DfMA: Towards an Integrated Strategy for a More Productive and Sustainable Construction Industry in Australia

Abstract

:1. Introduction

- DfMA is a systematic process that incorporates design, manufacture, and assembly using DfMA principles and adds value to the overall process.

- DfMA is an evaluation system that can assess the efficiency and productivity of manufacturing and assembly combined with the use of virtual design and construction.

- DfMA is a game-changing methodology that is closely associated with ever-changing prefabrication and modular construction methods.

1.1. DfMA and Lean Construction

“Using automated processes to manufacture construction components in a controlled offsite environment, DfMA allows us to calculate materials requirements with absolute precision. This way, the industry’s most sustainable construction solution allows us to eliminate waste from the outset and return would-be waste back into the production process. By taking work off site reducing onsite activities the construction process becomes inherently safer”.

1.2. DfMA and Prefabrication

1.3. DfMA and DfX

1.4. Benefits and Challenges of Adopting DfMA

1.5. Knowledge Gap

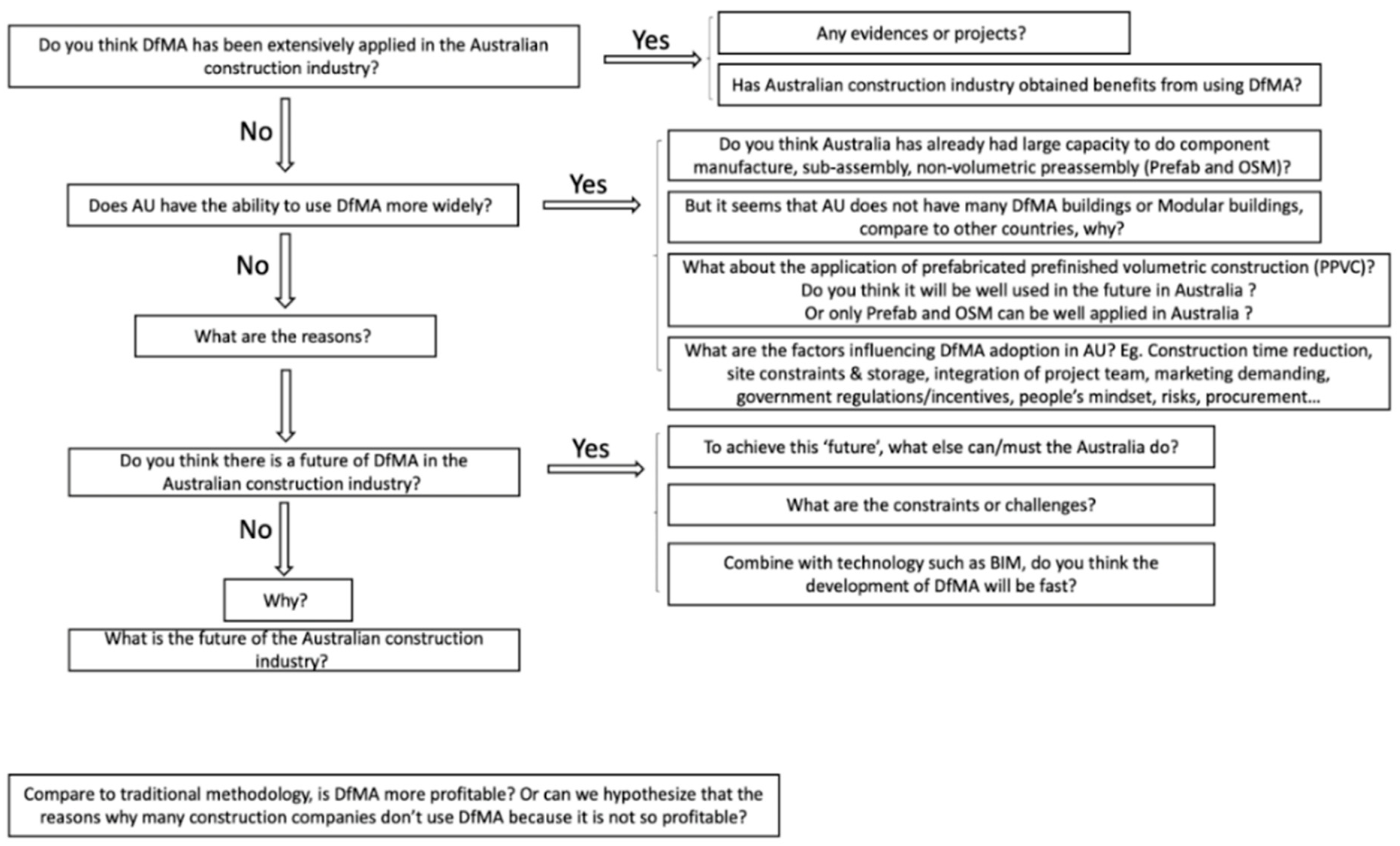

2. Materials and Methods

3. Results

3.1. Adopting DfMA in the Australian Construction Industry

“We should look at a material perspective. Among three major construction materials, steel, concrete, particularly precast concrete, and timber, not all of them have been combined with DfMA, but engineered timber, such as cross-laminated timber, is being applied extensively. Australia has the capacity to make DfMA-based high-rise modular buildings using timber but not precast concrete”.

3.2. Barriers

“to employ DfMA, two types of workers are required, one is labour, and the other type are workers with design ability. The core workers in Australia are the former who are onsite. They are protected by unions that will not allow workers to be unemployed. The union is very large, so it is difficult to change for a while”.

“People commonly think modular buildings mean square boxes, death of good architecture, or temporary places to stay. In addition, people are conservative and oppose to new things. Then, people think that they don’t need to change on site to offsite because they still make loads of money onsite”.

“A whole new realm of risk is opened up when the new methodology is adopted. Risks are rolled downhill from clients to contractors then to subcontractors in a traditional procurement process when contractors don’t know how to price projects when they do these new things”.

3.3. The Future of DfMA

“It takes quite a long time for the construction industry to adopt that way to combine high technology in this industry. It’s like a bright future but still takes time and costs a lot to get that point”.(Expert B)

