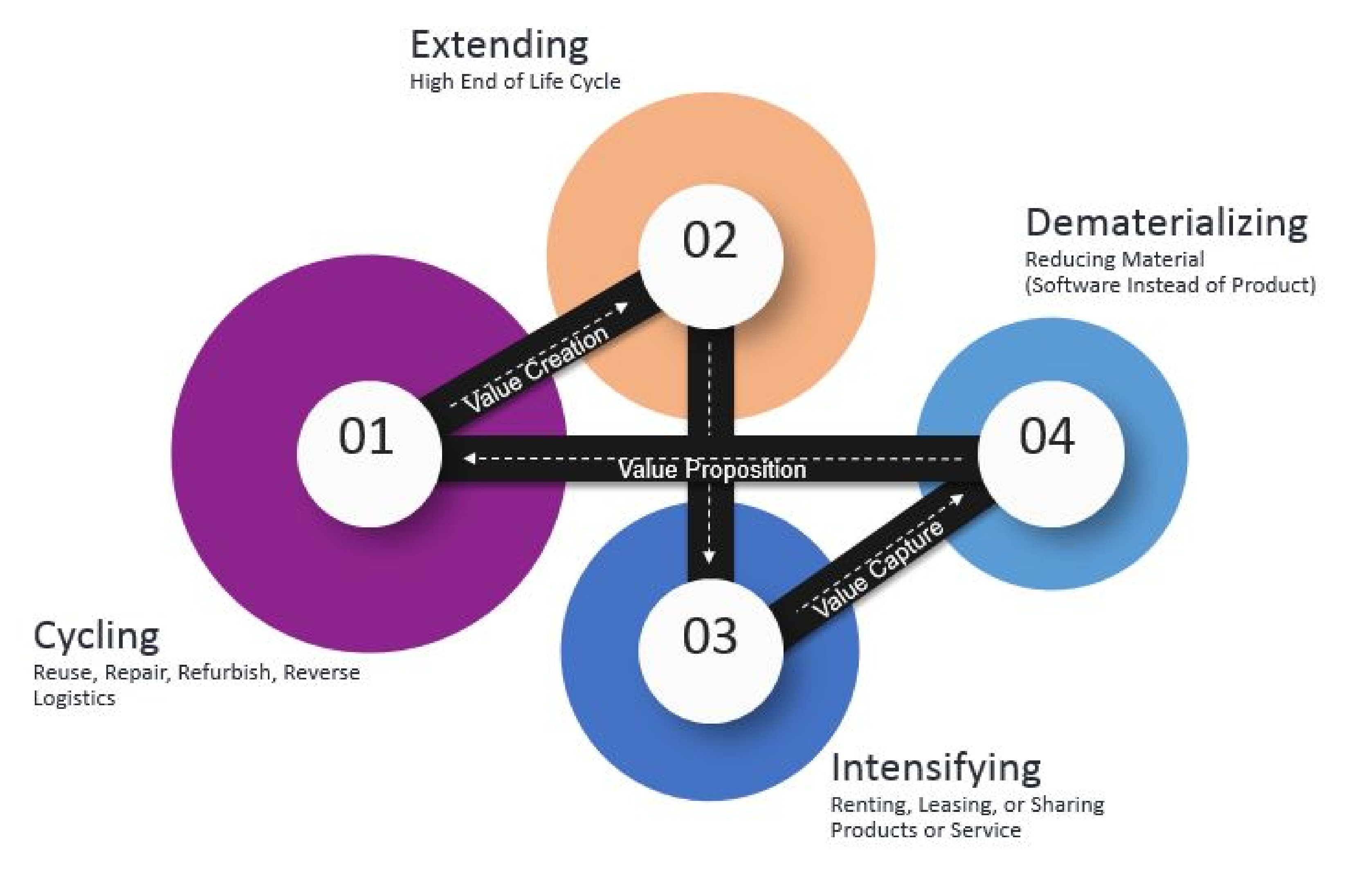

6.2. Circular Business Model Structures

There are four types of circular business models evolving in the industry, as shown in Figure 10. The circularity-based business model focuses on recall, reuse, refurbishment, and reverse logistics, with the circular economy as the main catalyst aimed at environmental sustainability. To adapt to this model, raw materials are responsibly procured at an affordable price. Next is the waste value generation or end-of-life extension model, in which the product’s design is centered on extending the product’s life cycle. The third form of CBM is the intensifying kind, in which the client leases the product for a set amount of time. The fourth type focuses on minimalizing the material usage to meet zero landfill standards and completely transforming it into a software product.

Figure 10.

Types of CBMs and conceptual linkages—adapted from [100].

