A Novel Taxonomy for Risks in Agribusiness Supply Chains: A Systematic Literature Review

Abstract

:1. Introduction

- What constructs can be used to define risks in ASCs?

- What kind of risks can be categorised within ASCs?

- How do they affect supply chain performance?

- The constructs used to define ASC risks are explored.

- A novel taxonomy is developed to enrich future research directions for ASC risks.

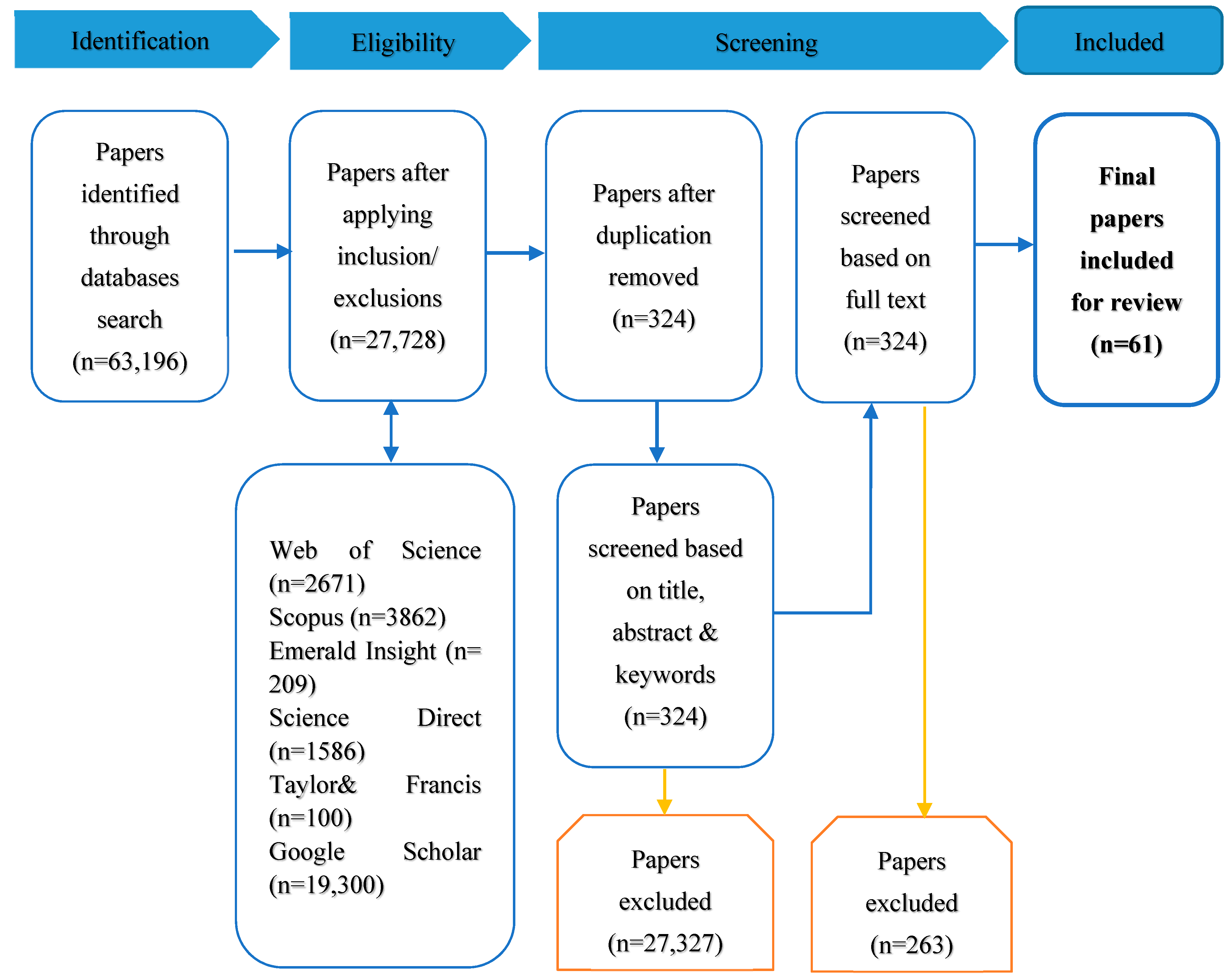

2. Materials and Methods

2.1. Phase 1: Identification

2.2. Phase 2: Eligibility

2.3. Phase 3: Screening

2.4. Phase 4: Included

3. Results

3.1. Descriptive Analysis

3.2. Thematic Analysis

3.2.1. Defining Agribusiness Supply Chain Risk

Supply Chain

Supply Chain Risk

Agribusiness Supply Chain Risk

Agribusiness Risk

| Author (s) | Agribusiness Risks | |

|---|---|---|

| Eremenko et al. (2020) [76] | Types of risks affecting agricultural enterprises | (1) Natural risks, (2) Environmental risks, (3) Field loss risks, (4) Inflationary and deflationary risks, (5) Transportation loss risks, (6) Risks of losses during storage of agricultural products, (7) Bankruptcy risks, (8) Selective risks, and (8) Risks of political instability. |

| Chandrasekaran and Raghuram (2014) [47]; OECD (2009) [75] | Risks in agriculture | (1) Market/price, (2) Production, (3) Financial, and (4) Legal/Institution. |

| Harwood et al. (1999) [77] | Sources of risk in farming | (1) Production or yield, (2) Price or Market, (3) Institutional, (4) Human or personal, and (5) Financial risks. |

| Just and Pope (2002) [78] | Major sources of farm risk | (1) Production, (2) Marketing, (3) Financial, (4) Legal and environmental, and (5) Human resources risks. |

| Hardaker et al. (2015) [79] | Types and sources of agriculture risk | (1) Production, (2) Price or market, (3) Institutional, (4) Political, (5) Sovereign, (6) Contractual, (7) Human or personal, and (8) Business risks. |

