1. Introduction

The textile and apparel industries are highly globalized, with mature and labor-intensive processes [

1,

2]. The sector is fast-paced and requires quick responses to changing customer demands, while maintaining quality and controlling costs [

3]. There are serious sustainability concerns in these industries regarding sourcing practices and the social and environmental impact of production [

4,

5]. Many consumers have become aware of the social and environmental impacts of textile and apparel production, including concerns related to child labor, health and safety, water consumption, the discharge of toxic chemicals, and links to deforestation [

6,

7]. Consumers are increasingly demanding ethically produced garments made from sustainable materials using environmentally friendly manufacturing processes [

4,

8]. Many governmental and non-governmental organizations are actively working to tackle both the environmental and social issues related to textile and apparel production. The Sustainable Apparel Coalition (SAC) has developed the Higg Index to assess the sustainability performance of organizations [

9]. The Canopy Planet Organization uses the Hot Button ranking system to assess the sustainability of fiber producers [

10]. Textile Exchange is a further example of an industry-wide non-profit organization that works on developing standards for the industry and provides industry insights on developments for sustainability in the sector [

11].

The textile and apparel industries suffer from opacity and a lack of visibility [

8,

12], which may conceal unethical practices and high global CO

2 emissions in the supply chain [

13]. Counterfeit products are a further problem, presenting challenges for both upstream suppliers producing sustainable fibers and downstream brands and retailers, particularly in the high-end luxury sector. Traditionally, apparel products have been labeled only at the garment manufacturing stage, with limited or no ability to determine the precise origin of the fibers used in their production or the stages in the manufacturing process [

14]. These factors have increased the pressure on brands and retailers to be transparent with consumers about product origin and production practices. Many of the top clothing brands and major retailers, including the H&M Group [

15], Inditex Zara [

16], and NEXT [

17], provide information about their suppliers in efforts to be more transparent and to assure sustainability. Such transparency drives improvements in sustainability but requires traceability across supply networks. Upstream players in this sector, including fiber producers, are increasingly engaged in developing and enhancing the sustainability of their operational practices [

18]. This is evident in the growth in the eco-fiber market, which is expected to reach over 79 billion USD by 2027 [

19]. Sustainable practices may also enhance an organization’s competitiveness, reputation, and recruitment [

20,

21]. Thus, sustainable business practices are imperative for responsible producers and manufacturers.

Advances in technology have encouraged the investigation and development of end-to-end supply chain traceability solutions. Existing technologies, such as barcodes and radio frequency identification (RFID) tags and sensors, have been widely deployed to collect and store data about products, processes, and services across the supply chain [

22,

23]. Enterprise Resource Planning (ERP) systems are widely used to record and process supply chain transactions, with such systems increasingly migrating to the cloud [

24]. However, conventional information systems and technologies have limitations in guaranteeing traceability. They raise issues related to identity management and data manipulation, and are prone to cyber-attacks [

25]. They are not tamper-proof, which raises questions on who did what and when in the supply chain [

22]. These issues are challenging when operating in untrusted environments, which is typical of many globally dispersed and fragmented supply chains. Blockchain has been recognized as a potential technology that enables supply chain traceability and that may help to address many of these issues [

8,

12].

Blockchain is a distributed ledger technology that provides an immutable decentralized digital record comprising a chain of blocks of transactions that is shared among a distributed network of participants. The technology has captured the interest of many supply chain researchers and practitioners, who argue for its potential benefits in overcoming supply chain traceability challenges when adopted across the supply chain [

12,

22,

26]. There is an increasing number of blockchain pilot projects in many industries and sectors [

27], including the textile and apparel industries. Notwithstanding the potential of blockchain technology to transform the management and control of supply chains, its adoption and application in practice are challenging [

28]. The literature is very limited in providing real cases that examine its adoption in practice [

29].

In this paper, we investigate and analyze the use of blockchain technology in the textile and apparel business ecosystems. We study one of the most prominent man-made cellulose fiber (MMCF) producers, the Lenzing Group, a company that has been a pioneer in the use of blockchain technology in the MMCF fiber supply chain. We analyze information from the academic and practice literatures and interviews with participants in blockchain projects at Lenzing to provide a critical analysis of their blockchain-enabled traceability system and its potential in the future. We make a number of significant contributions in this work. We present and analyze a case in an important sector, where supply chain transparency, traceability, and sustainability are of great importance. We identify two different but related perspectives in current blockchain applications in the sector, which depend on the objectives for traceability - ensuring authenticity and/or supporting sustainability. We highlight critical factors with regard to the scope of supply chain traceability and product identification across the supply chain. The discussion of these issues in the blockchain-enabled traceability literature has been very limited. We also identify opportunities and major challenges for extending traceability across the entire supply chain from raw material to end consumer in the textile and apparel sector. The insights have relevance to blockchain applications in many other sectors with different supply chain configurations.

The paper is structured as follows. We discuss the potential of blockchain technology to transform supply chain management in

Section 2. In

Section 3, we review the reported blockchain applications in the textile and apparel industries.

Section 4 presents a case study analysis of the approach taken by the major fiber producer, Lenzing, in using blockchain technology to track fiber in its downstream supply chain. We discuss the implications of the study in the broader context of supply chain traceability in

Section 5, highlighting both the challenges in scoping a traceability solution and the opportunities for end-to-end traceability in the textile and apparel sector.

Section 6 briefly concludes the study.

2. The Transformative Potential of Blockchain Technology in Supply Chain Management

Many supply chains lack visibility, trust, and effective information sharing. Different actors in the supply chain operate in silos with different and often incompatible systems [

30]. This gives rise to many challenges in managing supply chains—sustainability issues, difficulties in responding to supply chain risks and disruptions [

31], and demand signal distortion such as the well-known bullwhip effect [

32]. The disruption caused by the COVID-19 pandemic has highlighted the need for extended supply chain solutions that enable the whole supply ecosystem to interact, share necessary information, and collaborate in response to disruptions [

33].

Blockchain technology has the potential to transform the way supply chains are managed, as explained in a number of seminal studies [

22,

34,

35,

36]. Blockchain can provide a secure way of recording information about responsible parties and their actions in a supply chain in an immutable distributed ledger, including the time and locations of supply chain processes, operations, and transactions [

22,

23,

34]. The characteristics of blockchain have encouraged its adoption in a wide range of supply chain applications [

22,

26,

34,

36]. Four key capabilities of blockchain technology can be identified that make the technology attractive to address pressing problems and challenges in contemporary supply chains:

(1)

Traceability: The chronological record of blockchain transactions is the key principle underpinning blockchain traceability [

35]. Each block in the blockchain is linked cryptographically to the one that preceded it in the ledger using the block hash and the timestamped information, thus creating an immutable historical record of transactions. This capability ensures the validity of the ledger by keeping track of changes, allowing faults to be identified, and attempts at tampering to be highlighted [

34,

35].

