1. Introduction

In most countries, the ISO 14001 environmental management system has become compulsory in business operations [

1], so governments have developed guidelines for green regulations to be applied by all organizations [

2]. Organizations have to follow governmental environmental regulations to sustain environmental practices and to maximize their profits [

3,

4]. Environmental regulations and liabilities for hazardous products motivated organizations to incorporate GSCM practices into their operations [

5] to reduce industry challenges that affect the environment [

6]. The awareness of worldwide governments of environmental issues is increasing and some governments subsidize organizations for their green activities [

7,

8]

Due to globalization, organizations all over the world are under pressure to balance sustainable development related to social, economic, and environmental issues [

9], and to reform their activities to be competitive and sustainable [

10,

11]. Public awareness about environmental issues is increasing, which affects all business activities [

12]. Stakeholders keep continuous pressure on organizations to perform more environmentally friendly activities, which include green supply chain activities to create a competitive advantage [

13,

14]. Recent environmental and climate changes have forced organizations to consider the GSCM and develop a corporate environmental strategy for all products and processes to reduce waste and pollution, affecting the supply chain performance, competitive advantage, long-term survival, profitability, and business performance [

2,

15,

16]. Over the past few decades, several environmental changes took place, which necessitates environmentally friendly practices for organizations’ competition and survival [

1]. Organizations face ecological challenges and need green technologies to improve environmental performance and competitive position [

9]. Environmentally friendly processes and technologies prevent and reduce waste, including emissions, and create a competitive advantage [

13]. The industrial revolution created many challenges and increased environmental awareness, which forced organizations to change their environmental practices [

6,

17,

18]. Organizations should include environmental and social considerations in their procurement processes [

19,

20].

The purpose of GSCM is a clean environment in general, which includes clean and safe operations through reducing the use of hazardous substances, increased use of recycling products, renewable energy, and improving the information available to stakeholders [

1]. GSCM can be defined as adopting environmental management principles in all processes and practices in and between organizations, which are the members of the supply chain [

12]. GSCM is a strategy that helps to maintain social, economic, environmental, and national security [

21]. Organizations must integrate environmental management into their supply chain strategy to create sustainable competitiveness [

22]. Nowadays, with an escalating competition of the global market, organizations must implement corporate social responsibility indicators to improve environmental performance, financial performance, and to gain a competitive advantage [

3]. Environmental strategies are the primary sources of organizations’ competitive advantage [

23,

24,

25,

26]. GSCM reduces waste and pollutants to increase organization competitiveness by improving service quality, productivity, and profits [

27]. The environmental sustainability of the supply chain is critical for logistics service providers and their competitive advantage [

28]. GSCM aims to reduce the negative environmental effects of sourcing, purchasing, production, and distribution activities [

4]. Organizations should focus on the management of the whole supply chain to design and develop an environmentally friendly and sustainable supply chain network to enhance both competitive competence and sustainability [

29]. GSCM involves all supply chain processes and activities related to green procurement, green manufacturing, green sales, green logistics, green consumption, and green recycling [

30]. Green processes should be considered in every SC step [

11]. GSCM practices (green purchasing, eco-design, reverse logistics) reduce material waste and energy consumption to produce green products and reduce operations costs, which affect organizational performance [

10]. GSCM activities (eco-design, green purchasing, and green information systems) affect environmental performance, economic performance, operational performance, and organizations’ competitiveness [

31]. Organizations use GSCM for business operations to maintain environmental sustainability and achieve competitive advantages [

32]. Environmental innovations and development in the supply chain are critical to maximize performance and develop a sustainable competitive advantage [

33,

34]. GSCM uses different mechanisms to improve manufacturing efficiency by reducing pollution and waste in manufacturing, improving product quality and delivery, and reducing costs [

18]. Innovative GSC activities improve organizations’ performance and create a competitive advantage [

35,

36].

The above introduction shows that implementing GSCM is not an option; it is compulsory for all organizations, whatever they do and wherever they work, to be able to sustain their business and improve performance and achieve competitive advantage. However, the debate is about how GSCM affects organizations’ performance and competitive advantage is still ongoing. This research aims to investigate how Jordanian pharmaceutical manufacturing organizations implement GSCM practices and how the three main components of GSCM (green purchasing, green operation, and green selling) affect competitive advantage dimensions (cost, quality, time, reliability/flexibility, and innovation). Therefore, this research is dedicated to answering the following questions: Do Jordanian pharmaceutical manufacturing organizations implement GSCM within their daily practices? In addition, what are the effects of the three main GSCM components on the competitive advantage dimensions of Jordanian pharmaceutical manufacturing organizations? After the introduction, this research starts with hypothesis development, then literature review, methodology and data analysis, discussion of results, and finally, conclusions, recommendations, and practical and social implications.

