1. Introduction

A catalytic converter is a device that converts harmful pollutants, such as CO, nitrogen oxides, and unburnt hydrocarbons into less harmful pollutants by catalytic activity through the process of redox reactions. The pollutants are converted to CO2, N2, O2, and H2O, respectively, which are less harmful to humans as well as to the environment. These pollutants are responsible for ozone depletion and global warming. They have hazardous effects on human health that cause problems related to the respiratory system, as well as general health problems. Nitrogen oxide is responsible for smog formation and acid rain. In this study, the materials that were already used in catalytic converter were replaced by base earth metals that are not as expensive. Test sample catalysts were prepared, and the experimentation was performed.

After rigorous study of the literature, it was concluded that most of the research work was done on the selection of appropriate base metal catalysts for the redox reaction occurring inside the catalytic converter, in place of noble earth metals, because they are not only expensive but also have limited production. Guo et al. studied copper oxide along with cerium oxide and combined the doping of manganese oxide. The final catalyst was CuOx-MnOx-CeO

2, which gave more than a 99% conversion of CO “Guo16” [

1].

Qi and Li considered the oxidization of NO to NO

2 by using a catalyst that was a mixture of manganese and cerium oxides. The catalyst obtained conversion at about 350 °C with a percentage of ranging from 50 to 70% [

2]. Zhao et al. prepared CuO/Ce-Mn-O catalyst for the conversion of CO to CO

2 “Zha15” [

3]. The catalyst gave an almost complete conversion of CO at 160 °C. Alphonse used CoxMn

3−xO

4 oxides as a catalyst for the oxidation of CO and propane at mild temperatures. Co-Mn oxide spinel catalyst gave conversion of CO from 20 to 300 °C [

4]. Vasilyeva et al. prepared catalyst with Mn oxides, Si oxides, and Ti oxides for the conversion or oxidation of CO “Vas14” [

5]. This catalyst gave 50% conversion at 150 °C, and 100% conversion at about 210 °C. (Srivastava et al., 2012) used carbon-supported palladium catalyst for the removal of carbon monoxide: 5% Pd was coated on CeO

2 and ZrO

2 that have a CO to CO

2 conversion of 100% at 108 °C and 140 °C [

6]. Pakharukova et al. used the catalyst copper cerium oxide with monoclinic zirconia for assessing the oxidation of CO with excess of hydrogen and the catalyst obtained 100% conversion at 130 °C “Pak09” [

7]. Wojciechowska et al. used catalyst for the oxidation of CO by using copper and manganese, or cobalt oxides, supported on MgF

2 and Al

2O

3 [

8]. This catalyst gave a much smaller percentage of CO conversion of 51% at 300 °C for 15 min. Marbán and Fuertes used copper oxide and cerium oxide for the oxidation of CO. This catalyst obtained 90% conversion at about 165 °C “Mar05” [

9]. Hoflund et al. used gold with a MnO catalyst for the low-temperature oxidation of CO. This catalyst obtained about 90 to 100% conversion at about 225 °C in 17,000 min. [

10].

Energy is extracted by placing the turbine in an exhaust gas passage. Two-thirds of the energy from combustion in a vehicle is lost as waste heat, of which 40% is in the form of exhaust gases. Exhaust from an engine is used to generate electricity and can be stored in the battery after rectification for later consumption in various utilities. Hence stress and strain analysis have been carried out on the turbine. Podevin et al. provided a 3D CFD template for the friction failures of the turbocharger bearing [

11]. Alessandro et al. performed an experiment on the turbocharger efficiency, under nonadiabatic circumstances, to evaluate the thermal transfer effect. Quantify thermal fluxes through the use of the turbocharger evaluated their impact on engine reliability decay [

12]. Deligant et al. discussed the impact of axial force, oil inlet pressure, the delivery of rubbing force and oil mass stream among the push bearing and journal bearings, and the reckoning models for estimating the friction losses of the journal and thrust bearings [

13]. Mueller et al. carried out the optimization of radial turbine by using a two-level optimization algorithm created by the von Karman Institute for Fluid Dynamics [

14]. Ravindra et al. provided a guideline on the methods utilized in turbocharging to upsurge the engine productivity and decrease the exhaust gas secretion levels. Turbocharging is good with regard to economic considerations and engine efficiency [

15]. Emara et al. developed flow simulation modeling and performance prediction for the centrifugal compressor of a substantial diesel engine. Its results indicate that the developed mathematical computation model can give better predictions of performance for a centrifugal compressor stage in a turbocharger system [

16]. Salh et al. computationally analyzed the blade angle of the turbine rotor. He found that the blade angle impacts the air-compressed wheel’s stream area [

17].

