Product Design for Automated Remanufacturing—A Case Study of Electric and Electronic Equipment in Sweden

Abstract

:1. Introduction

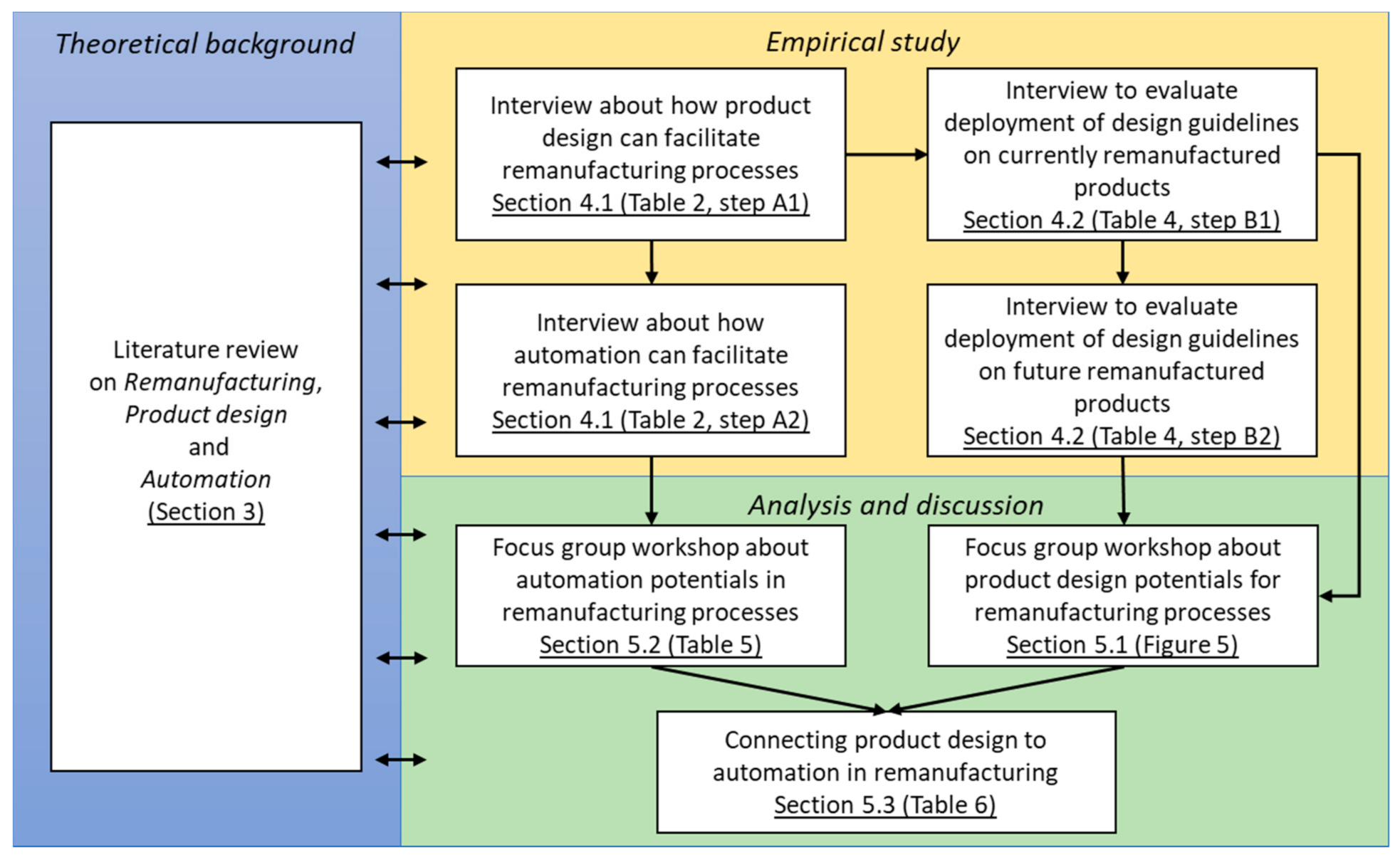

2. Methodology

3. Theoretical Background

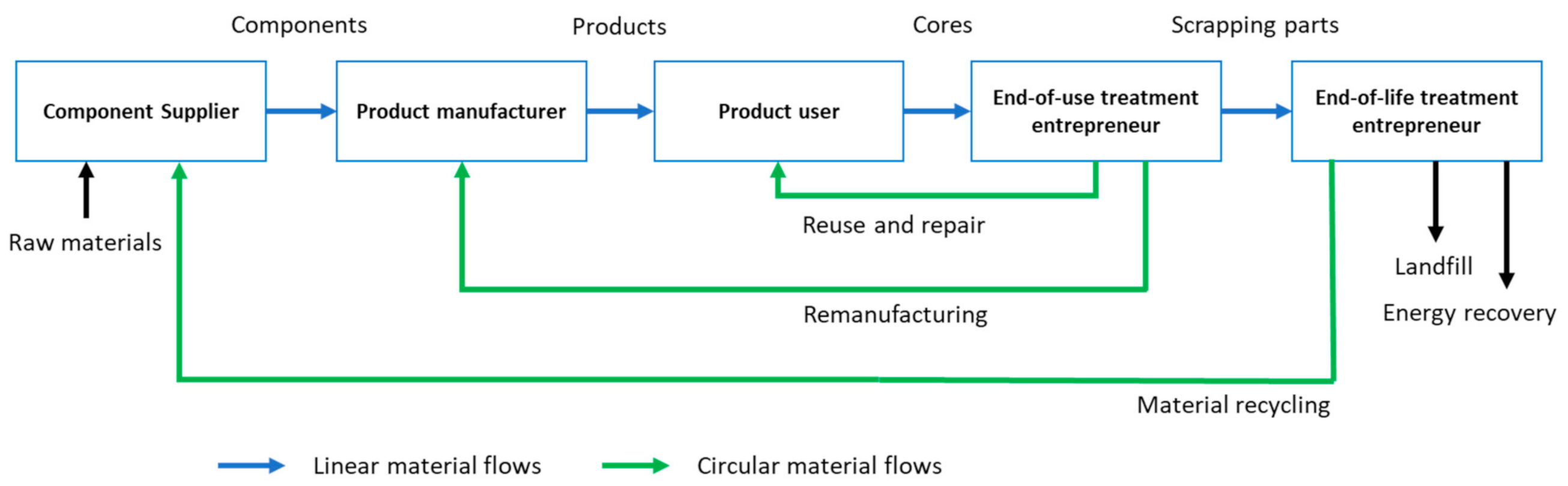

3.1. Remanufacturing

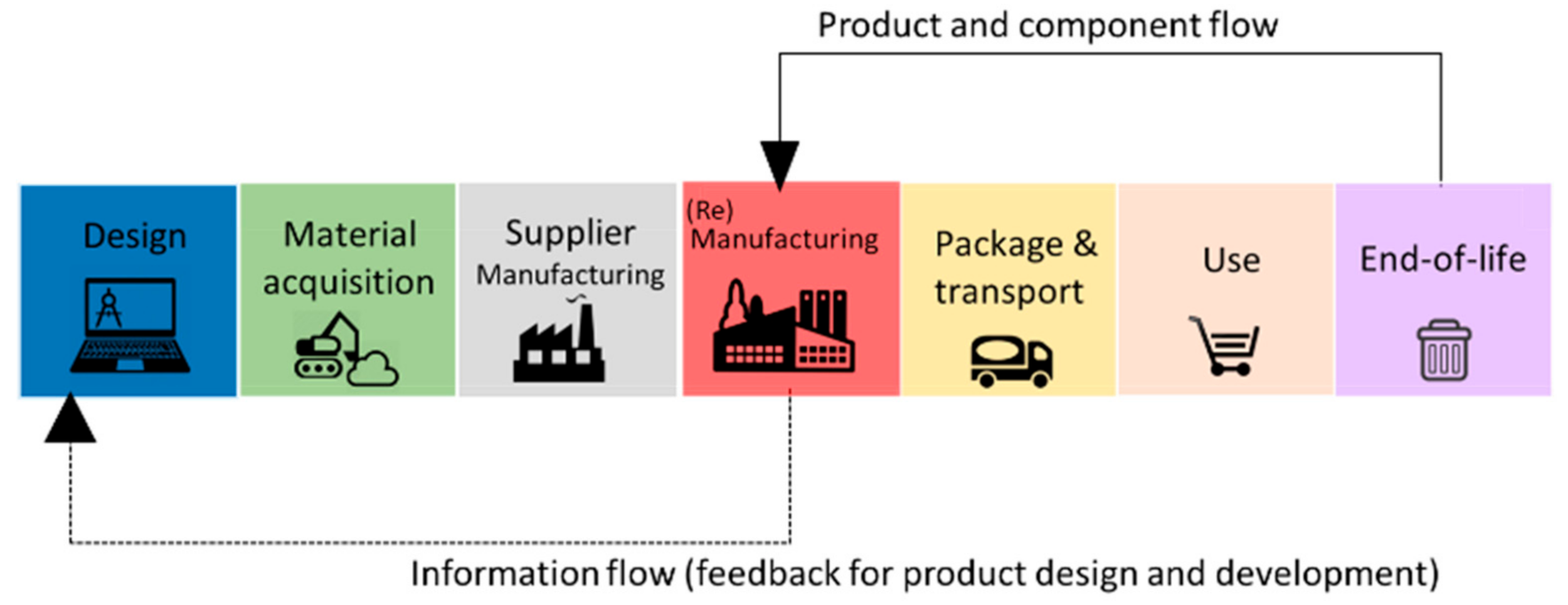

3.2. Product Design and Development

- Make exchange and faulty components easily accessible

- Make it easy to inspect the product and its components

- Make it easy to clean the product and its components

- Make it easy to disassemble the product and its components nondestructively

- Use durable and robust components and materials, e.g., corrosion-resistance

- Use fasteners and connectors that can be easily opened and closed multiple times

