Some Remarks towards a Better Understanding of the Use of Concrete Recycled Aggregate: A Review

Abstract

:1. Introduction

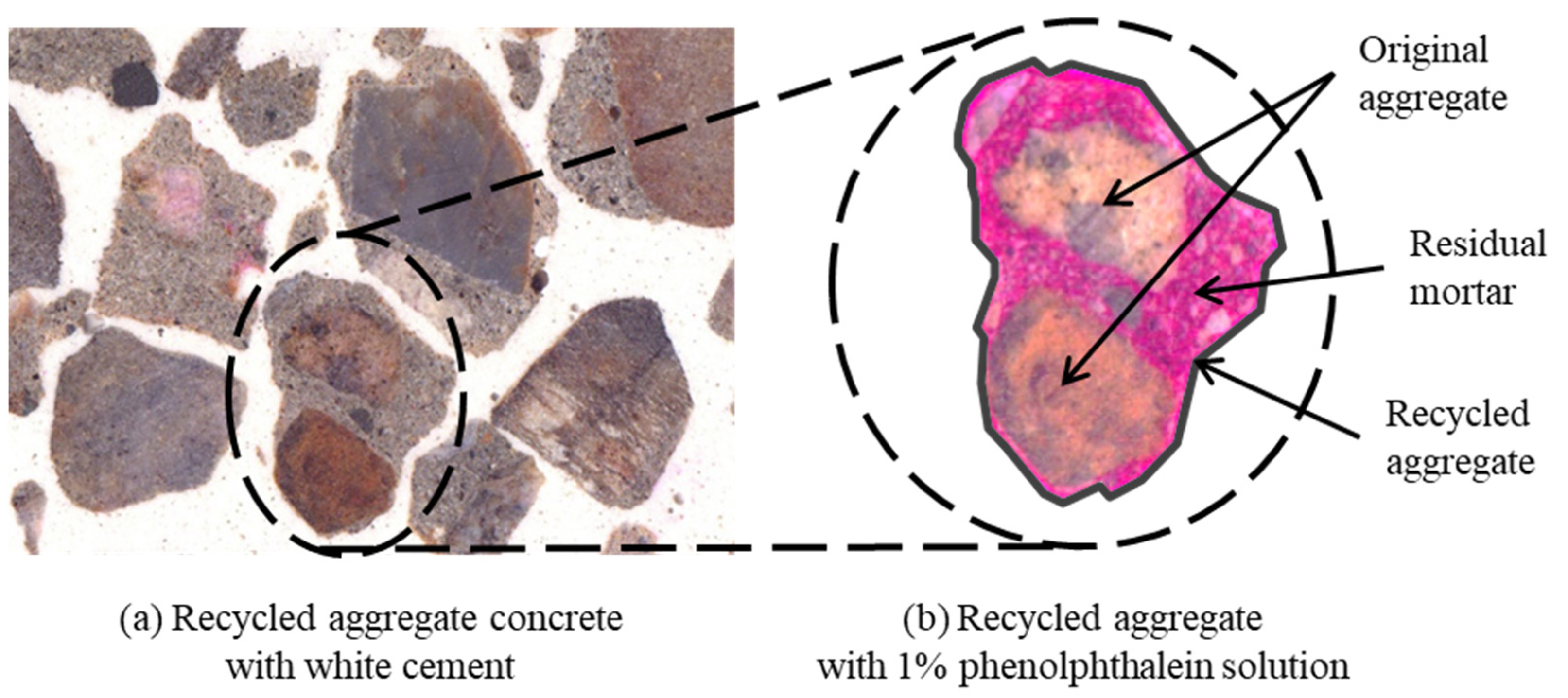

2. Recycled Concrete Aggregate

2.1. Characteristics

2.2. Production of Recycled Concrete Aggregate

3. Recycled Aggregate Concrete

3.1. The Effect of Parent Concrete on the Properties of Next Generation Concrete

3.2. The Effect of Repeated Use of Recycled Concrete Aggregate

3.3. Standards of Recycled Aggregate for Concrete

3.4. Barriers to the Use of Recycled Aggregate Concrete in Practice

3.4.1. Imbalance in Supply and Demand

3.4.2. Economic Viability

3.4.3. Negative Perceptions

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- USGS. Mineral Commodity Summaries 2021; USGS: Reston, VA, USA, 2021.

- UEPG. A Sustainable Industry for a Sustainable Europe; Annual Report; UEPG: Brussels, Belgium, 2020. [Google Scholar]

- PMR. Global Construction Aggregates Market; PMR: New York, NY, USA, 2020. [Google Scholar]

- Eurostat. Available online: https://ec.europa.eu/eurostat/tgm/refreshTableAction.do?tab=table&plugin=1&pcode=ten00106&language=en (accessed on 2 March 2021).

- EPA. Construction and Demolition Debris: Material-Specific Data. Available online: https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/construction-and-demolition-debris-material (accessed on 7 July 2021).

- Shi, J.; Xu, Y. Estimation and forecasting of concrete debris amount in China. Resour. Conserv. Recycl. 2006, 49. [Google Scholar] [CrossRef]

- Sobotka, A.; Sagan, J.; Sikora, A. Logistyka odzysku w remontach obiektów budowlanych. Mater. Bud. 2016, 134–136. [Google Scholar] [CrossRef]

- Eurostat. Generation of Waste by Waste Category, Hazardousness and NACE Rev. 2 Activity. Available online: https://ec.europa.eu/eurostat/databrowser/view/env_wasgen/default/table?lang=en (accessed on 14 November 2021).

