A Cloud-Based with Microcontroller Platforms System Designed to Educate Students within Digitalization and the Industry 4.0 Paradigm

Abstract

:1. Introduction

2. Literature Review

3. Materials and Methods

- Defining the architecture of the system while providing the necessary hardware and software, as well as accompanying laboratory equipment,

- Create the necessary cloud accounts,

- Presentation, visualization of data to students on the cloud system, connecting cloud systems with platforms for IoT control systems,

- Defining-assigning priorities, what a student can change on the system and what a mentor, and

- MATLAB data analysis.

- Provide the first platform NodeMCU Wi-Fi connection, connect two DHT11 sensors, one FC28 sensor. Provide connection of the platform with the Cloud system (ThingSpeak) and storage of data related to air humidity, air temperature, water temperature, soil moisture and display real-time graphs for the specified data.

- Connect another NodeMCU platform to Wi-Fi wireless internet and connect it with two DHT11 sensors, one FC28 sensor, and an ultrasonic sensor. Boot a server on the Virtuino platform, connect platforms, store data and display data related to air temperature, humidity, the liquid level in the tank, soil moisture, water temperature. Connect the Virtuino platform to the remote ThingSpeak database.

- Connect the Arduino Nano platform with the ultrasonic sensor, define the liquid level in the tank, connect the Arduino with the Realy module, control the liquid level in the defined range, control the irrigation process depending on the obtained data.