- Design with standardized fasteners and components across different products and models

- Design to use standard tools across different products and models

- Make spare parts and exchange components easily available

- Adapt a modular design

- Investigate how current and upcoming laws and regulations affect product design

- Design the product with a focus on functionality and upgradability

3.3. Automation

4. Empirical Study

4.1. Step A: Remanufacturing Processes—Connection to Product Design and Automation

4.2. Step B: Circular Design Guidelines—Connection to Current and Future Products

5. Analysis and Discussion

5.1. Product Design Potentials for Remanufacturing Processes

- (1)

- Designing products to be easily and nondestructively disassembled is vital for future remanufacturing; however, currently, remanufactured products can already be disassembled easily to a large extent.

- (2)

- Designing products and components with durable and robust materials is vital for future remanufacturing; however, currently remanufactured products are already robust to a large extent, i.e., they do not break with disassembly and reassembly.

- (3)

- Treating remanufacturing waste (faulty/broken/exchanging components) appropriately is vital for future remanufacturing; however, waste from remanufacturing processes is already being handled correctly.

- (4)

- Product design and development improvement to facilitate remanufacturing processes in the future mainly lies in design for accessibility, design for ease of cleaning, inspection and disassembly, the use of durable and robust materials and components, design improvements on fasteners and connectors, design standardization of components and tools, the adoption of modular design and the availability of spare parts and repair manuals. In addition, the exchanging component within the remanufacturing processes should be handled correctly for a proper end-of-life scenario.

- (1)

- Some guidelines, including using recyclable and recycled material, using renewable material, using digitalized solution and making it easy to identify the material, are not deployed for currently remanufactured products at the studied companies. However, some improvements are required for the future.

- (2)

- The guidelines for designing to ease inspection and providing repair manuals received completely diverse answers from each company (i.e., N- > y, N- > Y and y- > Y). Nevertheless, answers indicate improvement requirements for the future.

- (3)

- Several guidelines had been deployed to some extent for currently remanufactured products at the companies studied; however, the deployments need to be much better in the future. These guidelines include design for accessibility, design for ease of cleaning, design for standardized components and tools, design improvements on fasteners and connectors, the availability of spare parts, and the adoption of modular design.

- (1)

- Some design guidelines (in the red area) are vital and imperative to facilitate remanufacturing in the future, and these guidelines are not currently being deployed at all. Thus, these design guidelines need to be prioritized for future product development. These guidelines include making it easy to inspect, making it easy to identify materials and relevant information and providing repair manuals.

- (2)

- There are some potential product design improvements (in the yellow area) that can facilitate remanufacturing in the future. These potential product design improvements are either currently deployed to some extent but can be applied to a larger extent or they are not deployed at all but need to be.

- (3)

- There are several design guidelines (in the green area) that are currently deployed to the right extent and already facilitate remanufacturing. Hence, no product design changes are required now.

- (4)

- Timeless design and the adoption of customer requirements were not found to be a concern to the facilitation of remanufacturing at the studied companies. This can be basically justified by the product type at the studied remanufacturing companies as well as the absence of OEMs in our study.

5.2. Automation Potential in the Remanufacturing Processes

5.3. Connecting Automation to Product Design for Remanufacturing Processes

- Potential areas for automation in each remanufacturing process (shown in gray cells with ✓)

- Potential product design improvements in each remanufacturing process (imported guideline numbers and colors from Figure 4)

6. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Prendeville, S.; Bocken, N. Design for Remanufacturing and Circular Business Models. In Sustainability through Innovation in Product Life Cycle Design; Matsumoto, M., Masui, K., Fukushige, S., Kondoh, S., Eds.; Springer: Singapore, 2017; pp. 269–283. [Google Scholar]

- Hatcher, G.D.; Ijomah, W.L.; Windmill, J.F.C. Design for remanufacture: A literature review and future research needs. J. Clean. Prod. 2011, 19, 2004–2014. [Google Scholar] [CrossRef]

- Tukker, A. Product services for a resource-efficient and circular economy—A review. J. Clean. Prod. 2015, 97, 76–91. [Google Scholar] [CrossRef]