3.2.2. Categorising Risks in the Agribusiness Supply Chain (ASC)

Sustainability in the Agribusiness Supply Chain

3.2.3. Understanding How Risks Affect Agribusiness Supply Chain Performance

4. Discussion

4.1. Risk Categories and Risk Factors Exposure in the Agribusiness Supply Chain

4.1.1. Internal Risks

4.1.2. External Risks

- Man-made risks include policy/regulation and events-related disasters. Policy/regulation risks include changes in local policy/regulation; changes in regional/national policy/regulation; periodic changes in interest/exchange rate policies; uncertain land policies/tenure; political issues [47,84,110]; customary land ownership; program schemes of companies that affect local communities; high investment climate, particularly for plantation crops; conversion of forest into plantation crops; stealing of plantation land; and claims for land compensation by customary rights owners. Meanwhile, events-related disasters consist of work accidents and theft [36,47,110,115], for instance, work accidents that pose a risk to company performance and theft of products on the farms that have a significant impact on the profits obtained.

4.1.3. Network Risks

4.2. Future Research Directions

4.2.1. Risks and Sustainability in the Agribusiness Supply Chain

4.2.2. Resilience in the Agribusiness Supply Chain

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gaudenzi, B.; Borghesi, A. Managing risks in the supply chain using the AHP method. Int. J. Logist. Manag. 2006, 17, 114–136. [Google Scholar] [CrossRef]

- Jereb, B.; Cvahte, T.; Rosi, B. Mastering supply chain risks. Serbian J. Manag. 2012, 7, 271–285. [Google Scholar] [CrossRef] [Green Version]

- Yan, B.; Wu, J.; Wang, F. CVaR-based risk assessment and control of the agricultural supply chain. Manag. Decis. 2019, 57, 1496–1510. [Google Scholar] [CrossRef]

- Zsidisin, G.A.; Henke, M. (Eds.) Revisiting Supply Chain Risk; Springer: Gewerbestr, Switzerland, 2019. [Google Scholar]

- Baryannis, G.; Validi, S.; Dani, S.; Antoniou, G. Supply chain risk management and artificial intelligence: State of the art and future research directions. Int. J. Prod. Res. 2018, 57, 2179–2202. [Google Scholar] [CrossRef]

- Carballo, D.A.; Laura, R. Agricultural Supply Chain Risk Assessment in the Caribbean; World Bank: Washington, DC, USA, 2013; pp. 1–4. [Google Scholar]

- Behzadi, G.; O’Sullivan, M.J.; Olsen, T.L.; Zhang, A. Agribusiness supply chain risk management: A review of quantitative decision models. Omega 2018, 79, 21–42. [Google Scholar] [CrossRef]

- Mason-Jones, R.; Towill, D.R. Shrinking the supply chain uncertainty circle. Control 1998, 24, 17–22. [Google Scholar]

- Clay, P.M.; Feeney, R. Analyzing agribusiness value chains: A literature review. Int. Food Agribus. Manag. Rev. 2019, 22, 31–46. [Google Scholar] [CrossRef]

- FAO. The State of Food and Agriculture: Moving Forward on Food Loss Ans Water Reduction; The Food and Agriculture Organization of the United Nations: Rome, Italy, 2019. [Google Scholar]

- Zhao, G.; Liu, S.; Lopez, C.; Chen, H.; Lu, H.; Mangla, S.K.; Elgueta, S. Risk analysis of the agri-food supply chain: A multi-method approach. Int. J. Prod. Res. 2020, 58, 4851–4876. [Google Scholar] [CrossRef]

- Kahan, D. Farm Management Extension Guide: Managing Risk in Farming; Food and Agriculture Organization of the United Nations: New York, NY, USA, 2013. [Google Scholar]

- Leat, P.M.K.; Revoredo-Giha, C. Risk and resilience in agri-food supply chains: The case of the ASDA PorkLink supply chain in Scotland. Supply Chain Manag. Int. J. 2013, 18, 219–231. [Google Scholar] [CrossRef]

- Nyamah, E.Y.; Jiang, Y.; Feng, Y.; Enchill, E. Agri-food supply chain performance: An empirical impact of risk. Manag. Decis. 2017, 55, 872–891. [Google Scholar] [CrossRef]

- Behzadi, G.; O’Sullivan, M.; Olsen, T.L.; Scrimgeour, F.; Zhang, A. Robust and resilient strategies for managing supply disruptions in an agribusiness supply chain. Int. J. Prod. Econ. 2017, 191, 207–220. [Google Scholar] [CrossRef]

- Behzadi, G.; O’Sullivan, M.J.; Olsen, T.L.; Zhang, A. Allocation flexibility for agribusiness supply chains under market demand disruption. Int. J. Prod. Res. 2018, 56, 3524–3546. [Google Scholar] [CrossRef]

- Li, S.; Hu, L. Risk Assessment of Agricultural Supply Chain Based on AHP-FCS in Eastern Area of Hunan Province. In Proceedings of the 2015 International Conference on Logistics, Informatics and Service Sciences (LISS), Barcelona, Spain, 27–29 July 2015. [Google Scholar]

- Lipińska, I. Managing the Risk in Agriculture Production: The Role of Government. Eur. Countrys. 2016, 8, 86–97. [Google Scholar] [CrossRef] [Green Version]

