Textiles for Circular Fashion: The Logic behind Recycling Options

Abstract

:1. Introduction

2. Methods

3. Results

3.1. Classification of Textile Fibres

3.2. Categorising Textile Recycling and Recycling Methods

- Fibre recycling implies the preservation of the fibres after the disintegration of the fabric.

- Polymer recycling includes the disassembly of the fibres while the polymers remain intact.

- Monomer recycling implies that fibres and polymers are broken down into their chemical building blocks.

- Mechanical methods break down the fabric and retain the fibres by cutting, tearing, shredding or carding. The fibre length is reduced as an unwanted side effect, thereby affecting the spinnability and yarn strength [16]. The fibres will have a shorter fibre length than the original fibres, and some dust will be generated [17].

- Physical methods use physical processes to make the fibres or polymers suitable for reprocessing, either by melting or dissolving them. With physical recycling, the structure of the fibres is changed, but the polymer molecules that make up the fibres remain intact. After melting or dissolving, either melt spinning or solution spinning can be used to form a new filament (i.e., a fibre of infinite length).

- Chemical methods exploit chemical processes to break down fibres and polymers. The polymers that make up the fibres are either modified or broken down, sometimes to their original monomeric building blocks. This can be done by chemical or biological methods (e.g., with enzymes). After chemical recycling, the building blocks can be repolymerised into a new polymer.

3.3. Resources, Production Methods and Recycling Routes in the Linear and Circular Textile Industry

4. Discussion

4.1. Recycling Methods for Six Polymer Types: Theoretical Approach and Commercial Activities

4.1.1. Cellulose

- Mechanical recycling to fibresTable 3 shows that several mechanical cellulose recycling factories produce a variety of products and use cotton as input. Mechanical recycling of cotton yields fibres typically applied in the nonwoven industry and as flock (very small fibres used to create texture on surfaces). Recycled cotton fibres are shorter than virgin ones and thus more difficult to spin. Mechanically recycled fibres are often mixed with (longer) virgin fibres such as PET or cotton for woven applications. About 95% of the recovered fibres by the mechanical recycling of cotton are directly processed into nonwovens for the automotive industry, appliances, drainage systems and geotextiles [17].

- Physical recycling to polymersPolymer recycling of cellulose materials to yield regenerated cellulose fibres is an excellent option to recover and reuse cellulose polymers from residue streams. The resource to produce regenerated cellulose is usually wood, but other cellulose-containing resources could also be used, for example, post-consumer textiles. Possible bottlenecks are the contamination of the garments with other types of fibres and the presence of finishing agents and dyes. Cotton fibres are almost entirely made up of cellulose. They are excellent candidates as feedstock for the viscose and lyocell process, and this is applied on a small scale by several parties.

4.1.2. Polyester

- Physical recycling to polymersPET is a thermoplastic material; it melts at elevated temperature (>260 °C) and can be re-spun into fibres again. Contaminations may pose a problem in these kinds of processes, and this is therefore the reason that recycled fibres for textiles are often produced from transparent bottles (Table 4). Recycling bottles into fibres is implemented across the globe. Post-consumer transparent bottles are relatively clean and result in a high-quality rPET (recycled PET), suitable for yarn production. The use of less pure post-consumer PET items such as coloured bottles, trays and films and PET recovered from the ocean and textiles [8,33] is more challenging. If these sources cannot be sufficiently cleaned, it may be necessary to use chemical recycling methods.

- Chemical recycling to monomers and oligomersChemical recycling methods are well suited for the production of PET fibres (Table 4). During chemical recycling, the polyester molecules are broken down into smaller fragments. These smaller fragments are recovered by separation processes such as filtration, precipitation, centrifugation and crystallisation [34], making the removal of contaminants easier than in mechanical and physical recycling.

