Sustainability Performance of Port Infrastructure—A Case Study of a Quay Wall

Abstract

:1. Introduction

1.1. Background

1.2. Literature Review, Problem Statement and Research Objective

- Identify relevant themes of sustainability for port infrastructure and develop a generic framework to assess and manage the sustainability performance of port infrastructure. The framework should include a quantification tool.

- Apply the framework to a case study to improve the sustainability performance of quay walls in the Port of Rotterdam (PoR). Essential is evaluating the selected quantification tool to examine if all sustainability themes are covered and assessing objectively.

1.3. Structure of the Report

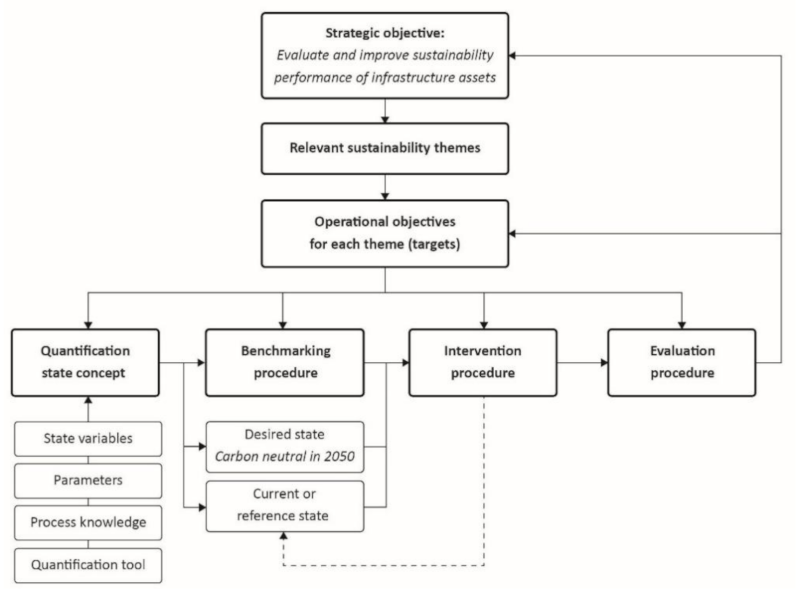

2. Framework for Assessment and Management of Sustainability of Port Infrastructure

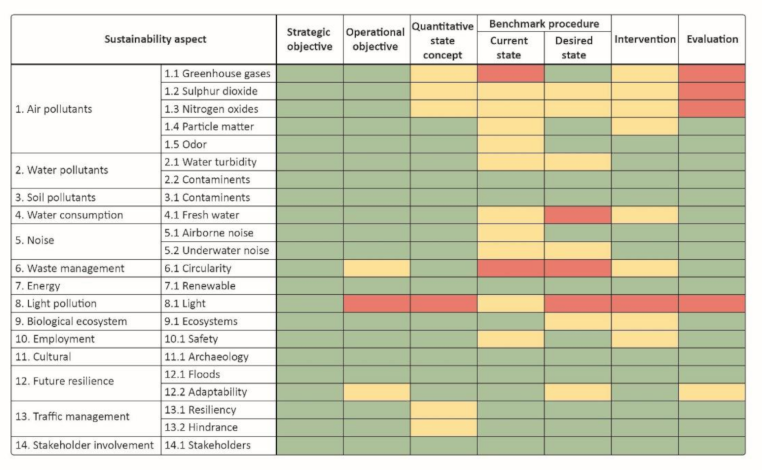

2.1. Identifying Key Sustainability Themes

2.2. Description of the Framework

2.3. Application of the Framework to Port Infrastructure

3. Application of the Framework to a Case Study

3.1. Introduction

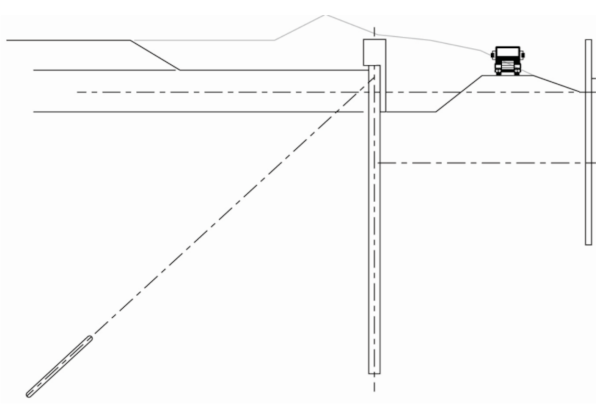

3.2. Case Study Description

3.3. Steps in Application of the Framework

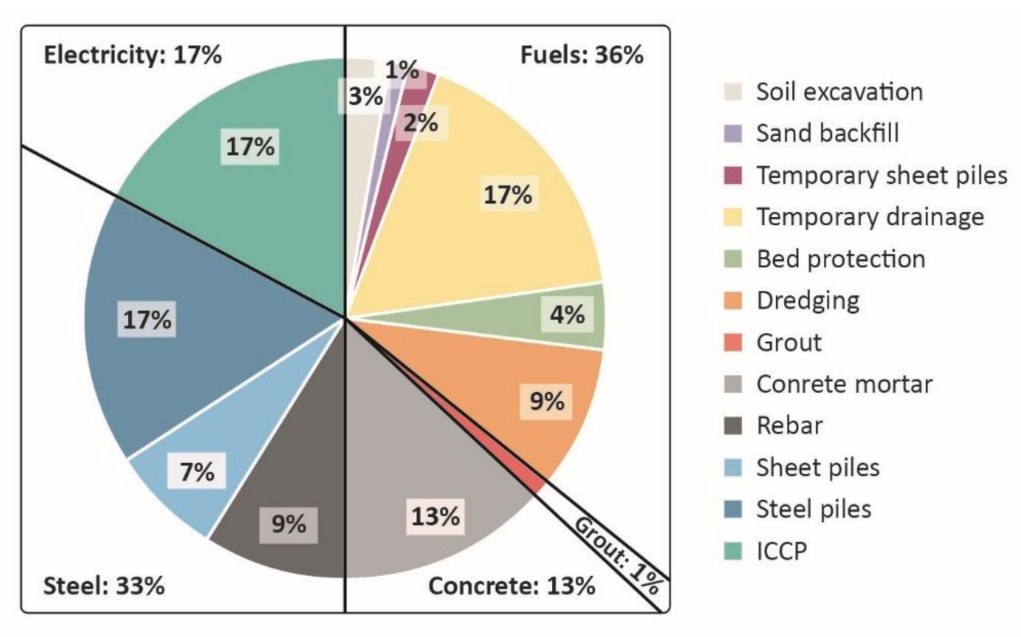

3.4. Quantification

- -

- The preparation phase includes earthwork and materials as well as the construction pit with temporary drainage systems;

- -

- construction of combined steel sheet pile wall system, anchorages, capping beam, bed protection, etc.;

- -

- dredging works, and

- -

- maintenance including corrosion protection of the steel sheet piles

4. Intervention Measures

4.1. Intervention Measures

- The carbon emissions of various materials to be used for quay wall construction were investigated. On a weight basis, the emission of steel at 908 kg CO2eq per ton is fifteen times larger than steel, which indicates that the steel use should be optimised, and the use of concrete should be preferred over steel. Moreover, any alternative material must satisfy the strength, serviceability, and durability requirements for the quay wall, while being commercially viable. Steel Fibre-Reinforced Concrete, HDPE, and tropical hardwood did not meet all the requirements. The emissions related to production of Recycled High Density Poly Ethylene (RE-HDPE) are low (1.85 kg CO2eq per ton) and this material can be used for quay walls.

- Possibilities to use a quay wall as a CO2 sink by using minerals like olivine to absorb CO2 or living organisms such as algae that adsorb CO2 to grow need further research and fall under Level 1 category.

