Abstract

Improving the efficiency and quality of construction mainly depends on the cost of building materials, which is about 55–65% of total capital-construction costs. The study aimed to obtain geopolymer fine-grained concrete with improved quality characteristics that meet the construction field’s sustainable development criteria and that have environmental friendliness, economic efficiency, and advantages over competing analogues. The dependences of strength characteristics on various compositions of geopolymer concrete were obtained. It was found that the most effective activator is a composition of NaOH and Na2SiO3 with a ratio of 1:2. The increase in the indicators of the obtained geopolymer concrete from the developed composition (4A) in relation to the base control (1X) was 17% in terms of compressive strength and 24% in tensile strength in bending. Polynomial equations were obtained showing the dependence of the change in the strength characteristics of geopolymer concrete on the individual influence of each of the activators. A significant effect of the composition of the alkaline activator on the strength characteristics of geopolymer fine-grained concrete was noted. The optimal temperature range of heat treatment of geopolymer concrete samples, contributing to the positive kinetics of compressive strength gain at the age of 28 days, was determined. The main technological and recipe parameters for obtaining geopolymers with the desired properties, which meet the ecology requirements and are efficient from the point of view of economics, were determined.

1. Introduction

1.1. The Relevance of Research

Composite binders are essential in providing the construction industry with materials and a raw-materials base and indicate its development. The scale of capital construction sets the primary growth rates in the production of composite binders, on which its efficiency and the technical level of the final construction products directly depend [1,2,3].

The use of high-performance multicomponent binders of a new generation is the basis for the creation of high-quality concrete for various purposes with an optimal structure and predetermined improved properties, and in some cases, fundamentally new ones.

The current construction industry makes high-quality requirements for binders. Simultaneously with the improvement in production technology, the range of produced binders is also expanding. However, improving the efficiency and quality of construction mainly depends on building materials, which are about 55–65% of total capital-construction costs.

At the same time, the consumption of natural mineral and energy resources in the world is increasing every year due to the increasing rates and volumes of production. Therefore, the world community was forced to develop a course of “sustainable development,” the benchmark for which was resource and energy conservation, and which increased safety in the field of ecology, which led to a rethinking of the further strategy for the development of energy and material-intensive industries, including cement production. Emissions of dust particles and gases have a significant impact on the environment in the production of cement binder. The main causes of emissions are kilns, clinker coolers, and cement mills.

1.2. Literature Review on the Research Topic

The investigation and development of materials based on alkali-activated binders using natural and artificial sources of aluminosilicates, the geopolymer binders, have been studied by many world scientific schools, including in Russia, Ukraine, Iran, the Czech Republic, Germany, France, Poland, Australia, Spain, the USA, and China. The processes of structure formation of geopolymers are described in detail in [4,5,6,7,8,9,10,11,12].

Researchers have paid much attention to the optimization of geopolymer binders and concrete compositions [13,14,15], the study of the physical and mechanical properties of concrete [16,17,18,19,20] and structures based on them [21], as well as various uses of the technology of geopolymer binders to obtain new materials [22]. At the same time, the authors touch upon topical environmental issues in the production of geopolymer concrete [23,24] and the problems of predicting the mechanical characteristics of finished materials, products, and structures using artificial-intelligence technology [25].

Liang Chen et al. [26] carried out studies to investigate the properties of geopolymers based on metakaolin. Based on the results of the experimental data, the authors developed the optimal geopolymer composition with the following weight ratios of the components: 41.6%—metakaolin, 6.7%—sodium hydroxide, 45.0%—sodium silicate, and 6.7%—water. It was also found that the best curing condition for this geopolymer composition is a heat treatment at 60 °C for 168 h. Under these conditions, an alkali-activated metakaolin-based geopolymer showed the highest compressive strength at 52.26 MPa [26].

Hamed Fazli et al. [27] studied the effect of the size of the coarse aggregate on the mechanical properties of geopolymer concrete based on metakaolin and conventional concrete. It was found that a change in the pore structure depending on the size of the coarse aggregate significantly affects the development of the strength of the test samples. Furthermore, an increase in the size of the coarse aggregate leads to a higher shrinkage of geopolymer concrete and, therefore, to a larger number of macropores. Consequently, the effect of macropores is significant [27].

Khadim Hussain et al. [28] carried out a study of the influence of quarry stone dust as a binder on the properties of fly ash and geopolymer concrete based on slag under the influence of the environment and elevated temperatures. Geopolymer samples showed the maximum strength characteristics of concrete with the following binder composition: 50% hall dust, 35% slag, and 15% quarry dust. Geopolymer concrete made with the binder of this composition can provide a compressive strength of 33.5 MPa, a breaking strength at the separation of 2.12 MPa, and flexural strength of 3.62 MPa. The authors summarize that the resulting optimal mixture can be used for monolithic work under natural hardening conditions [28].

An experimental study on the production of an optimized geopolymer material was presented by Alberto Longos, Jr. et al. [29], and it gives the highest compressive strength from a mixture of nickel laterite mine waste (NMW), coal fly ash (CFA), and an alkaline activator with sodium-hydroxide (SH) and silicate-sodium (SS) components. The authors have selected the optimal prescription geopolymer mixture with an average 28-day compressive strength of 36.3 MPa, which is comparable to conventional Portland cement for concrete structures [29].

Parametric studies were carried out by A.V. Lazarescu et al. [30] to develop geopolymer concrete based on alkali-activated fly ash using local Romanian raw materials. A significant influence was noted, and the importance of the ratio of sodium-silicate solution to sodium-hydroxide solution (Na2SiO3/NaOH) was noted not only in the process of geopolymerization but also on the mechanical properties of geopolymer concrete based on alkali-activated fly ash. The solubility of fly ash increased with an increase in the concentration of NaOH solution, which led to the formation of a denser material with higher compressive strength of the samples [30].

Rajab Abousnina et al. [31] studied the effect of short fibers on the mechanical properties of a geopolymer solution containing oil-contaminated sand. According to the results of the studies, the authors proved that the introduction of short polypropylene fibers contributes to a significant improvement in the compressive strength of the geopolymer solution. Straight polypropylene fibers improved tensile strength by 74% over non-fibrous samples. Furthermore, it has been established in the work that all types of fibers enhance the plasticity of the solution by increasing its displacement under braking loads. This is due to the geopolymer bond, which helps absorb maximum energy during compression [31].

1.3. Principles of Structure Formation in the “SiO2-Al2O3-NaK2O” System

Nowadays, the mechanisms of phase formation, as well as the peculiarities of the interaction of structural elements in the “SiO2-Al2O3-MeO” system (where “MeO” are oxides of alkali and alkaline earth elements, such as CaO, Na2O, K2O, etc.) are insufficiently studied due to the kinetics and nature of the processes of structure formation in the geopolymer matrix, which largely depends on the aluminosilicate materials and the alkaline-activating components used. On the other hand, as known, geopolymers are used in a particular case of alkaline binders. Therefore, the previously formulated general principles of the structure of the system are also applicable to geopolymers.

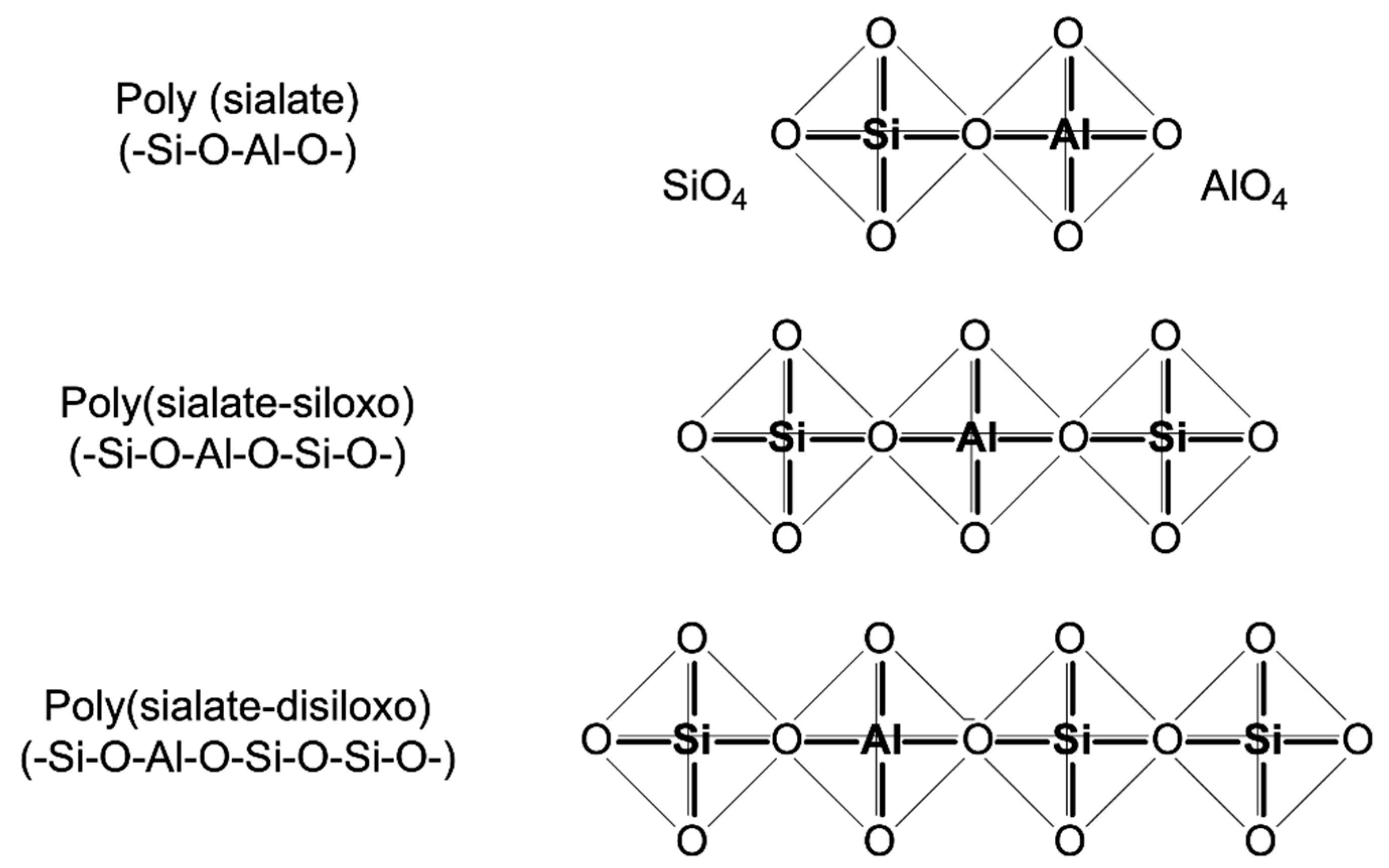

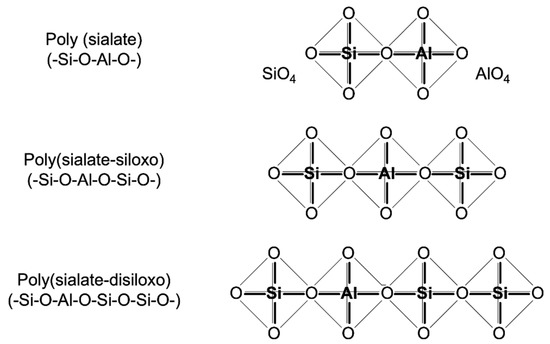

The processes of structure formation of alkaline binders in relation to geopolymer systems were considered in detail by J. Davidovits [5,6,7,8,9]. Scientists proposed a classification of structural geopolymers depending on the sequence, alternation, and also the chain length of the elements of structural units consisting of silicon, aluminum, and oxygen in the volume of the matrix: polysialats, sialat-siloxo, and polysilato-siloxo (disiloxo) (Figure 1).

Figure 1.

Classification of geopolymer structures according to J. Davidovits [5,6,7,8,9].

According to the scheme (Figure 1), structurally, sialates can be represented in the form of tetrahedra, the base of which consists of silicon and aluminum atoms, forming bonds with four oxygen atoms.

These elements are capable of forming multidimensional (two- and three-dimensional) structures, which are branched strong chains –Si–O–Al–O–, due to which the strength properties of geopolymers may not be inferior to rocks [12].

According to J. Davidovits, the formation of geopolymers proceeds in three stages [9]:

- -

- The first stage includes the dissolution of silicon and aluminum oxides in an alkaline medium—a concentrated solution of alkalis NaOH or KOH;

- -

- During the second stage, the polymer structures are split into monomers;

- -

- The third stage is characterized by the setting and compaction of the geopolymer matrix as a result of the binding of Si–O and Al–O monomers into polymer frameworks.

The formation of inorganic polymers occurs as a result of polycondensation of orthosilicate ions as a result of a chemical reaction between aluminosilicate raw materials and an alkaline component in an aqueous medium.

