Abstract

The supply chain risk management (SCRM) is very critical to strategically support the firms to continuous success. There are, at least, three basic steps in this SCRM process: risk identification, risk evaluation, and risk mitigation (treatment). Whatever happens, the main step is risk mitigation (RM) and mainly sustainable RM. In fact, every risk must be eliminated or controlled as much as possible. The purpose of this paper is to elaborate and evaluate various RM scenarios from an initial risk identification and prioritization solution. The proposed scenario modeling technique is based on morphological analysis (MA) as an explorative scenario tool for RM. MA is used to develop a framework to proactively assess critical risk variables. Firstly, MA is employed to exhaustively create possible RM scenarios and, secondly, to assess the likelihood of each scenario. The proposed approach addresses the need for a basic rubric to help identify and choose RM approaches. A real case study is provided from the food industry to illustrate the application of the proposed approach. To handle all possible MA strategies, a dedicated MORPHOL software package is used. In addition, RM strategies are selected based on sustainability indicators. The case study results prove that MA has a considerable value for SCRM. It shows that firms can adopt multiple robust strategies in the form of a scenario describing all stages of SCRM in an integrated representation.

1. Introduction

The risks associated with supply chain management (SCM) have created a discourse among practitioners and academics [1,2]. In fact, supply chains (SC) are becoming more complex and vulnerable. The main research question issue in SCM is still about how to mitigate supply chain risks [3].

In the literature, there are many risk mitigation (RM) scenarios as mentioned in [4,5]. So far, research has proposed several separate RM strategies based on the types of risk in supply chain risk management (SCRM), but few strategies for the entire SCRM process of an integrated network. This can be explained by the large number of both risk variables and their associated reduction strategies. Thus, the process by which conclusions are drawn from such studies is often difficult to trace. The performance of the supply chain can be affected by many events entering the system and affecting all exchanges of products, services, and information between actors in a supply chain network. SCRM is defined, in a collaborative way with partners, as a set of tools for dealing with risk and uncertainty caused by, or having an impact on, the activities and logistical resources. Essentially, a robust and established supply chain strategy would allow a firm to implement associated contingency plans efficiently and effectively when faced with a disruption. Therefore, having a robust supply chain strategy could make a company more resilient.

In recent years, many researchers have linked sustainability and SCRM in the common area named Sustainable Supply Chain Risk Management (SSCRM) [2,6,7,8]. In fact, the development of sustainable RM strategies is a complex task that requires expert knowledge and many years of practical experience in a wide range of disciplines. It also requires a scenario planning methodology that can organize this knowledge through a participatory dialogue process. In fact, scenario planning stimulates strategic thinking and helps to overcome thinking limitations by creating multiple futures [9]. Though, in the literature, there are various scenario modeling techniques, morphological analysis (MA) is the most used explorative tool [10,11]. Developed for scenario modeling in defense planning and used by researchers in the field of future studies and technological forecasting, MA can be used to visualize elements and dimensions to develop raw scenarios for the future [10]. The purpose of a MA is to identify and structure all possible aspects and solutions in situations where the problem space is complex and non-reducible [11]. MA is characterized by structuring a system into independent partial systems and quickly finding answers by combining the different solutions of these subsystems [12]. However, the MA is a method to structure a problem rather than solve it [13].

The process of SCRM contains mainly three phases: identification, evaluation (assimilated to an aggregated view of the stages of analysis and evaluation), and mitigation (assimilated to phase treatment). The above literature review concerns only the risk mitigation phase. The objective of this step is to protect proactively against risks through the application of appropriate scenarios. However, once risks are isolated and quantified, it is a question of establishing a plan for prevention and improvement of protections for the entire supply chain. The smartest supply chain recognizes risk as a systemic issue. These impact reduction strategies take advantage of the millions of smart objects that can impart threats to them. It also works with supply chain partners for joint strategies and tactics to reduce impacts. On the other hand, if problems arise, it takes advantage of real-time connectivity that extends to the expanded supply chain to respond in a fast and coordinated manner. We can conclude that the biggest advantage of a smarter supply chain is its ability to model and simulate the risks for the entire network.

Aqlan and Lam [14] proposed a methodology based on Bow-Tie analysis to quantify and mitigate supply chain risks. Their proposed methodology takes into account the interconnections of risks and identifies the best combination of RM strategies under budget constraints. Chang et al. [15] proposed a framework that uses probability and severity as contextual variables and redundancy and flexibility as primary RM strategies in supply chain RM strategies. Their research draws upon the theoretical foundations of contingency theory to propose a framework that aligns well-established aspects of SCRM to present a rubric for matching primary supply chain risk mitigation strategies with particular risk contexts. Tarei et al. [16] explored the relationship between various risk management strategies and risk management practices to design and therefore implement a suitable supply chain (SC) plan. Zhang et al. [17] proposed the application of the system dynamics method to simulate changes in inventory level, order accumulation, and profit level caused by disruption of supply, production, and sales of different node companies. Based on their results, corresponding RM strategies for enterprises to cope with different node interruptions are proposed to improve the overall efficiency and operational capabilities of the enterprise. Hsu et al. [18] developed an integrated approach based on the quality function deployment approach to define some RM strategies. Based on resilience capabilities and resilience-enhancing characteristics, they proposed a useful approach for the development of resilient and sustainable supply chains.

Based on the above literature review, which is related to risk mitigation in SCRM, it can be concluded that there was a series of research on RM strategies, but generally they did not go beyond the risk assessment stage and even the risk mitigation strategies were arbitrary and personal. This can be explained by the large number of risk variables and their interrelation complexity and the lack of coordination between experts in the field to find appropriate solutions as well as conflicts and divergences of objectives between the SC actors involved.

Moreover, the use of MA in risk management is a very recent research area. Ritchey [19] developed a prototype multi-hazard disaster reduction model. The model, developed with computer-aided morphological analysis, makes it possible to identify and compare risk reduction strategies and preparedness and mitigation measures for different types of hazards. Using the same prototype, Fernandez et al. [20] present how the prototype can be applied in the case of planning for earthquake disaster risk management. The influence of other hazards, when combined with planning for earthquake disaster risk management, is also examined. Jimenez et al. [21] apply MA to develop a framework to proactively assess the risk of a terrorist attack on the air transport system. MA is employed, firstly, to exhaustively create possible attack scenarios. Secondly, MA is used to assess the likelihood of each scenario. Akgun [22] proposes a novel intelligent technique called evidence-based MA model, which is based on the Dempster–Shafer theory of evidence and MA methodology to quantify the likelihood of intentional events as threats by identifying the number of intentional events, such as homeland and cyber security events. Lantada et al. [23] propose a methodology to support the decision-making process in the reduction of an urban area. It is based on an MA which involves firstly the results of a holistic evaluation of the disaster risk due to natural hazards and, secondly, 35 strategies to reduce the physical risk and the aggravating social conditions of the urban area. Johannessen [24] applies MA to future risk scenarios for the Northern Sea Route (in Norway), which is an area prone to wicked problems. Wicked problems are problems that are not predefined, nor do they have a single solution. They are problems that exist because of the opinions and desires of the stakeholders in the complex problem.

