Abstract

The preservation of cultural heritage needs a restoration design format that can only be achievable by an in-depth multidisciplinary approach. Besides, a sustainable project requires that the link between architecture and technology be expressed through a “conscious” approach to the building. Therefore, each design must be based on the in-depth knowledge of history, construction rules, and mechanical properties of buildings to be restored. The bell towers are among the most exposed to degradation and earthquake damage constructions for their intrinsic geometry and structure. The “Carmine Maggiore” bell tower is one of the most important symbols of Naples (Italy) and, at 72 m high, it has stood out for centuries against the city. The tower underwent many significant damages and structural changes over time. The design, here illustrated, was aimed at restoring and repairing this bell tower, preserving existing materials, without altering the signs of time. The paper shows the methodology followed in the project, which, starting from an in-depth historical analysis and a detailed geometric and diagnostic survey, through several structural analyses, allowed an “inclusive” project (restoration, structural, and lighting project) based on suitable solutions that meet all the requirements of compatibility, sustainability, and structural safety.

1. Introduction

In recent years, the growing interest in urban historical heritage and a greater sensitivity to a building’s authenticity has revised the common concept of considering restoration as a simple “nostalgic desire to return to the past at all costs”. The latter generated, in the operational phase, architectural patchworks, where each element follows its own “original” stylistic connotation, searching for a lost unity in the name of a senseless return to the ancient splendor. Today, the development of analytical methodologies in physical, chemical, and geognostical sciences, as well as computerized methods, offers a rich set of tools in the cultural heritage field for designing suitable treatments to reduce the degradation of materials [1,2,3]. Therefore, restoration is a tool of knowledge, simplification, and respect for building diversity, capable of preserving the signs that time has left and providing a cultural model aimed at returning the building to future generations in the fullness of its meaning, without arbitrary tampering. From this point of view, the restoration makes use of history, documents, scientific knowledge, and instrumental diagnostics to ensure the minimum and strictly necessary retrofitting. The restoration design must ensure the saving of precious economic resources and their correct distribution within well-calibrated projects, and as sustainable as possible.

The uniqueness of cultural heritage requires processes aimed at both the prevention of degradation phenomena and structural safety. Most of the historic structures have deteriorated because of natural and environmental effects and inadequate conservation. Structural behavior is also often compromised. Suitable preservation can only be achieved by in-depth and multidisciplinary knowledge of masonry buildings and construction rules, as well as a thorough mechanical characterization of materials [1,4,5]. Modifications and restorations that the building underwent over the centuries should be well analyzed, considering that, sometimes, the original structural design of the building or inadequate retrofit [6,7] can be the main cause of deterioration and collapse.

Damage caused by recent earthquakes, mainly to bell towers, highlighted their high seismic vulnerability, especially the upper part, where large openings and slender columns are often present. The vulnerability springs from small vertical loads (due to the self-weight only), which does not ensure the bending capacity to horizontal cross-sections and stabilizing effect regarding overturning and out-of-plane mechanisms [8,9]. However, the seismic behavior of bell towers depends on several specific factors: slenderness, the effectiveness of wall connection, bell action, presence of towering gables and battlements, adjacent structures in the lower part, etc. Lower structures, such as churches, buildings, or city walls, provide horizontal constraints that strongly change the seismic response, producing stress concentrations, and significantly increasing the vulnerability [10,11].

The Italian technical standards provide detailed information on how to analyze and strengthen existing masonry structures [12]. In particular, the “National guidelines for the assessment and mitigation of seismic risk for cultural heritage” [13], provide three approaches for analyzing the seismic behavior of historical masonry constructions, identified as LV1, LV2, and LV3. The method LV1 envisages simplified models and analytical procedures for the most common types of historical structures: buildings with walls and horizontal floor diaphragms, churches and structures with large halls without intermediate diaphragms, towers, bell towers, and tall structures [14,15,16,17,18], and bridges. The LV2 approach is directed towards the analysis of out-of-plane kinematic mechanisms [9]. The LV3 approach, used in this paper, requires, instead, refined models for analyzing the seismic response of the entire building [15,16,17,19,20,21,22,23,24].

