Hydrogen-Based Energy Storage Systems for Large-Scale Data Center Applications

Abstract

:1. Introduction

2. Discussion

2.1. Power Requirements for Data Centers

2.2. Hydrogen Fuel Cells for Data Centers

2.3. Hydrogen-Based Energy Storage for Data Centers

2.3.1. Physical Storage Options for Large-Scale Applications

2.3.2. Materials for Large-Scale Hydrogen-Based Energy Systems

2.4. Delivery and Distrubtion of Hydrogen for Data Center Applications

2.5. Current R&D for Hydrogen-Based Energy Storage for Large-Scale Applications

3. Future Outlook

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Disclaimer

References

- U.S. Department of Energy. Secretary Granholm Launches Hydrogen Energy Earthshot to Accelerate Breakthroughs Toward a Net-Zero Economy. Available online: https://www.energy.gov/articles/secretary-granholm-launches-hydrogen-energy-earthshot-accelerate-breakthroughs-toward-net (accessed on 2 July 2021).

- Hydrogen Council. Hydrogen, Scaling Up. Available online: https://hydrogencouncil.com/en/study-hydrogen-scaling-up/ (accessed on 2 July 2021).

- Staffell, I.; Scamman, D.; Velazquez Abad, A.; Balcombe, P.; Dodds, P.E.; Ekins, P.; Shah, N.; Ward, K.R. The role of hydrogen and fuel cells in the global energy system. Energy Environ. Sci. 2019, 12, 463–491. [Google Scholar] [CrossRef] [Green Version]

- Kast, J.; Vijayagopal, R.; Gangloff, J.J.; Marcinkoski, J. Clean commercial transportation: Medium and heavy duty fuel cell electric trucks. Int. J. Hydrogen Energy 2017, 42, 4508–4517. [Google Scholar] [CrossRef] [Green Version]

- Lee, D.-Y.; Elgowainy, A.; Kotz, A.; Vijayagopal, R.; Marcinkoski, J. Life-cycle implications of hydrogen fuel cell electric vehicle technology for medium- and heavy-duty trucks. J. Power Sources 2018, 393, 217–229. [Google Scholar] [CrossRef]

- Kast, J.; Morrison, G.; Gangloff, J.J.; Vijayagopal, R.; Marcinkoski, J. Designing hydrogen fuel cell electric trucks in a diverse medium and heavy duty market. Res. Transp. Econ. 2018, 70, 139–147. [Google Scholar] [CrossRef]

- FuelCellsWorks. DOE Sets Targets for Hydrogen Fuel Cell Trucks. Available online: https://fuelcellsworks.com/news/doe-sets-targets-for-hydrogen-fuel-cell-trucks/ (accessed on 3 December 2020).

- U.S. Department of Energy. DOE Launches Two Consortia to Advance Fuel Cell Truck and Electrolyzer R&D. Available online: https://www.energy.gov/eere/articles/doe-launches-two-consortia-advance-fuel-cell-truck-and-electrolyzer-rd (accessed on 13 January 2021).

- U.S. Department of Energy. Department of Energy Announces $50 Million for Commercial Truck, Off-Road Vehicle, and Gaseous Fuels Research. Available online: https://www.energy.gov/articles/department-energy-announces-50-million-commercial-truck-road-vehicle-and-gaseous-fuels-0 (accessed on 8 January 2021).

- Andersson, J.; Grönkvist, S. Large-scale storage of hydrogen. Int. J. Hydrogen Energy 2019, 44, 11901–11919. [Google Scholar] [CrossRef]

- U.S. Department of Energy. Hydrogen Shot. Available online: https://www.energy.gov/eere/fuelcells/hydrogen-shot (accessed on 7 July 2021).

- U.S. Environmental Protection Agency. Current Nonattainment Counties for All Criteria Pollutants. Available online: https://www3.epa.gov/airquality/greenbook/ancl.html (accessed on 28 July 2021).

- Bloomberg Law. Biden’s Hefty Clean Air To-Do List Follows Early Big Promises. Available online: https://news.bloomberglaw.com/environment-and-energy/bidens-hefty-clean-air-to-do-list-follows-early-big-promises (accessed on 28 July 2021).

- U.S. Environmental Protection Agency. Nonattainment Areas for Criteria Pollutants (Green Book). Available online: https://www.epa.gov/green-book (accessed on 28 July 2021).

