1. Introduction

With the rise of the globalization, the fashion industry has become a significant worldwide business (the global apparel market has been estimated in value to USD 1.5 trillion in 2020 [

1]) based upon lengthy and geographically fragmented value chains [

2,

3]. Production has shifted to southern countries, mainly in Asia, while design, marketing, and distribution activities have remained located in advanced countries [

4], with Europe representing an important apparel net importer (over EUR 80 billion of imported goods, mainly from China, Bangladesh, and Turkey, in 2019 [

5]). Characterized by a constant growth and driven by the so-called “fast-fashion” phenomenon [

3], the industry has resulted in tremendous environmental and social repercussions over the last decades [

3,

6]. Steadily scrutinized as a substantial impactful sector, a range of estimates have successively evaluated, depending on assumptions, the fashion industry to account for 4% [

7], 8% [

8], and up to 10% of global CO

2 emissions [

3] with the main environmental impacts imputed to the raw materials and manufacturing activities [

8,

10,

11]. Correlatively, this accelerated fashion consumption has led to the perception of clothes as disposable items, decreasing the garment’s lifetime [

9,

12,

13,

14,

15,

16]. Such a completely linear or “take make waste” model has resulted in an expanding amount of discarded textiles in Europe [

3,

12,

14,

16]. While assessing used textile flows remains challenging [

17], the amount of clothes bought in the EU has been estimated to have increased by 40% over the last decades [

18,

19]; Europeans consuming on average 26 kg and discarding 11 kg of textiles per person per year [

20]. Considering the alarming climate state [

21], decreasing the resource pressure is crucial to reduce the environmental footprint of the sector while ensuring viable business models in the long term to face up to forthcoming scarcity [

14,

22]. Therefore, enhancing recycling has been standing as a critical priority in this wider transition towards a “circular economy” [

9,

14].

The concept of “circular economy” has raised interest since the late 1970s [

14,

23] and derives from connected background concepts such as the famed cradle-to-cradle design philosophy [

23,

24]. The most renowned definition has been framed by the Ellen MacArthur Foundation, where the economy is “

restorative and regenerative by design, and aims to keep products, components, and materials at their highest utility and value at all times” [

25]. Binding economic performance, social inclusiveness, and environmental resilience [

26], this new industrial paradigm promotes material flows systems in which resources are optimized, thus enabling “sustainability” covering a broader framing [

23]. Indeed, by promoting the reduction of resources extraction, the extension of the product lifecycle, and the minimization of waste production [

27,

28], the transition to circular business models has the potential to decrease the environmental impact of the industry [

2,

6,

9,

29,

30]. However, the review suggests that companies are selectively implementing circular actions in their supply chains, rather than disrupting the entire business model [

9] and addressing the main environmental impacts of their activities [

12]. In fact, by bridging production and consumption activities [

12,

15,

25], “circular economy” involves the implementation of several strategies usually suggested through the “R framework” and requiring radical systemic changes in how products and materials are manufactured, used, and disposed of [

29,

30,

31]. A varying level of detail exist in the literature [

32] and up to “10R principles”can be found namely refuse, rethink, reduce, reuse, repair, refurbish, remanufacture, repurpose, recycle, and recover [

27,

32,

33]. Ordered by level of circularity, recycling rationally comes into play among the final options once the materials can no longer be reused, following the existing EU waste hierarchy of optimal treatment solutions [

34].

However, it is estimated that only 12% of global material flows for clothing are recycled, mainly into “open-loop” applications [

9] (such as insulation material, wiping cloths, or mattress stuffing), also referred to as “cascaded recycling” [

35] or “downcycling” [

36,

37] because of their lesser economic value [

38], while much higher rates are noticed in other industries [

39]. Only less than 1% of clothing textile material would be recycled into new clothes, referred as “closed-loop recycling” or “textile-to-textile recycling”, the 87% remainder ending up mainly in landfill or being incinerated [

9]. Therefore, lifecycle-extending practices are not sufficient in themselves and must be enhanced, along with improving recycling practices [

14]. Within this context, the sector is particularly targeted in the upcoming Green Deal strategy [

40] aiming to achieve climate neutrality in Europe by 2050, as shown by the foreseeing EU Strategy for Textiles [

41] ambitioning to boost the EU market for sustainable and circular textiles. The public consultations launched recently by the European Commission [

41,

42] reveal a wide range of dedicated policies to enhance textile recycling (i.e., separate collection mandatory by 2025, incorporation of recycled content, digital passport…).