- Ho, W.; Zheng, T.; Yildiz, H.; Talluri, S. Supply chain risk management: A literature review. Int. J. Prod. Res. 2015, 53, 5031–5069. [Google Scholar] [CrossRef]

- Wu, T.; Blackhurst, J. (Eds.) Managing Supply Chain Risk and Vulnerability: Tools and Methods for Supply Chain Decision Makers; Springer: London, UK, 2009. [Google Scholar]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a Methodology for Developing Evidence-Informed Management Knowledge by Means of Systematic Review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Green, K. Conducting Research Literature Reviews: From the Internet to Paper by Arlene Fink, SAGE, Los Angeles, CA. Libr. Inf. Sci. Res. 2010, 32, 290–291. [Google Scholar] [CrossRef]

- Elo, S.; Kyngäs, H. The qualitative content analysis process. J. Adv. Nurs. 2008, 62, 107–115. [Google Scholar] [CrossRef]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G. The PRISMA Group Preferred Reporting Items for Systematic Reviews and Meta-Analyses: The PRISMA Statement. PLoS Med. 2009, 6, e1000097. [Google Scholar] [CrossRef] [Green Version]

- Ali, A.; Mahfouz, A.; Arisha, A. Analysing supply chain resilience: Integrating the constructs in a concept mapping framework via a systematic literature review. Supply Chain Manag. Int. J. 2017, 22, 16–39. [Google Scholar] [CrossRef]

- Jayasinghe, R.S.; Rameezdeen, R.; Chileshe, N. Exploring sustainable post-end-of-life of building operations. Eng. Constr. Arch. Manag. 2019, 26, 689–722. [Google Scholar] [CrossRef]

- Shayan, S.; Kim, K.; Ma, T.; Nguyen, T. The First Two Decades of Smart City Research from a Risk Perspective. Sustainability 2020, 12, 9280. [Google Scholar] [CrossRef]

- Wijewickrama, M.; Chileshe, N.; Rameezdeen, R.; Ochoa, J.J. Quality assurance in reverse logistics supply chain of demolition waste: A systematic literature review. Waste Manag. Res. 2020, 39, 3–24. [Google Scholar] [CrossRef] [PubMed]

- Web of Science. Confident Research Begins Here. 2021. Available online: https://www.sciencedirect.com/topics/nursing-and-health-professions/web-of-science (accessed on 14 July 2021).

- Hosseini, M.R.; Maghrebi, M.; Akbarnezhad, A.; Martek, I.; Arashpour, M. Analysis of citation networks in building information modeling research. J. Constr. Eng. Manag. 2018, 144, 1–13. [Google Scholar] [CrossRef]

- Wikipedia. Scopus. Available online: https://en.wikipedia.org/wiki/Scopus (accessed on 19 April 2021).

- Fahimnia, B.; Tang, C.S.; Davarzani, H.; Sarkis, J. Quantitative models for managing supply chain risks: A review. Eur. J. Oper. Res. 2015, 247, 1–15. [Google Scholar] [CrossRef]

- Ghadge, A.; Dani, S.; Kalawsky, R. Supply chain risk management: Present and future scope. Int. J. Logist. Manag. 2012, 23, 313–339. [Google Scholar] [CrossRef] [Green Version]

- Prakash, S.; Soni, G.; Rathore, A.P.S. A critical analysis of supply chain risk management content: A structured literature review. J. Adv. Manag. Res. 2017, 14, 69–90. [Google Scholar] [CrossRef]

- Bearman, M.; Dawson, P. Qualitative synthesis and systematic review in health professions education. Med. Educ. 2013, 47, 252–260. [Google Scholar] [CrossRef] [PubMed]

- Khojasteh, Y. Developing Supply Chain Risk Mitigation Strategies; Springer Nature Singapore Pte Ltd.: Singapore, 2018. [Google Scholar]

- Qazi, A.; Dickson, A.; Quigley, J.; Gaudenzi, B. Supply chain risk network management: A Bayesian belief network and expected utility based approach for managing supply chain risks. Int. J. Prod. Econ. 2018, 196, 24–42. [Google Scholar] [CrossRef] [Green Version]

- Qazi, A.; Quigley, J.; Dickson, A. Supply Chain Risk Management: Systematic literature review and a conceptual framework for capturing inter dependencies between risks. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Dubai, United Arab Emirates, 3–5 March 2015. [Google Scholar]

- Svensson, G. A conceptual framework for the analysis of vulnerability in supply chains. Int. J. Phys. Distrib. Logist. Manag. 2000, 30, 731–750. [Google Scholar] [CrossRef]

- Monczka, R.M.; Handfield, R.B.; Giunipero, L.C.; Patterson, J.L. Purchasing and Supply Chain Management, 4th ed.; South-Western Cengage Learning: Mason, ON, Canada, 2009. [Google Scholar]

- Netro, Z.G.C.; De La Torre Romero, E.; Flores, J.L.M. Adaptation of the Fine-Kinney Method in Supply Chain Risk Assessment. In Safety and Security Engineering VII; Cengage: Toronto, ON, Canada, 2017; pp. 43–55. [Google Scholar]

- Puji, A.A.; Mansur, A.; Widodo, I.D. Analysis of supply chain risk mitigation integrated with fuzzy logic, house of risk and AHP: Case study at CV. Multiguna. In AIP Conference Proceedings; AIP Publishing: Sarawak, Malaysia, 2019; pp. 1–8. [Google Scholar]

- Aitken, J.M. Supply Chain Integration within the Context of a Supplier Association: Case Studies of Four Supplier Associations. Ph.D. Thesis, School of Management, Cranfield University, Cranfield, UK, 1998. [Google Scholar]

- Christopher, M. Logistics and Supply Chain Management, 5th ed.; Pearson Education: New York, NY, USA, 2016. [Google Scholar]

- LeMay, S.; Helms, M.M.; Kimball, B.; McMahon, D. Supply chain management: The elusive concept and definition. Int. J. Logist. Manag. 2017, 28, 1425–1453. [Google Scholar] [CrossRef]

- CSCMP. CSCMP Supply Chain Management Definitions and Glossary. 2021. Available online: https://cscmp.org/imis0/CSCMP/Educate/SCM_Definitions_and_Glossary_of_Terms/CSCMP/Educate/SCM_Definitions_and_Glossary_of_Terms (accessed on 30 July 2021).

