Regenerative Textiles: A Framework for Future Materials Circularity in the Textile Value Chain

Abstract

:1. Introduction

2. Method

3. Results and Discussion

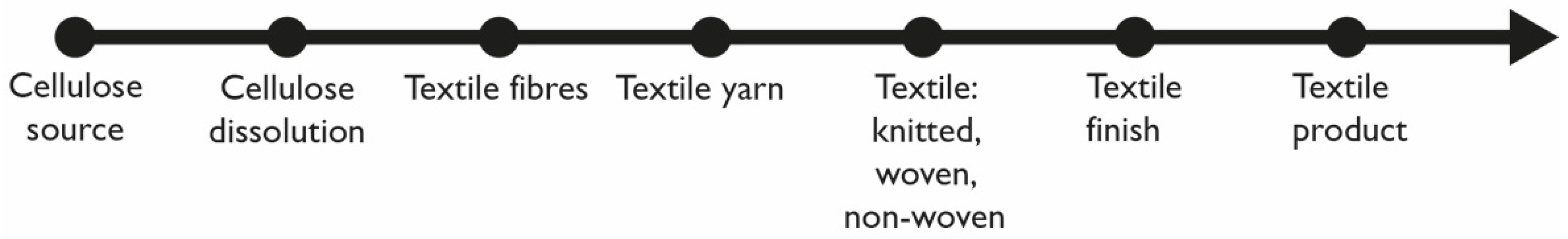

3.1. Textile Design and Regenerated Cellulose Projects

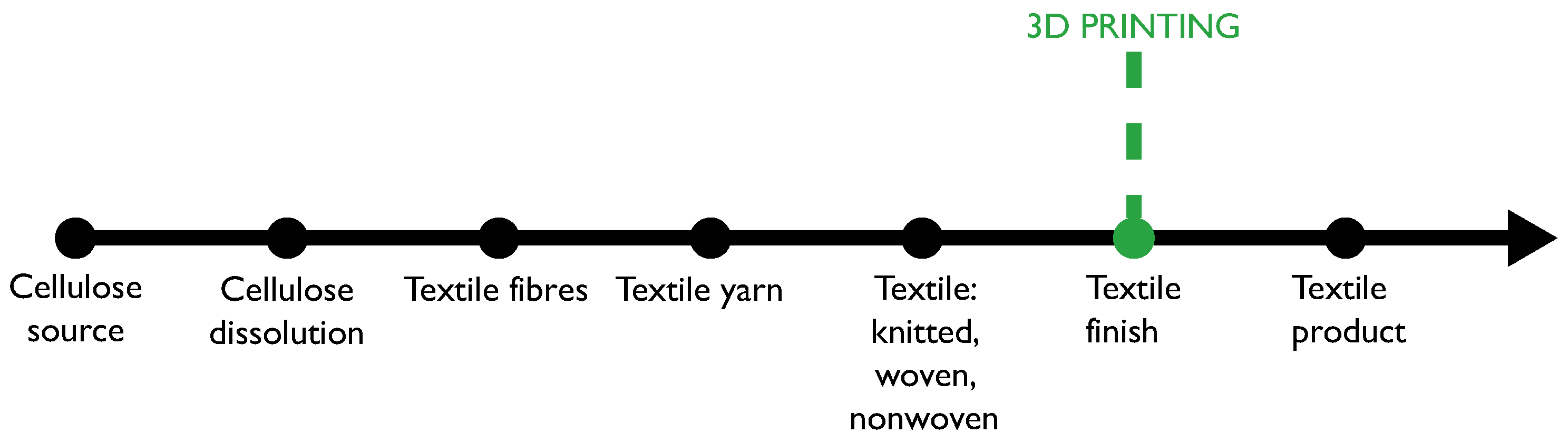