This research starts with an introduction to the importance of the green supply chain and its effect on competitive advantage. This is followed by the discussion of a practical and theoretical research gap to develop a hypothesis and research model, and then, a review of related studies. Overall, the research methodology includes data collection and analysis, research results, discussion, conclusions, limitations, recommendations, and practical and social implications.

2. Hypothesis Development

Environmental pollution has pushed scientists, researchers, policymakers, and ecologists to react rapidly to find solutions to mitigate further environmental deterioration [

18]. The relationship between GSCM and competitive advantages is an interesting topic for both academicians and professionals, but there is no consensus about the positive effect of GSCM on competitive advantages [

24] The global debate in this regard is growing [

2,

31].

Limited research has empirically examined the effect of green internal integration and external collaboration on green performance and organizations’ competitiveness [

37]. There is a lack of studies related to relationships between GSC and competitive advantage and success [

38]. There is a research gap related to the relationship between GSCM and competitive strategy [

14]. Previous studies do not discuss in depth how GSCM practices contribute to organizations’ competitiveness [

13] or impact. Research in the field of GSCM did not thoroughly investigate the effect of GSCM on green performance and organizational competitiveness [

27]. Most studies do not explain why organizations pursue GSCM practices and how such practices enhance organizational performance and competitive advantage [

10]. Furthermore, previous research on GSCM practices has failed to identify the effect of various factors on environmental performance and competitive advantage [

39]. Current literature does not thoroughly examine the effect of GSCM on environmental performance and competitive advantage [

40]. Organizations should focus on the management of the whole supply chain to enhance their competitive competencies and sustainability [

29]. From the discussion above, it seems that there is a debate about the effect of green supply chain components on organizations’ competitive advantage. Since the main components of the supply chain are procurement, internal operations, and selling, the following hypothesis is developed:

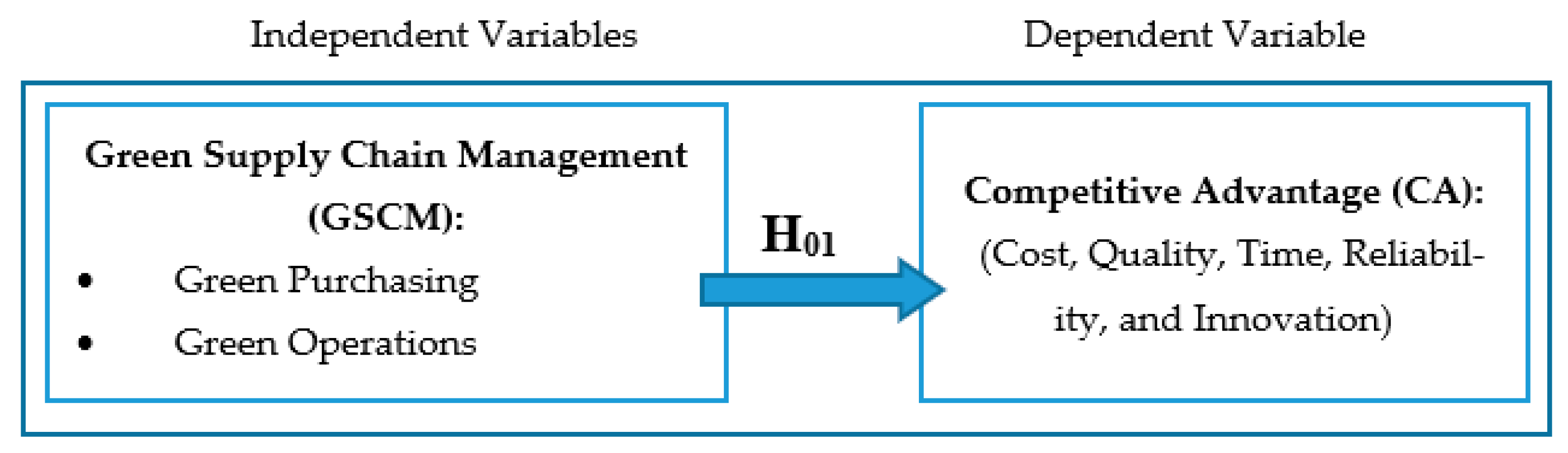

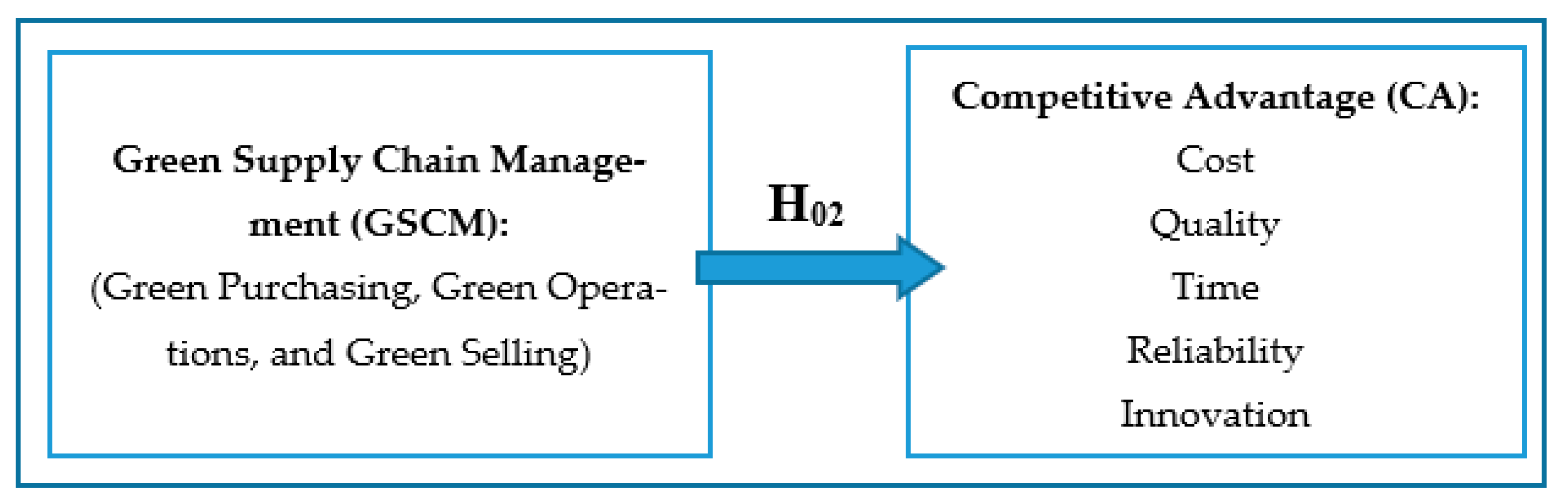

Hypothesis 1 (H1). Green supply chain components (green purchasing, green internal operations, and green selling) do not affect the competitive advantage of Jordanian pharmaceutical manufacturing organizations, at α ≤ 0.05.

Only a few studies have investigated the impact of implementing GSCM on the operational competitive performance related to quality, cost, flexibility, delivery time, and cost [

4]. Overall, green purchasing improves quality, delivery, and cost [

41]. Tan et al. concluded that GSCM improves product quality and delivery and reduces costs. Other authors [

3,

9] concur that GSCM enhances quality, flexibility, reliability, delivery, and reduces costs. Generally, green environmental practices reduce costs but not flexibility, while green purchasing improves quality, flexibility, and delivery time, but does not reduce the cost. Additionally, green purchasing practices improve operational performance and reduce inventory [

4]. Green internal environmental practices improve delivery time, quality, and cost. Green procurement and green supplier-customer collaboration affect costs, quality, and delivery [

18]. It seems to be there is a debate about the effect of GSCM on different competitive advantage components; therefore, the following hypothesis is developed:

Hypothesis 2 (H2). Green supply chain does not affect competitive advantage dimensions (cost, quality, time, reliability, and innovation) of Jordanian pharmaceutical manufacturing organizations, at α ≤ 0.05.

4. Literature Review

The following section includes brief conclusions of previous related literature about the relationship between GSCM and competitive advantage; they are arranged according to publishing year.