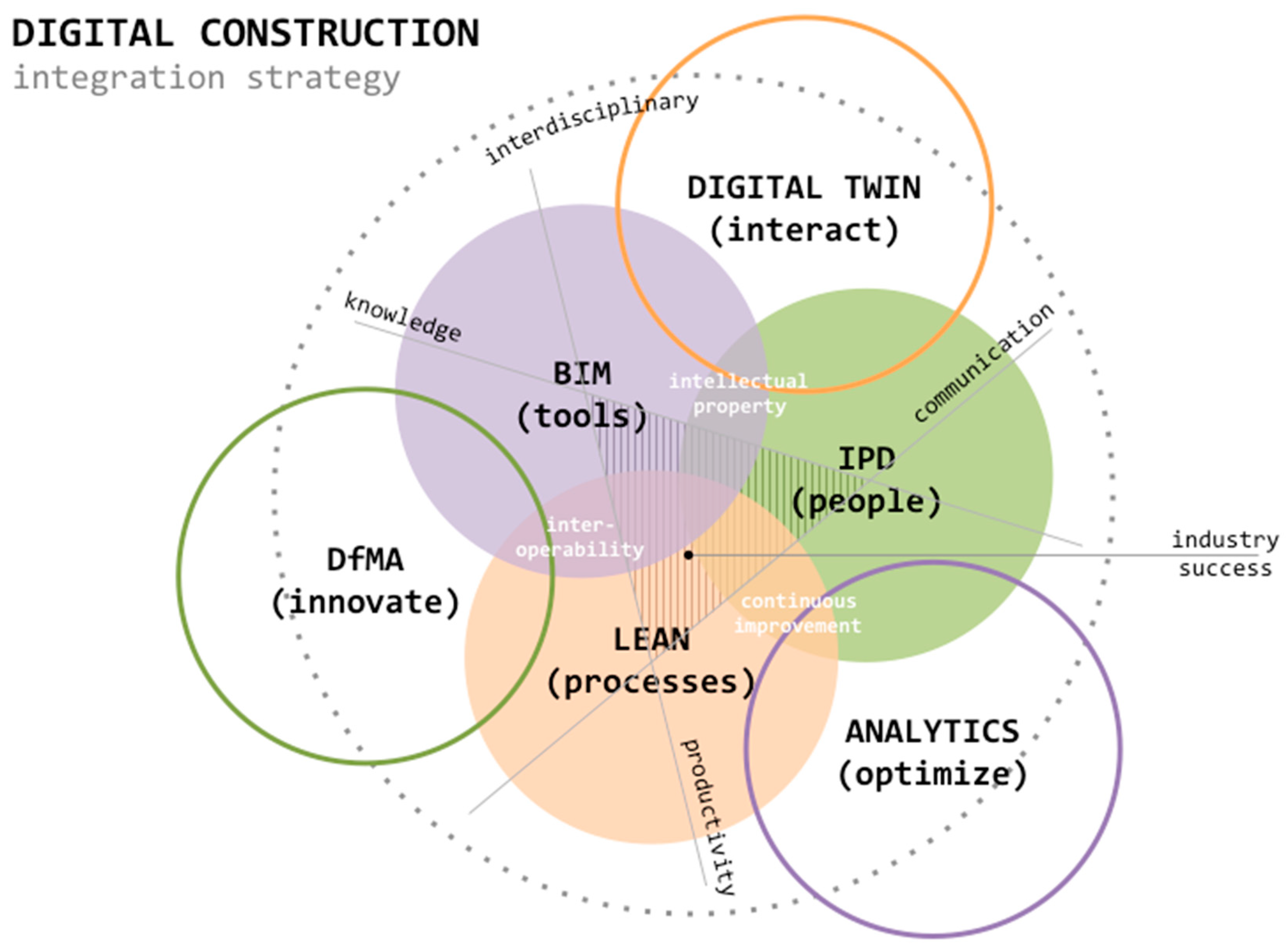

“In order to harness the power of DfMA, a lot of upfront work should be considered and done at the design stage. Digital technology facilitates this stage. At manufacturing and assembly, digital technology provides transformation. And future construction is a digital transformation, it doesn’t just only transform some current technology, but also transforms the traditional construction mode to more on DfMA, more modular”.(Expert D)

- The lighter unified structure of HBS enables Hickory to build on sites that would not otherwise withstand the weight of a more conventional building approach.

- There is potential to add several levels to high-rise projects given their fixed height limits without compromising internal ceiling clearance due to HBS floor-to-floor height advantages.

- Bathroom pods are fully enclosed and installed complete with all services, fittings, lighting, and finished wall surfaces, thus limiting onsite trades and raising finished quality.

- The external integrated façade is pre-attached in the factory and aligns precisely with neighboring structural units when installed onsite.

- HBS allows considerable freedom in scale and does not pose significant restrictions on building layouts or apartment size and configuration.

- Post-tensioned beams can be integrated into the concrete floor of each prefabricated unit as ‘wet joints’ and connected to in situ post-tensioned beams onsite.

- Recesses for prefinished bathroom pods are incorporated into the lightweight precast floor slabs to ensure smooth transitions at the floor level.

- Flexible structural unit size is scalable from small to large aspect ratios within the parameters of road transportation.

4. Discussion

- Community mindset.

- Government regulations and incentives.