- The White House. The Path to Achieving Justice40. Available online: https://www.whitehouse.gov/omb/briefing-room/2021/07/20/the-path-to-achieving-justice40/ (accessed on 28 July 2021).

- The White House. FACT SHEET: President Biden Takes Executive Actions to Tackle the Climate Crisis at Home and Abroad, Create Jobs, and Restore Scientific Integrity Across Federal Government. Available online: https://www.whitehouse.gov/briefing-room/statements-releases/2021/01/27/fact-sheet-president-biden-takes-executive-actions-to-tackle-the-climate-crisis-at-home-and-abroad-create-jobs-and-restore-scientific-integrity-across-federal-government/ (accessed on 28 July 2021).

- U.S. Department of Energy. Promoting Energy Justice. Available online: https://www.energy.gov/promoting-energy-justice (accessed on 28 July 2021).

- Ponemon Institute Research Report. Cost of Data Center Outages; Ponemon Institute LLC: Traverse City, MI, USA, 2016; pp. 1–20. [Google Scholar]

- U.S. Environmental Protection Agency. Summary of the Energy Policy Act (2005). Available online: https://www.epa.gov/laws-regulations/summary-energy-policy-act (accessed on 10 January 2021).

- U.S. Environmental Protection Agency. Diesel Emissions Reduction Act (DERA) Funding. Available online: https://www.epa.gov/dera (accessed on 14 January 2021).

- U.S. Environmental Protection Agency. Learn About Impacts of Diesel Exhaust and the Diesel Emissions Reduction Act (DERA). Available online: https://www.epa.gov/dera/learn-about-impacts-diesel-exhaust-and-diesel-emissions-reduction-act-dera (accessed on 8 July 2021).

- California SB 1099-Emergency Backup Generators: Critical Facilities: Exemptions; State of California: Sacramento, CA, USA, 2020.

- Worldwide Power Products. Noise Pollution in Diesel Generators. Available online: https://www.wpowerproducts.com/news/diesel-generator-noise-pollution/ (accessed on 8 January 2021).

- Techjury. How Much Data Is Created Every Day in 2020? Available online: https://techjury.net/blog/how-much-data-is-created-every-day/#gref (accessed on 8 December 2020).

- SeedScientific. How Much Data Is Created Every Day? [27 Staggering Stats]. Available online: https://seedscientific.com/how-much-data-is-created-every-day/#:~:text=Every%20day%2C%20we%20create%20roughly%202.5%20quintillion%20bytes%20of%20data (accessed on 14 April 2021).

- StatInvestor. Information Created Globally 2005–2025. Available online: https://statinvestor.com/data/35219/data-created-worldwide/ (accessed on 14 April 2021).

- Forbes. 175 Zettabytes By 2025. Available online: https://www.forbes.com/sites/tomcoughlin/2018/11/27/175-zettabytes-by-2025/?sh=bbfb42354597 (accessed on 14 April 2021).

- Statista. Volume of Data/Information Created, Captured, Copied, and Consumed Worldwide from 2010 to 2024. Available online: https://www.statista.com/statistics/871513/worldwide-data-created/#:~:text=Amount%20of%20information%20globally%202010%2D2024&text=The%20total%20amount%20of%20data,reaching%2059%20zettabytes%20in%202020 (accessed on 14 April 2021).

- Synergy Research Group. COVID-19 Helps to Accelerate the Shift to Hosted and Cloud Collaboration Solutions. Available online: https://www.srgresearch.com/articles/covid-19-helps-accelerate-shift-hosted-and-cloud-collaboration-solutions (accessed on 2 November 2020).

- Kurtz, J.; Saur, G.; Sprik, S.; Ainscough, C. Backup Power Cost of Ownership Analysis and Incumbent Technology Comparison; National Renewable Energy Laboratory: Golden, CO, USA, 2014; pp. 1–31. Available online: https://www.energy.gov/eere/fuelcells/downloads/backup-power-cost-ownership-analysis-and-incumbent-technology-comparison (accessed on 10 November 2020).

- European Committee for Electrotechnical Standarization. CLC/TC 215 Electrotechnical Aspects of Telecommunication Equipment. Available online: https://www.cenelec.eu/dyn/www/f?p=104:110:568580276559001::::FSP_ORG_ID,FSP_PROJECT,FSP_LANG_ID:1258297,56390,25 (accessed on 10 December 2020).

