Substitute Building Materials in Geogrid-Reinforced Soil Structures

Abstract

:1. Introduction

2. Materials and Methods

2.1. General Approach

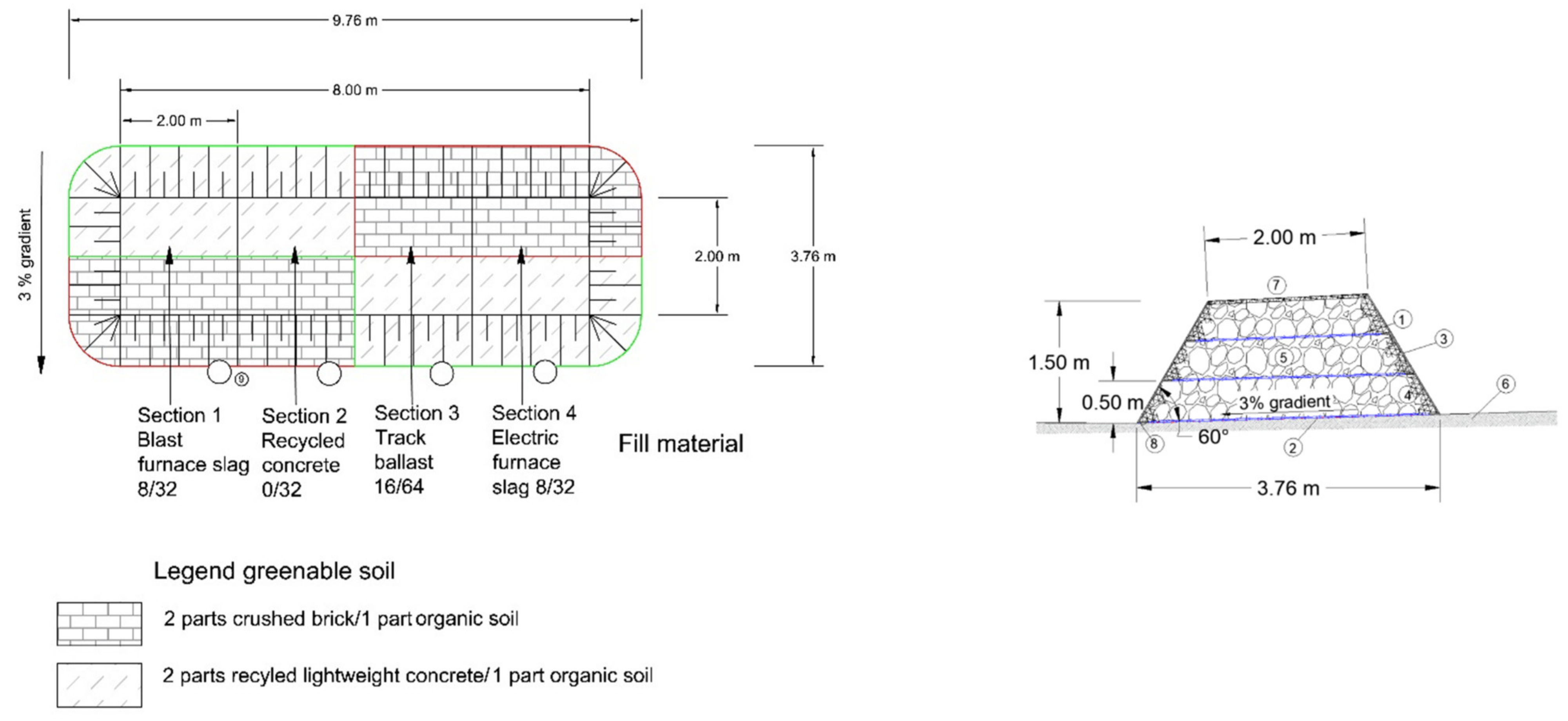