However, despite increasing interest in the industry, textile recycling is still a limited research area [

14], which has mostly been explored from a technical perspective, to improve textile recycling processes towards value-added products [

36]. An increasing body of research has been also dedicated to the study of the environmental benefits of textile recycling [

35]. However, while its improvement is consistently pointed out as requiring a “system-level change” with extensive stakeholders’ collaboration [

25], very few comprehensive studies have been conducted. The literature on the topic is fragmented, and empirical studies remain limited, which impedes an explicit evidence-based state-of-the art on the current challenges in the sector. Although a flourishing literature on textile-specific barriers to the implementation of the “circular economy” has advanced knowledge in the industry [

12,

29,

32], these studies do not provide a systematic analysis of the existing issues related to the textile recycling value chain.

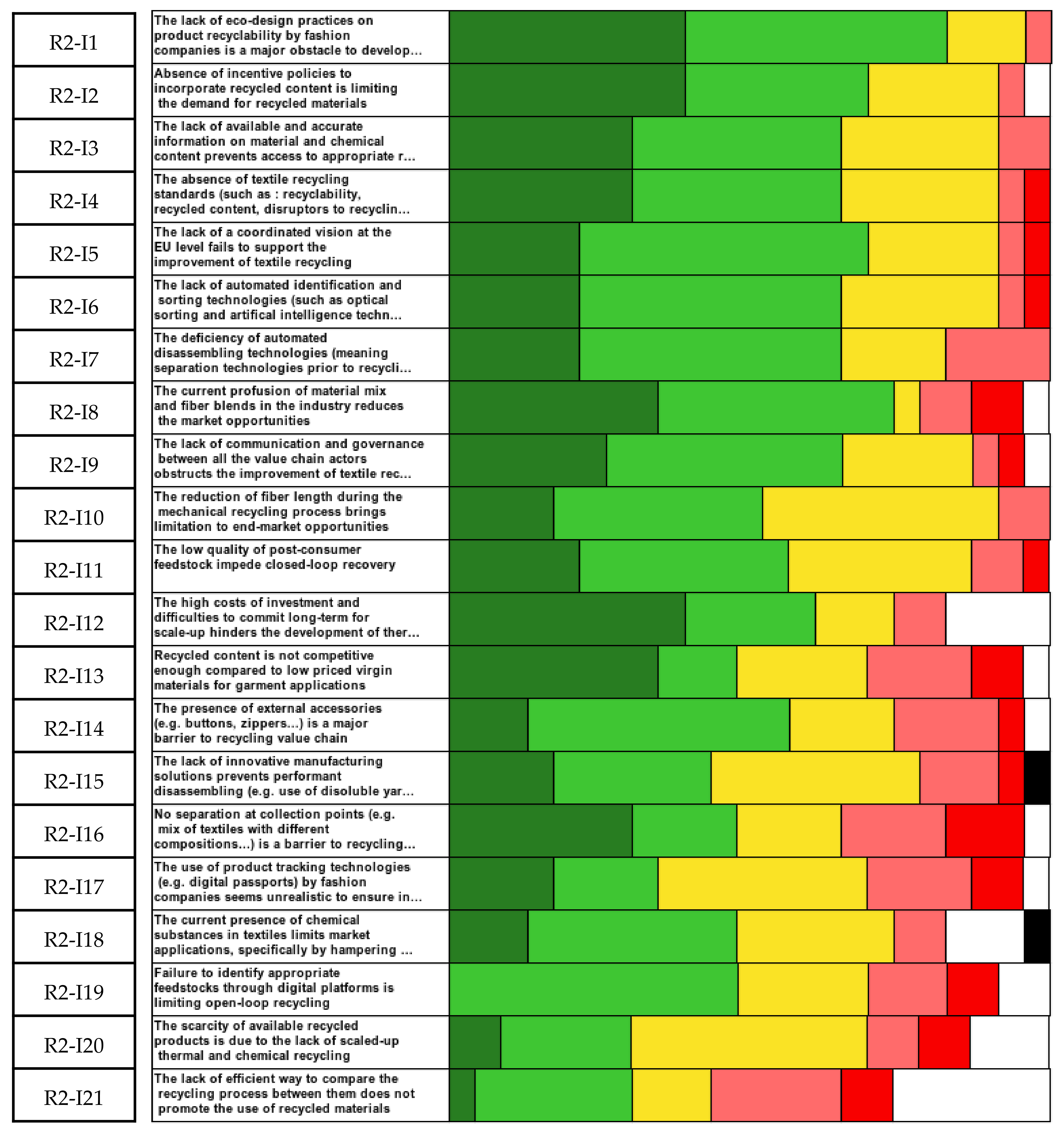

Subsequently, this paper aims to answer the following research questions: What are the current impediments in the textile recycling value chain? What are the priority challenges to address in order to enhance textile recycling in the sector? To achieve these research objectives, a systematic review was conducted to identify the recurring challenges acknowledged in the existing literature on textile recycling. Then, a purposely designed qualitative study using the Delphi method [

43] and applying the Abaque de Régnier technique (Regnier’s Abacus) [

44] was implemented, referred to as “Delphi-Régnier” in the remainder of the paper. With an unprecedented panel of 28 experts in the field representing the different stakeholders of the recycling value chain, the reported challenges in the extant literature were translated into statements and iteratively discussed through this group communication technique, using a color grid to collect experts’ opinions. The study is not strictly limited to textile-to-textile recycling but instead aims to explore the overall challenges related to the optimization of textile recycling, to better comprehend the current collection, sorting, and recycling system.

With regard to previous exhaustive research on the topic [

14], the originality of the study resides both in the representativeness of the panel and in the Delphi-Régnier method used. This method differs from a simple interview and helps to advance empirical knowledge on textile recycling with the confrontation of the experts’ opinions between the iterative rounds. Moreover, while barriers of textile recycling have started to be explored in the industry [