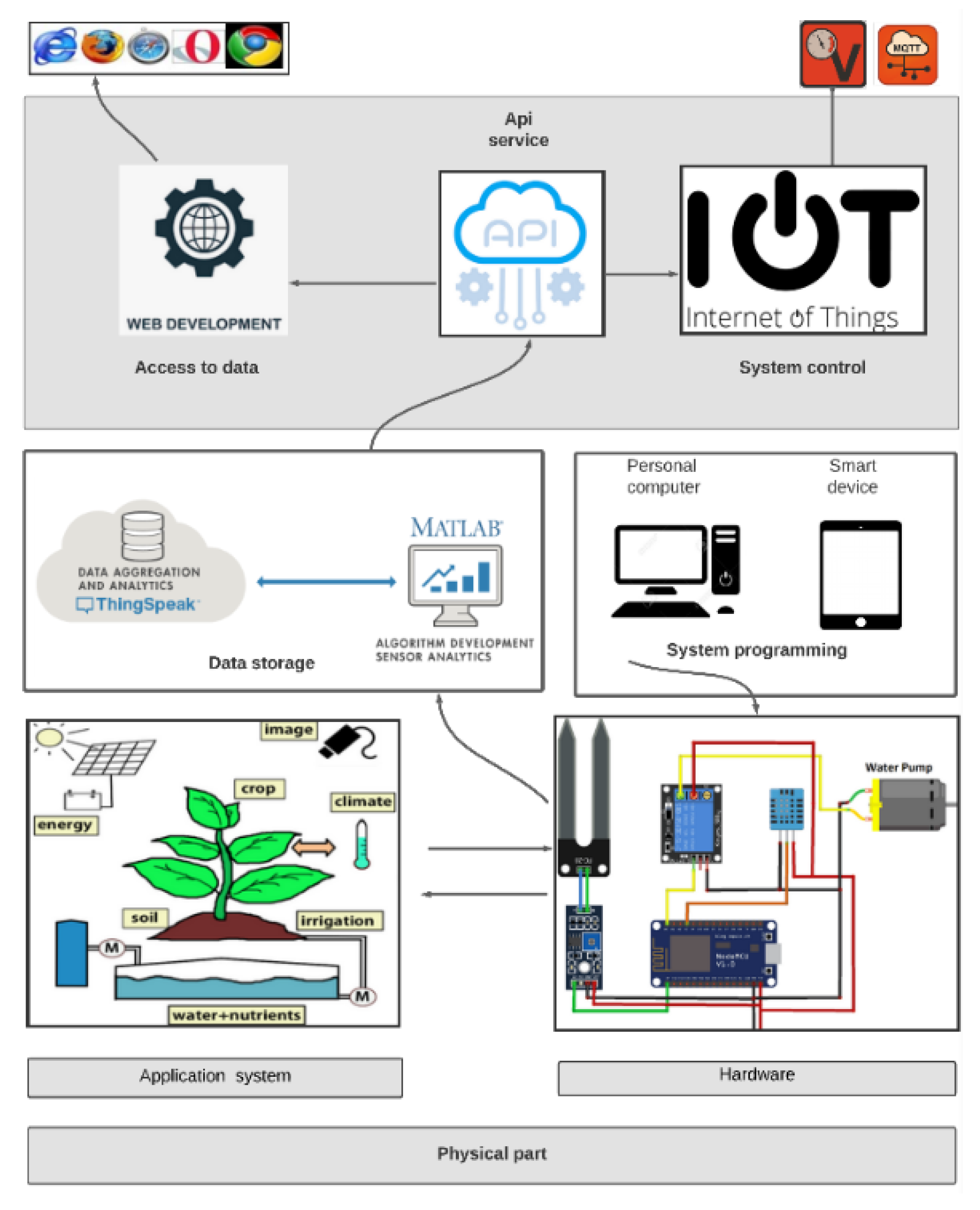

3.1. System Architecture

- NodeMCU is a microcontroller platform with an integrated microcontroller and a chip for wireless Wi-Fi connection, which gives this platform an advantage over other platforms requiring additional modules to connect to the Internet. It also belongs to the IoT platform group.

- Arduino nano has 14 digital pins and eight analog pins, which gives it fewer opportunities to connect to actuators; it is based on Serial Chip—ATmega328p has 32 KB flash memory and SRAM2 KB, operating voltage 5VDC.

- Sensor DHT11 was used to collect data related to temperature and humidity. It is a digital sensor with an operating voltage of 3.3VDC and a maximum signal transmission length of 20 m.

- Sensor FC28 presents an analog soil moisture sensor. The main application of this sensor in the project is the collection of data on soil moisture to apply irrigation timely.

- An ultrasonic sensor is a digital distance sensor, works by receiving a signal from the microcontroller platform in a software-defined interval at the input port, then sends that signal; when the signal bounces off an object, the sensor collects the returned signal and sends it back to the platform.

- Relay module—used to control electrical devices or turn them on and off, depending on the needs of the appropriate model is used.

- Power supply—within the project in laboratory conditions, one power supply was used: 5VDC, 2A. While in the conditions of project implementation, two would be used.

- Breadboard—allows faster connection of actuators and platforms.

- Internet access—it is necessary to provide a Wi-Fi connection using a router.

3.2. Software Infrastructure of the System

- NodeMCU platform that will collect data from sensor systems related to air temperature, humidity, water temperature, soil moisture and place them on the cloud (ThingSpeak) in real-time,

- The second NodeMCU platform will collect data from sensor systems related to the water level in the tank, water temperature, air temperature, humidity, soil moisture and place them on the Virtuino platform, and

- Arduino nano platform with the fundamental purpose of controlling the liquid level in the tank and controlling irrigation.

3.3. Implementation of the System

4. Student Education and Work Results

4.1. Role of the System in Students Education

- knowledge related to microcontroller platforms such as NodeMCU, Arduino (multiple development boards), Raspberry pi, Norvi, and other platforms intended for students and their education. This knowledge is directed towards the hardware performance of the mentioned platforms, memory, distribution of analog and digital pins, ports,

- method of programming microcontrollers, the syntax of programming languages, logic, choice of programming language where the emphasis is on C ++ language, and introduction to libraries necessary for communication of microcontrollers with actuators, sensors, modules,

- IOT-IIOT control-automation of electrical devices and communication with them via the Internet, where IoT is intended to develop academic applications while IIOT is intended for industrial use or more significant amounts of data,

- mode of communication that can be observed from several aspects of communication that take place between hardware and related to microcontrollers, sensors, and actuators then communication-related to communication that can be achieved by different types of networks such as Internet networks, as well as one of the basic division of communication into M2M communication that takes place between machines within an industry where one depends on the other, C2M communication that takes place between the employee, usually the operator and the machine, and C2C communication that takes place between employees through information and communication technologies,

- communication networks as a basic form of sending data between parts of the system, different systems, applications, servers, and clients. So they can be viewed from different angles, but primarily within the project, we mean internet networks, the necessary knowledge for connecting microcontroller platforms to both wireless Wi-Fi networks and using a LAN connection, acquiring the necessary knowledge about routers, switches, and the way of communication of these devices and sharing the IP address, which in these projects is very important for creating applications and the connection of the system,

- databases, the importance of databases as well as the method of data entry-storage, database selection, and essential differences in the purpose of specific databases, where the emphasis is placed on MySQL databases intended for web applications and the method of data storage,

- web programming since most projects-application part requires a web presentation or creating a software part that will be performed using a web browser, and it is necessary to know web programming (PHP, HTML, CSS) to be able to create this type of application,

- a web server as a location that the end-user accesses when he wants to access the system. It is imperative to understand the essence of client-server communication, create the entire system, and provide necessary information to the end-user who does not need to know the essence of the system outside the application.