(2)

Security: Blocks in the blockchain ledger are timestamped and identified using cryptographic keys [

34]. Once a block is added to the ledger, it is immutable as data can only be added, not deleted or edited [

37]. The tamper-proof architecture of blockchain technology is one of its most powerful capabilities, making it an attractive technology to use in many applications [

35].

(3)

Transparency: The decentralized blockchain network enables dispersed participants to interact and exchange information in a secure medium [

34]. All network participants can, in theory, be given access to the exact copy of the distributed ledger at any time [

22,

34].

(4)

Autonomous Smart Contracts: Smart contracts are computerized transaction protocols that execute the terms of a contract [

36,

38]. The use of smart contracts transforms the capabilities of a blockchain platform from a secure data storage platform to a computational platform that enables the automatic execution of transactions once triggered by other transactions [

39].

Several types of blockchain networks exist that differ with respect to who can access the distributed ledger (i.e., read rights), who can post transactions (i.e., write rights), and who can validate transactions (i.e., block review and validation rights). Three types of network are commonly distinguished: (1) public or permissionless blockchain networks, in which anyone can access the distributed ledger, post, and validate transactions; (2) private or permission-based blockchain networks, in which only permissioned participants can access the ledger, post, and validate transactions; and (3) consortium blockchain networks, in which selected participants are responsible for the validation process while access to the ledger and transaction posting can be public or private [

40,

41]. Most of the blockchain applications in supply chain management use permissioned or consortium blockchain networks [

42]. The way the blocks are created, validated, and distributed varies depending on the consensus mechanism used and the governance model of the blockchain network [

43].

The implications of the adoption of blockchain technology for the supply chain go beyond its technical capabilities and may significantly impact future business models [

42]. The characteristics of blockchain make it suitable as an inter-organization technology, enabling secure information sharing, while maintaining ownership of data. Blockchain may enhance trust and accountability in the supply chain ecosystem by providing a secure and tamper-proof medium for information sharing [

44]. Blockchain enables the provision of an immutable digital record of supply chain data to be shared across the supply chain, and helps in overcoming the problem of data being trapped in siloed organizational systems. There are many opportunities and potential advantages in combining blockchain with existing technologies. Data can be collected using technologies such as the internet of things (IoT), sensors, barcodes and RFID tags, and APIs, and then stored on a blockchain [

23,

30].

Blockchain technology can help in tackling many existing challenges in the textile and apparel supply chain and help to improve the transparency, traceability, and sustainability of apparel products [

5,

45]. The textile and apparel industry is globally dispersed, with complex supply network configurations and material flows [

1]. The fragmented structure of the industry can benefit from a decentralized blockchain architecture that promotes transparency and information sharing [

23]. With the provision of a chronological record of transactions, blockchain can enable materials tracking across the multi-tier apparel supply network [

8]. The use of smart contracts may help in enforcing sustainable practices and in identifying non-conformance, which can potentially encourage and support ethical practices [

8].

Blockchain adoption leverages the importance, power, and position of the different participants in the apparel value chain. Fiber producers play a crucial role in the apparel supply chain with regard to supply chain traceability and sustainability since they are responsible for production and sustainability at the beginning of the value chain. Fiber producers need to enable the identification of their fibers and ensure their provenance and sustainability before they enter complex downstream apparel supply chains. For major brands and retailers, collaborating with fiber producers is critical for the success of their traceability projects, helping to bridge the gap across the different segments of the supply chain. Besides the fiber producers, spinners, fabric makers, and garment makers are also essential participants in the apparel supply chain. Their involvement is crucial since products may need to be identified and tracked at each value-adding stage of the supply chain for effective traceability systems. All supply chain partners, including fiber producers, experience demand fluctuations due to a lack of visibility and information sharing and the bullwhip effect, which can negatively affect their supply chain planning and management processes [

46]. The rich data environment provided by a traceability system may help to improve inventory management and supply chain efficiency [

26,

47]; to support different administrative processes across the supply chain, such as the product recall processes [

4,

8,

48]; and to capture information such as CO

2 emissions [

49,

50]. We discuss applications of blockchain in the textile and apparel supply chain below.