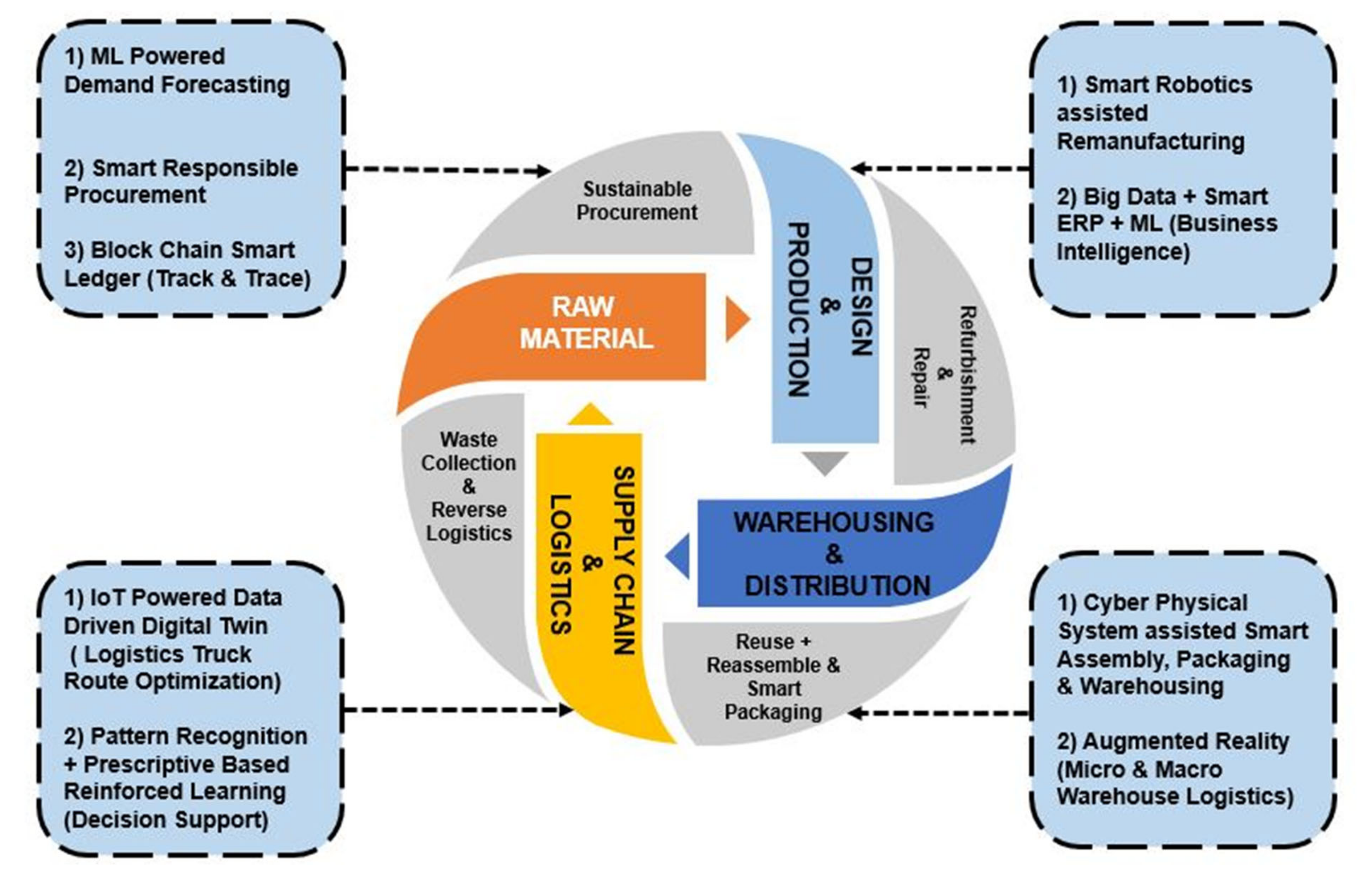

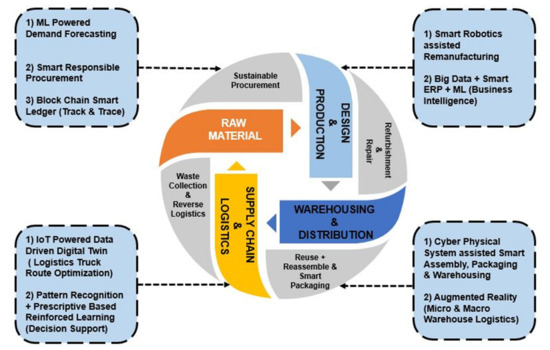

Following a thorough assessment of the literature data set and past research work, the authors made recommendations for technological tools and their associated points of inclusion in the first kind of circularity-based CBM model outlined above, as seen in Figure 10. This is primarily because CSC plays a significant role in improving, standardizing, and aiding in this circularity-based CBM. Furthermore, as shown in Figure 11, they can be referred to by researchers as future research objectives in terms of technology inclusion in the respective domain areas in order to improve and develop the CSC further to build a circularity-based CBM.

Figure 11.

Proposed CSC operational model.

6.3. A Pathway towards a Smart Sustainable Circular Supply Chain

The authors thoroughly examined all aspects of technological inclusions in the supply chain, as well as the respective specific domain or location in the chain, in order to develop a proposal of ideas or a future research paradigm (framework) that can strengthen circular supply chain logistics and introduce technological innovation in circular business models. The previous studies’ research gaps, limitations, and recommendations for further study were compiled to create this model. According to the resource-based view paradigm, technological innovation is a direct contributing resource for an organization’s competitive advantage [101,102]. A neat schematic is shown in Figure 11.

6.3.1. Inclusion of Machine Learning for Smart Sustainable Procurement

A machine learning algorithm can absorb humungous data patterns, create a predictive analytics platform, and build better decision support systems for many applications [103]. On top of this, an optimized real-time circular model to enhance the value creation in a sustainable supply chain network will require a data-driven gateway backed up by IoT-integrated hybrid simulation modeling and machine learning. Effective demand forecasting for a responsible and smart sustainable supply chain with circular parameters requires a sophisticated ML heuristic [104]. The review results show a need for an enterprise-level ML application platform for precisely forecasting demand while coordinating with the circularity of resources, avoiding the excess accumulation of waste.

6.3.2. Blockchain Ledger for Supply Chain Finance

Today, customers like to track and trace their products [57]. A blockchain ledger can create both safety and integrity as well as help in supply chain financial transactions in a manner that could ease the complexity of the circular model. Blockchain, digital currency’s underlying technology, possesses decentralizing, security, anonymity, and non-tamping features. Supply chain financing is a concept wherein banks link core businesses with upstream and downstream businesses for customizable payment methods. BC enhances financial circulation and information flow efficiency, decreases costs, and provides the appropriate supply chain stakeholders with improved financial services [105,106].

6.3.3. Smart Robotics (CPS) and Big Data-based Central ERP System (Manufacturing Shop Floor)

The refurbishment process needs sophistication, and human errors are prone to happen. The authors propose a cyber-physical system that coordinates these processes along with normal operations. The bill of materials section, the materials planning component, and the master production schedule may crash. Hence, a smart ERP system and Big Data cloud computing for data storage are proposed at this level.

6.3.4. Cyber-Physical Systems Assisted Smart Warehousing (Augmented Reality)

The warehouse is where all the reassembly, reworking, repacking, and rescheduling for the reverse supply chain occur. Through this study’s inferences, the authors suggest the installation of cyber-physical systems in the area of smart packaging, sorting, material handling, and pallet storage and retrieval. Automated warehousing systems play a vital role in industrial structures and are usually governed by hierarchical and centralized control architectures and standard programming techniques [25,107]. Cyber-physical systems have brought about a significant transformation. We consider that they are suited for application in many types of transport and material handling systems, especially automated storage systems. As a kind of cyber-physical system (CPS), automated storage technologies require multiple components to cooperate in order to achieve the unified business goals of sophisticated logistics systems. Several key performance indicators (KPIs) can be monitored during joint operations to understand the competence of the warehouse and to monitor decisions [108].

6.3.5. Augmented Reality

Based on the current findings, cyber-physical systems can be linked and merged with an augmented reality-based setup to enable human control and support without the need for a physical presence. These concepts are relevant and help reduce physical interaction in the present pandemic when industries and businesses are suspended. An operator can control procedures, including both micro-macro logistics and production, from a remote location through virtual, augmented reality.