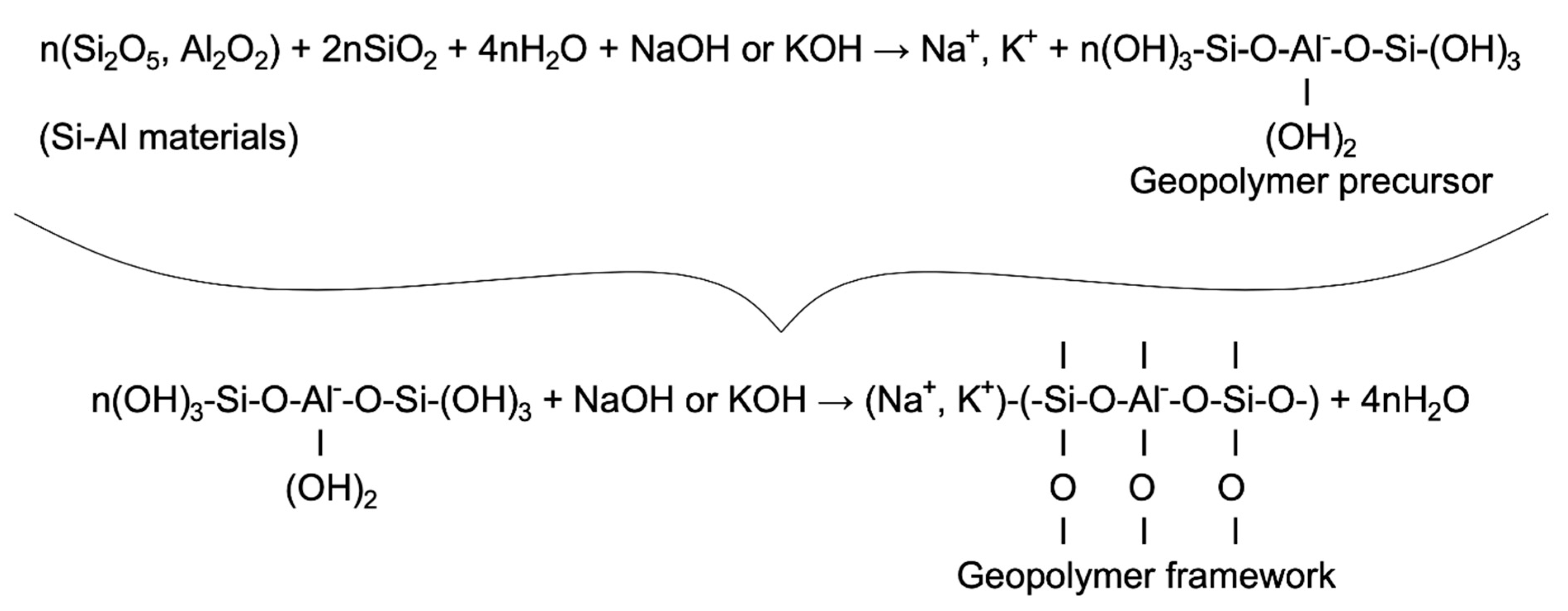

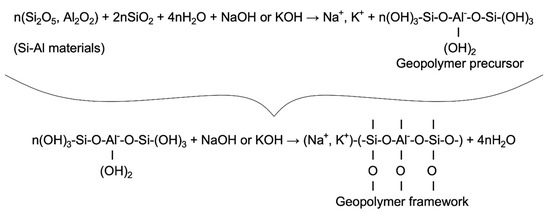

According to the hypothesis of J. Davidovits, during the course of polycondensation processes in an alkali-activated system, oligomers are formed, which subsequently play the role of structural units in the formation of a geopolymer framework (Figure 2).

Figure 2.

Polymerization reaction.

The duration of the dissolution and polycondensation processes in the geopolymer system mainly depends on the viscosity of the substance, which affects the mobility of ions, their degrees of freedom, and the intensity of movement of which determines the rate of the polymerization processes. Additionally, such systems are characterized by the simultaneous occurrence of polycondensation and dissolution processes, in which there is a gradual polymerization of the geopolymer structure.

Despite a fairly detailed description of the mechanism of structure formation proposed by J. Davidovits (Figure 2), attempts to look from a different angle at the processes occurring inside the alkali-activated aluminosilicate system were undertaken by Spanish scientists [4,10]. During their research, they identified two main models of alkaline activation of aluminosilicates.

The first model is based on the activation of granular blast-furnace slag by strong (NaOH, KOH, and Na2SiO3) and weak (Ca(OH)2, KCl, and NaCl) alkalis and their salts. The system received the symbolic designation “Si + Ca” and describes the general case of structure formation of an alkali-activated binder system of silicate/aluminosilicate composition, in which the formation of the structure of the final composite occurs during the interaction of calcium and silicon oxides by the hydration mechanism, which leads to the formation of calcium hydrosilicates, which are the main structural components in this system [4,10].

The second model is based on the activation of metakaolin by strong and medium alkalis. This model received the conventional designation “Si + Al” and is similar in the principles of structure formation to the model of geopolymerization by J. Davidovits (Figure 2). The formation of the structure according to this model occurs as a result of the interaction of aluminum oxides with silicon oxides in a highly alkaline environment, followed by polycondensation and the formation of an alkali-aluminosilicate spatial framework [4,10].

1.4. Purpose, Objectives, Scientific Novelty, and Practical Significance of the Research

The purpose of the study was to obtain geopolymer fine-grained concrete that meets the criteria of sustainable development with improved quality characteristics while having environmental friendliness and efficiency from the economic feasibility of producing such concrete and its advantages over competing analogues.

The research tasks included:

- -

- To analyze the scientific and technical literature on the technology of geopolymer fine-grained concrete, their raw materials, and the manufacturing process;

- -

- Based on the results of the analysis and the literature review, to identify the rational direction of research, to determine the initial components, to select the basic formulations, and to develop a research program;

- -

- To analyze the results to determine the most-rational composition and the parameters of the technological process;

- -

- To compare the indicators of economic efficiency, to assess the environmental friendliness of the developed technology and composition, to note the advantages and disadvantages, and also to compare the results obtained with the results of other authors;

- -

- To determine the prospects and to outline the goals of subsequent research in developing the carried-out studies.

The scientific and practical novelty of the research lies in the continuation of the scientific theory about environmentally friendly cementless building composites, the development of existing theoretical and practical ideas about the structure formation and properties of geopolymer concrete, experimental confirmation of the scientific hypothesis put forward by us about obtaining high-quality geopolymer concrete through the choice of components and rationally selected formulations, and studies of the compatibility of the applied components and their influence on the mechanical properties of the obtained hardened composites, obtaining new dependences of strength characteristics on the ratio of the components of the complex alkaline activator “Na2SiO3 + NaOH.”

The practical significance of the study is:

Firstly, in solving the environmental problem due to the production of geopolymer concrete with the help of production waste, while the production of geopolymer concrete itself is more environmentally friendly, due to the fact that the process of its production requires less production capacity, there is less impact on the environment; emissions into the atmosphere and the environment are significantly reduced; thereby, the process of manufacturing such geopolymer concrete contributes to the improvement of the ecological situation;

Secondly, in the economic efficiency of the obtained geopolymer concrete in comparison with the financial cost of production of competitors/analogues, in particular, concrete with similar characteristics, but made on a traditional cement binder;

Thirdly, in the creation of geopolymer concrete with the highest attributes at the lowest cost due to the obtained recipe and technology; thus, for industrial partners and consumers of the proposed technology and the resulting composition, the specified production will cost significantly fewer resources, while the time costs are also reduced, and the labor intensity with regards to the manufacture of this geopolymer concrete is also reduced.

2. Materials and Methods

2.1. Analysis of Raw Materials Used to Obtain Geopolymer Binders

Potentially possible and practically used today, aluminosilicate components for the synthesis of geopolymers are classified into three categories: technogenic, synthetic, and natural. The wastes of the metallurgical (blast-furnace slags and steel-making slags) and fuel (ash and fly ash from TPPs) industries are the most common types of technogenic aluminosilicate raw materials.

The use of artificial waste and by-products of aluminosilicate composition (blast-furnace slag, fly ash, etc.) in the production of geopolymer binders can provide an alternative to Portland cement in terms of environmental and economic efficiency.

However, the limited use of the technogenic variety of aluminosilicates is explained by the fact that their main properties, structure, mineral, and chemical compositions largely depend on the composition of the mineral part of the fuel, the mode, and the conditions of the technological process, as well as the methods of disposal and storage, etc., which cause significant fluctuations in chemical and mineral composition (Table 1).

Table 1.

Variations in the chemical composition of metallurgical slags from different manufacturers.

As a synthetic raw material in the production of geopolymers, metakaolin (Al2Si2O7) as the main raw material component is of considerable interest. The formation of the structure of metakaolin occurs as a result of firing kaolinite at a temperature of 550–900 °C for up to 24 h, and the resulting aluminosilicate material is characterized by the constancy of the chemical composition, morphology, and dispersion of particles, which provide it with high quality as a raw component.

The use of natural sources of aluminosilicate raw materials has become more widespread than synthetic analogues due to the wide variety of the raw-material base and extensive nature reserves. Additionally, it is due to the relative constancy of the chemical and mineral composition compared to technogenic analogues. Among the most common aluminosilicates that satisfy the requirements as a raw material for geopolymers in terms of chemical composition, acidic varieties of silicate rocks, such as granites, zeolites, and perlites, should be distinguished.

2.2. Materials

When carrying out this work, sodium hydroxide (NaOH) produced by PJSC “Khimprom” (Russia, Chuvash Republic, Novocheboksarsk) [32], potassium hydroxide (KOH) produced by LLC “Soda-chlorat” (Russia, Perm region, Berezniki) [33], and sodium liquid glass (Na2O(SiO2)n) produced by Kubanzheldormash JSC (Russia, Krasnodar Territory, Armavir) [34] were used.

Table 2.

Qualitative characteristics of NaOH.

Table 3.

Qualitative characteristics of sodium water glass.

Quartz sand was used as a fine aggregate (Yuzhny GOK, Rostov region, Russia); the physical characteristics presented in Table 4.

Table 4.

Physical characteristics of dense fine aggregate.

Metakaolin produced by OOO RossPolymer (Russia, Moscow Region, Noginsk) was used as the main component of the geopolymer binder. The chemical composition of metakaolin and its physical characteristics are presented in Table 5 and Table 6.

Table 5.

Chemical composition of metakaolin “MetaKaolin 1400.”

Table 6.

Physical characteristics of metakaolin.

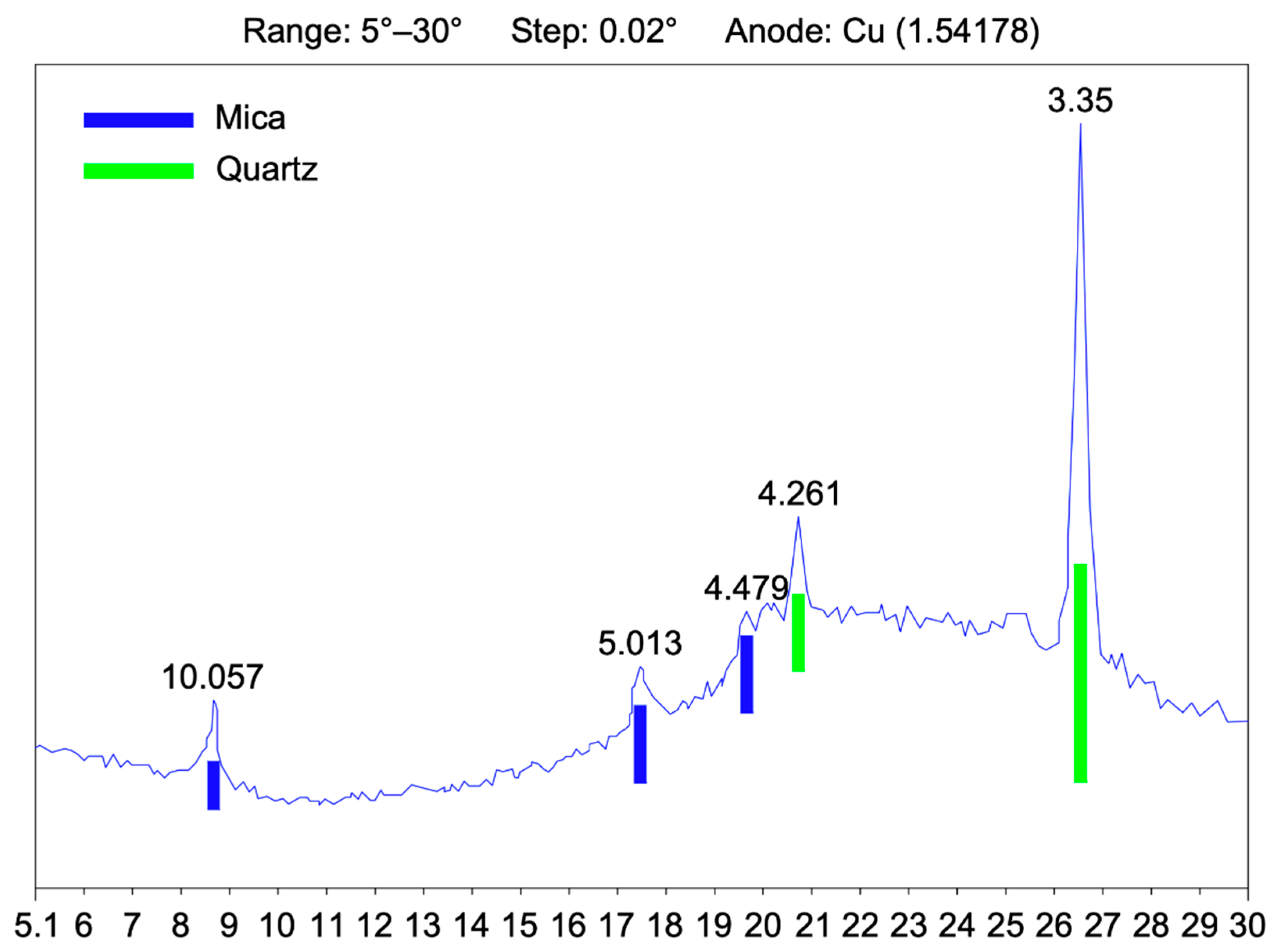

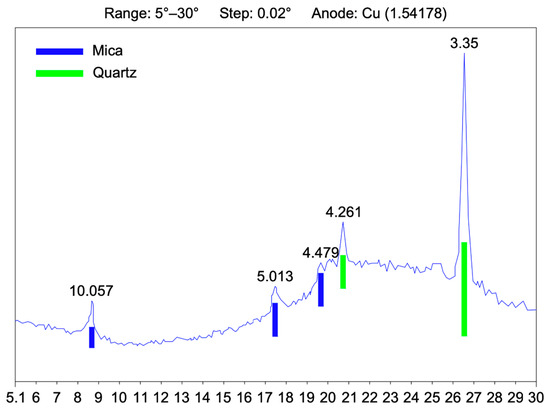

The X-ray diffraction of metakaolin is shown in Figure 3.

