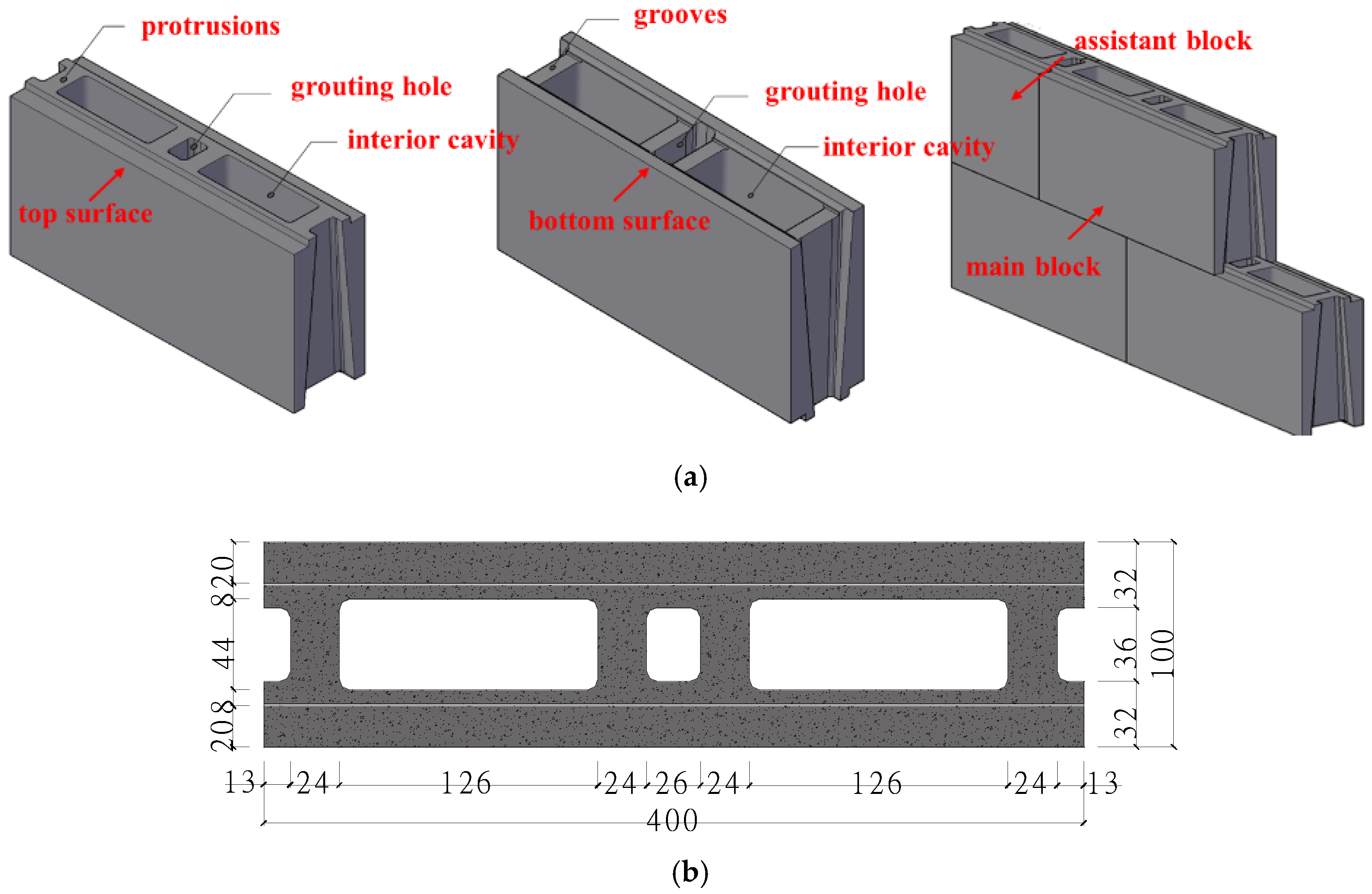

In order to study the axial load-bearing capacity and the shear strength of the masonry using IHB-RAC, 12 groups (5 specimens of each group for compressive strength test and 4 specimens of each group for shear strength test) of masonries considering different strength of mortar and the concrete used in the grouting holes were designed according to standard GB/T50129-2011 [