2. Selection of Catalyst Materials

After extensive research and study of the literature review, it has been observed that the important factors that must be considered for the selection of materials are: cost-effectiveness; the easy precipitation from its saturated solution; and having thermal durability and resistance to poison Sulphur, phosphorus, and lead. The best catalysts should have good active sites for the adsorption and desorption of the molecules of the pollutants. From the literature review, it is observed that the cerium, manganese, and copper nano particles have a great conversion rate for CO, NOx and HC. Thus, they are the best option for the synthesis of catalytic converter. Selected sulphates of these metals are cerium ulphate tetra hydrate (CeO8S2.4H2O), manganese sulphate mono hydrate (MnSO4.H2O), and copper sulphate penta hydrate (CuSO4.5H2O), which fulfill all the required factors explained above for the selection of the best catalysts for achieving the maximum conversion of pollutants.

3. Preparation of Sample Catalysts

Firstly, for the preparation of the saturated solution of each salt for the purpose of the coprecipitation of the catalysts, distilled water was selected as a solvent because all three base salts are easily soluble in water at room temperature. For the preparation of sample catalysts, the correct molar ratio for each base metal was selected for the best combination, as shown in

Table 1.

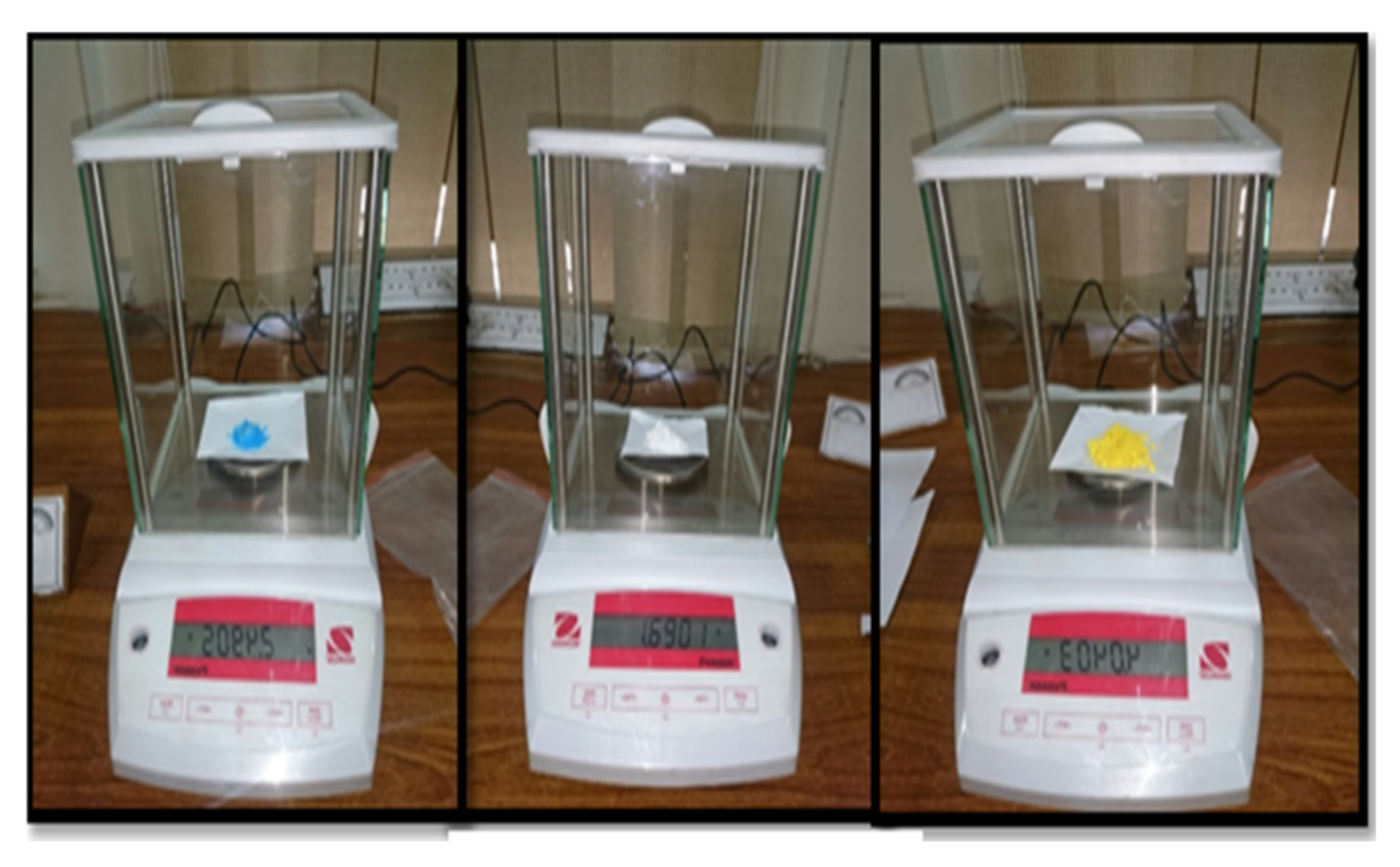

For the first sample catalyst, having all the base metal in a 1:1:1 combination, the correct molar ratio for each base metal was selected. For the measurement of each metal salt, an electronic balance having precision up to three decimals was used according to the required weights, as shown in

Table 1. For four test samples, the required combination of metals are weighed in grams in the electronic balance apparatus shown in

Figure 1.

For (CeO

8S

2.4H

2O), having a molecular weight of 404.304 g/mol, and yellow in color, 0.001 molar solution was prepared in 10 mL of distilled water by dissolving 4.04 g of salt with constant stirring for 5–10 min. After the solution was placed on the magnetic stirrer for 30 min, the complete dissolution of cerium sulphate in water and saturated solution was obtained. In the same manner, the manganese sulphate mono hydrate (MnSO

4.H

2O), having a pale white color, and copper sulphate penta hydrate (CuSO

4.5H

2O), which has a blue physical appearance and having a molecular weight of 169.02 g/mol and 249.677 g/mol, respectively, were dissolved in 10mL of distilled water to prepare 0.001 molar solution of each base metal salt with constant stirring on a magnetic stirrer for about 30 min each. Molar solution of each base metal in distilled water is shown in