- Planning and building codes.

- Unionization and business politics.

- Finance.

- Supply chain management.

4.1. Community Mindset

4.2. Government Regulations and Incentives

4.3. Planning and Building Codes

4.4. Unionization and Business Politics

4.5. Finance

4.6. Supply Chain Management

4.7. Reflection

4.8. A Roadmap for Australian Digital Construction

4.9. Limitations

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AUD | Australian Dollars |

| BCA | Building and Construction Authority |

| BIM | Building Information Modelling |

| BUHREC | Bond University Human Research Ethics Committee |

| CBD | Central Business District |

| COVID-19 | A disease caused by the SARS-CoV-2 virus |

| CRC | Collaborative Research Center |

| CTBUH | Council of Tall Buildings and Urban Habitat |

| DfA | Design for Assembly |

| DfM | Design for Manufacture |

| DfMA | Design for Manufacture and Assembly |

| DfX | Design for Excellence |

| GDP | Gross Domestic Product |

| HBS | Hickory Building System |

| IoT | Internet of Things |

| IPD | Integrated Project Delivery |

| LEAN | Lean Construction |

| MiC | Modular Integrated Construction |

| MMC | Modern Methods of Construction |

| OSM | Offsite Manufacture |

| PPVC | Prefabricated Prefinished Volumetric Construction |

| QR | QR (Quick Response) Code |

| RFID | Radio Frequency Identification |

| RIBA | Royal Institute of British Architects |

| RICS | Royal Institution of Chartered Surveyors |

| UK | United Kingdom |

References

- Bertram, N.; Fuchs, S.; Mischke, J.; Palter, R.; Strube, G.; Woetzel, J. Modular Construction: From Projects to Products; McKinsey & Company: New York, NY, USA, 2019; Available online: https://www.mckinsey.com/business-functions/operations/our-insights/modular-construction-from-projects-to-products (accessed on 26 June 2021).