- Chandrasekaran, N.; Raghuram, G. Agribusiness Supply Chain Management; CRC Press, Taylor & Francis Group: London, UK, 2014. [Google Scholar]

- Christopher, M. Logistics and Supply Chain Management, 4th ed.; Pearson Education Limited: Salford, UK, 2011. [Google Scholar]

- Shahbaz, M.S.; Rasi, R.Z.R.; Ahmad, F. A novel classification of supply chain risks: Scale development and validation. J. Ind. Eng. Manag. 2019, 12, 201–218. [Google Scholar] [CrossRef]

- Tse, Y.K.; Matthews, R.L.; Tan, K.H.; Sato, Y.; Pongpanich, C. Unlocking supply chain disruption risk within the Thai beverage industry. Ind. Manag. Data Syst. 2016, 116, 21–42. [Google Scholar] [CrossRef] [Green Version]

- Tang, O.; Musa, S.N. Identifying risk issues and research advancements in supply chain risk management. Int. J. Prod. Econ. 2011, 133, 25–34. [Google Scholar] [CrossRef] [Green Version]

- Sodhi, M.S.; Son, B.-G.; Tang, C.S. Researchers’ Perspectives on Supply Chain Risk Management. Prod. Oper. Manag. 2011, 21, 1–13. [Google Scholar] [CrossRef]

- Vilko, J. Approaches to Supply Chain Risk Management: Identification, Analysis and Control. Ph.D. Thesis, School of Business, Lappeenranta University of Technology, Lappeenranta, Finland, 2012. [Google Scholar]

- Tang, C.S. Perspectives in supply chain risk management. Int. J. Prod. Econ. 2006, 103, 451–488. [Google Scholar] [CrossRef]

- Zsidisin, G.A. Managerial Perceptions of Supply Risk. J. Supply Chain Manag. 2003, 39, 14–26. [Google Scholar] [CrossRef]

- Jüttner, U.; Peck, H.; Christopher, M. Supply chain risk management: Outlining an agenda for future research. Int. J. Logist. Res. Appl. 2003, 6, 197–210. [Google Scholar] [CrossRef] [Green Version]

- Waqas, U.; Rahman, A.B.A.; Ismail, N.W.; Basha, N.K.; Umair, S. Conceptualising the moderating role of knowledge management within supply chain risks and supply chain risk management. For. Soc. 2019, 3, 209. [Google Scholar] [CrossRef] [Green Version]

- Bogataj, D.; Bogataj, M. Measuring the supply chain risk and vulnerability in frequency space. Int. J. Prod. Econ. 2007, 108, 291–301. [Google Scholar] [CrossRef]

- Jüttner, U. Supply chain risk management: Understanding the business requirements from a practitioner perspective. Int. J. Logist. Manag. 2005, 16, 120–141. [Google Scholar] [CrossRef]

- Basole, R.C.; Bellamy, M.; Park, H.; Putrevu, J. Computational Analysis and Visualization of Global Supply Network Risks. IEEE Trans. Ind. Inform. 2016, 12, 1206–1213. [Google Scholar] [CrossRef]

- Ellis, S.C.; Shockley, J.; Henry, R.M. Making Sense of Supply Disruption Risk Research: A Conceptual Framework Grounded In Enactment Theory. J. Supply Chain Manag. 2011, 47, 65–96. [Google Scholar] [CrossRef] [Green Version]

- Lockamy, A.; McCormack, K. Analysing risks in supply networks to facilitate outsourcing decisions. Int. J. Prod. Res. 2009, 48, 593–611. [Google Scholar] [CrossRef] [Green Version]

- Tang, C.; Tomlin, B. The power of flexibility for mitigating supply chain risks. Int. J. Prod. Econ. 2008, 116, 12–27. [Google Scholar] [CrossRef] [Green Version]

- Wagner, S.; Bode, C. An Empirical Examination of Supply Chain Performance along Several Dimensions of Risk. J. Bus. Logist. 2008, 29, 307–325. [Google Scholar] [CrossRef]

- Wagner, S.; Bode, C. An empirical investigation into supply chain vulnerability. J. Purch. Supply Manag. 2006, 12, 301–312. [Google Scholar] [CrossRef]

- Kleindorfer, P.R.; Saad, G.H. Managing Disruption Risks in Supply Chains. Prod. Oper. Manag. Soc. 2005, 14, 53–68. [Google Scholar] [CrossRef]

- Chopra, S.; Sodhi, M.S. Managing Risk to Avoid Supply Chain Breakdown. MIT Sloan Manag. Rev 2004, 46, 53–61. [Google Scholar]

- Lin, Y.; Zhou, L. The impacts of product design changes on supply chain risk: A case study. Int. J. Phys. Distrib. Logist. Manag. 2011, 41, 162–186. [Google Scholar] [CrossRef]

- Enyinda, C.I.; Mbah, C.H. Quantifying Sources of Risk in Global Food Operations and Supply Chain. Thunderbird Int. Bus. Rev. 2016, 59, 653–661. [Google Scholar] [CrossRef]