- SCADA systems are used to control and monitor activities within significant industrial processes, use a large number of microcontrollers PLC, communication networks, computers, separate systems, using all these technologies to obtain large amounts of data processed following the needs and purpose precise controls of the entire system from a remote location,

- sensor systems, which consist of two or more sensors of different types as well as different types of data collected, the most used within the laboratory at the faculty are sensors from the group of analog and digital sensors, in addition to the above, RFID sensors are used,

- cloud systems are intended for direct communication between the microcontroller and this system, where data storage can be performed. Within this module, students had the opportunity to use the ThingSpeak cloud system, within which they could master the ways of data visualization, control, notification, data analysis, MATLAB, and ways of input from several different platforms simultaneously,

- embedded systems an increasingly common occurrence within I4.0 are embedded systems consisting of hardware and software that are usually physically small systems used to upgrade an existing system using new technologies such as microcontrollers-microchips, sensors, actuators, modules,

- distributed systems are systems that are physically distributed in different geographical locations, and students acquire the necessary knowledge related to how to communicate different parts of the system that are distributed, different types of connection and sending data, as well as downloading them and processing and further distribution to a more complex system, and

4.2. System Assessment by Students

5. Discussion

- (H1) hypothesis discussion,

- (H2) hypothesis discussion,

- (H3) hypothesis discussion.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Henao-Hernández, I.; Solano-Charris, E.; Muñoz-Villamizar, A.; Santos, J.; Henríquez-Machado, R. Control and monitoring for sustainable manufacturing in the industry 4.0: A literature review. IFAC-Pap. 2019, 52, 195–200. [Google Scholar] [CrossRef]

- Kozák, Š.; Ružický, E.; Štefanovič, J.; Schindler, F. Research and education for industry 4.0: Present development. In Proceedings of the 2018 Cybernetics & Informatics (K&I), Lazy pod Makytou, Slovakia, 31 January–3 February 2018; pp. 1–8. [Google Scholar] [CrossRef]

- Jovanović, J.; Mijailović, Đ.; Đorđević, A.; Stefanović, M. Application of prototyping microprocessor board and cloud system to teach industry 4.0 concepts. Int. J. Eng. Educ. 2020, 36, 929–939. [Google Scholar]

- Ekren, B.Y.; Kumar, V. Engineering education towards industry 4.0. In Proceedings of the International Conference on Industrial Engineering & Operations Management, Dubai, UAE, 10–12 March 2020; p. 8. [Google Scholar]

- Hernández-Muñoz, G.M.; Habib-Mireles, L.; García-Castillo, F.A.; Montemayor-Ibarra, F. Industry 4.0 and engineering education: An analysis of nine technological pillars inclusion in higher educational curriculum. In Best Practices in Manufacturing Processes; Springer: Cham, Switzerland, 2019; pp. 525–543. [Google Scholar]

- Mian, S.H.; Salah, B.; Ameen, W.; Moiduddin, K.; Alkhalefah, H. Adapting universities for sustainability education in industry 4.0: Channel of challenges and opportunities. Sustainability 2020, 12, 6100. [Google Scholar] [CrossRef]

- Galkin, P.; Umiarov, R.; Grigorieva, O. Design embedded system testbench based on FPGA and microcontrollers for TATU smart lab as education component of industry 4.0. In Proceedings of the 2019 IEEE 2nd Ukraine Conference on Electrical and Computer Engineering (UKRCON), Lviv, Ukraine, 2–6 July 2019; pp. 628–633. [Google Scholar]

- Gaspar, G.; Fabo, P.; Kuba, M.; Flochova, J.; Dudak, J.; Florkova, Z. Development of IoT applications based on the MicroPython platform for industry 4.0 implementation. In Proceedings of the 2020 19th International Conference on Mechatronics-Mechatronika (ME), Prague, Czech Republic, 2–4 December 2020; pp. 1–7. [Google Scholar]

