Abstract

With circular supply chain management, the need arises to measure circularity as well as economic, environmental, and social performance. This places higher demands on performance measurement systems for circular supply chain management. The current paper studies the extent to which performance measurement systems for circular supply chain management can meet these higher demands. To gain this insight, a systematic literature review is conducted. Moreover, existing definitions of circular supply chain management are reviewed and an improved definition of circular supply chain management is developed. The current paper finds, among other things, that the literature on performance measurement systems for circular supply chain management is scarce. Moreover, most of the available performance measurement systems for circular supply chain management have not been tested in practice and are therefore still in an early phase of development. Furthermore, none of the available performance measurement systems for circular supply chain management meet the requirements for effective performance measurement systems. More specifically, including interdependencies between performance measures is a requirement that none of the performance measurement systems for circular supply chain management can meet. Including interdependencies would better support the complex decision making that arises in circular supply chain management and enable one to challenge strategic assumptions about the improvement of circularity, economic, environmental, and social performance in parallel.

1. Introduction

A performance measurement system (PMS) plays a key role in the management of a supply chain. A performance measurement system (PMS) provides information necessary for decision making, enables one to control the execution of a strategy, and reports the performance of a supply chain towards a variety of stakeholders [1,2]. A performance measurement system (PMS) consists of a set of performance measures. Initially, this set of performance measures was exclusively focused on economic performance, with measures such as cost, asset management efficiency, reliability, and agility [1,3] Subsequently, the set of performance measures was extended to enable sustainable development. Sustainable development strives not only for economic prosperity but also for environmental quality and social equity [4,5,6,7]. As a result, measures which focus on environmental and social performance became relevant in addition to measures of economic performance [4,5,7].

Sustainable development often proved to be difficult to implement [8,9]. As a result, the concept of a circular economy has received much attention from practitioners and academics alike. The concept of a circular economy introduces various strategies to implement sustainable development (for example, ‘reduce, reuse and recycle’) [5,6,7,8].

However, the relationship between circular strategies and sustainable development is complex and has different characteristics. Whilst circularity is supposed to lead to more sustainability, it does not necessarily achieve that result. For example, the circular strategies of ‘reuse and recycle’ promote the return of products after end-of-use in order to reuse the products or its materials. This leads to less use of virgin materials and hence less resource depletion and less costs, which suggests an increase of sustainable development. However, simultaneously, the returns also require more transportation and an energy-intensive process for reusing the product or for the recycling of materials. This leads to more CO2 emissions and an increase of costs which rather suggests less sustainable development [10,11,12].

The complex relationship between circular strategies and economic, environmental, and social performance characterizes decision making in circular supply chain management (CSCM) [5,6,7,10,11,12]. This places higher demands on PMSs for CSCM. A PMS for CSCM has to report and control more performance measures. Moreover, a PMS for CSCM has to identify the interdependencies between economic performance, environmental performance, social performance, and circularity. Neglecting these interdependencies can lead to suboptimal results [13].

The complex relationship between circular strategies and economic, environmental, and social performance is the motivation for the current paper. The current paper aims to study the extent to which the currently available PMSs can meet the higher demands placed by circular supply chain management (CSCM).

Performance measurement is a topic which is frequently addressed in the supply chain literature. Various literature reviews on performance measurement or performance measures are available, including [14,15,16,17]. However, these literature reviews focus on performance measures and do not take into account the complex interdependence between measures. The focus of the current paper is on PMSs as the set of measures [2,3]. This set of measures takes into account the interdependence between its measures, which could address the complex interdependence between circularity and economic, environmental, and social performance.

Table 1 presents an overview of previous literature reviews on PMSs of supply chains. Moreover, this table positions the current paper in relation to existing literature reviews, based on its framework of analysis and its focus on circular supply chain management (CSCM).

Table 1.

Overview of previous literature reviews on supply chain PMSs.

This leads to the following research questions:

- (1)

- What is the current state of development of performance measurement systems for circular supply chain management?

- (2)

- Which opportunities exist for further development of performance measurement systems for circular supply chain management?

The current paper is structured as follows. Section 2 presents a theoretical background, introducing the framework of analysis of the literature review. The framework of analysis consists of the requirements for effective PMSs for CSCM and the phase of development of PMSs for CSCM. Section 3 describes the methodology. Section 4 presents the results of the literature review. Section 5 describes the discussion which includes various opportunities for further research, followed by Section 6, the conclusions.

2. Background

2.1. Circular Supply Chain Management

Circular supply chain management (CSCM) introduced the concept of a circular economy in the field of supply chain management. A circular economy is characterized by (1) restorative and regenerative cycles and (2) reducing, maintaining and recovering resources [8,22]. Restorative cycles refer to the ability to repair, refurbish, remanufacture, and recycle technical products/materials after end of life [22,23]. Regenerative cycles refer to the ability of biological products to become both biological nutrients and part of the biosphere as natural capital after end of life [22,23]. Reducing, maintaining, and recovering resources refers to various circular strategies, such as the ‘nine Rs’ (refuse, rethink, reduce, re-use, repair, refurbish, remanufacture, repurpose, recycle, recover). These circular strategies are used to implement sustainable development in CSCM [8,11,24]. The nine Rs suggest there is a hierarchy of strategies, wherein the former strategies (refuse, rethink, reduce) lead to more sustainable development compared to the latter strategies (repurpose, recycle, recover) [22,24]. Recent empirical research shows that this relationship is less clear than the hierarchy suggests [25].

There are multiple definitions of CSCM [5,7,10]. A definition should reflect the characteristics which make CSCM unique in relation to other supply chain concepts [5]. A clear definition enables the development of knowledge. This section of the current paper compares the definitions and their ability to reflect unique characteristics of CSCM. The definition of CSCM by [10] is “The coordinated forward and reverse supply chains via purposeful business ecosystem integration for value creation from products/services, by-products and useful waste flows through prolonged life cycles that improve the economic, social and environmental sustainability of organizations”. Ref [10] introduces this definition of CSCM by expanding the scope and focus of the definitions of closed-loop supply chain management and sustainable supply chain management. The expansion of scope by [10] is described by taking into account post-production stewardship, including goods flow into alternative supply chains. This expansion introduces the reverse flow of goods in another sector. However, this characteristic appears to have overlap with the concept of the open-loop supply chain [7]. The expansion of focus by [10] is described by including value creation from by-products and waste flows. However, this characteristic instead refers to the concept of industrial symbiosis [26]. Moreover, the definition of [10] is criticized by its overlap with the definition of sustainable supply chain management [5]. The definition of [5] is “Circular supply chain management is the integration of circular thinking into the management of the supply chain and its surrounding industrial and natural ecosystems. It systematically restores technical materials and regenerates biological materials toward a zero-waste vision through system-wide innovation in business models and supply chain functions from product/service design to end-of-life and waste management, involving all stakeholders in a product/service lifecycle including parts/product manufacturers, service providers, consumers, and users”. Ref [5] focuses in their definition on restorative and regenerative cycles and zero-waste. Restorative and regenerative cycles are a key characteristic of a circular economy [8,22]. However, for ‘zero-waste’ an alternative description is available which describes more accurately a key characteristic of the circular economy, namely its focus on reducing, maintaining and recovering resources [8,22]. Furthermore, the definition provided by [5] is extensive and contains elements of which it is unclear if these represent the characteristics which make CSCM unique in relation to other supply chain concepts (for example, ‘system-wide innovations’ or ‘involving all stakeholders’). If a supply chain focuses on reducing, maintaining and recovering resources without system-wide innovations involving all stakeholders, then we would still consider this to be CSCM based on its focus on circular strategies. Therefore, characteristics such as ‘system-wide innovations’ and ‘involving all stakeholders’ are not characteristics which make CSCM unique in relation to other supply chain concepts. The definition of [7] is: “the design and control of a network of organizations and end-users that strives for economic, environmental and social benefits by reducing, maintaining and recovering resources” [7]. This definition includes the key characteristic of reducing, maintaining, and recovering resources. Moreover, this definition contains a characteristic of CSCM which is also reflected in the definition of [5]. This characteristic is that CSCM does not only consist of organizations (manufacturers, service providers) but also of end-users. However, the definition of [7] does not include the key characteristic of restorative and regenerative cycles. Therefore, the definition of CSCM by [7] will be extended to include the key characteristic of restorative and regenerative cycles.

The definition of CSCM used in the current paper is: the design and control of a network of organizations and end-users that strives for economic, environmental, and social benefits by reducing, maintaining, and recovering resources in restorative and regenerative cycles.