- Jin, J.; Wang, Z.; Ran, S. Solid waste management in Macao: Practices and challenges. Waste Manag. 2006, 26, 1045–1051. [Google Scholar] [CrossRef] [PubMed]

- Kim, J. Construction and demolition waste management in Korea: Recycled aggregate and its application. Clean Technol. Environ. Policy 2021, 23, 2223–2234. [Google Scholar] [CrossRef]

- Aragão, H.G. Análise Estrutural de Lajes Pré-Moldadas Produzidas com Concreto Reciclado de Construção e Demolição; Universidade Federal de Alagoas: Maceió, Brazil, 2007. [Google Scholar]

- Assessment, M.E. Ecosystems and Human Well-Being; Island Press: Washington, DC, USA, 2005; Volume 5. [Google Scholar]

- Grabiec, A.M.; Zawal, D.; Rasaq, W.A. The effect of curing conditions on selected properties of recycled aggregate concrete. Appl. Sci. 2020, 10, 4441. [Google Scholar] [CrossRef]

- Rahal, K. Mechanical properties of concrete with recycled coarse aggregate. Build. Environ. 2007, 42, 407–415. [Google Scholar] [CrossRef]

- Tavakoli, M.; Soroushian, P. Strengths of recycled aggregate concrete made using field-demolished concrete as aggregate. Mater. J. 1996, 93, 178–181. [Google Scholar]

- Ajdukiewicz, A.B.; Kliszczewicz, A.T. Comparative tests of beams and columns made of recycled aggregate concrete and natural aggregate concrete. J. Adv. Concr. Technol. 2007, 5, 259–273. [Google Scholar] [CrossRef] [Green Version]

- Storey, J.B. Construction Materials Stewardship: The Status Quo in Selected Countries: CIB W115; Centre for Building Performance Research, Victoria University of Wellington: Wellington, New Zealand, 2008; ISBN 906363059X. [Google Scholar]

- Eurostat. Record Recycling Rates and Use of Recycled Materials in the EU. Available online: https://ec.europa.eu/eurostat/documents/2995521/9629294/8-04032019-BP-EN.pdf/295c2302-4ed1-45b9-af86-96d1bbb7acb1 (accessed on 7 July 2021).

- Tam, V.W.Y.; Soomro, M.; Evangelista, A.C.J. A review of recycled aggregate in concrete applications (2000–2017). Constr. Build. Mater. 2018, 172, 272–292. [Google Scholar] [CrossRef]

- Malešev, M.; Radonjanin, V.; Marinković, S. Recycled concrete as aggregate for structural concrete production. Sustainability 2010, 2, 1204–1225. [Google Scholar] [CrossRef] [Green Version]

- Fathifazl, G.; Razaqpur, A.G.; Burkan Isgor, O.; Abbas, A.; Fournier, B.; Foo, S. Shear capacity evaluation of steel reinforced recycled concrete (RRC) beams. Eng. Struct. 2011, 33, 1025–1033. [Google Scholar] [CrossRef]

- Barreto Santos, M.; de Brito, J.; Santos Silva, A. A review on alkali-silica reaction evolution in recycled aggregate concrete. Materials 2020, 13, 2625. [Google Scholar] [CrossRef]

- Bravo, M.; Duarte, A.P.C.; de Brito, J.; Evangelista, L. Tests and simulation of the bond-slip between steel and concrete with recycled aggregates from CDW. Buildings 2021, 11, 40. [Google Scholar] [CrossRef]

- Bravo, M.; de Brito, J.; Pontes, J.; Evangelista, L. Shrinkage and creep performance of concrete with recycled aggregates from CDW plants. Mag. Concr. Res. 2017, 69, 974–995. [Google Scholar] [CrossRef]

- Bravo, M.; de Brito, J.; Pontes, J.; Evangelista, L. Durability performance of concrete with recycled aggregates from construction and demolition waste plants. Constr. Build. Mater. 2015, 77, 357–369. [Google Scholar] [CrossRef]

- Junak, J.; Sicakova, A. Effect of surface modifications of recycled concrete aggregate on concrete properties. Buildings 2017, 8, 2. [Google Scholar] [CrossRef] [Green Version]

- Silva, R.V.; de Brito, J.; Dhir, R.K. Fresh-state performance of recycled aggregate concrete: A review. Constr. Build. Mater. 2018, 178, 19–31. [Google Scholar] [CrossRef]

- Mi, R.; Pan, G.; Liew, K.M.; Kuang, T. Utilizing recycled aggregate concrete in sustainable construction for a required compressive strength ratio. J. Clean. Prod. 2020, 276, 124249. [Google Scholar] [CrossRef]

- Silva, R.V.; de Brito, J.; Dhir, R.K. Use of recycled aggregates arising from construction and demolition waste in new construction applications. J. Clean. Prod. 2019, 236. [Google Scholar] [CrossRef]

- Silva, R.V.; de Brito, J.; Dhir, R.K. Tensile strength behaviour of recycled aggregate concrete. Constr. Build. Mater. 2015, 83, 108–118. [Google Scholar] [CrossRef]

- Silva, R.V.; de Brito, J.; Dhir, R.K. Comparative analysis of existing prediction models on the creep behaviour of recycled aggregate concrete. Eng. Struct. 2015, 100, 31–42. [Google Scholar] [CrossRef]

- Papatzani, S.; Paine, K. Construction, demolition and excavation waste management in EU/Greece and its potential use in concrete. Fresenius Environ. Bull 2017, 26, 5572–5580. [Google Scholar]

- Silva, R.V.; de Brito, J.; Dhir, R.K. Availability and processing of recycled aggregates within the construction and demolition supply chain: A review. J. Clean. Prod. 2017, 143, 598–614. [Google Scholar] [CrossRef] [Green Version]

- Behera, M.; Bhattacharyya, S.K.; Minocha, A.K.; Deoliya, R.; Maiti, S. Recycled aggregate from C&D waste & its use in concrete—A breakthrough towards sustainability in construction sector: A review. Constr. Build. Mater. 2014, 68, 501–516. [Google Scholar] [CrossRef]

- Silva, R.V.; de Brito, J.; Dhir, R.K. Properties and composition of recycled aggregates from construction and demolition waste suitable for concrete production. Constr. Build. Mater. 2014, 65, 202–217. [Google Scholar] [CrossRef]