Based on the above literature review, which is related to the use of MA in risk management, it can be concluded that there is no research yet that has used MA in the SCRM area. Our idea is based on taking advantage of its advantages. In fact, MA enables practitioners and researchers to structure their thinking and create a common terminology and modeling framework and to visualize the whole problem (risk sources, risk variables, risk mitigation strategies) in the same graph (scenarios table), as well as identifying the different scenarios created enclosing all areas of intervention for assessing risks, to present a new approach formulating the scenarios of RM strategies in the extended SCRM. The aim of this paper is to elaborate and evaluate various RM scenarios using the MA-based approach as an exploratory RM scenario tool. MA is used to develop a framework to proactively assess critical risk variables. Firstly, MA is employed to exhaustively create possible RM scenarios and, secondly, to assess the likelihood of each scenario. Finally, to validate the proposed approach, a real case study is considered.

2. Materials and Methods

2.1. The Morphological Analysis Approach

Modeling complex social, organizational, and political problems with traditional quantitative methods, mathematical (functional) modeling, and simulation are relatively useless. First of all, the uncertainties within such complex problems are in principle non- reducible, and often cannot be fully described or delineated. Secondly, many of the factors involved are not meaningfully quantifiable, since they contain strong social, political, and cognitive dimensions. Finally, most marginal factors can, under the right historical circumstances, become a dominating force of change because of the extreme non-linearity of social systems.

In this context, morphological analysis (MA) was developed in the 1940s and 1950s; Fritz Zwicky, Caltech astrophysicist, generalized the ”morphological approach” as a method for structuring and analyzing any type of complex multidimensional, essentially non-quantified problem [25]. In the literature, there are many applications of MA in the management and engineering area. Recently, Jimenez et al. [21] presented some applications of MA in systems engineering. Álvarez and Ritchey [26] review MA applications from engineering design to policy analysis.

In summary, MA is based on teamwork. A group of subject matter specialists can have vastly difference experiences, perspectives, and terminologies. These differences can make it difficult for them to agree on their objectives. MA has definite advantages for group discussions and modeling work. It enables practitioners and researchers to structure their thinking and create a common terminology and modeling framework. A morphological field is used as a design knowledge representation space and can be also used for various applications.

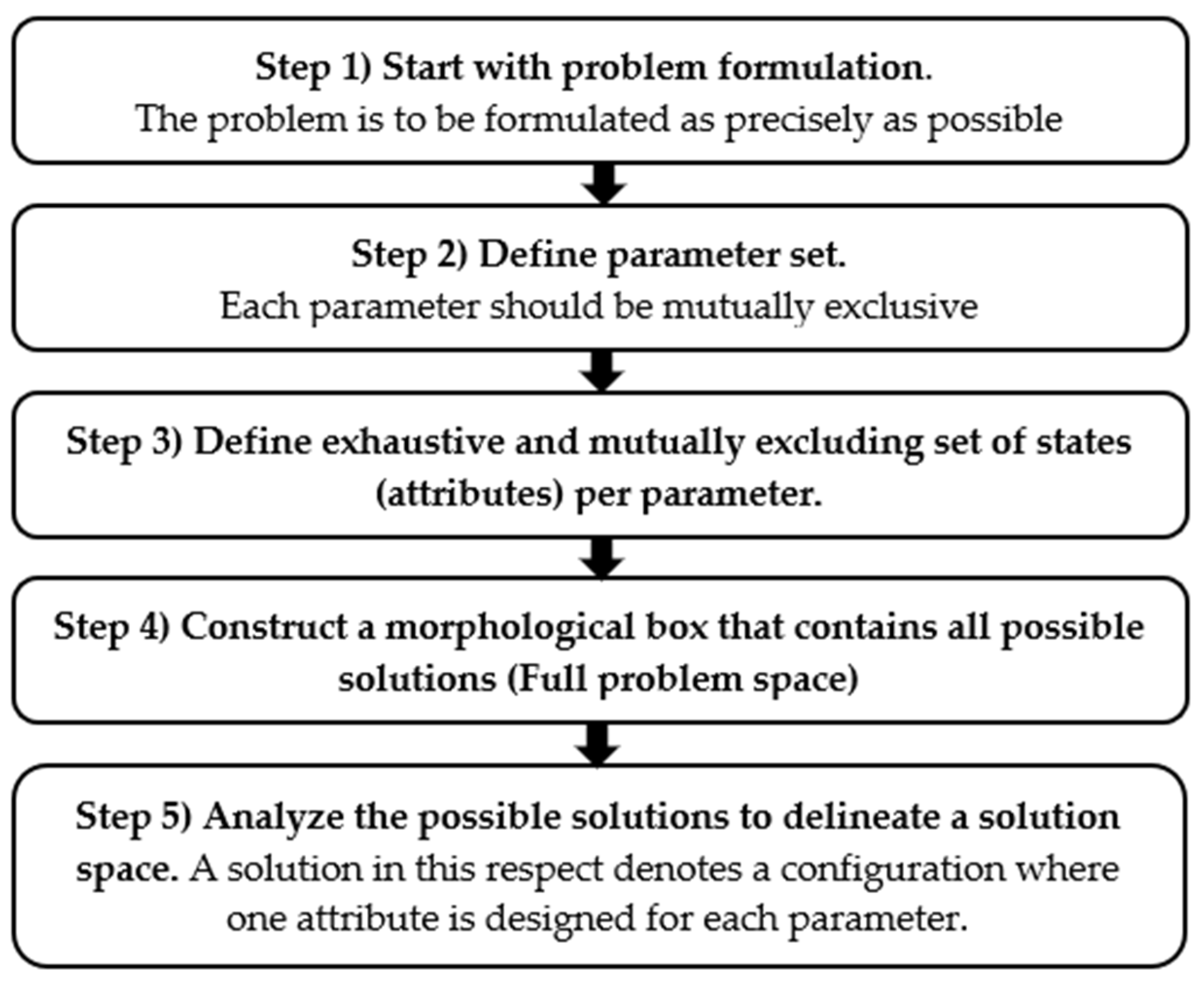

There are multiple advantages to the MA, such as it being a structured and transparent process, the identification of the entire solution space rather than focusing on a few scenarios, and the possibility to define solutions beyond those that are most likely and mainstream [8]. However, the full analysis is very resource consuming and can be claimed to rest on judgmental evaluations, though this is exactly what can be avoided through a well-structured process. The steps of the analysis are described in Figure 1.