2.2. Materials for Pilot Application

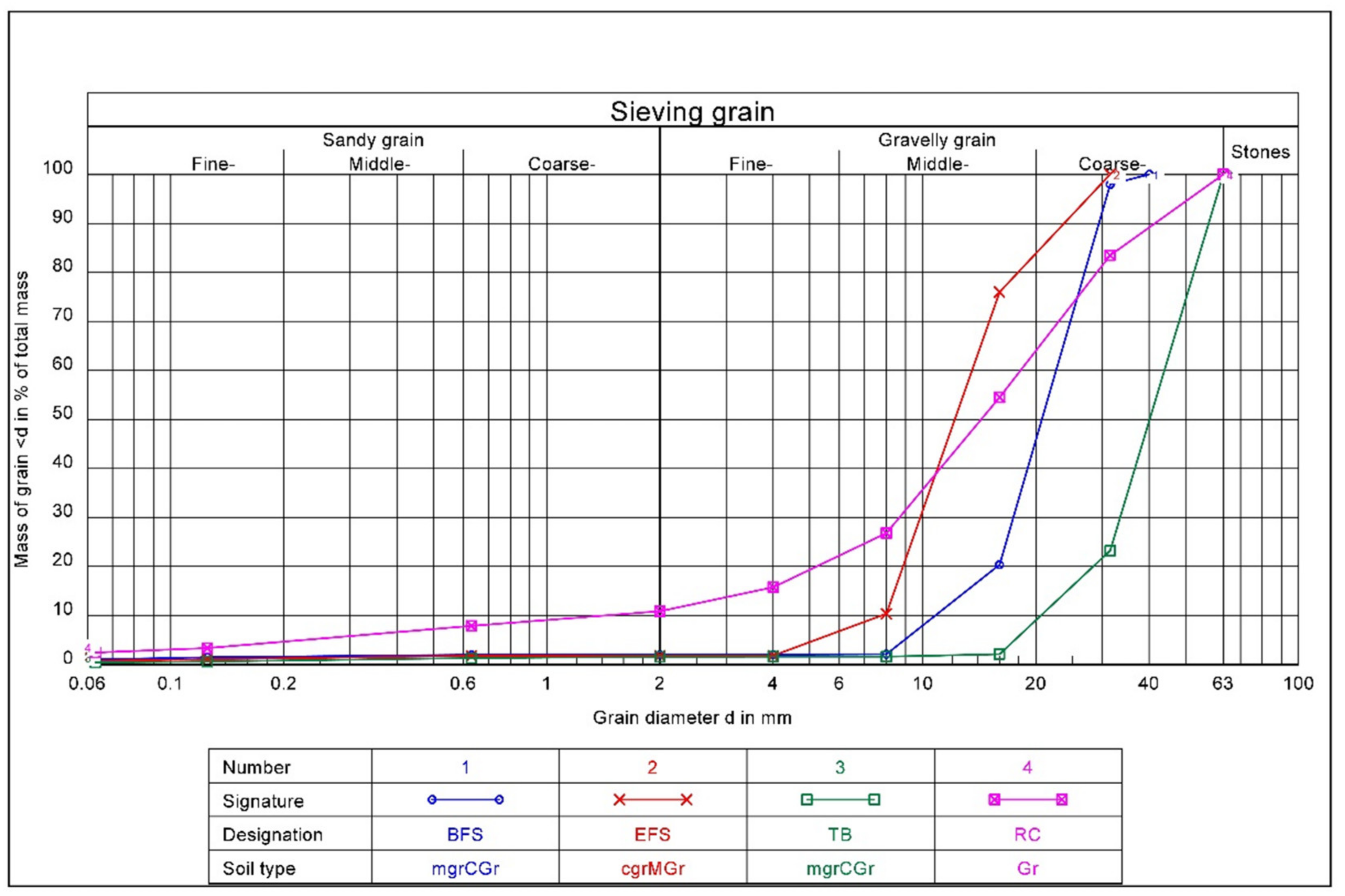

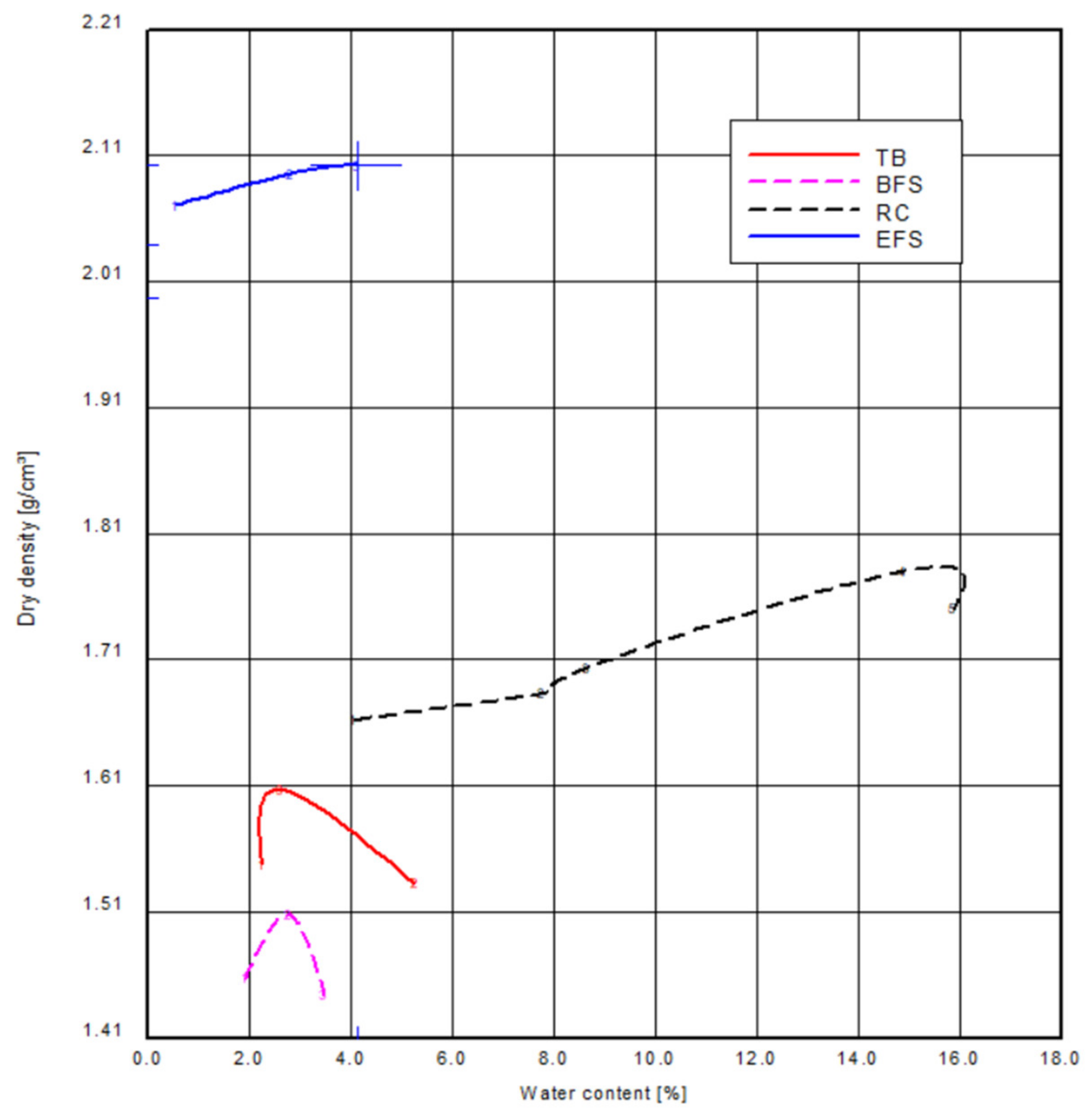

2.2.1. Fill Materials for Pilot Application

2.2.2. Materials for Facing Elements of Pilot Application

- Density of soil particles (g/cm³);

- Ignition loss (%);

- Proctor density (g/cm³);

- Field capacity (%);

- pH value;

- Chemical analyses.