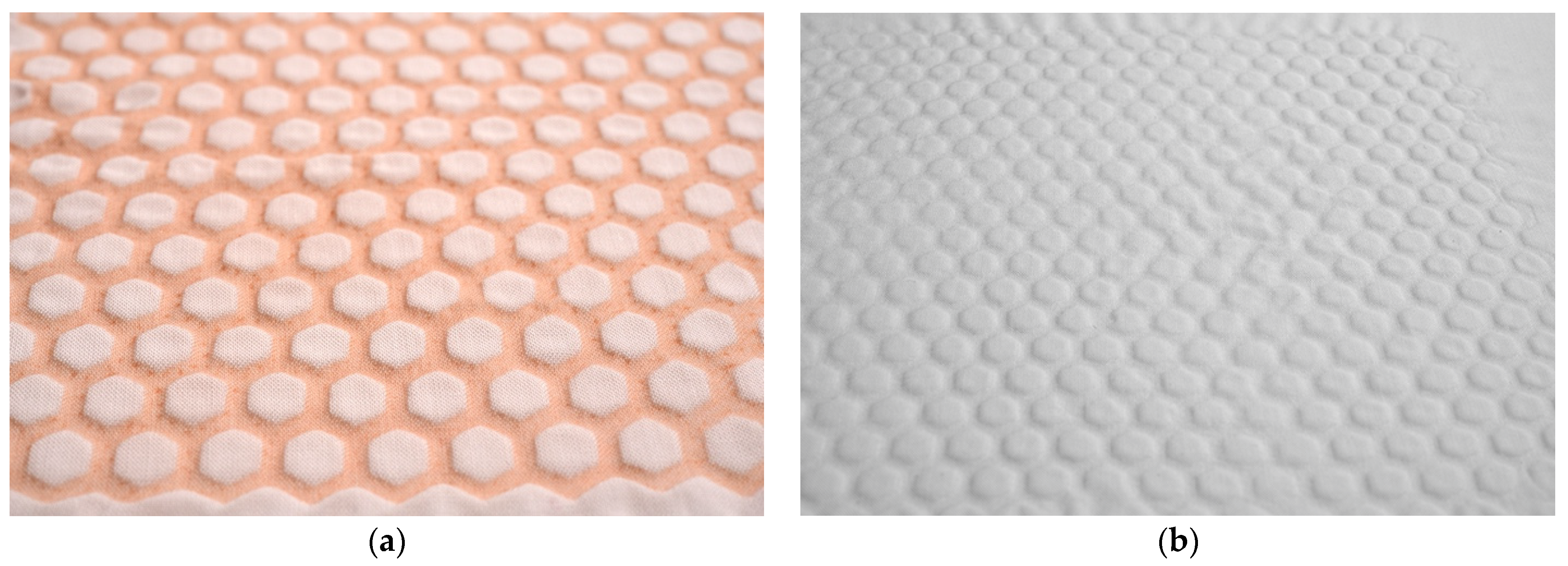

3.1.1. Textile Finishing Stage

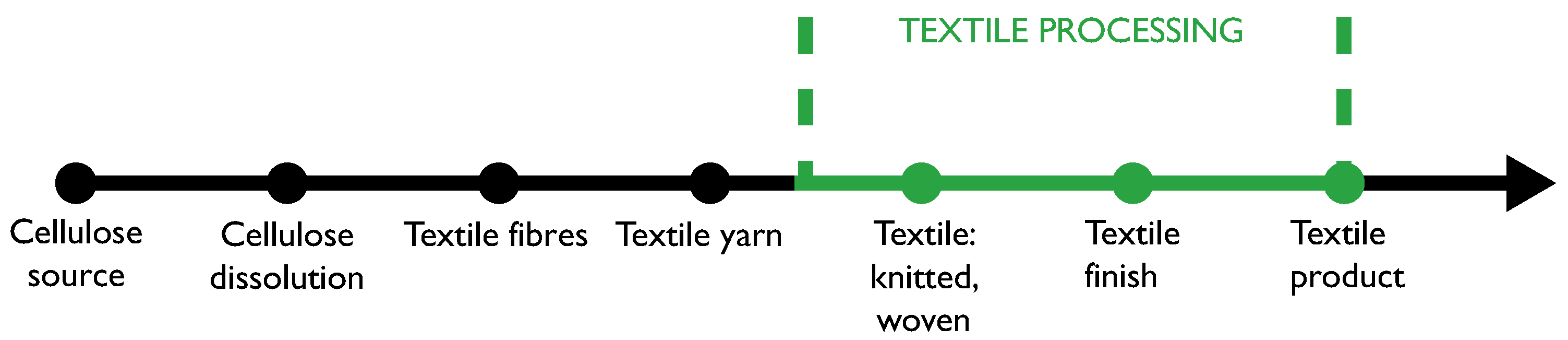

3.1.2. Textile and Yarn Stages

3.1.3. Textile Fibre Stage

3.1.4. Raw Material Stage

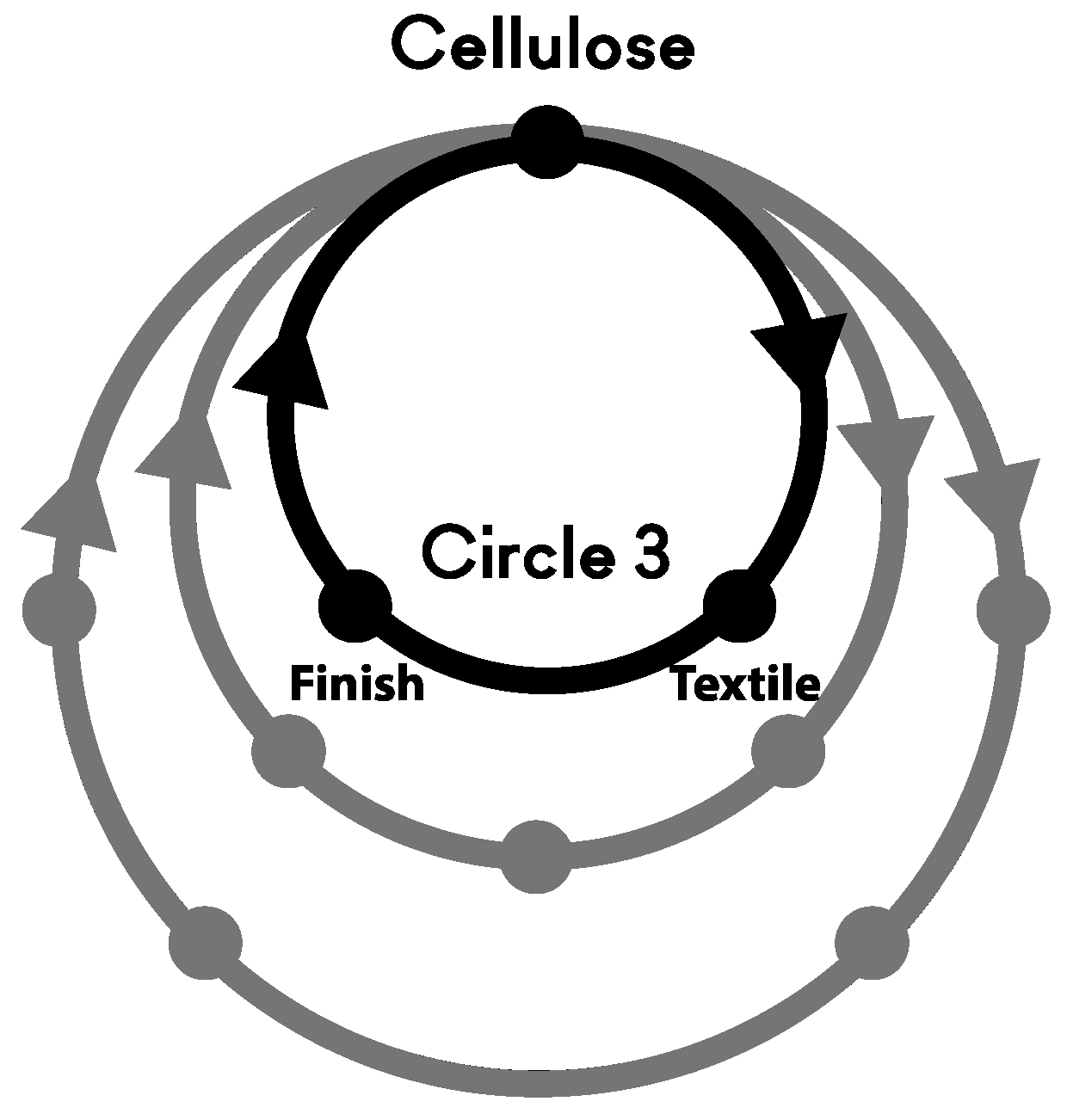