- Sobota, J.; PiŜl, R.; Balda, P.; Schlegel, M. Raspberry Pi and Arduino boards in control education. IFAC Proc. 2013, 46, 7–12. [Google Scholar] [CrossRef]

- Embong, A.H.B.; Akbar, M.A.; Rashid, M.M. Design and development of multipurpose educational and research platform (MERP) for learning control and IoT technologies. J. Eng. Sci. Technol. 2019, 14, 747–762. [Google Scholar]

- Saorín, J.L.; de la Torre-Cantero, J.; Melián Díaz, D.; López-Chao, V. Cloud-based collaborative 3D modeling to train engineers for the industry 4.0. Appl. Sci. 2019, 9, 4559. [Google Scholar] [CrossRef] [Green Version]

- Cagatay, C.; Bedir, T. Aligning education for the life sciences domain to support digitalisation and industry 4.0. Procedia Comput. Sci. 2019, 158, 99–106. [Google Scholar]

- Mingaleva, Z.A.; Vukovic, N.A. Development of engineering students competencies based on cognitive technologies in conditions of industry 4.0. Int. J. Cogn. Res. Sci. Eng. Educ. 2020, 8, 93–101. [Google Scholar]

- Hernandez-de-Menendez, M.; Diaz, C.A.E.; Morales-Menendez, R. Engineering education for smart 4.0 technology: A review. Int. J. Interact. Des. Manuf. 2020, 14, 789–803. [Google Scholar] [CrossRef]

- Muktiarni, M.; Widiaty, I.; Abdullah, A.G.; Ana, A.; Yulia, C. Digitalisation trend in education during industry 4.0. J. Phys. Conf. Ser. 2019, 1402, 077070. [Google Scholar] [CrossRef]

- Vujovic, A.; Todorovic, P.; Stefanovic, M.; Vukicevic, A.; Jovanovic, M.V.; Macuzic, I.; Stefanovic, N. The development and implementation of an aquaponics embedded device for teaching and learning varied engineering concepts. Int. J. Eng. Educ. 2019, 35, 88–98. [Google Scholar]

- Tosello, E.; Castaman, N.; Menegatti, E. Using robotics to train students for Industry 4.0. IFAC-Pap. 2019, 52, 153–158. [Google Scholar] [CrossRef]

- Dorofeeva, A.A.; Nyurenberger, L.B. Trends in digitalisation of education and training for industry 4.0 in the Russian Federation. IOP Conf. Ser. Mater. Sci. Eng. 2019, 537, 042070. [Google Scholar] [CrossRef]

- Onar, S.C.; Ustundag, A.; Kadaifci, Ç.; Oztaysi, B. The changing role of engineering education in industry 4.0 Era. In Industry 4.0: Managing the Digital Transformation; Springer: Cham, Switzerland, 2018; pp. 137–151. [Google Scholar]

- Asparuhova, K.; Shehova, D.; Lyubomirov, S. Using Proteus to support engineering student learning: Microcontroller-driven sensors case study. In Proceedings of the 2018 IEEE XXVII International Scientific Conference Electronics-ET, Sozopol, Bulgaria, 13–15 September 2018; pp. 1–4. [Google Scholar]

- Magro, A.; Silva, M.; Sousa, G.; Cardoso, F.; Guimarães, G.; Muniz, S.; Sarnighausen, V.; Fontes, M.; Simões, R. Development of a low-cost colorimeter-like for undergraduate classes using microcontroller board and RGB LED. Educ. Química 2020, 31, 36–48. [Google Scholar] [CrossRef]

- Chursin, G.; Semenov, M. Using an ESP8266 microcontroller to develop a learning game. J. Phys. Conf. Ser. 2020, 1611, 012059. [Google Scholar] [CrossRef]

- González, I.; Calderón, A.J.; Figueiredo, J.; Sousa, J.M. Design of an educational platform for automation and supervision under the industry 4.0 framework. In Proceedings of the 12th International Technology, Education and Development Conference (INTED), Valencia, Spain, 5–7 March 2018. [Google Scholar]

- Mogoş, R.I.; Bodea, C.N.; Dascălu, M.I.; Safonkina, O.; Lazarou, E.; Trifan, E.L.; Nemoianu, I.V. Technology enhanced learning for industry 4.0 engineering education. Rev. Roum. Sci. Techn. Électrotechn. Énerg. 2018, 63, 429–435. [Google Scholar]