Figure 3.

X-ray diffraction of metakaolin.

The mineral composition of metakaolin was represented by completely amorphous kaolinite (90–93%); the crystalline phase was represented by relict mica (2.5–3.0%) and quartz (4–5%); and crystalline new formations (mullite and crisstabolite) were practically absent.

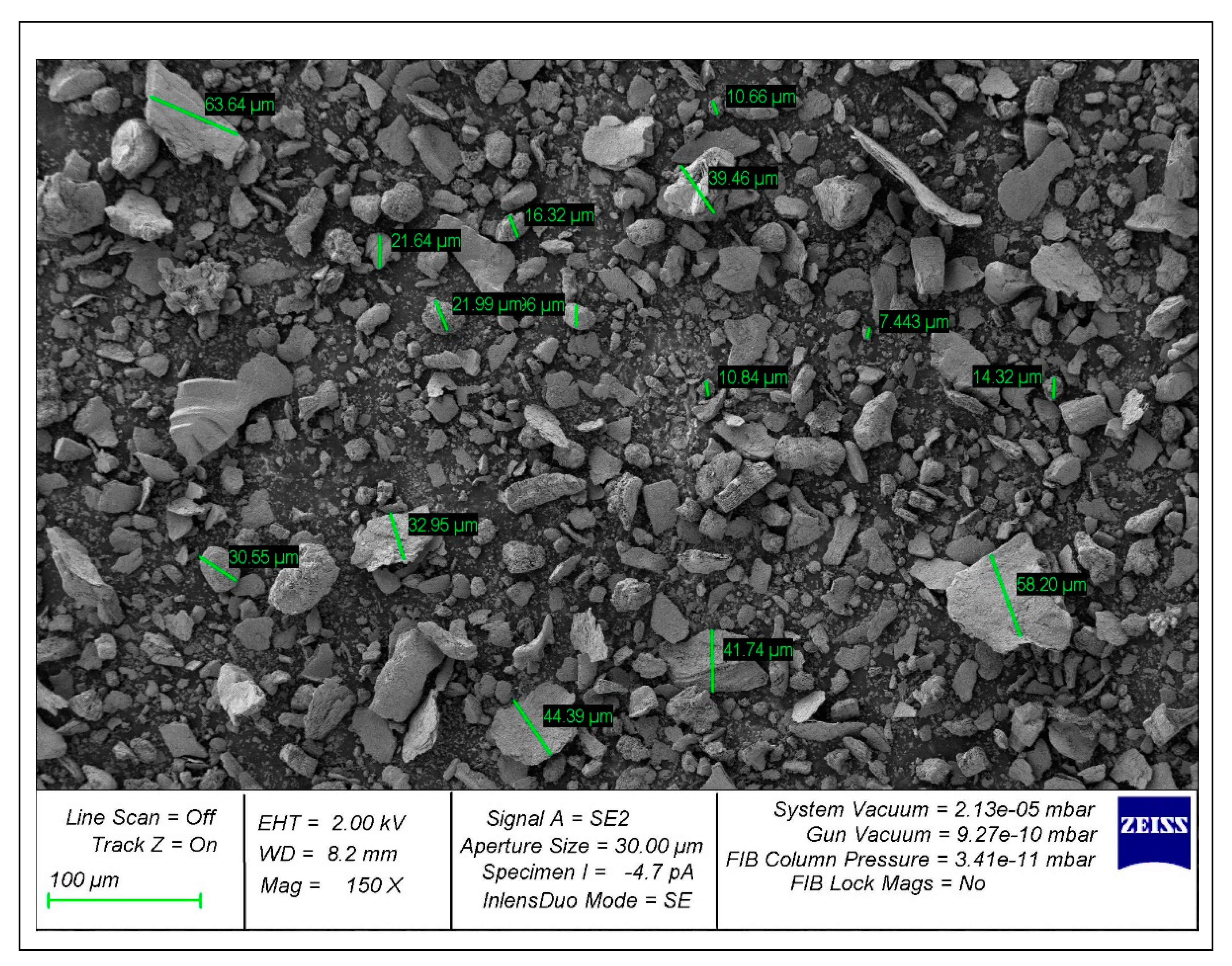

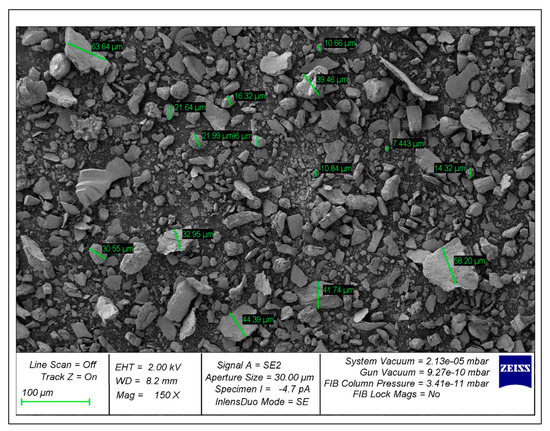

Granulometric analysis of metakaolin is shown in Figure 4.

Figure 4.

Granulometric analysis of metakaolin.

The granulometry analysis confirms the size range of metakaolin grains declared by the manufacturer.

The water used for laboratory research was tap water that fully met the requirements [35].

At the first stage of the study, the selection of the most-effective composition of the activator was carried out. The choice of activating agents was justified by their ability to provide a reaction medium with high alkalinity in an aqueous solution.

By combining sodium hydroxide (NaOH) with a molarity of 12 M with sodium silicate (Na2SiO3), the following geopolymer mixtures were developed (Table 7).

Table 7.

Experimental compositions of geopolymers.

2.3. Methods

For each experimental composition, 3 sample beams (4 × 4 × 16 cm) were made.

The evaluation of the effect of the activator composition was based on experimental data obtained from the results of testing beams for strength in compression and tensile bending.

The production of geopolymer samples was carried out in accordance with the requirements of GOST 30744 “Cements. Methods of testing with using polyfraction standard sand” [36].

Tensile bending tests were performed using the same load model as described in GOST 30744.

The molded binder compositions were heat treated at a temperature of 65 °C for 24 h, after which the strength of the samples continued under natural conditions until the age of 28 days.

The flexural strength Rbtb, MPa, of a separate sample-beam was calculated by the formula

where F is the breaking load, N;

b is the size of the side of the square section of the sample-beam, mm;

l is the distance between the axes of the supports, mm.

The bending strength was taken as the arithmetic mean of the test results of three samples. The calculation result was rounded to the nearest 0.1 MPa.

The compressive strength Rb, MPa, of an individual half of the sample-beam was calculated by the formula

where F is the breaking load, N;

S—the area of the working surface of the pressure plate, mm2.

The compressive strength was taken as the arithmetic mean of the test results of six halves of the beams. The calculation result was rounded to 0.1 MPa.

The study also applied:

- -

- Technological equipment—laboratory concrete mixer BL-10 (LLC “ZZBO,” Russia, Chelyabinsk region, Zlatoust); drying cabinet SPU ShS-160-02 (JSC “Smolenskoye SKTB SPU,” Russia, Smolensk); laboratory vibrating platform SMZh-539-220A (LLC “IMASH,” Armavir, Russia);

- -

- Testing equipment—hydraulic press IP-1000 (NPK TEKHMASH LLC, Neftekamsk, Republic of Bashkortostan, Russia);

- -

- Measuring instruments—measuring metal ruler 500 mm; laboratory scales [37,38,39,40].

The study of the microstructure of geopolymer concrete was carried out using a two-beam scanning electron/ion microscope ZEISS CrossBeam 340 (Carl Zeiss Microscopy GmbH (Factory), Jena Germany).

For X-ray diffractometric analysis of metakaolin, a general-purpose X-ray diffractometer DRON-7 (“Burevestnik,” St. Petersburg, Russia) was used.

The ready-made and in-the-process-of-manufacturing samples-beams of geopolymer fine-grained concrete obtained in the laboratory are shown in Figure 5 and Figure 6, respectively.

Figure 5.

Photo of samples of geopolymer fine-grained concrete.

Figure 6.

The process of making samples-beams of geopolymer fine-grained concrete.

3. Results

3.1. General Results

After the tests were carried out, all the obtained values were analyzed. Flexural tensile tests were carried out first, followed by compression tests of half specimens. A total of 27 beams were tested in flexural tensile tests and 54 halves in compression tests. All these tests were carried out after 28 days of hardening.