3.2. A Framework for Future Materials Circularity in the Textile Value Chain of Regenerative Textiles

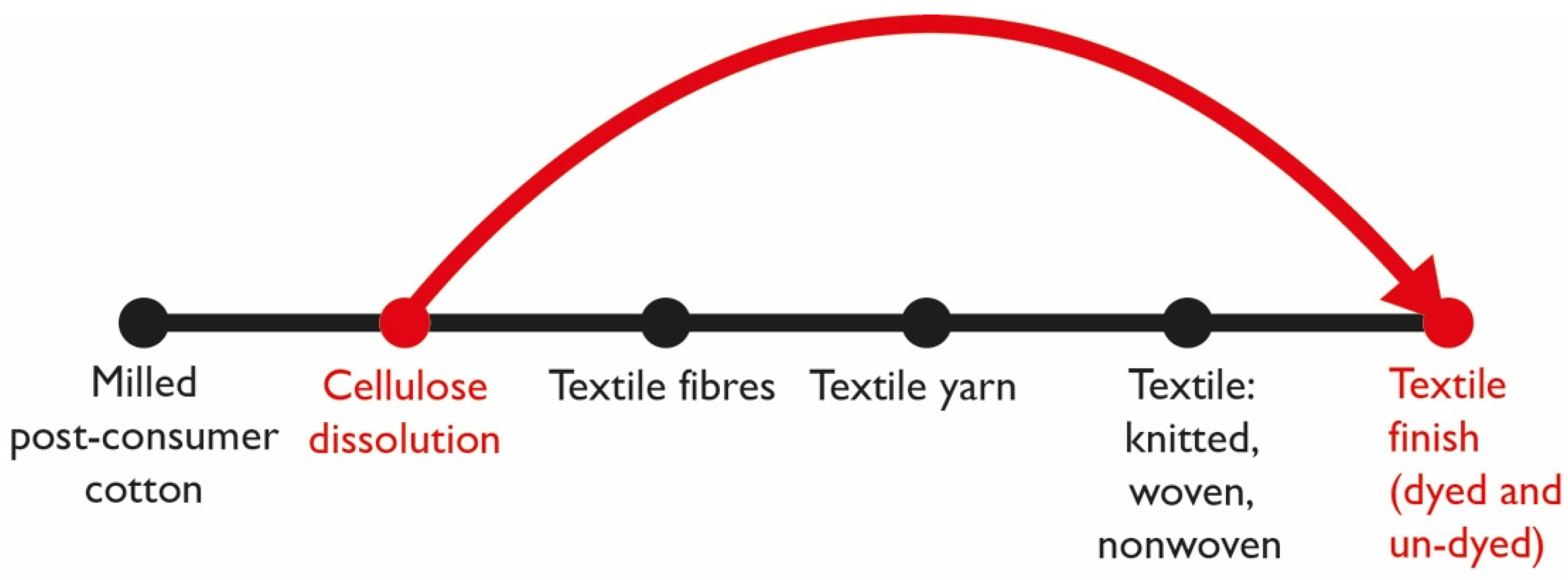

3.2.1. At the Finishing Stage

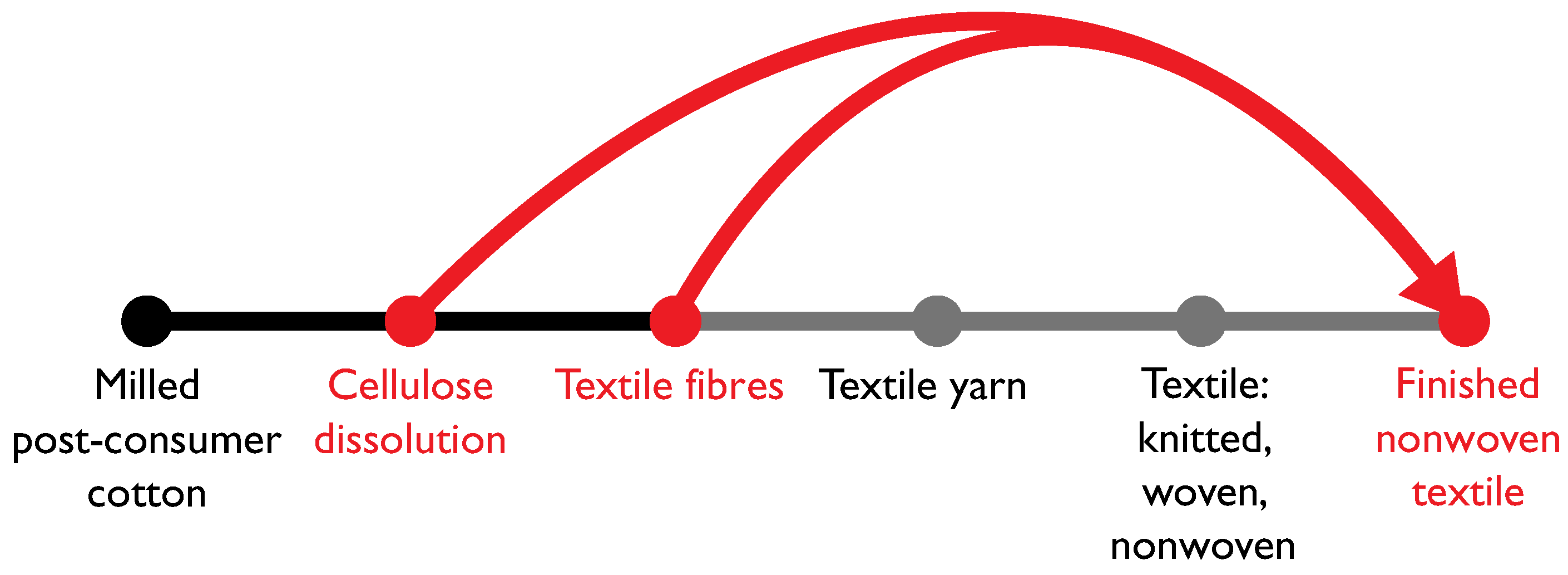

3.2.2. At the Fibre Stage

3.2.3. At the Raw Material Stage

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kääriäinen, P.; Tervinen, L. (Eds.) Lost in the Wood(s): The New Biomateriality in Finland, 1st ed.; Aalto University: Helsinki, Finland, 2017. [Google Scholar]

- Woodings, C. (Ed.) Regenerated Cellulose Fibres, 1st ed.; Woodhead Publishing in association with the Textile Institute: Cambridge, UK, 2000. [Google Scholar]

- Aalto University; VTT; Tampere University of Technology. Design Driven Value Chains in the World of Cellulose DWoC 2013–2015. Available online: http://www.vtt.fi/Documents/DWoC1.pdf (accessed on 28 February 2017).