- International Organization for Standarization. ISO/IEC TS 22237-1:2018 Information Technology—Data Centre Facilities and Infrastructures—Part 1: General Concepts. Available online: https://www.iso.org/standard/72925.html (accessed on 8 January 2021).

- International Organization for Standardization. ISO/IEC TS 22237-2:2018 Information Technology—Data Centre Facilities and Infrastructures—Part 2: Building Construction. Available online: https://www.iso.org/standard/73009.html (accessed on 8 January 2021).

- International Organization for Standardization. ISO/IEC TS 22237-3:2018 Information Technology—Data Centre Facilities and Infrastructures—Part 3: Power Distribution. Available online: https://www.iso.org/standard/73010.html (accessed on 8 January 2021).

- International Organization for Standardization. ISO/IEC TS 22237-4:2018 Information Technology—Data Centre Facilities and Infrastructures—Part 4: Environmental Control. Available online: https://www.iso.org/standard/73011.html (accessed on 8 January 2021).

- Telecommunications Industry Association. TIA 942 Certifications & Ratings. Available online: https://tiaonline.org/products-and-services/tia942certification/tia-942-certifications-ratings/ (accessed on 20 November 2020).

- Uptime Institute. Data Center Certification. Available online: https://uptimeinstitute.com/tier-certification (accessed on 4 November 2020).

- Shehabi, A.; Smith, S.; Sartor, D.; Brown, R.; Herrlin, M.; Koomey, J.; Masanet, E.; Horner, N.; Azevedo, I.; Lintner, W. United States Data Center Energy Usage Report; LBNL-1005775; Lawrence Berkley National Laboratory: Guangdong, China, 2016; pp. 1–65. [Google Scholar]

- Mitchell-Jackson, J.; Koomey, J.G.; Nordman, B.; Blazek, M. Data Center Power Requirements: Measurements from Silicon Valley. Energy 2003, 28, 837–850. [Google Scholar] [CrossRef]

- Masanet, E.; Shehabi, A.; Lei, N.; Smith, S.; Koomey, J. Recalibrating global data center energy-use estimates. Science 2020, 367, 984–986. [Google Scholar] [CrossRef]

- Fulton, S., III. How Hyperscale Data Centers Are Reshaping All of IT. Available online: https://www.zdnet.com/article/how-hyperscale-data-centers-are-reshaping-all-of-it/ (accessed on 22 November 2020).

- Allen, M. Data Center Redundancy N+1, N+2 vs. 2N vs. 2N+1. Available online: https://www.datacenters.com/news/data-center-redundancy-n-1-n-2-vs-2n-vs-2n-1 (accessed on 4 January 2021).

- Li, X.; Wang, H.; Yi, S.; Yao, X.; Zhu, F.; Zhai, L. Redundancy-Guaranteed and Receiving-Constrained Disaster Backup in Cloud Data Center Network. IEEE Access 2018, 6, 47666–47681. [Google Scholar] [CrossRef]

- Van der Berg, M. An Overview of Complete Power Failures in Data Centers. Available online: http://up2v.nl/2017/06/02/datacenter-complete-power-failures/ (accessed on 3 December 2020).

- DatacenterDynamics. 365 Main Offers Transparency with Detailed Root Cause Analysis of Power Outage. Available online: https://www.datacenterdynamics.com/en/news/365-main-offers-transparency-with-detailed-root-cause-analysis-of-power-outage-2/ (accessed on 3 December 2020).

- Gorman, S. Meltdowns Hobble NSA Data Center. Available online: https://www.wsj.com/articles/SB10001424052702304441404579119490744478398 (accessed on 20 November 2020).

- Zhao, L.; Brouwer, J.; James, S.; Peterson, E.; Wang, D.; Liu, J. Fuel Cell Powered Data Centers: In-Rack DC Generation. ECS Trans. 2016, 71, 131–139. [Google Scholar] [CrossRef]

- Saur, G.; Arjona, V.; Clutterbuck, A.; Parker, E. Hydrogen and Fuel Cells for Data Center Applications Project Meeting: Workshop Report; NREL/TP-5400-75355; National Renewable Energy Laboratory, U.S. Department of Energy Fuel Cell Technology Office: Golden, CO, USA, 2019; pp. 1–28. Available online: https://www.nrel.gov/docs/fy20osti/75355.pdf (accessed on 4 February 2021).