- Bogue, R. Design for manufacture and assembly: Background, capabilities and applications. Assem. Autom. 2012, 32, 112–118. [Google Scholar] [CrossRef]

- Royal Institute of British Architects. RIBA Plan of Work 2013: Designing for Manufacture and Assembly; RIBA: London, UK, 2013; Available online: http://consig.org/wp-content/uploads/2018/10/RIBAPlanofWorkDfMAOverlaypdf.pdf (accessed on 26 June 2021).

- Laing O’Rourke. The future of DfMA is the future of construction. In Engineering Excellence Journal, 1st ed.; Laing O’Rourke: Dartford, UK, 2013; Available online: https://www.laingorourke.com/media/publications/eej-landing.aspx (accessed on 26 June 2021).

- Parliamentary Office of Science and Technology. Modern Methods of Building Construction; Postnote No. 209; Parliamentary Office of Science and Technology: London, UK, 2003; Available online: https://researchbriefings.files.parliament.uk/documents/POST-PN-209/POST-PN-209.pdf (accessed on 26 June 2021).

- HM Treasury. Autumn Budget 2017; HM Treasury: London, UK, 2017. Available online: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/661480/autumn_budget_2017_web.pdf (accessed on 26 June 2021).

- HM Government. Construction 2025–Industry Strategy: Government and Industry in Partnership; HM Government: London, UK, 2013. Available online: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/210099/bis-13-955-construction-2025-industrial-strategy.pdf (accessed on 26 June 2021).

- Balfour Beatty. 25% by 2025–Streamlined Construction: Seven Steps to Offsite and Modular Building; Balfour Beatty: London, UK, 2018; Available online: https://www.balfourbeatty.com/media/317714/streamlined-construction-seven-steps-to-offsite-and-modular-building.pdf (accessed on 26 June 2021).

- RICS. Modern Methods of Construction: A Forward-Thinking Solution to the Housing Crisis; RICS: London, UK, 2018; Available online: https://www.rics.org/globalassets/rics-website/media/news/news--opinion/modern-methods-of-construction-paper-rics.pdf (accessed on 26 June 2021).

- Hong Kong Development Bureau. Construction 2.0: Time to Change; Hong Kong Development Bureau: Hong Kong, China, 2018. Available online: https://www.psgo.gov.hk/assets/pdf/Construction-2-0-en.pdf (accessed on 26 June 2021).

- What Is MiC? Available online: https://mic.cic.hk/en/AboutMiC (accessed on 26 June 2021).

- Codes and References: Modular Integrated Construction. Available online: https://www.bd.gov.hk/en/resources/codes-and-references/modular-integrated-construction/index.html (accessed on 26 June 2021).

- Gao, S.; Low, S.P.; Nair, K. Design for manufacturing and assembly (DfMA): A preliminary study of factors influencing its adoption in Singapore. Archit. Eng. Des. Manag. 2018, 14, 440–456. [Google Scholar] [CrossRef]

- Building and Construction Authority. BCA Identifies 35 Key Technologies for R&D to Drive Construction Productivity in the Next Lap; Building and Construction Authority: Singapore, 2016. Available online: https://www1.bca.gov.sg/docs/default-source/docs-corp-buildsg/digitalisation/media_release_scpw_2016_181016.pdf (accessed on 26 June 2021).

- Building and Construction Authority. Buildsmart: The Second Construction Productivity Roadmap; Building and Construction Authority: Singapore, 2015. Available online: https://www.bca.gov.sg/emailsender/BuildSmart-062015/microsite/others/bca-newsletter.pdf (accessed on 26 June 2021).

- Design for Manufacturing and Assembly (DfMA). Available online: https://www1.bca.gov.sg/buildsg/productivity/design-for-manufacturing-and-assembly-dfma (accessed on 26 June 2021).

- Industries: Construction. Available online: https://nationalindustryinsights.aisc.net.au/industries/construction (accessed on 26 June 2021).