Figure 1.

The flowchart of the MA.

- -

- First step: the problem to be solved must be very well formulated.

- -

- Second step: all parameters that might be of importance for the solution of the given problem must be localized and analyzed.

- -

- Third step: the morphological box or multidimensional matrix is constructed, which contains all potential solutions of the given problem.

- -

- Fourth step: all of the solutions contained in the morphological box are closely scrutinized and evaluated with respect to the purposes to be achieved.

- -

- Fifth step: optimal suitable solutions are selected and applied practically, provided that the necessary means are available. This reduction to practice requires, in general, a supplemental morphological study.

The MA is based on two beams: the morphological field and the cross-consistency matrix.

2.1.1. The Morphological Field

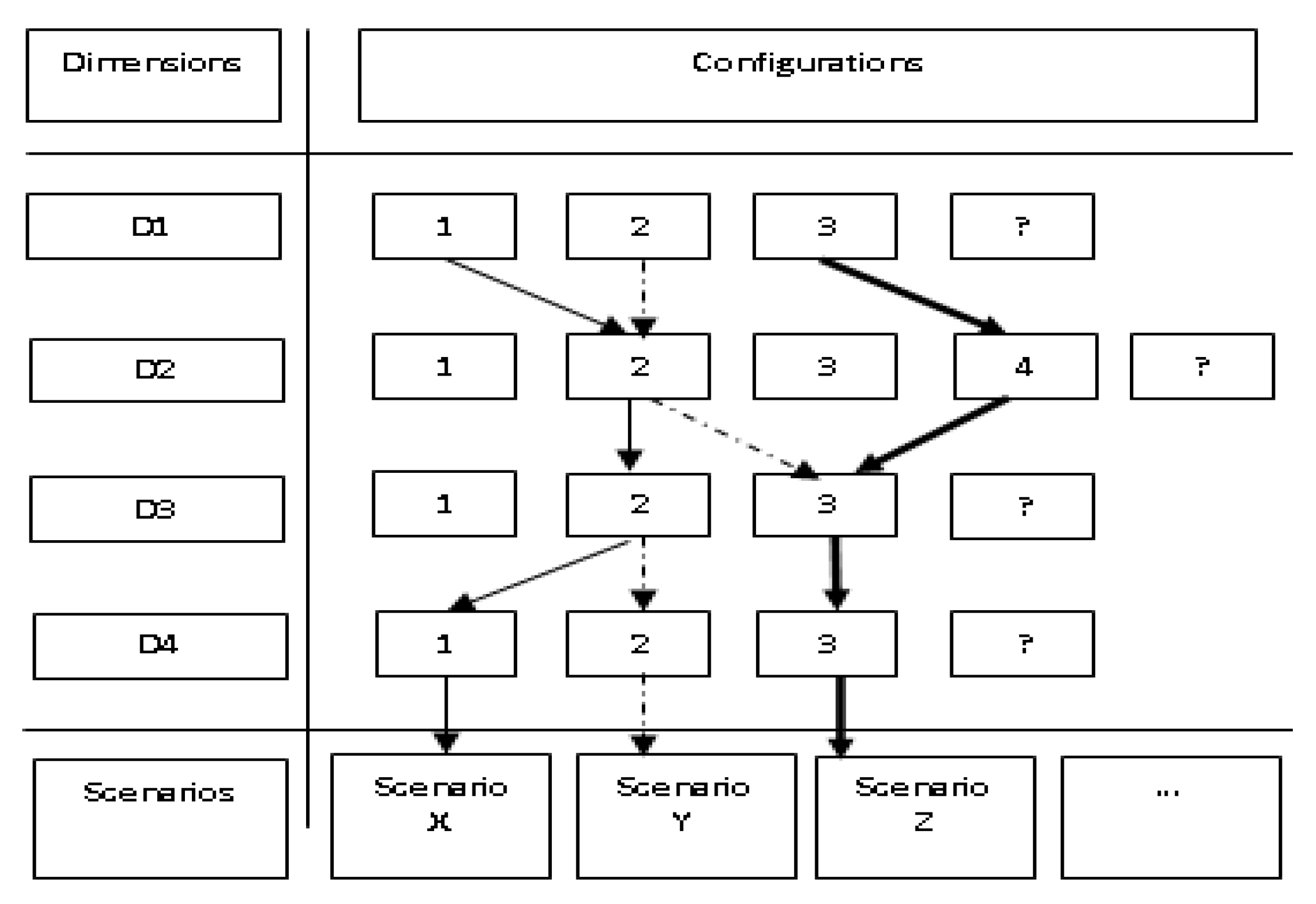

The morphological field is based on the principle of decomposition of the system into components (subsystems) as independent as possible and representative of the totality of the system. The combinations of the components with the different possible configurations constitute the field of possible futures, which is called a ”morphological space". Each combination is a scenario. We will call the “morphological space” the space of possible solutions. Figure 2 gives the structure of the morphological field.

Figure 2.

Morphological field.

The method begins by identifying and defining the most important parameters of a complex problem to be studied and by assigning to each parameter a range of relevant values or conditions. A morphological field is constructed by defining the parameters against each other in order to create an n-dimensional configuration space. A particular configuration in this space contains a “value” of each of the parameters, and thus marks a particular state or a possible formal solution of the problem.

The purpose is to examine all the configurations of the system in order to establish which of them are possible, viable, practical, interesting, and which are not. To do this, we mark a space with a relevant solution. The solution space of a Zwick morphological field consists of the subset of all possible configurations that satisfy certain criteria. It is called a “space” or alternative or a “scenario”. The main criterion is internal consistency.

In the following example, at least 320 scenarios are possible 4 × 5 × 4 × 4 = 320.

The next step in the analysis process is to examine the internal relationships between field parameters and to “reduce” the field by removing configurations that contain mutually contradictory conditions. In this way, we create a preliminary result or a solution space of the morphological field. This can be done by “the cross-consistency matrix”.

2.1.2. The Cross-Consistency Matrix

The cross-consistency matrix is a pairwise comparison matrix that serves to capture relational information among element alternatives and identifies impossible combinations. In turn, the total combinatorial space of possible system alternatives is reduced to a smaller subset featuring only those that are realizable or internally consistent.

In order to run the MORPHOL method, two main inputs, collected in two matrices, are needed: variables of the system, hypothesis related on each variable (probabilities of appearance of the hypothesis are a choice).

2.2. Evaluate Strategic Choices and Options

Although the risk management literature has proposed a variety of tools and techniques to assess and manage supply chain risks, a comprehensive assessment of the effectiveness of alternative RM strategies is rarely discussed. Such assessment will help managers choose the mitigation strategy for better decision-making.