Literature on CSCM often emphasizes the introduction of a return flow of goods. However, this is not a unique characteristic of circular supply chains. After all, the return flow of goods is also part of an open-loop and a closed-loop supply chain [5,10]. A circular supply chain distinguishes itself from an open-loop and closed-loop supply chain in that it takes into account the resources (materials, water, energy, land) it derives from the Earth′s ecosystem and uses and maintains resources in the most efficient way while simultaneously maximizing the availability of these resources for consumption [7]. According to the renowned SCOR-model, an open-loop and closed-loop supply chain consists of the processes ‘plan, source, make, deliver, return and enable’ [1]. In addition to these processes, the circular supply chain includes the processes ‘use’ (the use of the product by the end-user) and ‘recover’ (reuse, remanufacturing, refurbishing, upcycling, recycling and downcycling) [7].

CSCM strives for performance objectives on three distinct levels:

- (1)

- The overall performance objective of the circular economy which is to decouple economic growth from resource depletion [10,27,28];

- (2)

- Performance objectives aimed at sustainable development which is to strive for economic, environmental and social benefits in the supply chain [29];

- (3)

- Performance objectives that characterize CSCM, which is to minimize the use of materials, water and energy, minimize inventory, maximize the efficient use of supply chain assets (trucks, warehouses, machines, equipment), minimize waste, maximize the availability of the product, and maximize the number of recovery flows [7].

Interdependencies exist between performance objectives within a level as well as between levels. More circularity does not necessarily lead to more sustainable development [25,30].

2.2. Performance Measurement Systems for Circular Supply Chain Management

A performance measurement system (PMS) is a set of measures used to quantify the efficiency and effectiveness of actions [2,3,21,31]. A measure provides information of the current state of performance of a supply chain. Moreover, a measure enables to compare this current state with a desired state and supports the initiation of actions towards the desired state of performance [2,3,31].

A PMS for CSCM should meet certain requirements to be effective, including:

- Multiple dimensions of performance. The PMS system should capture the perspectives of multiple relevant stakeholders. Most common stakeholders of the circular supply chain are: shareholders, suppliers, distributors, end-users, employees, and local communities [1,2,6,7]. These stakeholders should be represented via a balanced portfolio of different dimensions of performance, covering long-term and short-term objectives [3,31]. In addition to the stakeholder’s perspective, different dimensions of performance arise as a result of circularity as the operationalization of sustainable development. Circularity as well as sustainable development each have their own specific dimensions of performance. Circularity focuses on reducing, maintaining and recovering resources (materials, water, energy). Sustainable development focuses on the impact of these resources on profitability (economic performance), the Earth’s ecosystem (environmental performance) and society (social performance). Circularity does not necessarily lead to sustainable development [25,30,32,33];

- Limited range of measures. The PMS should contain only critical performance measures that represent key dimensions of performance [1,2,3,31]. Literature does not provide a clearly substantiated standard for the desired number of measures. Ref [34] suggest that the total number of measures should be between 10 and 20 in total. A report by [35] describes that it is impossible to specify the number of measures. Their experience suggests between 4 and 10 measures in total;

- Vertical integration. The PMS should connect performance on different hierarchical levels, namely strategic, tactical, operational [1]. This enables one to link strategy to decision making at each level in the organization [32,36,37]. Multiple strategies are relevant for circular supply chains (circular strategies as well as sustainable development strategies [25,37,38]). Circular strategies focus on reducing, maintaining, and recovering resources (materials, water, energy). Circular strategies are strategies such as refuse, rethink, reduce, re-use, repair, refurbish, remanufacture, repurpose, recycle, and recover [22,24]. Sustainable development strategies focus on economic, environmental and social performance. Sustainable development strategies define the priorities between these performance dimensions [37,39]. Furthermore, sustainable development strategies define how supply chains create and maintain a competitive advantage via strategies such as cost leadership, differentiation, and focus [38];

- Horizontal integration. The PMS should contain measures that are aligned along processes [2,3,31,32,37]. The processes of the circular supply chain are: plan, source, make, deliver, use, return, recover, and enable [7]. The measures should promote practices for all processes which contribute in a consistent manner to the overall strategy. Moreover, a circular supply chain implies that its performance is aligned with the carrying capacity of the Earth’s ecosystem while maximizing the availability of resources for consumption [7];

- Interdependencies. The PMS should recognize and allow for trade-offs and synergies between different dimensions of performance. To enable this, the PMS should provide insight in the interdependencies among measures [39]. In CSCM the number of interdependencies increases. Interdependencies exist between circularity and sustainable development and between economic, environmental and social performance within sustainable development [5,7].

2.3. Phases of Development of Performance Measurement Systems

The currently available PMSs for circular supply chains will be classified according to the phases of development of PMSs. The development of a PMS follows four phases: (1) design, (2) implementation, (3) use, and (4) review [36,40]. Each phase will be subsequently described in detail.

Phase 1: Design

A PMS is in this phase of development when the key objectives to execute strategy are identified and measures are described [36,40]. A PMS in this phase captures the perspectives of multiple relevant stakeholders. Stakeholders are represented via a balanced portfolio of different dimensions of performance and covering long-term and short-term objectives [3,31,40].

Phase 2: Implementation

A PMS is in this phase of development when the data to measure the performance is collected, sorted and analyzed on a regular basis through systems and procedures. The results of the measurements are used to evaluate and improve the PMS [36,40]. The content, frequency, and transparency of the results of measurement are in line with the needs of multiple relevant stakeholders [40].

Phase 3: Use

A PMS is in this phase when it is capable of measuring the success of implementation of a strategy [36,40]. The PMS contains only critical measures that represent key dimensions of performance. Moreover, The PMS connects performance on different hierarchical levels which enables to link strategy to decision making at each level in the organization [1,2,3,34,37].

Phase 4: Review

A PMS is in this phase when the PMS is used to challenge the assumptions and test the validity of the strategy [36,40]. The PMS recognizes and allows for synergies and trade-offs between different dimensions of performance. The PMS provides insight in the interdependencies between measures [37,39].

3. Methods

The goal of the current paper is to describe the current state of development of PMSs for CSCM. To accomplish this goal, a systematic literature review will be executed to locate the currently available PMSs for CSCM. Subsequently, these PMSs will be classified according to the phases of development of PMSs as described in the previous section. For the systematic literature review the approach of [41] is used. This approach is common in systematic literature reviews on CSCM [6,10,27]. This approach is conducted following five phases: (1) question formulation, (2) locating studies, (3) study selection and evaluation, (4) analysis and synthesis, and (5) reporting and using the results [41]. These phases are described in more detail in this section.

3.1. Question Formulation

The research questions are formulated and motivated in Section 1.

3.2. Locating Studies

Papers on performance measurement systems for circular supply chain management have been identified via a search in July 2021 in the Scopus and Web of Science databases. The research question contains three key concepts which are ‘performance measurement systems’, ‘circular’ and ‘supply chain’. These key concepts serve as a basis to formulate search strings. The search strings have been formulated to identify the widest possible range of papers.

For the key concept ‘performance measurement system’ the search strings ‘performance measurement’, ‘performance management’ and ‘indicator’ has been formulated to identify papers which contain the terms ‘performance measurement’, ’performance measurement system’, ‘performance management’, ‘performance management system’, ‘performance indicator’ and ‘indicator’.

For the key concept ‘circular’ the search strings ‘circular’ has been formulated to identify papers which use the terms ‘circular economy’, ‘circular’, ‘circularity’. Moreover, the search strings ‘resource efficiency’, ‘reuse’, ‘refurbishing’, ‘remanufacturing’ or ‘recycling’ have been formulated to identify papers which focus on resource efficiency and circular strategies.

Furthermore, the search strings have been searched for in the title, abstract or key words, again to identify the widest possible range of papers. The result of the search string in the Scopus database was a set of 208 papers. The result of the search string in the Web of Science database was a set of 121 papers. The total result was a set of (208 + 121 =) 329 papers. 109 papers with double entries were removed, leading to a set of (329 − 109 =) 220 papers. This set of 220 papers have been used in the subsequent step of study selection and evaluation. The title and abstract of these papers have been read. Papers have been selected based on the inclusion and exclusion criteria as presented in the next section.

3.3. Study Selection and Evaluation

Table 2 presents the inclusion and exclusion criteria of papers for the literature review. The right column describes the number of papers which have been excluded based on this particular exclusion criterion.

Table 2.

Exclusion and inclusion criteria for this literature review.