- Smith, B. Microsoft Will Be Carbon Negative by 2030. Available online: https://blogs.microsoft.com/blog/2020/01/16/microsoft-will-be-carbon-negative-by-2030/ (accessed on 15 December 2020).

- Roach, J. Microsoft Tests Hydrogen Fuel Cells for Backup Power at Datacenters. Available online: https://news.microsoft.com/innovation-stories/hydrogen-datacenters/ (accessed on 3 December 2020).

- Fuel Cell & Hydrogen Energy Association. Fuel Cells and Data Centers; Fuel Cell & Hydrogen Energy Association: Washington, DC, USA; p. 1. Available online: www.fchea.org (accessed on 25 February 2021).

- Barthélemy, H.; Weber, M.; Barbier, F. Hydrogen storage: Recent improvements and industrial perspectives. Int. J. Hydrogen Energy 2017, 42, 7254–7262. [Google Scholar] [CrossRef]

- Kojima, Y. Hydrogen storage materials for hydrogen and energy carriers. Int. J. Hydrogen Energy 2019, 44, 18179–18192. [Google Scholar] [CrossRef]

- McWhorter, S.; Read, C.; Ordaz, G.; Stetson, N. Materials-based hydrogen storage: Attributes for near-term, early market PEM fuel cells. Curr. Opin. Solid State Mater. Sci. 2011, 15. [Google Scholar] [CrossRef]

- von Colbe, J.B.; Ares, J.-R.; Barale, J.; Baricco, M.; Buckley, C.; Capurso, G.; Gallandat, N.; Grant, D.M.; Guzik, M.N.; Jacob, I.; et al. Application of hydrides in hydrogen storage and compression: Achievements, outlook and perspectives. Int. J. Hydrogen Energy 2019, 44, 7780–7808. [Google Scholar] [CrossRef]

- James, B.D.; Huya-Kouadio, J.M.; Houchins, C.; DeSantis, D.A. Mass Production Cost Estimation of Direct H2 PEM Fuel Cell Systems for Transportation Applications: 2018 Update; Strategic Analysis Inc.: Washington, DC, USA, 2017; pp. 1–355. Available online: https://www.energy.gov/sites/prod/files/2019/12/f70/fcto-sa-2018-transportation-fuel-cell-cost-analysis.pdf (accessed on 10 December 2020).

- Züttel, A. Materials for hydrogen storage. Mater. Today 2003, 6, 24–33. [Google Scholar] [CrossRef]

- Krishna, R.; Titus, E.; Salimian, M.; Okhay, O.; Rajendran, S.; Rajkumar, A.; Sousa, J.M.G.; Ferreira, A.L.C.; Campos Gil, J.; Gracio, J. Hydrogen Storage for Energy Application. In Hydrogen Storage; Lui, J., Ed.; IntechOpen: London, UK, 2012; pp. 243–266. [Google Scholar]

- Niaz, S.; Manzoor, T.; Pandith, A.H. Hydrogen storage: Materials, methods and perspectives. Renew. Sustain. Energy Rev. 2015, 50, 457–469. [Google Scholar] [CrossRef]

- Ozarslan, A. Large-scale hydrogen energy storage in salt caverns. Int. J. Hydrogen Energy 2012, 37, 14265–14277. [Google Scholar] [CrossRef]

- Lankof, L.; Tarkowski, R. Assessment of the potential for underground hydrogen storage in bedded salt formation. Int. J. Hydrogen Energy 2020, 45, 19479–19492. [Google Scholar] [CrossRef]

- Lemieux, A.; Shkarupin, A.; Sharp, K. Geologic feasibility of underground hydrogen storage in Canada. Int. J. Hydrogen Energy 2020, 45, 32243–32259. [Google Scholar] [CrossRef]

- Liu, W.; Zhang, Z.; Chen, J.; Jiang, D.; Wu, F.; Fan, J.; Li, Y. Feasibility evaluation of large-scale underground hydrogen storage in bedded salt rocks of China: A case study in Jiangsu province. Energy 2020, 198, 117348. [Google Scholar] [CrossRef]

- Ahluwalia, R. 2020 Annual Merit Review: Progress Updates. Available online: https://www.hydrogen.energy.gov/annual_review20_h2fuel.html#stor-analysis (accessed on 15 April 2021).

