3.1. Raw Material Quality Analysis

Vegetable outgrades and vegetables such as potatoes and carrots, which were utilized as raw materials in laboratory tests, were characterized by the parameters presented in

Table 2. Average nutrient contents determined in the plant material were comparable to the data for full-value vegetables listed in nutritional tables [

28] and in the USDA National Nutrient Database for Standard Reference [

29]. Vegetable outgrade was characterized by a higher fiber content, ranging from 1.89 g/100 g for cauliflower to 4.74 g/100 g for string beans compared with the nutritional values of frozen vegetables shown in the tables.

Color is an important distinguishing feature of plant material quality.

Table 3 shows the colors of vegetable outgrades and vegetables. It was observed during the research that the technological process of obtaining vegetable outgrades, as well as the conditions of preparation of remaining vegetables, including blanching, did not affect their color. The potato had the lightest color (L* = 66.22), the cauliflower floret outgrades were a little darker (L* = 63.68), followed by onion outgrades (L* = 61.59); broccoli floret outgrades had the darkest color (L* = 27.20). The a* component of the color ranged from −11.51 for green bean outgrades to 24.02 for carrots. The b* index ranged from 3.3 for cauliflower head outgrades to 31.58 for carrots. These varied color results were caused by the natural colors of vegetables derived from natural pigments in fruits and vegetables, many of which differ with the variety, as well as with the plant’s growth and maturation. Natural pigments found in fruits and vegetables include chlorophylls (green), carotenoids (yellow, orange and red) and anthocyanins (red, blue), as well as flavonoids (yellow) and betalains (red). In addition, enzymatic and non-enzymatic browning reactions can produce brown, gray and black colors. Technological processes that vegetables are subjected to may cause changes in their colors. Chlorophylls are sensitive to heat and acid but stable in an alkaline environment, while carotenoids are susceptible to light and oxidation, but they are relatively stable at elevated temperatures. Anthocyanins are sensitive to both pH and temperature, while flavonoids are sensitive to oxidation, but they are relatively stable during temperature changes [

30].

Technological treatments related to thermal processing affect the color of vegetables to a varying degree [

31]. Literature data indicate a lower temperature stability of chlorophyll, which is responsible for the color in green vegetables [

32,

33,

34]. Yuan et al. [

35] showed that boiling water and microwave cooking resulted in high chlorophyll loss in broccoli, while steaming did not significantly reduce chlorophyll content. In contrast, blanched green peas were visually lighter than unblanched and frozen-stored peas [

36]. Lau et al. [

37] noticed an initial increase in the green color of green asparagus during heat treatment at 70–98 °C. Analogous results of the increase in the green color were also observed for broccoli subjected to blanching in hot water and steam [

38]. Blanching of vegetables changes their color and the degree of these changes depends on the type of blanching. Less color changes are observed in steam blanching compared with the process carried out in water. Sobol et al. [

39] demonstrated that the stimulation of potato tubers with UV-C rays before processing had a beneficial effect on the color of French fries, while blanching potato strips and soaking in water at 40 ºC resulted in the production of lighter colored French fries.

3.2. Vegeburger Properties

Vegeburgers were prepared in accordance with the presented workflow (

Figure 1), using a prototype test stand. The physicochemical properties of vegeburgers, depending on the formula (I-IV), are presented in

Table 4, the color is described in

Table 5 and texture in

Table 6. The amounts of basic nutrients, such as protein and fat, did not differ significantly depending on recipe composition (

Table 4). Protein content for the developed burgers ranged from 2.05 to 2.29 g∙100 g

−1, carbohydrate content was 7.27–10.36 g∙100 g

−1 and fiber content ranged from 3.97 to 4.92 g∙100 g

−1. Fat content in the developed vegeburgers was at the level of 0.20–0.24 g ∙ 100 g

−1. The content of ingredients such as salt and fat did not exceed 1 g and 0.3 g per 100 g of the product. The amount of disqualifying nutrients (fat, trans fat, saturated fat and cholesterol) was significantly lower compared to similar products on the market [

40].