- Bakker, C.; Wang, F.; Huisman, J.; Hollander, M.D. Products that go round: Exploring product life extension through design. J. Clean. Prod. 2014, 69, 10–16. [Google Scholar] [CrossRef]

- Sakao, T.; Sundin, E. How to improve remanufacturing?—A systematic analysis of practices and theories. J. Manuf. Sci. Eng. 2019, 141, 141. [Google Scholar] [CrossRef]

- Wang, L.; Gao, R.; Váncza, J.; Krüger, J.; Wang, X.; Makris, S.; Chryssolouris, G. Symbiotic human-robot collaborative assembly. CIRP Ann. 2019, 68, 701–726. [Google Scholar] [CrossRef] [Green Version]

- Sundin, E.; Backman, B.; Johansen, K.; Hochwallner, M.; Landscheidt, S.; Shahbazi, S. Automation Potential in the Remanufacturing of Electric and Electronic Equipment (EEE). In Proceedings of the 9th Swedish Production Symposium, Jönköping, Sweden, 7–8 October 2020. [Google Scholar]

- Ellen MacArthur Foundation. Towards the Circular Economy. Economic and Business Rationale for an Accelerated Transitio-Executive Summary; Ellen MacArthur Foundation: Cowes, UK, 2012. [Google Scholar]

- The European Commission. Closing the Loop—An EU Action Plan for the Circular Economy COM/2015/0614; The European Commission: Brussels, Belgium, 2015. [Google Scholar]

- Pigosso, D.; McAloone, T. How can design science contribute to a circular economy? In Proceedings of the International Conference on Engineering Design ICED, Vancouver, BC, Canada, 21–25 August 2017. [Google Scholar]

- Sundin, E. Product and Process Design for Successful Remanufacturing; Linköping University Electronic Press: Linköping, Sweden, 2004. [Google Scholar]

- Kerr, W.; Ryan, C. Eco-efficiency gains from remanufacturing: A case study of photocopier remanufacturing at Fuji Xerox Australia. J. Clean. Prod. 2001, 9, 75–81. [Google Scholar] [CrossRef]

- Nasr, N.; Russell, J. UNEP International Resource Panel, Re-Defining Value: The Manufacturing Revolution-Remanufacturing, Refurbishment, Repair and Direct Reuse in the Circular Economy. IRP Reports. Available online: https://www.resourcepanel.org/reports/re-defining-value-manufacturing-revolution (accessed on 20 December 2018).

- Kernbaum, S.; Franke, C.; Seliger, G. Flat screen monitor disassembly and testing for remanufacturing. Int. J. Sustain. Manuf. 2008, 1, 347. [Google Scholar] [CrossRef]

- Shahbazi, S.; Jönbrink, A.K. Design Guidelines to Develop Circular Products: Action Research on Nordic Industry. Sustainability 2020, 12, 3679. [Google Scholar] [CrossRef]

- Yin, R.K. Case Study Research: Design and Methods, 5th ed.; SAGE Publications, Inc: Thousand Oaks, CA, USA, 2014. [Google Scholar]

- Miles, M.B.; Huberman, A.M. Qualitative Data Analysis: An Expanded Sourcebook; SAGE Publications: Thousand Oaks, CA, USA, 1994. [Google Scholar]

- Blomsma, F.; Pieroni, M.; Kravchenko, M.; Pigosso, D.C.; Hildenbrand, J.; Kristinsdottir, A.R.; Kristoffersen, E.; Shahbazi, S.; Nielsen, K.; Jönbrink, A.K.; et al. Developing a circular strategies framework for manufacturing companies to support circular economy oriented innovation. J. Clean. Prod. 2019, 241, 118271. [Google Scholar] [CrossRef]

- Östlin, J. On Remanufacturing Systems: Analysing and Managing Material Flows and Remanufacturing Processes. In Linköping Studies in Science and Technology; Production Systems, Department of Management and Engineering, Linköping University: Linköping, Sweden, 2008. [Google Scholar]

- Lindkvist Haziri, L.; Sundin, E. Supporting design for remanufacturing—A framework for implementing information feedback from remanufacturing to product design. J. Remanuf. 2020, 10, 57–76. [Google Scholar] [CrossRef] [Green Version]

- Shao, J.; Huang, S.; Lemus-Aguilar, I.; Ünal, E. Circular business models generation for automobile remanufacturing industry in China. J. Manuf. Technol. Manag. 2019, 31, 542–571. [Google Scholar] [CrossRef]

- Wei, S.; Cheng, D.; Sundin, E.; Tang, O. Motives and barriers of the remanufacturing industry in China. J. Clean. Prod. 2015, 94, 340–351. [Google Scholar] [CrossRef]