4.1.3. Polyamide

- Wool: Mechanical recycling to fibresRecycled wool has a long tradition and is the single example of successful mechanical recycling of post-consumer textiles to new yarns for textiles. The mechanical recycling of wool is the only option for the time being. Woolen fabrics are predominantly made from long fibres and handled with care, making mechanical recycling into fibres achievable. The mechanical recycling of wool is done by similar steps as mechanical recycling of cotton. Sorted fabrics are cleaned and turned into fibres by cutting and tearing. Post-industrial wool processing residues (fibre, yarn and fabric generated during production) are routinely recycled back into the manufacturing process flow for reasons of economic efficiency [45]. Mechanical recycling of post-consumer streams is also feasible. The applicability of post-consumer residues is partly dependent upon effective ways to minimise fibre breakage and maximise residual fibre length after the mechanical pulling process.

- Nylon: Physical recycling to polymersNylon can be melted and reshaped into new fibres of appropriate length and strength. Nylon waste is available as carpets and fishing nets (composed of nylon 6), and these materials are an important feedstock for physical nylon recycling. Recycling fishing nets is technologically feasible, and recycled nylon 6 shows similar characteristics compared to commercial nylons [46]. Recycling carpets is also possible by blending various carpet components through reactive extrusion and compatibilisation, yielding lower-quality products [47].

- Nylon: Chemical recycling to monomersFor nylons, chemical recycling methods are well suited. Nylon 6 is depolymerised to retrieve its original building block caprolactam. The process design is suitable for processing ‘contaminated’ materials, as the product exits at the top of the reactor and residues remain on the bottom [47]. According to DSM [48], this process is not more expensive than the production of virgin caprolactam, and it is much more environmentally benign.

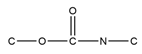

4.1.4. Polyurethane

4.1.5. Polyolefin

4.1.6. Polyacrylic

4.2. Feasibility Assessment for Main Textile Polymers and Fibres

4.3. The Challenge of Blended Textiles

4.3.1. Post-Industrial and Post-Consumer Waste Streams

4.3.2. Common Textile Blends

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Carr, D.J.; Gotlieb, M.R.; Lee, N.-J.; Shah, D.V. Examining overconsumption, competitive consumption, and conscious consumption from 1994 to 2004. Ann. Am. Acad. Politi-Soc. Sci. 2012, 644, 220–233. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. A New Textiles Economy: Redesigning Fashion’s Future. Available online: https://www.ellenmacarthurfoundation.org/publications/a-new-textiles-economy-redesigning-fashions-future (accessed on 5 February 2020).

- Saidani, M.; Yannou, B.; Leroy, Y.; Cluzel, F.; Kim, H. How circular economy and industrial ecology concepts are intertwined? A bibliometric and text mining analysis. In Proceedings of the Symposium on Circular Economy and Sustainability, Alexandroupolis, Greece, 1–3 July 2020. [Google Scholar]

- McDonough, W.; Braungart, M. Cradle to Cradle: Remaking the Way We Make Things; North Point Press: New York, NY, USA, 2010. [Google Scholar]

- Rosa, P.; Sassanelli, C.; Terzi, S. Towards Circular Business Models: A systematic literature review on classification frameworks and archetypes. J. Clean. Prod. 2019, 236, 117696. [Google Scholar] [CrossRef]

- Potting, J.; Hekkert, M.; Worrell, E.; Hanemaaijer, A. Circular Economy: Measuring Innovation in The Product Chain; PBL Publishers: The Hague, The Netherlands, 2017; Available online: https://dspace.library.uu.nl/handle/1874/358310 (accessed on 28 January 2021).

- European Parliament. Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on waste and repealing certain Directives. J. Eur. Union 2008, 312, 312–330. [Google Scholar]

- Piribauer, B.; Bartl, A. Textile recycling processes, state of the art and current developments: A mini review. Waste Manag. Res. 2019, 37, 112–119. [Google Scholar] [CrossRef] [PubMed]

- Mather, R.R.; Wardman, R.H. The Chemistry of Textile Fibres; Royal Society of Chemistry: London, UK, 2015. [Google Scholar]

- Sinclair, R. Understanding textile fibres and their properties: What is a textile fibre? In Textiles and Fashion; Sinclair, R., Ed.; Elsevier: London, UK, 2015; Chapter 1; pp. 3–27. [Google Scholar]