30], and the thickness of the mortar used was 8 mm, as shown in

Figure 2. Besides, in order to ensure a uniform load distribution on the specimens during the compression test, the rough upper and bottom surfaces of the masonries were made flat by using cement mortar with a thickness of 10 mm, and checked with a leveling instrument before the test. Among which, M7.5 grade mortar was used for groups A, B and C, and M15 grade mortar was used for groups D, E and F. In addition, the specimens of group A and D were designed without concrete cast into the grouting holes, as the grade of concrete used in the grouting holes for groups B, E and C, F were C30 and C40, respectively. The detailed characteristics of the specimens are shown in

Table 4.

3.3. Test Results and Observations

For the compressive strength test, the typical failure modes of each group of the test specimens are shown in

Figure 4. When the load came into over 60% of the peak load (as the mean values were 75%, 63%, 68%, 60%, 60%, 63% respectively for group A

c, B

c, C

c, D

c, E

c, F

c), vertical crushing cracks firstly appeared on the upper positions of the narrow surfaces of the specimens. With the increase of the axial load, more vertical cracks appeared independently from the top to the bottom along the height of the specimens, and the length and width of them developed constantly. When the vertical load reached about 90% of the peak load, horizontal cracks began to appear on the wide sides of the specimen, and an obvious and continuous cracking sound could be heard at the same time. And then, with a loud crushing sound to be heard suddenly, the specimens failed totally while the vertical crushing cracks on the narrow surfaces connected together, and the horizontal crushing cracks developed through the whole cross-section of the specimens at the same time. Through comparison, the failure modes of all the specimens were very similar, which were characterized by the emergence and development of the vertical cracks on the narrow surfaces as well as the horizontal crushing occurring on the wide surfaces. There was no obvious difference in crack developing and failure mode between the specimens with or without concrete used in the grouting holes, mainly because the cross-section area of the grouting hole was small compared to the whole cross-section of the block, as the cross-section area ratio of the block was just 0.0369 for the main block. What’s more, no obvious crack or failure was found of the mortar joint throughout the whole loading process, indicating that the interlocking keys of the blocks could work well with the mortar and provide a reliable connecting function.

For the shear strength test, the typical failure modes of each group of the test specimens are shown in

Figure 5. When the load came into over about 50% of the peak load (as the mean values were 48.3%, 51.7%, 52.5%, 50.8%, 53.4%, 55.1% respectively for group A

s, B

s, C

s, D

s, E

s, F

s), shearing cracks could be observed on the mortar joints from the narrow sides of the specimens. With the shear force increasing, the horizontal mortar cracks developed continuously from both sides to the middle part of the masonries. Then, when the load came into over about 75% of the peak load (as the mean values were 75.8%, 77.4%, 81.2%, 76.1%, 82.3%, 84.6% respectively for group A

s, B

s, C

s, D

s, E

s, F

s), the shearing cracks of the mortar joints developed throughout the whole cross-section of the masonries, and the mortar of the joints lost their shear strength after that. After that, the shear force began to be totally borne by the interlocking keys as well as the grouting hole concrete of the blocks, which was different from the traditional concrete hollow blocks, as the masonries using traditional hollow blocks almost lost their bearing capacity at this stage after the mortar joint completely cracked [

14,

15,

16,

17].

Through comparison, increasing the mortar grade and using grouting hole concrete had little effect on the failure mode of the specimens. In general, there are two main failure modes of the masonry, as double-surfaces shear failure (shown in

Figure 5a) and single-surface shear failure (shown in

Figure 5b), and the failure cross-sections are shown in

Figure 5a,b. Most of the test specimens showed double-surfaces shear failure, indicating that the shear strength of the two mortar shear joints of the test masonry were almost equal. This was because that the interlocking keys of the block could provide an excellent connecting function, which could avoid the big differences between the mortar joint strength caused by the uncertainty of the construction level as well as the uneven distribution of joint mortar. Nevertheless, only a few of the test specimens using grouting hole showed single-surface failure, which could mainly be attributed to the uniform shear force applied to the joints by the loading device. However, it could be observed that the joint mortar of the unseparated shearing surfaces had already cracked throughout the whole cross-section; but the interlocking keys and the grouting hole concrete had not been sheared off totally, further indicating the excellent performance of the masonry.