- Zhu, P.; Hao, Y.; Liu, H.; Wei, D.; Liu, S.; Gu, L. Durability evaluation of three generations of 100% repeatedly recycled coarse aggregate concrete. Constr. Build. Mater. 2019, 210, 442–450. [Google Scholar] [CrossRef]

- Huda, S.B.; Alam, M.S. Mechanical behavior of three generations of 100% repeated recycled coarse aggregate concrete. Constr. Build. Mater. 2014, 65, 574–582. [Google Scholar] [CrossRef]

- Abreu, V.; Evangelista, L.; de Brito, J. The effect of multi-recycling on the mechanical performance of coarse recycled aggregates concrete. Constr. Build. Mater. 2018, 188, 480–489. [Google Scholar] [CrossRef]

- Thomas, C.; de Brito, J.; Gil, V.; Sainz-Aja, J.A.; Cimentada, A. Multiple recycled aggregate properties analysed by X-ray microtomography. Constr. Build. Mater. 2018, 166, 171–180. [Google Scholar] [CrossRef] [Green Version]

- Zhu, P.; Zhang, X.; Wu, J.; Wang, X. Performance degradation of the repeated recycled aggregate concrete with 70% replacement of three-generation recycled coarse aggregate. J. Wuhan Univ. Technol. Sci. Ed. 2016, 31, 989–995. [Google Scholar] [CrossRef]

- Salesa, Á.; Pérez-Benedicto, J.A.; Colorado-Aranguren, D.; López-Julián, P.L.; Esteban, L.M.; Sanz-Baldúz, L.J.; Sáez-Hostaled, J.L.; Ramis, J.; Olivares, D. Physico-mechanical properties of multi-recycled concrete from precast concrete industry. J. Clean. Prod. 2017, 141, 248–255. [Google Scholar] [CrossRef]

- Marie, I.; Quiasrawi, H. Closed-loop recycling of recycled concrete aggregates. J. Clean. Prod. 2012, 37, 243–248. [Google Scholar] [CrossRef]

- Mi, R.; Pan, G.; Li, Y.; Kuang, T.; Lu, X. Distinguishing between new and old mortars in recycled aggregate concrete under carbonation using iron oxide red. Constr. Build. Mater. 2019, 222, 601–609. [Google Scholar] [CrossRef]

- Duan, Z.H.; Poon, C.S. Properties of recycled aggregate concrete made with recycled aggregates with different amounts of old adhered mortars. Mater. Des. 2014, 58, 19–29. [Google Scholar] [CrossRef]

- Thomas, C.; Setién, J.; Polanco, J.A.; Alaejos, P.; Sánchez De Juan, M. Durability of recycled aggregate concrete. Constr. Build. Mater. 2013, 40, 1054–1065. [Google Scholar] [CrossRef]

- Shi, M.; Ling, T.C.; Gan, B.; Guo, M.Z. Turning concrete waste powder into carbonated artificial aggregates. Constr. Build. Mater. 2019, 199, 178–184. [Google Scholar] [CrossRef]

- Etxeberria, M.; Vázquez, E.; Marí, A.; Barra, M. Influence of amount of recycled coarse aggregates and production process on properties of recycled aggregate concrete. Cem. Concr. Res. 2007, 37, 735–742. [Google Scholar] [CrossRef]

- De Juan, M.S.; Gutiérrez, P.A. Study on the influence of attached mortar content on the properties of recycled concrete aggregate. Constr. Build. Mater. 2009, 23, 872–877. [Google Scholar] [CrossRef]

- Suryawanshi, S.R.; Singh, B.; Bhargava, P. Characterization of recycled aggregate concrete. In Advances in Structural Engineering; Springer: Berlin/Heidelberg, Germany, 2015; pp. 1813–1822. [Google Scholar]

- Abbas, A.; Fathifazl, G.; Burkan Isgor, O.; Razaqpur, A.G.; Fournier, B.; Foo, S. Proposed method for determining the residual mortar content of recycled concrete aggregates. J. ASTM Int. 2008, 5, 1–12. [Google Scholar] [CrossRef]

- Arezoumandi, M.; Smith, A.; Volz, J.S.; Khayat, K.H. An experimental study on flexural strength of reinforced concrete beams with 100% recycled concrete aggregate. Eng. Struct. 2015, 88, 154–162. [Google Scholar] [CrossRef]

- Mi, R.; Liew, K.M.; Pan, G.; Kuang, T. Carbonation resistance study and inhomogeneity evolution of recycled aggregate concretes under loading effects. Cem. Concr. Compos. 2021, 118, 103916. [Google Scholar] [CrossRef]

- Sidorova, A.; Vazquez-Ramonich, E.; Barra-Bizinotto, M.; Roa-Rovira, J.J.; Jimenez-Pique, E. Study of the recycled aggregates nature’s influence on the aggregate-cement paste interface and ITZ. Constr. Build. Mater. 2014, 68, 677–684. [Google Scholar] [CrossRef]

- Afroughsabet, V.; Biolzi, L.; Ozbakkaloglu, T. Influence of double hooked-end steel fibers and slag on mechanical and durability properties of high performance recycled aggregate concrete. Compos. Struct. 2017, 181, 273–284. [Google Scholar] [CrossRef]

- Butler, L.J.; West, J.S.; Tighe, S.L. Towards the classification of recycled concrete aggregates: Influence of fundamental aggregate properties on recycled concrete performance. J. Sustain. Cem. Mater. 2014, 3, 140–163. [Google Scholar] [CrossRef]

- Nuaklong, P.; Sata, V.; Chindaprasirt, P. Influence of recycled aggregate on fly ash geopolymer concrete properties. J. Clean. Prod. 2016, 112, 2300–2307. [Google Scholar] [CrossRef]

- Gokce, A.; Nagataki, S.; Saeki, T.; Hisada, M. Freezing and thawing resistance of air-entrained concrete incorporating recycled coarse aggregate: The role of air content in demolished concrete. Cem. Concr. Res. 2004, 34, 799–806. [Google Scholar] [CrossRef]