- Ma, Y.; Hummel, M.; Määttänen, M.; Sixta, H. Upcycling of Waste Paper and Cardboard to Textiles. Green Chem. 2015, 18, 858–866. [Google Scholar] [CrossRef] [Green Version]

- Ma, Y.; Asaadi, S.; Johansson, L.; Ahvenainen, P.; Reza, M.; Alekhina, M.; Rautkari, L.; Michud, A.; Hauru, L.; Hummel, M.; et al. High-Strength Composite Fibers from Cellulose–Lignin Blends Regenerated from Ionic Liquid Solution. ChemSusChem 2015, 8, 4030–4039. [Google Scholar] [CrossRef] [PubMed]

- Boston Consulting Group. Global Fashion Agenda. The Pulse of the Fashion Industry. Available online: https://www.copenhagenfashionsummit.com/wp-content/uploads/2017/05/Pulse-of-the-Fashion-Industry_2017.pdf (accessed on 19 May 2017).

- The Fiber Year. The Fiber Year 2016: World Survey on Textiles and Nonwovens; The Fiber Year GmBH: Speicher, Switzerland, 2016. [Google Scholar]

- Östlund, Å.; Wedin, H.; Bolin, L.; Berlin, J.; Jönsson, C.; Posner, S.; Smuk, L.; Eriksson, M.; Sandin, G. Textilåtervinning: Tekniska Möjliheter och Utmaningar. Available online: https://www.naturvardsverket.se/Documents/publikationer6400/978-91-620-6685-7.pdf?pid=15536 (accessed on 5 July 2016).

- Re:newcell AB. Renewcell. Available online: http://renewcell.se/ (accessed on 7 November 2017).

- MISTRA Future Fashion. Future Fashion Manifesto. Available online: http://mistrafuturefashion.com/wp-content/uploads/2017/12/Future-Fashion-Manifesto-2015-1.pdf (accessed on 15 December 2015).

- Gullingsrud, A.; Williams, A. Fashion Fibers: Designing for Sustainability, 1st ed.; Bloomsbury Academic: New York, NY, USA, 2017. [Google Scholar]

- Sinclair, R. (Ed.) Textiles and Fashion: Materials, Design and Technology, 1st ed.; Woodhead Publishing in association with The Textile Institute: Cambridge, UK, 2014. [Google Scholar]

- Lenzing. The Global Fiber Market in 2015. Available online: http://www.lenzing.com/en/investors/equity-story/global-fiber-market.html (accessed on 13 January 2017).

- loncell. Research. Available online: https://ioncell.fi/research/ (accessed on 12 February 2018).

- Evrnu. The Problem: Textile Waste. Available online: https://www.evrnu.com/ (accessed on 26 July 2017).

- SaXcell. Saxcell: A Revolutionary New Fibre. Available online: http://saxcell.nl/ (accessed on 29 January 2019).

- Tencel. REFIBRA: Contributing to the Circular Economy. Available online: https://www.tencel.com/refibra (accessed on 20 June 2016).

- Worn Again Technologies. Worn Again. Available online: http://wornagain.info/ (accessed on 16 October 2017).

- Michud, A.; King, A.W.T.; Parviainen, A.P.; Sixta, H.; Hauru, L.; Hummel, M.; Kipeläinen, I.A. Process for the Production of Shaped Cellulose Articles from a Solution Containing Pulp Dissolved in Disttilable Ionic. Liquids. Patent No. 2014/162062 A1, 4 April 2014. [Google Scholar]

- Circulose. Project 001: The Process. Available online: https://circulo.se/project_1-1 (accessed on 27 August 2021).

- Ribul, M. Material Driven Textile Design: Designing Fully Integrated Fabrication and Finishing Processes with Regenerated Cellulose in the Materials Science Laboratory. Ph.D. Thesis, University of the Arts London, London, UK, 2019. [Google Scholar]

- Elasser, V.H. Textiles: Concepts and Principles, 2nd ed.; Fairchild Publications Inc.: New York, NY, USA, 2005. [Google Scholar]

- Kataja, K.; Kääriäinen, P. (Eds.) Designing Cellulose for the Future. Available online: https://cellulosefromfinland.fi/wp-content/uploads/2018/09/DWoC_Loppuraportti_FINAL_s%C3%A4hk%C3%B6inen.pdf (accessed on 21 November 2018).