Per serving, vegetables are high in essential vitamins, minerals, protein and dietary fiber, they do not contain cholesterol and are low in fat. Meat contains high amounts of protein, B vitamins and minerals such as iron and zinc per unit body weight, and minerals such as iron and zinc per serving unit. On a dietary level, replacing a portion of meatball meat in the daily diet can both reduce environmental impact and improve consumer nutritional outcomes [

41,

42,

43]. The results of the research confirmed the potential of vegetables, in this case also of vegetable outgrades, in terms of improving the nutritional value of food products and their great potential in formulating diets and food systems. Chaudhary and Tremorin [

44] demonstrated the potential of using lentils as a part of meat replacement in burgers.

Color parameters of vegeburgers are given in

Table 5. The light parameter (L*) ranged from 56.18 to 64.20, the a* index ranged from 5.49 to 6.73 and the b* parameter ranged from 18.21 to 28.20. Color parameters result from the natural color of the applied plant components. In addition, color discrepancies in individual formulas result from the application of a heterogenous raw material with a high basis weight.

Despite the variable composition of formulas, texture parameters of vegeburgers were comparable (

Table 6). However, the differences obtained in the values of the elasticity, gumminess and chewiness parameters were due to the non-uniform composition of the raw material of vegeburgers (vegetable outgrades) (

Figure 4). The presence of non-fragmented parts of vegetables, on the one hand, influences product attractiveness for consumers, and on the other hand, pose a technological challenge in the mechanical mass formation.

According to Bourne [

45], the properties of food texture are assessed as a group of physical features that result from the food structure and are sensed by touch, and at the same time are related to deformation, disintegration and the flow of products under force. For consumers, particle size is one of the key physical characteristics of a food that makes it attractive. For example, ice crystals with a volume of 10–20 μm cause ice creams to be perceived as very smooth, while larger crystals with a volume of 50 μm give the perception of graininess [

46]. The size of particles in chocolate influences the assessment of its desirability [

47], and in the case of syrups, their overall attractiveness [

48].

The analysis of textural properties was used to modify the technical assumptions of the model station and to identify the dependence of their influence on the hardness, cohesiveness, gumminess, springiness and chewiness of vegeburgers in various recipe combinations, and thus to develop methods to maintain product quality, while changing the composition.

3.3. Test Stand Analysis

During the analysis in the test stand, compact vegetable mass was placed in the mold, and subsequently the mold assembly was dynamically moved using a pneumatic drive and knocked out of the sleeve with a striker (

Figure 5). After forming, vegetable mass in the form of a cutlet remained compact. The burger did not come apart when it was knocked out of the mold and dropped onto the transport net.

Figure 6 shows the method of testing the effectiveness of transferring a vegeburger from one conveyor to another. Product transition was smooth, it did not stop at the set-off point. On the basis of the conducted research, it was found that vegeburgers retained a compact consistency and did not disintegrate during knocking out or passing from one net to another, and the process was smooth. It was found that the assumed concept of the machine forming process was effective.

Testing the functionality of the test stand provided important information about the effectiveness of the mechanisms provided in the project, the technological line for the production of vegeburgers. According to the WRAP report [

49], reduction in food waste at the preparation stage is 45% and the Sustainable Restaurant Association (SRA) [

50] estimate indicates that avoidable food waste at this stage is 65%.

It was found on the basis of the conducted experimental studies that the design assumptions of the net drive, enabling effective transport and transfer of vegeburgers from one conveyor to another, were correct and did not cause deformation or damage to the product. However, it was observed that the formed products fell out of the mold assembly aperture by themselves. This information was used in the process of designing the forming module included in the prototype technological line.

3.4. Carbon Footprint Determination

Data on electricity consumption for various processes along with the calculated carbon footprint of the experimental vegeburger production are presented in

Table 7. To calculate the carbon footprint, the CO

2 to kWh conversion factor was used, with the value of 0.765 kg CO

2∙kWh

−1 (CO

2 conversion factor for 2018, announced in December 2019 by the National Centre for Emissions Management (KOBIZE)).