- Hickory. Hickory Building Systems: Overview of Prefabricated Structural System; Hickory: Melbourne, Australia; Available online: https://www.hickory.com.au/docs/hickory-building-systems-overview.pdf (accessed on 26 June 2021).

- Tan, T.; Lu, W.; Tan, G.; Xue, F.; Chen, K.; Xu, J.; Wang, J.; Gao, S. Construction-oriented design for manufacture and assembly guidelines. J. Constr. Eng. Manag. 2020, 146, 04020085. [Google Scholar] [CrossRef]

- Wasim, M.; Vaz Serra, P.; Ngo, T.D. Design for manufacturing and assembly for sustainable, quick and cost-effective prefabricated construction: A review. Int. J. Constr. Manag. 2020, 1–9. [Google Scholar] [CrossRef]

- Crowther, P. Design for disassembly: Themes and principles. In BDP Environment Design Guide DES 31; Royal Australian Institute of Architects: Sydney, Australia, 2005; pp. 1–7. Available online: https://www.jstor.org/stable/26149108 (accessed on 26 June 2021).

- Fox, S.; Marsh, L.; Cockerham, G. Design for manufacture: A strategy for successful application to buildings. Constr. Manag. Econ. 2001, 19, 493–502. [Google Scholar] [CrossRef]

- Kim, M.K.; McGovern, S.; Belsky, M.; Middleton, C.; Brilakis, I. A suitability analysis of precast components for standardized bridge construction in the United Kingdom. Procedia Eng. 2016, 164, 185–195. [Google Scholar] [CrossRef]

- Gao, S.; Jin, R.; Lu, W. Design for manufacture and assembly in construction: A review. Build. Res. Inf. 2020, 48, 538–550. [Google Scholar] [CrossRef]

- Yuan, Z.; Sun, C.; Wang, Y. Design for manufacture and assembly-oriented parametric design of prefabricated buildings. Autom. Constr. 2018, 88, 13–22. [Google Scholar] [CrossRef]

- Lu, W.; Tan, T.; Xu, J.; Wang, J.; Chen, K.; Gao, S.; Xue, F. Design for manufacture and assembly (DfMA) in construction: The old and the new. Archit. Eng. Des. Manag. 2021, 17, 77–91. [Google Scholar] [CrossRef]

- Koskela, L.; Howell, G.; Ballard, G.; Tommelein, I. The foundations of lean construction. In Design and Construction: Building in Value; Best, R., de Valence, G., Eds.; Butterworth Heinemann: Oxford, UK, 2002; pp. 211–226. [Google Scholar]

- Gbadamosi, A.-Q.; Mahamadu, A.-M.; Oyedele, L.O.; Akinade, O.O.; Manu, P.; Mahdjoubi, L.; Aigbavboa, C. Offsite construction: Developing a BIM-based optimizer for assembly. J. Clean. Prod. 2019, 215, 1180–1190. [Google Scholar] [CrossRef]

- Koskela, L. Application of the New Production Philosophy to Construction (TR072); Stanford University: Stanford, CA, USA, 1992. [Google Scholar]

- Gerth, R.; Boqvist, A.; Bjelkemyr, M.; Lindberg, B. Design for construction: Utilizing production experiences in development. Constr. Manag. Econ. 2013, 31, 135–150. [Google Scholar] [CrossRef]

- Tam, V.W.; Hao, J.J. Prefabrication as a mean of minimizing construction waste on site. Int. J. Constr. Manag. 2014, 14, 113–121. [Google Scholar] [CrossRef]

- Ng, M.S.; Hall, D.M. Toward lean management for digital fabrication: A review of the shared practices of lean, DfMA and dfab. In Proceedings of the 27th Annual Conference of the International Group for Lean Construction (IGLC), Dublin, Ireland, 3–5 July 2019; pp. 725–735. [Google Scholar]

- Product and Process Innovation. Available online: https://www.cerm-ex.com/product-process-innovation (accessed on 26 June 2021).

- Tatum, C.B.; Vanegas, J.A.; Williams, J.M. Constructability Improvement Using Prefabrication, Preassembly, and Modularization; US Department of Justice, Office of Justice Programs: Washington, DC, USA, 1986.