- RISE Research Institutes of Sweden. Third Milestone Report. Available online: https://static1.squarespace.com/static/5891ce37d2b857f0c58457c1/t/5c0554e61ae6cfe5a110c824/1543853290648/D9.4+Third+Milestone+Report.pdf (accessed on 7 December 2018).

- Lu, J.; Hamouda, H. Current status of Fiber Waste Recycling and Its Future. Adv. Mater. Res. 2014, 878, 122–131. [Google Scholar] [CrossRef]

- Design Meets Cellulose. CHEMARTS. 2020. Available online: http://chemarts.aalto.fi/wp-content/uploads/2017/08/CHEMARTS12_Collaboration.pdf (accessed on 5 October 2017).

- American Chemical Society. Upcycling ‘Fast Fashion’ to Reduce Waste and Pollution. Available online: https://www.youtube.com/watch?v=BpUUWMd-05I (accessed on 18 October 2017).

- Innventia Global Outlook. A Cellulose-Based Society, 1st ed.; Innventia AB: Stockholm, Sweden, 2016. [Google Scholar]

- Wedin, H.; Gupta, C.; Mzikian, P.; Englund, F.; Hornbuckle, R.; Troppenz, V.; Kobal, L.; Krečič, M.; Micol Costi, M.; Ellams, D.; et al. Can automated NIR Technology Be a Way to Improve the Sorting Quality of Textile Waste? D4.1. Available online: https://issuu.com/trash2cash/docs/report4/1?ff=true&e=30581983/55544808 (accessed on 27 November 2017).

- Palme, A. Recycling of Cotton Textiles: Characterization, Pretreatment, and Purification. Ph.D. Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2017. [Google Scholar]

- Englund, F.; Wedin, H.; Ribul, M.; de la Motte, H.; Östlund, Å. Textile Tagging to Enable Automated Sorting and beyond: MISTRA Future Fashion Report. Available online: http://mistrafuturefashion.com/wp-content/uploads/2018/03/AutoSort-report-D4.3.4_3.pdf (accessed on 30 March 2018).

- Roos, S. Advancing Life Cycle Assessment of Textile Products to Include Textile Chemicals: Inventory Data and Toxicity Impact Assessment. Ph.D. Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2016. [Google Scholar]

- Ellen MacArthur Foundation. A New Textiles Economy: Redesigning Fashion’s Future. Available online: https://www.ellenmacarthurfoundation.org/assests/downloads/A-New-Textiles-Economy_Full-Report_Updated_1-12-17.pdf (accessed on 28 November 2017).

- Hummel, M.; Michud, A.; Tanttu, M.; Netti, E.; Asaadi, S.; Ma, Y.; Sixta, H. High Strength Fibers from Various Ligno-Cellulosic Materials Using the Ioncell-F Technology. Available online: http://costfp1205.com/wp-content/uploads/2017/schools/Documents/3rdtrainingschool/2_Hummel_HighStrength.pdf (accessed on 20 June 2016).

- The Fiber Year. The Fabric Year 2017: World Survey on Textiles and Nonwovens; The Fiber Year GmBH: Speicher, Switzerland, 2017. [Google Scholar]

- Ribul, M.; Goldsworthy, K.; Collet, C. Material-Driven Textile Design (MDTD): A Methodology for Designing Circular Material-Driven Fabrication and Finishing Processes in the Materials Science Laboratory. Sustainability 2021, 13, 1268. [Google Scholar] [CrossRef]

- Tanttu, M. Trends in Concept Design of Textile Materials. Master’s Thesis, Aalto University School of Arts, Design and Architecture, Helsinki, Finland, 2015. [Google Scholar]

- CelluloseFromFinland.fi. Functional Cellulosic Structures on Fabrics by 3D Printing. Available online: http://cellulosefromfinland.fi/functional-cellulosic-structures-by-3d-printing/ (accessed on 18 May 2018).