- Notardonato, W.U.; Swanger, A.M.; Fesmire, J.E.; Jumper, K.M.; Johnson, W.L.; Tomsik, T.M. Final test results for the ground operations demonstration unit for liquid hydrogen. Cryogenics 2017, 88, 147–155. [Google Scholar] [CrossRef] [Green Version]

- Swanger, A. Transient Modeling of Large Scale Integrated Refrigeration and Storage Systems. Available online: https://ntrs.nasa.gov/api/citations/20180006597/downloads/20180006597.pdf (accessed on 10 December 2020).

- HyMARC. The Hydrogen Materials Advanced Research Consortium. Available online: https://www.hymarc.org/ (accessed on 19 February 2021).

- Hirscher, M.; Yartys, V.A.; Baricco, M.; von Colbe, J.B.; Blanchard, D.; Bowman, R.C.; Broom, D.P.; Buckley, C.E.; Chang, F.; Chen, P.; et al. Materials for hydrogen-based energy storage—Past, recent progress and future outlook. J. Alloys Compd. 2020, 827, 153548. [Google Scholar] [CrossRef]

- Rusman, N.A.A.; Dahari, M. A review on the current progress of metal hydrides material for solid-state hydrogen storage applications. Int. J. Hydrogen Energy 2016, 41, 12108–12126. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, L.; Ma, H.; Lu, C.; Luo, H.; Wang, X.; Huang, X.; Lan, Z.; Guo, J. Aluminum hydride for solid-state hydrogen storage: Structure, synthesis, thermodynamics, kinetics, and regeneration. J. Energy Chem. 2021, 52, 428–440. [Google Scholar] [CrossRef]

- Sakintuna, B.; Lamari-Darkrim, F.; Hirscher, M. Metal hydride materials for solid hydrogen storage: A review. Int. J. Hydrogen Energy 2007, 32, 1121–1140. [Google Scholar] [CrossRef]

- Milanese, C.; Jensen, T.R.; Hauback, B.C.; Pistidda, C.; Dornheim, M.; Yang, H.; Lombardo, L.; Zuettel, A.; Filinchuk, Y.; Ngene, P.; et al. Complex hydrides for energy storage. Int. J. Hydrogen Energy 2019, 44, 7860–7874. [Google Scholar] [CrossRef] [Green Version]

- Sulic, M.; Cai, M.; Kumar, S. Cycling and engineering properties of highly compacted sodium alanate pellets. Int. J. Hydrogen Energy 2012, 37, 15187–15195. [Google Scholar] [CrossRef]

- Sulic, M.; Cai, M.; Kumar, S. Controlled degradation of highly compacted sodium alanate pellets. Int. J. Hydrogen Energy 2013, 38, 3019–3023. [Google Scholar] [CrossRef]

- Ali, N.A.; Ismail, M. Modification of NaAlH4 properties using catalysts for solid-state hydrogen storage: A review. Int. J. Hydrogen Energy 2021, 46, 766–782. [Google Scholar] [CrossRef]

- Chen, W.; You, L.; Xia, G.; Yu, X. A balance between catalysis and nanoconfinement towards enhanced hydrogen storage performance of NaAlH4. J. Mater. Sci. Technol. 2021, 79, 205–211. [Google Scholar] [CrossRef]

- Poirier, E.; Chahine, R.; Bose, T.K. Hydrogen adsorption in carbon nanostructures. Int. J. Hydrogen Energy 2001, 26, 831–835. [Google Scholar] [CrossRef]

- Barath, J.G.N.; Husev, O.; Manonmani, N. Overview of Energy Storage Technologies for Renewable Energy. Int. J. Innov. Sci. Eng. Technol. 2015, 2, 749–754. [Google Scholar]

- Srinivasan, S.; Demirocak, D.; Kaushik, A.; Sharma, M.; Chaudhary, G.; Hickman, N.; Stefanakos, E. Reversible Hydrogen Storage Using Nanocomposites. Appl. Sci. 2020, 10, 4618. [Google Scholar] [CrossRef]

- Broom, D.P.; Webb, C.J.; Fanourgakis, G.S.; Froudakis, G.E.; Trikalitis, P.N.; Hirscher, M. Concepts for improving hydrogen storage in nanoporous materials. Int. J. Hydrogen Energy 2019, 44, 7768–7779. [Google Scholar] [CrossRef]