Sustainable development considers the three P’s (people, profit, and planet) to create the green value chain, which in turn creates a sustainable competitive advantage [

1]. GSCM elements (green manufacturing, green purchasing, green distribution, and green logistics) strongly affect competitive advantage and organizations’ performance [

22]. There is a strong relationship between environmental practices (green purchase, customer cooperation, and investment recovery) and corporate performance and competitiveness [

42]. There are relationships between GSCM practices (reduce hazardous substances and waste material, reuse, and recycle materials) and environmental performance, operational performance, competitive advantage, and financial performance [

21]. There are relationships among internal green practices, external green integration, green performance, and an organizations’ competitiveness. Internal green practices and external green collaboration positively affect green performance, which in turn enhances firm competitiveness [

43]. GSCM reduces the negative environmental effect of manufacturing activities, increases energy utilization efficiency, and reduces production costs, which increases competitiveness through improving quality, flexibility, reliability, delivery, and costs [

3]. The literature review of many research papers showed that GSC practices create sustainable competitive advantages [

24]. Implementing GSCM within the three drivers of environmental, social, and economic performance creates and sustains a company’s competitive advantage. Better use of these drivers improves internal resource utilization and external relationships [

23]. Using GSCM in the transportation of raw materials and/or finished products minimizes gas emissions, risks, and overall supply chain costs [

29]. DHL, for example, uses innovative green technologies to be more environmentally friendly throughout SCM, which reduces its ecological effect, improves quality, reliability, performance, and energy efficiency, which in turn combine to reduce costs and enhance the company’s economic performance and competitive position [

9]. There are strong relationships among GSCM, supply chain performance, and competitive advantage. GSCM practices affect supply chain management to achieve competitive advantage. Supply chain management and environmentally friendly practices (green purchasing, green manufacturing, green distribution, and reserve logistic) affect competitive advantage [

15]. The integration of the three GSC dimensions (internal, supplier, and customer integration) to develop green product strongly affect incremental environmental innovation, while only customer integration affects radical environmental innovation [

25].

Collaborations with upstream and downstream supply chain partners improve GSCM practices (pollution prevention, product stewardship, and sustainable development), which affect organizations’ assets and competencies, in turn creating competitive advantage. Integration with all supply chain partners to facilitate knowledge sharing, competency building, and coordination skills leads to accumulating highly valuable and rare resources and capabilities to achieve competitive advantage [

13]. GSCM reduces the environmental effect of manufacturing organizations by eliminating production waste, which reduces environmental costs and improves GSC capability and competitive advantage [

38]. Adopting GSCM in all supply chain stages (green purchasing, green manufacturing, and green distribution) and all the processes (supply, manufacturing, shipping, storing, sale, and after the sale services) reduces costs and increases patient satisfaction [

12]. There are relationships among green suppliers, green innovation, environmental performance, and competitive advantage. Green innovation affects environmental performance, which in turn affects competitive advantage. The collaboration with suppliers affects green innovation and environmental performance. Green innovation affects environmental performance and competitive advantage [

2]. GSCM practices (green procurement, green production, green distribution, and reverse logistics) affect environmental performance and organizations’ competitiveness. They reduce waste and improve operational efficiency, which in turn improves financial performance and competitive advantage [

19]. There is a relationship between GSC practices green purchasing, green manufacturing, and investment recovery (reverse logistics) and organizations’ competitiveness. Both green production and green purchasing directly affect competitiveness. Green production (reuse, reduce, recycle) reduces material costs and total production costs. Green purchasing improves quality, cost, and delivery [

41]. Interaction among the GSCM processes (eco-design, IT infrastructure integration, process integration capabilities, and internal environmental management) improves organizational performance and competitive advantage [

16]. GSC elements (green consumption, green packaging, green transportation and distribution, green production, green design, green marketing, green supplier, and green purchasing) affect organizations’ performance [

26]. An organization’s upstream supply chain involves a supplier network and other stakeholders. The downstream supply chain involves logistics, intermediaries, and retailers that support the prevention of waste and/or emissions. Organizations should develop partnerships with global suppliers, wholesalers, and retailers to reuse and recycle products. Environmentally oriented resources and capabilities should be accumulated over time, which leads to competitive advantage [

13].