- Fernández-Pacheco, A.; Martin, S.; Castro, M. Implementation of an Arduino remote laboratory with raspberry Pi. In Proceedings of the 2019 IEEE Global Engineering Education Conference (EDUCON), Dubai, United Arab Emirates, 9–11 April 2019; pp. 1415–1418. [Google Scholar]

- Jamieson, P.; Herdtner, J. More missing the Boat—Arduino, Raspberry Pi, and small prototyping boards and engineering education needs them. In Proceedings of the 2015 IEEE Frontiers in Education Conference (FIE), El Paso, TX, USA, 21–24 October 2015. [Google Scholar]

- Reguera, P.; García, D.; Domínguez, M.; Prada, M.A.; Alonso, S. A low-cost open source hardware in control education. case study: Arduino-feedback ms-150. IFAC-Pap. 2015, 48, 117–122. [Google Scholar] [CrossRef]

- Hajjar, S.; Spears, T. Hardware microprogramming education using raspberry PI and Arduino technologies. Int. J. Intell. Inf. Syst. 2019, 8, 47. [Google Scholar] [CrossRef]

- AlMetwally, S.A.H.; Hassan, M.K.; Mourad, M.H. Real time internet of things (IoT) based water quality management system. Procedia CIRP 2020, 91, 478–485. [Google Scholar] [CrossRef]

- Barber, R.; Horra, M.; Crespo, J. Control practices using simulink with arduino as low cost hardware. IFAC Proc. Vol. 2013, 46, 250–255. [Google Scholar] [CrossRef]

- Mykoniatis, K. A real-time condition monitoring and maintenance management system for low voltage industrial motors using internet-of-things. Procedia Manuf. 2020, 42, 450–456. [Google Scholar] [CrossRef]

- Hang, N.P.T.; Tam, P.T. Impacting the industry 4.0 on the training quality and student’s satisfaction at Lac Hong University. J. Manag. Inf. Decis. Sci. 2018, 21, 1–18. [Google Scholar]

- Özbilge, E.; Kırsal, Y.; Çaglar, E. Modelling and analysis of IoT technology using neural networks in agriculture environment. Int. J. Comput. Commun. Control 2020, 15, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Chen, D.; Wang, S.; Tian, L. A promising trend for field information collection: An air-ground multi-sensor monitoring system. Inf. Process. Agric. 2018, 5, 224–233. [Google Scholar] [CrossRef]

- Liqiang, Z.; Shouyi, Y.; Leibo, L.; Zhen, Z.; Shaojun, W. A crop monitoring system based on wireless sensor network. Procedia Environ. Sci. 2011, 11, 558–565. [Google Scholar] [CrossRef] [Green Version]

- Vij, A.; Vijendra, S.; Jain, A.; Bajaj, S.; Bassi, A.; Sharma, A. IoT and machine learning approaches for automation of farm irrigation system. Procedia Comput. Sci. 2020, 167, 1250–1257. [Google Scholar] [CrossRef]

- Zhai, Z.; Martínez, J.F.; Martínez, N.L.; Díaz, V.H. Applying case-based reasoning and a learning-based adaptation strategy to irrigation scheduling in grape farming. Comput. Electron. Agric. 2020, 178, 105741. [Google Scholar] [CrossRef]

- Villa-Henriksen, A.; Edwards, G.T.; Pesonen, L.A.; Green, O.; Sørensen, C.A.G. Internet of things in arable farming: Implementation, applications, challenges and potential. Biosyst. Eng. 2020, 191, 60–84. [Google Scholar] [CrossRef]

- Thakur, D.; Kumar, Y.; Vijendra, S. Smart irrigation and intrusions detection in agricultural fields using IoT. Procedia Comput. Sci. 2020, 167, 154–162. [Google Scholar] [CrossRef]

- Zhu, Y.; Song, J.; Dong, F. Applications of wireless sensor network in the agriculture environment monitoring. Procedia Eng. 2011, 16, 608–614. [Google Scholar] [CrossRef] [Green Version]