Recent research defines a robust risk reduction strategy as one that ensures the sustainable development of business operations. Seuring et al. [27] emphasize that: “a strategy that is not sustainable is not a risk reduction strategy.” They add that to be sustainable the SCRM must consider the objectives related to the three dimensions of sustainability: social, environmental, and economic. Sustainable development has been the subject of several recent in-depth studies.

Sustainability can be thought of as “the degree to which current decisions of organizations impact the future state of the natural environment, societies, and the viability of businesses” [28]. With this broad definition, sustainable strategies should consider the future level of uncertainty and therefore the risks that decisions can impose on natural and social environments, in addition to the investment costs required to make supply chains more sustainable.

The literature shows a variety of approaches and methods to demonstrate this problem. Wenyan et al. [29] proposed a method called DEMATEL, which can be an effective tool to identify critical issues in sustainable supply chain management and relationships between different risk factors. The results obtained by Harclerode et al. [30] encourage the consideration of sustainability and risk management concepts at all stages of the life cycle to achieve a sustainable result.

However, the notion that sustainability and supply chain sustainability and risk should be considered collectively is not widely recognized. The interactions are always interesting. Exploring the interactions between supply chain risk and supply chain sustainability is instructive. Some studies explicitly examine the relationship between sustainability and risk, as examples [29,30,31,32,33].

There are three different approaches to explaining the relationship between these two concepts in the literature. “Businesses can increase their sustainability by effectively managing inherent risks” [33]. Risk management can be seen as a tool for creating sustainable SCs. Furthermore, “by incorporating sustainability into risk management systems, companies examine a wider range of concepts and can increase the effectiveness of their risk management process” [34]. In addition, sustainable efforts can create a new category of risk: sustainability risk [35]. A survey planning and developing the best risk reduction strategies based on the criteria of sustainable development within organizations and describing the risk/sustainability interactions for them would be extremely interesting.

2.3. Case Study

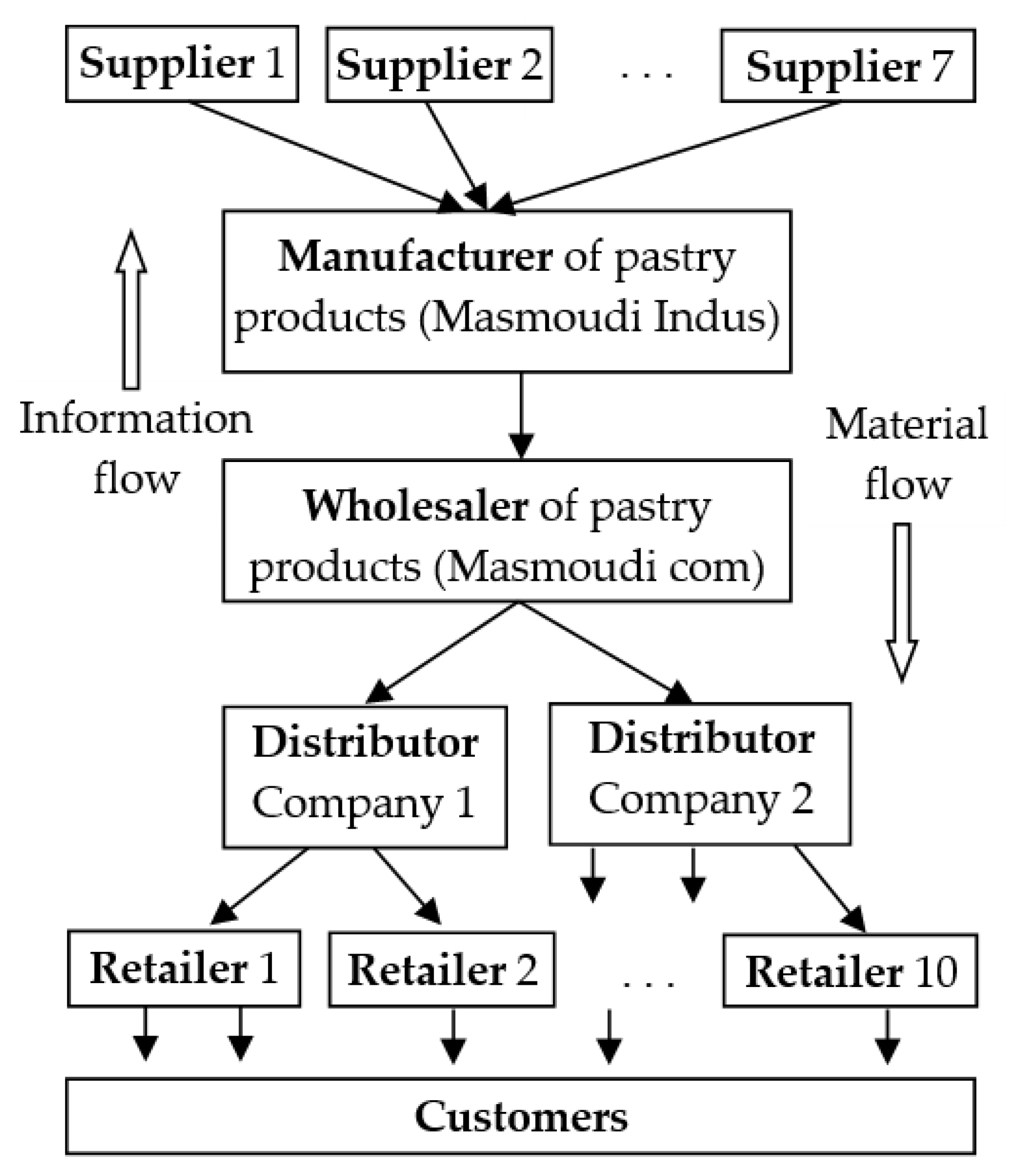

The supply network under study is inspired by the literature [36,37]. It concerns the Masmoudi company, one of the leading producers of pastry products in Tunisia. The company manufactures and distributes many products which mix almond, pistachios, and pine nuts, with the benefits of olive oil. Masmoudi is famous for the quality and nobility of the components used in the manufacturing of its cakes, and so took advantage of its location in Sfax, the city famous for the specificities of its olive trees, almond trees, and pistachio trees.

The manufacturer obtains the required raw materials from around seven suppliers. The packaged food product manufactured is distributed through a wholesaler in and around the state through a network of two main distributors. The product reaches the customer with the help of ten retailers. An overview of Masmoudi’s supply chain is shown in Figure 3.

Figure 3.

Overview of the Masmoudi supply chain network.

For the same case study, Hachicha and Elmsalmi [36] have identified eight main critical risk variables as follows:

- Retailer order partially delivered;

- Delayed delivery to retailer;

- Inventory and stock failure;

- Productivity and quality failure;

- Error in forecasting;

- Craft and manual production;

- Seasonal production;

- Poor harvest.