12,

14,

29,

32], this Delphi-Régnier study provides a holistic analysis of the contextual challenges and addresses the priority concerns in the sector, by allowing consensus and dissensus on the topic to arise. The research focuses on the European situation but still provides general findings advancing the literature on sustainability in the fashion and apparel industry. If the method has inherent limitations, the findings can support relevant initiatives for practitioners or policymakers and research opportunities to advance textile recycling in the sector.

The paper is structured as follows:

Section 2 introduces the systematic literature review conducted.

Section 3 describes the Delphi method and the Regnier’s Abacus technique, together with the associated research steps.

Section 4 is devoted to the presentation and discussion of the results.

Section 5 introduces the limitations and research perspectives. At last,

Section 6 concludes on the main findings.

2. Literature Review

A prior systematic review [

45] was developed on the research problem, to explore the challenges of textile recycling with regards to the fashion and apparel sector. It was done using the databases Scopus, Science Direct, and Web of Science to guarantee an extensive coverage. As a relatively new and transdisciplinary area, we decided not to limit the scope of the review and include empirical studies, review papers, conference proceedings, and book chapters as long as they served the research objective. An additional search was done through Google Scholar to make sure that on-topic publications, unavailable on specific databases, were not omitted. Preliminary research suggested a limited academic literature, corroborated by Sandvik et al. [

14]. Following the review protocol from preceding reviews on textile recycling [

46], white papers and public reports from well-established organizations or institutions were also considered, after an extensive search on Google. By contrast, we noticed an extensive grey literature, especially several studies that have been published by practitioners for public institutions to improve resource management. However, the priority was given to peer-reviewed journals, and only the most relevant publications were cautiously included. Even if no limitation on the publication date was pre-established, research has significantly increased since 2005 with a clear rise in publications starting from 2018, and only the most recent papers were selected to ensure a contemporary state-of-the-art.