- According to the report of Energy Transitions Commission [37], extending the lifetime of a structure can reduce emissions significantly if the function (loading) of a quay wall is not likely to change. According to an internal PoR report, the lifetime can be prolonged from 50 to 100 years, through the use of extra steel (factor 1.016) and concrete (factor 1.032). The peak emission at the end of life is significantly lower in the latter case.

- Shortening transport distances, economical designs employing less material, and an alternative quay wall design type are other possible measures. For the case study, a diaphragm wall design and a combiwall were compared. Results showed that the diaphragm wall has about 50% more emissions compared to a combiwall.

- The carbon emissions of various alternative materials for quay wall construction were investigated. On a weight basis, the emission of steel at 908 kg CO2eq per ton is fifteen times larger than steel, which indicates that the use of steel should be optimised, and concrete be preferred over steel. Moreover, any alternative material must satisfy the strength, serviceability, and durability requirements for the quay wall, while being commercially viable. Steel Fibre-Reinforced Concrete, HDPE, and tropical hardwood did not meet all the requirements. The emissions related to the production of Recycled High-Density Poly Ethylene (RE-HDPE) are low (1.85 kg CO2eq per ton) and this material can be used for quay walls. Since more research is needed, it can be seen as Level 1.

- Possibilities to use a quay wall as a CO2 sink by using minerals like olivine to absorb CO2 or living organisms such as algae that adsorb CO2 to grow needs further research and fall in Level 1 category.

- According to the report of the Energy Transitions Commission [37], extending the lifetime of a structure can reduce emissions significantly if the function (loading) of a quay wall is not likely to change. According to an internal PoR report, the lifetime can be prolonged from 50 to 100 years, through the use of extra steel (factor 1.016) and concrete (factor 1.032). The peak emission at the end of life is significantly lower in the latter case.

- Steel production: [38] mentions three intervention measures for the decarbonisation of the steel industry: circularity, hydrogen used as a reduction agent, and Carbon Capture and Storage (CCS). Salzgitter in Germany, a leader in the field of steel production, plans to focus on hydrogen-as-a-reduction-agent to reduce their emission by 82% in 2050. This reduction was adopted for the case study.

- Dredging: Alternative fuels (Table 1) were investigated for emission reduction during dredging by comparing the fuels, based on the energy content per weight. As can be seen, LNG has a low reduction potential. Biofuels such as HVO have a smaller footprint allowing emission reduction of about 75%. However, HVO is a transition fuel, not produced on a global scale, therefore, more expensive. Hydrogen is assumed to be produced 50% with renewable electricity and allows approximately 66% reduction. Green hydrogen from 100% renewable energy (green hydrogen) in the future could offer a better solution.

- Heavy-duty transport: Many seaports start to install fully electrified equipment and use electricity as the source of energy [20], also for heavy-duty road transport that generates large emissions. According to [38], the use of alternative low-carbon fuels in internal combustion engines, a shift to electric drive trains with energy storage in battery (Battery Electric Vehicles or BEVs) or hydrogen (Fuel Cell Electric Vehicles or FCEVs) is the most likely options for emission reduction. It is expected that BEV trucks using renewable electricity will be fully exploited in 2025 for regional haul trucks and urban trucks. A reduction of 100% in 2025 is assumed, neglecting the emissions during truck production and renewable electricity generation.

- Concrete production: Emission reduction in concrete production was also investigated. A pathway to decarbonize cement production fully is not yet defined. A most likely scenario developed by Material Economics, in which concrete is recycled, suggests that European construction emissions for concrete in 2050 could be reduced up to 45%. With the development of a CCS infrastructure, the reduction would amount to 90%.

- Construction equipment: Well-known brands of construction equipment have started electrifying their urban fleet. The battery technology is advancing fast with reduced costs. According to [39], construction machinery can be fully electrified in 2030, reducing emissions up to 90% using renewable energy.