Moreover, Elmsalmi and Hachicha [37] have identified (Table 1) the list of the actors involved in the supply chain network and the list of their objectives.

Table 1.

List of the identified actors and their associated objectives.

3. Results

Based on a review of the literature and discussion with four experts in the field, possible RM strategies are studied and identified for the Masmoudi company. The input data for all the matrix are based on the Delphi method. To apply the proposed approach and to handle all possible MA strategies, a dedicated MORPHOL software package is used. Finally, RM strategies are selected based on sustainability indicators.

3.1. Selection of Possible Risk Mitigation Strategies

The first step is to determine possible strategies. In the literature, many researchers [4,38] have proposed various RM strategies as follows:

- Postponement: Using product or process design concepts to delay the point of product differentiation;

- Strategic stock: Companies should have additional stock inventories of certain critical components to ensure the continuity of its functions when facing a supply disruption;

- Flexible supply base: This enables a firm to handle regular demand fluctuations and to maintain continuous supply materials;

- Make and buy: Companies should produce their items in-house and outsource other basic items to their suppliers. This allows firms to shift production quickly;

- Economic supply incentives: To gain the flexibility to change production between suppliers, the buyer can provide certain economic incentives to cultivate additional suppliers. As such, the company can share some financial risks with the supplier;

- Flexible transportation: There are three basic approaches explaining this.

- -

- Multimodal transportation: Some companies use a flexible logistics strategy that relies on multiple modes of transportation to prevent supply chain operations from coming to a halt when disruptions occur in the ocean, in the air, on the road, etc.;

- -

- Multi-carrier transportation: Various companies have formed an alliance that will enable them to switch carriers quickly in the event of political disruptions to ensure continuous flow of materials in the case of political disruptions (landing rights, labor strikes, etc.). This alliance provides low-cost global deliveries;

- -

- Multiple routes: Various companies are considering alternative routes to ensure smooth material flows along supply chains. So, it avoids a complete shutdown.

- Revenue management via dynamic pricing and promotion: This can be an effective way to manage demand when the supply of a particular product is disrupted. Specifically, a retailer can use pricing mechanisms to entice customers to choose products that are widely available;

- Dynamic assortment: Enables a firm to influence the demands of different products quickly and increases control of product demand;

- Silent Product Rollover: Substitutable products are very desirable for handling demand fluctuations in both normal circumstances and in a supply disruption.

Therefore, companies should take into account:

- -

- Sharing both risks and rewards between members of the supply chain;

- -

- The need for a high degree of interdependence along the supply chain;

- -

- Supply chain partnerships: Moving from open-market negotiations, to cooperation, to coordination and finally to collaboration. In addition to having the buyers develop flexible supply bases, suppliers (contract manufacturers, airline cargo companies, trucking companies, logistics providers) can proactively form strategic alliances with other suppliers in different countries. These partnerships can serve as a ”safety net” for each member, who will receive help from other members if a disturbance strikes;

- -

- Trust among actors, developed through effective communication, creates resources that lead to a competitive advantage and contribute significantly to the long-term stability of an organization and its supply chain;

- -

- Use RFID tags: Some retailers are pushing for auto-ID technology, such as radio frequency identification technology (RFID), to improve supply chain visibility. It can also help the supply chain reduce shrinkage, misplacement, and transaction errors.

3.2. Constructing the Multidimensional Matrix (Table of Scenarios)

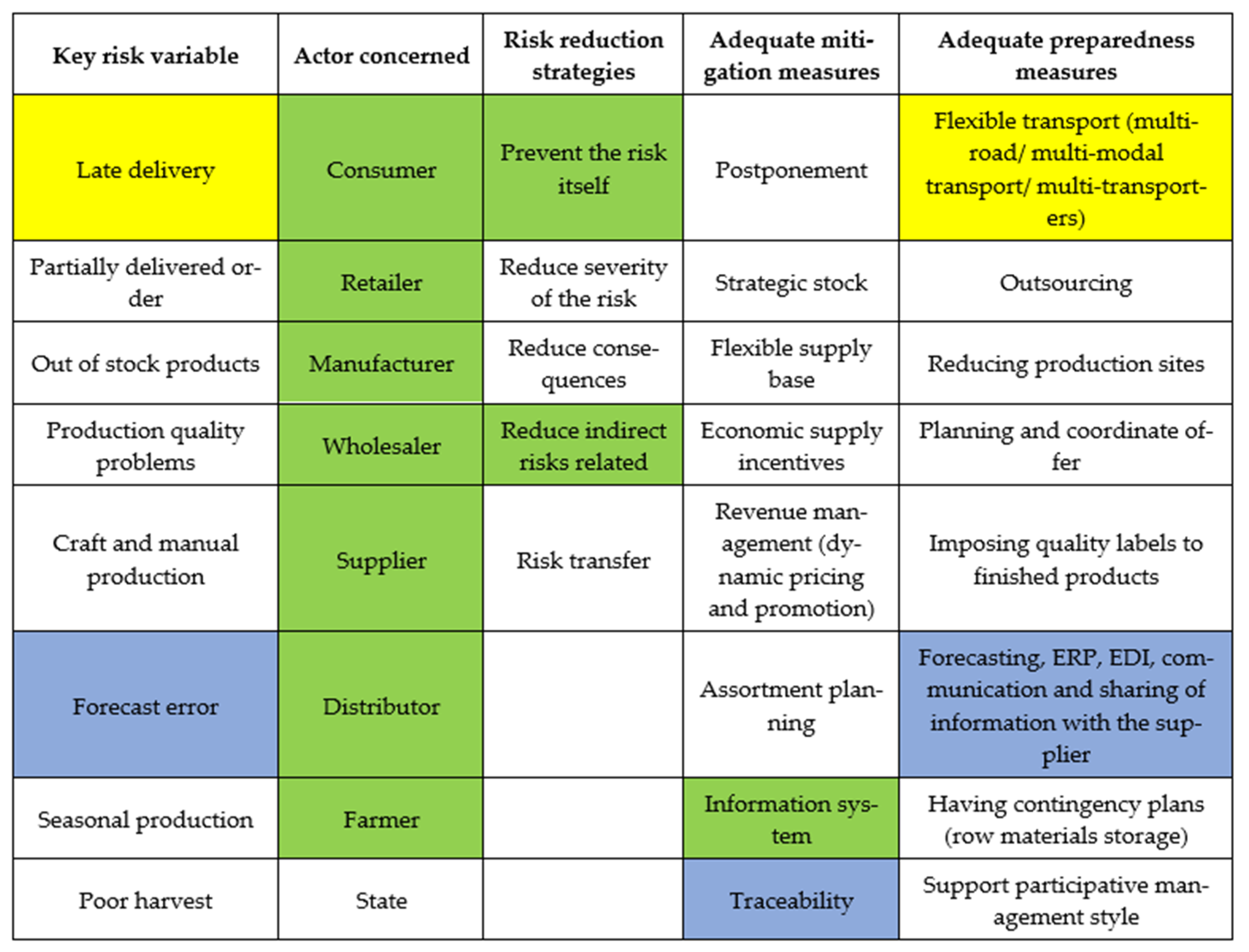

The second step is about the construction of the multidimensional matrix. In Table 2, “dimensions” of the system are associated with key risk variables of the supply chain. Configurations are actors affected, risk reduction strategies, risk mitigation measures, and adequate preparedness measures. One possible scenario is the combination between one “dimensions” and one or more “configurations”.