- Wasim, M.; Han, T.M.; Huang, H.; Madiyev, M.; Ngo, T.D. An approach for sustainable, cost-effective and optimised material design for the prefabricated non-structural components of residential buildings. J. Build. Eng. 2020, 32, 101474. [Google Scholar] [CrossRef]

- Jensen, P.; Olofsson, T.; Sandberg, M.; Malmgren, L. Reducing complexity of customized prefabricated buildings through modularization and IT support. In Proceedings of the 25th International Conference on Information Technology in Construction (CIB-W78), Santiago, Chile, 15–17 July 2008; pp. 429–437. [Google Scholar]

- Kuo, T.-C.; Huang, S.H.; Zhang, H.-C. Design for manufacture and design for ‘X’: Concepts, applications, and perspectives. Comput. Ind. Eng. 2001, 41, 241–260. [Google Scholar] [CrossRef]

- Vokes, C.; Brennan, J. Technology and Skills in the Construction Industry; Evidence Report 74; UK Commission for Employment and Skills (UKCES): London, UK, 2013. Available online: https://dera.ioe.ac.uk/18470/7/evidence-report-74-technology-skills-construction_Redacted.pdf (accessed on 26 June 2021).

- Bröchner, J.; Josephson, P.; Kadefors, A. Swedish construction culture, management and collaborative quality practice. Build. Res. Inf. 2002, 30, 392–400. [Google Scholar] [CrossRef]

- Lu, W.; Chen, K.; Xue, F.; Pan, W. Searching for an optimal level of prefabrication in construction: An analytical framework. J. Clean. Prod. 2018, 201, 236–245. [Google Scholar] [CrossRef]

- Pan, W.; Gibb, A.; Dainty, A. Perspectives of UK housebuilders on the use of offsite modern methods of construction. Constr. Manag. Econ. 2007, 25, 183–194. [Google Scholar] [CrossRef] [Green Version]

- Abowitz, D.A.; Toole, T.M. Mixed method research: Fundamental issues of design, validity, and reliability in construction research. J. Constr. Eng. Manag. 2010, 136, 108–116. [Google Scholar] [CrossRef]

- Rowley, J. Conducting research interviews. Manag. Res. Rev. 2012, 35, 260–271. [Google Scholar] [CrossRef]

- Bryman, A. Social Research Methods, 5th ed.; Oxford University Press: London, UK, 2016. [Google Scholar]

- Bogner, A.; Littig, B.; Menz, W. Introduction–Expert interviews: An introduction to a new methodological debate. In Interviewing Experts; Bogner, A., Littig, B., Menz, W., Eds.; Palgrave Macmillan: London, UK, 2009; pp. 1–13. [Google Scholar] [CrossRef]

- Namey, E. Riddle Me This: How Many Interviews (or Focus Groups) Are Enough? Available online: https://researchforevidence.fhi360.org/riddle-me-this-how-many-interviews-or-focus-groups-are-enough (accessed on 10 July 2021).

- Morgan, M.G.; Fischhoff, B.; Bostrom, A.; Atman, C.J. Risk Communication: A Mental Models Approach; Cambridge University Press: Cambridge, UK, 2002. [Google Scholar]

- Ezzy, D. Qualitative Analysis: Practice and Innovation; Allen & Unwin: Sydney, Australia, 2002. [Google Scholar]

- Francis, J.J.; Johnston, M.; Robertson, C.; Glidewell, L.; Entwistle, V.; Eccles, M.P.; Grimshaw, J.M. What is an adequate sample size? Operationalising data saturation for theory-based interview studies. Psychol. Health 2010, 25, 1229–1245. [Google Scholar] [CrossRef] [Green Version]

- Given, L.M. (Ed.) The SAGE Encyclopedia of Qualitative Research Methods; SAGE Publications: New York, NY, USA, 2008. [Google Scholar] [CrossRef]

- Bonde, D. Qualitative Interviews: When Enough Is Enough; Research by Design: Birmingham, UK, 2013; Available online: http://www.raptureconsulting.com/uploads/2/4/3/8/24380515/how_many_qualitative_interviews.pdf (accessed on 26 June 2021).