One case study on tea products found that there is a relationship between GSC and long-term competitiveness, but that there are many barriers to applying GSC, such as managers’ weak commitment, small handicraft production, trading, quality of human resources, and difficulties of logistics management [

44]. GSCM improves green performance, which in turn increases organizations’ competitiveness. Internal green practices affect external green collaboration, which affects an organization’s green performance [

27]. GSCM strategy and competitive strategy are strongly related. Organizations use GSCM to differentiate their products and services and to minimize the risk created by suppliers [

14]. The leading logistics service providers use GSCM better than other organizations to create competitive priorities. GSCM practices are positively related to environmental performance, but not to financial performance [

28]. There are strong relationships between GSCM practices (green purchasing, green environment) and organizations’ operational competitive performance (quality, flexibility, cost, and delivery time). Green environmental practices reduce costs due to the practice of reverse logistics but do not improve flexibility, while green purchasing improves material sourcing, quality, flexibility, and delivery time, but does not reduce the cost. Green internal environmental practices improve delivery time, quality, and cost. Operational performance satisfies customer needs related to quality, flexibility, delivery time, and cost. Eco-design improves operational performance, reduces inventory, improves product flexibility, and enhances quality [

4]. GSCM involves all supply chain processes and activities related to green procurement, green manufacturing, green sales, green logistics, green consumption, and green recycling; they improve GSC performance and competitive advantage [

30]. All organizations should organize and enhance supply chain cooperation to create competitive advantages [

32]. Green purchasing has the most significant effect on both manufacturing and marketing performances. Internal environmental management affects manufacturing and marketing performances, whereas cooperation with customers and reverse logistics have no significant effect on organizations’ manufacturing and marketing performances [

10]. Eco-design, green information, and green purchasing directly affect organizations’ competitiveness. Competitiveness directly affects operational performance, environmental performance, and economic performance [

31]. Green SC initiatives affect both performance and competitive advantage [

11]. Competitive pressure for environmental management is a driving force for SMEs to incorporate internal and external collaboration in developing green product innovation. Organizations must implement the internal green product development process and then pursue external green management innovation with their suppliers and customers. Internal integration of green product innovation affects the external integration of green product innovation [

33]. There are relationships among all GSCM variables, which include internal environmental management, top management commitment, green purchasing, eco-design, cooperation with customers, environmental performance, supplier relations, economic benefits, markets, and regulations [

39]. There is a strong relationship between environmental responsibility and business performance [

45]. There are strong relationships among GSCM practices (green manufacturing, green procurement, green marketing, and green logistics), non-finance performance, and competitive advantages. Green procurement, green manufacturing, green marketing, and green logistics affect non-financial performance. Green manufacturing and green logistics affect financial performance, but green purchasing and green marketing do not [

33,

34]. Green procurement and green supplier and customer collaboration affect both environmental performance and competitiveness related to cost, quality, and delivery [

18]. All GSCM practices positively affect environmental performance [

46]. The main barriers for GSCM initiatives include high costs, lack of government support, and pressure to reduce selling prices [

17]. There are many obstacles related to GSCM implementation in the pharmaceutical industry. For example, a company lacks environmental knowledge and government support, and its employees did not believe in environmental advantages and green production [

47]. GSC integration includes green production, inventory, location, transportation, and packaging, all of which are important to achieve the best combination of responsiveness and efficiency. Aligning GSCM with marketing strategies is important for organizational performance [

20]. Thailand’s manufacturing organizations, for example, highly implement GSC practices that affect organizations’ business performance and competitiveness [

35]. GSCM enhances sustainable development, organization performance, and competitive advantage [

48]. There is a strong relationship between GSCM (green market orientation, GSC relationship quality, and green absorptive capacity) and green competitive advantage. Greenmarket orientation and GSC relationship quality affect green competitive advantage. Green absorptive capacity does not directly affect green competitive advantage. The employee culture and the environmentally responsible employees are key in ensuring GSC relationship quality, green absorptive capacity, and green competitive advantage [

5]. GSCM is crucial for the healthcare industry, which includes social, economic, and environmental responsibility to reduce all types of waste [

6]. Government subsidies on green products and tax policies concerning non-green products affect the profitability of supply chain members [

7]. GSCM practices (green design, green purchasing, green manufacturing, green distribution, and packaging) affect environmental performance and create a competitive advantage [

40].