The values of the determined carbon footprint of vegeburger production (experimental production), regardless of the formula used, ranged from 0.26 to 0.28 kg CO

2 per kilogram of product. The lowest CF values were obtained for the largest productions (vegetable mass, 5.0 kg and 9.5 kg). Pie charts were prepared to assess the impact of individual steps on the carbon footprint (

Figure 7,

Figure 8,

Figure 9). The following individual processes of vegeburger production were analyzed: potato blanching, potato shredding, green bean shredding, mixing ingredients of vegetable mass and forming vegeburgers. The conducted analyses showed that the highest CO

2 emission occurred during the blanching process. The percentage of this process for small productions (2 kg) ranged from 62% to 68%. The higher the volume of vegeburger production, the bigger the share of the blanching process in the total emission, i.e., also in the carbon footprint (up to approximately 80%). The process of vegeburger formation had the second largest percentage in emissions and accounted for 22% to 24% for small productions (2.0 kg), and decreased drastically to about 15% for larger productions. The smallest percentage was associated with shredding (potatoes and beans).

CF calculation for food products involves different approaches and test ranges. Considering all stages (from agricultural production, through the processing plant, to the consumer) allows the relationships between materials and processes to be determined. For example, it was found when analyzing the carbon footprint for croissants (1.5 kg CO

2/kg of product) that the processing and supply chain had the greatest impact on greenhouse gas emissions [

51]. CF analysis of dairy products, e.g., cheeses (9.88 kg CO

2/kg product) showed that emissions from the production chain (from farm to retailer) accounted for less than 10% of total emissions from cheese production, while it was identified that the highest energy consumption was related to dairy production, including refrigerated storage under the appropriate conditions [

52]. Analogous results showing a significant share of refrigerated storage in food production were confirmed in the carbon footprint analysis only for the production of homogenized strawberry paste (2.47 kg CO

2/kg of product) [

53]. On one hand, the highest CO

2 emission in the production of vegeburgers occurred during the blanching process and its proportion increased with production volume. On the other hand, the shredding of ingredients was associated with the lowest percentage.

The carbon footprint for vegetable outgrades was also determined. The carbon footprint of the plant’s total production (global CF value calculated for the plant) was determined and distributed among individual products based on the data obtained from Unifreeze Sp. z o.o. for a period of three years. The allocation was performed in proportion to the production volume of individual products. The production carbon footprint was calculated for all frozen products produced in the plant, taking into account the sum of all direct and indirect emissions. The amount of emissions was determined based on the data provided by the company for previous years, using the developed methodology, narrowing down the range only to production at the plant (i.e., internal transport, fuel and electricity consumption).