- Cherrad, N.; Selloum, D.; Tingry, S. Modeling the control of the desorption rate of hydrogen released from the adsorption storage bed to supply a fuel cell. Int. J. Hydrogen Energy 2020, 45, 17605–17612. [Google Scholar] [CrossRef]

- O’Malley, K.; Ordaz, G.; Adams, J.; Randolph, K.; Ahn, C.C.; Stetson, N.T. Applied hydrogen storage research and development: A perspective from the U.S. Department of Energy. J. Alloys Compd. 2015, 645, S419–S422. [Google Scholar] [CrossRef] [Green Version]

- Makepeace, J.W.; He, T.; Weidenthaler, C.; Jensen, T.R.; Chang, F.; Vegge, T.; Ngene, P.; Kojima, Y.; de Jongh, P.E.; Chen, P.; et al. Reversible ammonia-based and liquid organic hydrogen carriers for high-density hydrogen storage: Recent progress. Int. J. Hydrogen Energy 2019, 44, 7746–7767. [Google Scholar] [CrossRef]

- Teichmann, D.; Arlt, W.; Schlücker, E.; Wasserscheid, P. Transport and Storage of Hydrogen via Liquid Organic Hydrogen Carrier (LOHC) Systems. In Hydrogen Science and Engineering: Materials, Processes, Systems and Technology; Stolten, D., Emonts, B., Eds.; Wiley: Weinhein, Germany, 2016; Volume 1, pp. 811–830. [Google Scholar]