Table 2.

Multidimensional matrix/scenario of multikey risk reduction strategy field.

The multidimensional matrix allows one to visualize the whole problem (key risk variable, actors concerned, risk reduction strategies, adequate mitigation measures, and adequate preparedness measures) in the same graph, as well as to identify the different scenarios created.

3.3. Cross-Consistency Assessment

The multi-dimensional matrix (Table 2) represents the entire morphological field of the system, which is 8 × 8 × 5 × 8 × 8 = 20480 unique configurations. The cross-consistency assessment (Table 3) involves a thorough examination of each pair in the matrix. Here, the number of pairs is 8 × 29 + 8 × 21 + 5 × 16 + 8 × 8= 544. The results of the cross-consistency assessment are presented in Table 3. Cells with an “*” indicate an inconsistent value pair. The open cells indicate that the relevant value is considered to be consistent.

Table 3.

Cross-consistency matrix.

Hence, as it was clarified in the theoretical part, “a scenario is not an end in itself but it only makes sense through its results and its consequences for action”. As consequences, three cases arise in our case:

- -

- Presence of a single risk with a single RM strategy;

- -

- Presence of a single risk with several RM strategies (the actors are in conflict over the choice of the appropriate RM strategy);

- -

- Presence of several risks (more than two) (the actors choose several RM strategies).

The choice between the RM strategies in the last two cases is the most frequent and follows the same approach as proposed. At this stage, evaluation of the impact of the strategies in relation to the robustness of the strategic options for each strategy (using the appropriate criteria) is needed.

Figure 4 compares two different risks: late delivery and forecast error. Green represents common configurations (actor concerned, risk reduction strategies, risk mitigation measures, and adequate preparedness measures). Yellow represents configurations for “late delivery” only, and blue represents configurations for risk of “predicted error”.

Figure 4.

Example of comparison between late delivery and forecast error morphologies.

From this presentation given in Figure 4, managers can choose not only adequate risk reduction strategies, but also adequate mitigation measures and adequate preparedness measures for each risk variable. Then, they can elaborate the final scenario RM strategies of all risk variables of the system.

Let us take the example of the risk “late delivery” and “forecast error”. Most of the actors are concerned and have agreed on risk reduction strategies: Prevent the risk itself and to reduce indirect risks related. They converge on the use of the “information system” as adequate mitigation measures. Then, for the risk "forecast error", more investment must be made in traceability tools (ERP, EDL, communication and information sharing with the supplier). For “late delivery”, the experts require that the best preparedness measure is to have flexible transport. Three approaches can be applied to transport:

- -

- Multimodal transport. There are companies that use a flexible logistics strategy that links between several modes of transport to prevent risks in the oceans, on roads, or in the air;

- -

- Multicarrier transport to ensure the continuity of material flows in the event of a political risk (e.g., work strikes, etc.);

- -

- Multi-route transport. Various companies are considering alternative routes to ensure the flow of material flows along the supply chain.

Using the model in this way also allows them to compare different spaces of RM strategies to determine whether the measures for one or more risk variables are in conflict with those for other risk variables. Taking a variable “all risks” is useful to examine which configurations might be applicable to a specified risk variable combined with other risk variables. To do this, it is necessary to evaluate the identified strategies.

4. Discussion

According to the literature, a survey planning and developing the best risk reduction strategies based on the criteria of sustainable development within organizations and describing the risk/sustainability connections for them would be amazingly fascinating. The Masmoudi experts agree to take sustainable criteria for the evaluation of risk mitigation strategies.

The first step comprises the allocation of coefficients to each measure by the actors involved according to the criteria of environmental, economic, and social sustainable development. Their preferences are expressed through different weights assigned to the criteria (Table 4). This selected example research presents policies for both the "retailer" and "distributor” for the risk “late delivery to the retailer”.

Table 4.

Sets of criterion weights expressing the preferences of the two actors.

The “information system” risk mitigation measure has the highest average in both the retailer’s ranking and the distributor’s ranking (Table 5). Therefore, this is the most suitable strategy for those actors to this risk.

Table 5.

Retailer and distributor policy.

In fact, since there are two different opinions about a single risk or more than one, we still have to choose the priority strategy or measure. Here, the study of the divergences and convergences of the actors seems to be useful for us. So, the strength of the actor is much or less important than that of the other ones. We should therefore reconcile the strategy chosen by the actor how the higher influencing power.

This work enables practitioners and researchers to structure their thinking and create a common terminology and modeling framework. Integration of strategic option evaluation is proposed, based on quantifying the impact assessment of strategies against a hierarchy of organizational objectives for each scenario and making a selection based on the robustness of the strategic options for each scenario using the appropriate criteria. The aim is to examine all the risk mitigation strategies, in order to establish which of them are viable, feasible, suitable, and acceptable and which are not.

Without some form of traceability, we have little possibility of scientific control over the results, let alone reproducibility. Most of the literature works are related to a specific area of intervention and not to the entire logistics process. Thus, the interactions between its links are not considered. Most of the risk reduction methods were limited to the likelihood of the risk occurring while the biggest problems are because of unforeseen disasters, whose probability of occurrence is negligible. That prompted us to think about ‘MA’, which consists of building the future rather than predicting it.

Although simple, MA methods must be well studied to apply them and require a good understanding and knowledge from experts, who will be the basis of all the data. These tools should never be used for itself but only as needed and considering the problem posed, the time constraints, and the resources available.

Its interest is directed towards:

- -

- Collective reflections which often prove to be very difficult in the absence of a common language and working method;

- -

- The counterintuitive aspects of the behavior of a system. It is not intended to accurately describe how the system works or to remove risks, but the point is to identify the main organizational elements of the system and prepare for the risks and challenges;

- -

- The design of a useful model for studying complex, unquantified problems that cannot be addressed by causal modeling, simulation and mathematical methods;

- -

- “Cross-consistency assessment (CCA),” which is an effective way to iron out vague concepts, referencing terminological differences, and assessing their internal consistency;

- -

- Creation of an audit trail by the traceability of the formulation and structure process going from the initial formulation of the problem to specific solutions or conclusions of these problems, as well by the documentation of each concept and each evaluation of cross-consistency in a model.