6.3.6. IoT powered Digital Twin (To handle Complexities in Reverse Logistics Model)

Strategic and robust simulation models are required to make efficient and cost-effective decisions [33,109]. Digital twins will play a major role in forecasting future dynamics. Optimum network design, inventory management practices, supply and distribution techniques, logistics integration, outsourcing and procurement approaches, and other related systems must be mapped and monitored in the supply chain system [110,111]. Demand-specific uncertainties like work in process time, lead time, supply chain queues, delays, etc., play a major role in the supply chain that can easily be projected using a simulation model [18,112,113]. However, to establish and perfect real-time data monitoring systems in the supply chain network, tools like IoT are also needed [114].

Therefore, simulation modeling, if integrated with IoT, can establish dynamic and virtual supply chains along with traceability and tracking options [115]. IoT-based modeling allows supply chains to use virtualizations to actively assist manufacturers in grappling with perishable products, volatile supply fluctuations, safety, and sustainability specifications. Virtualization allows supply chain members to track, manage, schedule, and automate logistics networks remotely and in real-time over the Internet, focusing mainly on physical reality instead of post-data observation [116,117]. While the latest revolution in digital transformational technologies provides new opportunities, logistics models should be re-evaluated by data-driven platforms. Extracting insights from operational data assists in predicting uncertainties and reducing inefficiencies in logistics operations by making them more resilient and sustainable [118,119].

6.3.7. Reinforced Learning Application in the Circular Supply Chain and Reverse Logistics

All parameters/variables required to simulate the dynamic complexity of the logistic model in actual time will help us identify the logistic model’s segments and dynamics. This can be strengthened further by machine learning and prescriptive reinforced decision support systems. In the literature, this combination has received very little attention. Furthermore, at this time of crisis where there are shortages of goods, these smart technologies are critical for a circular supply chain environment. Further study is necessary to elucidate theoretical elements of the circular loop. A complete description of resources systems must be set to increase future business development with the most efficient usage of resource elements [120].

7. Future Research Direction

CBMs are designed, developed, and practiced according to their purpose and functionality. Global demand for products and service consumption is growing at a rapid pace. Customers expect sustainable brands that are smart. More research should be focused on developing state-of-the-art machine learning algorithms to get hold of sustainable procurement and demand forecasting. IoT-assisted data-driven digital twins can be integrated with reinforced learning platforms to assist truck route optimization, automated warehouse storage and retrieval systems, and other micro and macro reverse logistics procedures. This idea can be streamlined to build a prescriptive decision support system. Augmented reality coupled with cyber-physical systems could assist in the refurbishing, re-assembly, and packaging division at the shop floor or warehouse level. The benefits of Big Data and blockchain technology can be leveraged at the procurement and production levels to build smart contract-based ledgers which allow the stakeholders to effectively track and trace the source of the product in the CSC. Moreover, since the product volume would be doubled at the manufacturing facility for product recall, reuse, and refurbishing processes, smart enterprise resource planning (ERP) is needed. A combination of Big Data and cloud computing technology can address this issue by building wireless ERP systems for the CSC.

8. Limitations of the Study

This study utilized only the Web of Science core collection database as mentioned in the methodology section. Researchers can opt for the inclusion of other databases for additional insights. Moreover, there is a possibility of missing some keywords at the keyword selection stage since the technology-related terminology is not standard yet. Other advanced keywords, such as deep learning, augmented virtual reality, machine vision, Industry 4.0, etc., can be included in future studies.

9. Conclusions

To conclude, the findings of the research show that more work still has to be carried out to ascertain what technological inclusions are needed, to what degree, targeting which area or domain of the supply chain, and how to use them efficiently to transform a conventional business model into a circular model. The main agenda that should be fulfilled to create a circular business model is circularity, or circular inputs that replace linear inputs with fully renewable resources and completely recycled materials. A sharing platform where businesses encourage collaboration among users to maximize the use of assets is ideal. A new service-based paradigm known as Product as a Service (PaaS) exists in another dimension, in which the customer does not buy the equipment but rather uses it as a service and returns it. Rework and refurbishment can extend the life cycle of a product in some situations.

Companies must work with suppliers and design goods that follow a circular supply chain to have a circular life cycle. Remanufacturing has a crucial role to play in the achievement of a circular economy. It decreases the impact on the environment, boosts profit margins, reduces supply risk, and reduces lead time. Corporations need to redefine customer connections in this supply chain so that old products from customers may be tracked and collected. New technology and circular business models are essential for enabling a circular economy, yet they are still insufficient. We must engage customers to hasten this shift, as consumers expect items that are circularly designed and eco-friendly. Companies can create supply chains and infrastructure that allow for successful and efficient reverse logistics. There are only a few prerequisites for organizations and supply chains to migrate to a circular economy: transparency, visibility, innovation, and efficiency.

For the next five years, industry leaders will be focusing on gaining a competitive advantage. Corporations will seek to win market share by incorporating creativity into their business models, establishing reverse cycle capabilities, and utilizing the brand strength of leading companies. The economic outcome and feasibility of this approach are greatly impacted by the relationship between consumer behavior and the manufacturer’s strategic decisions [121]. Incorporating technology into various circular business strategies aids across multiple design choices in circular value chains. They may be routinely investigated as modules and their data tracked during the simulation period. According to industrial system parameters, product returns can be considered at varying levels of price, quantity, and timing [24]. In addition to that, since the circularity further needs historical and up-to-date information to build a strong decision support system, the data-driven gateway shall assist in creating a resilient benchmark.

The literature on reuse or remanufacture is very limited in assessing the environmental, economic, and social impact of different variants of remanufacturing processes in organizations [100,122]. Furthermore, studies on how supply chain and logistic networks have to be designed for circular business models for various platforms such as SMEs and other public sectors, etc., are very scarce [38]. This study shall be a steppingstone for other empirical and qualitative studies that are yet to come.

Author Contributions

Conceptualization, methodology, validation, J.P.; software, data curation, writing—original draft preparation, A.Z.A.; supervision V.P.K.S.; revision and supervision, M.-L.T.; reviewing and editing, review protocol, investigations, S.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research is funded by the Institute of Business Excellence (IBE), Universiti Teknologi MARA, 40450, Shah Alam, Malaysia.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

Authors would like to acknowledge the financial support from the Institute of Business Excellence (IBE), Universiti Teknologi MARA, 40450, Shah Alam, Malaysia, and also are very grateful to the reviewers for their constructive comments.