3.4. Tested Compressive and Shear Strength of the IHB-RAC Masonry

For the compressive strength test, the peak load of the specimens is shown in

Table 8. According to the calculation method specified in Chinese code GB/T50129-2011 [

30], the corresponding compressive strength could be obtained. As shown in Equation (1), a reduction coefficient

should be used in the formula to represent the influence of the stability when the ratio of height to thickness (

) is larger than 5 for the specimens:

where

is the tested axial compressive strength of the masonry in units of Mpa;

is the axial load of the specimens;

is the area of cross-section of the specimens; and

is the stability coefficient for the masonry under axial load, which could be determined according to Chinese code GB50003-2011 [

18]. As the ratio of height to thickness (

) of the tested masonries was 6.952 (

), the corresponding stability coefficient calculated was 0.93 for the masonry specimens.

The mean values of the compressive strength of the tested specimens were shown in

Figure 6, and the test results were compared from different perspectives. Through comparison, improving the strength grade of mortar had a positive effect on increasing the compressive strength of the IHB-RAC masonry. As shown in

Figure 6a, the compressive strength of each group of the specimens were all increased by more than 20% while the Mb15 grade mortar was used compared to using Mb7.5 grade mortar. Furthermore, increasing the mortar grade had a most obvious improvement (increased by 29.2%) on the compressive strength of the ungrouted specimens. The influence of the concrete used in the grouting holes of the specimens was compared in

Figure 6b. Through comparison, the concrete used could also increase the compressive strength of the specimens obviously. While the Mb7.5 grade mortar was used, the compressive strength of the specimens using C40 grade concrete in the grouting holes were increased by 38.7% compared to the ones without concrete used. While the Mb15 grade mortar was used, the corresponding strength was increased by 28.9%

For the shear strength test, the peak load of the specimens tested were shown in

Table 9. According to the calculation method specified in Chinese code GB/T50129-2011 [

30], the corresponding shear strength of the specimens could be obtained by Equation (2),

where

is the tested shear strength of the masonry in units of Mpa;

is the horizontal shear force of the specimens;

is the area of cross-section of the specimens.

Through the comparison of the mean values of the tested specimen shear strength, both increasing the mortar strength and using grouting hole concrete could obviously increasing the shear strength of the IHB-RAC masonry too. As shown in

Figure 7a, the shear strength of each group of the specimens were all increased by more than 25% while the Mb15 grade mortar was used compared to using Mb7.5 grade mortar. Furthermore, increasing the mortar grade had a most obvious improvement (increased by 29.6%) on the compressive strength of the specimens with C30 grade concrete used in the grouting holes. The influence of using grouting hole concrete on the shear strength was compared in

Figure 7b. Through comparison, the shear strength of the specimens using C30 grouting hole concrete were increased by above 35% than the ones without using grouting hole concrete (as increased by 35.0% and 40.0% while using Mb7.5 and Mb15 grade mortar respectively), and the values were increased by above 55% while using C40 grouting concrete than the ones without using grouting concrete (as increased by 55.0% and 60.0% while using Mb7.5 and Mb15 grade mortar respectively). However, the effect of increasing the grouting concrete grade on improving the shear strength of the IHB-RAC masonry was not so high, as the values were increased by within 15% for the masonries using C40 concrete compared to C30.

3.5. Calculation of the Compressive and Shear Strength of the IHB-RAC Masonry

In order to better study the mechanical properties of the IHB-RAC masonry, the experimental results of the test specimens were compared with the calculated results obtained from Chinese code GB50003-2011 [

18] to check the suitability of the standards, as shown in

Table 10 and

Table 11. In order to make an accurate prediction of the compressive strength of the masonry, modifying coefficients were used considering the positive contributions of the connecting keys. In addition, according to the test results, an appropriate calculation method for accurately predicting the shear strength of the grouted IHB-RAC masonry was proposed by separately considering the effort of the mortar and the grouting hole concrete.