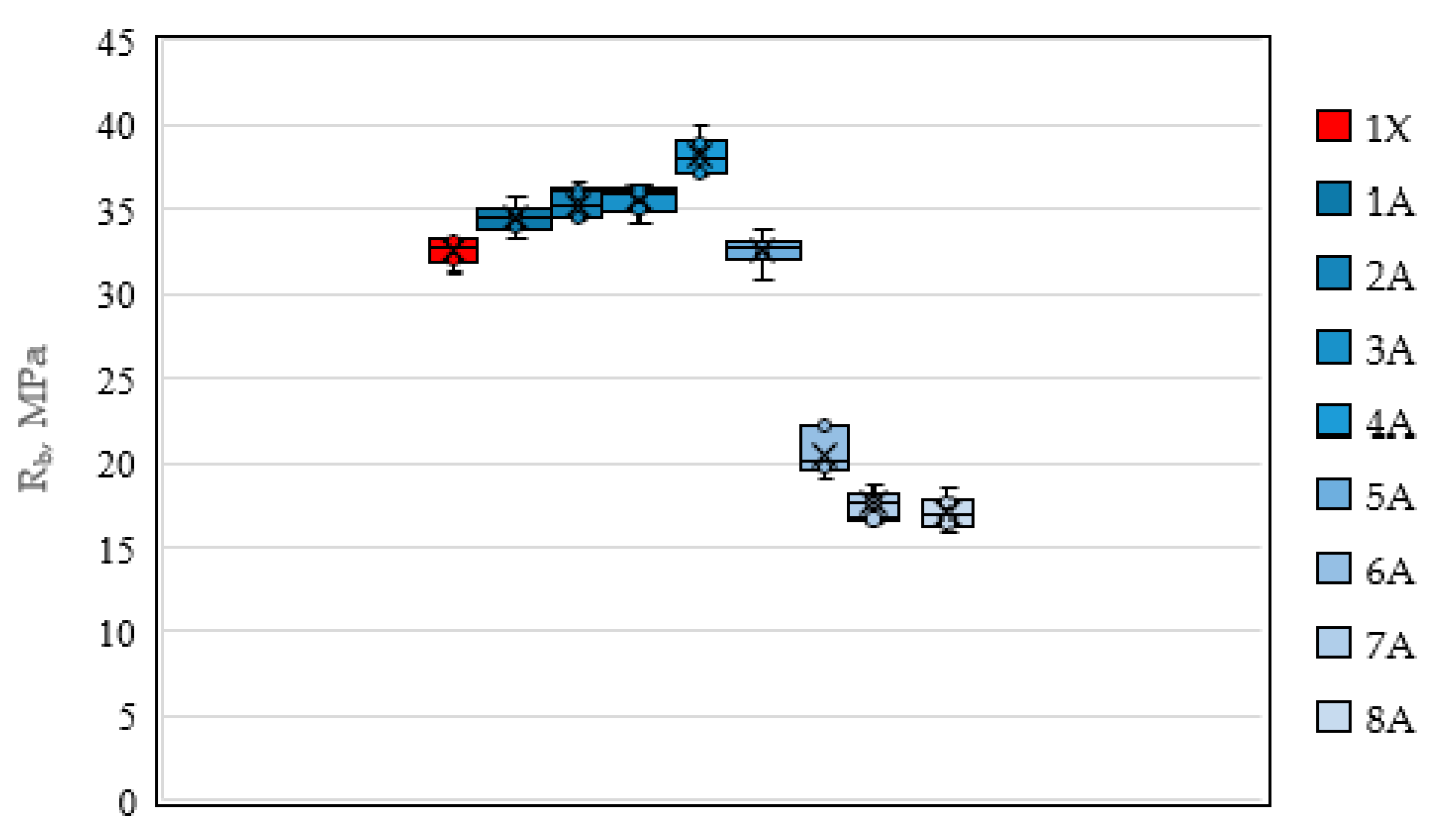

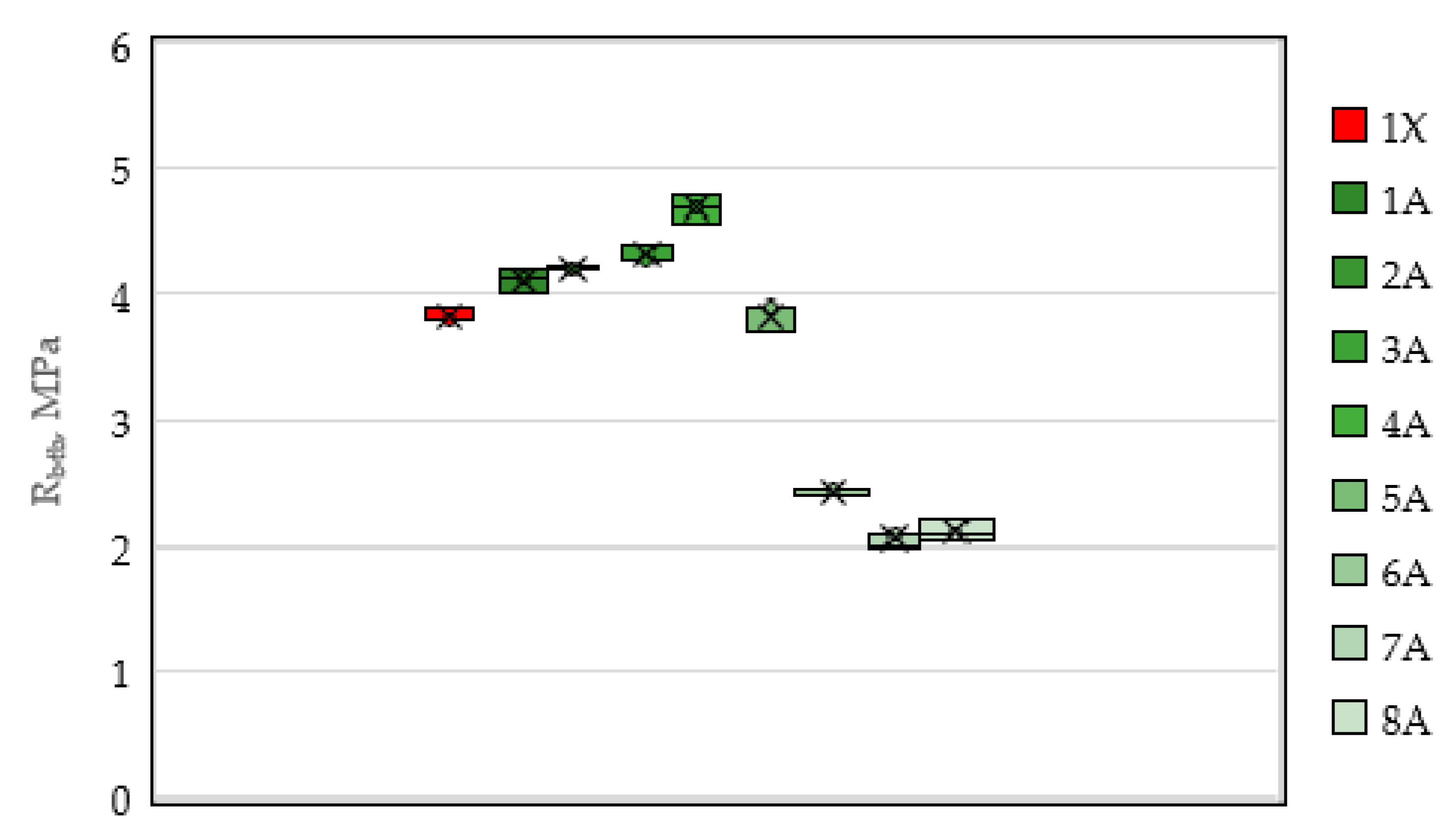

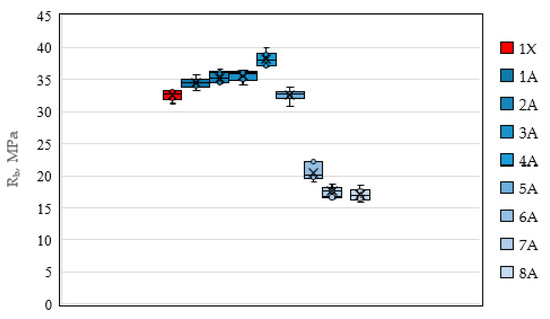

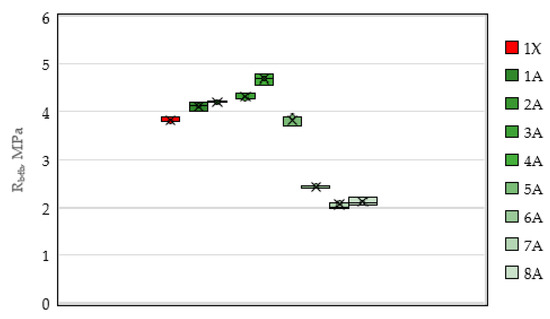

Figure 7 and Figure 8 show the values of the compressive strength and the flexural tensile strength, respectively, for all the compositions.

Figure 7.

Compressive strength values.

Figure 8.

Tensile strength in bending values.

As can be seen, the highest compressive strength of 38.1 MPa was observed for a mixture of composition 4A, where the ratio of NaOH and Na2SiO3 was 1:2. As for the mechanical characteristics of compositions 1A, 2A, and 3A, their values differed slightly from composition 4A, and this difference did not exceed 10%. Control composition 1X and composition 5A had the same compressive strength, which was equal to 32.5 MPa. Analyzing the behavior of the compressive strength for compositions 5A, 6A, 7A, and 8A, it a rather sharp drop in strength could be observed, starting with composition 6A. So, in comparison with the maximum value of the compressive strength for composition 4A for 6A, this indicator decreased by 45%. For compositions 7A and 8A, it decreased by 55%. This tendency towards a decrease in strength with an increase in the proportion of sodium silicate in the total mass of the activating component can be explained because sodium silicate has a low activating ability. Some of the substances introduced into the composition do not react with metakaolin, and, as a result, the strength characteristics decrease.

From Figure 8 it follows that the maximum value of the tensile strength in bending was observed, in the same way as for the compressive strength of the composition 4A, and it was 4.7 MPa. As for the values of tensile strength in bending for compositions 1A, 2A, and 3A, they differed insignificantly and varied from 4.1 MPa to 4.3 MPa. For control composition 1X and composition 5A, the values of tensile strength in bending were approximately the same and equal to 3.8 MPa. In general, the pattern of changes in tensile strength in bending was the same as for compressive strength. Compositions 6A, 7A, and 8A exhibited the same sharp drop in strength, and, in comparison with the maximum strength recorded for composition 4A, the tensile strength in bending decreased by more than two times.

In general, during testing, the standard deviation for all compositions did not exceed 3.1 MPa, which can be considered a good value.

One of the objectives of this study was to find the most effective composition of the activator, but the results give a definite conclusion about this. However, it seems that composition 4A, where the ratio of NaOH to Na2SiO3 was (1:2), is a good solution, and compositions 1A, 2A, and 3A are equally acceptable from a practical point of view.

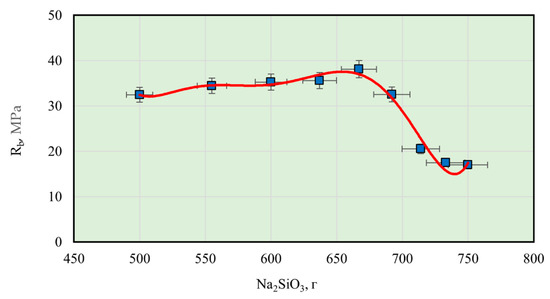

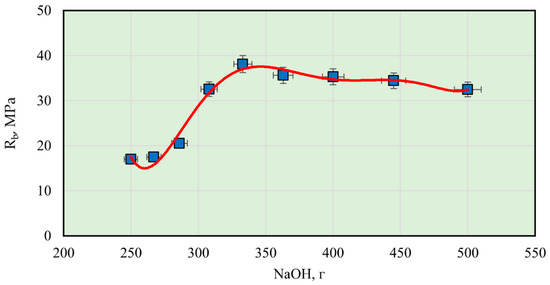

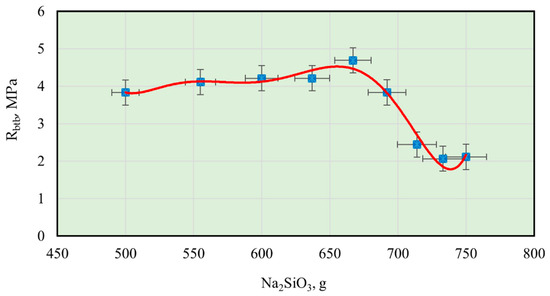

It is known that sodium hydroxide is responsible for the destruction of the internal bonds of the binder at the beginning of the process, and then sodium silicate activates the necessary bonds between the binder and aggregates [7,20]. Therefore, for a certain amount of metakaolin, an optimal balance between the amounts of these components can be expected. In order to find this optimal balance, each of the activators was separated, and polynomial equations of the sixth degree were obtained, showing the dependence of the change in the strength characteristics of geopolymer concrete on the individual influence of each of the activators. Equations (1) and (2) describe the dependence of the change in compressive strength, and Equations (3) and (4) describe the tensile strength in bending on the content of Na2SiO3 (in equation variable x) and NaOH (variable y), respectively. Additionally, graphical interpretations of these polynomial equations were constructed for the individual influence of each of the activators on the compressive and the flexural strength. The values of the determination coefficients given in Equations (1)–(4) showed a good relationship between the regression curve and the data points of the strength characteristics of geopolymer mixtures.