- Cook, M.L.; Chaddad, F.R. Agroindustrialization of the global agrifood economy: Bridging development economics and agribusiness research. Agric. Econ. 2000, 23, 207–218. [Google Scholar] [CrossRef]

- King, R.P.; Boehlje, M.; Cook, M.L.; Sonka, S.T. Agribusiness Economics and Management. Am. J. Agric. Econ. 2010, 92, 554–570. [Google Scholar] [CrossRef]

- Rust, I.W. Reviewed Work(s): A Concept of Agribusiness by John H. Davis and Ray A. Goldberg. J. Farm Econ. 1957, 39, 5. [Google Scholar]

- Fleet, D.D.V.; Fleet, E.W.V.; Seperich, G.J. Agribusiness: Principles of Management, Delmar, Cengage Learning; Cengage Publishing: South Melbourne, VIC, Australia, 2014. [Google Scholar]

- Konig, G.; Da Silva, C.A.; Mhlanga, N. Enabling Environments for Agribusiness and Agro-Industries Development: Regional and Country Perspectives; FAO: Rome, Italy, 2013. [Google Scholar]

- OECD. Managing Risk in Agriculture: A Holistic Approach; Organisation for Economic Co-Operation and Development: Paris, France, 2009. [Google Scholar]

- Eremenko, V.; Shumilin, P.; Shamkina, E.; Shumilina, V.; Makartsova, T.; Kravchenko, A.; Evsyukova, O.; Filippova, A.; Yatsuk, D. Adaptation of accounting in agribusiness risk management system. E3S Web Conf. 2020, 164, 10006. [Google Scholar] [CrossRef]

- Harwood, J.; Heifner, R.; Coble, K.; Perry, J.; Somwaru, A. Market and Trade Economics Division and Resource Economics Division, Economic Research Service, U.S. In Managing Risk in Farming: Concepts, Research, and Analysis; Department of Agriculture: Washington, DC, USA, 1999. [Google Scholar]

- Just, R.E.; Pope, R.D. A Comprehensive Assessment of the Role of Risk in U.S. Agriculture; Kluwer Academic Publishers: New York, NY, USA, 2002. [Google Scholar]

- Hardaker, J.B.; Lien, G.; Anderson, J.R.; Huirne, R.B.M. Coping with Risk in Agriculture: Applied Decision Analysis, 3rd ed.; CABI: Wallingford, UK, 2015; Available online: www.cabi.org (accessed on 14 July 2021).

- Bhagat, D.; Dhar, U.R. Agriculture Supply Chain Management—A Review. IUP J. Supply Chain. Manag. 2011, 3, 20. [Google Scholar]

- Bryceson, K.P.; Smith, C.S. Abstraction and modelling of agri-food chains as complex decision making system. In Proceedings of the 110th EAAE Seminar System Dynamics and Innovation in Food Networks, Innsbruck, Austria, 5–9 February 2008; p. 15. [Google Scholar]

- Jaffee, S.; Siegel, P.; Andrews, C. Rapid Agricultural Supply Chain Risk Assessment (RapAgRisk): Methodological Guidelines; World Bank: Washington, DC, USA, 2008. [Google Scholar]

- Abdel-Basset, M.; Mohamed, R. A novel plithogenic TOPSIS-CRITIC model for sustainable supply chain risk management. J. Clean. Prod. 2019, 247, 119586. [Google Scholar] [CrossRef]

- Chileshe, N.; Wilson, L.; Zuo, J.; Zillante, G.; Pullen, S. Strategic risk assessment for pursuing sustainable business in the construction industry: Diagnostic models. In Sustainable Business: Theory and Practice of Business under Sustainability Principles; Wells, G., Ed.; Edward Elgar Publishing Limited: Cheltenham, UK, 2013; pp. 155–177. [Google Scholar]

- Hopwood, A.; Unerman, J.; Fries, J. Introduction to the accounting for sustainability case studies. In Accounting for Sustainability Practical Insights; Taylor & Francis Group: Abingdon, UK, 2010; p. 28. [Google Scholar]

- Foerstl, K.; Reuter, C.; Hartmann, E.; Blome, C. Managing supplier sustainability risks in a dynamically changing environment—Sustainable supplier management in the chemical industry. J. Purch. Supply Manag. 2010, 16, 118–130. [Google Scholar] [CrossRef]

- Misra, A.K.; Lence, S.H. Risk management by farmers, agribusiness, and lenders. Agric. Financ. Rev. 2005, 65, 18. [Google Scholar]

- Waters, D. Supply Chain Risk Management, 2nd ed.; Kogan Page Limited: New York, NY, USA, 2011. [Google Scholar]

- Knight, F.H. Risk Uncertainty and Profit; The Riverside Press Cambridge: Boston, MA, USA, 1921; p. 381. [Google Scholar]

- Helbing, D. Globally networked risks and how to respond. Nat. Cell Biol. 2013, 497, 51–59. [Google Scholar] [CrossRef]

- ISO 2018. ISO 31000:2018 Risk Management: Guidelines. Available online: https://www.iso.org/obp/ui/#iso:std:iso:31000:ed-2:v1:en (accessed on 7 October 2020).