The first criterion for study selection is the topic of the papers. The motivation for this criterion is that this literature review aims to provide an overview of the state of development of currently available PMSs. Therefore, papers which present a PMS or a framework of performance measures have been included. Various papers which focus on circular economy in relation to management practices, business models or technologies have been excluded. The second criterion for study selection is the focus of the papers. The motivation for this criterion is that this literature review is focused on supply chains. Therefore, papers which focus on supply chains have been included. No further selection is applied regarding the number of parties in the supply chain. Papers which focus on the supply chain of one company are selected, as well as papers which focus on a network of companies. Information on the scope of performance measurement (company, supply chain) is included in the results. Various papers present the performance of new products or materials developed for the circular economy. These papers have been excluded from the research. The third criterion for study selection is the sector. The motivation for this criterion is that we decided to limit the current paper to supply chains of products. The supply chains of products and the supply chains of services have different characteristics. Therefore, their PMSs cannot be compared with each other. Various papers on the circular performance of educational organizations, healthcare, events, and humanitarian supply chains have been excluded. Finally, the fourth criterion for study selection is the type of papers. All proceedings of conferences have been studied and did not contain valuable information for this study. Therefore, these proceedings have been excluded.

In total, 205 papers have been excluded by study selection, from the total of 220 papers which initially have been located. This has resulted in a set of 15 papers. A citation search of these papers has identified three other papers relevant for the current paper: [11,42,43]. These papers have also been included for further analysis. In conclusion, this literature review has located in total (15 + 3 =) 18 papers.

3.4. Analysis and Synthesis

For the analysis of the PMSs an analytical framework is developed in Section 2, the theoretical background. The analytical framework consists of two pillars: the phases of development of PMSs and the requirements for effective PMSs of CSCM.

Each PMS has been classified according to its phase of the development: (1) design, (2) implementation, (3) use and (4) review. Since all PMSs are designed, all PMSs meet the requirements of phase 1: Design. A PMS has been classified as phase 2: Implementation, when a PMS is tested in practice and this test is described in one or more case studies. A PMS has been classified as phase 3: Use, when the PMS is used to measure the success of the implementation of a strategy. This requires that the PMS should have a vertical hierarchy for economic, environmental, social and circular performance. This vertical hierarchy enables one to link strategy to decision making on each level of the organization: strategic, tactical, and operational. A PMS has been classified as phase 4: review, when the PMS is used to challenge the assumptions and test the validity of the strategy.

The requirements for effective PMSs for CSCM are that a PMS should consist of multiple dimensions of performance, a limited range of measures, horizontal integration, vertical integration and interdependence between measures. For every PMS has been described whether the PMS meets each specific requirement. This information then provides insight into the effectiveness of each PMS for CSCM.

3.5. Reporting and Using the Results

When presenting descriptive results, particular attention is paid to the number of publications per year, per journal, and per research method. However, literature on circular supply chains is still in its infancy [5]. Therefore, presenting descriptive results seems to provide little insight during this phase of theory development [44]. Therefore, reporting the results has focused on presenting the thematic results. The thematic results reported are selected based on their ability to provide insight in the current state of development of PMSs for CSCM, which is the key research question of the current paper. Therefore, the thematic results will focus on presenting the methodology and approaches used in developing a PMS, their phase of development and their ability to meet the requirements of effectiveness. These thematic results will be subsequently described in the next section.

4. Results

The results are subdivided into descriptive results (number of publications per year, per journal and per research method), approach used in developing a PMS, phase of development, and the ability of a PMS to meet the requirements for effective PMSs for CSCM.

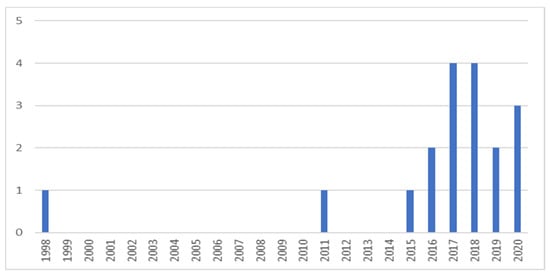

4.1. Descriptive Results

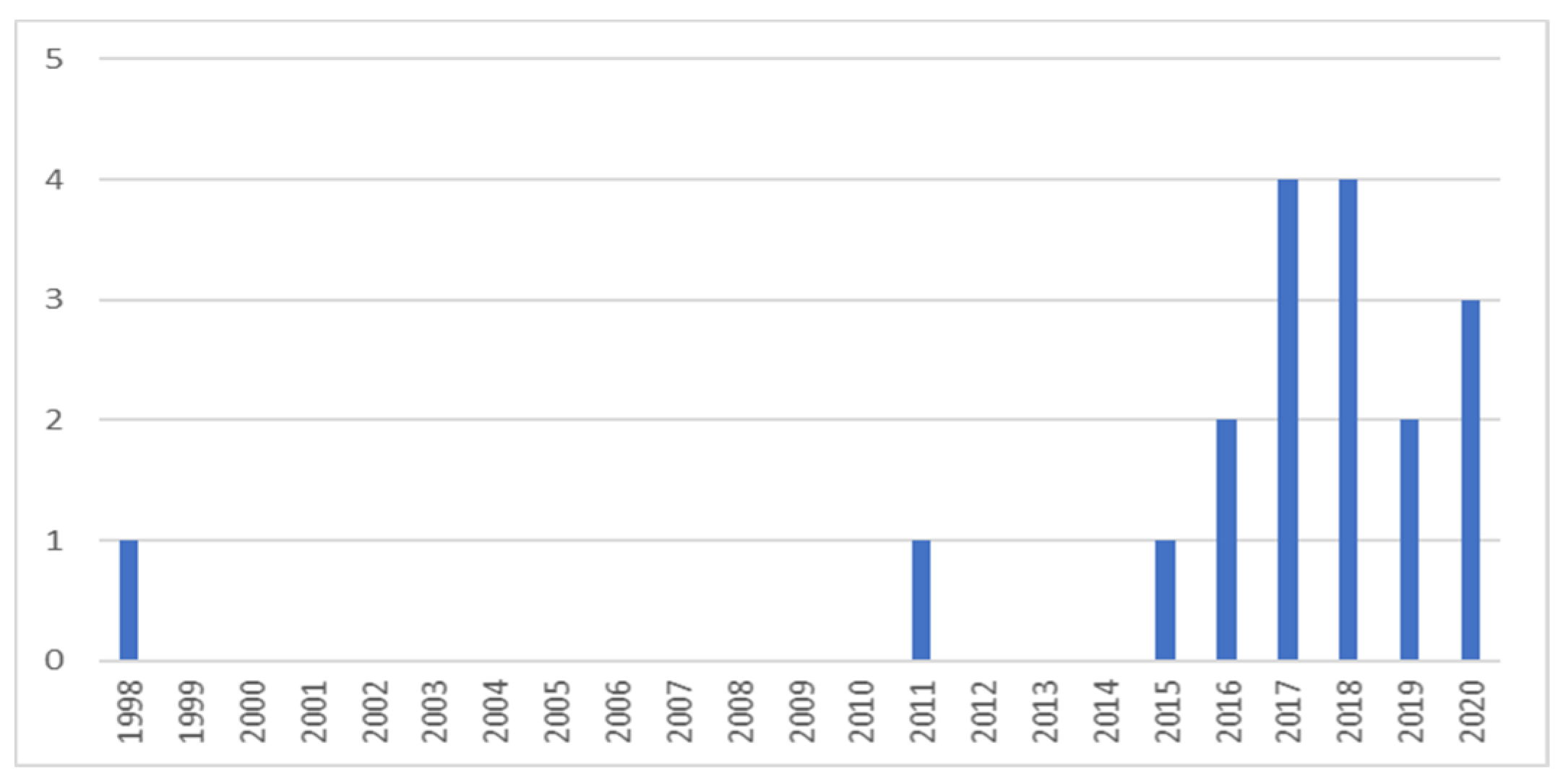

In total, eighteen PMSs for CSCM have been identified during this literature review. These PMSs for CSCM have mainly been published in the past five years. Figure 1 presents the number of publications per year.

Figure 1.

Number of publications per year.