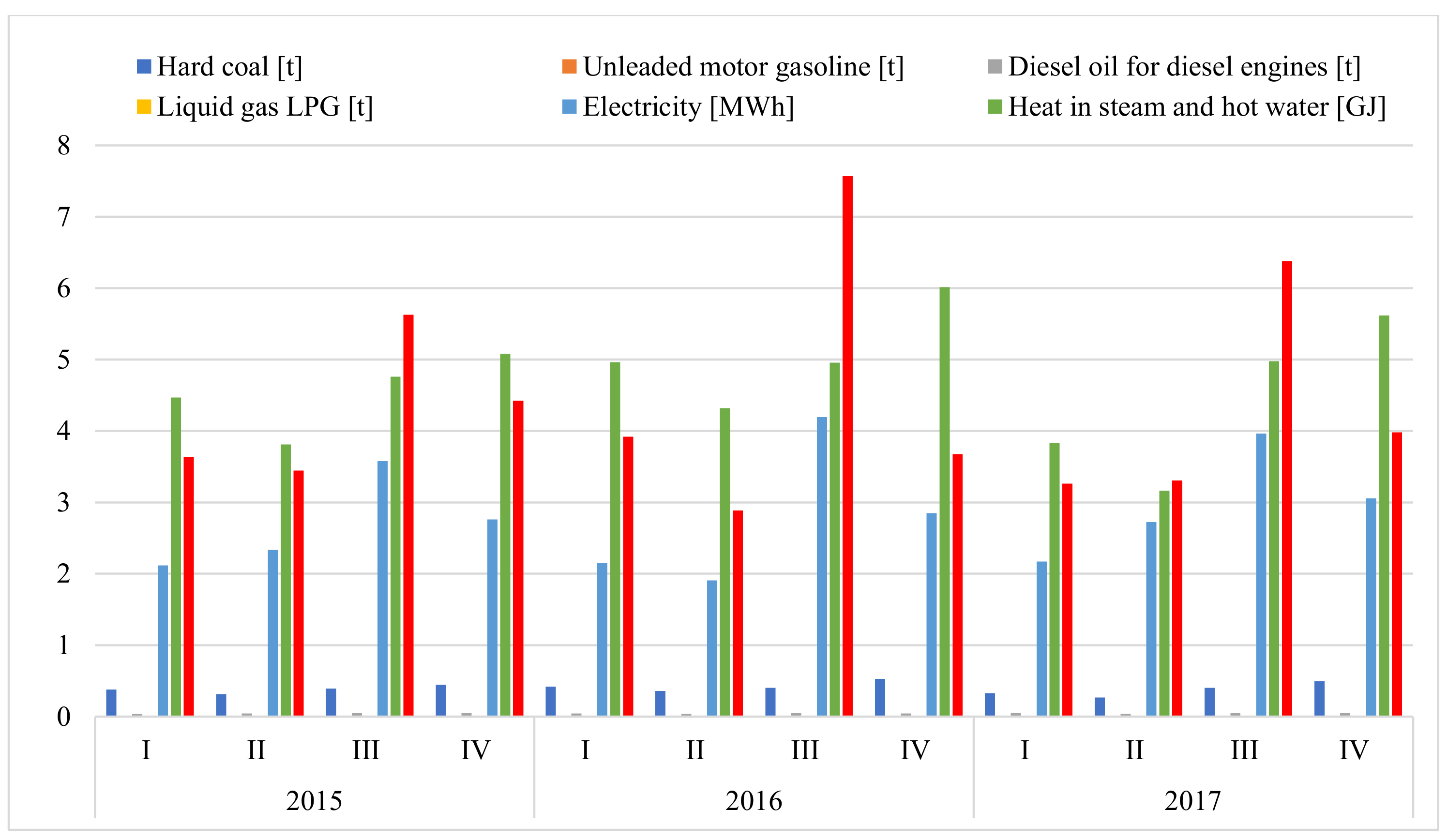

Figure 10 and

Figure 11 show the structure of the production volume and the energy media consumed for three years (2015, 2016, 2017) in a plant producing frozen food. The analysis was based on previously developed process schemes and the prepared indicator base [

20,

22]. On this basis, the carbon footprint of individual frozen products produced in the plant during this period was determined (

Table 8). The carbon footprint of vegetables frozen in the plant, associated only with production, ranged from about 0.6 to 1.1 kg CO

2/kg product. Plant-based protein raw materials usually have a much lower carbon, water and soil footprint than animal raw materials [

54,

55].

In the composition of a vegeburger, depending on the formula (

Table 9), vegetable outgrades accounted for 44% to 54%, while potato content ranged from 23% to 36%. The carbon footprint in experimental production was calculated using the CF values from 2017 based on the calculated carbon footprints of frozen vegetables produced by Unifreeze Sp. z o.o. and the percentages of individual ingredients in vegeburgers. Potato flour and spices used in this study were not included in this analysis due to the lack of CF data, as well as the small percentage of these ingredients. The determined carbon footprint of vegetable outgrades for different formulas and the amount of substrates used in the experimental production of vegeburgers is presented in

Table 10. Depending on the production volume, the CF value was 0.83 kg CO

2/kg vegetable outgrades and 0.85 kg of CO

2/kg vegetable outgrades, respectively. Then, total vegeburger CF was determined for different formulas of vegeburger experimental production taking into account the carbon footprint of vegetable outgrades production in the production plant and vegeburger experimental production. Data are summarized in

Table 11. The total carbon footprint was 1.09–1.13 kg CO

2/kg of product, respectively, i.e., about 0.10–0.12 kg CO

2 per one vegeburger. This method of carbon footprint analysis enables data comparison with other technologies; however, it is necessary to take into account the measurement range adopted for analysis in other cases.

In order to compare carbon footprints of food products, we must take into account the same ranges of applied indices due to the different methods of calculating CFs for these products. Comparison of the CF obtained for vegeburger production (0.26–0.28 kg CO2 per kg of product) with the presented literature data (e.g., CFcroissant = 0.59 kg CO2/kg product, CFcheese = 0.99 kg CO2/kg product, CFstrawberry paste = 2.47 kg of CO2/kg product) showed that production is low energy intensive. On the other hand, extending the scope of the carbon footprint analysis, e.g., by taking into account the production of vegetable outgrades, caused a 4-fold increase in the index, reaching a value of approximately 1.11 per kilogram of product. Nevertheless, the process has a low emission compared with other agri-food technologies.