- Cathodic protection: The ICCP currently runs on fossil electricity. With renewable electricity, emissions can be reduced by 86.6%.

- Temporary drainage of the construction pit: The electricity for the temporary drainage systems is provided by the diesel generators and is responsible for 16.4% of the emissions. An electrical grid for the drainage systems can be provided. The energy required is estimated by converting the diesel (in litres) to energy (kWh). The emissions will increase by 3% with the use of fossil energy and reduce by 14% with renewable energy.

4.2. Results

5. Conclusions and Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Brundtland, G.H. Our common future: Call for action. Environ. Conserv. 1987, 14, 291–294. [Google Scholar] [CrossRef]

- AAPA. An Environmental Management System (EMS) Primer for Ports: Advancing Port Sustainability; U.S. Environmental Protection Agency in partnership with American Association of Port Authorities (Tech.Rep.): 2007. Available online: https://archive.epa.gov/sectors/web/pdf/ems_primer.pdf (accessed on 10 March 2021).

- Vos, R.O. Defining sustainability: A conceptual orientation. J. Chem. Technol. Biotechnol. 2007, 82, 334–339. [Google Scholar] [CrossRef]

- Nigri, G.; Del Baldo, M. Sustainability Reporting and Performance Measurement Systems: How do Small- and Medium-Sized Benefit Corporations Manage Integration? Sustainability 2018, 10, 4499. [Google Scholar] [CrossRef] [Green Version]

- Schaltegger, S.; Burritt, R.L. Sustainability accounting for companies: Catchphrase or decision support for business leaders? J. World Bus. 2010, 45, 375–384. [Google Scholar] [CrossRef]

- UNECE. Framework and Suggested Indicators to Measure Sustainable Development. Prepared by The Joint UNECE/Eurostat/OECD Task Force 2013. Available online: http://www.un.org/esa/sustdev/natlinfo/indicators/guidelines.pdf (accessed on 10 March 2021).

- PIANC. EnviCom 188: Carbon Management for Port and Navigation Infrastructure; PIANC: Brussels, Belgium, 2019. [Google Scholar]

- Economist Intelligent Unit. Global Trends in Sustainability Performance Management. Available online: https://www.environmentalleader.com/wp-content/uploads/2011/05/Global-trends-in-sustainability-performance-management.pdf (accessed on 10 March 2021).

- Zhang, Y.; Kim, C.W.; Tee, K.F.; Lam, J.S.L. Optimal sustainable life cycle maintenance strategies for port infrastructures. J. Clean. Prod. 2017, 142, 1693–1709. [Google Scholar] [CrossRef]

- Lam, J.S.L.; Notteboom, T. The greening of ports: A comparison of port management tools used by leading ports in Asia and Europe. Transp. Rev. 2014, 34, 169–189. [Google Scholar] [CrossRef]

- Vellinga, T.; de Kaene, K.; Rijks, D.; Schrerrer, P.; Uelman, F. Sustainable ports: Green growth as an economic driver. In Proceedings of the PIANC MMX Congress, San Francisco, CA, USA, 1–5 June 2014. [Google Scholar]

- Asgari, N.; Hassani, A.; Jones, D.; Nguye, H.H. Sustainability ranking of the UK major ports: Methodology and case study. Transp. Res. Part E Logist. Transp. Rev. 2015, 78, 19–39. [Google Scholar] [CrossRef] [Green Version]

- Kuznetsov, A.; Dinwoodie, J.; Gibbs, D.; Sansom, M.; Knowles, H. Towards a sustainability management system for smaller ports. Mar. Policy 2015, 54, 59–68. [Google Scholar] [CrossRef]

- Di Vaio, A.; Varriale, L.; Alvino, F. Key performance indicators for developing environmentally sustainable and energy efficient ports: Evidence from Italy. Energy Policy 2018, 122, 229–240. [Google Scholar] [CrossRef]