- Wagner, M.; Heinzel, T. Human perceptions of recycled textiles and circular fashion: A systematic literature review. Sustainability 2020, 12, 10599. [Google Scholar] [CrossRef]

- Sandin, G.; Peters, G.M. Environmental impact of textile reuse and recycling—A review. J. Clean. Prod. 2018, 184, 353–365. [Google Scholar] [CrossRef]

- Tomaney, M. Sustainable textile production. In Textiles and Fashion; Sinclair, R., Ed.; Elsevier: Amsterdam, The Netherlands, 2015; Chapter 22; pp. 547–560. [Google Scholar]

- Landi, S. The Textile Conservator’s Manual; Routledge: London, UK, 1998. [Google Scholar]

- Hiemenz, P.C. Polymer Chemistry-The Basic Concepts; Marcel Dekker: New York, NY, USA, 1984; pp. 211–215. [Google Scholar]

- Lindström, K.; Sjöblom, T.; Persson, A.; Kadi, N. Improving Mechanical Textile Recycling by Lubricant Pre-Treatment to Mitigate Length Loss of Fibers. Sustainability 2020, 12, 8706. [Google Scholar] [CrossRef]

- Gulich, B. Development of products made of reclaimed fibres. In Recycling in Textiles; Cambridge University Press: Cambridge, UK, 2006; Chapter 9. [Google Scholar]

- Vadicherla, T.; Saravanan, D. Textiles and apparel development using recycled and reclaimed fibers. In Roadmap to Sustainable Textiles and Clothing; Springer: Berlin/Heidelberg, Germany, 2014; pp. 139–160. [Google Scholar]

- Textile Exchange Preferred Fiber and Materials Market Report 2020. Textile Exchange 2020. Available online: https://store.textileexchange.org/product-category/corporate-fiber-materials-reports/ (accessed on 12 March 2021).

- Frankenhuis. Textielrecycling Sluit de Keten in de Circulaire Economie voor Textielafval. Available online: https://www.frankenhuisbv.nl/ (accessed on 12 March 2021).

- Wolkat Circulaire Textiel Recycling. Available online: https://www.wolkat.com/ (accessed on 12 March 2021).

- Belda Lloréns Ecolife Products. Available online: https://www.ecolifebybelda.com/ecolife-products/ (accessed on 12 March 2021).

- Geetanjali Woollens Dyed Wool, Cotton and Acrylic Blended Yarns. Available online: https://www.geetanjaliwoollens.com/yarns.html (accessed on 30 March 2021).

- Ferre. From Waste to Yarn. A Circular Process. Available online: https://ferreyarns.com/products/ (accessed on 30 March 2021).

- Velener Textil: Our No-Waste Model for Cotton Processing. Available online: https://www.velener.de/en/wecycled.html (accessed on 30 March 2021).

- Lenzing. TENCEL™ x REFIBRA™ Technology. Available online: https://www.tencel.com/refibra (accessed on 30 March 2021).

- Asahi Kasei Bemberg™—The Cupro Fiber from Asahi Kasei. Available online: https://www.asahi-kasei.co.jp/fibers/en/bemberg/ (accessed on 30 March 2021).

- Renewcell Recycling Clothes Finally Works. Available online: https://www.renewcell.com/en/ (accessed on 30 March 2021).

- Evrnu with NuCycl™ Technology. The World’s Waste No Longer Has To Go To Waste. Available online: https://www.evrnu.com/nucycl (accessed on 30 March 2021).

- Infinited Fibre. It’s Time for the Textile Industry to Lose Its Virginity. Available online: https://infinitedfiber.com/ (accessed on 12 March 2021).

- Ioncell. Research. Available online: https://ioncell.fi/research/ (accessed on 12 March 2021).

- Saxion SaXCell Maakt van Gebruikt Textiel Nieuw Textiel in Pilotfabriek in Enschede. Available online: https://www.saxion.nl/nieuws/2020/april/saxcell-maakt-van-gebruikt-textiel-nieuw-textiel-in-pilotfabriek-in-enschede (accessed on 29 March 2021).