3. Blockchain Applications in the Textile and Apparel Supply Chain

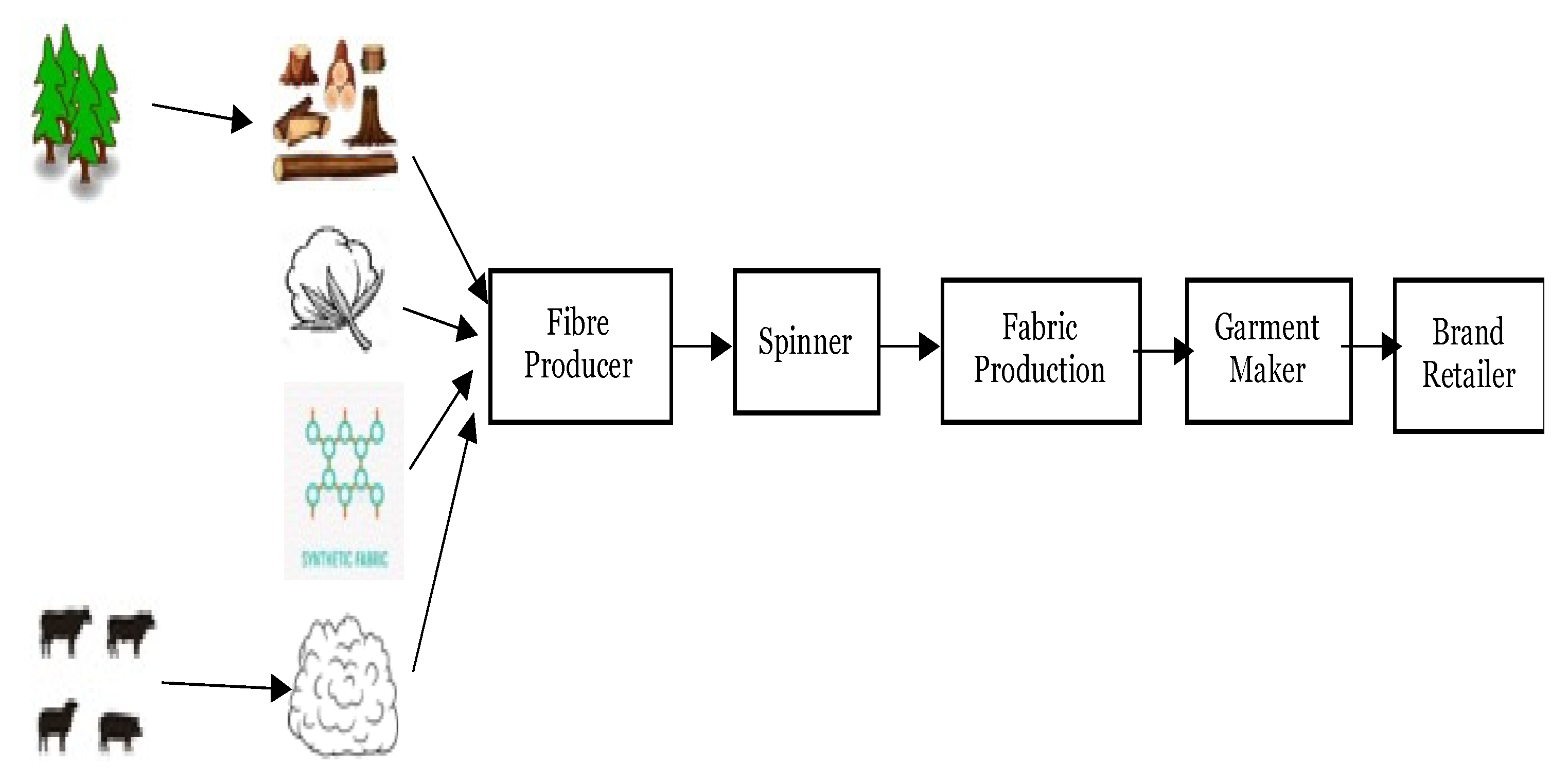

The textile and apparel supply network configuration varies in terms of complexity, geographical spread, and size. A diverse range of natural and synthetic fibers are used in garment production (e.g., cotton, wool, silk, viscose, polyester, etc.). Notwithstanding the geographical spread of the industry and the diversity of materials used, six main value-adding stages are evident in most textile and apparel supply chains: (1) raw material sources (e.g., farm, forest, fiber plant, etc.); (2) fiber producers; (3) spinners; (4) fabric makers; (5) garment makers; and (6) brands or retailers (see

Figure 1). In addition, there are many other intermediaries, trading entities, and logistics providers involved in buying, selling, and transporting textile and apparel products across the principal value-adding activities and/or carrying out specific processing activities such as fabric dyeing and finishing. Many production activities occur in developing countries (e.g., spinning, fabric manufacture, cutting, sewing, and finishing), whereas most product design and development occurs in developed countries. Major retailers and brand owners frequently lead the design and development of garments [

51].

Blockchain technology can be applied in different ways in supply chain configurations. Various blockchain projects are evident in the textile and apparel industry.

Table 1 presents some of the most prominent blockchain applications in the industry that use permissioned or consortium network models. Most blockchain projects undertaken to date in this industry have sought to ensure the authenticity and sustainability of apparel products in response to increasing demand for sustainable practices from customers, governments, and non-governmental organizations. Blockchain has been used to identify and track product provenance by capturing information on product ownership, material processing, and material movements as the product flows across the supply chain. Permanent product records and related information are stored on the blockchain-enabled distributed ledger, which acts as a supply chain digital twin.

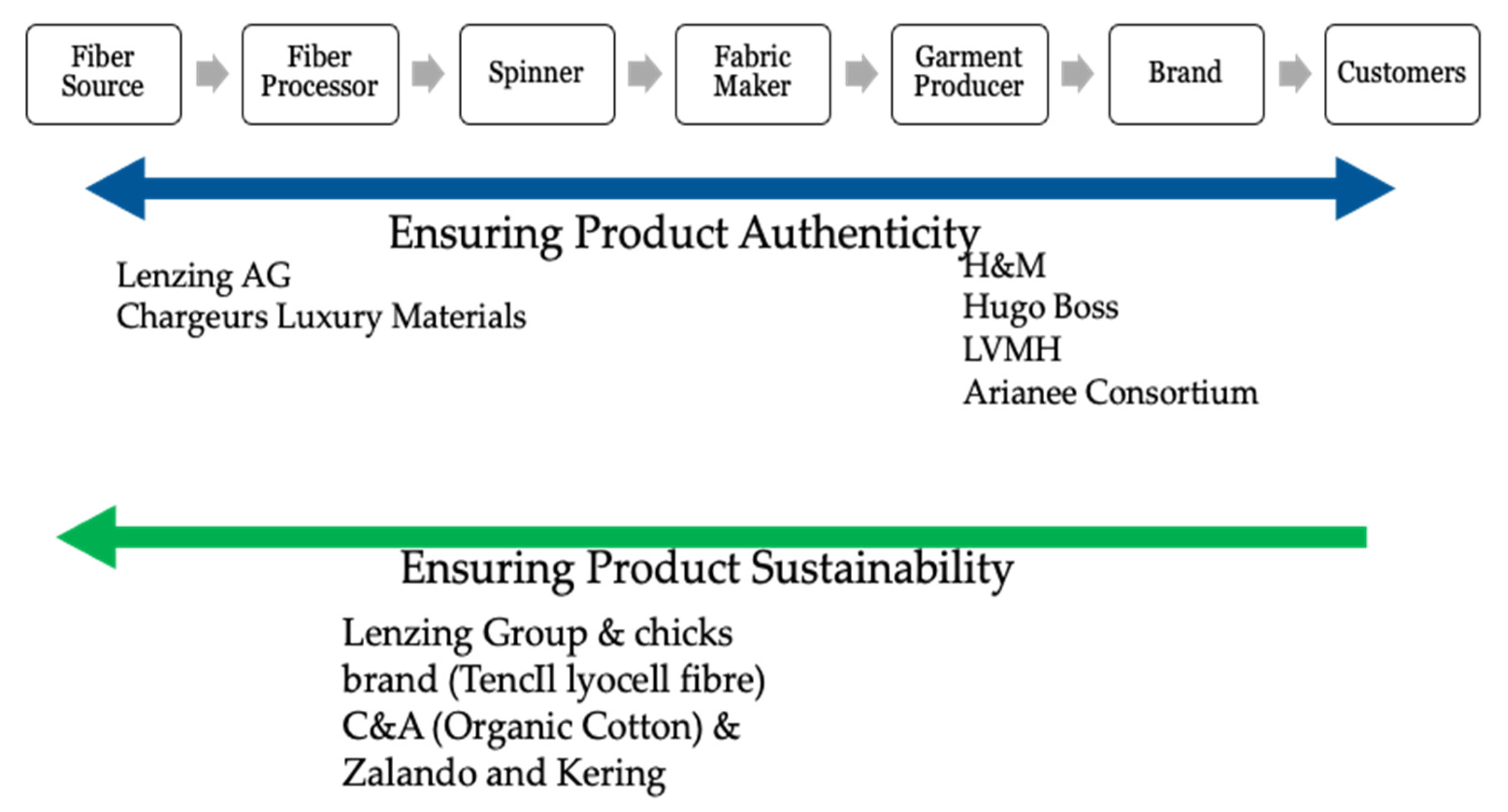

We distinguish between two main application areas from the current blockchain applications in the textile and apparel industry:

- (1)

Blockchain applications to ensure product authenticity

Fighting fraud and ensuring product authenticity have been significant drivers for many blockchain pilots, especially but not exclusively for luxury brands with high-value end-products. In most of these pilots, the traceability solution starts from the point of final product creation. Some of the high-sustainability fiber producers also use the technology to authenticate their fiber and fight counterfeiting. Examples of such blockchain pilot projects in the supply chains of specific organizations include Hugo Boss (Hackling, 2019), Chargeurs Luxury Materials [

52], and Lenzing [

53]. Examples of blockchain projects undertaken by consortia include the AURA Consortium, developed by LVMH [

54,

55], and the Arianee Consortium, which use blockchain to enable the digital certification of luxury goods [

56].

- (2)

Blockchain applications to ensure product sustainability

Due to the sustainability concerns related to apparel sourcing and production, many brand retailers and fiber producers have started to use blockchain technology to ensure garment sustainability. This is achieved by identifying and verifying garment origin and through the use of certified suppliers at each stage in the supply chain. Examples of brands and retailers who have explored or piloted blockchain to ensure the sustainability of their products, include Martine Jarlgaard [

57], C&A Foundation [

58], and Armedangels [

59,

60].

Table 1.

Examples of prominent blockchain applications in the textile and apparel industry.

Table 1.

Examples of prominent blockchain applications in the textile and apparel industry.

| Organization/Blockchain Consortium | Blockchain Project Description | Reference |

|---|

- 1.

AURA Consortium

| LVMH partnered with ConsenSys, and Microsoft Azure formed the AURA consortium to lead and call for industry-wide collaboration to examine and deploy blockchain technology for product traceability and authenticity. Prada and Cartier have recently joined the consortium. AURA aims to prove authenticity to customers and track products from the origin of the raw materials to the point of sale.

| [54,55] |

- 2.

Arianee Consortium

| | [56] |

- 3.

HUGO BOSS

| Hugo Boss, the luxury clothing and fashion goods brand, has collaborated with ASTRATUM to develop Tracey, a blockchain platform to track products across their supply chain and ensure their authenticity.

| [61] |

- 4.

Chargeurs Luxury Materials

| Chargeurs Luxury Materials, a world-leading wool supplier, has developed a label named Organica Precious Fibers based on blockchain technology to ensure the quality of its fibers and enable traceability from the sheep to the retail customer.

| [52] |

- 5.

Martine Jarlgaard

| | [57] |

- 6.

C&A Foundation

| A blockchain pilot led by Bext360 has been carried out to trace organic cotton from the farm to the ginning process with a plan to extend it to the consumers. In the pilot, blockchain was used as a secure data platform that integrates information across the supply chain. Other technologies such as machine vision, artificial intelligence, and on-product markers are used to ensure the accuracy of the data stored on the blockchain. Several organizations have been involved, including C&A Foundation, Fashion for Good, Organic Cotton Accelerator, and several brands, including Kering, Zalando, and C&A.

| [58] |

- 7.

Armedangels

| Many brands, including Armedangels, Boyish, and CANO, have piloted the use of retraced solutions. Retraced, a blockchain solution provider, has developed a tool based on the Oracle Hyperledger Fabric blockchain platform and the use of QR barcodes and NFC chips to trace products across the supply chain to enable transparency.

| [59] |

- 8.

Lenzing AG

| | [53,60] |

The scope of product traceability in the supply chain varies depending on the purpose of the blockchain project. When the purpose is solely to ensure the authenticity of products, then the scope of traceability can vary and include different stages in the upstream or downstream supply chain. For example, to authenticate an LVMH garment piece, the traceability system might start from the garment manufacturing stage, but if the purpose is to ensure that the garment is made from organic cotton, then the scope of traceability might start from the source of raw materials or the fiber producer. When the purpose of traceability is to ensure the sustainability of products, then the upstream stages of the supply chain should be included. However, some applications may aim to ensure both product authenticity and sustainability when implementing supply chain traceability.

Figure 2 presents the potential span and direction of traceability across the main value-adding stages for product authenticity and sustainability, based on the current blockchain applications presented in

Table 1. We analyze in detail one of the prominent blockchain applications in the textile and apparel supply chain below.

4. Blockchain-Enabled Traceability in the Textile and Apparel Supply Chain: A Case Study of a Fiber Producer

Blockchain provides many opportunities for the different supply chain partners that participate in the textile and apparel sectors, and especially for fiber producers. Despite the efforts that fiber producers may make in ensuring the sustainability of their sourcing and production activities, their efforts may not be fully recognized by brand retailers or by end-consumers. Additionally, there is no guarantee that what reaches the end-consumer has been produced from an authentic and sustainably produced fiber [

25]. With the use of blockchain and appropriate product identification techniques [

62], fiber producers can securely identify and track the use of their fibers at each stage of the downstream supply chain, assure the authenticity and sustainability of their fibers, and gain a competitive advantage against rivals. They can also potentially improve their operational performance through improved visibility, information sharing, and transparency across the supply chain. We describe and analyze how the innovative man-made cellulose fiber (MMCF) producer, the Lenzing Group, has adopted blockchain technology in its supply chain. We discuss the challenges, implications, and opportunities associated with this solution for the whole textile and apparel ecosystem.