Conflicts of Interest

The authors declare that they have no known competing conflict of interests that could have appeared to influence the work reported in this paper.

References

- Rizos, V.; Behrens, A.; Kafyeke, T.; Hirschnitz-Garbers, M.; Ioannou, A. The Circular Economy: Barriers and Opportunities for SMEs; CEPS: Brussels, Belgium, 2015. [Google Scholar]

- Lewandowski, M. Designing the business models for circular economy—Towards the conceptual framework. Sustainability 2016, 8, 43. [Google Scholar] [CrossRef] [Green Version]

- Pearce, D.W.; Turner, R.K. Economics of Natural Resources and the Environment; John Hopkins University Press: Baltimore, MD, USA, 1990; ISBN 0801839874. [Google Scholar]

- Boulding, K.E. The Economics of the Coming Spaceship Earth; NCSE, Boston Univerisy: New York, NY, USA, 1966. [Google Scholar]

- Lahti, T.; Wincent, J.; Parida, V. A definition and theoretical review of the circular economy, value creation, and sustainable business models: Where are we now and where should research move in the future? Sustainability 2018, 10, 2799. [Google Scholar] [CrossRef] [Green Version]

- Rizos, V.; Tuokko, K.; Behrens, A. The Circular Economy: A Review of Definitions, Processes and Impacts; Centre for European Policy Studies: Boston, MA, USA, 2017. [Google Scholar]

- Caldera, H.T.S.; Desha, C.; Dawes, L. Evaluating the enablers and barriers for successful implementation of sustainable business practice in ‘lean’ SMEs. J. Clean. Prod. 2019, 218, 575–590. [Google Scholar] [CrossRef]

- Wu, K.-J.; Liao, C.-J.; Tseng, M.-L.; Lim, M.K.; Hu, J.; Tan, K. Toward sustainability: Using big data to explore the decisive attributes of supply chain risks and uncertainties. J. Clean. Prod. 2017, 142, 663–676. [Google Scholar] [CrossRef]

- Tseng, M.-L.; Chiu, A.S.F.; Liu, G.; Jantaralolica, T. Circular economy enables sustainable consumption and production in multi-level supply chain system. Resour. Conserv. Recycl. 2020, 154, 104601. [Google Scholar] [CrossRef]

- Frei, R.; Jack, L.; Krzyzaniak, S.-A. Sustainable reverse supply chains and circular economy in multichannel retail returns. Bus. Strateg. Environ. 2020, 29, 1925–1940. [Google Scholar] [CrossRef]

- Govindan, K.; Hasanagic, M. A systematic review on drivers, barriers, and practices towards circular economy: A supply chain perspective. Int. J. Prod. Res. 2018, 56, 278–311. [Google Scholar] [CrossRef]

- De Jesus, A.; Mendonça, S. Lost in transition? Drivers and barriers in the eco-innovation road to the circular economy. Ecol. Econ. 2018, 145, 75–89. [Google Scholar] [CrossRef] [Green Version]

- Parida, V.; Sjödin, D.; Reim, W. Reviewing literature on digitalization, business model innovation, and sustainable industry: Past achievements and future promises. Sustainability 2019, 11, 391. [Google Scholar] [CrossRef] [Green Version]

- Pieroni, M.P.P.; McAloone, T.C.; Pigosso, D.C.A. Business model innovation for circular economy and sustainability: A review of approaches. J. Clean. Prod. 2019, 215, 198–216. [Google Scholar] [CrossRef]

- Rosa, P.; Sassanelli, C.; Terzi, S. Towards Circular Business Models: A systematic literature review on classification frameworks and archetypes. J. Clean. Prod. 2019, 236, 117696. [Google Scholar] [CrossRef]

- Manninen, K.; Koskela, S.; Antikainen, R.; Bocken, N.; Dahlbo, H.; Aminoff, A. Do circular economy business models capture intended environmental value propositions? J. Clean. Prod. 2018, 171, 413–422. [Google Scholar] [CrossRef] [Green Version]

- Aryanasl, A.; Ghodousi, J.; Arjmandi, R.; Mansouri, N. Can excellence management models encompass “cleaner production” and “sustainable business” revolution? (European Foundation for Quality Management as a case study). Int. J. Environ. Sci. Technol. 2016, 13, 1269–1276. [Google Scholar] [CrossRef] [Green Version]

- Abideen, A.Z.; Mohamad, F.B. Advancements in industrial supply chain through lean implementation-a review. Int. J. Logist. Syst. Manag. 2021, 38, 45–64. [Google Scholar]

- Blomsma, F.; Pieroni, M.; Kravchenko, M.; Pigosso, D.C.A.; Hildenbrand, J.; Kristinsdottir, A.R.; Kristoffersen, E.; Shahbazi, S.; Nielsen, K.D.; Jönbrink, A.-K. Developing a circular strategies framework for manufacturing companies to support circular economy-oriented innovation. J. Clean. Prod. 2019, 241, 118271. [Google Scholar] [CrossRef]

- Zhang, D.; Huang, X.; Wen, Y.; Trivedi, P.; Joghee, S. Sustainable Circular Business Model for Transparency and Uncertainty Reduction in Supply Chain Management. J. Theor. Appl. Electron. Commer. Res. 2021, 16, 959–975. [Google Scholar] [CrossRef]

- Rovanto, I.K.; Bask, A. Systemic circular business model application at the company, supply chain and society levels-A view into circular economy native and adopter companies. Bus. Strat. Environ. 2021, 30, 1153–1173. [Google Scholar] [CrossRef]

- Tsanakas, J.A.; van der Heide, A.; Radavicius, T.; Denafas, J.; Lemaire, E.; Wang, K.; Poortmans, J.; Voroshazi, E. Towards a circular supply chain for PV modules: Review of today’s challenges in PV recycling, refurbishment and re-certification. Prog. Photovolt. 2020, 28, 454–464. [Google Scholar] [CrossRef]

- Vegter, D.; van Hillegersberg, J.; Olthaar, M. Supply chains in circular business models: Processes and performance objectives. Resour. Conserv. Recycl. 2020, 162, 105046. [Google Scholar] [CrossRef]

- Lieder, M.; Asif, F.M.A.; Rashid, A.; Mihelič, A.; Kotnik, S. Towards circular economy implementation in manufacturing systems using a multi-method simulation approach to link design and business strategy. Int. J. Adv. Manuf. Technol. 2017, 93, 1953–1970. [Google Scholar] [CrossRef] [Green Version]