Keyword identification was challenging as in primary enquiries, engineering, material, environmental sciences, and chemistry fields prevailed, confirmed by the review performed by Shirvanimoghaddam et al. [

36]. Initial extensive research was conducted using the combination (textile OR apparel OR garment) AND (recycling) AND (challenge OR obstacle OR limit OR complex OR barrier). Numerous papers on wastewater treatment were raised while our research focused on the narrowed understanding of textile recycling as the “

breakdown and reclaiming of textile raw materials to new ones” [

38]. Following an inductive and flexible process [

45], the research protocol was progressively revised based on subsequent findings. We replaced (“recycling”) with the keywords and Boolean connector (“circular” AND “waste”) in the research string to broaden the scope and target papers on textile flows management that were relevant to the research problem. A total number of 1414 articles resulted from those two keyword equations, which were applied to titles, abstracts, and keywords for Scopus and Science Direct, and to “all fields category” for Web of Science.

The filtering process was another obstacle due to the fragmented literature. It was initiated by checking titles and abstracts, firstly excluding publications unrelated (1) to the aforementioned delineation of textile recycling and (2) to the textile and apparel industry. After removing the duplicates, this process resulted into 98 references. Then, full reading was performed to successively define inclusion and exclusion criteria. As a lot of papers were related to the aforementioned technical fields, we first only included articles providing overarching discussions on textile recycling, and we started classifying the reported challenges. Based on the initial findings, a second round of reading was carried out, and only publications either providing empirical knowledge or further supporting some of the challenges identified were incorporated, diminishing the sample to 20 publications. A flowchart of the literature review process is shown in

Figure 1.

The review starts with a general discussion on the key findings, supported by a mapping eliciting the outlined challenges and their recurrence rate in the academic literature, presented subsequently in

Table 1.

2.1. Complexity of the Textile Recycling Value Chain

Consistent with the definition from the EU Waste Framework Directive [

56], textile recycling is essentially designated from a technical perspective as the “

breakdown and reclaiming of textile raw materials to new ones” [

25,

35,

36] involving a degree of deconstruction [

49]. However, textile recycling is actually embedded in a broader and complex textile flow management system involving several preceding stages.

Starting with the collection, textiles are usually classified depending on their collection point along the value chain: textile flows are either designated upon “pre-consumer” if collected at the industrial level or “post-consumer” if collected after use [

25,

32,

57]. “Pre-consumer” usually comprises all types of waste from companies resulting from manufacturing and distribution activities, from textile offcuts to unsold products, whereas “post-consumer” refers to used articles discarded by consumers once no longer wanted. Upstream, some also distinguish between the “post-industrial” (side-effect of clothing manufacture) and the “pre-consumer” (inferior quality garments or unsold product at the retail stage) feedstocks depending on the source in the value chain [

16,

58]. Nevertheless, while the “pre-consumer” fraction in general is underreported [

59], the post-consumer part entails the major challenges for the sector. Overall, 15%–20% of clothes have been estimated to be collected for reuse and recycling practices within Europe [

35,

46], and important disparities of collection schemes are addressed [

9,

46]. Attempting mappings on textile flows highlights collection rates varying from 22% (Sweden) [

60], 39% (France) [

61], and 45% (Denmark) [

60], up to 75% in Germany [

9] of overall textiles put on the market.

Once collected, items undergo thorough manual sorting, which is resting upon a business model towards the second-hand market [

46,

54] and the quest for high-quality clothing [

46], also referred as “diamonds” [

57] or “cream” [

17,

61]. While oversimplified, the reusable feedstock is separated from the nonreusable stock. A significant fraction is exported abroad, while the most valuable part is directed to fine sorting for nearby markets [

11,

40,

41,

54]. Still, for the majority being sold in global markets, the question of their subsequent treatment is left untackled, which explains the current low estimates of textile recycling [

9]. Moreover, some exports markets are becoming saturated [

54,

62], and the quality of reusable textiles appears to have fallen [

54,

61], a situation further exacerbating the primary issue of textile recycling for the coming years in the sector.