- Faisal, M.N.; Banwet, D.K.; Shankar, R. Mapping supply chains on risk and customer sensitivity dimensions. Ind. Manag. Data Syst. 2006, 106, 878–895. [Google Scholar] [CrossRef]

- Heshmati, A. (Ed.) Sustainable Agriculture and Agribusiness in Iran; Springer: Tabriz, Iran, 2019. [Google Scholar]

- Munir, M.; Jajja, M.S.S.; Chatha, K.A.; Farooq, S. Supply chain risk management and operational performance: The enabling role of supply chain integration. Int. J. Prod. Econ. 2020, 227, 107667. [Google Scholar] [CrossRef]

- Liu, F.; Park, K. Managing firm risk through supply chain dependence: An SME perspective. J. Bus. Ind. Mark. 2020. [Google Scholar] [CrossRef]

- Saglam, Y.C.; Çankaya, S.Y.; Sezen, B. Proactive risk mitigation strategies and supply chain risk management performance: An empirical analysis for manufacturing firms in Turkey. J. Manuf. Technol. Manag. 2020. [Google Scholar] [CrossRef]

- Vishnu, C.R.; Sridharan, R.; Gunasekaran, A.; Kumar, P.R. Strategic capabilities for managing risks in supply chains: Current state and research futurities. J. Adv. Manag. Res. 2019, 17, 173–211. [Google Scholar] [CrossRef]

- Iyer, P.; Bozzola, M.; Hirsch, S.; Meraner, M.; Finger, R. Measuring Farmer Risk Preferences in Europe: A Systematic Review. J. Agric. Econ. 2019, 71, 3–26. [Google Scholar] [CrossRef] [Green Version]

- McNairn, H.; Merzouki, A.; Pacheco, A.; Fitzmaurice, J. Monitoring Soil Moisture to Support Risk Reduction for the Agriculture Sector Using RADARSAT-2. In Proceedings of the IEEE Journal of Selected Topics in Applied Earth Observations and Remote Sensing, Vancouver, BC, Canada, 24–29 July 2012; Volume 5, pp. 824–834. [Google Scholar]

- Asfaw, D.; Black, E.; Brown, M.; Nicklin, K.J.; Otu-Larbi, F.; Pinnington, E.; Challinor, A.; Maidment, R.; Quaife, T. TAMSAT-ALERT v1: A new framework for agricultural decision support. Geosci. Model Dev. 2018, 11, 2353–2371. [Google Scholar] [CrossRef] [Green Version]

- Alahacoon, N.; Edirisinghe, M.; Ranagalage, M. Satellite-Based Meteorological and Agricultural Drought Monitoring for Agricultural Sustainability in Sri Lanka. Sustainability 2021, 13, 3427. [Google Scholar] [CrossRef]

- Finger, R.; el Benni, N. Farm income in European agriculture: New perspectives on measurement and implications for policy evaluation. Eur. Rev. Agric. Econ. 2021, 48, 253–265. [Google Scholar] [CrossRef]

- Chavas, J.P. Agricultural policy in an uncertain world. Eur. Rev. Agric. Econ. 2011, 38, 383–407. [Google Scholar] [CrossRef]

- Ojala, M.; Hallikas, J. Investment decision-making in supplier networks: Management of risk. Int. J. Prod. Econ. 2006, 104, 201–213. [Google Scholar] [CrossRef]

- Thakur, D.S.; Sharma, K.D. Organic farming for sustainable agriculture and meeting the challenges of food security in 21st century: An economic analysis. Indian J. Agric. Econ. Org. 2005, 60, 205. [Google Scholar]

- Elahi, E.; Weijun, C.; Zhang, H.; Nazeer, M. Agricultural intensification and damages to human health in relation to agrochemicals: Application of artificial intelligence. Land Use Policy 2019, 83, 461–474. [Google Scholar] [CrossRef]

- Leppälä, J.; Murtonen, M.; Kauranen, I.; Lepp, M.M.J. Farm Risk Map: A contextual tool for risk identification and sustainable management on farms. Risk Manag. 2012, 14, 42–59. [Google Scholar] [CrossRef]

- Noordwijk, M. (Ed.) Sustainable Development through Trees on Farms: Agroforestry in Its Fifth Decade; The World Agroforestry (ICRAF): Bogor, Indonesia, 2019. [Google Scholar]

- Susilo, L.J.; Kaho, V.R. Manajemen Risiko Berbasis ISO 31000:2018: Panduan Untuk Risk Leaders Dan Risk Practitioners; PT. Grasindo: Jakarta, Indonesia, 2019. [Google Scholar]

- Andersen, T.J.; Schrøder, P.W. Strategic Risk Management Practice: How to Deal Effectively with Major Corporate Exposures; Cambridge University Press: New York, NY, USA, 2010. [Google Scholar]

- Manners-Bell, J. Supply Chain Risk: Understanding Emerging Threats to Global Supply Chains; Kogan Page Limited: New York, NY, USA, 2014. [Google Scholar]

- Christopher, M.; Peck, H. Building the resilient supply chain. Int. J. Logist. Manag. 2004, 15, 13. [Google Scholar] [CrossRef] [Green Version]

- Manuj, I.; Mentzer, J.T. Global supply chain risk management strategies. Int. J. Phys. Distrib. Logist. Manag. 2008, 38, 192–223. [Google Scholar] [CrossRef] [Green Version]

- Tang, C.S. Robust strategies for mitigating supply chain disruptions. Int. J. Logist. Res. Appl. 2006, 9, 33–45. [Google Scholar] [CrossRef]

- Bode, C.; Wagner, S. Structural drivers of upstream supply chain complexity and the frequency of supply chain disruptions. J. Oper. Manag. 2015, 36, 215–228. [Google Scholar] [CrossRef]

- Statsenko, L.; Gorod, A.; Ireland, V. A complex adaptive systems governance framework for regional supply networks. Supply Chain Manag. Int. J. 2018, 23, 293–312. [Google Scholar] [CrossRef]

- Ye, F.; Lin, Q.; Li, Y. Coordination for contract farming supply chain with stochastic yield and demand under CVaR criterion. Oper. Res. 2017, 20, 369–397. [Google Scholar] [CrossRef]