- Berisch, G.; Donath, H.; Heinrich, F.; Huebener, I.; Lipke, T.; Mende, T.; Schriefer, M.; Schulte, H.; Zajac, M. Design and development of a low cost rapid control prototyping system applied to an air suspension system. IFAC Proc. Vol. 2012, 45, 194–199. [Google Scholar] [CrossRef]

- Talaviya, T.; Shah, D.; Patel, N.; Yagnik, H.; Shah, M. Implementation of artificial intelligence in agriculture for optimisation of irrigation and application of pesticides and herbicides. Artif. Intell. Agric. 2020, 4, 58–73. [Google Scholar] [CrossRef]

- Shaari, A.M.; Nor, N.S.M. Position and orientation detection of stored object using RFID tags. Procedia Eng. 2017, 184, 708–715. [Google Scholar] [CrossRef]

- Rahimi, Y.; Matyshenko, I.; Kapitan, R.; Pronchakov, Y. Organization the information support of full logistic supply chains within the industry 4.0. Int. J. Qual. Res. 2020, 14, 1279–1290. [Google Scholar] [CrossRef]

- Thach, N.N.; Hanh, H.T.; Huy, D.T.N.; Vu, Q.N. Technology quality management of the industry 4.0 and cyber security risk management on current banking activities in emerging markets-the case in Vietnam. Int. J. Qual. Res. 2021, 15, 845–856. [Google Scholar] [CrossRef]

- Grenčíková, A.; Kordoš, M.; Berkovič, V. Expected changes in Slovak industry environment in terms of Industry 4.0. Int. J. Qual. Res. 2021, 15, 225–240. [Google Scholar] [CrossRef]

- Maisiri, W.; Darwish, H.; Van Dyk, L. An investigation of I4.0 skills requirements. S. Afr. J. Ind. Eng. 2019, 30, 90–105. [Google Scholar]

- Talebian, S.; Mohammadi, H.M.; Rezvanfar, A. Information and communication technology (ICT) in higher education: Advantages, disadvantages, conveniences and limitations of applying e-learning to agricultural students in Iran. Procedia Soc. Behav. Sci. 2014, 152, 300–305. [Google Scholar] [CrossRef] [Green Version]

- Antonelli, D.; D’Addona, D.M.; Maffei, A.; Modrak, V.; Putnik, G.; Stadnicka, D.; Stylios, C. Tiphys: An open networked platform for higher education on industry 4.0. Procedia CIRP 2019, 79, 706–711. [Google Scholar] [CrossRef]

- Aesaert, K.; Van Braak, J. Gender and socioeconomic related differences in performance based ICT competences. Comput. Educ. 2015, 84, 8–25. [Google Scholar] [CrossRef]

- Umachandran, K.; Corte, V.D.; Amuthalakshmi, P.; Ferdinand-James, D.; Said, M.M.T.; Sawicka, B.; Jurcic, I. Designing learning-skills towards industry 4.0. World J. Educ. Technol. Curr. Issues 2019, 11, 12–23. [Google Scholar]

| Step No. | Steps in Project Implementation | Description | Presented Project to Students |

|---|---|---|---|

| 1. | defining the problem | the student’s proposal of a problem or the choice of one of the proposed problems | task definition: a cloud-based system for data collection and system management |

| 2. | defining parameters | defining the data that the system will collect and analyze | Air temperature, water temperature, humidity, soil moisture, the liquid level in the tank |

| 3. | choice of hardware-microcontroller | the choice of a microcontroller that will represent the main part of the system | NodeMCU, Arduino nano |

| 4. | selection of sensors and actuators | selecting the appropriate sensor according to the given problem | DHT11, FC28, Ultrasonic sensor, Relay module |

| 5. | connection method | consider the place of application of the system and the possibility of connection | Wi-Fi wireless connection |

| 6. | software selection | the choice of the environment in which the platform will be programmed is necessary since specific platforms can be programmed in several ways | Arduino IDE |

| 7. | data presentation | way of presenting data, access using smartphones | Virtuino |

| 8. | data storage | cloud storage | ThingSpeak |

| 9. | control | irrigation system control | automatic mode, manual mode (IoT) |

| 10. | continuity | ensure the operation of the system even in the event of a power outage or power failure | store the necessary data locally, provide an additional power source |

| No. | Question | The Result 1–5 |

|---|---|---|

| 1. | Assessment of the satisfaction with the content of the course: | 4.81 |

| 2. | Assessment of the satisfaction with the way knowledge is presented: | 4.58 |