- Dworkin, S.L. Editorial: Sample size policy for qualitative studies using in-depth interviews. Arch. Sex. Behav. 2012, 41, 1319–1320. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Baker, S.E.; Edwards, R. How Many Qualitative Interviews Is Enough? Expert Voices and Early Career Reflections on Sampling and Cases in Qualitative Research; National Center for Research Methods: Southampton, UK, 2012; Available online: http://eprints.ncrm.ac.uk/2273/4/how_many_interviews.pdf (accessed on 26 June 2021).

- Guest, G.; Bunce, A.; Johnson, L. How many interviews are enough? An experiment with data saturation and variability. Field Methods 2006, 18, 59–82. [Google Scholar] [CrossRef]

- Postgraduate Study Skills. Available online: https://help.open.ac.uk/conducting-an-interview (accessed on 10 July 2021).

- Bryman, A.; Cassell, C. The researcher interview: A reflexive perspective. Qual. Res. Organ. Manag. 2006, 1, 41–55. [Google Scholar] [CrossRef]

- Taylor-Powell, E.; Renner, M. Analyzing Qualitative Data; University of Wisconsin: Madison, WI, USA, 2003; Available online: https://deltastate.edu/docs/irp/Analyzing%20Qualitative%20Data.pdf (accessed on 26 June 2021).

- HBS Projects. Available online: https://www.hickory.com.au/projects/filter/prefabricated/ (accessed on 13 August 2021).

- Collins House Wins 2021 CTBUH Construction Awards for Excellence. Available online: https://www.hickory.com.au/news/hickory-news-updates/collins-house-wins-2021-ctbuh-construction-awards-for-excellence/ (accessed on 26 June 2021).

- Thai, H.T.; Ngo, T.; Uy, B. A review on modular construction for high-rise buildings. Structures 2020, 28, 1265–1290. [Google Scholar] [CrossRef]

- House of Commons; Housing, Communities and Local Government Committee. Modern Methods of Construction; House of Commons: London, UK, 2019; Available online: https://publications.parliament.uk/pa/cm201719/cmselect/cmcomloc/1831/1831.pdf (accessed on 26 June 2021).

- Wuni, I.Y.; Shen, G.Q.P.; Mahmud, A.T. Critical risk factors in the application of modular integrated construction: A systematic review. Int. J. Constr. Manag. 2019, 1–15. [Google Scholar] [CrossRef]

- Burgess, J.C.; Buckett, N.R.; Page, I.C. Prefabrication Impacts in the New Zealand Construction Industry (SR279); BRANZ: Judgeford, New Zealand, 2013; Available online: https://www.branz.co.nz/pubs/research-reports/sr279/ (accessed on 26 June 2021).

- Švajlenka, J.; Kozlovská, M. Evaluation of the efficiency and sustainability of timber-based construction. J. Clean. Prod. 2020, 259, 120835. [Google Scholar] [CrossRef]

- Hardy, T.; Howe, J. Partners in enforcement? The new balance between government and trade union enforcement of employment standards in Australia. Aust. J. Labour Law 2009, 23, 306–336. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=1720662 (accessed on 26 June 2021).

- Council on Tall Buildings and Urban Habitat. DfMA: Engineering the future. In Proceedings of the CTBUH Annual Conference, Shanghai, China, 16–19 September 2014; Available online: https://www.researchgate.net/publication/282331071_DfMA-Engineering_the_Future (accessed on 26 June 2021).

- Chen, Y.; Okudan, G.E.; Riley, D.R. Sustainable performance criteria for construction method selection in concrete buildings. Autom. Constr. 2010, 19, 235–244. [Google Scholar] [CrossRef]

- Xue, H.; Zhang, S.; Su, Y.; Wu, Z. Factors affecting the capital cost of prefabrication: A case study of China. Sustainability 2017, 9, 1512. [Google Scholar] [CrossRef] [Green Version]

- Modular Construction Codes Board. Handbook for the Design of Modular Structures; Monash University: Melbourne, Australia, 2017; Available online: https://en.calameo.com/read/005664529a009d7488ed6 (accessed on 26 June 2021).

- DfMA: One of the Keys to Unlocking a More Efficient Industry. Available online: https://www.mottmac.com/views/dfma---the-key-to-a-more-efficient-industry (accessed on 26 June 2021).

- Ferdous, W.; Bai, Y.; Ngo, T.D.; Manalo, A.; Mendis, P. New advancements, challenges and opportunities of multi-storey modular buildings: A state-of-the-art review. Eng. Struct. 2019, 183, 883–893. [Google Scholar] [CrossRef]

- DFMA® Boothroyd Dewhurst Inc. Available online: https://www.dfma.com/default.asp#top (accessed on 26 June 2021).