2.2.3. Additional Materials for Pilot Application and for Greening Tests

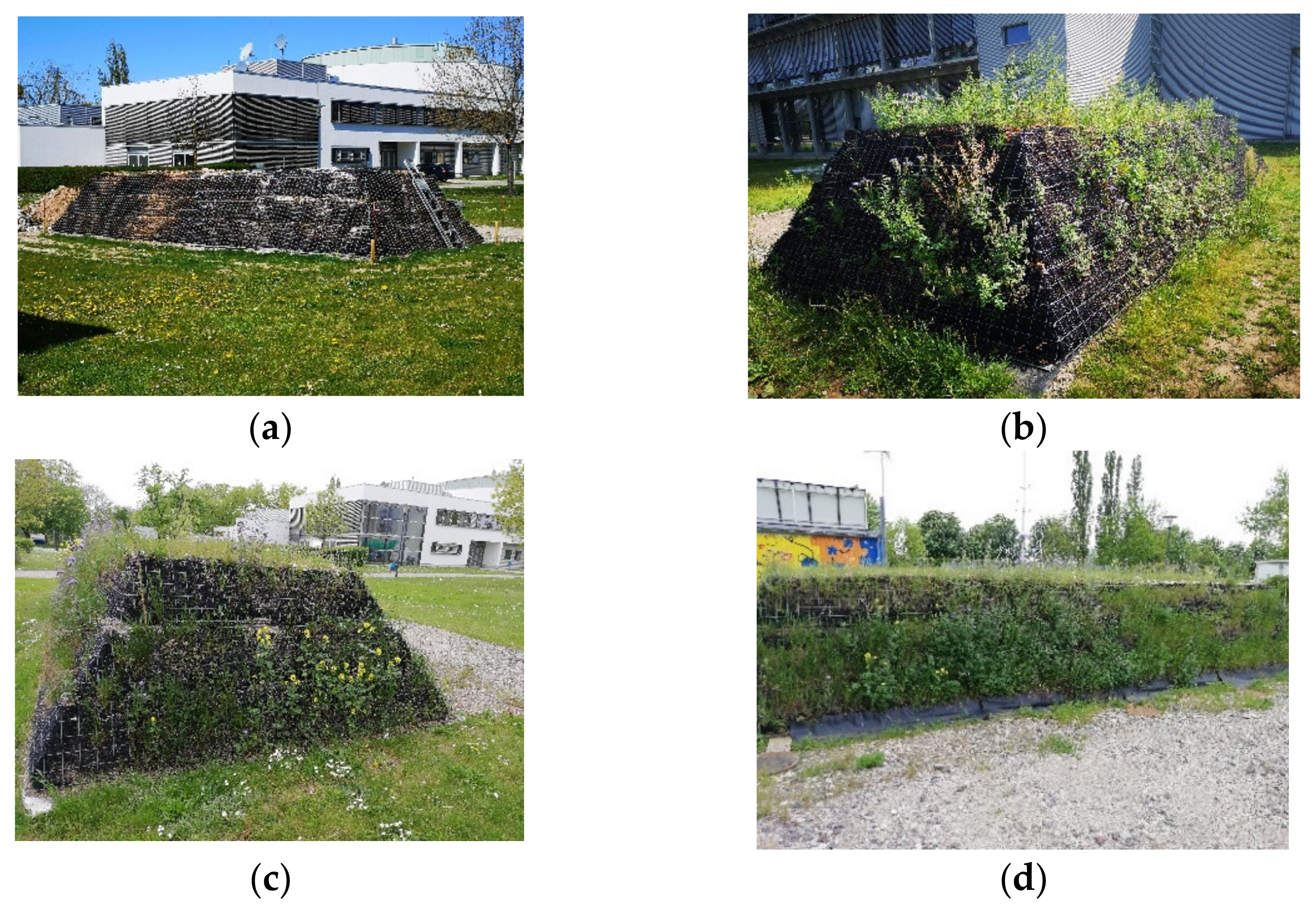

2.3. Pilot Application

3. Results

3.1. Soil Mechanical and Chemical Test Results

- -

- Roads, paths, traffic areas (superstructure and substructure);

- -

- Industrial, commercial, and storage areas (superstructure and substructure);

- -

- Substructures of buildings;

- -

- Below the rootable soil layer of earthworks (noise and protection walls);

- -

- Substructures of sports facilities.

3.2. Preliminary Greening Test Results

3.3. Pilot Application

- -

- RB material is coarser-grained compared to LC. As a result, it has a higher pore volume, which supports water flow and air capacity. The large pore spaces also give roots better opportunities to grow. The brick acts as a drainage layer. The RB’s disadvantage is that it has no real storage capacity due to high water permeability. A long-lasting, stable moisture level can therefore not be expected;

- -

- LC, on the other hand, is very fine-pored, and this property gives it a high storage capacity. With many small cavities, the water has plenty of room to spread and to be stored. Due to its good heat capacity, this SBM can store heat well when the outside temperature is too low and can insulate against heat when it is very hot. This offers the advantage that plants can thrive even on colder days/months and survive better in hot conditions. The disadvantage of the fine pores is that there is no good water permeability. When water enters LC, it runs off on the surface because the pores are too fine to allow the water to penetrate quickly. This characteristic does not guarantee fast plant growth. Furthermore, the pores block possible space for rapid root development. They, therefore, need more time to break through.