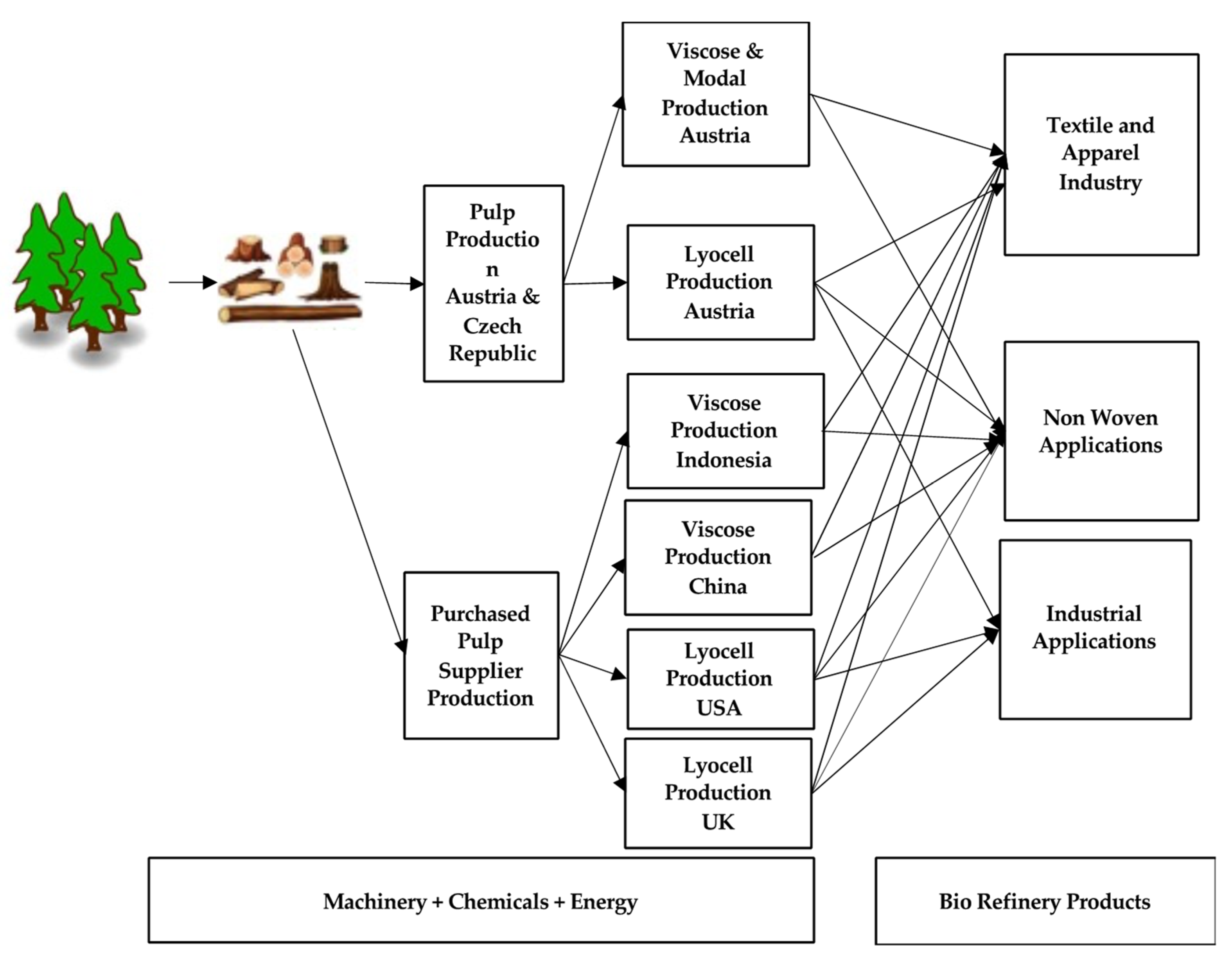

4.1. Overview of the Lenzing Group

Lenzing AG, an Austrian company, is a world-leading specialized fiber producer that produces a variety of sustainable and biodegradable fibers made from wood. Lenzing produces three types of fiber: (1) the highly innovative and specialized fiber, lyocell, (2) the 2nd-generation specialized fiber, modal, and (3) the 1st-generation viscose fiber. The company sources wood from certified forests and carries out pulp production on its premises in Austria and in the Czech Republic. For its other plants, Lenzing sources pulp from qualified producers [

63]. There are three main downstream applications for Lenzing fibers: textile and apparel applications; nonwoven applications (e.g., baby care and sanitary products); and industrial applications (e.g., packaging material) [

63]. Each of these applications leads to a different downstream supply network configuration.

Figure 3 presents a high-level map of Lenzing’s supply chain configuration.

Table 2 presents Lenzing’s fibers, their production volume, market share, fiber characteristics and application areas, and highlights the main challenges for each fiber. The majority of Lenzing’s fibers go into textile applications and become part of the global complex multi-tier apparel industry. There is a lack of transparency and traceability downstream for Lenzing, especially beyond the fabric makers, which affects the company’s planning processes and capacity management as it frequently suffers from high demand fluctuations.

Lenzing’s corporate strategy highlights sustainability. The company promotes collaboration with wood suppliers that adhere to EU regulations and it sources wood pulp from certified suppliers [

63]. Lenzing has also engaged in novel sustainability initiatives and in promoting the circular economy through its Refibra technology and the use of recycled cotton (

https://www.tencel.com/refibra (accessed on 24 July 2021). The branded viscose fibers of Lenzing are innovative and significantly more sustainable than traditional viscose fibers, generating lower emissions and having a reduced water impact [

63]. The company seeks to protect this novelty and innovation against counterfeiting and to share and educate its customers about its sustainable practices. Hence, traceability is crucial for Lenzing in order to (1) protect and authenticate its innovative and sustainable fibers in the final garment products, (2) promote its sustainable products in the market for competitive advantage, (3) fight counterfeit products, and (4) improve the efficiency of the supply chain by enhancing visibility, thereby supporting the supply chain planning and management processes.

The downstream supply chain which Lenzing supplies encompasses an extensive range and diversity of clothing brands of different sizes. Two major categories of apparel brands that use Lenzing fibers are highlighted in

Figure 4. The first category consists of big brands with complex and large supply networks (hundreds to thousands of suppliers). This category usually has a lower percentage of Lenzing fiber in their products than other fibers. However, such brands are keen on promoting their use of sustainable fibers. Generally, enabling traceability is more difficult in these gigantic types of supply networks. The second category is for highly sustainable brands with a niche market and less extensive supply networks (in some cases, only a few main players). Apparel brands and retailers in this category may have a higher percentage of Lenzing fiber in their products, and it is relatively easier to implement traceability in their supply chains. Lenzing has successfully conducted several blockchain pilot projects across the two categories, with the major retailer, H&M, and other relatively smaller retailers such as Chicks. Lenzing’s current blockchain projects include:

- (1)

Tencel (lyocell) traceability pilot with the Indonesian supply chain for H&M,

- (2)

EcoVero (viscose) traceability pilot with the Portuguese supply chain for Armed Angels,

- (3)

Tencel (lyocell) traceability pilot with Korean and Indian supply chains for Mara Hoffman and,

- (4)

Tencel (modal) traceability pilot with Chinese supply chain and

Chicks [

53].