- Boothroyd, G. Product design for manufacture and assembly. Comput. Aided Des. 1994, 26, 505–520. [Google Scholar] [CrossRef]

- Boothroyd, G. Assembly Automation and Product Design: Manufacturing Engineering and Materials Processing, 2nd ed.; Taylor & Francis: London, UK, 2005. [Google Scholar]

- Nguyen, P.; Akhavian, R. Synergistic effect of integrated project delivery, lean construction, and building information modeling on project performance measures: A quantitative and qualitative analysis. Adv. Civ. Eng. 2019. [Google Scholar] [CrossRef] [Green Version]

- Lean IPD. Available online: https://leanipd.com/ (accessed on 10 July 2021).

- Master of Science in Integrated Project Delivery. Available online: https://www.arch.hku.hk/programmes/rec/master-of-science-in-integrated-project-delivery/ (accessed on 10 July 2021).

- Master of Building Information Modelling and Integrated Project Delivery. Available online: https://bond.edu.au/program/master-building-information-modelling-and-integrated-project-delivery (accessed on 10 July 2021).

- Digital Twin Challenge to Lead Global Push to Accelerate More Sustainable Environments. Available online: https://www.digitaltwinhub.org/post/digital-twin-challenge-to-lead-global-push-to-accelerate-more-sustainable-environments (accessed on 10 July 2021).

- Measuring Project Success. Available online: https://www.i3d3.net (accessed on 10 July 2021).

- Building 4.0 CRC. Available online: https://building4pointzero.org/ (accessed on 10 July 2021).

- Kolb, B. Marketing Research: A Practical Approach; SAGE Publications Ltd.: London, UK, 2008. [Google Scholar] [CrossRef]

- Boafo, F.E.; Kim, J.; Kim, J. Performance of modular prefabricated architecture: Case study-based review and future pathways. Sustainability 2016, 8, 558. [Google Scholar] [CrossRef] [Green Version]

- Chen, K.; Lu, W. Design for manufacture and assembly-oriented design approach to a curtain wall system: A case study of a commercial building in Wuhan, China. Sustainability 2018, 10, 2211. [Google Scholar] [CrossRef] [Green Version]

- Banks, C.; Kotecha, R.; Curtis, J.; Dee, C.; Pitt, N.; Papworth, R. Enhancing high-rise residential construction through design for manufacture and assembly: A UK case study. Manag. Procure. Law 2018, 171, 164–175. [Google Scholar] [CrossRef] [Green Version]

| Project Name | Contractor/Location | Offsite Content | Key Features of DfMA | Benefits of DfMA |

|---|---|---|---|---|

| Salford and Wigan Building Schools | Laing O’Rourke (UK) | 70% |

| Considerable reduction of time in the production of component drawings |

| Water Treatment Plant | Laing O’Rourke (Australia) | 300 ‘module transportable packages’ |

|

|

| Davyhulme Wastewater Treatment Plant | Mott Macdonald (UK) | 5000 precast elements |

|

|

| Leadenhall Building | Laing O’Rourke (UK) | 85% |

|

|

| Battersea Power Station Site Redevelopment Phase 1 | Carillion and Skanska (UK) | Manufactured 540 utility cupboards |

|

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Langston, C.; Zhang, W. DfMA: Towards an Integrated Strategy for a More Productive and Sustainable Construction Industry in Australia. Sustainability 2021, 13, 9219. https://doi.org/10.3390/su13169219

Langston C, Zhang W. DfMA: Towards an Integrated Strategy for a More Productive and Sustainable Construction Industry in Australia. Sustainability. 2021; 13(16):9219. https://doi.org/10.3390/su13169219

Chicago/Turabian StyleLangston, Craig, and Weiwei Zhang. 2021. "DfMA: Towards an Integrated Strategy for a More Productive and Sustainable Construction Industry in Australia" Sustainability 13, no. 16: 9219. https://doi.org/10.3390/su13169219

APA StyleLangston, C., & Zhang, W. (2021). DfMA: Towards an Integrated Strategy for a More Productive and Sustainable Construction Industry in Australia. Sustainability, 13(16), 9219. https://doi.org/10.3390/su13169219