- -

- Effective long-distance dispersal mechanism: Pioneer habitats emerge unpredictably and in isolation. Therefore, species with high seed numbers and with dispersal by wind (anemochory) and animal (ornithochory) are typical pioneers;

- -

- High hardiness: Tolerate extreme environmental conditions, established vegetation stands reduces occurring maxima e.g., in terms of temperature and soil water; furthermore, the soils usually show nutrient deficiencies or imbalances.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| BFS | Blast furnace slag |

| CDW | Construction and demolition waste |

| cmd | Cross machine direction (secondary direction of geosynthetics reinforcement) |

| EFS | Electric furnace slag |

| EPA | Environmental Protection Agency |

| GRSS | Geogrid-reinforced soil structure |

| LC | (crushed) Lightweight concrete material |

| md | Machine direction (main direction of geosynthetics reinforcement) |

| PAH | Polycyclic aromatic hydrocarbons |

| PET | Polyethylenterephthalat |

| RB | Recycled brick material |

| RC | Recycled concrete material |

| RFID | Reduction factor of installation damage |

| RSS | Reinforced soil structure |

| SBM | Substitute building material |

| TB | Track ballast |

References

- Bundesministerium für Umwelt, Entwurf der Mantelverordnung. Available online: https://www.bmu.de/fileadmin/Daten_BMU/Download_PDF/Gesetze/mantelv_text.pdf (accessed on 3 October 2019).

- Kreislaufwirtschaft Bau. Kreislaufwirtschaft-Bau.de. Available online: http://kreislaufwirtschaft-bau.de/#aktuelleDaten (accessed on 30 October 2019).

- Ministerium für Umwelt, Landwirtschaft und Energie, Sachsen-Anhalts. Leitfaden zur Wiederverwendung und Verwertung von Mineralischen Abfällen in Sachsen-Anhalt; Ministerium für Umwelt, Landwirtschaft und Energie, Sachsen-Anhalts: Magdeburg, Germany, 2018.

- European Comission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions-Green Infrastructure (GI)—Enhancing Europe’s Natural Capital. 2013. Available online: https://eur-lex.europa.eu/resource.html?uri=cellar:d41348f2-01d5-4abe-b817-4c73e6f1b2df.0014.03/DOC_1&format=PDF (accessed on 3 October 2019).

- Krawczyk, A.; Domagała-Świątkiewicz, I.; Lis-Krzyścin, A.; Daraż, M. Waste Silica as a Valuable Component of Extensive Green-Roof Substrates. Pol. J. Environ. Stud. 2017, 26, 643–653. [Google Scholar] [CrossRef]

- Molineux, C.; Gange, A.C.; Connop, S.P.; Newport, D. Using recycled aggregates in green roof substrates for plant diversity. Ecol. Eng. 2015, 82, 596–604. [Google Scholar] [CrossRef]

- Carson, T.; Hakimdavar, R.; Sjoblom, K.; Culligan, P. Viability of Recycled and Waste Materials as Green Roof Substrates. In Proceedings of the GeoCongress 2012, Oakland, CA, USA, 25–29 March 2012. [Google Scholar] [CrossRef]

- Gargari, C.; Bibbiani, C.; Fantozzi, F.; Campiotti, C.A. Environmental Impact of Green Roofing: The Contribute of a Green Roof to the Sustainable use of Natural Resources in a Life Cycle Approach. Agric. Agric. Sci. Procedia 2016, 8, 646–656. [Google Scholar] [CrossRef]

- Santos, E.; Palmeira, E.; Bathurst, R. Performance of two geosynthetic reinforced walls with recycled construction waste backfill and constructed on collapsible ground. Geosynth. Int. 2014, 21, 256–269. [Google Scholar] [CrossRef]