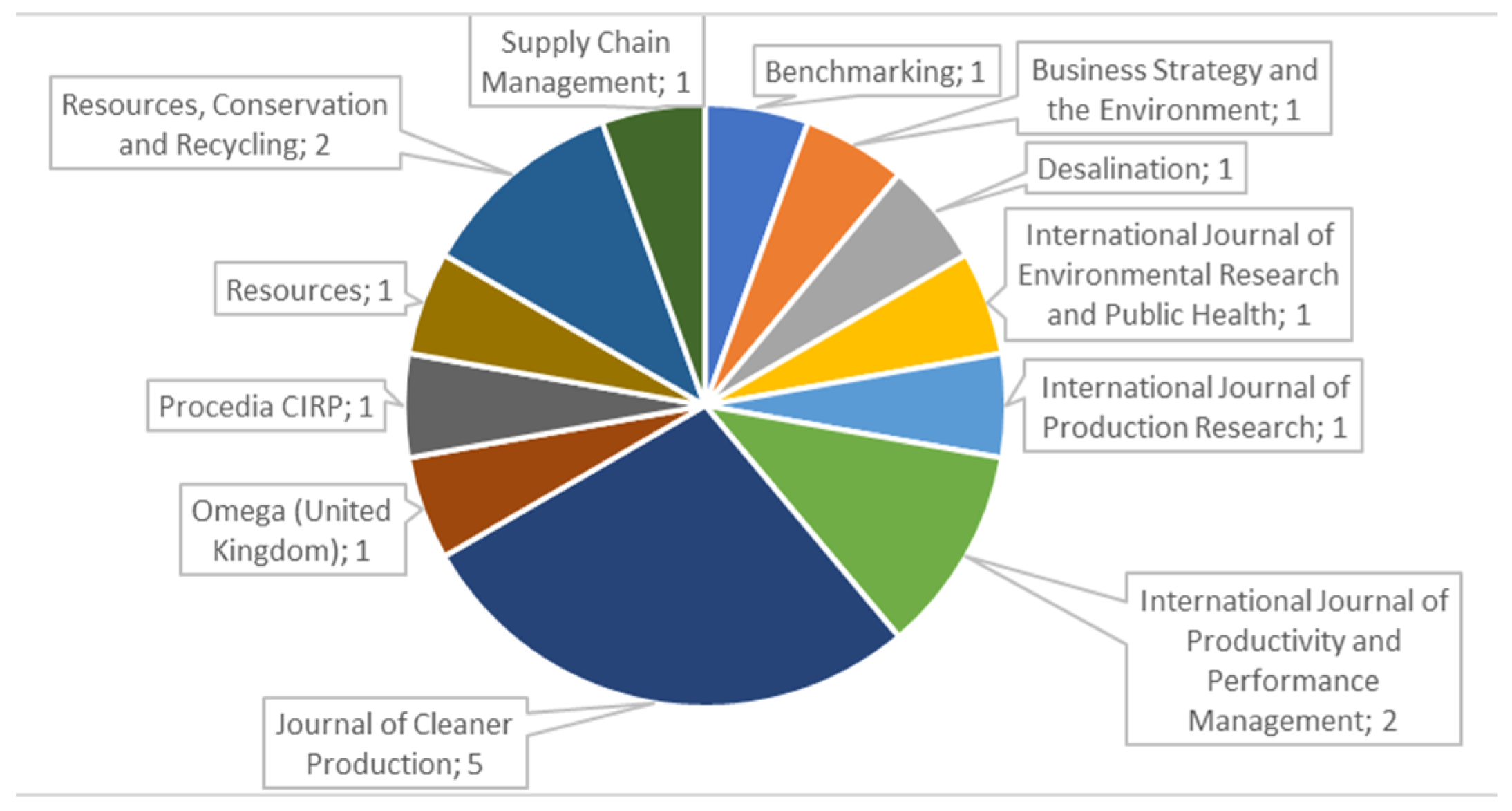

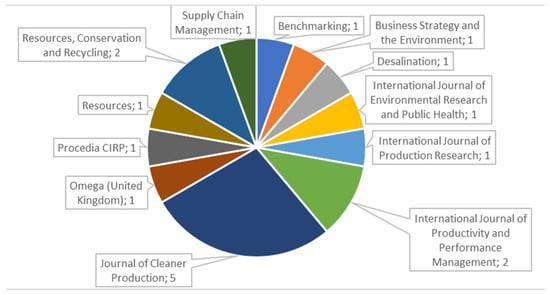

The publications are spread over a total of 12 different journals, as presented in Figure 2 ‘Journal of Cleaner Production’ is the most represented with 5 publications, followed by ‘International Journal of Productivity and Performance Management’ and ‘Resources, Conservation and Recycling’ with 2 publications.

Figure 2.

Number of publications per journal.

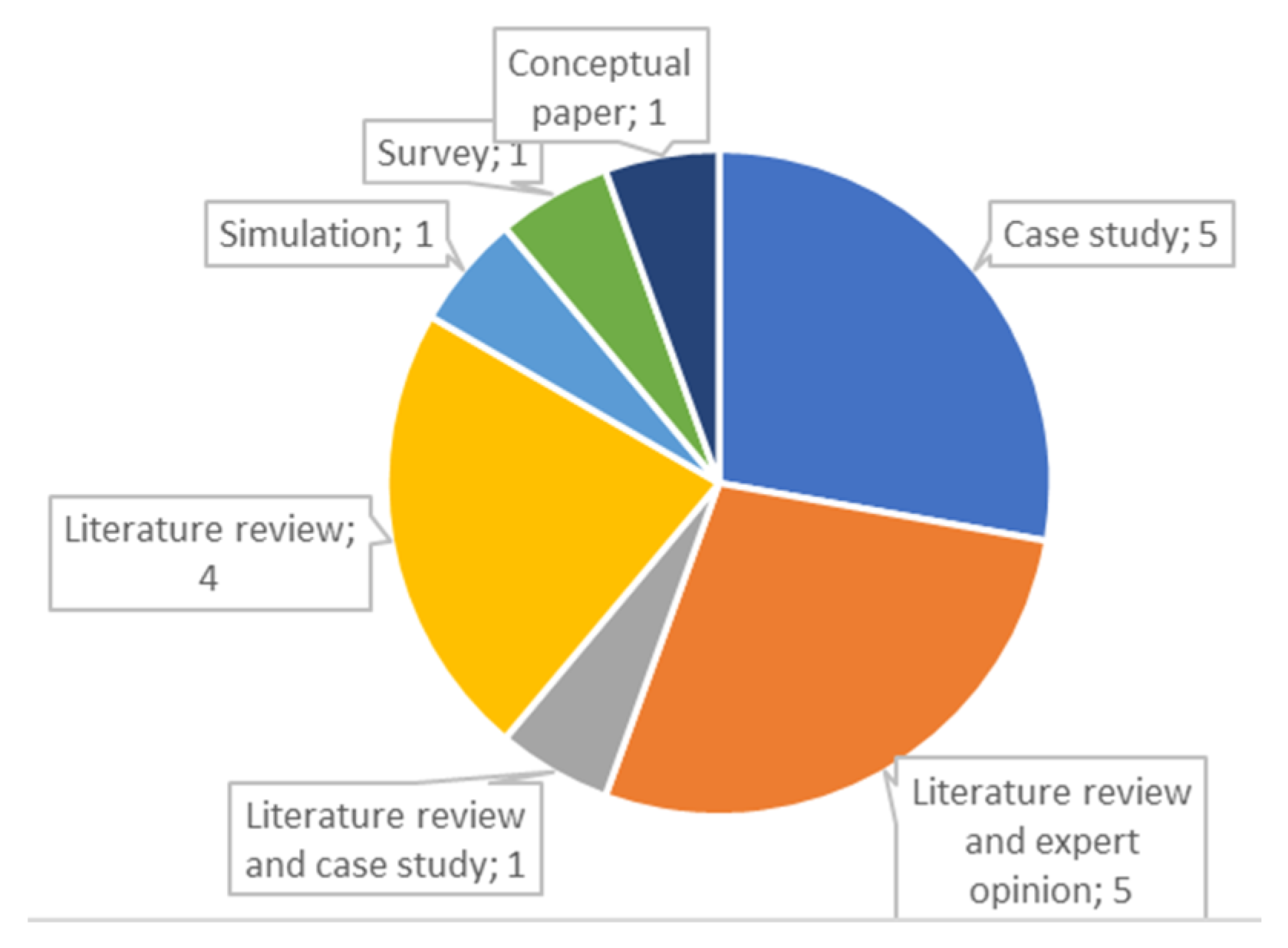

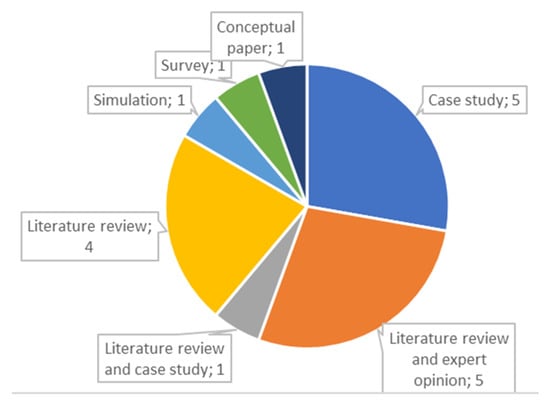

Nine of eighteen papers use a literature review as methodology [11,20,28,42,43,45,46,47,48,49]. This can be only a literature review or a literature review in combination with an expert opinion or a case study. The literature review is then mostly used to select a number of performance measures from the available literature. Based on expert opinion, a set of relevant performance measures is selected. In a case study the relevance of this set of performance measures is then tested in practice. An overview of the number of publications per methodology used is presented in Figure 3.