- Gunasekara, H.; Gamage, J.; Punchihewa, H. Remanufacture for sustainability: Barriers and solutions to promote automotive remanufacturing. Procedia Manuf. 2020, 43, 606–613. [Google Scholar] [CrossRef]

- Shahbazi, S.; Wiktorsson, M.; Kurdve, M.; Jönsson, C.; Bjelkemyr, M. Material efficiency in manufacturing: Swedish evidence on potential, barriers and strategies. J. Clean. Prod. 2016, 127, 438–450. [Google Scholar] [CrossRef]

- Kurilova-Palisaitiene, J.; Sundin, E.; Poksinska, B. Remanufacturing challenges and possible lean improvements. J. Clean. Prod. 2018, 172, 3225–3236. [Google Scholar] [CrossRef]

- Lee, H.M. An Ontology-Based Product Design Adviser for Assessing End-of-Life (EoL) Performance. Ph.D. Thesis, Nanyang Technological University, Singapore, 2008. [Google Scholar]

- Kuo, T.-C.; Huang, S.H.; Zhang, H.-C. Design for manufacture and design for ‘X’: Concepts, applications, and perspectives. Comput. Ind. Eng. 2002, 41, 241–260. [Google Scholar] [CrossRef]

- Go, T.; Wahab, D.A.; Hishamuddin, H. Multiple generation life-cycles for product sustainability: The way forward. J. Clean. Prod. 2015, 95, 16–29. [Google Scholar] [CrossRef]

- Vezzoli, C.; Manzini, E. Design for Environmental Sustainability; Springer: London, UK, 2008. [Google Scholar]

- Branowski, B.; Zabłocki, M.; Sydor, M. The Material Indices Method in the Sustainable Engineering Design Process: A Review. Sustainability 2019, 11, 5465. [Google Scholar] [CrossRef] [Green Version]

- Battaïa, O.; Dolgui, A.; Heragu, S.S.; Meerkov, S.M.; Tiwari, M.K. Design for manufacturing and assembly/disassembly: Joint design of products and production systems. Int. J. Prod. Res. 2018, 56, 7181–7189. [Google Scholar] [CrossRef] [Green Version]

- Soh, S.; Ong, S.; Nee, A. Design for assembly and disassembly for remanufacturing. Assem. Autom. 2016, 36, 12–24. [Google Scholar] [CrossRef]

- Boks, C.; McAloone, T.C. Transitions in sustainable product design research. Int. J. Prod. Dev. 2009, 9, 429. [Google Scholar] [CrossRef]

- Knight, P.; Jenkins, J.O. Adopting and applying eco-design techniques: A practitioners perspective. J. Clean. Prod. 2009, 17, 549–558. [Google Scholar] [CrossRef] [Green Version]

- Rodrigues, V.P.; Pigosso, D.C.A.; McAloone, T.C. Measuring the implementation of ecodesign management practices: A review and consolidation of process-oriented performance indicators. J. Clean. Prod. 2017, 156, 293–309. [Google Scholar] [CrossRef] [Green Version]

- Hultgren, N. Guidelines and Design Strategies for Improved Product Recyclability—How to Increase the Recyclability of Consumer Electronics and Domestic Appliances through Product Design. Master’s Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2012. [Google Scholar]

- Hu, Q.; Peng, Y.; Guo, C.; Cai, D.; Su, P. Dynamic Incentive Mechanism Design for Recycling Construction and Demolition Waste under Dual Information Asymmetry. Sustainability 2019, 11, 2943. [Google Scholar] [CrossRef] [Green Version]

- Lindkvist Haziri, L.; Sundin, E.; Sakao, T. Feedback from Remanufacturing: Its Unexploited Potential to Improve Future Product Design. Sustainability 2019, 11, 4037. [Google Scholar] [CrossRef] [Green Version]

- Sundin, E.; Elo, K.; Lee, H.M. Design for automatic end-of-life processes. Assem. Autom. 2012, 32, 389–398. [Google Scholar] [CrossRef] [Green Version]

- Browne, J.; Dubois, D.; Rathmill, K.; Sethi, S.P.; Stecke, K.E. Classification of flexible manufacturing systems. FMS Mag. 1984, 2, 114–117. [Google Scholar]

- Zheng, C.; Qin, X.; Eynard, B.; Bai, J.; Li, J.; Zhang, Y. SME-oriented flexible design approach for robotic manufacturing systems. J. Manuf. Syst. 2019, 53, 62–74. [Google Scholar] [CrossRef]

- Vincent, L.W.H.; Ponnambalam, S.; Kanagaraj, G. Differential evolution variants to schedule flexible assembly lines. J. Intell. Manuf. 2014, 25, 739–753. [Google Scholar] [CrossRef]