- Vieira, C.S.; Pereira, P.; Ferreira, F.; Lopes, M.D.L. Pullout behaviour of Geogrids embedded in a recycled construction and demolition material. Effects of specimen size and displacement rate. Sustanability 2020, 12, 3825. [Google Scholar] [CrossRef]

- Fleury, M.P.; Santos, E.C.G.; Da Silva, J.L.; Palmeira, E.M. Geogrid installation damage caused by recycled construction and demolition waste. Geosynth. Int. 2019, 26, 641–656. [Google Scholar] [CrossRef]

- Vibha, S.; Divya, P.V. Geosynthetic-Reinforced Soil Wall with Sustainable Backfills. Indian Geotech. J. 2020, 51, 1–10. [Google Scholar] [CrossRef]

- Ferreira, F.; Pereira, P.; Vieira, C.; Lopes, M. Time-Dependent Response of a Recycled C&D Material-Geotextile Interface under Direct Shear Mode. Materials 2021, 14, 3070. [Google Scholar] [CrossRef] [PubMed]

- Vieira, C.S. Valorization of Fine-Grain Construction and Demolition (C&D) Waste in Geosynthetic Reinforced Structures. Waste Biomass-Valoriz. 2018, 11, 1615–1626. [Google Scholar] [CrossRef]

- Schneider, P.; Schwerdt, S.; Schulz, K.; Fiebig, S.; Mirschel, D. Feasibility of substitute building materials for circular use in urban green infrastructure. Civ. Eng. Des. 2020, 2, 159–168. [Google Scholar] [CrossRef]

- EN ISO 14688-1: Geotechnical Investigation and Testing-Identification and Classification of Soil-Part 1: Identification and Description (ISO 14688-1:2017), German version EN ISO 14688-1:2018; Beuth-Verlag: Berlin, Germany, 2018.

- EN ISO 14688-2: Geotechnical Investigation and Testing-Identification and Classification of Soil-Part 2: Principles for a Classification (ISO 14688-2:2017), German version EN ISO 14688-2:2018; Beuth-Verlag: Berlin, Germany, 2018.

- EN ISO 17892-10: Geotechnical Investigation and Testing-Laboratory Testing of Soil-Part 10: Direct Shear Test (ISO 17892-10:2018); German Version EN ISO 17892-10:2018; Beuth-Verlag: Berlin, Germany, 2019.

- EN ISO 12957-1: Geosynthetics-Determination of Friction Characteristics-Part1: Direct Shear Test (ISO/DIS 12957-1: 2018); German and English Version prEN ISO 12957-1:2018; Beuth-Verlag: Berlin, Germany, 2018.

- DGGT. EBGEO Empfehlungen für Planung und Bemessung von Bewehrungen mit Geokunststoffen; Deutsche Gesellschaft für Geotechnik, Ed.; Verlag W. Ernst und Sohn: Berlin, Germany, 2010; ISBN 978-3-433-02950-3. [Google Scholar]

- EN ISO 10319-Geotextiles-Wide-Width Tensile Test (ISO 10319: 1993); German Version EN ISO 10319:1996; Beuth-Verlag: Berlin, Germany, 1996.

- Schwerdt, S.; Schneider, P.; Mirschel, D. Abschlussbericht Forschungsprojekt Verbesserung und Stärkung der Urbanen Grünen Infrastruktur durch Einsatz von Ersatzbaustoffen in Kunststoff-Bewehrte-Erde-Konstruktionen (Recycle-KBE); Final Report; Magdeburg-Stendal University of Applied Sciences: Magdeburg, Germany, 2020. [Google Scholar]

- Hildebrandt, T.; Wilke, M. Verwendbarkeit von Recyclingbaustoffen als Ersatz zu Primärbaustoffen in Kunststioff-Bewehrte-Erde-Konstruktionen. Master’s Thesis, Magdeburg-Stendal University of Applied Sciences, Magdeburg, Germany, 2020, unpublished. [Google Scholar]

- Länderarbeitsgemeinschaft Abfall-LAGA. Mitteilungen der Länderarbeitsgemeinschaft (LAGA) 20 Anforderungen an die stoffliche Verwertung von mineralischen Reststoffen/Abfällen-Technische Regeln. Available online: https://www.laga-online.de/documents/m20_nov2003u1997_2_1517834540.pdf (accessed on 3 October 2019).