Figure 3.

Number of papers per methodology used for PMSs for CSCM.

4.2. Approach

There are two approaches in developing a PMS for CSCM: as a variant of an existing PMS or as a stand-alone PMS. Five of eighteen papers develop a PMS for CSCM as a variant of an existing PMS [45,48,50,51,52]. The existing PMS then provides various performance dimensions. Per performance dimension, one or more performance measures related to CSCM are developed. This leads to a set of performance measures. The existing PMSs used are the balanced scorecard (BSC), ESSENZ, quality function deployment (QFD) and the supply chain operations reference model (SCOR). Thirteen of eighteen papers develop a stand-alone PMS [11,18,20,28,42,43,46,47,49,53,54,55,56]. These papers develop a PMS by selecting a set of measures based on their relevance for CSCM. Subsequently, the performance measures from the set are interconnected. For the interconnection various techniques are used, such as data envelopment analysis (DEA), weighted index, analytical hierarchy process (AHP), input-output, grounded theory, systems theory, DEMATEL, and system dynamics. These techniques interconnect the performance measures to arrive at a single outcome regarding the performance of the circular supply chain. The interdependence between performance measures is indicated by different weighting indices or by sensitivity analyses.

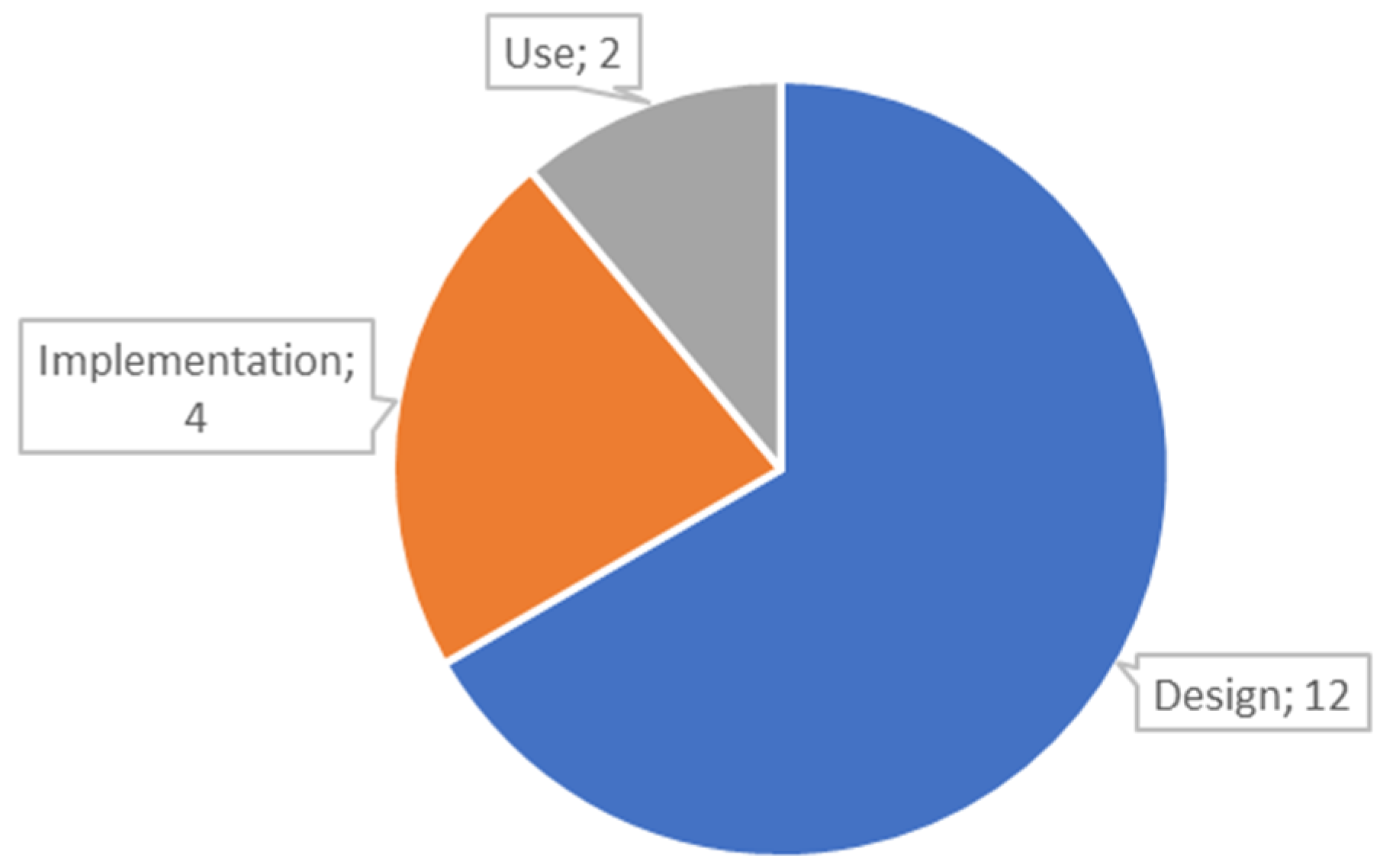

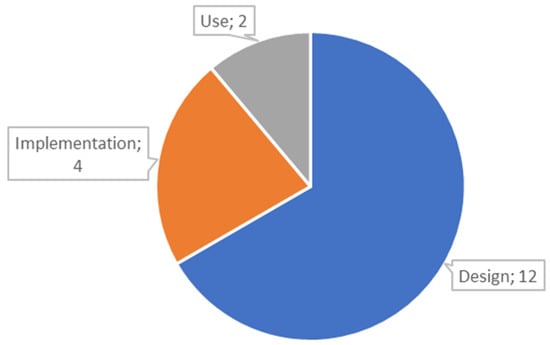

4.3. Phase of Development

Twelve of eighteen PMSs for CSCM are in the design phase and still need to be tested in practice. These PMS may be described in the selected papers, after which the PMS will be tested and implemented in a subsequent paper. Therefore, follow-up research was executed to determine whether there are papers that test the selected PMSs in practice, that use the PMS to assess the implementation of their strategy, or that use the PMS to challenge strategic assumption. The follow-up research indicated that these papers do not exist.

Four of eighteen PMSs are implemented, tested in practice and this test is described in a case study [50,54,55,56]. Two of eighteen PMSs for CSCM are in use, meaning the PMS is used to implement a strategy via a vertical hierarchy of economic, environmental, social and circular performance [28,52]. None of the eighteen PMSs for CSCM are in the phase of ‘review’, in which the validity of the strategy is challenged and synergies and trade-offs between performance measures is clarified. An overview of the number of publications per phase of development is presented in Figure 4.

Figure 4.

Phases of development of PMS for CSCM.