- Huang, J.; Pham, D.T.; Li, R.; Qu, M.; Wang, Y.; Kerin, M.; Su, S.; Ji, C.; Mahomed, O.; Khalil, R.; et al. An experimental human-robot collaborative disassembly cell. Comput. Ind. Eng. 2021, 155, 107189. [Google Scholar] [CrossRef]

- Gopinath, V.; Johansen, K. Understanding situational and mode awareness for safe human-robot collaboration: Case studies on assembly applications. Prod. Eng. 2019, 13, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Wegener, K.; Chen, W.H.; Dietrich, F.; Dröder, K.; Kara, S. Robot assisted disassembly for the recycling of electric vehicle batteries. Procedia Cirp 2015, 29, 716–721. [Google Scholar] [CrossRef]

- Bauer, W.; Bauer, W.; Bender, M.; Braun, M.; Rally, P.; Scholtz, O. Lightweight Robots in Manual Assembly—Best to Start Simply; Frauenhofer-Institut für Arbeitswirtschaft und Organisation IAO: Stuttgart, Germany, 2016. [Google Scholar]

- Pigosso, D.C.; Zanette, E.T.; Filho, A.G.; Ometto, A.R.; Rozenfeld, H. Ecodesign methods focused on remanufacturing. J. Clean. Prod. 2010, 18, 21–31. [Google Scholar] [CrossRef]

- Sundin, E.; Östlin, J.; Öhrwall Rönnbäck, A.; Lindahl, M.; Sandström, G. Remanufacturing of products used in product service system offerings. In Manufacturing Systems and Technologies for the New Frontier; Springer: Berlin/Heidelberg, Germany, 2008; pp. 537–542. [Google Scholar]

- Charter, M.; Gray, C. Remanufacturing and product design. Int. J. Prod. Dev. 2008, 6, 375–392. [Google Scholar] [CrossRef] [Green Version]

- ISO. 10218–1/2:2011, Robots and Robotic Devices—Safety Requirements for Industrial Robots—Part 1: Robots/Part 2: Robot Systems and Integration; International Organization for Standardization: Geneva, Switzerland, 2011. [Google Scholar]

- Wilson, M. Implementation of Robot Systems: An Introduction to Robotics, Automation, and Successful Systems Integration in Manufacturing; Butterworth-Heinemann: Oxford, UK, 2014. [Google Scholar]

- Liker, J. The Toyota Way: 14 Management Principles from the World’s Greatest Manufacturer: 14 Management Principles from the World’s Greatest Manufacturer; Mcgraw-Hill: New York, NY, USA, 2003. [Google Scholar]

- Subramoniam, R.; Sundin, E.; Subramoniam, S.; Huisingh, D. Riding the Digital Product Life Cycle Waves towards a Circular Economy. Sustainability 2021, 13, 8960. [Google Scholar]

| Company | Product | Type of Remanufacturer | Experience |

|---|---|---|---|

| Company A | IT equipment | Independent | 21 years |

| Company B | Photocopiers | Contracted | 36 years |

| Company C | Car electronics | Contracted | 43 years |

| Remanufacturing Processes | If Product Design Facilitates? (A1) | If Automation Facilitates? (A2) | ||||

|---|---|---|---|---|---|---|

| Companies | Companies | |||||

| A | B | C | A | B | C | |

| Inspection | Y | Y | y | y | y | y |

| Disassembly | Y | Y | Y | y | y | Y |

| Cleaning | Y | Y | y | y | y | y |

| Reprocess | y | y | y | y | y | Y |

| Reassembly | Y | Y | Y | y | y | Y |

| Testing | N | N | N | N | N | N |

| Design Guidelines | Brief Description | Relevancy to Remanufacturing |

|---|---|---|

| (1) Make exchanging and faulty components easily accessible | Make disassembly points and components subject to break, wear or fail easily accessible and preferably from one side | *** very relevant |

| (2) Make it easy to inspect the product and its components | Make it easy and safe to inspect the product and components, particularly exchanging components. Use indications and repair manuals for testing and inspections | *** very relevant |

| (3) Make it easy to clean the product and its components | Avoid shapes and areas that dirt might collect in such as small holes, nooks, grooves and sharp edges. Select materials that are easy to clean. All components should be able to withstand the same chemicals, mechanical cleaning processes, and temperatures | *** very relevant |

| (4) Make it easy to disassemble the product and its components nondestructively | Make it easy to open and dismount in a nondestructive way. Use less glue and adhesives. Ensure the robustness and wear resistance of fasteners. Allow disassembly from one side. Provide manuals | *** very relevant |