For SCRM, in addition to the specified advantages, MA has enabled us to:

- -

- Summarize all the components of the logistics chain: the key risk variables, the actors involved, risks mitigation measures, and adequate preparedness measures, for better decision-making;

- -

- Choose the most appropriate strategies. Managers can then develop strategy scenarios to mitigate the risk variables of the system;

- -

- Compare different areas of “risk mitigation strategies” to determine whether a strategy of one risk variable conflicts with those of other risk variables.

However, there are two limits to this approach. First, the forward-looking strategy is based on the opinions of experts, which can be subjective. Whether in the choice of variables or in the filling of matrices. Second, the results of the analysis are often tables and figures, which should be read well and interpreted as a verbal description.

For better SCRM, organizations will increasingly need to inform their actions in light of potential risks and desirable futures. This paper presents the application of MA in SCRM to develop risk mitigation strategies. To validate the efficacity of the proposed approach, a real case study of Massoudi company is fully studied. It is a specific case study application and it is not possible to make comparisons with the results of other studies. The main thing is the satisfaction of the company managers and how they make the results useful. In fact, they now have a dashboard which can help them for risk mitigation and monitoring.

5. Conclusions

The purpose of this paper is to elaborate and evaluate various risk mitigation (RM) scenarios from an initial risk identification and prioritization solution. The proposed scenario modeling technique is based on morphological analysis (MA) as an explorative scenario tool for RM. MA is used to develop a framework to proactively assess critical risk variables. Firstly, MA is employed to exhaustively create possible RM scenarios and, secondly, to assess the likelihood of each scenario. The proposed approach addresses the need for a basic rubric to help them identify and choose RM approaches.

MA has considerable value for supply chain risk management (SCRM). It represents a proof-of-principle, since it makes it possible to compare adequate risk reduction strategies for different risk variables and their associated sources. It also shows that firms can adopt multiple robust strategies in the form of scenario, but how should one measure the effectiveness of a robust scenario of risk reduction strategies? What are the underlying conditions or criteria for one robust scenario that dominates another?

The methodology proposed in this study is easy to adapt to different areas of SC and to any risk variable. The results obtained from this methodology could be applied by decision makers and administrators as a guide to implement effective risk mitigation strategies. However, studying some risk dimensions at the supply chain level faces two main problems that include the following: The correlation of the identified dimension, even when they are related to different categories, and the relevance of the proposed MA application at the analyzed perimeter.

This research has many perspectives. The first one is about the extension of the proposed approach with the probability analysis (Smic Prob-Expert method) developed by concentrating on combinations. The second perspective concerns the applications of a multicriteria decision analysis to choose the best risk mitigation strategy for each identified risk variable and then elaborate an efficient SCRM to the Masmoudi. The third perspective should give more extensive testing on different problems to support the proposed approach application in SCRM. Details and others real benefits of the proposed approach into real-life case study will be presented in our subsequent publications.

Another perspective is the use of the Matrix of Alliances and Conflicts: Tactics, Objectives and Recommendations (MACTOR) method to consider the balance of power of the actors, which can change their positions and implications according to their strategic objectives and so influence the choice of adequate mitigation strategies and reduction measures.

Author Contributions

Conceptualization, M.E. and W.H.; methodology, M.E., W.H. and A.M.A.; validation, W.H. and A.M.A.; formal analysis, M.E., and W.H.; investigation, M.E.; resources, M.E.; data curation, M.E. and W.H.; writing—original draft preparation, M.E.; writing—review and editing, W.H. and A.M.A.; visualization, A.M.A.; supervision, W.H.; project administration, W.H. and A.M.A.; funding acquisition, A.M.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by Taif University Researchers who supported project number (TURSP-2020/229), Taif University, Taif, Saudi Arabia.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

This research was supported by Taif University Researchers who supported project number (TURSP-2020/229), Taif University, Taif, Saudi Arabia. First, the authors are grateful for this financial support. Second, the authors would like to express thanks to all the experts for their implication during the Delphi technique application. Third, the authors express thanks to all Masmoudi company workers for their help. Finally, the authors warmly thank the editor and the anonymous reviewers for their detailed and constructive comments, which were a great help in improving the earliest version of this manuscript.

Conflicts of Interest

The authors declare that they have no conflict of interest.

References

- Gurtu, A.; Johny, J. Supply Chain Risk Management: Literature Review. Risks 2021, 9, 16. [Google Scholar] [CrossRef]

- Elmsalmi, M.; Hachicha, W.; Aljuaid, A.M. Prioritization of the Best Sustainable Supply Chain Risk Management Practices Using a Structural Analysis-Based Approach. Sustainability 2021, 13, 4608. [Google Scholar] [CrossRef]

- Li, Z.; Gulati, R.K. Supply Chain Risk Mitigation and the Application Potential of Complex Systems Approaches. In Proceedings of the 18th Asia Pacific Symposium on Intelligent and Evolutionary Systems—Volume 1, Singapore, 10–12 November 2014; Proceedings in Adaptation, Learning and Optimization Series; Handa, H., Ishibuchi, H., Ong, Y.S., Tan, K., Eds.; Springer: Cham, Switzerland, 2015; Volume 1. [Google Scholar]

- Rajagopal, V.; Venkatesan, S.P.; Goh, M. Decision-making models for supply chain risk mitigation: A review. Comput. Ind. Eng. 2017, 113, 646–682. [Google Scholar] [CrossRef]

- Yu, Y.; Xiong, W.; Cao, Y. A conceptual model of supply chain risk mitigation: The role of supply chain integration and organizational risk propensity. J. Coast. Res. 2015, 73, 95–98. [Google Scholar] [CrossRef]

- Mari, S.I.; Lee, Y.H.; Memon, M.S. Sustainable and resilient garment supply chain network design with fuzzy multi-objectives under uncertainty. Sustainability 2016, 8, 1038. [Google Scholar] [CrossRef] [Green Version]

- Abdel-Basset, M.; Mohamed, R. A novel plithogenic TOPSIS-CRITIC model for sustainable supply chain risk management. J. Clean. Prod. 2020, 247, 119586. [Google Scholar] [CrossRef]

- Lis, A.; Sudolska, A.; Tomanek, M. Mapping Research on Sustainable Supply-Chain Management. Sustainability 2020, 12, 3987. [Google Scholar] [CrossRef]

- Amer, M.; Daim, T.U.; Jetter, A. A review of scenario planning. Futures 2013, 46, 23–40. [Google Scholar] [CrossRef]

- Nordström, M.; Engholm, A. The complexity of value of travel time for self-driving vehicles—A morphological analysis. Transp. Plan. Technol. 2021, 44, 400–417. [Google Scholar] [CrossRef]

- Johansen, I. Scenario Modelling with Morphological Analysis. Technol. Forecast. Soc. Chang. 2018, 126, 116–125. [Google Scholar] [CrossRef]