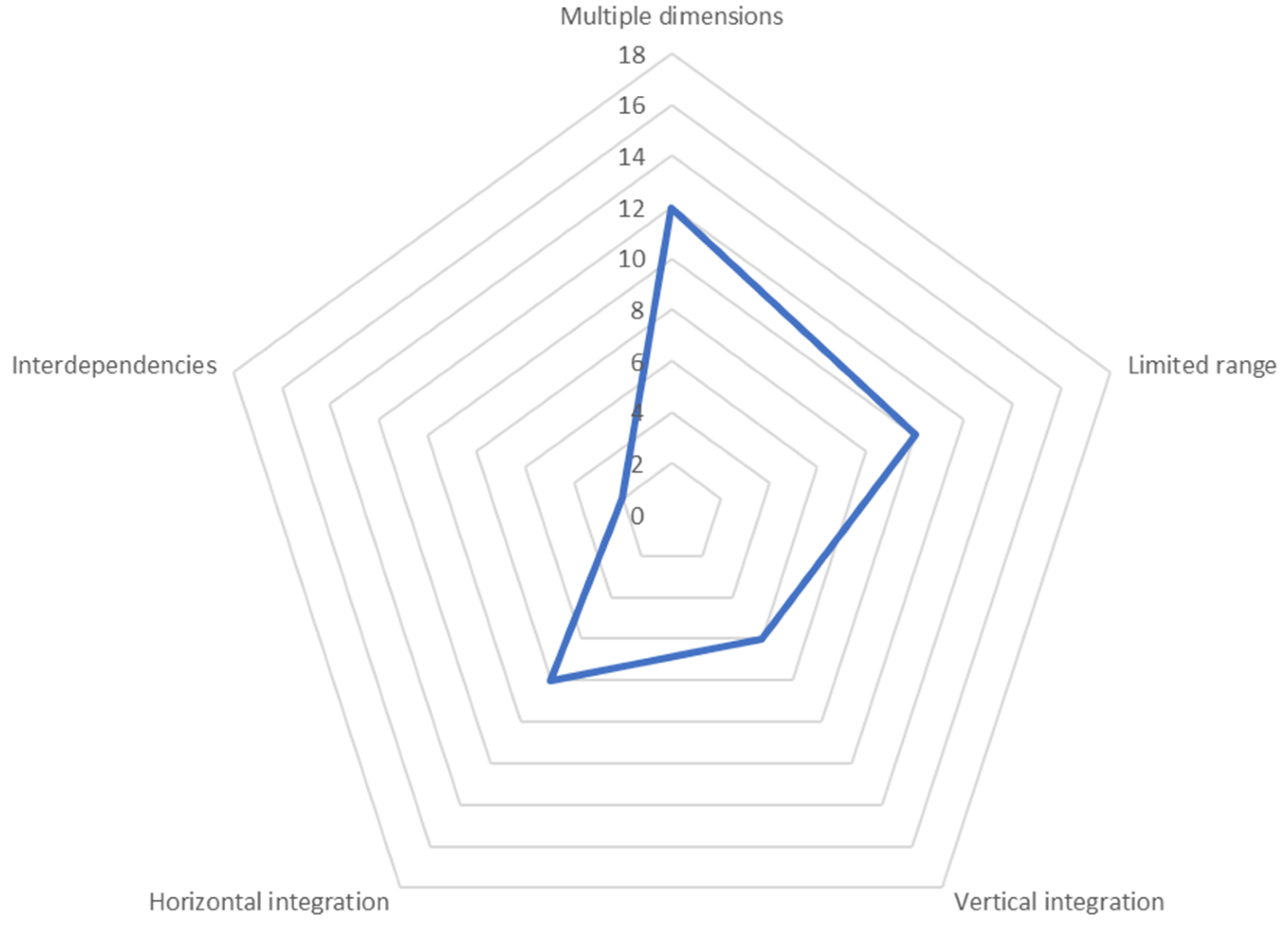

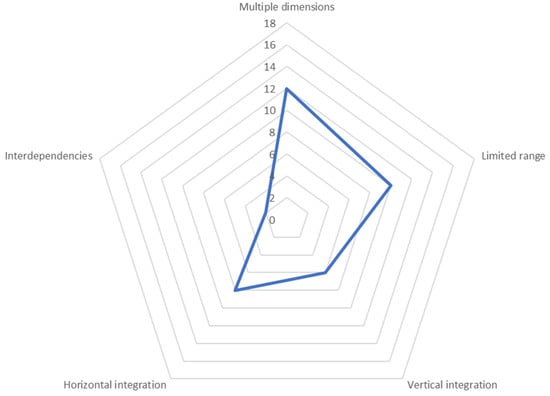

4.4. Requirements for Effective PMSs of CSCM

To provide insight in the state of development of the PMSs of CSCM, it is subsequently described to what extent each PMS meets the various requirements for effective PMSs. An overview of the number of PMSs that meet a specific requirement is presented in Figure 5.

Figure 5.

Number of PMSs which meet a specific requirement.

A requirement for effective PMSs is to include multiple dimensions of performance. Circularity does not necessarily lead to sustainable development and sustainable development consists of multiple performance dimensions. To support decision making, all performance dimensions should be represented in a PMS for CSCM. Five of eighteen PMSs include performance measures for all relevant dimensions: economic, environmental and social performance and circularity [11,18,42,51,53]. Three of eighteen PMSs include performance measures for economic, environmental and social performance and not for circularity [48,50,52]. Three of eighteen PMSs include performance measures for economic and environmental performance and not for social performance and not for circularity [20,47,49]. Ref [55] focus on performance measures for environmental performance and circularity. Finally, six PMSs focus exclusively on one performance dimension. This can be either economic performance [45], environmental performance [56], or circularity [28,43,46,54].

A requirement for effective PMSs is to have a limited range of measures, more specific between 4 to 20 in total. The number of measures ranges between 3 and 59, with an average of 19 measures. Ten of the eighteen PMSs consist of between four to twenty performance measures in total. The distribution of measures over the various dimensions of performance has a large variation. In [42,53] the number of measures per dimension is almost the same. In [18,51], the number of measures per dimension of performance is much more unevenly distributed.

The overall overview of all PMSs for CSCM, their methodology, approach, and a summary is presented in Table 3. Subsequently, the overview of their phase of development and the extent to which PMSs for CSCM meet the requirements for effectiveness is presented in Table 4.

Table 3.

PMSs for CSCM: methodology, approach, and summary.

Table 4.

PMSs for CSCM: phase of development and requirements for effectiveness of PMSs for CSCM.

A requirement for effective PMSs for CSCM is to have horizontal integration to align measures along processes of the circular supply chain. Ten of eighteen PMSs for CSCM do not provide horizontal integration. Eight of eighteen PMSs for CSCM provide horizontal integration along the forward and the reverse processes of the circular supply chain: ‘source, make, deliver, use, return, and recover’ [11,42,45,46,47,49,53,56]. In these PMSs, horizontal integration is provided by subdividing the supply chain into different processes and subsequently developing different measures per process. None of the PMSs includes the processes plan (=planning process) and enable (=the management process) in their horizontal integration. Most PMSs for CSCM focus on maximizing the availability of resources for consumption, usually with a measure for life time or quality of the product. However, none of the PMSs for CSCM include a measure to assess if its performance is aligned with the carrying capacity of the Earth’s ecosystem.

A requirement for effective PMSs is to recognize for interdependence between performance measures. Sixteen of eighteen PMSs for CSCM do not provide any interdependence between performance measures. Two of eighteen PMSs for CSCM recognize interdependencies between performance measures and provide insight in trade-offs and synergies. Ref [45] develop a PMS based on SCOR using DEMATEL. Ref [53] develop a PMS of a reverse supply chain using system dynamics. Refs [42,47,54] develop an index which consists of several subindices composed from different performance measures. In this approach, the measures seem to be interdependent since they together form the outcome of the index. However, interdependence as requirement of effective PMSs is not so much referring to combining different measures into one index. Rather, it is referring to clarifying possible trade-offs and synergies between economic, environmental, and social performance. An index does not clarify the way that improving one measure might affect the performance of another measure. Rather an index clarifies how improving one measure might affect the outcome as represented by the index.

5. Discussion

The importance of PMSs in CSCM is widely recognized [5,7]. Eighteen PMSs for CSCM have been developed in the past years. However, the overview in Section 4 indicates that PMSs for CSCM are still in the initial stages of development. Most PMSs of CSCM–twelve of in total eighteen–are designed but not tested in practice and not used to implement a strategy. Testing the PMSs in practice, can provide valuable feedback on how the PMSs works in practice. This information can then be used to further develop the PMSs to meet the specific challenges in CSCM [7]. None of the PMSs of CSCM can used to clarify synergies and trade-offs between performance measures.

The most commonly used methodology is a literature review, possibly in combination with an expert opinion or a case study. The literature review is used to select performance measures from available literature. This seems to be a necessary first step in developing a PMS for CSCM. However, the phases of development indicate that subsequent steps in the development of PMSs for CSCM is to implement and test PMSs in practice and to challenge strategies by clarifying synergies and trade-offs. Other methodologies seem to be more appropriate in these phases, such as case studies to test a PMS in practice or system dynamics and DEMATEL to clarify synergies and trade-offs.

PMSs for CSCM can be developed as a variant of an existing PMS or as a stand-alone PMS. In either way, it seems particularly important to clarify the relationships between the various strategies (circular strategy and sustainable development strategy) and between the various performance measures (economic, environmental, social performance measures). Some PMSs for CSCM motivate that environmental and social performance supports economic performance. In these PMSs, sustainability is focused on creating value for shareholders and economic performance is the most important pillar of the triple bottom line [39]. This is evident in a PMS, for example, when environmental performance is measured as environmental costs and environmental revenues [47]. A topic for debate is whether these PMSs actually strive to improve economic, environmental and social performance in parallel or that they only deploy environmental and social performance to improve economic performance. Striving for the ‘triple bottom line’ implies equity of short-term and long-term objectives [42]. If measuring environmental costs and revenues might lead to an undue focus on costs and benefits on the short term is a promising opportunity for further research and development.

Currently two of eighteen PMSs of CSCM provide insight in the interdependencies between circularity and sustainable development [45,53]. However, these PMSs do not focus on all circular strategies and the entire circular supply chain. Ref [45] develop a PMS of a reverse supply chain using system dynamics. Ref [53] develop a PMS of a remanufacturing supply chain based on SCOR using DEMATEL. Techniques, such as system dynamics and DEMATEL provide interesting opportunities to further research the interdependencies between circularity and sustainable development.