Figure 2.

All the above sample solutions of metal salts were poured in a beaker with constant stirring until a chemical reaction occurred between base salts metals. The resultant solution was dark brown in color, which indicated that the reaction had been completed. The resultant solution contained the precipitates of the catalyst. Like the preparation of Sample 1, all four samples were prepared by dissolving the base metals in water in different ratios after weighing on an electronic balance, and stirring through a magnetic stirrer according to the table provided above, so that the best combination of base metals could be selected for the preparation of the final catalyst that gives the best results for the conversion of pollutants into less harmful pollutants. According to

Table 1, four samples were prepared, having different molar ratios, as shown below.

All four samples obtained were kept at room temperature for 4–6 days in open air and in a vibrationless place; otherwise, the base metal catalyst particles could again dissolve back into solution and, thus, lengthen the process. The process of the crystallization of the saturated solutions is referred to as the coprecipitation method. After 2 days, crystals began initiating in the solutions and started settling down at the bottom of the beaker. The process of crystallization was completed in 6 days, where matured crystals were developed in a solution, which can be easily seen by the naked eye. To completely filter the catalysts, a vacuum suction assembly apparatus was used. The dark brown color of the catalyst was obtained and it was kept at room temperature to completely dry the catalyst. Four sample catalysts were obtained in dried form which acted as a conversion agent for the pollutants.

4. Preparation of Test Samples

The next step was the application of the catalysts on the ceramic plates, having uniform thickness and pores, so that the exhaust gases can easily flow out and react on their way out to the atmosphere. Ceramic plates also have great thermal resistance, as exhaust gasses have very high temperatures. The catalysts were dissolved in acetone, which is an excellent solvent, evaporates easily, and obtains good adhesion to the catalyst on the ceramic plate. These catalysts were applied on the ceramic plate. In the same way, different catalysts were dissolved in acetone and were applied on different ceramic plates. Four test samples were obtained and dried at room temperature.