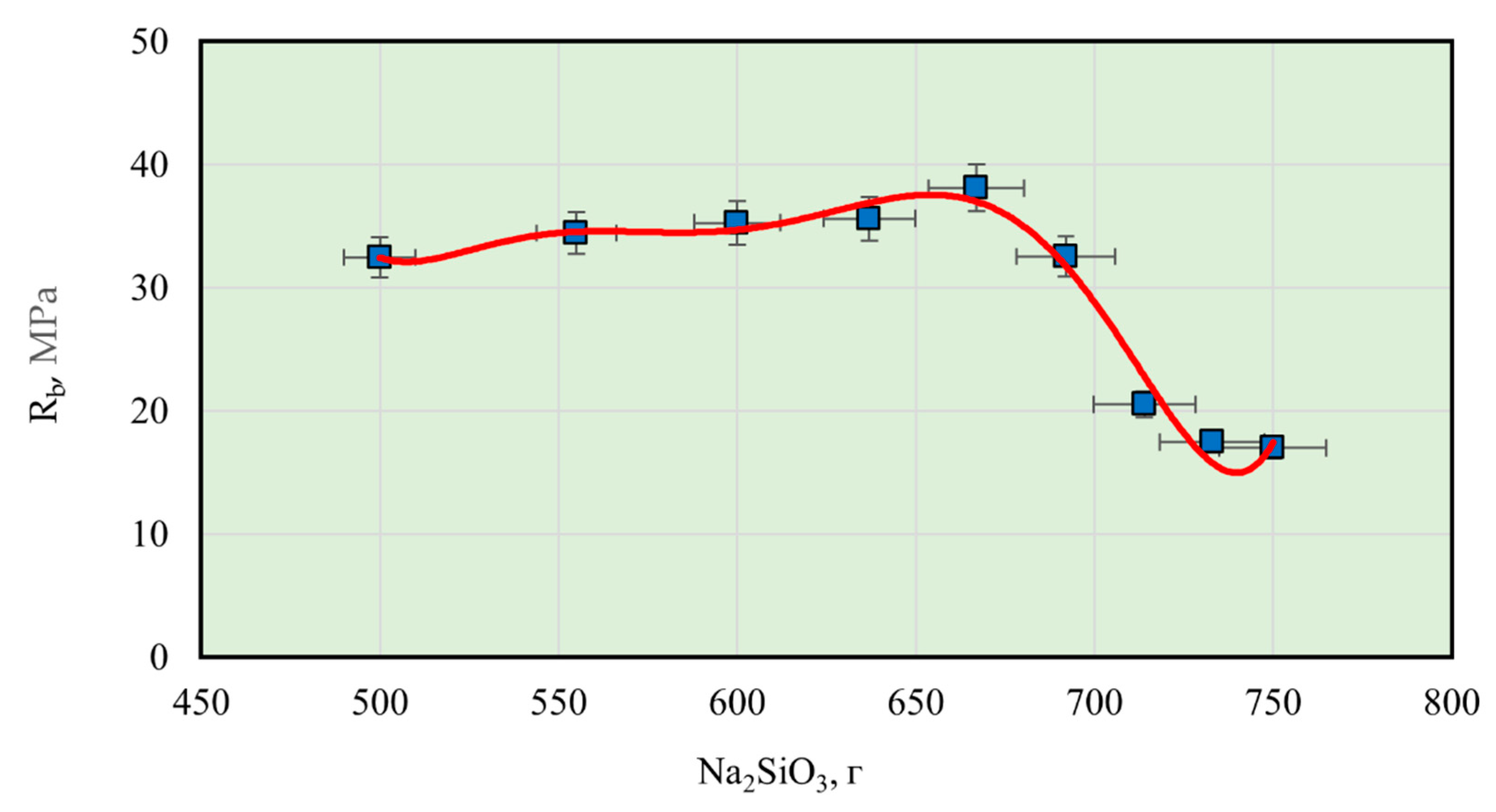

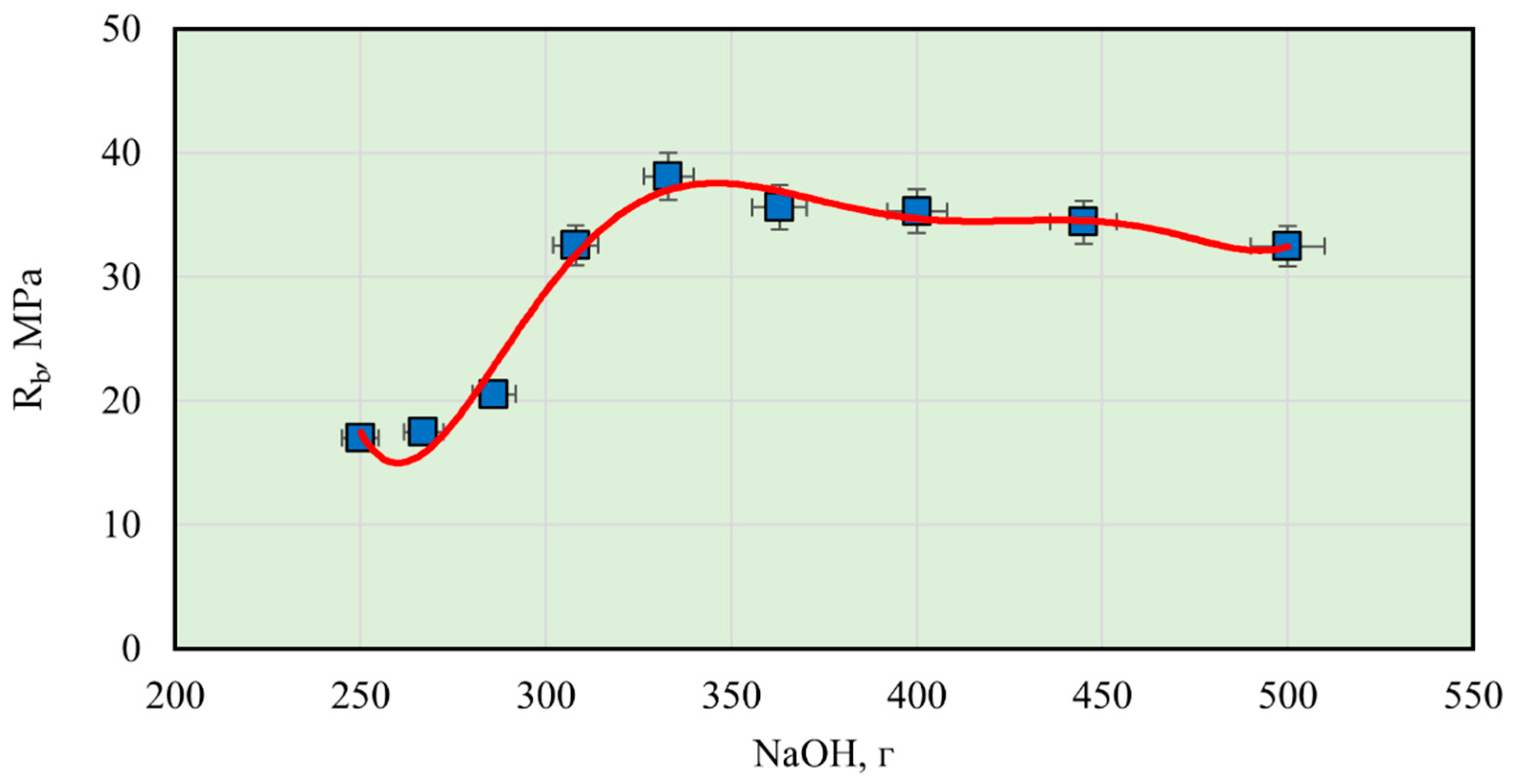

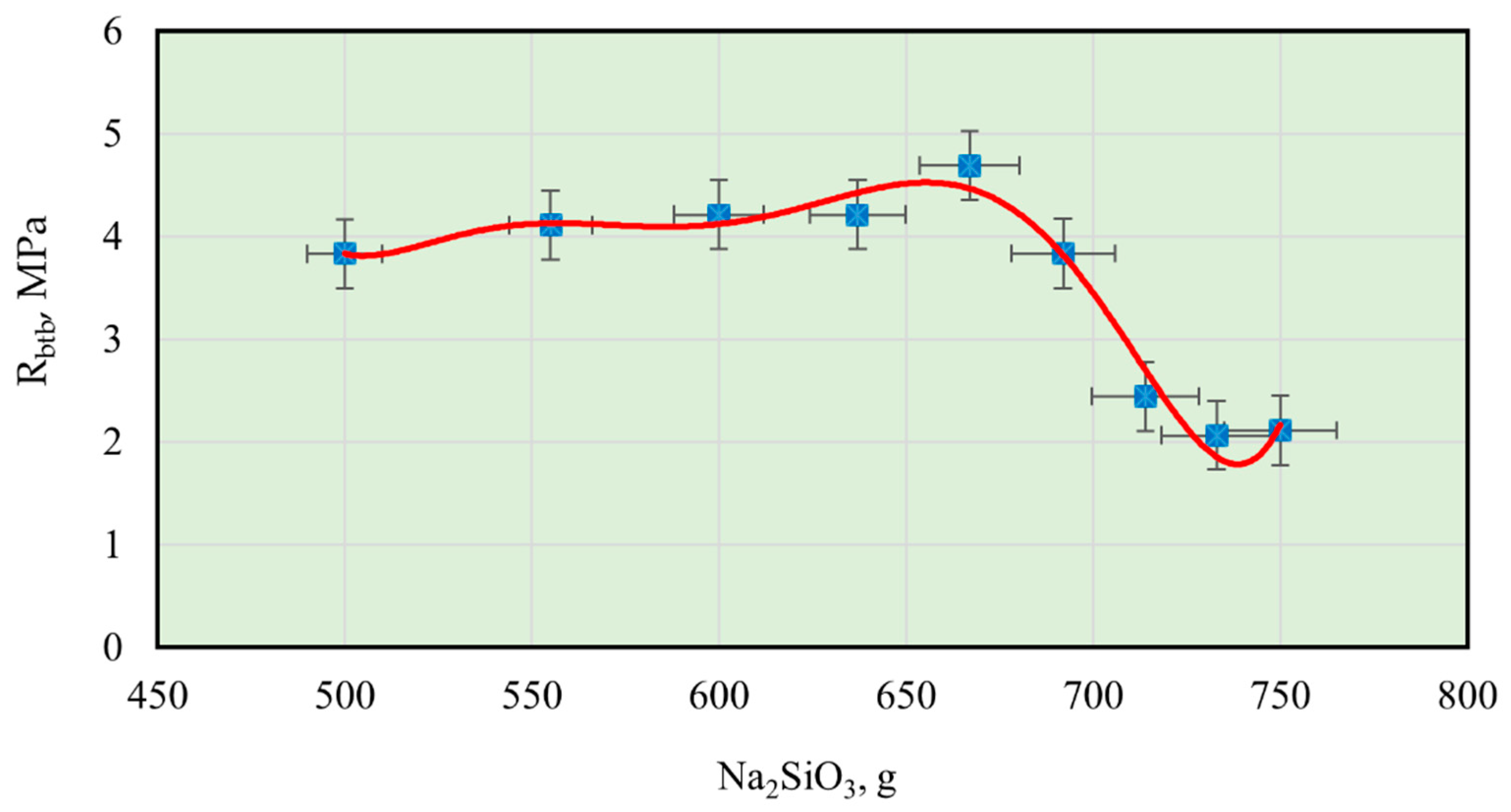

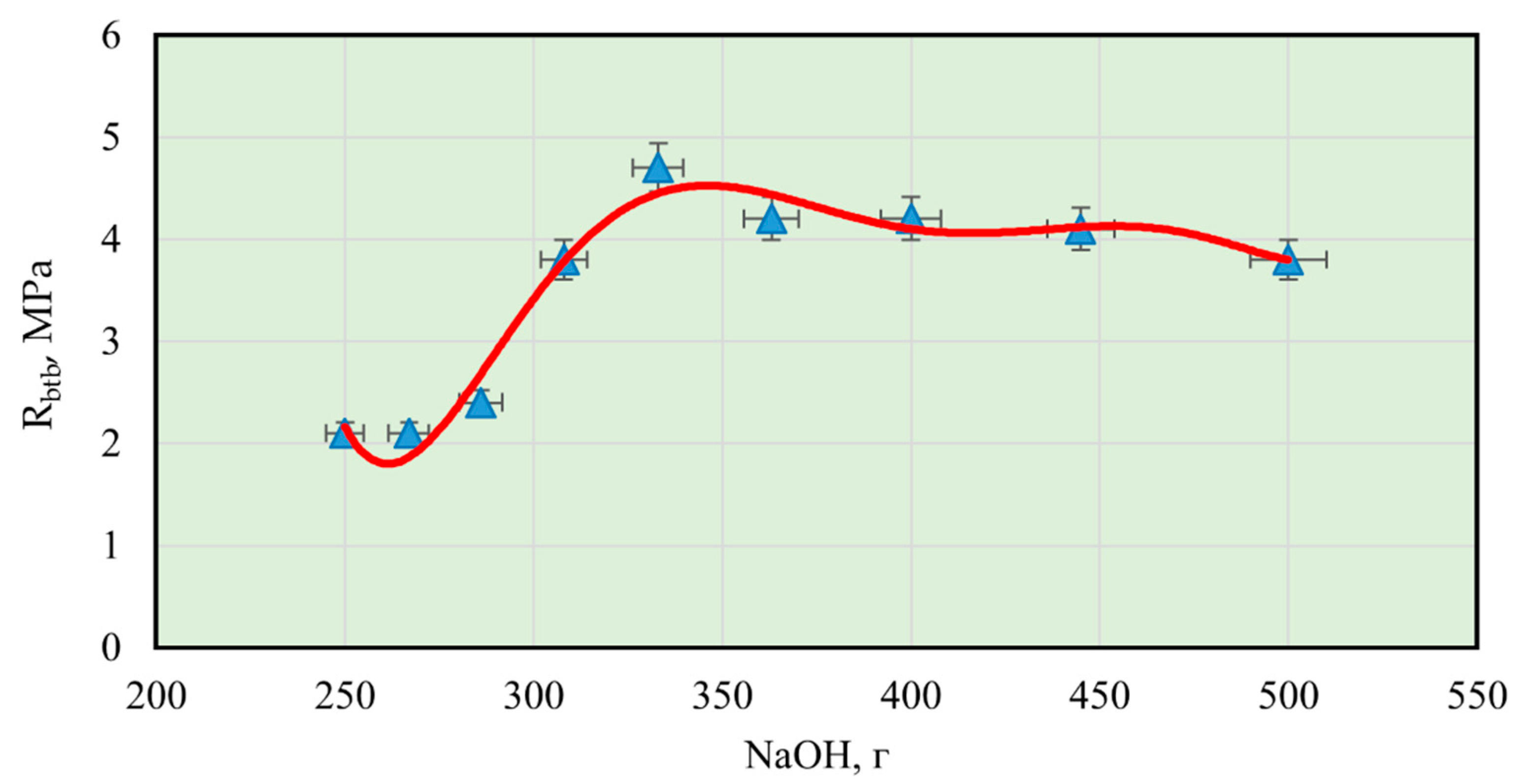

Figure 9, Figure 10, Figure 11 and Figure 12 show the change in ultimate strength in compression and bending depending on the amount of NaOH and Na2SiO3, respectively.

Figure 9.

Influence of sodium silicate (Na2SiO3) on compressive strength.

Figure 10.

Effect of sodium hydroxide (NaOH) on compressive strength.

Figure 11.

Influence of sodium silicate (Na2SiO3) on tensile flexural strength.

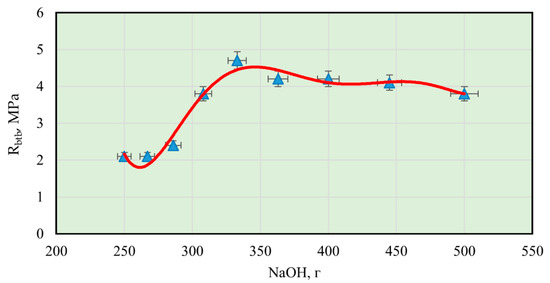

Figure 12.

Effect of sodium hydroxide (NaOH) on flexural tensile strength.

Figure 9 and Figure 10 show the correlation between the content of sodium silicate and the strength characteristics of geopolymer mixtures, and Figure 11 and Figure 12 show a similar correlation only for sodium hydroxide.

Analysis of the graphical dependencies presented in Figure 9, Figure 10, Figure 11 and Figure 12 revealed:

- -

- When the content of Na2SiO3 changed from 500 to 637 g, the value of the compressive strength of geopolymer fine-grained concrete changed insignificantly; the peak value of this indicator corresponded to the content of sodium silicate, equal to 667 g; then, a sharp drop in the dependence curve was observed, which indicated a decrease in the strength of concrete, starting from 690 and up to 750 g. It is logical to assume that a further increase in the sodium silicate content will lead to even-greater drops in strength. A similar picture was observed for the nature of the change in tensile strength in bending.

- -

- When the NaOH content changes from 250 to 283 g, the minimum values of the compressive strength and the tensile strength in bending were observed. The maximum values of these strength characteristics were recorded with a sodium-hydroxide content of 333 g. A change in the NaOH content from 363 to 500 g, both in the case of the compressive strength and the tensile strength in bending, did not lead to a significant change in the strengths; the dependence curve had an almost horizontal character.