A PMS which indicates interdependencies between circularity and sustainable development would enable to identify synergetic effects and trade-offs between performance objectives. Insights in synergetic effects are important. Synergetic effects enable supply chains to determine which actions will improve economic, environmental, social and circular performance in parallel. These actions provide the most benefits compared to the required efforts [9]. Insights in trade-offs are important. Trade-offs are a starting point for disruptive innovation towards the improvement of circular, economic, environmental and social performance in parallel [13,14]. Therefore, a PMS which indicates interdependencies between performance measures would provide a promising opportunity for further research and development.

Restorative and regenerative cycles are a key aspect of CSCM [5,7]. Some PMSs for CSCM focus exclusively on regenerative cycles [20,28]. Most PMSs for CSCM do not explicitly define its focus. Restorative and regenerative cycles seem to have different characteristics, different barriers, and opportunities. Developing distinct PMSs for CSCM for restorative and regenerative cycles seem to be the direction for further research.

Several PMSs have an imbalance in the number of measures per economic, environmental, social, and circularity performance [28,43,46,47,54]. For some PMSs the number of performance measures for circularity is much higher than for economic, environmental, and social performance [28,43,46,54]. Other PMSs include performance measures for economic and environmental performance and exclude social performance and circularity [47]. Future PMSs would benefit from a balanced composition of performance measures. This balanced composition should include economic, environmental, social, and circular performance and a clarification of the role of circularity towards sustainable development. Social performance measures have been under-represented in performance measurement of sustainable supply chain management [14]. The current paper indicates that social performance is also under-represented in performance measurement for CSCM. This does not seem to support balanced decision making. Integrating a set of social performance measures is therefore a promising opportunity for further development of PMSs for CSCM.

Various authors connect waste to environmental performance [42,47]. Others connect waste to circular performance [43,54]. This indicates that the distinction between sustainability and circularity in supply chains is still unclear and requires clarification. The choice for appropriate performance measures plays a key role in the effective use of a PMS for CSCM. Therefore, a promising opportunity for further research is to develop performance measures which enable a clear distinction between sustainability and circularity.

Furthermore, it has been found that the effectiveness of performance measures could be better substantiated during the development of PMSs for CSCM. The effectiveness of performance measures depends on requirements such as its validity and robustness, whether users can influence or control its outcome, its ability to benchmark and provide fast feedback to stimulate learning and continuous improvement. These requirements are underexposed in the PMSs for CSCM. This puts into question the usability of the PMSs in practice.

6. Conclusions

The current paper aims to give an overview of the currently available PMSs for CSCM, information concerning their state of development, and to provide suggestions for their further development.

The scientific value of the current paper is that the state of development of PMSs has been assessed based on the requirement of effective PMSs. Per PMS is indicated which requirements of effectiveness it meets. This creates a detailed insight in the quality of the currently available PMSs for CSCM. Moreover, it provides detailed suggestions on which requirements are still not met and should be developed in future PMSs for CSCM.

A key requirement for effective PMSs not met by the currently available PMSs for CSCM is to recognize interdependencies between performance measures. The PMSs for CSCM which recognizes interdependence are based on a reverse supply chain [53] or only considers remanufacturing as circular strategy [45]. Recognizing interdependence leads to complex decision making and the need amongst managers for PMSs which can support complex decision making. To date, there is no PMS for CSCM available which recognizes these multiple interdependencies. Development of a PMS which recognize interdependence between performance measures would certainly be valuable. This PMS can support managers in complex decision making in CSCM.

Moreover, the development of a PMS which recognizes interdependencies is a valuable addition to existing collection of PMSs for another reason. With insight in the tensions between dimensions of performance, existing assumptions can be challenged. Tensions are an important starting point for disruptive innovation which opens ways to performance improvement on multiple dimensions of performance in parallel [13]. A PMS which provides insight in tensions between dimensions of performance is a valuable feature of PMSs for CSCM.

Finally, a contribution of the current paper is that it provides requirements for effective PMSs as a starting point for future developers of PMSs. The requirements that result from PMS literature appear to be a sound framework to assess quality of PMSs. Future developers of PMSs could use this framework to assess their own design during the development phase.

Author Contributions

Conceptualization, D.V., J.v.H. and M.O.; methodology, D.V., J.v.H. and M.O.; software, D.V.; validation, D.V., J.v.H. and M.O.; formal analysis, D.V.; investigation, D.V.; resources, D.V.; data curation, D.V.; writing—original draft preparation, D.V. and M.O.; writing—review and editing, J.v.H. and M.O.; visualization, D.V.; supervision, M.O.; project administration, D.V.; funding acquisition, D.V. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- APICS. Supply Chain Operations Reference (SCOR) Model: Version 12.0; APICS: Chicago, IL, USA, 2017. [Google Scholar]

- Maestrini, V.; Luzzini, D.; Maccarrone, P.; Caniato, F. Supply chain performance measurement systems: A systematic review and research agenda. Int. J. Prod. Econ. 2017, 183, 299–315. [Google Scholar] [CrossRef]

- Neely, A.; Gregory, M.; Platts, K. Performance measurement system design: A literature review and research agenda. Int. J. Oper. Prod. Manag. 2005, 25, 1228–1263. [Google Scholar] [CrossRef]

- Bentahar, O.; Benzidia, S. Sustainable supply chain management: Trends and challenges. Transp. Res. Part E Logist. Transp. Rev. 2018, 119, 202–204. [Google Scholar] [CrossRef]

- Farooque, M.; Zhang, A.; Thürer, M.; Qu, T.; Huisingh, D. Circular supply chain management: A definition and structured literature review. J. Clean. Prod. 2019, 228, 882–900. [Google Scholar] [CrossRef]

- Govindan, K.; Hasanagic, M. A systematic review on drivers, barriers, and practices towards circular economy: A supply chain perspective. Int. J. Prod. Res. 2018, 56, 278–311. [Google Scholar] [CrossRef]

- Vegter, D.; van Hillegersberg, J.; Olthaar, M. Supply chains in circular business models: Processes and performance objectives. Resour. Conserv. Recycl. 2020, 162, 105046. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Batista, L.; Bourlakis, M.; Smart, P.; Maull, R. In search of a circular supply chain archetype–a content-analysis-based literature review. Prod. Plan. Control. 2018, 29, 438–451. [Google Scholar] [CrossRef]

- Kravchenko, M.; Pigosso, D.C.; McAloone, T.C. Towards the ex-ante sustainability screening of circular economy initiatives in manufacturing companies: Consolidation of leading sustainability-related performance indicators. J. Clean. Prod. 2019, 241, 118318. [Google Scholar] [CrossRef]

- Sehnem, S.; Vazquez-Brust, D.; Pereira, S.C.F.; Campos, L.M. Circular economy: Benefits, impacts and overlapping. Supply Chain Manag. Int. J. 2019, 24, 784–804. [Google Scholar] [CrossRef]

- Pagell, M.; Shevchenko, A. Why research in sustainable supply chain management should have no future. J. Supply Chain Manag. 2014, 50, 44–55. [Google Scholar] [CrossRef]

- Beske-Janssen, P.; Johnson, M.P.; Schaltegger, S. 20 years of performance measurement in sustainable supply chain management–what has been achieved? Supply Chain Manag. Int. J. 2015, 20, 664–680. [Google Scholar] [CrossRef]

- Moraga, G.; Huysveld, S.; Mathieux, F.; Blengini, G.A.; Alaerts, L.; Van Acker, K.; De Meester, S.; Dewulf, J. Circular economy indicators: What do they measure? Resour. Conserv. Recycl. 2019, 146, 452–461. [Google Scholar] [CrossRef] [PubMed]

- Saidani, M.; Yannou, B.; Leroy, Y.; Cluzel, F.; Kendall, A. A taxonomy of circular economy indicators. J. Clean. Prod. 2019, 207, 542–559. [Google Scholar] [CrossRef] [Green Version]

- Taticchi, P.; Garengo, P.; Nudurupati, S.S.; Tonelli, F.; Pasqualino, R. A review of decision-support tools and performance measurement and sustainable supply chain management. Int. J. Prod. Res. 2015, 53, 6473–6524. [Google Scholar] [CrossRef]

- Cuthbertson, R.; Piotrowicz, W. Performance measurement systems in supply chains: A framework for contextual analysis. Int. J. Product. Perform. Manag. 2011, 60, 583–602. [Google Scholar] [CrossRef]

- Gopal, P.; Thakkar, J. A review on supply chain performance measures and metrics: 2000–2011. Int. J. Product. Perform. Manag. 2012, 61, 518–547. [Google Scholar] [CrossRef]

- Balfaqih, H.; Nopiah, Z.M.; Saibani, N.; Al-Nory, M.T. Review of supply chain performance measurement systems: 1998–2015. Comput. Ind. 2016, 82, 135–150. [Google Scholar] [CrossRef]