5. Testing and Analyzing

All four plates were installed in a box wrapped in aluminum foil so that the exhaust gasses could not escape from the box without coming into contact with the catalysts. The testing was done on the engine exhaust. The boxes were cut according to the dimensions of the silencer and were fitted on it with the plate facing the front face of the exhaust. The flue gas analyzer was placed in the exhaust to take a sample of the gasses coming out from the catalyst to give results. All four samples, with different molar ratios, were tested one by one through the flue gas analyzer (E-Instruments Model: E-4400-S, E-4400-C) to check the conversion of pollutants by each catalyst. Each catalyst gave different rates for the conversion of pollutants, as shown in

Table 2.

The graph below (

Figure 3) shows the comparison between different catalysts.

On the basis of the above discussion and verified results, it was decided to choose the base metals in the ratios of Cu (1): Ce (1): Mn (1) because of the higher conversion rate of pollutants as compared to the other molar ratios of Cu, Ce and Mn.

6. Preparation of New Catalytic Convertor

The final catalyst was prepared according to the above given ratios of the base metals. The method used for the preparation of the catalyst was the same as when the sample was prepared before. The ratios used for the preparation of the catalyst are shown in

Table 3.

After being weighed on the electronic balance, the solution of each was made by dissolving them into 30 mL of distilled water with constant stirring on a magnetic stirrer. The resultant black solution was obtained after mixing all the solutions. The solution was left for about 5–6 days in order to obtain the mature catalyst. The resultant catalyst was obtained by evaporating the water by use of a rotary evaporating apparatus for 3–4 h, which was then further crushed into a fine powder. After being dissolved in acetone, the catalysts were applied on a monolithic honeycomb structure of catalytic converter because it counters the phenomenon of back pressure due to its greater cell density for conversion to less harmful gasses.

7. Infrared Spectroscopy of Synthesized Materials

Spectroscopy is a useful method for providing structural clues as to the overall molecular structure of the unknown chemical composition in order to identify it. The large number of wavelengths emitted by this technique makes it possible to investigate their structures. In

Figure 4,

Figure 5 and

Figure 6, it is clearly observed that the transmittance value was above 95%, which showed that the new catalyst materials absorbed a smaller amount of radiation. In

Figure 4, large broad band at 3415 cm

−1 is ascribed to the O-H stretching vibration in the OH− groups of absorbent water molecules. The intense band at 500 cm

−1 corresponds to the Ce-O stretching vibration. A band near 1625 cm

−1 represents the carbonate-like group on the surface of the catalyst. Overall, FTIR spectra confirm the formation of the desired catalyst.

In

Figure 5 that presents the FTIR spectra of MnSO

4.H

2O, the bands at around 3200 and 1499 cm

−1 correspond to the O–H vibrating modes of the traces of absorbed water. The bands at 761.9, 623.6, and 604.3 cm

−1 that are below 750 cm

−1 can be attributed to the Mn–O vibrations. Overall, the FTIR spectra confirm the formation of the desired catalyst.

In

Figure 6, a CuSO

4.5H

2O spectrum has the characteristic peaks at the band values of 3114, 1667, 1063, and 860 cm

−1. In these spectra, the peaks over 3000 cm

−1 may be explained by the crystal water in the structure. The peaks at lower band values can be explained as the vibrations between O and nonmetal atoms. Overall, FTIR spectra confirm the formation of the desired catalyst.

8. Final Testing and Comparison with Old Installed Catalytic Converter

The original company provided catalytic converter that contains the catalyst combination of noble metals, such as platinum, rhodium, and palladium. Noble metals are very expensive because of their limited production, which increases their cost. The old catalytic converter was first tested by using flue gas analyzer. The results obtained are shown in

Table 4.

After removing the old catalytic converter, the upgraded catalytic converter was installed on an engine test bench. It was then tested by the flue gas analyzer by placing its probe in the exhaust duct. The results obtained are shown in

Table 5.

8.1. Conversion Comparison of Exhaust Gases Produced by Both Catalytic Convertors

A graph was plotted to have a clear idea as to the conversion efficiency of the old and upgraded catalytic convertor, as depicted in

Figure 7.

Figure 7 shows that there has been a strong increase in the conversion rate of CO, but a slight increase in NO. There is decrease in the conversion rate of HC as compared to the original catalytic converter. The efficiency of the conversion of newly manufactured catalytic converter is:

Upgraded catalytic convertor, 59.77% and 4.69% efficient in reducing CO and NO, respectively.