4.2. Lenzing Blockchain Solution–Description and Analysis

Blockchain’s capabilities to enable secure information sharing, data record immutability, and traceability made the technology an attractive solution for Lenzing to adopt in their supply chain. The company has collaborated with the solution provider, TextileGenesis (TG), that has developed a blockchain-based platform for fiber-to-retail traceability (

https://textilegenesis.com/ (accessed on 30 August 2021). The TG blockchain platform is a cloud-based platform based on Hyperledger Fabric, enabling easy access and integration with other IT systems [

64]. The TG platform adopts the global GS1 traceability standards, which are used mainly in the healthcare and food sectors, to create similar fiber-to-retail traceability data standards for the textile and apparel industries [

64]. Using blockchain technology along with the GS1 standard framework enables the TG platform to be an easy-to-adopt industry solution that can track and trace any type of textile fibers. The platform captures the fiber information from shipment transactions, including invoices and purchase orders, and tracks the transported and produced fiber volume using its patent-pending fibercoin technology. Despite their name, fibercoins are blockchain-based digital tokens that represent the textile assets on the TG platform (e.g., fiber, yarn, fabric, and/or garments) and are not linked to any crypto-currencies such as Bitcoin [

64]. The link between the physical textile material and fibercoins is captured and validated through forensic audits for the physical textile products [

64]. For example, Lenzing uses embedded tracers in their fibers that can be checked at the different downstream stages through auditing.

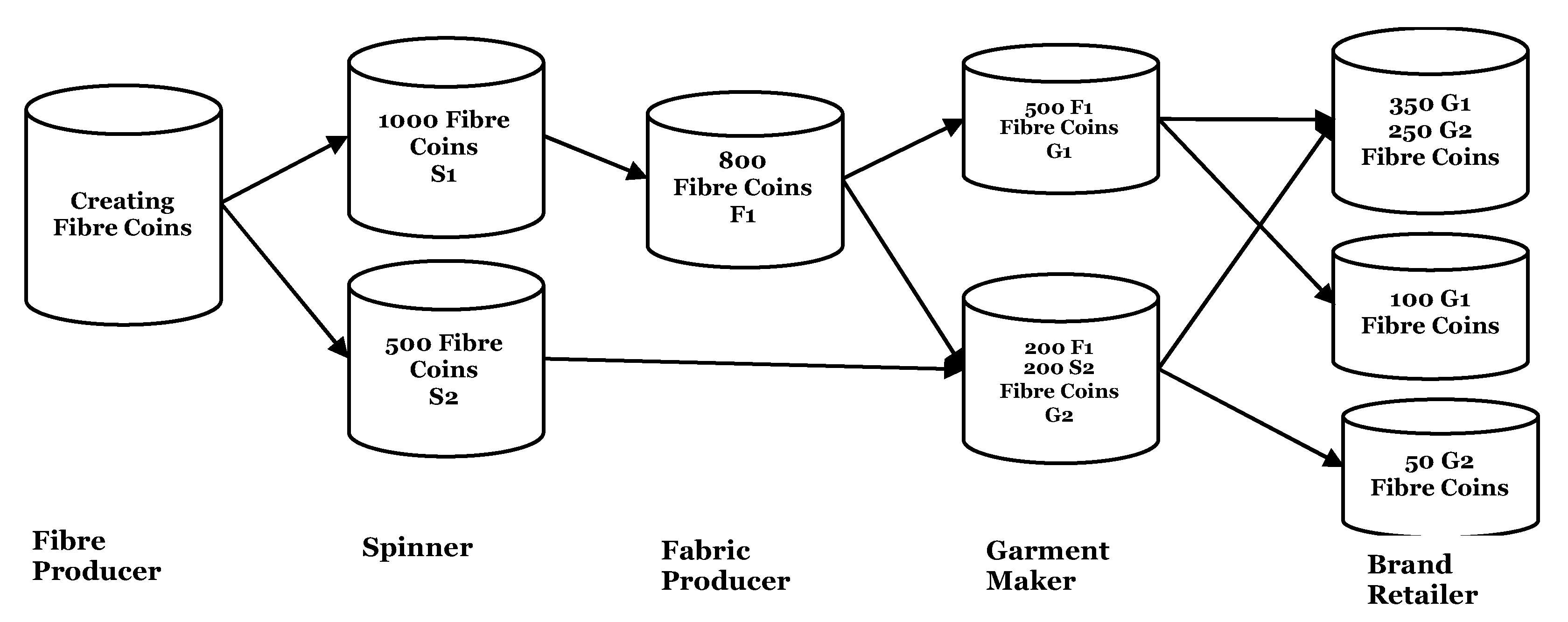

The underlying principle of the TG platform is straightforward. A fibercoin represents a fiber volume unit that allows fractional weights. Only fiber producers can create fibercoins. Fiber producers send fibercoins to other supply chain members that are equivalent to the amount of physical fiber captured in the shipment transaction. Other supply chain partners can only transfer an equal or lower amount of fibercoins than the total amount of physical fiber they possess. By tracking the flow of the limited fibercoins through the platform, the fiber producer can know where its products are being used in the downstream supply network. Similarly, by receiving fibercoins with finished garments, the brand or retailer can identify the origin of their products.

The TG platform mirrors the flow of the physical fibers in the downstream supply chain. TG does not use the mass balancing approach [

64], but rather captures the composition of each article/SKU and the average waste percentage at each production stage in the downstream supply chain to calculate accurately the amount of fiber produced, stored, and transferred across the supply chain. In the Lenzing blockchain pilot for example, a fibercoin represents 1 kg of Lenzing fiber. For each shipment transaction that Lenzing sends to a spinner, an equivalent amount of fibercoins is created and transferred to that spinner. The TG then captures the details of the yarn production at the spinner facility, including blend ratios, yarn ID, and average waste, and when the spinner sends a shipment of yarn to the fabric maker and/or garment producer, an equivalent amount of fibercoins is calculated based on the production information and is transferred from the spinner to the yarn receiver. The TG platform captures this transaction and updates the fibercoin account balances of both the spinner and the yarn receiver. The same process takes place at the different stages in the supply chain (e.g., fabric and garment manufacturing) to ensure that the fibercoin balances match the amount of the physical product. All fibercoin transactions are recorded on the TextileGenesis platform, powered by blockchain technology, and are linked to the shipment transactions issued by the respective companies. The use of fibercoins keeps track of fiber volume throughout the downstream supply chain. Without the possession of Lenzing’s fibercoins, no supply chain partner can claim their use of Lenzing sustainable fibers. Furthermore, the platform can signal any mass transactions or discrepancies between the physical inventory and fibercoin balances, i.e., the fiber volumes captured in the shipment documents and fibercoin transactions, and indicate the need for auditing. The cross-validation of transactions is also supported by the TG platform since, at each stage, the fiber receiver has to confirm the physical quantities sent to them by the sender and its equivalent amount of fibercoins. An illustrative example is presented in

Figure 5. The TG platform captures all shipment transactions between the six main steps in the apparel supply chain: fiber producer—spinner—fabric maker—dyeing/finishing—garment maker—brand retailer.