Following reuse, the nonreusable fraction is directed across different recovery avenues (recycling, energy recovery, or incineration) or landfilled with varying rates depending on the countries. In preparation for recycling, textiles are further sorted manually based on their composition [

61] and color [

54], vis-à-vis recyclers’ specifications requirements. In addition, external components (i.e., metallic parts, buttons, zippers) are disassembled prior to recycling mostly through a manual process [

38,

46]. To put this into perspective, in France, where an Extended Producer Responsibility (ERP) has been in place since 2007 for clothing, linen, and shoes [

55], 56.5% of the items sorted in facilities under contract are reused, mainly overseas (95%), 33.3% is recycled, 9.1% is recovered for solid fuel, 0.7% is incinerated for energy recovery, and only 0.4% is disposed, either through incineration or landfill [

61]. The ERP is a policy tool for encouraging and enabling recycling by giving financial and/or physical responsibility to producers for treating and disposing of post-consumer products [

17], which is particularly considered in the upcoming EU strategy for the textile sector [

41].

Even when nonreusable textiles are recycled, the main destinations remain “open-loop” applications such as wipers, nonwoven, or insulation felts towards other industries [

9,

14,

63]. Therefore, a technological barrier is commonly outlined, and a strong technical emphasis has been featured in the literature on textile recycling.

2.2. The Technological Barriers of Textile Recycling

The lack of technologies to support the development of textile-to-textile recycling is identified as a crucial persisting barrier, as attested by the recurrence rate documented in

Table 1. Indeed, textile recycling is predominantly based on established mechanical recycling [

9,

26]. As regards to the existing processing routes, a typical classification is made between mechanical and chemical recycling [

38,

58].

Mechanical recycling implies cutting the fabric into smaller pieces and then progressively shredding them through a rotating drum until reaching a fibrous state, suitable for re-spinning into new yarn or for other manufacturing products. Less common, “thermal recycling” is occasionally specified [

36] to recycle synthetic fibers by melt extrusion, regularly mentioned under “mechanical recycling” as implying prior mechanical processing [

35]. The process can be used to recycle fabrics made from natural fibers as well as synthetic fibers [

38]. However, the shredding of the fabric during the mechanical process shortens the fiber length and thus, reduces the quality output [

37,

51,

53]. In “fiber recycling” [

9], recycled fibers need to be blended with virgin fibers to reach a satisfactory quality level for yarn spinning [

38,

46]. Therefore, pre-consumer flows are considered more suitable than post-consumer waste for textile-to-textile recycling, as they are more consistent in quality and color [

35,

38], with exceptions such as wool, made up of long fibers [

58]. Polyester and other thermoplastics can be recycled through thermal recycling, also referred as “mechanical polymer recycling” [

9], during which the garments are cut and granulated into PET pellets by applying heat [

49] with a certain loss of quality [

49,

64]. Despite being technologically feasible, this process is however not yet applied at scale [

9]. Moreover, apparel textiles are often composed of fiber blends, thereby introducing the challenge of separation [

14,

58,

65] and limiting the range of recycled commodities [

51]. Consequently, the main destinations remain shredding the textiles to fiber for applications such as nonwoven or insulations, explaining the negligible “textile-to-textile” recycling share previously mentioned [

38]. As such, the distinction between “open-loop” and “closed-loop” aims to reflect the outcome level of refinement [

35]: “closed-loop recycling” designates “material recycling for a more or less identical product” [

17,

38] while “open-loop recycling” appoints processes in which the material is used in another product [

17,

38], typically towards other industries. In this perspective, a body of scientific research has explored potential applications via mechanical recycling, including composites, sound absorber, or thermal insulation [

36].