8.2. Cost Comparison

In the old manufactured catalytic converter, the precious noble metals, such as platinum, rhodium, and palladium were used, which also have limited production. Base metals salts of Cu, Ce, and Mn were used as catalysts in the newly manufactured catalytic converter, which are easily available as well as cost-effective.

9. 3D Modeling, Stress-Strain, and Flow Analysis of Turbine

The aim of the study was to install the turbine in the exhaust passage to extract power from the exhaust gases, which would later be utilized to run the electrical accessories of the engine. For this purpose, a typical turbine was modeled over SOLIDWORKS. The 2D drawing of the turbine with various views is shown in

Figure 8a, and a machined turbine is shown in

Figure 8b.

The power generated from the exhaust gases of an internal combustion engine is a process of the production of energy. The engine converts chemical energy into mechanical energy, and waste is extracted in the form of exhaust gases from the engine, which further moves towards the tail pipe of an engine. These gases move at high temperatures and pressures towards the outlet. The turbine is placed in the pathway of these exhaust gases which is designed in a way so that these exhaust gases tend to rotate the blades of the turbine, following the measurements that were taken by the help of a tachometer, as shown in

Table 6.

The strain analysis of the turbine was done at a 5500 engine speed (rpm), and is shown in

Figure 9. The static structural analysis on ANSYS was carried out and equivalent elastic strain distributions on various section of the turbine is shown below with the minimum value at the turbine shaft, i.e., 6.5 × 10

−9 m/m, and the maximum value was observed where the exhaust flow at the inlet of the turbine casing exerts a force on the turbine blade, which produces the maximum elastic strain at the edge of the turbine blade, right in front of the turbine casing inlet. The maximum value of the equivalent elastic strain observed was 1.42 × 10

−6 m/m.

Stress analysis of the turbine was done at 5500 engine speed (rpm) and is shown in

Figure 10. The static structural analysis on ANSYS was carried out, and the equivalent elastic stress distribution on various sections of the turbine is shown below, with the minimum value at the turbine shaft, i.e., 932.35 Pa, and the maximum value observed at the edge of the turbine blade, right in front of the turbine casing inlet is 2.46 × 10

5 Pa, which is in the range and majority section. The observed Von Mises stress value is 55,588 Pa.

In

Figure 11a,b it is clearly observed that there is no backflow of the exhaust gases. Hence, there is no excess load produced on the engine. The inlet and outlet values of pressure are 136,846.86 Pa and 101,718.72 Pa. The inlet value of the velocity is 7.6 m/s, and the outlet value is in the range of 3.04 m/s–6.08 m/s.

10. Conclusions

From the above discussion and experimentation, it is concluded that base metals have greater conversion efficiency of CO into CO2, and NOx into N2, as compared to noble metals. However, in the case of HC, original catalytic converter gives good results. On the basis of the prior discussion, it is proven that base metals have greater efficiency according to their performance, and that they are economical as well. Thus, the noble metals, which are platinum, palladium, and rhodium, could be replaced by the base metals cerium, manganese, and copper. During the experimentation work, it was observed that base metals catalysts have low thermal stability at higher temperatures and this adversely alters the performance of the catalysts.

Moreover, the pressure reduction from the inlet to the outlet indicates the transfer of momentum from the exhaust gases to the turbine. Further focus on the velocity contour and pressure contour clearly indicates that there is no backflow of the exhaust gases in an engine.

Author Contributions

Conceptualization, R.K. and J.T.; methodology, R.K.; software, R.K.; validation, R.K.; formal analysis, R.K.; investigation, R.K. and J.T.; resources, R.K.; data curation, R.K.; writing-original draft preparation, R.K.; writing-review and editing, R.K.; visualization, J.T. and K.M.; Supervision, J.T. and H.M.A.; project administration, J.T. and H.M.A.; funding acquisition, R.K. and J.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

This work was supported by the Interdisciplinary Graduate School of Energy Systems, Prince of Songkla University. Special thanks to University of Wah, M. Ahsaan Yousaf, M. Wajahat Rasool and Maryam Arshad for the fabrication of engine bench, catalytic converter and facilitation.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Guo, X.; Li, J.; Zhou, R. Catalytic performance of manganese doped CuO–CeO2 catalysts for selective oxidation of CO in hydrogen-rich gas. Fuel 2016, 163, 56–64. [Google Scholar] [CrossRef]