- Schulz, K. Untersuchung zu Einsatzmöglichkeiten von Ersatzbaustoffen in Bewehrter Erde als Grüne Infrastruktur. Bachelor’s Thesis, Magdeburg-Stendal University of Applied Sciences, Magdeburg, Germany, 2019, unpublished. [Google Scholar]

- M TS E. Merkblatt über Bauweisen für Technische Sicherungsmaßnahmen beim Einsatz von Böden und Baustoffen mit umweltrelevanten Inhaltsstoffen im Erdbau; FGSV Verlag: Köln, Germany, 2017; ISBN 978-3-86446-203-0. Available online: https://www.fgsv-verlag.de/pub/media/pdf/559.i.pdf (accessed on 30 October 2019).

| BFS | EFS | RC | TB | |

|---|---|---|---|---|

| Soil classification (EN ISO 14688-1) | mgrCGr | cgrMGr | Gr | mgrCGr |

| Soil classification (EN ISO 14688-2) | Uniformly graded gravel | Uniformly graded gravel | Medium to well-graded gravel | Uniformly graded gravel |

| Density of soil particles (g/cm³) | 2.41–2.83 | 3.84–3.96 | 2.55–2.57 | 2.66 |

| Ignition loss (%) | 0 | 0 | 0 | 0 |

| Water absorption (%) | 24.5 | 25.8 | n.d. | n.d. |

| Proctor density (g/cm³) | 1.51–1.58 | 2.10–2.16 | 1.78 | 1.61 |

| pH value | 10.2 | 10.7 | 9.3 | 9.3 |

| Field capacity (%) | 2.29 | 1.81 | 9.97 | n.d. |

| Air capacity (%) | 7.90 | 6.20 | 9.53 | n.d. |

| Shear parameter (soil) (φ’/c’) (°/kN/m²) | 54.3/0 | 53.6/0 | 53.2/0 | 59.6/0 |

| Friction ratio (–) | 0.91 | 0.94 | 0.81 | 0.75 |

| Chemical classification according to LAGA M20 * [24] | Z2 (sulfate) | Z0 | Z1.2 (sulfate) | Z0 |

| LC + Soil | RB + Soil | |

|---|---|---|

| Soil classification (EN ISO 14688-1) | grcsiSa | csisaGr |

| Soil classification (EN ISO 14688-2) | Well-graded sand | Well-graded gravel |

| Density of soil particles (g/cm³) | 1.89 | 2.47–2.64 |

| Proctor density (g/cm³) | 1.24 | 1.96 |

| Ignition loss (%) | 7.04 | 2.5 |

| Field capacity (%) | 14.96 | 13.96 |

| Air capacity (%) | 2.13 | 5.55 |

| pH value | 8.8 | 8.0 |

| Chemical classification according to LAGA M20 * [24] | Z2 (sulfate) | Z1.2 (sulfate) |

| SBM | A2–Value (md) (–) | A2–Value (cmd) (–) |

|---|---|---|

| EFS | 1.01 | 1.03 |

| BFS | 1.00 | 1.00 |

| RC | 1.01 | 1.00 |

| TB | 1.08 | 1.06 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schwerdt, S.; Mirschel, D.; Hildebrandt, T.; Wilke, M.; Schneider, P. Substitute Building Materials in Geogrid-Reinforced Soil Structures. Sustainability 2021, 13, 12519. https://doi.org/10.3390/su132212519

Schwerdt S, Mirschel D, Hildebrandt T, Wilke M, Schneider P. Substitute Building Materials in Geogrid-Reinforced Soil Structures. Sustainability. 2021; 13(22):12519. https://doi.org/10.3390/su132212519

Chicago/Turabian StyleSchwerdt, Sven, Dominik Mirschel, Tobias Hildebrandt, Max Wilke, and Petra Schneider. 2021. "Substitute Building Materials in Geogrid-Reinforced Soil Structures" Sustainability 13, no. 22: 12519. https://doi.org/10.3390/su132212519

APA StyleSchwerdt, S., Mirschel, D., Hildebrandt, T., Wilke, M., & Schneider, P. (2021). Substitute Building Materials in Geogrid-Reinforced Soil Structures. Sustainability, 13(22), 12519. https://doi.org/10.3390/su132212519