By contrast, “chemical recycling” implies a higher degree of processing through depolymerization (process of breaking polymeric bonds, for synthetics fibers only) or dissolution (for natural or synthetic cellulosic fibers) [

35]. However, chemical recycling is still limited [

9,

62]. Several innovative processes have been developed [

52], especially towards pure cotton and cotton–polyester blends [

9]. However, the current technological state is ambiguous, the review suggesting a lack of technological maturity, [

9] a deficient economic viability, [

9] or the need for investment in research and development [

46]. Consequently, the market share of recycled fibers was estimated in 2020 at 8.1% of global fiber production, but such incorporation of recycled fibers mainly derives from the recycling of PEF bottles [

66] established since the 1970s [

38,

67]. In addition, it must be noted that this typology appears oversimplified, as recycling operations often comprise a mix of mechanical, chemical, and thermal processes [

35]. Therefore, further classifications have been proposed according to the level of disassembly [

9,

35] and more recently to the polymer structure of the fibers [

27] to promote a clearer communication on the technological progress of textile recycling.

Another technological barrier resulting from the sorting stage is reported in the literature [

9,

17,

47,

48,

50,

68]. As previously outlined, sorting is a manual and costly phase, and therefore, there is a need for an economically viable and effective way to recognize and sort textile materials, to further advance textile-to-textile recycling as requiring homogenous feedstocks [

48,

50]. This current manual sorting is lacking reliability to recognize and sort the items according to their material content, jeopardizing the subsequent recycling process [

48]. The item’s composition is often varying over its lifetime, and the care labels are often cut-off or inaccurate. According to a study conducted by Circle Economy, up to 41% of labels on blended materials contain incorrect information [

68].

2.3. Systemic Challenges to Enhance Textile Recycling

As part of this complex textile flow management system, textile recycling involves a myriad of other stakeholders [

9,

35,

47,

57] such as charities, municipal waste-collection services, or resell organizations. Only a few mappings of textile flows can be found in the academic literature [

16,

57], and empirical studies investigating textile flows in these sorting facilities are lacking [

54]. However, changes are required throughout the whole value chain, as the performance of this eco-system determines the amount of collected textiles than can be further reused and recycled [

54]. Therefore, beyond technical matters [

14], numerous obstacles are encountered in the optimization of textile recycling, entailing it as a systemic challenge [

14,

38].

Several studies, both theoretical [

16,

51] and empirical [

26,

29,

32], have started to explore the textile-specific barriers related to the implementation of circular economy. While some studies provide in-depth analysis [

29,

32], they investigate the impediments related to the circular economy as a whole and therefore do not enable a holistic and systematic analysis of the recycling value chain. To the best of our knowledge, the most recent extensive research was carried out by Sandvik et al. in 2019 [

14]. The study took a qualitative approach through semi structured interviews with 11 stakeholders and investigated the drivers, inhibitors, and enablers of creating a textile-to-textile recycling system in the Scandinavian fashion industry. The main inhibitors found were the limited recycling technology to separate materials, high costs of research and development, supporting logistics, and complexity of supply chains including multiple stakeholders. However, while extending knowledge on the types of systemic and technological changes required, the study does not allow to leverage the amplitude of opinions and the sample’s lack of representativity. Moreover the study only focuses on textile-to-textile recycling, while both closed-loop and open-loop applications have their importance to reintegrate the increasing nonreusable feedstock [

38].

The remainder of the research remains theoretical and only looks over some challenges, without further investigation. Therefore, the literature is scattered, as shown by the fluctuated attendance rate in

Table 1. Although some challenges stand out more than others, the current analysis is unable to provide a clear vision on the research problem. Among the most comprehensive articles, Filho et al. [

46] investigated the socio-economic advantages of textile recycling and provided the most systematic review we found on textile recycling. The review explored the socio-economic advantages of textile recycling and pinpointed barriers to the optimization of textile recycling without specifying if they were arranged by importance: (1) economic viability, (2) composition of textile products, (3) non availability of recyclable textile materials, (4) technological limitations, (5) lack of information and limited public participation, and (6) poor coordination, and weak policies and standards. In comparison, Holes and Holes investigated effective policies and incentives worldwide for increased recycling from other sectors to reveal opportunities for extrapolation to the textile sector. A brief overview over the challenges identified is exposed, respectively: (1) the lack of incentives to motivate consumers for recycling; (2) informational and educational programs; (3) collection options of textile waste; (4) absence of policies and regulations concerning textile recycling; (5) variety of textile fibers and chemicals.