In code GB50003-2011, the calculation formula for predicting the mean value of the compressive strength of hollow block masonry was shown as Equation (3),

where

is the mean value of the hollow block masonry compressive strength in units of Mpa (without concrete in the grouting holes);

and

are the mean value of the compressive strength of the block and mortar used respectively;

and

are the reduction coefficients related to the block type, taking as 0.46 and 0.9 for concrete hollow block respectively; and

is the modifying coefficient related to the strength of the mortar used, taking as 1.0 here. Lastly, another modifying coefficient as (

) should be multiplied in the formula if the value of

is larger than 10 Mpa.

The calculation formula for predicting the mean value of the axial compressive strength of masonry with concrete in the grouting holes is shown as Equation (4),

where

is the mean value of the hollow block masonry compressive strength with concrete in the grouting holes;

is the same as in Equation (3);

is an enhancing coefficient considering the positive effect of the grouting hole concrete, taking as 0.63 here;

is the cross-section area of the grouting holes, taking as the mean value of the grouting holes on the top and bottom surfaces of the specimens;

is the area of the cross-section of the masonry specimen; and

is the mean value of the compressive strength of the grouting hole concrete used.

According to the comparison in

Table 10, the tested values of the compressive strength of the IHB-RAC masonry were higher than that of the code formula calculated results, indicating that the calculation formulas provided in code GB50003-2011 were relatively safer to be used to predict the axial load-bearing capacity of the masonry in structural designing. Among these, the difference between the test and calculated values for specimens without grouting hole concrete (group A

c, D

c) was relatively smaller, as within 15% overall. There was a big difference (above 20%) between the test and calculated values for the specimens with grouting hole concrete (group B

c, C

c, E

c, F

c). Among them, the biggest difference was group C

c, which was 29%.

In order to accurately predict the compressive strength of the masonry, the calculation method was modified based on the formulas in the code GB50003-2011. Considering the positive contributions of the connecting keys and the grouting hole concrete on the compressive strength of the masonry, based on the univariate linear-regression analysis of the tested and calculated results, an amplification coefficient as 1.1 was suggested to be multiplied to in Equation (3), as the modified value of was 0.51. Similarly, an amplification coefficient as 1.3 was multiplied to in Equation (4), as the modified value of was 0.82. By comparison, the difference between the calculated values of the modified formulas and the test values were within 4%.

In code GB50003-2011, the calculation formulas for both predicting the mean values of the shear strength of hollow block masonry with or without grouting hole concrete are shown in Equations (5) and (6) respectively:

where

is the mean value of the hollow block masonry shear strength in units of Mpa (without concrete in the grouting holes);

is the coefficient to represent the different types of block (as 0.069 for concrete block masonry).

is the compressive strength of the mortar used.

is the mean value of the hollow block masonry shear strength in units of Mpa (using concrete in the grouting holes); and

is the compressive strength of the hollow block masonry with concrete in the grouting holes (using the same value as

in Equation (4)).

According to the comparison in

Table 11, Equation (5) could accurately predict the shear strength of the non-grouted IHB-RAC masonry, and the difference between the test and the code calculation values were within 4%. However, for masonries with grouting hole concrete, the code calculation results were much higher than the test results, as the test shear strength was only 25~35% of the calculated values. The main reason was that Equation (6) did not reasonably consider the influence of the concrete filling rate of the masonry, and the equation overestimated the contribution of the grouting hole concrete, as the concrete filling rate of the IHB-RAC block was only 0.036, which was relatively lower than traditional ones.

In order to reasonably consider the positive effect of the grouting hole concrete and make a precise prediction, previous studies [

17,

35,

36] tried to separately consider the effort of the mortar and the grouting hole concrete by adding the contribution of the concrete core to Equation (5). Considering the complex interaction between the grouting concrete core and the block, the calculation method proposed by Gao Xiang [

34] considering the filling rate of the concrete is shown as in Equation (6):

where

is the cross-section area ratio of the grouting hole (0.0369 for the IHB-RAC block);

is the coefficient associate with the block type, and the value of it was 0.46 determined by the univariate linear-regression analysis of the tested and calculated results of the IHB-RAC masonry.

From the comparison of the calculation results in

Table 11, Equation (7) could accurately predict the shear strength of the IHB-RAC masonry while using grouting hole concrete, and the difference with the test values were within 7% on the whole.