No sensitive or commercial data are shared on the TG platform and a minimum amount of data is required from the different supply chain partners to facilitate the targeted level of supply chain traceability. This has helped in overcoming the issue of supply chain partners’ unwillingness to share information by simplifying their engagement in the solution. Furthermore, different access rights are given to the SC partners. Full supply chain visibility is granted to the brand retailers. Lenzing knows the location of other SC partners and their inventory balances of Lenzing fiber. Other SC partners between the fiber producer and brand owner or retailer are given limited visibility of the blockchain data, with access to only one step upstream and one step downstream in their supply chain.

Table 3 shows examples of the type of information shared and accessed by each supply chain partner in the Lenzing pilot project.

Considering the capabilities of the TG platform, we argue that it provides supply chain traceability but at a high level rather than a detailed level. The TG platform enables the identification of the fiber source (i.e., the fiber producer) and the different processing stages it goes through until the final point of sale. The use of embedded tracers can identify that the fibers used are Lenzing’s. However, it does not support supply-chain traceability at a more granular level such as the batch level or the garment unit level, since the link between the physical product and digital tokens at these levels of granularity are not established. We discuss the different levels of traceability in more detail below.

5. Discussion

Different applications of blockchain technology in the textile and apparel supply chain have been reported in

Section 3. These applications vary in both their purpose and the scope of traceability sought across the supply chain. In the case study, Lenzing uses the blockchain solution to ensure the authenticity of their sustainable fibers in the final garments, and to fight counterfeiting. The use of embedded tracers and blockchain technology has helped Lenzing to identify and track their fiber in their downstream complex supply chain. The blockchain-based platform also supports secure information sharing between the dispersed supply chain partners and the provision of a single source of data, where participants can access, share, and validate their supply chain data and sustainability practices and certifications. Sharing sustainability-related information and certifications enables Lenzing to ensure that their sustainable fibers are used in a sustainable manner. This is also important for end brands and retailers who can identify, through the blockchain platform, all the sustainability credentials of the suppliers in their network. The use of a third-party auditing company to validate the captured data on the blockchain platform across the supply chain is still crucial to ensure the validity of the traceability data and to verify the link between the physical and digital worlds. We argue that external audits will constitute an important part of future approaches and standards that aim at enabling supply chain traceability using blockchain technology.

The Lenzing case study also highlights vital considerations regarding product traceability in the supply chain in general, and in the textile and apparel industry in particular. These issues are critical when considering blockchain-enabled supply chain traceability solutions. Two fundamental questions can be posed:

1. How should we define the scope of the supply chain traceability system?

2. How can products be tracked across the supply chain?

We discuss and analyze each of these questions below, making reference to the Lenzing case study.

5.1. Supply Chain Traceability Scope

As defined by the International Standards Organisation (ISO), traceability is “the ability to trace the history, application or location of an object. For products and services, traceability relates to: The origin of materials and parts, the processing history, and the distribution and location of the product of service after delivery” [

65]. Many factors can influence the traceability system requirements in the supply chain, including the purpose of traceability, the desired level of granularity, the supply chain configuration, the diversity of suppliers, the volume of supply, regulatory and customer requirements, the level of trust in the network, and the capabilities of existing traceability systems and technologies. We distinguish two dimensions for supply chain traceability that need to be considered when implementing a traceability system. These dimensions define the scope of traceability and help in assessing the feasibility and scalability of a traceability system.

5.1.1. Supply Chain Traceability—Horizontal Dimension (Start and Endpoints)

This dimension refers to the start and endpoints of the traceability system in the supply chain. Full horizontal traceability starts from the origin of the raw materials to the end customers and can further include the reuse or recyclability of end products. However, not every traceability system needs to or can provide end-to-end supply chain traceability. The end- and start-points vary depending on the purpose of the traceability. This is evident in the textile and apparel industry, where different projects have different start and endpoints for traceability, depending on their need to ensure product authenticity and/or sustainability (

Section 3).

5.1.2. Supply Chain Traceability—Vertical Dimension (Level of Granularity)

The vertical dimension of supply chain traceability investigates the granularity level targeted by the supply chain traceability system. Granularity can be defined as “different levels of traceable units and are determined by the size of a traceable unit and the number of the smallest traceable units necessary to make up the traceable unit at a specific granularity level” [

66]. Dasaklis et al. [

67] adopted the GS1 guidelines to define three different levels of granularity for supply chain traceability across three categories: stakeholders, processes, and units.

The higher the level of granularity required for the SC traceability solution, the higher the costs and the more complex the traceability solution becomes. This affects the implementation and practicability of a traceability system [

66]. Hence, it is crucial to find the optimal level of granularity for the traceability system where the benefits exceed the costs [

48,

66]. The optimal level of granularity for the supply chain traceability system can differ depending on the specific characteristics of the supply chain [

48].

In the textile and apparel supply chain, higher levels of granularity will indicate supply chain traceability at the batch or garment unit levels. The provision of full vertical supply chain traceability for each garment piece across the supply chain could result in many additional business benefits such as providing high assurance for the authenticity and sustainability of each garment piece and having access to accurate and rich information to inform and improve the product demand fulfilment process. However, the value generated or perceived from the higher level of granularities differs across sectors and supply network configurations and depends on their characteristics. For example, in the textile and apparel industry, this level of traceability has been achieved in the blockchain pilot of Provenance that aimed to track a Martine Jarlgaard jumper across its UK-based supply chain [

57]. However, it would be very challenging to implement such a solution in more complex high-volume apparel supply networks.