- Abideen, A.; Mohamad, F.B. Improving the performance of a Malaysian pharmaceutical warehouse supply chain by integrating value stream mapping and discrete event simulation. J. Model. Manag. 2021, 16, 70–102. [Google Scholar] [CrossRef]

- Dev, N.K.; Shankar, R.; Qaiser, F.H. Industry 4.0 and circular economy: Operational excellence for sustainable reverse supply chain performance. Resour. Conserv. Recycl. 2020, 153, 104583. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A. Viability of intertwined supply networks: Extending the supply chain resilience angles towards survivability. A position paper motivated by COVID-19 outbreak. Int. J. Prod. Res. 2020, 58, 2904–2915. [Google Scholar] [CrossRef] [Green Version]

- Goodall, P.; Sharpe, R.; West, A. A data-driven simulation to support remanufacturing operations. Comput. Ind. 2019, 105, 48–60. [Google Scholar] [CrossRef]

- Charnley, F.; Tiwari, D.; Hutabarat, W.; Moreno, M.; Okorie, O.; Tiwari, A. Simulation to enable a data-driven circular economy. Sustainability 2019, 11, 3379. [Google Scholar] [CrossRef] [Green Version]

- Abideen, A.Z.; Mohamad, F.B. Empowering Supply Chain through Discrete-Event and Agent-Based Simulation—A Systematic Review and Bibliometric Analysis. In Proceedings of the 2019 IEEE Conference on Sustainable Utilization and Development in Engineering and Technologies (CSUDET), Penang, Malaysia, 7–9 November 2019; pp. 69–74. [Google Scholar]

- Soo, V.K.; Compston, P.; Doolan, M. Life cycle modelling of end-of-life products: Challenges and opportunities towards a circular economy. Procedia CIRP 2019, 80, 607–612. [Google Scholar] [CrossRef]

- Lee, J.-E.; Chung, K.-Y.; Lee, K.-D.; Gen, M. A multi-objective hybrid genetic algorithm to minimize the total cost and delivery tardiness in a reverse logistics. Multimed. Tools Appl. 2015, 74, 9067–9085. [Google Scholar] [CrossRef] [Green Version]

- Abideen, A.Z.; Mohamad, F.B.; Fernando, Y. Lean simulations in production and operations management–a systematic literature review and bibliometric analysis. J. Model. Manag. 2020, 12, 623–650. [Google Scholar] [CrossRef]

- Shi, X.; Li, L.X.; Yang, L.; Li, Z.; Choi, J.Y. Information flow in reverse logistics: An industrial information integration study. Inf. Technol. Manag. 2012, 13, 217–232. [Google Scholar] [CrossRef]

- Kumar, V.; Amorim, M.; Bhattacharya, A.; Garza-Reyes, J.A.; Parry, G.C.; Brax, S.A.; Maull, R.S.; Ng, I.C.L. Operationalising IoT for reverse supply: The development of use-visibility measures. Supply Chain Manag. 2016, 21, 228–244. [Google Scholar]

- Xu, X.; Wu, X.; Guo, W. Applications of IoT to reverse supply chain. In Proceedings of the 2011 7th International Conference on Wireless Communications, Networking and Mobile Computing, Wuhan, China, 23–25 September 2011; pp. 1–4. [Google Scholar]

- Pandian, G.R.S.; Abdul-Kader, W. Performance evaluation of reverse logistics enterprise—An agent-based simulation approach. Int. J. Sustain. Eng. 2017, 10, 384–398. [Google Scholar] [CrossRef] [Green Version]

- Liao, T.-Y. Reverse logistics network design for product recovery and remanufacturing. Appl. Math. Model. 2018, 60, 145–163. [Google Scholar] [CrossRef]

- Onggo, B.S.S.; Proudlove, N.C.; D’Ambrogio, S.A.; Calabrese, A.; Bisogno, S.; Ghiron, N.L. A BPMN extension to support discrete-event simulation for healthcare applications: An explicit representation of queues, attributes and data-driven decision points. J. Oper. Res. Soc. 2018, 69, 788–802. [Google Scholar] [CrossRef] [Green Version]

- Abideen, A.Z.; Mohamad, F.B. Supply chain lead time reduction in a pharmaceutical production warehouse—A case study. Int. J. Pharm. Healthc. Mark. 2019, 14, 61–88. [Google Scholar] [CrossRef]

- Li, Y.; Shekhar, S.; Vorobeychik, Y.; Koutsoukos, X.; Gokhale, A. Simulation-Based Optimization as a Service for Dynamic Data-Driven Applications Systems. In Handbook of Dynamic Data Driven Applications Systems; Springer: Berlin, Germany, 2018; pp. 589–614. [Google Scholar]

- Vladimirova, D.; Geissdoerfer, M.; Yang, M.; Zaki, M.; Turner, C.; Tiwari, A. A conceptual framework for sustainable re-distributed manufacturing business models based on data-driven decision making. In Proceedings of the British Academy of Management (BAM) Conference, Warwick, UK, 4–7 September 2017. [Google Scholar]

- Wojtusiak, J.; Warden, T.; Herzog, O. Machine learning in agent-based stochastic simulation: Inferential theory and evaluation in transportation logistics. Comput. Math. Appl. 2012, 64, 3658–3665. [Google Scholar] [CrossRef] [Green Version]

- Knoll, D.; Prüglmeier, M.; Reinhart, G. Predicting Future Inbound Logistics Processes Using Machine Learning. Procedia CIRP 2016, 52, 145–150. [Google Scholar] [CrossRef] [Green Version]

- Asadi, A.; Alsubaey, M.; Makatsoris, C. A machine learning approach for predicting delays in construction logistics. Int. J. Adv. Logist. 2015, 4, 115–130. [Google Scholar] [CrossRef]

- Yang, B. Machine learning-based evolution model and the simulation of a profit model of agricultural products logistics financing. Neural Comput. Appl. 2019, 31, 4733–4759. [Google Scholar] [CrossRef]

- Arumugam, S.S.; Umashankar, V.; Narendra, N.C.; Badrinath, R.; Mujumdar, A.P.; Holler, J.; Hernandez, A. IOT enabled smart logistics using smart contracts. In Proceedings of the 2018 8th International Conference on Logistics, Informatics and Service Sciences (LISS), Toronto, ON, Canada, 3–6 August 2018; pp. 1–6. [Google Scholar]