| (5) Use durable and robust components and materials | Choose durable, corrosion-resistant and robust components and materials with a long lifespan. The lifespan of the different parts should be recognizable with indicators for wear. Avoid materials that might lose strength, get brittle or get discolored | *** very relevant |

| (6) Use fasteners and connectors that can be easily opened and closed multiple times | Minimize the number of connectors and fasteners. Ensure the robustness and wear resistance of fasteners. Prioritize latch, snaps, clips, bolts and screws over welding, rivets, folding, staples and gluing, which make fasteners more difficult to demount | *** very relevant |

| (7) Design with standardized fasteners and components across different products and models | The compatibility and exchangeability of components are required across other models and products, e.g., same type and size of screws | *** very relevant |

| (8) Design to use standard tools across different products and models | The compatibility and adaptability of tools are required across other models and products, e.g., same type and size of screwdriver to dismantle | *** very relevant |

| (9) Make spare parts and exchanging components easily available | Exchanging components of products must be easy to find on the market and preferably be inexpensive or 3D-printable with additive manufacturing technologies | *** very relevant |

| (10) Adapt a modular design | Divide the product into different modules and put all of the components that need to be exchanged or upgraded into one single module, thus lowering the effort | *** very relevant |

| (11) Investigate current and upcoming laws and regulations | Comply with applicable laws and regulations such as those regarding hazardous materials or chemicals that are or will be thought to be harmful and might be banned | *** very relevant |

| (12) Focus mainly on functionality and quality performance | Focus mainly on functionality and quality performance, as age, make and model are less important as long as the quality-performance is delivered. Ensure plan upgradability | *** very relevant |

| (13) Make it easy to identify the materials and relevant information | Create a system for the identification of the individual components by, for example, RFID, barcode, tag or QR-code. Provide additional information about the product regarding the material’s content, the material’s age, the number of times recycled, the additives used, the guide to component separation and the process for the recycling. | ** relevant |

| (14) Consider the toxicity and other environmental aspects of the materials | Use materials that that do not threaten biodiversity and do not contain hazardous chemicals. Select materials that do not degenerate during multiple lifecycles. Select materials with verified reliability. Avoid materials that lose strength, get brittle or get discolored | ** relevant |

| (15) Provide repair manuals and documentation | Provide user-friendly repair manuals and documentation on how to repair, upgrade, etc. with signs on how to open the product and exchange components | ** relevant |

| (16) Think about activity support in the operational stage | Think about activity support during the operational stage of the product/service to make the system run as efficiently as possible, e.g., supplying replacement materials, maintenance services, repair and control in post-use | ** relevant |

| (17) Focus to fulfill the customer’s requirements and value creation | Develop a close relationship with the customer to understand their requirements, develop capabilities accordingly and adjust personalized services with individual access. The service design cycle is continuously repeated and improved to be able to adapt to various human factors and requirements | ** relevant |

| (18) Consider timeless design, emotional attachment and compatibility | Think about the effects that time and fashion will have on your product. Simplicity, timeless design and compatibility can be some ways to give the product longevity (e.g., a USB device) | ** relevant |

| (19) Treat remanufacturing waste appropriately | Think about the type and amount of waste generated in remanufacturing processes. What segment and fraction of those broken/exchanging components can be separated to be able to facilitate recycling? | ** relevant |

| (20) Try to use digitalization, ICT and IoT solutions | IoT and digitalization enable data collection about the usage behavior and product performance throughout a product’s lifecycle. This aids in the discovery of latent design errors and in the understanding of what components are going to fail and when, such that repair and maintenance can be planned with minimum effect on the products’ performance | * can be relevant |

| (21) Design using renewable materials | Reduce the use of materials that are limited in quantities such as tin and precious metals, and use more renewable and bio-based materials, if possible | * can be relevant |

| (22) Design using recyclable and secondary (recycled) materials | Choose materials that have a high recycling rate and an available recycling technology and market. Increase the materials’ compatibility so that only one recycling method is needed. Increase the proportion of recycled materials in your product and use less virgin raw materials | * can be relevant |

| (23) Favor cleaner production, processes, machines and equipment | Favor manufacturing processes, machines and equipment that use less energy and materials, generate less waste and discharges less into the air and water. Select machines and equipment that require less frequent maintenance and cleaning and possess a good working environment and ergonomic value | * can be relevant |

| (24) Design for reduced energy consumption and usage of renewable energy | Design the product with reduced energy consumption by using renewable and clean energy. Select production processes with high energy efficiency to reduce energy consumption. Consider the energy recovery of biological nutrients | * can be relevant |

| (25) Minimize the number of different incompatible or dissimilar materials | Minimize the number of different incompatible or dissimilar materials to facilitate shredding, regeneration and recycling. Avoid molding and fusing incompatible materials. Avoid multi-materials and composites | * can be relevant |