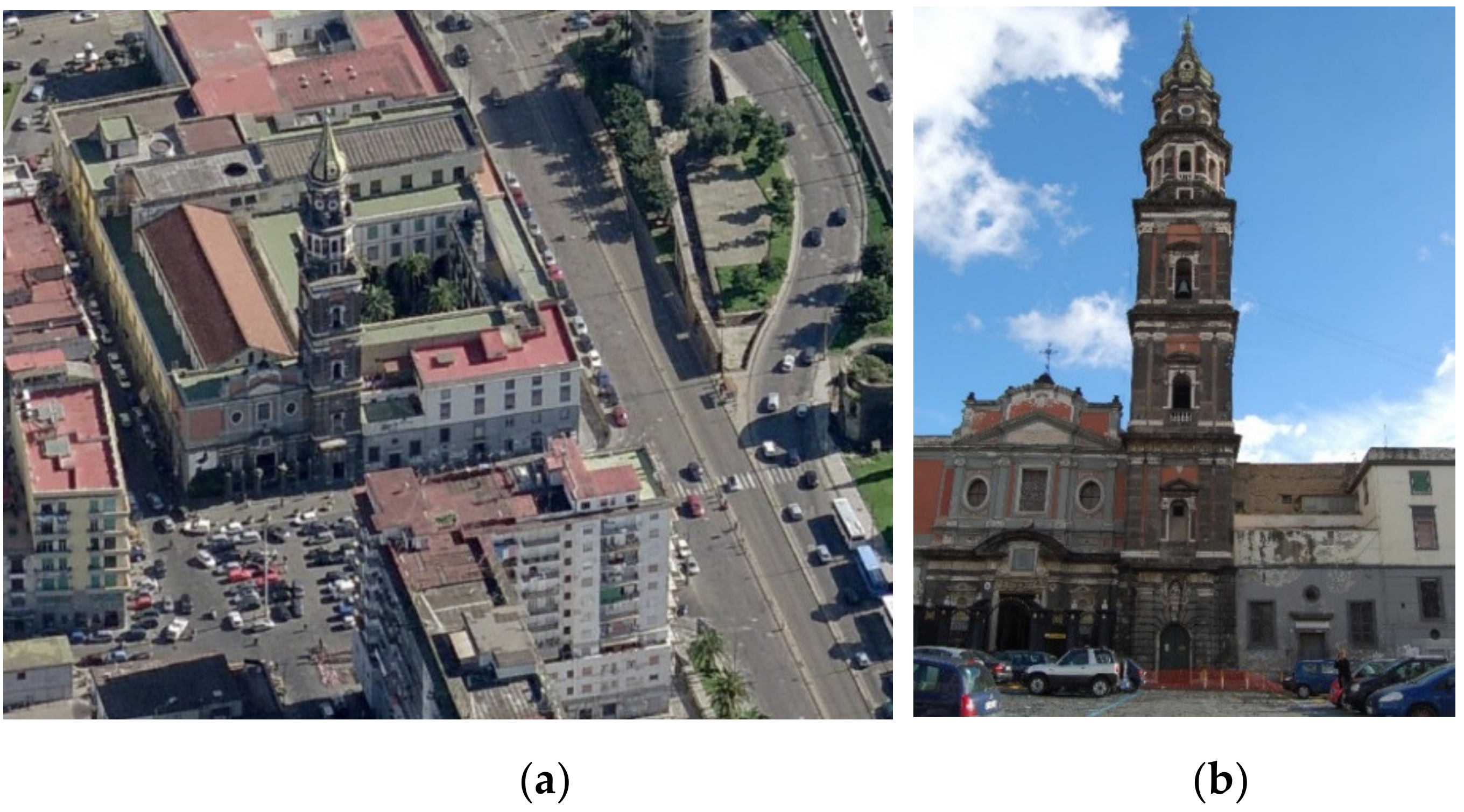

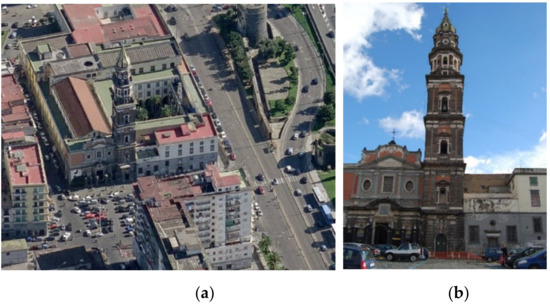

This paper presents the integrated and sustainable approach followed in drafting the project of restoration and repairing of the bell tower of the Basilica Sanctuary of “Carmine Maggiore” (Figure 1) in Naples (Italy). The bell tower is one of the most important symbols of the Neapolitan city and at 72 m high, it has stood out for centuries against the city of Naples.

Figure 1.

The Convent of “Carmine Maggiore” in Naples: (a) overhead sight; (b) bell tower.

The bell tower belongs to the monumental complex that also consists of the “Basilica Santuario di Maria Santissima del Carmine Maggiore” and the Convent of the Confraternity of “Santa Maria della Misericordia e Sant’Angelo Custode”. The bell tower borders the church on the north side, the convent on the east side, and a building on the south side. The bell tower, and the urban context where it is set, underwent significant building and structural changes over time.

2. Materials and Methods

Restoration, which implies in its etymology the sense of recovering the lost functionality of a building, belongs fully to the culture of intervening sustainably, as it uses resources already present.

A sustainable project requires that the existing link between architecture and technology be expressed through a conscious approach to the building, and of its repercussions on the surroundings, according to a timeline that considers the development of the present and future mutually dependent. This requires an in-depth knowledge of the construction and performance of materials that constitute cultural heritage, their physical-chemical properties, as well as the impact they have on the environment in the different phases from production to use and disposal at the end of the life cycle.

The knowledge of existing buildings allows an understanding of how the construction methods of the past are consistent with what is nowadays recognized to be the basic principles of sustainability, especially about procuring raw materials, their processing, use, and possible reuse, and the techniques used for a wise interface with environmental constraints. Building geometry and characteristics and performance of materials are now well known using the many techniques available for the survey and structural diagnostics [1,2,3,25,26].

To restore a monument means learning from the past, respecting the building’s traditions, using ancient materials with innovative techniques, and technologies and innovative materials with deep attention to compatibility with those of the past. The restoration and repairing project of the “Carmine Maggiore” bell-tower, therefore, started with an exhaustive historical analysis of the construction and an in-depth geometric and diagnostic survey. This allowed, together with the structural analysis, to select the most compatible and sustainable materials and processing, as illustrated below.