- Bell, N.C.; Lee, P.; Riley, K.S.; Slater, S. Tackling Problematic Textile Waste Streams. RESYNTEX. Available online: http://www.resyntex.eu (accessed on 26 July 2018).

- Shen, L.; Worrell, E.; Patel, M.K. Open-loop recycling: A LCA case study of PET bottle-to-fibre recycling. Resour. Conserv. Recycl. 2010, 55, 34–52. [Google Scholar] [CrossRef]

- Datta, J.; Kopczyńska, P. From polymer waste to potential main industrial products: Actual state of recycling and recovering. Crit. Rev. Environ. Sci. Technol. 2016, 46, 905–946. [Google Scholar] [CrossRef]

- VelenerTextil WETURNED®. PET-Bottles in Our Fabric, Not Our Oceans. Available online: https://www.velener.de/en/weturned.html (accessed on 29 March 2021).

- Cumapol CuRe. Join the Polyester Rejuvenation Revolution! A Low Energy Recycling Solution for Used Polyester. Available online: https://www.cumapol.nl/curepolyester/ (accessed on 12 March 2021).

- Ioniqa A Game Changer. Available online: https://ioniqa.com/ (accessed on 30 March 2021).

- Jeplan Bring Technology. Making Clothing from Clothing. Available online: https://www.jeplan.co.jp/en/technology/fashion/ (accessed on 12 March 2021).

- Teijin Ecopet. Quality from Waste. Available online: https://ecopet.info/en/ (accessed on 29 March 2021).

- Eastman Polyester Renewal Technology. Available online: https://www.eastman.com/Company/Circular-Economy/Solutions/Pages/Polyester-Renewal.aspx (accessed on 30 March 2021).

- Ambercycle. We Make Garments from Garbage. Available online: https://www.ambercycle.com/ (accessed on 30 March 2021).

- Carbios Biorecycling. Available online: https://carbios.fr/en/technology/biorecycling/ (accessed on 30 March 2021).

- Gr3n Long Life to Plastic Bottles. Available online: http://gr3n-recycling.com/ (accessed on 30 March 2021).

- Russell, S.; Swan, P.; Trebowicz, M.; Ireland, A. Review of Wool Recycling and Reuse; Springer: Dordrecht, The Netherlands, 2016; pp. 415–428. [Google Scholar]

- Mondragon, G.; Kortaberria, G.; Mendiburu, E.; González, N.; Arbelaiz, A.; Peña-Rodriguez, C. Thermomechanical recycling of polyamide 6 from fishing nets waste. J. Appl. Polym. Sci. 2019, 137, 48442. [Google Scholar] [CrossRef]

- Mihut, C.; Captain, D.K.; Gadala-Maria, F.; Amiridis, M.D. Review: Recycling of nylon from carpet waste. Polym. Eng. Sci. 2001, 41, 1457–1470. [Google Scholar] [CrossRef]

- DSM Cradle to Cradle, Nylon-6 en Caprolactam. Available online: https://www.duurzaammbo.nl/images/pdf/Presention%20DSM%20Nylon-6%20Recycling%20C2C%20Desso_WB.pdf (accessed on 26 March 2021).

- Boer Group: Material Re-Use. Available online: http://boergroup-recyclingsolutions.com/textile-recycling/material-re-use/ (accessed on 12 March 2021).

- Novetex.The Billie Upcycling. Available online: https://www.novetex.com/the-billie-upcycling/ (accessed on 12 March 2021).

- Fulgar. Q-NOVA®. Available online: https://www.fulgar.com/eng/products/q-nova (accessed on 12 March 2021).

- Aquafil. The ECONYL® yarn. Available online: https://www.aquafil.com/sustainability/econyl/ (accessed on 30 March 2021).