- Aalto University. Materials Platform. Available online: https://www.aalto.fi/aalto.fi/aalto-university-materials-platform (accessed on 10 September 2017).

- CelluloseFromFinland.fi. Fabrics from Waste Cellulose—How to Wear Old Newspapers. Available online: http://cellulosefromfinland.fi/fabrics-from-waste-cellulose-how-to-wear-old-newspapers/ (accessed on 12 February 2018).

- Saxion. People behind SaXcell. Available online: https://www.saxion.nl/site.nl/site/index/saxcell/peoplebehindSaXcell (accessed on 1 August 2016).

- Fast Company. Peters, A. Levi’s Made the First Ever 100% Recycled Cotton Jeans (Updated). Available online: https://www.fastcompany.com/3059826/levis-made-the-first-ever-100-recycled-cotton-jeans (accessed on 26 July 2016).

- De la Motte, H. Derivatization and Characterization of Cellulosic Materials: Synthetic Procedures towards Sustainable Reactions. Ph.D Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2012. [Google Scholar]

- CelluloseFromFinland.fi. Foam Formed Non-Wovens from Yarns and Fibres. Available online: http://cellulosefromfinland.fi/foam-formed-multi-layer-textile-structures/ (accessed on 11 July 2018).

- Ribul, M.; de la Motte, H. The Material Affinity of Design and Science for a Circular Economy. In Proceedings of the Circular Transitions Conference, London, UK, 23–24 November 2016; pp. 236–248. Available online: http://circulartransitions.org/media/downloads/Circular-Transitions-Proceedings.pdf (accessed on 15 January 2018).

- CelluloseFromFinland.fi. 3D-Printing of Cellulose Based Materials by Nscrypt Method. Available online: https://cellulosefromfinland.fi/3d-printing-of-cellulose-based-materials-by-nscrypt-method/ (accessed on 10 October 2018).

- Chalmers. Cellulose from Wood Can Be Printed in 3D. Available online: https://www.chalmers.se/en/departments/chem/news/Pages/Cellulose-from-wood-can-be-printed-in-3D.aspx (accessed on 1 March 2016).

- Ribul, M. Novel Circular Fabrication and Finishing Processes with Regenerated Cellulose Obtained from Waste Textiles; Manuscript in preparation, Materials Science Research Centre, Royal College of Art: London, UK, 2022. [Google Scholar]

- Spathas, T. The Environmental Performance of High Value Recycling for the Fashion Industry: LCA for Four Case Studies. Master’s Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2017. [Google Scholar]

| Date | Research Lab | Waste Stream Used for Cellulose Regeneration |

|---|---|---|

| 2012 | Re:newcell, Sweden | Cotton textile waste |

| 2014 | Ioncell, Finland | Cotton textile, paper and cardboard waste |

| 2014 | Evrnu, US | Cotton textile waste |

| 2015 | SaXcell, Netherlands | Cotton textile waste |

| 2015 | Worn Again, UK | Cotton textile waste separation from polyester |

| 2017 | Refibra, Austria | Cotton textile waste mixed with virgin wood pulp |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ribul, M. Regenerative Textiles: A Framework for Future Materials Circularity in the Textile Value Chain. Sustainability 2021, 13, 13910. https://doi.org/10.3390/su132413910

Ribul M. Regenerative Textiles: A Framework for Future Materials Circularity in the Textile Value Chain. Sustainability. 2021; 13(24):13910. https://doi.org/10.3390/su132413910

Chicago/Turabian StyleRibul, Miriam. 2021. "Regenerative Textiles: A Framework for Future Materials Circularity in the Textile Value Chain" Sustainability 13, no. 24: 13910. https://doi.org/10.3390/su132413910

APA StyleRibul, M. (2021). Regenerative Textiles: A Framework for Future Materials Circularity in the Textile Value Chain. Sustainability, 13(24), 13910. https://doi.org/10.3390/su132413910