- Kim, N.; Kim, J.; Yang, S. Mechanical strength properties of RCA concrete made by a modified EMV method. Sustainability 2016, 8, 924. [Google Scholar] [CrossRef] [Green Version]

- Yang, S.; Lee, H. Mechanical properties of recycled aggregate concrete proportioned with modified equivalent mortar volume method for paving applications. Constr. Build. Mater. 2017, 136, 9–17. [Google Scholar] [CrossRef]

- Fan, Y.; Xiao, J.; Tam, V.W.Y. Effect of old attached mortar on the creep of recycled aggregate concrete. Struct. Concr. 2014, 15, 169–178. [Google Scholar] [CrossRef]

- Padmini, A.K.; Ramamurthy, K.; Mathews, M.S. Influence of parent concrete on the properties of recycled aggregate concrete. Constr. Build. Mater. 2009, 23, 829–836. [Google Scholar] [CrossRef]

- Dimitriou, G.; Savva, P.; Petrou, M.F. Enhancing mechanical and durability properties of recycled aggregate concrete. Constr. Build. Mater. 2018, 158, 228–235. [Google Scholar] [CrossRef]

- Rajhans, P.; Chand, G.; Kisku, N.; Panda, S.K.; Nayak, S. Proposed mix design method for producing sustainable self compacting heat cured recycled aggregate concrete and its microstructural investigation. Constr. Build. Mater. 2019, 218, 568–581. [Google Scholar] [CrossRef]

- Pandurangan, K.; Dayanithy, A.; Om Prakash, S. Influence of treatment methods on the bond strength of recycled aggregate concrete. Constr. Build. Mater. 2016, 120, 212–221. [Google Scholar] [CrossRef]

- Domingo-Cabo, A.; Lázaro, C.; López-Gayarre, F.; Serrano-López, M.A.; Serna, P.; Castaño-Tabares, J.O. Creep and shrinkage of recycled aggregate concrete. Constr. Build. Mater. 2009, 23, 2545–2553. [Google Scholar] [CrossRef]

- Sasanipour, H.; Aslani, F. Durability properties evaluation of self-compacting concrete prepared with waste fine and coarse recycled concrete aggregates. Constr. Build. Mater. 2020, 236, 117540. [Google Scholar] [CrossRef]

- Fan, Y.; Niu, H.; Zhang, X. Impact of the properties of old mortar on creep prediction model of recycled aggregate concrete. Constr. Build. Mater. 2020, 239, 117772. [Google Scholar] [CrossRef]

- Abbas, A.; Fathifazl, G.; Isgor, O.B.; Razaqpur, A.G.; Fournier, B.; Foo, S. Durability of recycled aggregate concrete designed with equivalent mortar volume method. Cem. Concr. Compos. 2009, 31, 555–563. [Google Scholar] [CrossRef]

- Anike, E.E.; Saidani, M.; Ganjian, E.; Tyrer, M.; Olubanwo, A.O. Evaluation of conventional and equivalent mortar volume mix design methods for recycled aggregate concrete. Mater. Struct. 2020, 53, 1–15. [Google Scholar] [CrossRef]

- McGinnis, M.J.; Davis, M.; de la Rosa, A.; Weldon, B.D.; Kurama, Y.C. Strength and stiffness of concrete with recycled concrete aggregates. Constr. Build. Mater. 2017, 154, 258–269. [Google Scholar] [CrossRef]

- Gholampour, A.; Ozbakkaloglu, T. Time-dependent and long-term mechanical properties of concretes incorporating different grades of coarse recycled concrete aggregates. Eng. Struct. 2018, 157, 224–234. [Google Scholar] [CrossRef]

- Kim, Y.; Hanif, A.; Usman, M.; Park, W. Influence of bonded mortar of recycled concrete aggregates on interfacial characteristics—Porosity assessment based on pore segmentation from backscattered electron image analysis. Constr. Build. Mater. 2019, 212, 149–163. [Google Scholar] [CrossRef]

- KATS. KS L5201 Portland Cement; Korean Agency Technology Standards: Eumseong-gun, Korea, 2016.

- ASTM. ASTM C150/C150M-20 Standard Specification for Portland Cement; ASTM: West Conshohocken, PA, USA, 2020. [Google Scholar]

- Limbachiya, M.C.; Marrocchino, E.; Koulouris, A. Chemical-mineralogical characterisation of coarse recycled concrete aggregate. Waste Manag. 2007, 27, 201–208. [Google Scholar] [CrossRef]

- Bui, N.K.; Satomi, T.; Takahashi, H. Recycling woven plastic sack waste and PET bottle waste as fiber in recycled aggregate concrete: An experimental study. Waste Manag. 2018, 78, 79–93. [Google Scholar] [CrossRef]

- Kim, J.; Kim, N.; Yang, S. The effect of the residual mortar of recycled concrete aggregate on alkali silica reaction. Int. J. Highw. Eng. 2015, 17, 19–24. [Google Scholar] [CrossRef]

- Medina, C.; Zhu, W.; Howind, T.; Frías, M.; de Sánchez Rojas, M.I. Effect of the constituents (asphalt, clay materials, floating particles and fines) of construction and demolition waste on the properties of recycled concretes. Constr. Build. Mater. 2015, 79, 22–33. [Google Scholar] [CrossRef]

- Sánchez-Cotte, E.H.; Pacheco-Bustos, C.A.; Fonseca, A.; Triana, Y.P.; Mercado, R.; Yepes-Martínez, J.; Lagares Espinoza, R.G. The chemical-mineralogical characterization of recycled concrete aggregates from different sources and their potential reactions in asphalt mixtures. Materials 2020, 13, 5592. [Google Scholar] [CrossRef] [PubMed]

- Saravanakumar, P.; Abhiram, K.; Manoj, B. Properties of treated recycled aggregates and its influence on concrete strength characteristics. Constr. Build. Mater. 2016, 111, 611–617. [Google Scholar] [CrossRef]