- Van Dam, J.E.G.; Knoop, J.R.I.; Van Den Oever, M.J.A. Method for Removal of Polyurethane Fibres from a Fabric or Yarn Comprising Polyurethane Fibres and Cellulose-Based Fibres. WO Patent 2,020,130,825, 20 December 2020. [Google Scholar]

- Ignatyev, I.A.; Thielemans, W.; Vander Beke, B. Recycling of polymers: A review. ChemSusChem 2014, 7, 1579–1593. [Google Scholar] [CrossRef] [PubMed]

- Radhakrishnan, S. Denim recycling. In Textiles and Clothing Sustainability; Springer: Berlin/Heidelberg, Germany, 2017; pp. 79–125. [Google Scholar]

- Deopura, B.L.; Padaki, N.V. Synthetic textile fibres: Polyamide, polyester and aramid fibres. In Textiles and Fashion; Sinclair, R., Ed.; Elsevier: Amsterdam, The Netherlands, 2015; Chapter 5; pp. 97–114. [Google Scholar]

- Greenblue. Chemical Recycling; Making Fibre-to-Fibre Recycling A Reality For Polyester Textiles. 2018. Available online: http://greenblueorg.s3.amazonaws.com/smm/wp-content/uploads/2018/05/Chemical-Recycling-Making-Fiber-to-Fiber-Recycling-a-Reality-for-Polyester-Textiles-1.pdf (accessed on 26 March 2021).

- Hopstaken, F.; van der Schalk, A.; van der Maesen, M.; Custers, F. Massabalans Textiel 2018. FFact: 27-3-2020. 2020. Available online: https://www.verenigingafvalbedrijven.nl/userfiles/files/rapport-massabalans-textiel-2018-2020.pdf (accessed on 30 March 2021).

- van der Wal, E.; Verrips, A. Textiel als Secundaire Grondstof. Centraal Planbureau: 2019. Available online: https://www.cpb.nl/sites/default/files/omnidownload/CPB-Achtergronddocument-nov2019-Textiel-als-secundaire-grondstof.pdf (accessed on 26 March 2021).

- Harmsen, P.F.H.; (Wageningen Food and Biobased Research, Wageningen, The Newtherlands). Personal communication, April 2021.

- Ishfaq, M. Infrared Technology and Its Applications Iin Textile Recycling Technology: Improving Sustainability in Clothing Industry. Master’s Thesis, Lahti University of Applied Sciences, Lahti, Finland, November 2015. [Google Scholar]

- H&M Foundation. Recycling Revolution—Inventing New Ways to Recycle Textiles. Available online: https://hmfoundation.com/project/recycling-revolution/ (accessed on 29 March 2021).

- Worn Again: A World Where Resources Are Kept in Constant Circulation, Driving Economic, Social and Environmental Benefits. Available online: https://wornagain.co.uk/ (accessed on 29 March 2021).

- Sustainordic. Blend Rewind. Available online: https://www.sustainordic.com/portfolio/items/blend-rewind/ (accessed on 29 March 2021).

- Sodra. Once More. Available online: https://www.sodra.com/en/global/pulp/oncemorebysodra (accessed on 29 March 2021).

- Textile World. Tyton BioSciences Developer of Recycling Technology For the Fashion Industry, Closes Series a Funding Round. Available online: https://www.textileworld.com/textile-world/knitting-apparel/2020/01/tyton-biosciences-llc-developer-of-recycling-technology-for-the-fashion-industry-closes-series-a-funding-round/ (accessed on 30 March 2021).

- Block Texx. What We Do: S.O.F.T.—Separation of Fibre Technology. Available online: https://www.blocktexx.com/ (accessed on 30 March 2021).

- Resyntex: A New Circular Economy Concept for Textiles and Chemicals. Available online: http://www.resyntex.eu/downloads (accessed on 30 March 2021).

- Trash2Cash. Taking Waste & Making New Fibres. Available online: https://www.trash2cashproject.eu/ (accessed on 30 March 2021).