- De Oliveira, M.M.; Lago, A.; Magro, G.P.D. Food loss and waste in the context of the circular economy: A systematic review. J. Clean. Prod. 2021, 294, 126284. [Google Scholar] [CrossRef]

- Cucagna, M.E.; Goldsmith, P.D. Value adding in the agri-food value chain. Int. Food Agribus. Manag. Rev. 2018, 21, 293–316. [Google Scholar] [CrossRef]

- Pelicice, F.M.; Castello, L. A political tsunami hits Amazon conservation. In Aquatic Conservation: Marine and Freshwater Ecosystems; Department of Fish & Wildlife Conservation: Blacksburg, VA, USA, 2021. [Google Scholar]

- Gardas, B.; Raut, R.; Jagtap, A.H.; Narkhede, B. Exploring the key performance indicators of green supply chain management in agro-industry. J. Model. Manag. 2019, 14, 260–283. [Google Scholar] [CrossRef]

- Sehnem, S.; Oliveira, G.P. Analysis of the supplier and agribusiness relationship. J. Clean. Prod. 2017, 168, 1335–1347. [Google Scholar] [CrossRef]

- Magar, D.B.T.; Pun, S.; Pandit, R.; Rola-Rubzen, M.F. Pathways for building resilience to COVID-19 pandemic and revitalizing the Nepalese agriculture sector. Agric. Syst. 2020, 187, 103022. [Google Scholar] [CrossRef]

- Canevari-Luzardo, L.M. Value chain climate resilience and adaptive capacity in micro, small and medium agribusiness in Jamaica: A network approach. Reg. Environ. Chang. 2019, 19, 2535–2550. [Google Scholar] [CrossRef] [Green Version]

- Firsova, N.; Abrhám, J. Economic perspectives of the Blockchain technology: Application of a SWOT analysis. Terra Econ. 2021, 19, 78–90. [Google Scholar] [CrossRef]

- Enescu, F.M.; Ionescu, V.M. Using Blockchain in the agri-food sector following SARS-CoV-2 pandemic. In Proceedings of the 12th International Conference on Electronics, Computers and Artificial Intelligence (ECAI), Bucharest, Romania, 25–27 June 2020; p. 6. [Google Scholar]

- Ghanbaria, S.; Bashiria, M. A resilient agribusiness supply chain network design in a two-stage stochastic programming framework. In Proceedings of the 15th Iran International Industrial Engineering Conference, Yazd, Iran, 23–24 January 2019; p. 5. [Google Scholar]

- Sheffi, Y.; Rice, J.B., Jr. A supply chain view of the resilient enterprise. MIT Sloan Manag. Rev. 2005, 47, 41–48. [Google Scholar]

| No | Keywords | |

|---|---|---|

| I | Agribusiness supply chain risk | AND “definition” AND “classification” OR “categorization” |

| II | Agribusiness supply chain | AND “definition” |

| III | Agribusiness | AND “definition” AND “supply chain” AND supply chain risk” AND “risk” OR “disruption” OR “vulnerability” |

| IV | Supply chain | AND “definition” |

| V | Supply chain risk | AND “definition” AND “categorisation” OR “classification” |

| Inclusion Criteria | Rationale | Exclusion Criteria |

|---|---|---|

| Published in peer-reviewed journals, books and conference papers. | Peer-reviewed journals are of higher quality and reliability than non-peer-reviewed articles. Besides, books and conference papers are also relevant and reliable for addressing the research questions. | Any papers in non-peer-reviewed journals, books and conference papers will be eliminated. |

| Selection of papers published 2000–2021 | The year 2000 was selected as a starting point because supply chain risk management (SCRM) has been an essential research topic in the past two decades [32]; it has transitioned from an emerging topic to a growing and broad research area [7,32,33,34], and risk in agribusiness supply chain is one of the research areas that is related to SCRM. | Up to the end of January 2021. |

| Published in the English language. | English is the dominant language in the field of agribusiness supply chain risk research. | Any publication before 2000 will be excluded. |

| Author (s) | Types and Categories of Supply Chain Risks | |

|---|---|---|

| Shahbaz, Rm Rasi and Bin Ahmad (2019) [49] | Seven categories of SCR | (1) Supply-side risks, (2) Process-side risks, (3) Demand-side risks, (4) Logistic-side risks, (5) Collaboration-side risks, (6) Financial-side risks, and (7) Environment-side risks. |

| Waqas et al. (2019) [57] | Five SCR sources | (1) Supply risk, (2) Process risk, (3) Demand risk, (4) Environmental risk, and (5) Financial risks. |

| Christopher (2011) [48]; Prakash, Soni and Rathore (2017) [34]; Bogataj and Bogataj (2007) [58]; Jüttner (2005) [59] | Five categories of SCR sources | (1) Supply risk, (2) Demand risk, (3) Process risk, (4) Control risk, and (5) Environmental risk. |

| Basole et al. (2016) [60]; Ellis, Shockley and Henry (2011) [61]; Lockamy and McCormack (2010) [62] | Three major categories of SCR | (1) Internal to organisation also called organisational factors, (2) External to organisation but internal to network also known as industry factors, and (3) External risk sources also called environmental factors. |

| Ho et al. (2015) [19] | Two categories of SCR | (1) Macro risks (consist of natural risks, e.g., earthquakes and weather-related disasters and man-made risks, e.g., war and terrorism and political instability); (2) Micro risks (demand risk, manufacturing risk, supply risk and infrastructural risk). |