- Martínez, I.; Etxeberria, M.; Pavón, E.; Díaz, N. Influence of demolition waste fine particles on the properties of recycled aggregate masonry mortar. Int. J. Civ. Eng. 2018, 16, 1213–1226. [Google Scholar] [CrossRef] [Green Version]

- Moreno-Pérez, E.; Hernández-Ávila, J.; Rangel-Martínez, Y.; Cerecedo-Sáenz, E.; Arenas-Flores, A.; Reyes-Valderrama, M.; Salinas-Rodríguez, E. Chemical and mineralogical characterization of recycled aggregates from construction and demolition waste from Mexico City. Minerals 2018, 8, 237. [Google Scholar] [CrossRef] [Green Version]

- Krour, H.; Trauchessec, R.; Lecomte, A.; Diliberto, C.; Barnes-Davin, L.; Bolze, B.; Delhay, A. Incorporation rate of recycled aggregates in cement raw meals. Constr. Build. Mater. 2020, 248, 118217. [Google Scholar] [CrossRef]

- Park, S.S.; Kim, S.J.; Chen, K.Q.; Lee, Y.J.; Lee, S.B. Crushing characteristics of a recycled aggregate from waste concrete. Constr. Build. Mater. 2018, 160, 100–105. [Google Scholar] [CrossRef]

- Rajan, B.; Singh, D. Investigation on effects of different crushing stages on morphology of coarse and fine aggregates. Int. J. Pavement Eng. 2020, 21, 177–195. [Google Scholar] [CrossRef]

- Matias, D.; de Brito, J.; Rosa, A.; Pedro, D. Mechanical properties of concrete produced with recycled coarse aggregates—Influence of the use of superplasticizers. Constr. Build. Mater. 2013, 44, 101–109. [Google Scholar] [CrossRef]

- Öztürk, A.U.; Erdem, R.T.; Kozanoglu, C. Investigation of crushing type of concrete aggregates on mechanical properties of concrete. Int. J. Mater. Eng. 2012, 2, 6–9. [Google Scholar] [CrossRef] [Green Version]

- Cepuritis, R.; Garboczi, E.J.; Jacobsen, S. Three dimensional shape analysis of concrete aggregate fines produced by VSI crushing. Powder Technol. 2017, 308, 410–421. [Google Scholar] [CrossRef] [Green Version]

- Ulsen, C.; Tseng, E.; Angulo, S.C.; Landmann, M.; Contessotto, R.; Balbo, J.T.; Kahn, H. Concrete aggregates properties crushed by jaw and impact secondary crushing. J. Mater. Res. Technol. 2019, 8, 494–502. [Google Scholar] [CrossRef]

- Kamani, M.; Ajalloeian, R. The effect of rock crusher and rock type on the aggregate shape. Constr. Build. Mater. 2020, 230, 117016. [Google Scholar] [CrossRef]

- Liu, Y.; Sun, W.; Nair, H.; Lane, D.S.; Wang, L. Quantification of aggregate morphologic characteristics with the correlation to uncompacted void content of coarse aggregates in Virginia. Constr. Build. Mater. 2016, 124, 645–655. [Google Scholar] [CrossRef]

- Nagataki, S.; Gokce, A.; Saeki, T.; Hisada, M. Assessment of recycling process induced damage sensitivity of recycled concrete aggregates. Cem. Concr. Res. 2004, 34, 965–971. [Google Scholar] [CrossRef]

- Pedro, D.; de Brito, J.; Evangelista, L. Performance of concrete made with aggregates recycled from precasting industry waste: Influence of the crushing process. Mater. Struct. 2015, 48, 3965–3978. [Google Scholar] [CrossRef]

- KORAS. Casebook of Recycled Aggregate and Recycled Aggregate Product; KORAS: Seoul, Korea, 2020. Available online: https://www.me.go.kr/home/file/readDownloadFile.do?fileId=158651&fileSeq=1 (accessed on 2 March 2021).

- Tam, V.W.Y.; Tam, C.M. Crushed aggregate production from centralized combined and individual waste sources in Hong Kong. Constr. Build. Mater. 2007, 21, 879–886. [Google Scholar] [CrossRef] [Green Version]

- Hiete, M. Waste management plants and technology for recycling construction and demolition (C&D) waste: State-of-the-art and future challenges. In Handbook of Recycled Concrete and Demolition Waste; Elsevier Inc.: Amsterdam, The Netherlands, 2013; pp. 53–75. ISBN 9780857096906. [Google Scholar]

- Tam, V.W.Y.; Tam, C.M.; Le, K.N. Removal of cement mortar remains from recycled aggregate using pre-soaking approaches. Resour. Conserv. Recycl. 2007, 50, 82–101. [Google Scholar] [CrossRef] [Green Version]

- Kim, Y.; Hanif, A.; Kazmi, S.M.S.; Munir, M.J.; Park, C. Properties enhancement of recycled aggregate concrete through pretreatment of coarse aggregates—Comparative assessment of assorted techniques. J. Clean. Prod. 2018, 191, 339–349. [Google Scholar] [CrossRef]

- Akbarnezhad, A.; Ong, K.C.G.; Zhang, M.H.; Tam, C.T.; Foo, T.W.J. Microwave-assisted beneficiation of recycled concrete aggregates. Constr. Build. Mater. 2011, 25, 3469–3479. [Google Scholar] [CrossRef]

- Linß, E.; Mueller, A. High-performance sonic impulses—An alternative method for processing of concrete. Proc. Int. J. Miner. Process. 2004, 74, S199–S208. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Butera, A.; Le, K.N.; Li, W. Utilising CO2 technologies for recycled aggregate concrete: A critical review. Constr. Build. Mater. 2020, 250, 118903. [Google Scholar] [CrossRef]

- Grabiec, A.M.; Klama, J.; Zawal, D.; Krupa, D. Modification of recycled concrete aggregate by calcium carbonate biodeposition. Constr. Build. Mater. 2012, 34, 145–150. [Google Scholar] [CrossRef]