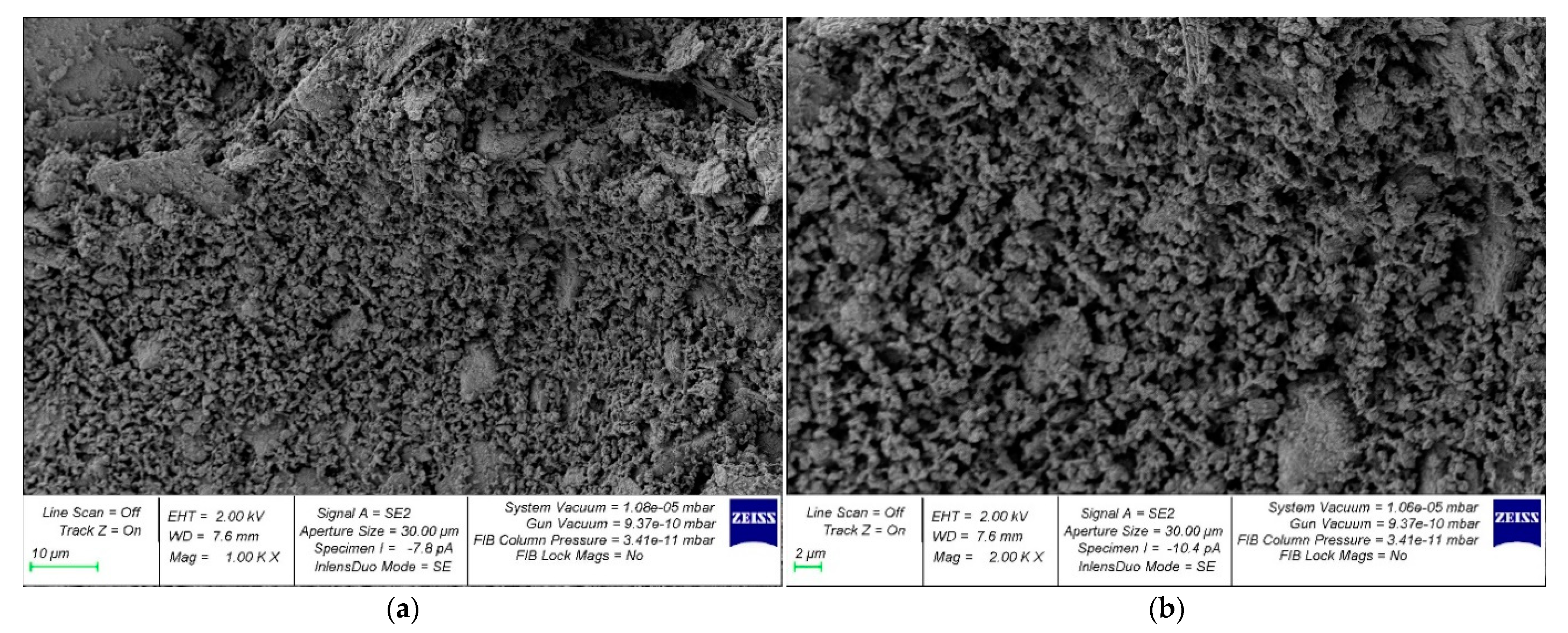

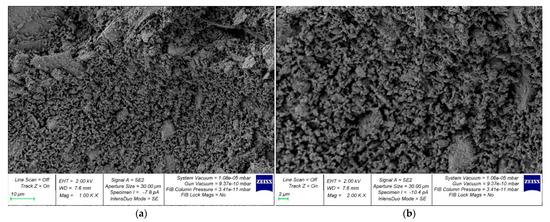

To identify the features of the structure-forming processes in the geopolymer binder system, an analysis of the microstructure of concrete composites based on them was carried out.

According to the data of microstructural studies (Figure 13), the structure of the geopolymer composite samples is characterized by the presence of an amorphous substance—an aluminosilicate component dissolved in alkali, which confirms the course of geopolymerization processes and the formation of a strong structure.

Figure 13.

Photographs of the microstructure of samples of geopolymer concrete of composition 4A: (a) 1000× magnification; (b) 2000× magnification.

The microstructural features of the composition of the type-4A geopolymer composite using a combination of NaOH and Na2SiO3 as an alkaline component in a ratio (1:2) showed the presence of separate areas of a dense monolithic structure (Figure 13).

In addition, in the structure of the binding matrix, there are rounded particles of incompletely reacted pearlite with an almost indistinguishable contact zone at the interface between the phases “newly formed phase—metakaolin grain,” which speaks of two facts:

- -

- An unfinished polymerization process—dissolution of the aluminosilicate component with the subsequent formation of an aluminosilicate gel;

- -

- The presence of high adhesion between the newly formed phases and unreacted particles of the aluminosilicate component.

3.2. Influence of Heat-Treatment Parameters on the Strength Properties of Geopolymer Concrete

It is generally accepted that the application of heat treatment (HT) to various types of binders and composites can intensify the hardening processes and provide higher strength characteristics of the finished product in a shorter time compared to hardening in natural conditions. So, the use of HT for a geopolymer binder when using the optimal mode also contributes to the intensification of structure-forming processes and, consequently, a set of strength indicators of the final composite.

To determine the influence of HT parameters on the kinetics of the strength gain of geopolymers, five series of samples-beams of geopolymer binder composition 4A were made (Figure 14).

Figure 14.

The process of heat treatment of samples-beams of geopolymer fine-grained concrete.

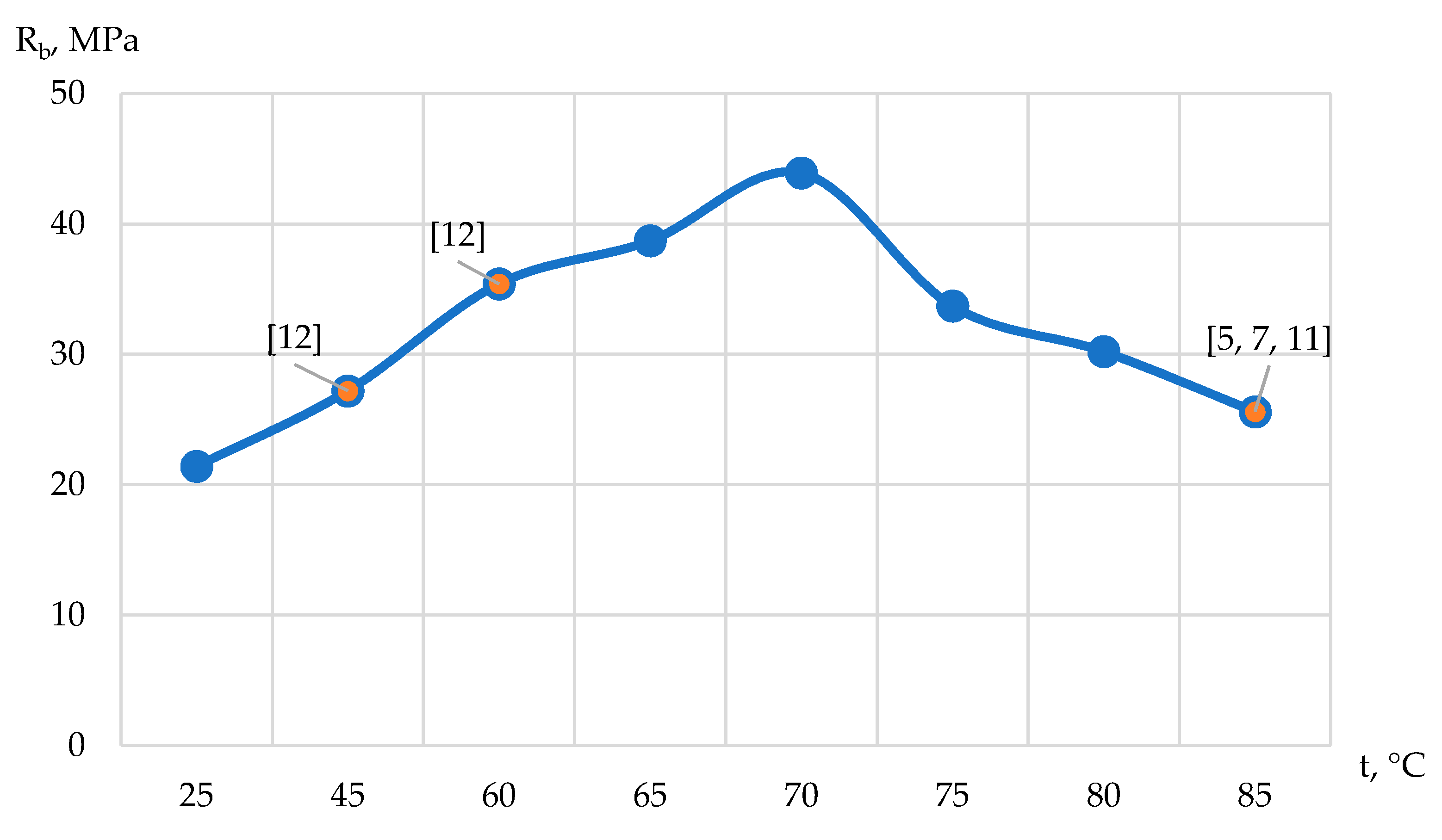

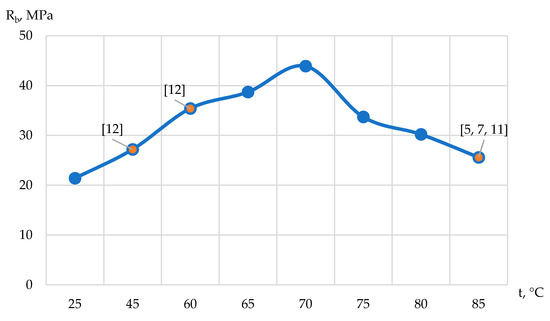

The change in the ultimate strength in compression of samples of geopolymer fine-grained concrete, depending on the parameters of heat treatment, is shown in Figure 15.

Figure 15.

Compressive strength of geopolymer fine-grained concrete specimens depending on heat-treatment temperature: [5,7,11,12]—data obtained by other researchers according to references.

The duration of heat treatment of the test samples was 24 h.

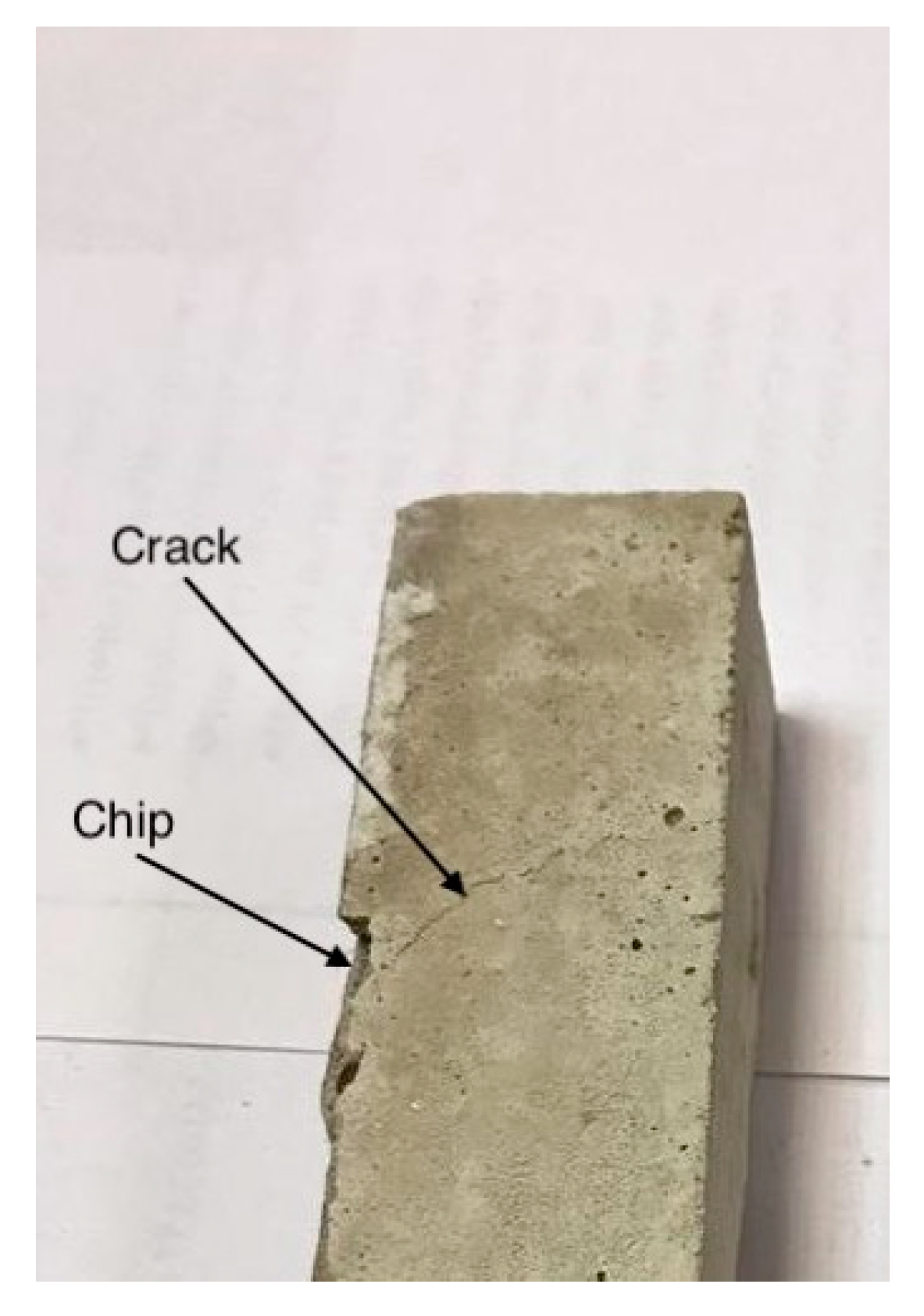

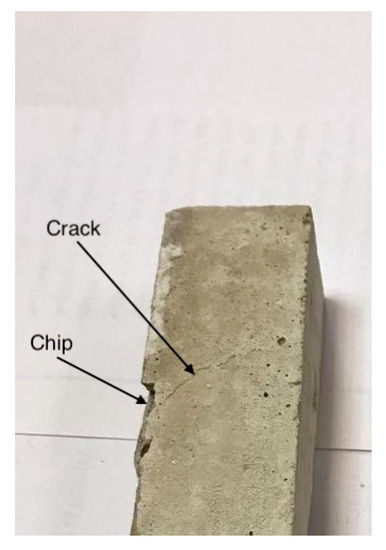

Based on the data obtained and [5,7,11,12], it should be noted that the processing temperature has a significant effect on the investigated compositions of geopolymer binders. Figure 15 shows that an increase in temperature in the range from 25 °C to 65 °C provides a strength gain at the age of 28 days up to 110% and in the range from 65 °C to 70 °C up to 130% compared to a heat-treatment temperature of 25 °C. The lowest values of the compressive strength were recorded for the samples of geopolymer fine-grained concrete treated at a temperature of 25 °C. A further increase in temperature to 75–80 °C and to 85 °C [5,7,11] leads to a decrease in strength characteristics, which is caused by the occurrence of micro- and macro-destructive processes, which are especially clearly observed in the samples of geopolymer concrete after HT at 80 °C in the form of cracks. A visual assessment of these compositions demonstrates the formation of structural deformations (cracks and chips) in the studied samples of geopolymer fine-grained concrete (Figure 16).