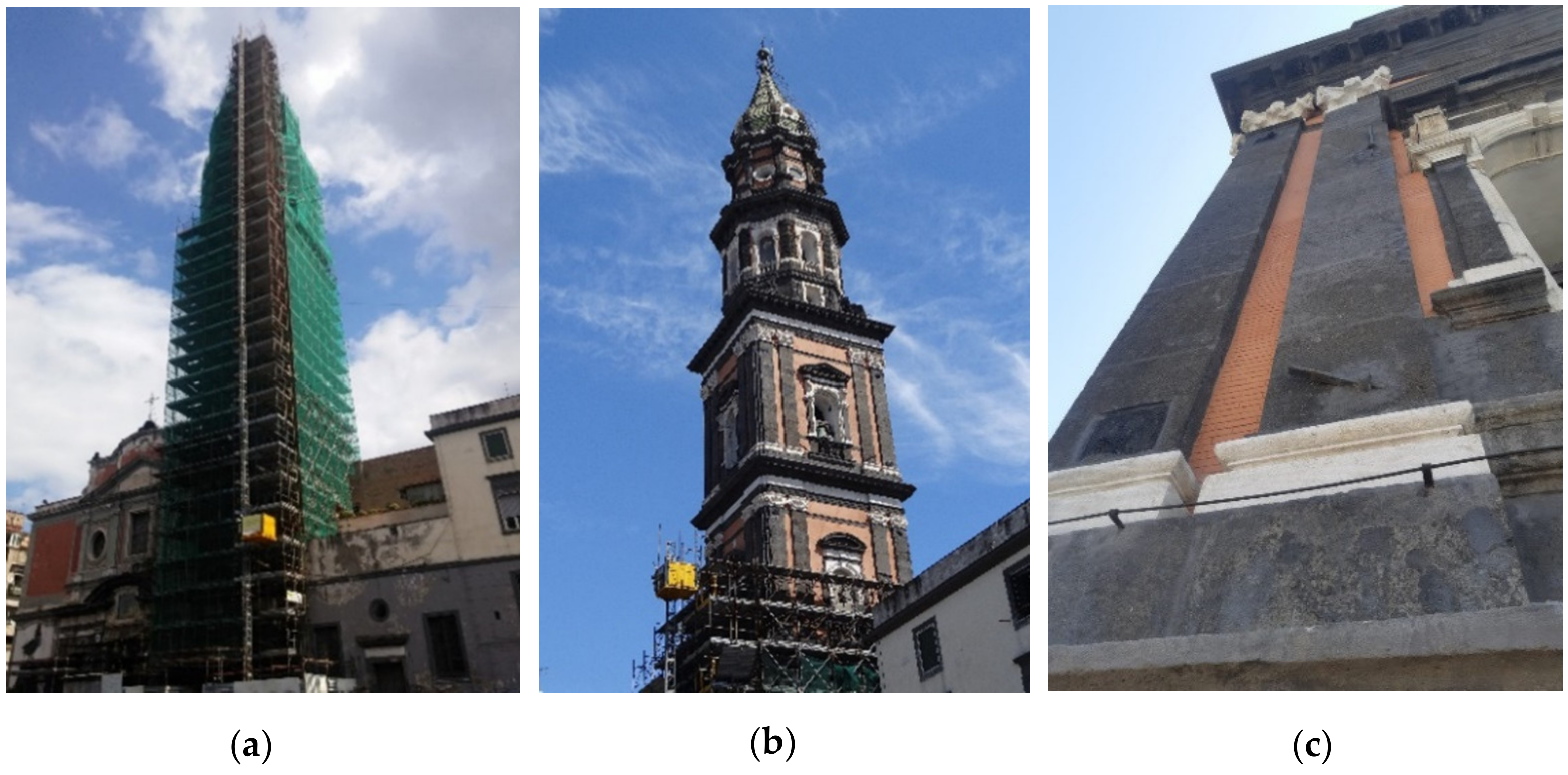

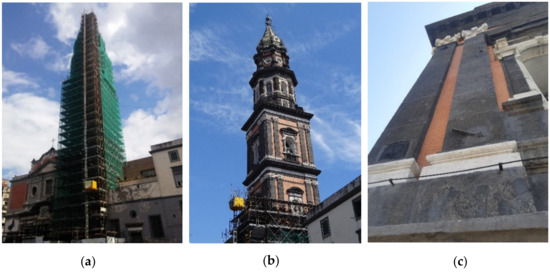

The restoration of the bell tower was part of the activities of the “Protection of the historical and artistic heritage” of the Italian State, achieved through close collaboration between institutes and public offices that carry out the task of ensuring the protection, enhancement, and conservation of the architectural heritage. The project was initiated and commissioned by the “Central Office for Faith Affairs and the Administration of the Faith Buildings Funds” of the Ministry of the Interior, the owner of the building, in collaboration with the Convent of “Carmine Maggiore” of Naples. The “Archeology, Fine Arts and Landscape Office” of Naples controlled the project. The restoration and repairing work began in February 2017 and was completed in July 2019. Figure 2 shows the bell tower with the scaffolding, during the dismantling of the scaffolding and after completion of works.