- Quattrone, M.; Angulo, S.C.; John, V.M. Energy and CO2 from high performance recycled aggregate production. Resour. Conserv. Recycl. 2014, 90, 21–33. [Google Scholar] [CrossRef]

- Ahmad Bhat, J. Effect of strength of parent concrete on the mechanical properties of recycled aggregate concrete. Mater. Today Proc. 2021, 42, 1462–1469. [Google Scholar] [CrossRef]

- Tabsh, S.W.; Abdelfatah, A.S. Influence of recycled concrete aggregates on strength properties of concrete. Constr. Build. Mater. 2009, 23, 1163–1167. [Google Scholar] [CrossRef]

- Xiao, J.; Li, J.; Zhang, C. Mechanical properties of recycled aggregate concrete under uniaxial loading. Cem. Concr. Res. 2005, 35, 1187–1194. [Google Scholar] [CrossRef]

- Vieira, G.L.; Schiavon, J.Z.; Borges, P.M.; da Silva, S.R.; de Oliveira Andrade, J.J. Influence of recycled aggregate replacement and fly ash content in performance of pervious concrete mixtures. J. Clean. Prod. 2020, 271, 122665. [Google Scholar] [CrossRef]

- Kou, S.C.; Poon, C.S. Effect of the quality of parent concrete on the properties of high performance recycled aggregate concrete. Constr. Build. Mater. 2015, 77, 501–508. [Google Scholar] [CrossRef]

- Wang, Q.; Geng, Y.; Wang, Y.; Zhang, H. Drying shrinkage model for recycled aggregate concrete accounting for the influence of parent concrete. Eng. Struct. 2020, 202, 109888. [Google Scholar] [CrossRef]

- Geng, Y.; Wang, Q.; Wang, Y.; Zhang, H. Influence of service time of recycled coarse aggregate on the mechanical properties of recycled aggregate concrete. Mater. Struct. 2019, 52, 97. [Google Scholar] [CrossRef]

- Abed, M.; Nemes, R.; Tayeh, B.A. Properties of self-compacting high-strength concrete containing multiple use of recycled aggregate. J. King Saud Univ. Eng. Sci. 2020, 32, 108–114. [Google Scholar] [CrossRef]

- Thomas, C.; de Brito, J.; Cimentada, A.; Sainz-Aja, J.A. Macro- and micro- properties of multi-recycled aggregate concrete. J. Clean. Prod. 2020, 245, 118843. [Google Scholar] [CrossRef]

- Mi, R.; Pan, G.; Kuang, T. Reducing the carbonation zone and steel corrosion zone widths of recycled aggregate concrete by optimizing its mixing process. J. Mater. Civ. Eng. 2021, 33, 04021061. [Google Scholar] [CrossRef]

- Mi, R.; Pan, G.; Li, Y.; Kuang, T. Carbonation degree evaluation of recycled aggregate concrete using carbonation zone widths. J. CO2 Util. 2021, 43, 101366. [Google Scholar] [CrossRef]

- Possan, E.; Felix, E.F.; Thomaz, W.A. CO2 uptake by carbonation of concrete during life cycle of building structures. J. Build. Pathol. Rehabil. 2016, 1, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Hansen, T.C.; Hedegkd, S.E. Properties of recycled aggregate concretes as affected by admixtures in original concretes. Proc. J. Proc. 1984, 81, 21–26. [Google Scholar]

- PKN. PN-EN 12620:2013 Aggregates for Concrete; Polish Committee for Standardization: Warsaw, Poland, 2013. [Google Scholar]

- PKN. PN-EN—206:2014 Concrete—Requirements, Properties and Conformity; Polish Committee for Standardization: Warsaw, Poland, 2014. [Google Scholar]

- CENELEC. FprEN 12620:2017 Aggregates for Concrete; CENELEC: Brussels, Belgium, 2017. [Google Scholar]

- CENELEC. FprEN 13139:2017 Aggregates for Mortar; CENELEC: Brussels, Belgium, 2017. [Google Scholar]

- CENELEC. FprEN 13242:2017 Aggregates for Unbound and Hydraulically Bound Materials for Use in Civil Engineering Work and Road Construction; CENELEC: Brussels, Belgium, 2017. [Google Scholar]

- JSA. JIS A 5023 Recycled Aggregate for Concrete-Class L; Japanese Standards Association: Tokyo, Japan, 2018. [Google Scholar]

- JSA. JIS A 5022 Recycled Aggregate for Concrete-Class M; Japanese Standards Association: Tokyo, Japan, 2018. [Google Scholar]

- JSA. JIS A 5021 Recycled Aggregate for Concrete-Class H; Japanese Standards Association: Tokyo, Japan, 2018. [Google Scholar]

- CNS. GB/T 25177-2010 Standard for Recycled Coarse Aggregate for Concrete; China National Standard: Beijing, China, 2010. [Google Scholar]

- WBTC. WBTC No.12/2002 Specifications Facilitating the Use of Recycled Aggregates; Works Bureau Technical Circular: Hong Kong, China, 2004.

- KATS. KS F2527 Aggregates for Concrete; Korean Agency for Technology Standards: Eumseong-gun, Korea, 2020.