- Yu, X.; Liao, X.; Li, W.; Liu, X.; Tao, Z. Logistics automation control based on machine learning algorithm. Clust. Comput. 2019, 22, 14003–14011. [Google Scholar] [CrossRef]

- Capalbo, V.; Ghiani, G.; Manni, E. The Role of Optimization and Machine Learning in e-Commerce Logistics in 2030. Int. J. Econ. Manag. Engineering 2021, 15, 290–294. [Google Scholar]

- Bricher, D.; Müller, A. A Supervised Machine Learning Approach for Intelligent Process Automation in Container Logistics. J. Comput. Inf. Sci. Eng. 2020, 20, 031006. [Google Scholar] [CrossRef]

- Fernando, Y.; Abideen, A.Z.; Shaharudin, M.S. The nexus of information sharing, technology capability and inventory efficiency. J. Glob. Oper. Strateg. Sourc. 2020, 33, 327–351. [Google Scholar] [CrossRef]

- Jiang, W. An Intelligent Supply Chain Information Collaboration Model Based on Internet of Things and Big Data. IEEE Access 2019, 7, 58324–58335. [Google Scholar] [CrossRef]

- Raut, R.D.; Yadav, V.S.; Cheikhrouhou, N.; Narwane, V.S.; Narkhede, B.E. Big data analytics: Implementation challenges in Indian manufacturing supply chains. Comput. Ind. 2021, 125, 103368. [Google Scholar] [CrossRef]

- Sorkun, M.F. Digitalization in Logistics Operations and Industry 4.0: Understanding the Linkages with Buzzwords. In Digital Business Strategies in Blockchain Ecosystems; Springer: Berlin, Germany, 2020; pp. 177–199. [Google Scholar]

- Omitola, T.; Wills, G. Towards Mapping the Security Challenges of the Internet of Things (IoT) Supply Chain. In Proceedings of the Knowledge-Based and Intelligent Information & Engineering Systems, Vietri sul Mare, Italy, 12–14 September 2007 (kes-2018); Howlett, R.J., Toro, C., Hicks, Y., Jain, L.C., Eds.; Elsevier Science Bv: Amsterdam, The Netherlands, 2018; Volume 126, pp. 441–450. [Google Scholar]

- Woschank, M.; Rauch, E.; Zsifkovits, H. A Review of Further Directions for Artificial Intelligence, Machine Learning, and Deep Learning in Smart Logistics. Sustainability 2020, 12, 3760. [Google Scholar] [CrossRef]

- Fernando, Y.; Darun, M.R.; Abideen, A.Z.; Ibrahim, D.N.; Tieman, M.; Mohamad, F. Adoption of Blockchain Technology to Improve Integrity of Halal Supply Chain Management. In Encyclopedia of Organizational Knowledge, Administration, and Technology; IGI Global: Hershey, PA, USA, 2021; pp. 2488–2496. [Google Scholar]

- Yuan, H.; Qiu, H.; Bi, Y.; Chang, S.-H.; Lam, A. Analysis of coordination mechanism of supply chain management information system from the perspective of block chain. Inf. Syst. E-Bus. Manag. 2020, 18, 681–703. [Google Scholar] [CrossRef]

- Fink, A. Conducting Research Literature Reviews: From the Internet to Paper; SAGE: Thousand Oaks, CA, USA, 2005; ISBN 141290904X. [Google Scholar]

- Webster, J.; Watson, R.T. Analyzing the Past to Prepare for the Future: Writing a Literature Review. MIS Q. 2002, 26, 13–22. [Google Scholar]

- Downe-Wamboldt, B. Content analysis: Method, applications, and issues. Health Care Women Int. 1992, 13, 313–321. [Google Scholar] [CrossRef]

- Seuring, S.; Gold, S. Conducting content-analysis based literature reviews in supply chain management. Supply Chain Manag. 2012, 17, 544–555. [Google Scholar] [CrossRef]

- Sánchez, A.D.; Del Río, M.d.l.C.; García, J.Á. Bibliometric analysis of publications on wine tourism in the databases Scopus and WoS. Eur. Res. Manag. Bus. Econ. 2017, 23, 8–15. [Google Scholar] [CrossRef] [Green Version]

- Cavacini, A. What is the best database for computer science journal articles? Scientometrics 2015, 102, 2059–2071. [Google Scholar] [CrossRef]

- Benzidia, S.; Makaoui, N.; Bentahar, O. The impact of big data analytics and artificial intelligence on green supply chain process integration and hospital environmental performance. Technol. Forecast. Soc. Chang. 2021, 165, 120557. [Google Scholar] [CrossRef]

- Dumitrascu, O.; Dumitrascu, M.; Dobrota, D. Performance Evaluation for a Sustainable Supply Chain Management System in the Automotive Industry Using Artificial Intelligence. Processes 2020, 8, 1384. [Google Scholar] [CrossRef]

- Kantasa-ard, A.; Bekrar, A.; el Cadi, A.A.; Sallez, Y. Artificial intelligence for forecasting in supply chain management: A case study of White Sugar consumption rate in Thailand. IFAC Pap. 2019, 52, 725–730. [Google Scholar] [CrossRef]

- Konovalenko, I.; Ludwig, A. Comparison of machine learning classifiers: A case study of temperature alarms in a pharmaceutical supply chain. Inf. Syst. 2021, 100, 101759. [Google Scholar] [CrossRef]

- Sardar, S.K.; Sarkar, B.; Kim, B. Integrating Machine Learning, Radio Frequency Identification, and Consignment Policy for Reducing Unreliability in Smart Supply Chain Management. Processes 2021, 9, 247. [Google Scholar] [CrossRef]

- Abbasi, B.; Babaei, T.; Hosseinifard, Z.; Smith-Miles, K.; Dehghani, M. Predicting solutions of large-scale optimization problems via machine learning: A case study in blood supply chain management. Comput. Oper. Res. 2020, 119, 104941. [Google Scholar] [CrossRef]

- Park, K.T.; Son, Y.H.; Noh, S. Do The architectural framework of a cyber physical logistics system for digital-twin-based supply chain control. Int. J. Prod. Res. 2020, 1–22. [Google Scholar] [CrossRef]