- Liu, Z.; Feng, J.; Wang, J. Resource-Constrained Innovation Method for Sustainability: Application of Morphological Analysis and TRIZ Inventive Principles. Sustainability 2020, 12, 917. [Google Scholar] [CrossRef] [Green Version]

- Wissema, J.G. Morphological analysis: Its application to a company’s TF investigation. Futures 1976, 8, 146–153. [Google Scholar] [CrossRef]

- Aqlan, F.; Lam, S.S. Supply chain risk modelling and mitigation. Int. J. Prod. Res. 2015, 53, 5640–5656. [Google Scholar] [CrossRef]

- Chang, W.; Ellinger, A.E.; Blackhurst, J. A contextual approach to supply chain risk mitigation. Int. J. Logist. Manag. 2015, 26, 642–656. [Google Scholar] [CrossRef]

- Tarei, P.K.; Thakkar, J.J.; Nag, B. Benchmarking the relationship between supply chain risk mitigation strategies and practices: An integrated approach. Benchmark. Int. J. 2020, 27, 1683–1715. [Google Scholar] [CrossRef]

- Zhang, Q.; Fan, W.; Lu, J.; Wu, S.; Wang, X. Research on dynamic analysis and Mitigation Strategies of supply chains under Different Disruption Risks. Sustainability 2021, 13, 2462. [Google Scholar] [CrossRef]

- Hsu, C.-H.; Chang, A.-Y.; Zhang, T.-Y.; Lin, W.-D.; Liu, W.-L. Deploying Resilience Enablers to Mitigate Risks in Sustainable Fashion Supply Chains. Sustainability 2021, 13, 2943. [Google Scholar] [CrossRef]

- Ritchey, T. Modeling Multi-Hazard Disaster Reduction Strategies with Computer-Aided Morphological Analysis. In Proceedings of the 3rd International ISCRAM Conference, Newark, NJ, USA, 3 May 2006. [Google Scholar]

- Fernandez, A.L.; Britton, N.R.; Ritchey, T. Application of a prototype morphological model for earthquake disaster risk management. In Proceedings of the 2nd Asia Conference on Earthquake Engineering, Manila, Philippines, 10–11 March 2006. [Google Scholar]

- Jimenez, H.; Stults, I.; Mavris, D. A Morphological Approach for Proactive Risk Management in Civil Aviation Security. In Proceedings of the 47th AIAA Aerospace Sciences Meeting, Orlando, FL, USA, 5–8 January 2009. [Google Scholar]

- Akgun, I. Chapter 3: Likelihood Estimation of Intentional Events in Risk Management: Evidence Based Intelligent Morphological Analysis Approach. In Intelligent Techniques in Engineering Management: Theory and Applications, an Evolution of Morphological Analysis Applications in Systems Engineering, Proceedings of the 48th AIAA Aerospace Sciences Meeting Including the New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 4–7 January 2010; Jimenez, H., Mavris, D., Eds.; Springer: Cham, Switzerland, 2015. [Google Scholar]

- Lantada, N.; Carreo, M.L.; Jaramillo, N. Disaster risk reduction: A decision-making support tool based on the morphological analysis. Int. J. Disaster Risk Reduct. 2020, 42, 101342. [Google Scholar] [CrossRef]

- Johannessen, S.A. Future Risk Scenarios of the Northern Sea Route. Master’s Thesis, Risk Management and Societal Safety, University of Stavanger, Stavanger, Norway, 15 June 2020. [Google Scholar]

- Zwicky, F. Discovery, Invention, Research—Through the Morphological Approach; The Macmillan Company: Toronto, ON, Canada, 1969. [Google Scholar]

- Álvarez, A.; Ritchey, T. Applications of General Morphological Analysis: From Engineering Design to Policy Analysis. Acta Morphol. Gen. 2015, 4. ISSN 2001-2241. Available online: https://www.researchgate.net/publication/275970050_Applications_of_General_Morphological_Analysis_From_Engineering_Design_to_Policy_Analysis (accessed on 1 November 2021).

- Seuring, S.; Sarkis, J.; Müller, M.; Rao, P. Sustainability and supply chain management an introduction to the special issue. J. Clean. Prod. 2015, 16, 1545–1551. [Google Scholar] [CrossRef]

- Krysiak, F. Risk management as a tool for sustainability. J. Bus. Ethics 2009, 85, 483–492. [Google Scholar] [CrossRef] [Green Version]

- Wenyan, S.; Xinguo, M.; Hu-Chen, L. Identifying critical risk factors of sustainable supply chain management: A rough strength-relation analysis method. J. Clean. Prod. 2016, 143, 100–115. [Google Scholar]

- Harclerode, M.A.; Macbeth, T.W.; Miller, M.E.; Gurr, C.J.; Myers, T.S. Early decision framework for integrating sustainable risk management for complex remediation sites: Drivers, barriers, and performance metrics. J. Environ. Manag. 2016, 184, 57–66. [Google Scholar] [CrossRef]

- Carter, C.R.; Rogers, D.S. A framework of sustainable supply chain management: Moving toward new theory. Int. J. Phys. Distrib. Logist. Manag. 2008, 38, 360–387. [Google Scholar] [CrossRef]

- Buddress, L. Managing Supply Chain Sustainability and Risk: Keys to Success. Int. J. Strateg. Manag. Decis. Support Syst. Strateg. Manag. 2013, 18, 3–16. [Google Scholar]

- Govindan, K.; Azevedo, S.G.; Carvalho, H.; Cruz-Machado, V. Impact of supply chain management practices on sustainability. J. Clean. Prod. 2014, 85, 212–225. [Google Scholar] [CrossRef]

- AON. Sustainability—Beyond Enterprise Risk Management. Aon Environmental Services Group; Global Corporate Marketing and Communications: Arlington, MA, USA, 2007; #2919–05/2007. [Google Scholar]

- Willard, M.; Hitchcock, D. The Business Guide to Sustainability: Practical Strategies and Tools for Organizations; Routledge: London, UK, 2009. [Google Scholar]

- Hachicha, W.; Elmsalmi, M. An integrated approach based-structural modeling for risk prioritization in supply network management. J. Risk Res. 2014, 17, 1301–1324. [Google Scholar] [CrossRef]

- Elmsalmi, M.; Hachicha, W. Risk Mitigation Strategies According to the Supply Actors’ Objectives by Using the MACTOR Method. In Proceedings of the International Conference on Advanced Logistics and Transport (ICALT’2014), Hammamet, Tunisia, 1–3 May 2014; pp. 362–367. [Google Scholar]

- Tang, C.S. Robust strategies for mitigating supply chain disruptions. Int. J. Logist. Res. Appl. Lead. J. Supply Chain. Manag. 2006, 9, 33–45. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).