- Palme, A. Recycling of Cotton Textiles: Characterization, Pretreatment, and Purification; Chalmers University of Technology: Göteborg, Sweden, 2016; Available online: https://publications.lib.chalmers.se/records/fulltext/246506/246506.pdf (accessed on 30 March 2021).

| Polymer | Polysaccharides: Cellulose | Polyester | Polyamide | Polyurethane | Polyolefin | Polyacrylic |

|---|---|---|---|---|---|---|

| Essential linkage 1 | β-glycosidic | ester | amide | urethane | alkane | acrylonitrile |

|  |  |  |  |  | |

| Fibre examples | Cotton (natural) | PET 2 (condensation) | Wool (natural) | Elastane (condensation) | PP 2 (addition) | Acryl (addition) |

| Linen (natural) | Silk (natural) | PE 2 (addition) | Modacryl (addition) | |||

| Viscose (natural) | Nylon (condensation) | |||||

| Lyocell (natural) | ||||||

| Melting point | No | Yes | No (natural) Yes (condensation) | Yes | Yes | No |

| Classification of Textile Recycling | Recycling Methods | |

|---|---|---|

| Fibre recycling | Mechanical methods | |

| Polymer recycling | Mechanical methods | Physical methods |

| Monomer recycling | Mechanical methods | Chemical methods |

| Company | Input Stream | Product | Status | Ref. |

|---|---|---|---|---|

| Mechanical recycling to fibres | ||||

| Frankenhuis | Post-consumer textile waste (cotton) | Textile fibres for nonwovens | Commercial, the Netherlands | [20] |

| Wolkat | Post-consumer textile waste (cotton) | Yarns for textiles and nonwovens | Commercial, the Netherlands and Morocco | [21] |

| Belda Llorens | Cotton waste a.o. | EcoLife yarns, blended with virgin, for textiles | Commercial, Spain | [22] |

| Geetanjali Woollens | Cotton waste a.o. | Recycled cotton fibre and yarn, blended with virgin for textiles | Commercial, India | [23] |

| Ferre | Cotton waste | Recover yarns, blended with virgin for textiles | Commercial, Spain | [24] |

| Velener Textil GmbH | Post-industrial cotton yarns | WECYCLED® cotton fibres, blended with virgin for textiles | Commercial, Germany | [25] |

| Physical recycling to polymers | ||||

| Lenzing AG with Refibra™ (lyocell) | 20% post-industrial cotton scraps combined with 80% virgin cellulose pulp from wood | Tencel™ lyocell fibres (regenerated cellulose fibres) | Commercial, Austria | [26] |

| Asahi Kasei | 100% cotton linter, post-industrial residue of cotton processing | Bemberg™ cupro fibre (regenerated cellulose fibres) | Commercial, Japan, 17.000 mt/y | [27] |

| Renewcell | High-content cellulose waste (cotton, regenerated cellulose) | Dissolving pulp (Circulose pulp) | Demonstration, Sweden, 7000 mt/y | [28] |

| Evrnu with NuCycle™ | High-content cellulose waste (cotton, regenerated cellulose) | Regenerated cellulose fibres | In development, USA | [29] |

| Infinited Fibre | High-content cellulose waste (cotton, regenerated cellulose) | Regenerated cellulose fibres | In development, Finland | [30] |

| Aalto University with Ioncell™ | High-content cellulose waste (cotton, regenerated cellulose) | Ioncell™ fibres (regenerated cellulose fibres) | In development, Finland | [31] |

| SaXcell with SaXcell® (lyocell) | High-content cellulose waste (cotton, regenerated cellulose) | SaXcell® fibres (regenerated cellulose fibres) | In development, the Netherlands | [32] |

| Company | Input Stream | Product | Status | Ref. |

|---|---|---|---|---|

| Physical recycling to polymers | ||||

| Velener Textil GmbH | PET bottles | WETURNED® PET-woven fabric | Commercial, Germany | [36] |

| Cumapol with CuRe Technology | Coloured PET from various sources | Transparent PET granulate | In development, the Netherlands | [37] |

| Chemical recycling to monomers and oligomers | ||||

| Ioniqa with glycolysis | (Coloured) PET from various packaging materials | BHET and rPET | Commercial, the Netherlands, 10 ktons/y | [38] |

| Jeplan with glycolysis | (Coloured) PET from various packaging materials | BHET | Commercial, Japan | [39] |

| Teijin | Bottles and other PET materials | DMT to ECOPET™ filament yarns | Commercial, Japan | [40] |

| Eastman with chemical recycling (PRT) | Polyester | Unknown | Commercial, USA | [41] |