Considering the two dimensions of supply chain traceability, it is clear that Lenzing aims to achieve partial horizontal supply chain traceability at a low level of granularity. The blockchain solution adopted by Lenzing enables the traceability of fiber after it leaves its premises. It starts from the fiber producers and extends downstream to the brand retailer but does not include Lenzing’s upstream suppliers from the timber industry. Lenzing relies on the certifications of its suppliers to ensure the sustainability of its wood. In Europe, the Forest Stewardship Council (FSC) and the Programme for the Endorsement of Forest Certification (PEFC) are the two certifications related to sustainable forest management [

68]. The certification process itself is costly and requires substantial resources [

69]. To enable more horizontal supply chain traceability, Lenzing could consider extending its blockchain-enabled traceability system to the upstream origin of wood from forests. Besides wood traceability, blockchain can potentially transform the forestry industry by improving transparency and streamlining the documentation processes across the entire supply network [

69]. It provides a secure way of capturing all the information related to upstream woodcutting, logging, and transportation, which can be used to certify its origin and prohibit illegal practices [

68].

The achieved level of traceability meets the current needs of Lenzing, which are to ensure the authenticity of products (i.e., that they are genuine Lenzing fibers), their provenance from a particular source (i.e., Lenzing premises), and tracking of their use downstream in the supply chain (i.e., gaining knowledge about their use by downstream supply chain partners). The current Lenzing solution does not provide a higher level of granularity at the fiber batch or garment piece levels. To enable deeper vertical supply chain traceability, Lenzing could trace its fiber at a higher granular level, e.g., the garment piece level. There are different blockchain solutions and other technologies in the industry that may make it possible to digitally identify the wood and fibers and that show promise for the development of a complete traceability solution from the tree to the garment piece at the point of sale. This leads us to the second consideration.

5.2. Product Tracking across the Supply Chain

Three general requirements for product traceability indicated in the ISO 9001checklist are: “(1) establish the identity and status of products, (2) maintain the identify and status for products, and (3) maintain a record of serial and/or batch numbers.” [

70]. A significant issue that is linked to the required level of traceability is how the unit of traceability is identified and tracked throughout the supply chain [

48]. The creation of a ‘digital twin’ [

71] is a pre-requisite for the success of a traceability solution [

72]. Establishing an accurate and reliable digital twin is critical to ensure the credibility of the traceability system and the validity of its data. Blockchain-enabled traceability helps to facilitate and guarantee both the accuracy and reliability of the digital supply chain record.

Product identification is not a straightforward process. It varies depending on the nature of the product and its manufacturing processes. For example, in the textile and apparel industries, enabling the traceability of each garment piece will require additional work and a better understanding of the entire supply chain, the characteristics of each manufacturing process, the product structure, and the bill of materials. Various techniques can be used for textile product identification across a supply chain, including embedded in-product tracers, barcodes, and labels. Using embedded tracers is an emerging identification technique that is currently gaining more interest (e.g., DNA tracers). Ravasio [

62] has categorized three techniques for in-product identification: (1) dyes, tags, or particles, in which physical particles are embedded in the fiber; (2) naked DNA tracers, where DNA segments are embedded in the product surface at the nano-level; and (3) encapsulated DNA tracers, where DNA segments are encapsulated into a medium and then embedded into a product surface at the nano-level. Fiber Trace is an example of a technology that uses a natural luminescent pigment that can be embedded into any type of fiber and can be identified at any stage in the supply chain [

73]. Haelixa has developed DNA markers for cotton traceability in the Organic Cotton Traceability Pilot with C&A and other partners [

74].

Currently, Lenzing uniquely identifies its fibers by embedding tracers in the fiber. These tracers can be checked in the auditing process. The inclusion of tracers facilitates the identification of fibers at any stage across the supply chain. To enable downstream traceability at a deeper level of granularity, additional product identification techniques might need to be used. For example, batch level traceability will require a unique identification for each batch of products across the supply chain. For upstream traceability, the product’s characteristics need to be considered to determine how it can be identified as it flows across the supply chain from trees to logs, pulp, and fiber production. Figorilli et al. [

68] developed a blockchain prototype for wood traceability across the supply chain using RFID, barcodes, and NFC chips. They simulated the traceability of 10 trees in Italy from the tree to the finished product, which was a table. RFID tags were applied to the main tree and each log. The use of smartphones enabled information to be captured on the locations of the trees through the use of GPS. Additional information related to the tree and log was captured using a smart app (e.g., tree marking date, qualitative class, cutting date, log dimensions, etc.). The Chainwood project has also experimented with technology to trace pine, eucalyptus, poplar, and chestnut trees in Spain over two years and has recently announced the success of their pilots [

75]. The project aimed to use blockchain and IoT approaches to identify and trace wood at its initial transformation stages from solid wood, disintegration, cellulose pulp, and biomass [

75,

76]. The software, web, and a smart devices were used to capture the blockchain data. Although these projects are in their embryonic stages, they show promise, suggesting that in the future, technologies will be available that can support the traceability of raw materials for fiber production from forestry sources.

Hence, there are opportunities to use various emerging product identification techniques at different supply chain stages to extend the scope of the traceability system and to link these in the overall traceability system.

Figure 6 illustrates the different product identification techniques that can be used at each cellulosic fiber SC stage to further enhance and extend product traceability across the entire tree-to-garment supply chain.

6. Conclusions

Supply chain traceability has become a dominant concern for many industries, regulators, and policymakers. Increasingly, end customers are seeking assurances on the origin and sustainability of the products they purchase. The textile and clothing industries are important globally. However, social, environmental, and sustainability issues are a frequent cause for concern across this sector. Blockchain shows promise in improving transparency, enabling traceability, and supporting sustainability in the textile and apparel supply chain, but the technology is still at an early stage of adoption.

Here we have examined blockchain-enabled traceability in the textile and apparel sector, noting that different perspectives may be taken depending on the traceability objectives and the supply chain positioning of the lead players in a blockchain initiative. The case of a leading major textile fiber producer, Lenzing, has been presented. Lenzing’s blockchain initiative focuses on downstream supply chain traceability to the retailer. Their solution provides traceability at a high SC level across the major actors in Lenzing’s downstream supply chain and is relatively easy to adopt. The case study has enriched the discussion about major considerations regarding the scope of supply chain traceability and product identification across the supply chain. We have discussed these considerations with reference to Lenzing’s case study, along with possible extensions for their current traceability system. Two extensions were discussed—traceability upstream from the raw material source to the fiber producer and implementing a more granular downstream solution. The extension of blockchain-enabled traceability upstream requires the implementation of unproven emerging technologies, which need to be trialed and tested further.

The literature to date on blockchain applications in the supply chain lacks discussion of empirical cases. The issues highlighted by the case discussed here are of relevance to blockchain adoption in the textile and clothing sector more generally, but they are also relevant to other commodities and consumer products that have many actors involved in the supply of products. Further empirical work is needed, examining blockchain adoption across many sectors to understand how the technology can be deployed more extensively to enable and support traceability.