- Rilem, T.C. 121-DRG. Specifications for concrete with recycled aggregates. Mater. Struct. 1994, 27, 557–559. [Google Scholar]

- ABNT. NBR 15116 Recycled Aggregates from Construction and Demolition Waste: Non-Structural Concrete—Requirements; Assoiacao Brasileira de Normas Tecnicas: São Paulo, Brazil, 2005. [Google Scholar]

- LNEC. LNEC E 471 Guideline for the Use of Recycled Coarse Aggregates in Hydraulic Binders’ Concrete; LNEC: Lisboa, Portugal, 2006. [Google Scholar]

- CRISO. HB-155, 2002 Guide to the Use of Recycled Concrete and Masonry Materials; Commonwealth Scientific and Industrial Research Organisation: Canberra, Austraila, 2002. [Google Scholar]

- Spanish Ministry of Public Works. EHE-08 Instrucción Del Hormigón Estructural EHE-08 (Spanish Structural Concrete Code); Spanish Ministry of Public Works: Madrid, Spain, 2008. [Google Scholar]

- Gonçalves, P.; de Brito, J. Recycled aggregate concrete (RAC)–comparative analysis of existing specifications. Mag. Concr. Res. 2010, 62, 339–346. [Google Scholar] [CrossRef]

- Pani, L.; Francesconi, L.; Rombi, J.; Mistretta, F.; Sassu, M.; Stochino, F. Effect of parent concrete on the performance of recycled aggregate concrete. Sustainability 2020, 12, 9399. [Google Scholar] [CrossRef]

- Katz, A. Treatments for the improvement of recycled aggregate. J. Mater. Civ. Eng. 2004, 16, 597–603. [Google Scholar] [CrossRef]

- Kim, J. Properties of recycled aggregate concrete designed with equivalent mortar volume mix design. Constr. Build. Mater. 2021, 301, 124091. [Google Scholar] [CrossRef]

- Bravo-German, A.M.; Bravo-Gómez, I.D.; Mesa, J.A.; Maury-Ramírez, A. Mechanical properties of concrete using recycled aggregates obtained from old paving stones. Sustainability 2021, 13, 44. [Google Scholar] [CrossRef]

- Hossain, M.U.; Poon, C.S.; Lo, I.M.C.; Cheng, J.C.P. Comparative environmental evaluation of aggregate production from recycled waste materials and virgin sources by LCA. Resour. Conserv. Recycl. 2016, 109, 67–77. [Google Scholar] [CrossRef]

- Ding, T.; Xiao, J.; Tam, V.W.Y. A closed-loop life cycle assessment of recycled aggregate concrete utilization in China. Waste Manag. 2016, 56, 367–375. [Google Scholar] [CrossRef]

- Zhang, C.; Hu, M.; Dong, L.; Xiang, P.; Zhang, Q.; Wu, J.; Li, B.; Shi, S. Co-benefits of urban concrete recycling on the mitigation of greenhouse gas emissions and land use change: A case in Chongqing metropolis, China. J. Clean. Prod. 2018, 201, 481–498. [Google Scholar] [CrossRef]

- Estanqueiro, B.; Dinis Silvestre, J.; de Brito, J.; Duarte Pinheiro, M. Environmental life cycle assessment of coarse natural and recycled aggregates for concrete. Eur. J. Environ. Civ. Eng. 2018, 22, 429–449. [Google Scholar] [CrossRef]

- Mesa, J.A.; Fúquene-Retamoso, C.; Maury-Ramírez, A. Life cycle assessment on construction and demolition waste: A systematic literature review. Sustainability 2021, 13, 7676. [Google Scholar] [CrossRef]

- Böhmer, S.; Moser, G.; Neubauer, C.; Peltoniemi, M.; Schachermayer, E.; Tesar, M.; Walter, B.; Winter, B. Aggregates Case Study; Contract No 150787-2007 F1SC-AT; ISO: Geneva, Switzerland, 2008. [Google Scholar]

- Xiao, J.; Ma, Z.; Sui, T.; Akbarnezhad, A.; Duan, Z. Mechanical properties of concrete mixed with recycled powder produced from construction and demolition waste. J. Clean. Prod. 2018, 188, 720–731. [Google Scholar] [CrossRef]

- Ahmari, S.; Ren, X.; Toufigh, V.; Zhang, L. Production of geopolymeric binder from blended waste concrete powder and fly ash. Constr. Build. Mater. 2012, 35, 718–729. [Google Scholar] [CrossRef]

- Earle, J.; Ergun, D.; Gorgolewski, M. Barriers for Deconstruction and Reuse/Recycling of Construction Materials in Canada; CIB: Ottawa, ON, Canada, 2014; Volume 20. [Google Scholar]

- Tam, V.W.Y. Economic comparison of concrete recycling: A case study approach. Resour. Conserv. Recycl. 2008, 52, 821–828. [Google Scholar] [CrossRef] [Green Version]

- MoE. Construction Waste Recycling Promotion Act, No. 16317; Ministry of Environment: Seoul, Korea, 2019.

- MOLIT. Regulations on the Mandatory Use of Recycled Aggregates for Construction Projects; Ministry of Land, Infrastructure and Transport: Seoul, Korea, 2009.

- Manowong, E. Investigating factors influencing construction waste management efforts in developing countries: An experience from Thailand. Waste Manag. Res. 2012, 30, 56–71. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.; Yu, A.T.W.; Shen, L. Investigating the determinants of contractor’s construction and demolition waste management behavior in Mainland China. Waste Manag. 2017, 60, 290–300. [Google Scholar] [CrossRef]

- Nagapan, S.; Rahman, I.A.; Asmi, A.; Memon, A.H.; Latif, I. Issues on construction waste: The need for sustainable waste management. In Proceedings of the 2012 IEEE Colloquium on Humanities, Science and Engineering (CHUSER), Kota Kinabalu, Malaysia, 3–4 December 2012. [Google Scholar]

- Lu, W. Big data analytics to identify illegal construction waste dumping: A Hong Kong study. Resour. Conserv. Recycl. 2019, 141, 264–272. [Google Scholar] [CrossRef]

- Dladla, I.; Machete, F.; Shale, K. A review of factors associated with indiscriminate dumping of waste in eleven African countries. Afr. J. Sci. Technol. Innov. Dev. 2016, 8, 475–481. [Google Scholar] [CrossRef]

- Martínez-Lage, I.; Vázquez-Burgo, P.; Velay-Lizancos, M. Sustainability evaluation of concretes with mixed recycled aggregate based on holistic approach: Technical, economic and environmental analysis. Waste Manag. 2020, 104, 9–19. [Google Scholar] [CrossRef]

- Marinković, S.; Radonjanin, V.; Malešev, M.; Ignjatović, I. Comparative environmental assessment of natural and recycled aggregate concrete. Waste Manag. 2010, 30, 2255–2264. [Google Scholar] [CrossRef] [PubMed]