- Defraeye, T.; Shrivastava, C.; Berry, T.; Verboven, P.; Onwude, D.; Schudel, S.; Buehlmann, A.; Cronje, P.; Rossi, R.M. Digital twins are coming: Will we need them in supply chains of fresh horticultural produce? Trends Food Sci. Technol. 2021, 109, 245–258. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A. New disruption risk management perspectives in supply chains: Digital twins, the ripple effect, and resileanness. IFAC Pap. 2019, 52, 337–342. [Google Scholar] [CrossRef]

- Al-Rakhami, M.S.; Al-Mashari, M. A Blockchain-Based Trust Model for the Internet of Things Supply Chain Management. Sensors 2021, 21, 1759. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.; Gong, Z. Supply Chain Inventory Collaborative Management and Information Sharing Mechanism Based on Cloud Computing and 5G Internet of Things. Math. Probl. Eng. 2021, 2021, 6670718. [Google Scholar] [CrossRef]

- Yadav, S.; Luthra, S.; Garg, D. Modelling Internet of things (IoT)-driven global sustainability in multi-tier agri-food supply chain under natural epidemic outbreaks. Environ. Sci. Pollut. Res. 2021, 28, 16633–16654. [Google Scholar] [CrossRef] [PubMed]

- Garrido-Hidalgo, C.; Javier Ramirez, F.; Olivares, T.; Roda-Sanchez, L. The adoption of internet of things in a circular supply chain framework for the recovery of WEEE: The case of lithium-ion electric vehicle battery packs. Waste Manag. 2020, 103, 32–44. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Huang, Y.; Xia, P.; Zhang, Y.; Zhong, Y. Design and implementation of real-time traceability monitoring system for agricultural products supply chain under Internet of Things architecture. Concurr. Comput. Exp. 2018, 31, e4766. [Google Scholar] [CrossRef]

- Morella, P.; Lamban, M.P.; Royo, J.; Sanchez, J.C.; Ng Corrales, L.d.C. Development of a New Green Indicator and Its Implementation in a Cyber-Physical System for a Green Supply Chain. Sustainability 2020, 12, 8629. [Google Scholar] [CrossRef]

- Smetana, S.; Aganovic, K.; Heinz, V. Food Supply Chains as Cyber-Physical Systems: A Path for More Sustainable Personalized Nutrition. Food Eng. Rev. 2021, 13, 92–103. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, Y. Linear approximation fuzzy model for fault detection in cyber-physical system for supply chain management. Enterp. Inf. Syst. 2020. [Google Scholar] [CrossRef]

- Kazancoglu, Y.; Pala, M.O.; Sezer, M.D.; Luthra, S.; Kumar, A. Drivers of implementing Big Data Analytics in food supply chains for transition to a circular economy and sustainable operations management. J. Enterp. Inf. Manag. 2021. [Google Scholar] [CrossRef]

- Bamakan, S.M.H.; Faregh, N.; ZareRavasan, A. Di-ANFIS: An integrated blockchain-IoT-big data-enabled framework for evaluating service supply chain performance. J. Comput. Des. Eng. 2021, 8, 676–690. [Google Scholar] [CrossRef]

- Liu, P.; Long, Y.; Song, H.-C.; He, Y.-D. Investment decision and coordination of green agri-food supply chain considering information service based on blockchain and big data. J. Clean. Prod. 2020, 277, 123646. [Google Scholar] [CrossRef]

- Bamel, N.; Bamel, U. Big data analytics based enablers of supply chain capabilities and firm competitiveness: A fuzzy-TISM approach. J. Enterp. Inf. Manag. 2021, 34, 559–577. [Google Scholar] [CrossRef]

- Sundarakani, B.; Ajaykumar, A.; Gunasekaran, A. Big data driven supply chain design and applications for blockchain: An action research using case study approach. Omega-Int. J. Manag. Sci. 2021, 102, 102452. [Google Scholar] [CrossRef]

- Afrianto, I.; Djatna, T.; Arkeman, Y.; Hermadi, I.; Sitanggang, I.S. Block Chain Technology Architecture for Supply Chain Traceability of Fisheries Products in Indonesia: Future Challenge. J. Eng. Sci. Technol. 2020, 15, 41–49. [Google Scholar]

- Li, Y.; Wang, B.; Yang, D. Research on Supply Chain Coordination Based on Block Chain Technology and Customer Random Demand. Discret. Dyn. Nat. Soc. 2019, 2019, 4769870. [Google Scholar] [CrossRef]

- Jan van Eck, N.; Waltman, L. Software survey: VOSviewer, a computer program for bibliometric mapping. Scientometrics 2010, 84, 523–538. [Google Scholar] [CrossRef] [Green Version]

- Saroha, M.; Garg, D.; Luthra, S. Identification and analysis of circular supply chain management practices for sustainability: A fuzzy-DEMATEL approach. Int. J. Product. Perform. Manag. 2021. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Morioka, S.N.; de Carvalho, M.M.; Evans, S. Business models and supply chains for the circular economy. J. Clean. Prod. 2018, 190, 712–721. [Google Scholar] [CrossRef]

- Mastos, T.D.; Nizamis, A.; Terzi, S.; Gkortzis, D.; Papadopoulos, A.; Tsagkalidis, N.; Ioannidis, D.; Votis, K.; Tzovaras, D. Introducing an application of an industry 4.0 solution for circular supply chain management. J. Clean. Prod. 2021, 300, 126886. [Google Scholar] [CrossRef]

- Kumar, S.; Raut, R.D.; Nayal, K.; Kraus, S.; Yadav, V.S.; Narkhede, B.E. To identify industry 4.0 and circular economy adoption barriers in the agriculture supply chain by using ISM-ANP. J. Clean. Prod. 2021, 293, 126023. [Google Scholar] [CrossRef]

- Kazancoglu, I.; Sagnak, M.; Mangla, S.K.; Kazancoglu, Y. Circular economy and the policy: A framework for improving the corporate environmental management in supply chains. Bus. Strateg. Environ. 2021, 30, 590–608. [Google Scholar] [CrossRef]

- Ozkan-Ozen, Y.D.; Kazancoglu, Y.; Mangla, S.K. Synchronized barriers for circular supply chains in industry 3.5/industry 4.0 transition for sustainable resource management. Resour. Conserv. Recycl. 2020, 161, 104986. [Google Scholar] [CrossRef]

- Farooque, M.; Zhang, A.; Liu, Y. Barriers to circular food supply chains in China. Supply Chain Manag. Int. J. 2019, 24, 677–696. [Google Scholar] [CrossRef]