Figure 16.

Sample of geopolymer fine-grained concrete after heat treatment at 80 °C.

Thus, the optimal temperature range of heat treatment of geopolymer concrete samples with a duration of 24 h was determined, which contributes to the acquisition of the highest compressive strength at the age of 28 days. In addition, points based on the data [5,7,11,12] were added to the graphical dependence, as a result of which the similarity of the data obtained in the presented study with the results of other authors were found.

4. Discussion

After reviewing and analyzing the literature [4,5,6,7,8,9,10,11,12,13,14,15,16,17,18,19,20,21,22,23,24,25,26,27,28,29,30,31], the task was to compare the theoretical concepts of the formation of the structure of geopolymer concrete with the ideas of other authors and researchers. In particular, the mechanism of structure formation that described the chemical essence of the process was reflected and revealed, as well as its physical mechanism.

In addition, after conducting experimental studies, a comparative analysis was carried out between various types of components and raw materials for obtaining geopolymer concrete in this study and in studies previously conducted by other scientists. In particular, the ratios of sodium hydroxide and sodium silicate in the composition of the resulting geopolymer concrete were most interested.

The role of the combined alkaline activator on the strength characteristics of geopolymer fine-grained concrete was revealed, rational dosages of the components of geopolymer concrete were given, recommended compositions were given, and technological parameters were determined.

Previously, the studies carried out in [4,5,6,7,8,9,10,11,12,13,14,15,16,17,18,19,20,21,22,23,24,25,26,27,28,29,30,31] did not consider the parameters related to the ratio of sodium hydroxide and sodium silicate in the composition of the resulting geopolymer concrete. In addition, for the first time, we gave recommendations on specifically applied materials, which were selected based not only on their qualitative characteristics but also on their criterion of environmental friendliness and economic efficiency.

Below is a comparative assessment of the effectiveness of resource-saving technologies in the direction of obtaining geopolymer concrete.

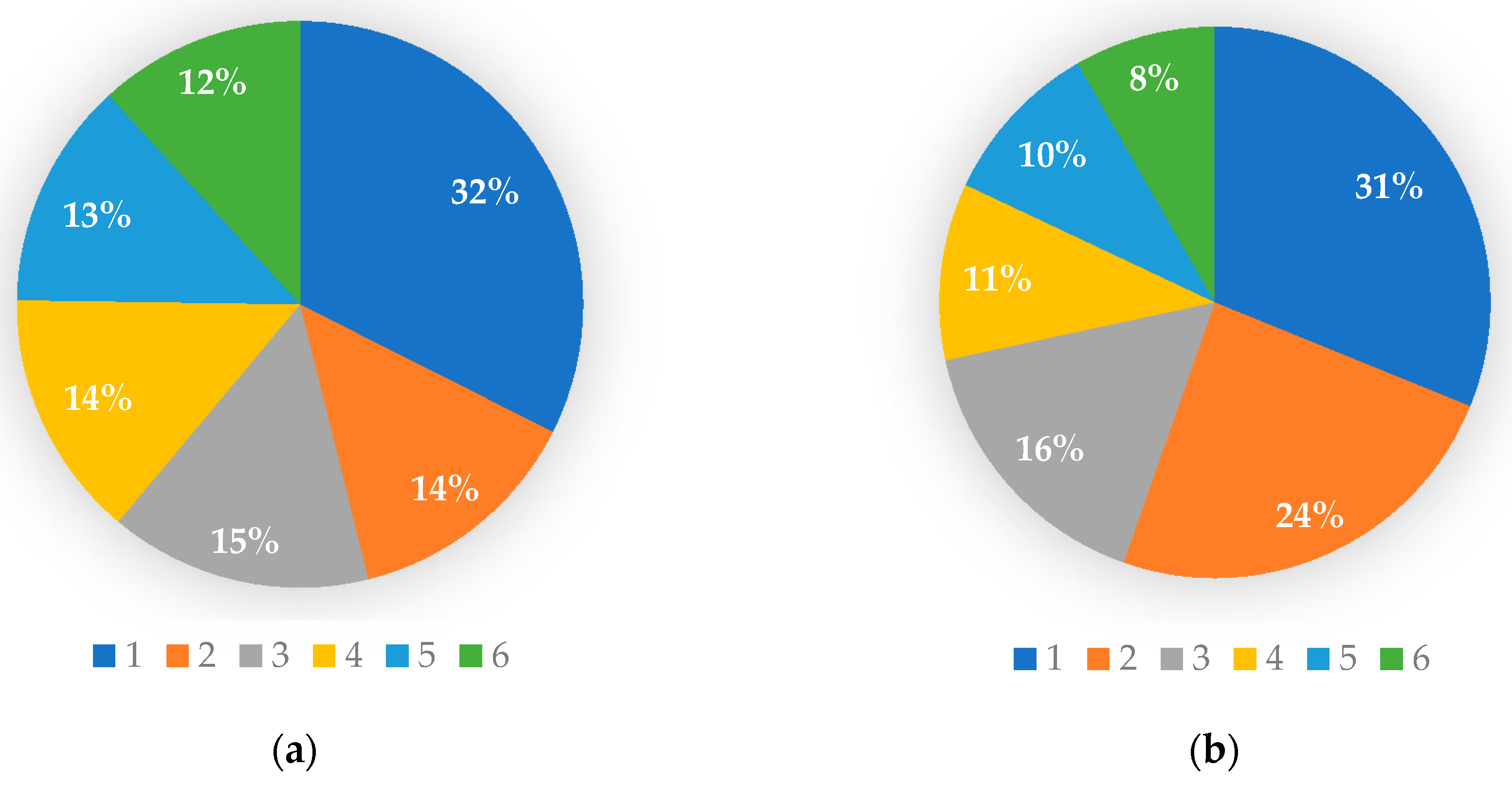

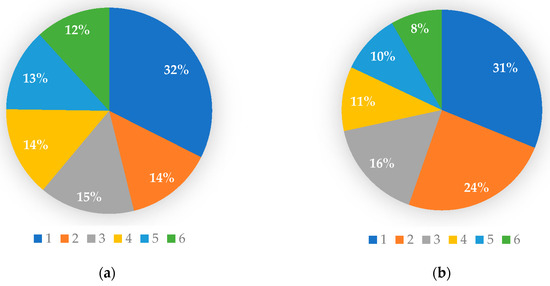

The largest share of energy consumption in the production of geopolymers falls on the production of a hardening activator, which includes sodium or potassium metasilicate (soluble glass). This component of the binder is obtained at specialized enterprises in the process of high-temperature cooking. The production of metasilicate is not directly included in the technology for the production of geopolymer binder, but due to the fact that this process is energy intensive, the energy consumption for the production of alkali metal metasilicates is taken into account in the calculations. Replacing Portland cement with geopolymer binders allows obtaining a resource-saving effect by replacing carbonate raw materials, which, during firing, lose almost half of their mass due to the release of carbon dioxide (Figure 17a). The technology for producing geopolymer materials belongs to “green technologies” [23,24]. In the production of geopolymer binders, carbon dioxide emissions into the atmosphere are three to four times lower than in the production of Portland cement (Figure 17b) [11].

Figure 17.

Consumption of raw materials (a), as well as the emission of carbon dioxide (b) when obtaining various types of building materials: 1—Portland cement (wet method); 2—Portland cement (dry method); 3—brick; 4—slag-alkaline binder; 5—geopolymer binder based on metakaolin; 6—mineral-alkaline geopolymer binder.

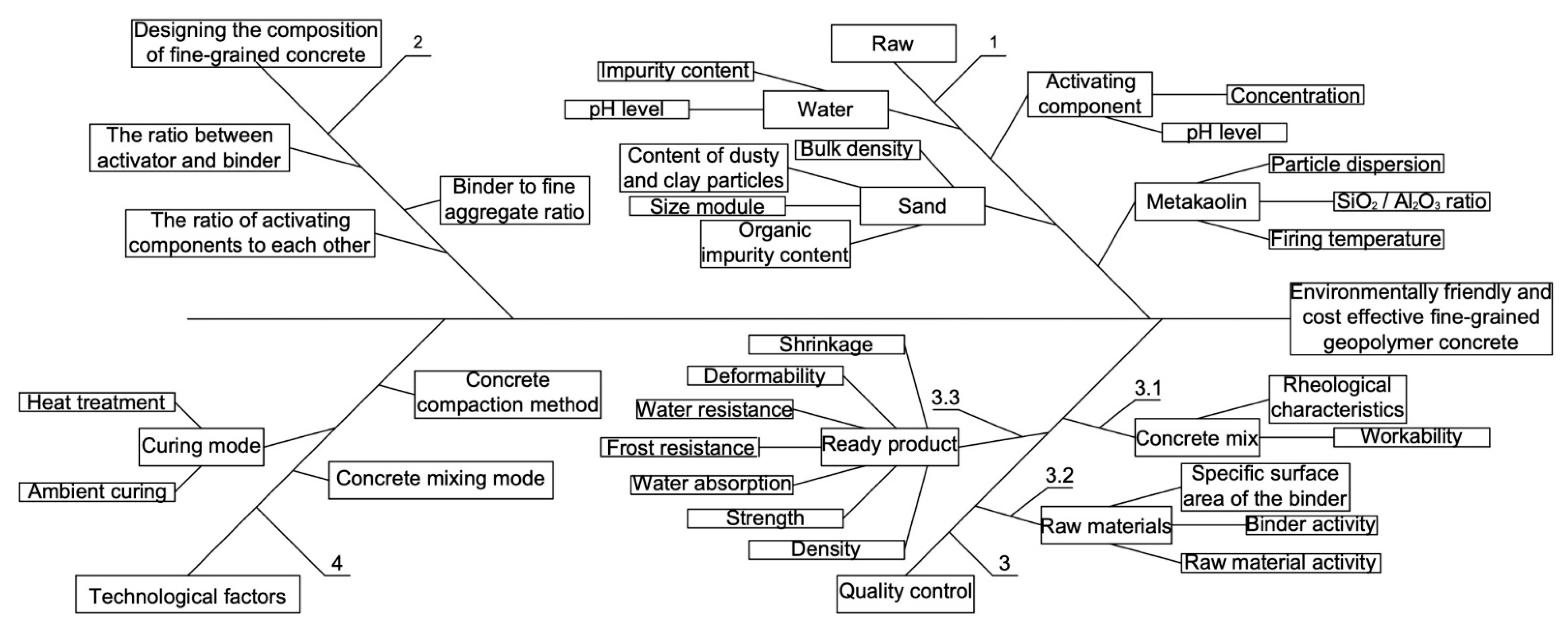

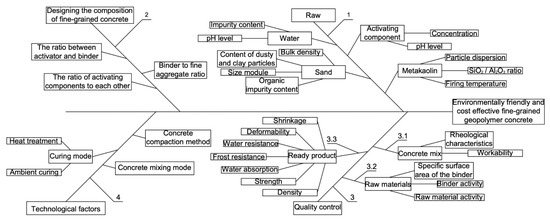

For visualization of the analysis of the proposed technology, Figure 18 shows a cause-and-effect diagram of the problem of obtaining environmentally friendly and cost-effective geopolymer fine-grained concrete.

Figure 18.

Cause-and-effect diagram of the problem of obtaining environmentally friendly and cost-effective geopolymer fine-grained concrete.

Thus, the most important and significant factors influencing the formation of the quality of geopolymer concrete were grouped and analyzed.

Branch 1 (Figure 18) of the upper part of the diagram reflects the characteristics of raw materials that affect the quality of geopolymer concrete as a final product. On branch 2 (Figure 18) of the upper part of the diagram, recipe parameters are shown, which also significantly affect the values of the final physical and mechanical characteristics of the geopolymer composite.

On branch 3 of the lower part of the diagram in its right part (3.1 and 3.2), the characteristics of the geopolymer mixture and raw materials that are mandatory for quality control are reflected. As for the right side (3.3) of branch 3, it presents the most-important physical and mechanical characteristics of geopolymer concrete, on the actual values of which in the future the field of application and the environment of operation of this concrete will depend. On branch 4 of the diagram, technological factors are presented, which, like those previously listed, are no less important, and the actual physical and mechanical characteristics of geopolymer concrete will directly depend on them.

5. Conclusions

The change in mechanical properties depending on the composition of geopolymer fine-grained concrete was estimated. Various activator compositions were tested to draw conclusions in terms of mechanical properties and the use of these materials in structural elements and ultimately in the construction industry.

It was found that for this type of aluminosilicate component, the most effective activator is a composition of NaOH and Na2SiO3 with a ratio of 1:2, which is probably due to the good size-atomic compatibility of the alkali-aluminosilicate system, as well as the optimal combination of the sequence and the intensity of chemical processes.