| 3. | Assessment of lecturers and course associates: | 5 |

| 4. | Evaluation of provided literature for the course: | 4.92 |

| 5. | Assessment of course organization: | 4.75 |

| No. | Area of Acquired Knowledge | Assessment of Acquired Knowledge in the Range between 1–5 |

|---|---|---|

| 1. | Microcontroller platforms, hardware, programming method | 4.85 |

| 2. | I4.0 | 4.81 |

| 3. | cloud systems | 4.78 |

| 4. | IoT-IIoT | 4.69 |

| 5. | Internet networks | 4.35 |

| 6. | Web programming | 4.52 |

| 7. | Databases | 4.32 |

| 8. | Ways of communication between hardware-software-employees | 4.15 |

| 9. | Local presentation—automatic system mode | 3.95 |

| 10. | Assessment of the presented task | 4.88 |

| 11. | Assessment of the entire acquired knowledge on the course | 4.96 |

| No. | Question | The Grade Ranges from 1 to 5, with One Being the Lowest and 5 Being the Highest Grade (a Total of 102 Students Were Surveyed in the Teaching Group That Used the System) | ||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | ||

| Concept | ||||||

| 1. | There is a clear need for additional education and training in the field of I4.0 | 0% | 0% | 9% | 16% | 75% |

| 2. | The practical knowledge and expertise, especially in the field of digitalization, are essential for I4.0 | 0% | 13% | 19% | 22% | 46% |

| 3. | Problem-solving approach and work on real-life problems are suitable solutions for learning and teaching I4.0 | 1% | 6% | 14% | 27% | 52% |

| 4. | Evaluate total satisfaction with the system | 2% | 5% | 18% | 26% | 49% |

| The character of the approach | ||||||

| 1. | A learning outcome is clear and educational goals are well presented on the system | 3% | 9% | 13% | 32% | 43% |

| 2. | The system facilitates better learning and has several services | 0% | 4% | 21% | 24% | 51% |

| 3. | Digital “e” character of the course is increased | 0% | 1% | 12% | 41% | 46% |

| 4. | System presents clear improvement | 0% | 0% | 18% | 33% | 49% |

| 5. | System is stimulative and interesting | 4% | 9% | 17% | 27% | 43% |

| 6. | System enables easier knowledge acquisition | 5% | 11% | 15% | 29% | 40% |

| 7. | System enables individual learning paths | 5% | 10% | 27% | 29% | 29% |

| Platform | ||||||

| 1. | Usage of low-cost boards such as Arduino and Raspberry Pi enables several advantages | 0% | 5% | 20% | 28% | 47% |

| 2. | Importance of integration of different components and components are important | 0% | 10% | 21% | 29% | 40% |

| 3. | It is important to enable sensors selection | 5% | 15% | 26% | 28% | 26% |

| 4. | Usage of services and different forms of data presentation | 5% | 13% | 23% | 27% | 32% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mijailović, Đ.; Đorđević, A.; Stefanovic, M.; Vidojević, D.; Gazizulina, A.; Projović, D. A Cloud-Based with Microcontroller Platforms System Designed to Educate Students within Digitalization and the Industry 4.0 Paradigm. Sustainability 2021, 13, 12396. https://doi.org/10.3390/su132212396

Mijailović Đ, Đorđević A, Stefanovic M, Vidojević D, Gazizulina A, Projović D. A Cloud-Based with Microcontroller Platforms System Designed to Educate Students within Digitalization and the Industry 4.0 Paradigm. Sustainability. 2021; 13(22):12396. https://doi.org/10.3390/su132212396

Chicago/Turabian StyleMijailović, Đorđe, Aleksandar Đorđević, Miladin Stefanovic, Dejan Vidojević, Albina Gazizulina, and Damir Projović. 2021. "A Cloud-Based with Microcontroller Platforms System Designed to Educate Students within Digitalization and the Industry 4.0 Paradigm" Sustainability 13, no. 22: 12396. https://doi.org/10.3390/su132212396

APA StyleMijailović, Đ., Đorđević, A., Stefanovic, M., Vidojević, D., Gazizulina, A., & Projović, D. (2021). A Cloud-Based with Microcontroller Platforms System Designed to Educate Students within Digitalization and the Industry 4.0 Paradigm. Sustainability, 13(22), 12396. https://doi.org/10.3390/su132212396