- Pan, S.-Y.; Du, M.A.; Huang, I.-T.; Liu, I.-H.; Chang, E.-E.; Chiang, P.-C. Strategies on implementation of waste-to-energy (WTE) supply chain for circular economy system: A review. J. Clean. Prod. 2015, 108, 409–421. [Google Scholar] [CrossRef]

- De Oliveira, C.T.; Luna, M.M.M.; Campos, L.M.S. Understanding the Brazilian expanded polystyrene supply chain and its reverse logistics towards circular economy. J. Clean. Prod. 2019, 235, 562–573. [Google Scholar] [CrossRef]

- Clark, N.; Trimingham, R.; Wilson, G.T. Incorporating Consumer Insights into the UK Food Packaging Supply Chain in the Transition to a Circular Economy. Sustainability 2020, 12, 6106. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Pieroni, M.P.; Pigosso, D.C.; Soufani, K. Circular business models: A review. J. Clean. Prod. 2020, 22, 123741. [Google Scholar] [CrossRef]

- Liu, J.; Baskaran, A.; Li, S. Building technological-innovation-based strategic capabilities at firm level in China: A dynamic resource-based-view case study. Ind. Innov. 2009, 16, 411–434. [Google Scholar] [CrossRef]

- Markard, J.; Worch, H. Technological innovation systems and the resource based view-Resources at the firm, network and system level. In Proceedings of the DIME Workshop on Environmental Innovation, Industrial Dynamics and Entrepreneurship, Utrecht, The Netherlands, 10–12 May 2009; pp. 10–12. [Google Scholar]

- Gately, C. Vekia: Pioneering machine learning in retail supply chain. Small Enterp. Res. 2017, 24, 326–332. [Google Scholar] [CrossRef]

- Baryannis, G.; Dani, S.; Antoniou, G. Predicting supply chain risks using machine learning: The trade-off between performance and interpretability. Futur. Gener. Comput. Syst. Int. J. Escience 2019, 101, 993–1004. [Google Scholar] [CrossRef]

- Du, M.; Chen, Q.; Xiao, J.; Yang, H.; Ma, X. Supply chain finance innovation using blockchain. IEEE Trans. Eng. Manag. 2020, 67, 1045–1058. [Google Scholar] [CrossRef]

- Chen, J.; Cai, T.; He, W.; Chen, L.; Zhao, G.; Zou, W.; Guo, L. A blockchain-driven supply chain finance application for auto retail industry. Entropy 2020, 22, 95. [Google Scholar] [CrossRef] [Green Version]

- Trab, S.; Bajic, E.; Zouinkhi, A.; Thomas, A.; Abdelkrim, M.N.; Chekir, H.; Ltaief, R.H. A communicating object’s approach for smart logistics and safety issues in warehouses. Concurr. Eng. 2017, 25, 53–67. [Google Scholar] [CrossRef]

- Gürdür, D.; Vulgarakis Feljan, A.; El-khoury, J.; Kumar Mohalik, S.; Badrinath, R.; Pradeep Mujumdar, A.; Fersman, E. Knowledge Representation of Cyber-physical Systems for Monitoring Purpose. Procedia CIRP 2018, 72, 468–473. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A. A digital supply chain twin for managing the disruption risks and resilience in the era of Industry 4.0. Prod. Plan. Control 2021, 32, 775–788. [Google Scholar] [CrossRef]

- Georgiadis, P.; Vlachos, D.; Iakovou, E. A system dynamics modeling framework for the strategic supply chain management of food chains. J. Food Eng. 2005, 70, 351–364. [Google Scholar] [CrossRef]

- Ray, Z.; Xun, X.; Lihui, W. Food supply chain management: Systems, implementations, and future research. Ind. Manag. Data Syst. 2017, 117, 2085–2114. [Google Scholar] [CrossRef]

- Abideen, A.Z.; Mohamad, F.B. Improving Pharmaceutical Warehouse Supply Chain Lead Time–From Production to Cross-Docking. In Proceedings of the 2019 IEEE Conference on Sustainable Utilization and Development in Engineering and Technologies (CSUDET), Penang, Malaysia, 7–9 November 2019; pp. 63–68. [Google Scholar]

- Reiner, G.; Trcka, M. Customized supply chain design: Problems and alternatives for a production company in the food industry. A simulation based analysis. Int. J. Prod. Econ. 2004, 89, 217–229. [Google Scholar] [CrossRef]

- Wang, J.; Yue, H. Food safety pre-warning system based on data mining for a sustainable food supply chain. Food Control 2017, 73, 223–229. [Google Scholar] [CrossRef]

- Pang, Z.; Chen, Q.; Han, W.; Zheng, L. Value-centric design of the internet-of-things solution for food supply chain: Value creation, sensor portfolio and information fusion. Inf. Syst. Front. 2015, 17, 289–319. [Google Scholar] [CrossRef]

- Verdouw, C.N.; Wolfert, J.; Beulens, A.J.M.; Rialland, A. Virtualization of food supply chains with the internet of things. J. Food Eng. 2016, 176, 128–136. [Google Scholar] [CrossRef] [Green Version]

- Qu, T.; Thürer, M.; Wang, J.; Wang, Z.; Fu, H.; Li, C.; Huang, G.Q. System dynamics analysis for an Internet-of-Things-enabled production logistics system. Int. J. Prod. Res. 2017, 55, 2622–2649. [Google Scholar] [CrossRef]

- Heilig, L.; Stahlbock, R.; Voß, S. From Digitalization to Data-Driven Decision Making in Container Terminals. arXiv 2019, arXiv:1904.13251. [Google Scholar]

- Wu, L.; Yue, X.; Jin, A.; Yen, D.C. Smart supply chain management: A review and implications for future research. Int. J. Logist. Manag. 2016, 27, 395–417. [Google Scholar] [CrossRef]

- Ghisellini, P.; Ripa, M.; Ulgiati, S. Exploring environmental and economic costs and benefits of a circular economy approach to the construction and demolition sector. A literature review. J. Clean. Prod. 2018, 178, 618–643. [Google Scholar] [CrossRef]

- Nassehi, A.; Colledani, M. A multi-method simulation approach for evaluating the effect of the interaction of customer behaviour and enterprise strategy on economic viability of remanufacturing. CIRP Ann. 2018, 67, 33–36. [Google Scholar] [CrossRef] [Green Version]

- Golinska-Dawson, P.; Pawlewski, P. Simulation Modelling of Remanufacturing Process and Sustainability Assessment. In Sustainability in Remanufacturing Operations; Springer: Berlin, Germany, 2018; pp. 141–155. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).