- Hossain, T.; Adams, M.; Walker, T.R. Sustainability initiatives in Canadian ports. Mar. Policy 2019, 16, 103519. [Google Scholar] [CrossRef]

- Lalla-Ruiz, E.; Heilig, L.; Voß, S. Environmental Sustainability in Ports. In Sustainable Transportation and Smart Logistics Decision-Making Models and Solutions; Elsevier: Amsterdam, The Netherlands, 2019; pp. 65–89. [Google Scholar]

- Ashrafi, M.; Acciaro, M.; Walker, T.R.; Magnan, G.M.; Adams, M. Corporate sustainability in Canadian and US maritime ports. J. Clean. Prod. 2019, 220, 386–397. [Google Scholar] [CrossRef]

- Bjerkan, K.Y.; Seter, H. Reviewing tools and technologies for sustainable ports: Does research enable decision making in ports? Transp. Res. Part D Transp. Environ. 2019, 72, 243–260. [Google Scholar] [CrossRef]

- Stanković, J.J.; Marjanović, I.; Papathanasiou, J.; Drezgić, S. Social, Economic and Environmental Sustainability of Port Regions: MCDM Approach in Composite Index Creation. J. Mar. Sci. Eng. 2021, 9, 74. [Google Scholar] [CrossRef]

- Iris, Ç.; Lam, J.S.L. Optimal energy management and operations planning in seaports with smart grid while harnessing renewable energy under uncertainty. Omega 2021, 103, 102445. [Google Scholar] [CrossRef]

- Woo, J.K.; Moon, D.S.H.; Lam, J.S.L. The impact of environmental policy on ports and the associated economic opportunities. Transp. Res. Part A Policy Pract. 2018, 20110, 234–242. [Google Scholar] [CrossRef]

- PIANC. Renewables and Energy Efficiency for Maritime Ports; PIANC: Brussels, Belgium, 2019. [Google Scholar]

- Iris, Ç.; Lam, J.S.L. A review of energy efficiency in ports: Operational strategies, technologies and energy management systems. Renew. Sustain. Energy Rev. 2019, 112, 170–182. [Google Scholar] [CrossRef]

- van Rhede van der Kloot, G. Sustainability Assessment of Quay Wall Development in the Port of Rotterdam. Master’s Thesis, Delft University of Technology, Delft, The Netherlands, 2019. [Google Scholar]

- van Koningsveld, M.; Mulder, J. Sustainable coastal policy developments in the Netherlands. A systematic approach revealed. J. Coast. Res. 2004, 20, 375–385. [Google Scholar] [CrossRef]

- Port of Rotterdam Authority. Duurzame GWW: Visie en Aanpak, Internal Port of Rotterdam report. Unpublished work. 2019.

- Port of Rotterdam Insight. Zero-Emission Port by 2050. Available online: https://www.portofrotterdam.com/en/news-and-press-releases/zero-emission-port-by-2050 (accessed on 10 March 2021).

- Port of Rotterdam Authority. Mission, Vision and Strategy. Available online: https://www.portofrotterdam.com/en/port-authority/about-the-port-authority/organisation/mission-vision-and-strategy (accessed on 10 March 2021).

- Port of Rotterdam Authority. Sustainability. Available online: https://www.portofrotterdam.com/en/our-port/our-themes/a-sustainable-port/sustainability (accessed on 10 March 2021).

- Port of Rotterdam Authority. Progress Report 2014: Port Vision 2030. Available online: https://www.portofrotterdam.com/sites/default/files/Progress-report-port-vision-2030.pdf (accessed on 10 March 2021).