| Sodhi, Son and Tang (2012) [52] | Two categories of SCR | (1) Operational risks (frequent risk events stemming from inherent supply-demand uncertainty), (2) Catastrophic risks (caused by natural or man-made disasters). |

| Tang, O and Nurmaya Musa (2011) [51] | Three classification of SCR | (1) Material flow risk (single sourcing risk, sourcing flexibility risk, supplier selection/outsourcing, supply product monitoring/quality and supply capacity), (2) Information flow risk (information accuracy, information system security and disruption), and (3) Financial flow risk (exchange rate risk, price and cost risk, financial strength of supply chain partners and financial handling/practice). |

| Tang and Tomlin (2008) [63] | Six major types of SCR | (1) Supply risks (supply cost risks, supply commitment risk), (2) Process risks, (3) Demand risks, (4) Intellectual property risks, (5) Behavioral risks, and (6) Political/social risks. |

| Wagner and Bode (2008) [64]; Wagner and Bode (2006) [65] | Five sources of SCR | (1) Demand-side; (2) Supply-side; (3) Regulatory, legal and bureaucratic; (4) Infrastructure; and (5) Catastrophic. |

| Kleindorfer and Saad (2005) [66] | Two broad categories of risk affecting SC design and management | (1) Risks arising from the problems of coordinating supply and demand; (2) Risks arising from disruptions to normal activities such as natural disasters, from strikes and economic disruptions, and from acts of purposeful agents, including terrorists. |

| Chopra and Sodhi (2004) [67] | Nine potential SCR | (1) Disruptions, (2) Delays, (3) System, (4) Forecast, (5) Intellectual property, (6) Procurement, (7) Receivables, (8) Inventory, and (9) Capacity. |

| Jüttner, Peck and Christopher (2003) [56]; Lin and Zhou (2011) [68]; Enyinda and Mbah (2017) [69]; Ghadge, Dani and Kalawsky (2012) [33] | Three categories of risk sources in supply chains | (1) Environmental risk sources (man-made and natural disruptions), (2) Network-related risk sources, and (3) Organisational risk sources (inventory risk, process/operational risk, quality risk and management risk). |

| Author (s) | Risks in Agribusiness Supply Chain | |

|---|---|---|

| Behzadi, Golnar et al. (2018a) [7]; Nyamah et al. (2017) [14] | Risk sources in agrifood SC | (1) Weather, (2) Biological/environment (e.g., excess rainfall; pests; and diseases), (3) Logistical/infrastructure, (4) Market including demand and supply (e.g., labour shortage and volatile customer demand), (5) Policy/regulation (e.g., periodic change in interest/exchange rate policies, uncertain land policies/tenure, and political-related issues), (6) Financial, and (7) Operational/managerial factors. |

| Behzadi, Golnar et al. (2018a) [7]; Behzadi, G. et al. (2018b) [16] | Risk management for agriculture SC | (1) Seasonality, (2) Supply spikes, (3) Long supply lead times, and (4) Perishability. |

| Chandrasekaran and Raghuram (2014) [47] | Risk management for ASC | Product characteristics such as seasonality, long lead time and bulkiness, and inherent unpredictability such as due to climatic, economic or social-environmental changes. |

| Behzadi, G. et al. (2018b) [16] | Risks in ASC | (1) Supply-side risks, such as weather variability, disease and pests, affect the quantity and timing of supply, (2). Demand-side risks mainly affect market capacity and sales price. |

| Behzadi, Golnar et al. (2017) [15] | Sources of uncertainty in ASC | Agribusiness SC involves more sources of uncertainty than typical manufacturing SC because of attributes such as long supply lead times, seasonality and perishability. |

| Jaffee, Siegel and Andrews (2008) [82] | Major risks facing food and agribusiness firms | (1) Weather/natural disaster-related risks, (2) Biology and environmental risks, (3) Market (demand and supply) risks, (4) Logistical/infrastructural risks, (5) Managerial and operational risks, (6) Policy and institutional risks, and (7) Political risks. |

| Peck, cited in Enyinda and Mbah (2017) [69] | Risks in the food supply chain | (1) Product contamination and recall; (2) loss of access—terrorism; (3) Loss of access (protesters), site, people and supplier; (4) Reduced capacity; (5) Contractual cover; (6) Dual sourcing; and (7) Market force. |

| Risk Categories | Risk Factors/Risk Sources Exposure to Agribusiness Supply Chain |

|---|---|

| 1. Internal risks (Organisational risk factors) |

|

| 2. External risks (Environmental risk factors) |

|

| 3. Network risks (Network-related risk factors) |

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Imbiri, S.; Rameezdeen, R.; Chileshe, N.; Statsenko, L. A Novel Taxonomy for Risks in Agribusiness Supply Chains: A Systematic Literature Review. Sustainability 2021, 13, 9217. https://doi.org/10.3390/su13169217

Imbiri S, Rameezdeen R, Chileshe N, Statsenko L. A Novel Taxonomy for Risks in Agribusiness Supply Chains: A Systematic Literature Review. Sustainability. 2021; 13(16):9217. https://doi.org/10.3390/su13169217

Chicago/Turabian StyleImbiri, Soleman, Raufdeen Rameezdeen, Nicholas Chileshe, and Larissa Statsenko. 2021. "A Novel Taxonomy for Risks in Agribusiness Supply Chains: A Systematic Literature Review" Sustainability 13, no. 16: 9217. https://doi.org/10.3390/su13169217

APA StyleImbiri, S., Rameezdeen, R., Chileshe, N., & Statsenko, L. (2021). A Novel Taxonomy for Risks in Agribusiness Supply Chains: A Systematic Literature Review. Sustainability, 13(16), 9217. https://doi.org/10.3390/su13169217