- Faleschini, F.; Zanini, M.A.; Pellegrino, C.; Pasinato, S. Sustainable management and supply of natural and recycled aggregates in a medium-size integrated plant. Waste Manag. 2016, 49, 146–155. [Google Scholar] [CrossRef]

- Nunes, K.R.A.; Mahler, C.F.; Valle, R.; Neves, C. Evaluation of investments in recycling centres for construction and demolition wastes in Brazilian municipalities. Waste Manag. 2007, 27, 1531–1540. [Google Scholar] [CrossRef]

- Jin, R.; Li, B.; Zhou, T.; Wanatowski, D.; Piroozfar, P. An empirical study of perceptions towards construction and demolition waste recycling and reuse in China. Resour. Conserv. Recycl. 2017, 126, 86–98. [Google Scholar] [CrossRef]

- Shooshtarian, S.; Caldera, S.; Maqsood, T.; Ryley, T. Using Recycled Construction and demolition waste products: A review of stakeholders’ perceptions, decisions, and motivations. Recycling 2020, 5, 31. [Google Scholar] [CrossRef]

- Rao, A.; Jha, K.N.; Misra, S. Use of aggregates from recycled construction and demolition waste in concrete. Resour. Conserv. Recycl. 2007, 50, 71–81. [Google Scholar] [CrossRef]

- Min, B.; Park, J.-W.; Choi, W.-K.; Lee, K.-W. Separation of radionuclide from dismantled concrete waste. J. Nucl. Fuel Cycle Waste Technol. 2009, 7, 79–86. [Google Scholar]

- Taylor-Lange, S.C.; Stewart, J.G.; Juenger, M.C.G.; Siegel, J.A. The contribution of fly ash toward indoor radon pollution from concrete. Build. Environ. 2012, 56, 276–282. [Google Scholar] [CrossRef]

- De Jong, P.; Van Dijk, W.; Van Hulst, J.G.A.; Van Heijningen, R.J.J. The effect of the composition and production process of concrete on the 222Rn Exhalation rate. In Proceedings of the 1995 6th International Symposium on the Natural Radiation Environment, Montreal, QC, Canada, 5–9 June 1995; Elsevier Science Ltd.: Amsterdam, The Netherlands, 1997; Volume 22, pp. 287–293. [Google Scholar]

- Lee, Y.J.; Hwang, D.S.; Lee, K.W.; Jeong, G.H.; Moon, J.K. Characterization of cement waste form for final disposal of decommissioned concrete waste. J. Nucl. Fuel Cycle Waste Technol. 2013, 11, 271–280. [Google Scholar] [CrossRef] [Green Version]

| Test | RAC1 | RAC2 | RAC3 | RAC4 | |

|---|---|---|---|---|---|

| Compressive strength of parent concrete, MPa | 40 | 110 | 20 | 110 | |

| Target strength, MPa | 40 | 80 | |||

| Slump, mm | 115 | 115 | 140 | 150 | |

| Density, kg/m3 | Fresh | 2351 | 2364 | 2356 | 2407 |

| Hardened | 2330 | 2345 | 2341 | 2381 | |

| Compressive strength, MPa | 32.0 | 36.8 | 64.3 | 80.1 | |

| Elastic modulus, GPa | 26.7 | 29.1 | 31.9 | 41.5 | |

| Tensile strength, MPa | 3.22 | 3.36 | 3.90 | 5.11 | |

| Standard | Classification | Minimal Density, kg/m3 | Maximal Water Absorption, % | Maximal Chloride, Content, % | Maximal Sulphate Content, % |

|---|---|---|---|---|---|

| JIS A5021 [124] (Japan) | High | 2500 | 3 | 0.04 | - |

| JIS A5022 [123] (Japan) | Medium | 2300 | 5 | 0.04 | - |

| JIS A5023 [122] (Japan) | Low | - | 7 | 0.04 | - |

| GB/T 25177 [125] (China) | Class 1 | 2450 | 3 | 0.06 | 2 |

| Class 2 | 2350 | 5 | 0.06 | 2 | |

| Class 3 | 2250 | 8 | 0.06 | 2 | |

| WBTC-No.12 [126] (Hong Kong) | - | 2000 | 10 | 0.05 | - |

| KS F2527 [127] (Korea) | - | 2500 | 3 | - | - |

| RILEM [128] | Type I | 1500 | 20 | - | 1 |

| Type II | 2000 | 10 | - | 1 | |

| Type III | 2400 | 3 | - | 1 | |

| HB-155 [131] (Australia) | - | 2100 | 6 | 0.05 | 0.5 |

| NBR-15116 [129] (Brazil) | - | - | 7 | 1 | 1 |

| LNEC-E471 [130] (Portugal) | - | 2200 | 7 | - | 0.8 |

| EHE-08 [132] (Spain) | - | - | 7 | - | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grabiec, A.M.; Kim, J.; Ubysz, A.; Bilbao, P. Some Remarks towards a Better Understanding of the Use of Concrete Recycled Aggregate: A Review. Sustainability 2021, 13, 13336. https://doi.org/10.3390/su132313336

Grabiec AM, Kim J, Ubysz A, Bilbao P. Some Remarks towards a Better Understanding of the Use of Concrete Recycled Aggregate: A Review. Sustainability. 2021; 13(23):13336. https://doi.org/10.3390/su132313336

Chicago/Turabian StyleGrabiec, Anna M., Jeonghyun Kim, Andrzej Ubysz, and Pilar Bilbao. 2021. "Some Remarks towards a Better Understanding of the Use of Concrete Recycled Aggregate: A Review" Sustainability 13, no. 23: 13336. https://doi.org/10.3390/su132313336

APA StyleGrabiec, A. M., Kim, J., Ubysz, A., & Bilbao, P. (2021). Some Remarks towards a Better Understanding of the Use of Concrete Recycled Aggregate: A Review. Sustainability, 13(23), 13336. https://doi.org/10.3390/su132313336