| Generic Design Guidelines | Company A | Company B | Company C | |||

|---|---|---|---|---|---|---|

| Current Products | Future Products | Current Products | Future Products | Current Products | Future Products | |

| (1) Make exchanging and faulty components easily accessible | N | Y | y | Y | y | Y |

| (2) Make it easy to inspect the product and its components | N | Y | y | Y | N | y |

| (3) Make it easy to clean the product and its components | y | Y | y | Y | N | y |

| (4) Make it easy to disassemble the product and its components nondestructively | Y | Y | Y | Y | N | Y |

| (5) Use durable and robust components and materials | Y | Y | y | y | Y | Y |

| (6) Use fasteners and connectors that can be easily opened and closed multiple times | y | Y | y | Y | y | Y |

| (7) Design with standardized fasteners and components across different products and models | y | Y | y | Y | N | Y |

| (8) Design to use standard tools across different products and models | N | Y | y | Y | y | Y |

| (9) Make spare parts and exchanging components easily available | y | Y | y | Y | y | Y |

| (10) Adapt a modular design | N | Y | y | Y | y | Y |

| (11) Investigate current and upcoming laws and regulations | y | y | y | y | y | y |

| (12) Focus mainly on functionality and quality performance | y | y | y | y | y | y |

| (13) Make it easy to identify the materials and relevant information | N | y | y | y | N | y |

| (14) Consider toxicity and other environmental aspects of materials | y | y | y | y | y | y |

| (15) Provide repair manuals and documentation | N | y | N | Y | y | Y |

| (16) Think about activity support in the operational stage | y | y | y | y | - | - |

| (17) Focus to fulfill the customer’s requirements and value creation | - | - | y | y | - | - |

| (18) Consider timeless design, emotional attachment and compatibility | - | - | - | - | - | - |

| (19) Treat remanufacturing waste appropriately | Y | Y | Y | Y | Y | Y |

| (20) Try to use digitalization, ICT and IoT solutions | N | y | y | y | N | y |

| (21) Design using renewable materials | N | y | N | y | N | N |

| (22) Design using recyclable and secondary (recycled) materials | N | y | N | y | N | y |

| (23) Favor cleaner production, processes, machines and equipment | y | y | y | y | y | Y |

| (24) Design for reduced energy consumption and usage of renewable energy | y | y | y | y | y | y |

| (25) Minimize the number of different incompatible or dissimilar materials | y | y | y | y | N | y |

| Remanufacturing Process | Company A | Company B | Company C |

|---|---|---|---|

| Inspection | Software upgrade for faster inspection (N/A) | ||

| Disassembly | Disconnecting laptops (Coexistence) | Dismantling toner cartridges (Synchronized) | Removing sealant (Cell) |

| Cleaning | Removing toner (Synchronized) | Cleaning the core (Cooperation) | |

| Reprocessing | Data erasing (N/A) | Refilling (Coexistence) | Exchange of components (Coexistence) |

| Reassembly | Connecting laptops for data erasing (Coexistence) | Sealing (Coexistence) | |

| Testing |

| Remanufacturing Processes | Product Design Facilitation via Guidelines (Section 5.1) | Automation Facilitation (Section 5.2) | |

|---|---|---|---|

| Vital and Imperative Design Changes | Potential Design Improvements | ||

| Inspection | 2, 15 | 20 | ✓ |

| Disassembly | 15 | 6, 7, 8, 10 | ✓ |

| Cleaning | 15 | 3 | ✓ |

| Reprocess | 13, 15 | 1, 7, 8, 9, 10, 20, 21, 22 | ✓ |

| Reassembly | 15 | 6, 7, 8, 10 | ✓ |

| Testing | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shahbazi, S.; Johansen, K.; Sundin, E. Product Design for Automated Remanufacturing—A Case Study of Electric and Electronic Equipment in Sweden. Sustainability 2021, 13, 9039. https://doi.org/10.3390/su13169039

Shahbazi S, Johansen K, Sundin E. Product Design for Automated Remanufacturing—A Case Study of Electric and Electronic Equipment in Sweden. Sustainability. 2021; 13(16):9039. https://doi.org/10.3390/su13169039

Chicago/Turabian StyleShahbazi, Sasha, Kerstin Johansen, and Erik Sundin. 2021. "Product Design for Automated Remanufacturing—A Case Study of Electric and Electronic Equipment in Sweden" Sustainability 13, no. 16: 9039. https://doi.org/10.3390/su13169039

APA StyleShahbazi, S., Johansen, K., & Sundin, E. (2021). Product Design for Automated Remanufacturing—A Case Study of Electric and Electronic Equipment in Sweden. Sustainability, 13(16), 9039. https://doi.org/10.3390/su13169039