| Ambercycle with enzymatic hydrolysis | Post-consumer textile waste | Cycora™yarn for new textiles | In development, USA | [42] |

| Carbios with enzymatic hydrolysis | PET | Monomers EG and TPA | In development, France | [43] |

| Gr3n with microwave radiation | PET | Monomers | In development, Switzerland | [44] |

| Company | Input Stream | Product | Status | Ref. |

|---|---|---|---|---|

| Wool: mechanical recycling to fibres | ||||

| Cardato | Post-industrial Post-consumer | Yarns, “Cardato Recycled” Brand | Commercial, 22.000 mt/y, Italy (Prato) | [19] |

| Boer Group | Post-consumer | Yarns | Commercial, Netherlands | [49] |

| Geetanjali Woollens | Unknown | Recycled sheep wool and cashmere | Commercial, India | [23] |

| Novetex (Billie System) | Various | Unknown | Commercial, Hong Kong | [50] |

| Nylon: physical recycling to polymers | ||||

| Fulgar with the MSC process | Post-industrial waste | Q-Nova®, 50/50 regenerated/virgin nylon 6,6 fibre | Unknown | [51] |

| Nylon: chemical recycling to monomers | ||||

| Aquafil with Econyl® technology (depolymerisation to caprolactam) | Nylon 6 fishing nets, carpets, post-industrial textiles | Econyl® yarn, nylon 6 | Commercial, Italy | [52] |

| Classification of Textile Recycling | Cellulose | Polyamide | Polyester | Polyurethane | Polyolefin | Polyacrylic | ||

|---|---|---|---|---|---|---|---|---|

| Natural | Condensation | Addition | ||||||

| Cotton, Linen | Viscose, Lyocell | Wool | Nylon | PET | Elastane | PP, PE | Acrylics | |

| Fibre recycling | ||||||||

| Polymer recycling | * | |||||||

| Monomer recycling | ||||||||

| Company | Input Stream | Product | Status | Ref. |

|---|---|---|---|---|

| HKRITA/H&M Foundation with hydrothermal method | Cotton/PET | New textile fibres | Pre-industrial size facility in Hong-Kong | [62] |

| Worn Again with dissolution of PET and cellulose | Cotton/PET | Cellulose pulp for regenerated cellulose fibre and PET | Industrial demonstration plant to be launched in 2021 | [63] |

| Blend Re:Wind (Rise and Chalmers University) | Cotton/PET | Viscose filaments and PET monomers | Sweden, status unknown | [64] |

| Sodra with Once More | Cotton/PET | Cellulose pulp for textile | Sweden, commercial | [65] |

| Tyton Biosciences | Cotton, PET, polycotton | Cellulose and PET monomers | USA, status unknown | [66] |

| Block Texx | Cotton/PET | Cellulose pulp and PET | Australia, status unknown | [67] |

| Resyntex with monomer recycling | Cotton, nylon, PET, wool | Monomers (glucose, TPA, EG) protein hydrolysates, polyamide oligomers | Closed EU-project | [68] |

| Trash2Cash with polymer recycling | Blended textile and paper waste | Regenerated cellulose | Closed EU-project | [69] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Harmsen, P.; Scheffer, M.; Bos, H. Textiles for Circular Fashion: The Logic behind Recycling Options. Sustainability 2021, 13, 9714. https://doi.org/10.3390/su13179714

Harmsen P, Scheffer M, Bos H. Textiles for Circular Fashion: The Logic behind Recycling Options. Sustainability. 2021; 13(17):9714. https://doi.org/10.3390/su13179714

Chicago/Turabian StyleHarmsen, Paulien, Michiel Scheffer, and Harriette Bos. 2021. "Textiles for Circular Fashion: The Logic behind Recycling Options" Sustainability 13, no. 17: 9714. https://doi.org/10.3390/su13179714

APA StyleHarmsen, P., Scheffer, M., & Bos, H. (2021). Textiles for Circular Fashion: The Logic behind Recycling Options. Sustainability, 13(17), 9714. https://doi.org/10.3390/su13179714