Conversely, several reports and white papers on textile recycling [

9,

17,

62] have been published over the years, providing flourishing grey literature on the topic. Especially, the Ellen MacArthur Foundation identified four priorities to improve textile-to-textile recycling [

9]: align clothing design and recycling processes, pursue technological innovation to improve the economics and quality of recycling, stimulate demand for recycled materials, and implement clothing collection at scale. Several other publications have addressed the challenges of textile recycling. For instance, Elander and Ljungkvist investigated through in-depth interviews with fashion companies, textile sorters, and recyclers 43 critical aspects for increasing textile-to-textile recycling [

63]. Roos et al. [

17] compiled a state-of-the-art on existing technologies while outlining the important factors for the future of textile recycling.

Based on the reported challenges in the academic literature, a thorough mapping was framed, as shown in

Table 1. The mapping essentially emphasizes the academic literature to outline the studies conducted so far while highlighting the fragmented state of the research. This literature review supported the implementation of our Delphi-Régnier study, and the challenges are further elaborated together with the findings in the dedicated section.

6. Conclusions

This paper aimed to deepen understanding of the current challenges of textile recycling and the priority concerns to address in the fashion and apparel sector. To achieve these research objectives, a systematic literature review supplemented by a Delphi-Régnier study was performed.

Regarding the first research question, the coding process applied during the literature review allowed us to discern a set of challenges in the recycling value chain. Through the iterative process of the Delphi-Régnier study, those challenges were discussed and revised, based on experts’ comments between the two rounds, advancing empirical knowledge on the topic. Based on the findings, the lack of eco-design practices emerges consensually as the major barrier preventing the enhancement of textile recycling. Innovative recycling technologies are crucial to develop textile-to-textile recycling and are now available for the main material streams. At this stage, industrialization is rather problematic and is interrelated with several other critical aspects. Beyond requiring substantial investments, recycling technologies entail abundant and suitable textile flows input to scale-up. Yet, the current manual sorting system arises as a significant bottleneck in the value chain, due to discrepancies with the paramount separation for material composition towards recycling applications. The lack of information availability and accuracy on products components hinders directing textile feedstocks to appropriate recycling routes. Hence, improving textile recycling is closely related to the identification of technologies. As one of the main original findings, a strong dissidence prevails on the potential of product-tracking technologies to convey information up to downstream in the value chain, and experts are more inclined to automated sorting technologies. Still, the business case needs to be resolved as the entire management system of used textiles flows is rationally structured around reusability, in accordance with the waste hierarchy. Consequently, more than a technical issue, the study instead suggests an essential restructuring of this complex value chain to support the improvement of this resource management system, highlighted by the strong focus on challenges at the sector level.

Through the emergence of consensus and dissensus on the topic, we were able to answer the second research question. The lack of eco-design practices, the absence of incentive policies, and the lack of available and accurate information on the product components emerge as the most consensual statements in the second round. Based on the results obtained from this iterative process, three dominant challenges distinctively stand out, without specific order of importance: (1) The need to advance eco-design practices consistently with respect to reusability and recyclability strategies; (2) The strong requisite of policies and governance to advance textile recycling; (3) The necessity to unravel the deficiencies related to the current manual sorting system.

Based on a European perspective, the study significantly emphasizes the critical impact of public policies and provides support for several recommendations to enhance textile recycling in the sector. Especially, in the perspective of the mandatory separate collection [

41], the findings call for measures endorsing the optimization and industrialization of the recycling value chain, rather than an increased collection of used textiles in Europe. Finally, by refining some general assertions on the topic and providing extensive empirical knowledge on the topic, this paper can help practitioners to advance relevant initiatives. The study also highlights several research opportunities, especially on the leverage of traceability technologies to enhance textile recycling in the industry. However, the method used has inherent limitations, and further statistical analysis should be conducted to further explore the priorities or interrelations between such challenges in the sector.