- Lam, J.S.L.; van de Voorde, E. Green Port Strategy for Sustainable Growth and Development. In Proceedings of the Transport Logistics for Sustainable Growth at a New Level, International Forum on Shipping, Ports and Airports (IFSPA), Hong Kong, China, 27–30 May 2012. [Google Scholar]

- PIANC. EnviCom 150: Sustainable Ports—A Guide for Port Authorities; PIANC: Brussels, Belgium, 2014. [Google Scholar]

- Wuppertal Institut. Decarbonisation Pathways for the Industrial Cluster of the Port of Rotterdam, September 2016. Available online: https://www.portofrotterdam.com/sites/default/files/rapport-decarbonization-pathways-for-the-industrial-cluster-of-the-port-of-rotterdam.pdf (accessed on 10 March 2021).

- PoR Transport. Deep Decarbonisation Pathways for Transport and Logistics Related to the Port of Rotterdam Synthesis Report, April 2018. Available online: https://www.portofrotterdam.com/sites/default/files/wuppertal-institut-2018-decarbonization-of-transport-and-logistics-synthesis-report.pdf?token=oA814CU1 (accessed on 10 March 2021).

- Dubocalc. Available online: https://www.dubocalc.nl/en/what-is-dubocalc/ (accessed on 30 March 2021).

- Herrmann, I.; Moltesen, A. Does it matter which Life Cycle Assessment (LCA) tool you choose?—A comparative assessment of SimaPro and GaBi. J. Clean. Prod. 2015, 86, 163–169. [Google Scholar] [CrossRef]

- van Driel, J. Circulair, Circulairder, Circulairst: Een Vergelijking Van Tien Veelgebruikte Tools Voor Circulair Inkopen; Utrecht Sustainability Institute: Utrecht, The Netherlands, 2017. (In Dutch) [Google Scholar]

- Energy Transitions Commission. Mission Possible: Reaching Net-Zero Carbon Emission from Harder-to Abate Sectors by Mid-Century 2018. Available online: https://www.ieta.org/resources/COP24/Misc%20Media%20Files/Dec7/SE16%20(3).pdf (accessed on 10 March 2021).

- Energy Markets & Technology. Perspectives on Zero Emission Construction (Tech. Rep.). City of Oslo: Climate Agency 2019. Available online: https://www.klimaoslo.no/wp-content/uploads/sites/88/2019/06/Perspectives-on-zero-emission-construction.pdf (accessed on 10 March 2021).

| Material | Kg CO2eq/ton | MJ/kg |

|---|---|---|

| Marine Diesel Oil (MDO) [1 ton] | 3749.92 | 42 |

| Liquified Natural Gas [1 ton] | 3987.11 | 49 |

| Hydrotreated Vegetable Oil (HVO) [1 ton] | 979.46 | 44 |

| Level 1 | Level 2 | Level 3 | Level 4 |

|---|---|---|---|

| Production of steel with a lower CO2 emission | Electric machinery | Temporary drainage on renewable energy | ICCP on renewable electricity |

| Dredging operations on hydrogen | Electric operating heavy-duty transport | Dredging operating on HVO | |

| Production of concrete with a lower CO2 emission |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Taneja, P.; van Rhede van der Kloot, G.; van Koningsveld, M. Sustainability Performance of Port Infrastructure—A Case Study of a Quay Wall. Sustainability 2021, 13, 11932. https://doi.org/10.3390/su132111932

Taneja P, van Rhede van der Kloot G, van Koningsveld M. Sustainability Performance of Port Infrastructure—A Case Study of a Quay Wall. Sustainability. 2021; 13(21):11932. https://doi.org/10.3390/su132111932

Chicago/Turabian StyleTaneja, Poonam, Godert van Rhede van der Kloot, and Mark van Koningsveld. 2021. "Sustainability Performance of Port Infrastructure—A Case Study of a Quay Wall" Sustainability 13, no. 21: 11932. https://doi.org/10.3390/su132111932

APA StyleTaneja, P., van Rhede van der Kloot, G., & van Koningsveld, M. (2021). Sustainability Performance of Port Infrastructure—A Case Study of a Quay Wall. Sustainability, 13(21), 11932. https://doi.org/10.3390/su132111932