- Ka, J.M.R.; Ab, N.R.; Lb, K. A review on supply chain performance measurement systems. Procedia Manuf. 2019, 30, 40–47. [Google Scholar]

- MacArthur, E. Towards the Circular Economy, Economic and Business Rationale for an Accelerated Transition; Ellen MacArthur Foundation: Cowes, UK, 2013; pp. 21–34. [Google Scholar]

- Morseletto, P. Restorative and regenerative: Exploring the concepts in the circular economy. J. Ind. Ecol. 2020, 24, 763–773. [Google Scholar] [CrossRef]

- Potting, J.; Hekkert, M.P.; Worrell, E.; Hanemaaijer, A. Circular Economy: Measuring Innovation in the Product Chain; PBL Publishers: Sydney, Australia, 2017. [Google Scholar]

- Braun, G.; Som, C.; Schmutz, M.; Hischier, R. Environmental Consequences of Closing the Textile Loop—Life Cycle Assessment of a Circular Polyester Jacket. Appl. Sci. 2021, 11, 2964. [Google Scholar] [CrossRef]

- Fraccascia, L.; Giannoccaro, I.; Yazan, D.M.; Choi, T.; Ivanov, D. Managing supply chain operations in industrial symbiosis networks. Resour. Conserv. Recycl. 2019, 151, 104323. [Google Scholar]

- Bressanelli, G.; Perona, M.; Saccani, N. Challenges in supply chain redesign for the Circular Economy: A literature review and a multiple case study. Int. J. Prod. Res. 2019, 57, 7395–7422. [Google Scholar] [CrossRef] [Green Version]

- Howard, M.; Hopkinson, P.; Miemczyk, J. The regenerative supply chain: A framework for developing circular economy indicators. Int. J. Prod. Res. 2019, 57, 7300–7318. [Google Scholar] [CrossRef] [Green Version]

- Carter, C.R.; Rogers, D.S. A framework of sustainable supply chain management: Moving toward new theory. Int. J. Phys. Distrib. Logist. Manag. 2008, 38, 360–387. [Google Scholar] [CrossRef]

- Blum, N.U.; Haupt, M.; Bening, C.R. Why “Circular” doesn’t always mean “Sustainable”. Resour. Conserv. Recycl. 2020, 162, 105042. [Google Scholar] [CrossRef]

- Elgazzar, S.; Tipi, N.; Jones, G. Key characteristics for designing a supply chain performance measurement system. J. Product. Perform. Manag. 2019, 68, 296–318. [Google Scholar] [CrossRef] [Green Version]

- Negri, M.; Neri, A.; Cagno, E.; Monfardini, G. Circular Economy Performance Measurement in Manufacturing Firms: A Systematic Literature Review with Insights for Small and Medium Enterprises and New Adopters. Sustainability 2021, 13, 9052. [Google Scholar] [CrossRef]

- Cagno, E.; Neri, A.; Howard, M.; Brenna, G.; Trianni, A. Industrial sustainability performance measurement systems: A novel framework. J. Clean. Prod. 2019, 230, 1354–1375. [Google Scholar] [CrossRef]

- Kravchenko, M.; Pigosso, D.C.; McAloone, T.C. A procedure to support systematic selection of leading indicators for sustainability performance measurement of circular economy initiatives. Sustainability 2020, 12, 951. [Google Scholar] [CrossRef] [Green Version]

- PriceWaterhouseCoopers. Guide to Key Performance Indicators. Available online: https://www.pwc.com/gx/en/audit-services/corporate-reporting/assets/pdfs/uk_kpi_guide.pdf (accessed on 21 September 2021).

- Bourne, M.; Mills, J.; Wilcox, M.; Neely, A.; Platts, K. Designing, implementing and updating performance measurement systems. Int. J. Oper. Prod. Manag. 2000, 20, 754–771. [Google Scholar] [CrossRef] [Green Version]

- Papulová, Z.; Gažová, A.; Šlenker, M.; Papula, J. Performance Measurement System: Implementation Process in SMEs. Sustainability 2021, 13, 4794. [Google Scholar] [CrossRef]

- Cetinkaya, B. Developing a Sustainable Supply Chain Strategy; Sustainable Supply Chain Management; Springer: Berlin/Heidelberg, Germany, 2010; pp. 17–55. [Google Scholar]

- Hansen, E.G.; Schaltegger, S. Sustainability balanced scorecards and their architectures: Irrelevant or misunderstood? J. Bus. Ethics 2018, 150, 937–952. [Google Scholar] [CrossRef] [Green Version]

- Maestrini, V.; Luzzini, D.; Caniato, F.; Maccarrone, P.; Ronchi, S. Measuring supply chain performance: A lifecycle framework and a case study. Int. J. Oper. Prod. Manag. 2018, 38, 934–956. [Google Scholar] [CrossRef]

- Denyer, D.; Tranfield, D. Producing a systematic review. In The Sage Handbook of Organizational Research Methods; Buchanan, D.A., Bryman, A., Eds.; Sage Publications Ltd.: New York, NY, USA, 2009; pp. 671–689. [Google Scholar]

- Azevedo, S.G.; Godina, R.; Matias, J.C.D.O. Proposal of a sustainable circular index for manufacturing companies. Resources 2017, 6, 63. [Google Scholar] [CrossRef] [Green Version]

- Brown, P.J.; Bajada, C. An economic model of circular supply network dynamics: Toward an understanding of performance measurement in the context of multiple stakeholders. Bus. Strategy Environ. 2018, 27, 643–655. [Google Scholar] [CrossRef]

- Edmondson, A.C.; McManus, S.E. Methodological fit in management field research. Acad. Manag. Rev. 2007, 32, 1246–1264. [Google Scholar] [CrossRef] [Green Version]

- Ansari, Z.N.; Kant, R.; Shankar, R. Remanufacturing supply chain: An analysis of performance indicator areas. J. Product. Perform. Manag. 2020. preprint. [Google Scholar] [CrossRef]

- Jain, S.; Jain, N.K.; Metri, B. Strategic framework towards measuring a circular supply chain management. Benchmarking Int. J. 2018, 25, 3238–3252. [Google Scholar] [CrossRef]

- Kazancoglu, Y.; Kazancoglu, I.; Sagnak, M. A new holistic conceptual framework for green supply chain management performance assessment based on circular economy. J. Clean. Prod. 2018, 195, 1282–1299. [Google Scholar] [CrossRef]

- Haghighi, S.M.; Torabi, S.A.; Ghasemi, R. An integrated approach for performance evaluation in sustainable supply chain networks (with a case study). J. Clean. Prod. 2016, 137, 579–597. [Google Scholar] [CrossRef]

- Olugu, E.U.; Wong, K.Y.; Shaharoun, A.M. Development of key performance measures for the automobile green supply chain. Resour. Conserv. Recycl. 2011, 55, 567–579. [Google Scholar] [CrossRef]

- Bach, V.; Berger, M.; Henßler, M.; Kirchner, M.; Leiser, S.; Mohr, L.; Rother, E.; Ruhland, K.; Schneider, L.; Tikana, L. Integrated method to assess resource efficiency–ESSENZ. J. Clean. Prod. 2016, 137, 118–130. [Google Scholar] [CrossRef] [Green Version]

- Butzer, S.; Schötz, S.; Petroschke, M.; Steinhilper, R. Development of a performance measurement system for international reverse supply chains. Procedia Cirp 2017, 61, 251–256. [Google Scholar] [CrossRef]

- Wu, Z.; Zhai, S.; Hong, J.; Zhang, Y.; Shi, K. Building sustainable supply chains for organizations based on QFD: A case study. Int. J. Environ. Res. Public Health 2018, 15, 2834. [Google Scholar] [CrossRef] [Green Version]

- Beiler, B.C.; de Arruda Ignácio, P.S.; Júnior, A.C.P.; Anholon, R.; Rampasso, I.S. Reverse logistics system analysis of a Brazilian beverage company: An exploratory study. J. Clean. Prod. 2020, 274, 122624. [Google Scholar] [CrossRef]

- Bracquené, E.; Dewulf, W.; Duflou, J.R. Measuring the performance of more circular complex product supply chains. Resour. Conserv. Recycl. 2020, 154, 104608. [Google Scholar] [CrossRef]

- Genovese, A.; Acquaye, A.A.; Figueroa, A.; Koh, S.L. Sustainable supply chain management and the transition towards a circular economy: Evidence and some applications. Omega 2017, 66, 344–357. [Google Scholar] [CrossRef]

- McIntyre, K.; Smith, H.; Henham, A.; Pretlove, J. Environmental performance indicators for integrated supply chains: The case of Xerox Ltd. Supply Chain. Manag. Int. J. 1998, 3, 149–156. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).