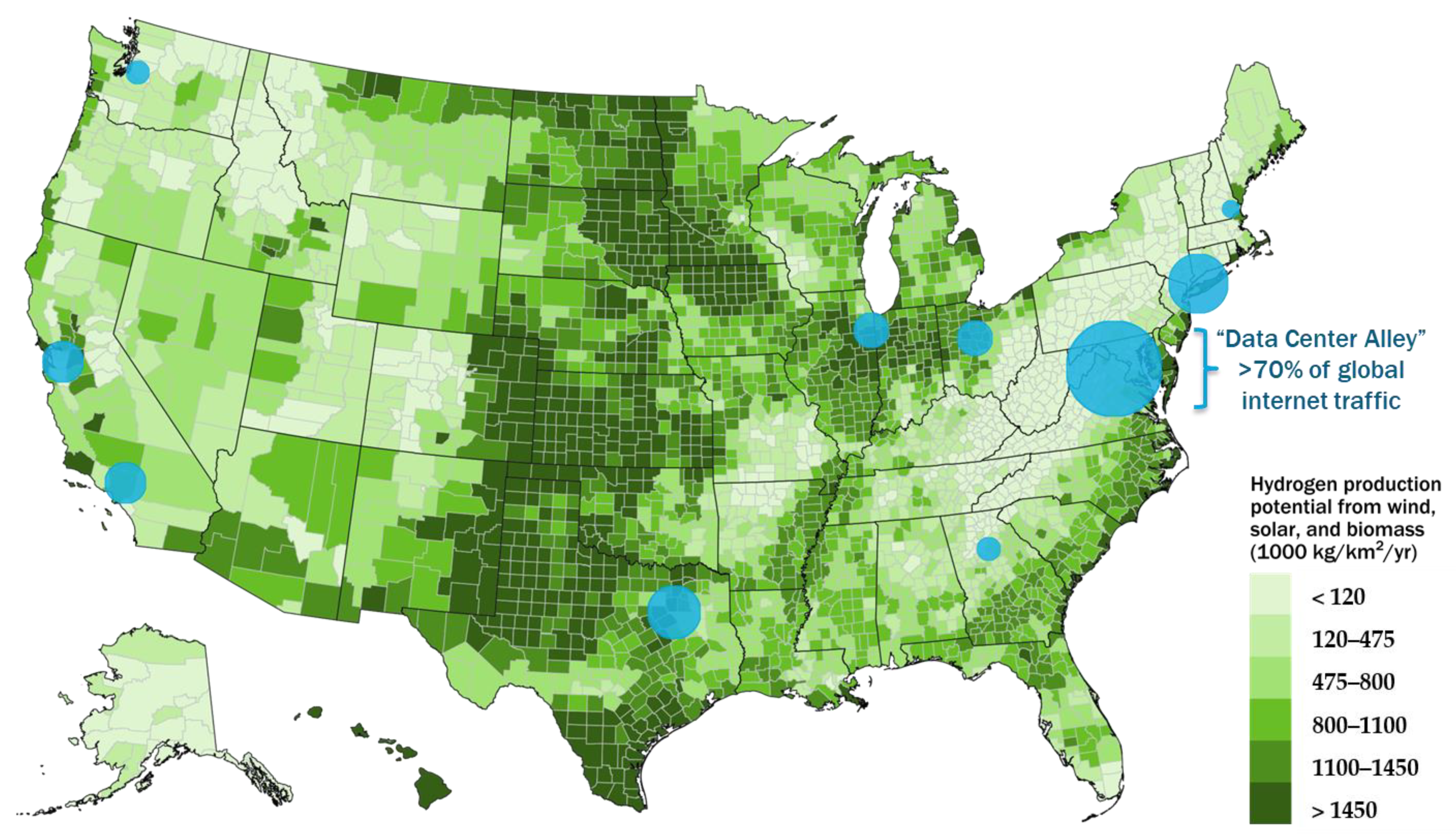

- Fairfax County Economic Development Agency. Northern Virginia Leads the World in the Data Center Market. Available online: https://www.fairfaxcountyeda.org/media-center/northern-virginia-leads-world-data-center-market/ (accessed on 10 March 2021).

- DigitalTech. Data Center Alley: Why 70% of Internet Traffic Flows through Ashburn Virginia. Available online: https://digitaltech.com/data-center-alley-why-70-of-internet-traffic-flows-through-ashburn-virginia/ (accessed on 10 March 2021).

- National Renewable Energy Laboratory. Geospatial Data Science. Available online: https://www.nrel.gov/gis/data-tools.html (accessed on 11 April 2021).

- Data Center Map. Data Center Map. Available online: https://www.datacentermap.com/ (accessed on 4 April 2021).

- Data Centers. Available online: https://www.datacenters.com/ (accessed on 4 April 2021).

- ThoughtCo. What Is a Metal Hydride? Available online: https://www.thoughtco.com/metal-hydrides-2340044 (accessed on 1 March 2021).

- Businesswire. NuMat Technologies Closes $12.4M Funding Round to Accelerate Commercialization of Molecularly Engineered Products. Available online: https://www.businesswire.com/news/home/20180426005011/en/NuMat-Technologies-Closes-12.4M-Funding-Round-to-Accelerate-Commercialization-of-Molecularly-Engineered-Products (accessed on 1 March 2021).

- Chemical & Engineering News. Round Two for MOF Commercialization. Available online: https://cen.acs.org/articles/95/i24/Round-two-MOF-commercialization.html (accessed on 10 March 2021).

- Faust, T. MOFs move to market. Nat. Chem. 2016, 8, 990–991. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Zheng, L.; Yang, Y.; Qian, X.; Fu, T.; Li, X.; Yang, Z.; Yan, H.; Cui, C.; Tan, W. Metal–Organic Framework Nanocarriers for Drug Delivery in Biomedical Applications. Nano-Micro Lett. 2020, 12, 103. [Google Scholar] [CrossRef]

- Ahmed, A.; Seth, S.; Purewal, J.; Wong-Foy, A.G.; Veenstra, M.; Matzger, A.J.; Siegel, D.J. Exceptional hydrogen storage achieved by screening nearly half a million metal-organic frameworks. Nat. Commun. 2019, 10, 1568. [Google Scholar] [CrossRef] [Green Version]

- Niermann, M.; Drünert, S.; Kaltschmitt, M.; Bonhoff, K. Liquid organic hydrogen carriers (LOHCs)—Techno-economic analysis of LOHCs in a defined process chain. Energy Environ. Sci. 2019, 12, 290–307. [Google Scholar] [CrossRef]

- U.S. Energy Information Association. Weekly Natural Gas Storage Report. Available online: https://ir.eia.gov/ngs/ngs.html (accessed on 15 April 2021).

- Magnum Development. Magnum Development and Mitsubishi Hitachi Power Systems to Develop 1000 Megawatts of Clean Energy Storage in Central Utah. Available online: https://magnumdev.com/ (accessed on 15 April 2021).

- Energy Information Administration. The Basics of Underground Natural Gas Storage. Available online: http://large.stanford.edu/publications/power/references/gastore/ (accessed on 16 April 2021).