- Qi, G.; Li, W. NO oxidation to NO2 over manganese-cerium mixed oxides. Catal. Today 2015, 258, 205–213. [Google Scholar] [CrossRef]

- Zhao, F.; Gong, M.; Zhang, G.; Li, J. Effect of the loading content of CuO on the activity and structure of CuO/Ce-Mn-O catalysts for CO oxidation. J. Rare Earths 2015, 33, 604–610. [Google Scholar] [CrossRef]

- Alphonse, P. Alphonse Co–Mn-oxide spinel catalysts for CO and propane oxidation at mild temperature. Appl. Catal. B Environ. 2016, 180, 715–725. [Google Scholar]

- Vasilyeva, M.S.; Rudnev, V.S. Composition, surface structure and catalytic properties of manganese-and cobalt-containing oxide layers on titanium. Adv. Mater. Res. 2014, 875, 351–355. [Google Scholar] [CrossRef]

- Srivastava, A.K.; Saxena, A.; Shah, D.; Mahato, T.H.; Singh, B.; Shrivastava, A.R.; Gutch, P.K.; Shinde, C.P. Catalytic removal of carbon monoxide over carbon supported palladium catalyst. J. Hazard. Mater. 2012, 241, 463–471. [Google Scholar] [CrossRef] [PubMed]

- Pakharukova, V.P.; Moroz, E.M.; Kriventsov, V.V.; Zyuzin, D.A.; Kosmambetova, G.R.; Strizhak, P.E. Copper–cerium oxide catalysts supported on monoclinic zirconia: Structural features and catalytic behavior in preferential oxidation of carbon monoxide in hydrogen excess. Appl. Catal. A Gen. 2009, 365, 159–164. [Google Scholar] [CrossRef]

- Wojciechowska, M.; Przystajko, W.; Zieliński, M. CO oxidation catalysts based on copper and manganese or cobalt oxides supported on MgF2 and Al2O3. Catal. Today 2007, 119, 338–341. [Google Scholar] [CrossRef]

- Marbán, G.; Fuertes, A.B. Marban and Fuertes Highly active and selective CuOx/CeO2 catalyst prepared by a single-step citrate method for preferential oxidation of carbon monoxide. Appl. Catal. B Environ. 2005, 57, 43–53. [Google Scholar] [CrossRef]

- Hoflund, G.B.; Gardner, S.D.; Schryer, D.R.; Upchurch, B.T.; Kielin, E.J. Effect of CO2 on the performance of Au/MnOx and Pt/SnOx low-temperature CO oxidation catalysts. Langmuir 1995, 11, 3431–3434. [Google Scholar] [CrossRef]

- Deligant, M.; Podevin, P.; Descombes, G. CFD model for turbocharger journal bearing performances. Appl. Eng. 2011, 31, 811–819. [Google Scholar] [CrossRef]

- Romagnoli, A.; Martinez-Botas, R. Heat transfer analysis in a turbocharger turbine: An experimental and computational evaluation. Appl. Therm. Eng. 2012, 38, 58–77. [Google Scholar] [CrossRef] [Green Version]

- Deligant, M.; Podevin, P.; Descombes, G. Experimental identification of turbocharger mechanical friction losses. Energy 2012, 39, 388–394. [Google Scholar] [CrossRef]

- Mueller, L.; Alsalihi, Z.; Verstraete, T. Multidisciplinary optimization of a turbocharger radial turbine. J. Turbomach. 2013, 135, 021022. [Google Scholar] [CrossRef]

- Sanap, R.S.; Gite, R.E.; Patel, K.M.; Patel, D.H. Design and Development of Turbo-Charger for Two Stroke Engine. Int. Adv. Res. J. Sci. Eng. Technol. 2016, 3, 144–149. [Google Scholar]

- Soliman, I.M.; Emara, A.A.; Razek, A.M.E.; Moneib, H.A. Modeling and CFD Analysis of Air Flow through Automotive Turbocharger Compressor: Analytical Approach and Validation. In Proceedings of the International Conference on Aerospace Sciences and Aviation Technology, Cairo, Egypt, 11–13 April 2017; Volume 17, pp. 1–15. [Google Scholar]

- Sawadi, A.S.; Shkhair, M.M.; Tilefih, R.J. Optimize and Analysis Compressor Wheel of Turbo Charger. J. Mech. Eng. Res. Dev. 2018, 41, 59–64. [Google Scholar] [CrossRef]

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).