One case study examines how green marketing components (green product, green price, green promotion, and green place) affect the competitive advantage of Palestine Cellular Communications, or “Jawwal” [

49]. Additionally, green supply chain management practices (green purchasing, green packaging, green manufacturing, green design, and green marketing) affect organizations’ performance in the shipping and automobile industry. Green manufacturing has the largest impact in this regard, followed by green marketing and green purchasing. However, green packaging and green design negatively affect organizations’ performance, according to [

50]. The authors of [

51] examined how internal social capital and logistics capabilities affect supply chain risk management capabilities, which influence supplier performance in public healthcare organizations in Uganda. There are strong relationships between supply chain management practices, logistics capabilities, logistics integration, and the competitive advantage of SMEs particularly in a developing country, according to [

52].

From the above literature review, we can conclude that in general, GSCM components affect competitive advantage, but the debate is about which GSCM component affects CA more than others.

5. Research Methodology

This research is quantitative; it uses a cross-sectional sample method to test the cause and effect relationship of GSCM on organizations’ competitive advantage. The primary data were collected by questionnaires, which were developed based on previous studies and tailored according to the pharmaceutical industry. All Jordanian pharmaceutical manufacturing organizations were targeted (14 organizations registered in the Jordanian Pharmaceutical Manufacturing Association), which negates the need for sampling. Data were collected from different manager levels, and then answers were checked, coded, and registered against SPSS.

Two types of data were used to develop the research concept, model, hypothesis, and questionnaire. First, secondary data were collected from books, scientific research papers, journals, dissertations, theses, and the Internet. Then, primary data were collected via the questionnaire, which was developed based on previous literature and tailored to fit the purpose of this research, Jordanian culture, and the country’s pharmaceutical industry. The questionnaire included three sections: demographic information, independent variables, and dependent variables.

The demographic section includes gender, age, experience, education, position, and department or division. Based on previous studies, the independent variable, green supply chain management (GSCM), was divided into three sub-variables as follows: green purchasing (supplier), green operations (internally), and green selling (customer). Each sub-variable was measured by seven questions. The dependent variable competitive advantage was divided into five sub-variables: cost, quality, speed (time), reliability (flexibility), and innovation. Each sub-variable was measured by five questions. A five-point Likert scale was used to rate the implementation of each paragraph from “1” not implemented at all to “5” highly implemented.

7. Discussion

The results show that Jordanian pharmaceutical manufacturing organizations implement green selling and green purchasing, but weakly implement green operations. At the same time, for competitive advantage dimensions, the results show that Jordanian pharmaceutical organizations are highly concerned with reliability, then quality, and speed (time), and are less concerned with cost reduction and innovation. I believe this to be a logical result because there are strong regulations and guidelines for the pharmaceutical manufacturing industry in Jordan, such as good manufacturing practices (GMP) and international norms and standards. Secondly, Jordanian pharmaceutical manufacturing organizations are small and generic organizations that manufacture old products already invented by multinational companies. Therefore, they take time to implement new standards and their financial positions do not allow them to align with recent technological development. Previous studies show many reasons for the weak GSCM implementations, namely the many barriers such as weak managerial commitment, small handicraft production, and trading, quality of human resources, and the difficulties of logistics management [

44]. Other obstacles related to GSCM implementation in the pharmaceutical industry include a lack of environmental knowledge, government support, and employees’ beliefs about GSCM environmental advantages and green production [

47]. The main barriers for GSCM initiatives include high costs, lack of government support, and pressure to reduce selling prices [

17].

Moreover, the results of this study show that the relationships among GSCM components are medium to strong; the relationships among competitive advantage dimensions are medium to strong; and finally, the relationship between GSCM and competitive advantage is very strong. These results correspond with most previous literature in concluding that there is a strong relationship between environmental practices and corporate performance and competitiveness [

42]. There is a relationship between GSCM practices, environmental performance, operational performance, competitive advantage, and financial performance [

21]. There are relationships among internal green practices, external green integration, green performance, and an organizations’ competitiveness [

43]. There are strong relationships among GSCM, supply chain performance, and competitive advantage [

15]. There are relationships among green suppliers, green innovation, environmental performance, and competitive advantage [

2]. There is a relationship between GSC practices (green purchasing, green manufacturing, and investment recovery (reverse logistics)) and organizations’ competitiveness [

41]. There is a relationship between GSC and long-term competitiveness [

44]. GSCM strategy and competitive strategy are strongly related [

14]. There are strong relationships between GSCM practices (green purchasing, green environment) and organizations’ operational competitive performance (quality, flexibility, cost, and delivery time) [

4]. There are relationships among all GSCM variables, namely green purchasing, eco-design, cooperation with customers, environmental performance, supplier relations, and economic benefits [

39]. There are strong relationships among GSCM practices (green manufacturing, green procurement, green marketing, and green logistics), non-financial performance, and competitive advantages [

33,

34]. There is a strong relationship between GSCM (green market orientation, GSC relationship quality, and green absorptive capacity) and green competitive advantage [

5].