- Tarkowski, R. Underground hydrogen storage: Characteristics and prospects. Renew. Sustain. Energy Rev. 2019, 105, 86–94. [Google Scholar] [CrossRef]

- Bünger, U.; Michalski, J.; Crotogino, F.; Kruck, O. 7—Large-scale underground storage of hydrogen for the grid integration of renewable energy and other applications. In Compendium of Hydrogen Energy; Ball, M., Basile, A., Veziroğlu, T.N., Eds.; Woodhead Publishing: Oxford, UK, 2016; pp. 133–163. [Google Scholar] [CrossRef]

- Penev, M.; Hunter, C. Regional Supply of Hydrogen. Available online: https://www.hydrogen.energy.gov/pdfs/review18/sa063_penev_2018_p.pdf (accessed on 16 April 2021).

- U.S. Energy Information Association. Natural Gas Explained—Natural Gas Pipelines. Available online: https://www.eia.gov/energyexplained/natural-gas/natural-gas-pipelines.php (accessed on 10 April 2021).

- San Marchi, C.W.; Simmons, K.L. Considerations of Hydrogen Compatibility of Materials for Blending Hydrogen into the Natural Gas Network. United States, 2020-04-01. Available online: https://www.osti.gov/biblio/1775062-considerations-hydrogen-compatibility-materials-blending-hydrogen-natural-gas-network (accessed on 14 January 2021).

- National Renewable Energy Laboratory. New Report Analyzes Options for Blending Hydrogen into Natural Gas Pipelines. Available online: https://www.nrel.gov/news/program/2013/2143.html (accessed on 2 July 2021).

- National Renewable Energy Laboratory. HyBlend Project to Accelerate Potential for Blending Hydrogen in Natural Gas Pipelines. Available online: https://www.nrel.gov/news/program/2020/hyblend-project-to-accelerate-potential-for-blending-hydrogen-in-natural-gas-pipelines.html (accessed on 15 April 2021).

- Fuel Cell & Hydrogen Energy Association. Road Map to a U.S. Hydrogen Economy. Available online: https://static1.squarespace.com/static/53ab1feee4b0bef0179a1563/t/5e7ca9d6c8fb3629d399fe0c/1585228263363/Road+Map+to+a+US+Hydrogen+Economy+Full+Report.pdf (accessed on 28 December 2020).

- U.S. Department of Energy. Energy Department Announces Approximately $64M in Funding for 18 Projects to Advance H2@Scale. Available online: https://www.energy.gov/articles/energy-department-announces-approximately-64m-funding-18-projects-advance-h2scale (accessed on 8 December 2020).

- Hardy, B.; Ruth, M. Determining the Value Proposition of Materials-Based Hydrogen Storage for Stationary Bulk Storage of Hydrogen. Available online: https://www.hydrogen.energy.gov/pdfs/review21/st228_hardy_2021_o.pdf (accessed on 1 July 2021).

| Data Center Scale (m2) | Power Requirements (MW) | 24 h Backup H2 (Tonnes) | 72 h Backup H2 (Tonnes) |

|---|---|---|---|

| <10 | 0.1 | 0.14 | 0.43 |

| 1000 | 10 | 14.4 | 43.2 |

| >40,000 | 150 | 216 | 648 |

| Citadel | 650 1 | 936 | 2808 |

| Kolos | 1000 1 | 1440 | 4320 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Celestine, A.-D.N.; Sulic, M.; Wieliczko, M.; Stetson, N.T. Hydrogen-Based Energy Storage Systems for Large-Scale Data Center Applications. Sustainability 2021, 13, 12654. https://doi.org/10.3390/su132212654

Celestine A-DN, Sulic M, Wieliczko M, Stetson NT. Hydrogen-Based Energy Storage Systems for Large-Scale Data Center Applications. Sustainability. 2021; 13(22):12654. https://doi.org/10.3390/su132212654

Chicago/Turabian StyleCelestine, Asha-Dee N., Martin Sulic, Marika Wieliczko, and Ned T. Stetson. 2021. "Hydrogen-Based Energy Storage Systems for Large-Scale Data Center Applications" Sustainability 13, no. 22: 12654. https://doi.org/10.3390/su132212654

APA StyleCelestine, A.-D. N., Sulic, M., Wieliczko, M., & Stetson, N. T. (2021). Hydrogen-Based Energy Storage Systems for Large-Scale Data Center Applications. Sustainability, 13(22), 12654. https://doi.org/10.3390/su132212654