The main technological and recipe parameters for obtaining geopolymers with desired properties, which meet the requirements of ecology and are efficient from the point of view of economics, were determined. A significant effect of the composition of the alkaline activator on the strength characteristics of geopolymer fine-grained concrete was established. The increase in the indicators of the obtained geopolymer concrete from the developed composition (4A) in relation to the base control (1X) was 17% in terms of compressive strength and 24% in terms of tensile strength in bending.

The microstructural features of the composition of the type-4A geopolymer composite showed the presence of particular areas of a dense monolithic structure with an incomplete dissolution of the aluminosilicate component followed by forming an aluminosilicate gel and high adhesion zones between the newly formed phases and unreacted particles of the aluminosilicate component in the structure of the binder matrix.

It was also noted that the temperature of heat treatment has a positive effect on the kinetics of strength gain in the studied compositions. The optimal temperature range of heat treatment of geopolymer concrete samples with a duration of 24 h was determined, which contributes to the acquisition of the highest compressive strength at the age of 28 days (up to 130%).

This gives us a cost-effective material at a substantially reduced production cost. According to preliminary estimates of interested industrial partners, economic efficiency will be up to 25% in terms of the cost of the finished product.

It is advisable to consider the prospects for further research in the direction of expanding the range of building composites for both general and special purposes based on the geopolymer binder.

Author Contributions

Conceptualization, L.R.M., S.A.S., E.M.S., A.N.B. and D.E.; methodology, S.A.S. and E.M.S.; software, S.A.S., E.M.S., A.N.B. and D.E.; validation, L.R.M., S.A.S., E.M.S. and A.N.B.; formal analysis, S.A.S. and E.M.S.; investigation, L.R.M., S.A.S., E.M.S., A.N.B., V.V. and B.M.; resources, B.M.; data curation, S.A.S. and E.M.S.; writing—original draft preparation, S.A.S., E.M.S. and A.N.B.; writing—review and editing, S.A.S. and E.M.S. and A.N.B.; visualization, S.A.S., E.M.S., A.N.B. and D.E.; supervision, L.R.M. and B.M.; project administration, L.R.M. and B.M.; funding acquisition, A.N.B. and B.M. All authors have read and agreed to the published version of the manuscript.

Funding

The APC was funded by Don State Technical University.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The study did not report any data.

Acknowledgments

The authors would like to acknowledge the administration of Don State Technical University for their resources and financial support.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Anysz, H.; Narloch, P. Designing the composition of cement stabilized rammed earth using artificial neural networks. Materials 2019, 12, 1396. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Beskopylny, A.; Kadomtseva, E.; Strelnikov, G.; Morgun, L.; Berdnik, Y.; Morgun, V. Model of heterogeneous reinforced fiberfoam concrete in bending. IOP Conf. Ser. Mater. Sci. Eng. 2018, 365, 032023. [Google Scholar] [CrossRef]

- Mailyan, L.R.; Beskopylny, A.N.; Meskhi, B.; Shilov, A.V.; Stel’makh, S.A.; Shcherban’, E.M.; Smolyanichenko, A.S.; El’shaeva, D. Improving the Structural Characteristics of Heavy Concrete by Combined Disperse Reinforcement. Appl. Sci. 2021, 11, 6031. [Google Scholar] [CrossRef]

- Criado, M.; Fernández-Jiménez, A.; Palomo, A. Alkali activation of fly ash. Part III: Effect of curing conditions on reaction and its graphical description. Fuel 2010, 89, 3185–3192. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymers: Ceramic-Like Inorganic Polymers. J. Ceram. Sci. Technol. 2017, 8, 335–350. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymer Cement a review. Geopolymer Sci. Tech. 2013, 21, 1–11. Available online: https://www.researchgate.net/publication/306946529_Geopolymer_Cement_a_review_2013 (accessed on 8 December 2021).

- Davidovits, J. Geopolymer Chemistry and Applications, 5th ed.; Geopolymer Institute: Saint-Quentin, France, 2020; 680p, ISBN 9782954453118. [Google Scholar]

- Davidovits, J. Global Worming Impact on the Cement and Aggregates Industries. World Resour. Rev. 1994, 6, 263–278. Available online: https://www.researchgate.net/publication/236503901 (accessed on 8 December 2021).

- Davidovits, J.; Davidovits, R. Pat. US 7,229,491 United States, C04B 12/04, CO1B 33/26, Red Lion Cement Technology Limited, Road Town, Tortola (VG) No. WO03/099738; Publ. 12.06.07, 7p. Available online: https://patents.google.com/patent/US7229491B2/en (accessed on 25 October 2021).

- Fernandez-Jimenez, A.; Palomo, A. Composition and microstructure of alkali activated fly ash binder: Effect of the activator. Cem. Concr. Res. 2005, 35, 1984–1992. [Google Scholar] [CrossRef]

- Eroshkina, N.A.; Korovkin, M.O.; Korovchenko, I.V. Resource-saving effectiveness of technologies geopolymer binders based on magmatic rocks. Mod. Sci. Res. Innov. 2015, 3, 50975. Available online: https://web.snauka.ru/issues/2015/03/50975 (accessed on 8 December 2021).

- Kozhukhova, N.I.; Fomina, E.V.; Zhernovsky, I.V.; Strokova, V.V.; Chizhov, R.V. The Utilization Efficiency of Natural Alumosilicates in Composite Binders. Appl. Mech. Mater. 2014, 670–671, 182–186. [Google Scholar] [CrossRef]

- Karthik, S.; Mohan, K.S.R. A Taguchi Approach for Optimizing Design Mixture of Geopolymer Concrete Incorporating Fly Ash, Ground Granulated Blast Furnace Slag and Silica Fume. Crystals 2021, 11, 1279. [Google Scholar] [CrossRef]

- Lei, J.; Fu, J.; Yang, E.-H. Alkali-Silica Reaction Resistance and Pore Solution Composition of Low-Calcium Fly Ash-Based Geopolymer Concrete. Infrastructures 2020, 5, 96. [Google Scholar] [CrossRef]

- Sathish Kumar, V.; Ganesan, N.; Indira, P.V. Effect of Hybrid Fibres on the Durability Characteristics of Ternary Blend Geopolymer Concrete. J. Compos. Sci. 2021, 5, 279. [Google Scholar] [CrossRef]

- Waqas, R.M.; Butt, F.; Zhu, X.; Jiang, T.; Tufail, R.F. A Comprehensive Study on the Factors Affecting the Workability and Mechanical Properties of Ambient Cured Fly Ash and Slag Based Geopolymer Concrete. Appl. Sci. 2021, 11, 8722. [Google Scholar] [CrossRef]

- Mohammed, A.A.; Ahmed, H.U.; Mosavi, A. Survey of Mechanical Properties of Geopolymer Concrete: A Comprehensive Review and Data Analysis. Materials 2021, 14, 4690. [Google Scholar] [CrossRef]

- Ding, Y.; Bai, Y.-L.; Dai, J.-G.; Shi, C.-J. An Investigation of Softening Laws and Fracture Toughness of Slag-Based Geopolymer Concrete and Mortar. Materials 2020, 13, 5200. [Google Scholar] [CrossRef] [PubMed]

- Nikoloutsopoulos, N.; Sotiropoulou, A.; Kakali, G.; Tsivilis, S. Physical and Mechanical Properties of Fly Ash Based Geopolymer Concrete Compared to Conventional Concrete. Buildings 2021, 11, 178. [Google Scholar] [CrossRef]

- Rehman, S.K.U.; Imtiaz, L.; Aslam, F.; Khan, M.K.; Haseeb, M.; Javed, M.F.; Alyousef, R.; Alabduljabbar, H. Experimental Investigation of NaOH and KOH Mixture in SCBA-Based Geopolymer Cement Composite. Materials 2020, 13, 3437. [Google Scholar] [CrossRef] [PubMed]

- Goonewardena, J.; Ghabraie, K.; Subhani, M. Flexural Performance of FRP-Reinforced Geopolymer Concrete Beam. J. Compos. Sci. 2020, 4, 187. [Google Scholar] [CrossRef]

- Hsieh, Y.-C.; Lee, W.-H.; Liao, P.-H. Using Geopolymer Technology on Synthesizing Leucite Ceramics. Polymers 2021, 13, 3621. [Google Scholar] [CrossRef]

- Azad, N.M.; Samarakoon, S. Utilization of Industrial By-Products/Waste to Manufacture Geopolymer Cement/Concrete. Sustainability 2021, 13, 873. [Google Scholar] [CrossRef]

- Imtiaz, L.; Rehman, S.K.U.; Ali Memon, S.; Khizar Khan, M.; Faisal Javed, M. A Review of Recent Developments and Advances in Eco-Friendly Geopolymer Concrete. Appl. Sci. 2020, 10, 7838. [Google Scholar] [CrossRef]

- Dao, D.V.; Ly, H.-B.; Trinh, S.H.; Le, T.-T.; Pham, B.T. Artificial Intelligence Approaches for Prediction of Compressive Strength of Geopolymer Concrete. Materials 2019, 12, 983. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, L.; Wang, Z.; Wang, Y.; Feng, J. Preparation and Properties of Alkali Activated Metakaolin-Based Geopolymer. Materials 2016, 9, 767. [Google Scholar] [CrossRef] [Green Version]

- Fazli, H.; Yan, D.; Zhang, Y.; Zeng, Q. Effect of Size of Coarse Aggregate on Mechanical Properties of Metakaolin-Based Geopolymer Concrete and Ordinary Concrete. Materials 2021, 14, 3316. [Google Scholar] [CrossRef] [PubMed]

- Hussain, K.; Butt, F.; Alwetaishi, M.; Waqas, R.M.; Aslam, F.; Ibraheem, M.; Xulong, Z.; Ahmad, N.; Tufail, R.F.; Musarat, M.A.; et al. Effect of Quarry Rock Dust as a Binder on the Properties of Fly Ash and Slag-Based Geopolymer Concrete Exposed to Ambient and Elevated Temperatures. Appl. Sci. 2021, 11, 9192. [Google Scholar] [CrossRef]

- Longos, A., Jr.; Tigue, A.A.; Dollente, I.J.; Malenab, R.A.; Bernardo-Arugay, I.; Hinode, H.; Kurniawan, W.; Promentilla, M.A. Optimization of the Mix Formulation of Geopolymer Using Nickel-Laterite Mine Waste and Coal Fly Ash. Minerals 2020, 10, 1144. [Google Scholar] [CrossRef]

- Lăzărescu, A.-V.; Szilagyi, H.; Baeră, C.; Hegyi, A. Parametric Studies Regarding the Development of Alkali-Activated Fly Ash-Based Geopolymer Concrete Using Romanian Local Raw Materials. Proceedings 2020, 63, 11. [Google Scholar] [CrossRef]

- Abousnina, R.; Alsalmi, H.I.; Manalo, A.; Allister, R.L.; Alajarmeh, O.; Ferdous, W.; Jlassi, K. Effect of Short Fibres in the Mechanical Properties of Geopolymer Mortar Containing Oil-Contaminated Sand. Polymers 2021, 13, 3008. [Google Scholar] [CrossRef]

- GOST R 55064-2012 Sodium Hydroxide for Industrial Use. Specifications. Available online: https://docs.cntd.ru/document/1200101778 (accessed on 25 October 2021).

- GOST 24363-80 Reagents. Potassium Hydroxide. Specifications. Available online: https://docs.cntd.ru/document/1200017451 (accessed on 25 October 2021).

- GOST 13078-81 Sodium Silicate Solute. Specifications. Available online: https://docs.cntd.ru/document/1200019060 (accessed on 25 October 2021).

- GOST 23732-2011 Water for Concrete and Mortars. Specifications. Available online: https://docs.cntd.ru/document/1200093835 (accessed on 25 October 2021).

- GOST 30744-2001 CEMENTS. Methods of Testing with Using Polyfraction Standard Sand. Available online: https://docs.cntd.ru/document/1200011363 (accessed on 25 October 2021).

- Stel’makh, S.A.; Shcherban’, E.M.; Beskopylny, A.N.; Mailyan, L.R.; Meskhi, B.; Butko, D.; Smolyanichenko, A.S. Influence of Composition and Technological Factors on Variatropic Efficiency and Constructive Quality Coefficients of Lightweight Vibro-Centrifuged Concrete with Alkalized Mixing Water. Appl. Sci. 2021, 11, 9293. [Google Scholar] [CrossRef]

- Khalyushev, A.K.; Scherban, E.M.; Stelmakh, S.A.; Nalimova, A.V.; Egorochkina, I.O.; Sysoev, A.K.; Zholobova, E.A. Force modeling of interparticle pair interaction of spheroid in composite cement. IOP Conf. Ser. Mater. Sci. Eng. 2020, 905, 012061. Available online: https://iopscience.iop.org/article/10.1088/1757-899X/905/1/012061 (accessed on 8 December 2021). [CrossRef]

- Khalyushev, A.; Stelmakh, S.; Shcherban, E.; Chernilnik, A. Structural Formation of the Cement Pastes Based on the Concrete Modified Dispersed Mineral Components. Mater. Sci. Forum 2020, 1011, 14–22. [Google Scholar] [CrossRef]

- Mailyan, L.R.; Beskopylny, A.N.; Meskhi, B.; Stel’makh, S.A.; Shcherban, E.M.; Ananova, O. Optimization of Composition and Technological Factors for the Lightweight Fiber-Reinforced Concrete Production on a Combined Aggregate with an Increased Coefficient of Structural Quality. Appl. Sci. 2021, 11, 7284. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).