For the first hypothesis, the study results show that green supply chain components (green purchasing, green internal operations, and green selling) affect the competitive advantage of Jordanian pharmaceutical manufacturing organizations, at α ≤ 0.05, where green operations have the highest effect on total CA, then green purchasing and green selling. For the second hypothesis, the results show that green supply chain affects competitive advantage dimensions (cost, quality, time, reliability, and innovation) of Jordanian pharmaceutical manufacturing organizations, at α ≤ 0.05, where GSCM highly affects quality, then innovation and time, but does not have a significant effect on reliability and cost. These results correspond with most of the previous studies and contradict a few previous studies, especially for those related to non-significant sub-variables, which may be related to industry differentiation. GSCM elements (green manufacturing, green purchasing, green distribution, and green logistics) strongly affect competitive advantage and organizations’ performance [

22]. Internal green practices and external green collaboration positively affect green performance, which in turn enhances firm competitiveness [

37]. GSCM reduces production costs, which increases competitiveness through improving quality, flexibility, reliability, delivery, and cost [

3]. Better use of GSCM drivers affect organizations’ performance and competitive advantage [

55]. DHL, for example, uses innovative green technologies to improve quality, reliability, performance, and energy efficiency [

9]. GSCM practices (green purchasing, green manufacturing, green distribution, and reserve logistic) affect organizations’ competitive advantage [

15]. GSCM reduces production waste and environmental costs and improves competitive advantage [

38]. Adopting GSCM activities (green purchasing, green manufacturing, and green distribution) reduces costs and increases consumer satisfaction [

12]. GSCM practices (green procurement, green production, green distribution, and reverse logistics) reduce waste and improve operational efficiency, financial performance, and competitive advantage [

19]. Both green production and green purchasing directly affect competitiveness. Green production reduces cost. Green purchasing improves quality, cost, and delivery [

41]. GSC elements (green consumption, green packaging, green transportation and distribution, green production, green design, green marketing, green supplier, and green purchasing) affect an organization’s performance [

26]. Internal green practices affect external green collaboration, which affects an organization’s green performance and competitiveness [

27]. Green environmental practices reduce costs but do not improve flexibility, while green purchasing improves quality, flexibility, and delivery time, but does not reduce costs. Green internal environmental practices improve delivery time, quality, and costs [

4]. Green purchasing has the highest effect on both manufacturing and marketing performances, and then internal environmental management, whereas cooperation with customers and reverse logistics have no significant effect on an organization’s manufacturing and marketing performances [

10]. Green procurement and green supplier and customer collaboration affect both environmental performance and competitiveness related to cost, quality, and delivery [

18]. All GSCM practices positively affect environmental performance [

46]. GSCM reduces all types of waste and affects competitive advantage [

6]. GSCM practices (green design, green purchasing, green manufacturing, green distribution, and packaging) affect environmental performance and create a competitive advantage [

40].

Finally, the misconduct of some people and some business operational processes are extremely harmful to the environment, which affect human health and can cause serious diseases [

50]. This also creates many challenges for the supply chain. For example, during COVID-19 the global supply chain was significantly disrupted, which negatively affected organizations’ performance [

56]. In particular, the global healthcare supply chain was disrupted and suffered from many problems and shortages, which increased the cost to maintain supply chain performance [

51]. At the same time, nowadays, people and governments are keeping pressure on organizations to improve their environmental performance and to balance their economic, social, and environmental performances to gain a competitive advantage [

50,

57]. Moreover, organizations should be ready to face such crises and should review and update their strategies and business models to pursue market opportunities [

56]. Supply chains rely on traditional systems for information sharing for supply tracking, and this also needs to be improved to enhance decision-making processes. Therefore, there is a need to conduct a strategic evaluation for assessing supply chain management [

57]. Blockchain is one of the emerging technologies that can enhance the complex processes of supply chain management and logistics [

57]. Moreover, green marketing (green product, green price, green promotion, and green place) enhances environmental awareness and social responsibility to provide customers with environmentally safe products and services and create a competitive advantage for companies [

49].