Figure 2.

The bell tower with the scaffolding (a), during the dismantling of the scaffolding (b) and after completion of works (c).

2.1. Historical Notes

The “Carmine Maggiore” bell tower dates back to the seventeenth century and stands on a previous fourteenth-century plan, which was severely damaged in the upper part by a violent earthquake in 1456 [27]. The ashlar base in piperno stone is the only remaining portion of the original construction. The three stories above have a quadrangular plan and were rebuilt between 1612 and 1620, according to a design by Giovanni Giacomo Conforto. In 1622, two other stories, with an octagonal plan, were added by Fra’ Nuvolo, crowning them with a pear-shaped polygonal majolica cusp. The entire structure is surmounted today by a copper sphere in which a metal cross is inserted.

The description of the bell tower, written in 1885 by Gaetano Filangieri, Prince of Satriano [28], was very helpful in understanding the construction events: it is rich in historical construction details and provides useful indications and comments illustrating the various phases of re-construction. Its major source of reference, “unpublished” at that time, is the Chronicle of the Royal Convent of the Carmine Maggiore in Naples, written by Carmelite Piertommaso Moscarella in 1699.

The first news of the bell tower dates back to 1439, on the occasion of the “Miracle of the Crucifix”. Later, in 1456, the earthquake of 5 December caused serious damage to the bell tower, so that, in the same year, it was demolished up to the level of the entrance door to the adjacent convent, which is up to the level of the cornice of the second story. The reconstruction of the bell tower probably began in March 1458, the year in which Master Paldimessa completed “the last finishing touch to the damaged bell tower and began of the new one”. Filangieri, reporting Moscarella’s remarks, writes that the bell tower “was halved” in 1459 and the building work continued throughout the sixteenth century. He also reports that in 1615 there was the will to achieve a “great bell tower”. In 1620, the entire quadrangular base of the bell tower was completed and the construction of the fourth story, used as a belfry, was finalised. Filangieri also states: “four silver medals, with the effigy of St. Barbara, having a worth of four ‘carlini’ and twenty boxes of relics are placed” in the corners.

Three years later, in 1622, the bell tower was completed by building the other two stories with an octagonal plan, made of “stone and marble of Caserta” and connected to the last quadrangular story through four volutes. The design of the reconstruction is attributed to Giovanni Giacomo Conforto, while the completion of the building and the cusp, shaped like a polygonal “carmosina pear”, is attributed to the Dominican Fra’ Giuseppe Nuvolo and dated back to 1631 when he was awarded the title of “engineer of the real convent”. In 1655, the encumbrances due to “hearthstones and kitchens”, placed inside the bell tower by the soldiers of garrison at the convent, after the revolt of Masaniello, were removed.

In 1656, the first of many lightning struck and damaged the bell tower, and Filangieri describes the works performed on the medium-sized bell in 1664. The Sannio earthquake of 5 June 1688, damaged again the bell tower, the adjacent church, and the convent. To repair such damages “it was necessary to force the bell tower in several parts by iron tie rod and to reinforce it by new elements”. In 1728, a new thunderbolt hit the bell tower, causing the detachment of marble and piperno stones that broke through the roof of the church and reached the choir, damaging the organ. The choir and the church roof were restored; and once again, the badly damaged bell tower was repaired, and the damaged large bell was replaced. The top of the bell tower was yet again hit in 1745 by a third lightning bolt. There is no detailed information on damage yielded, but there were reports about the relocation of the big sphere with the cross on the top of the bell tower. A fourth lightning strike still seriously damaged the bell tower in 1762, which was repaired with the sacrifice of large sums of money donated by the faithful. Filangieri remembers that twenty years earlier, in about 1865, the priests of the convent felt the need to set a lightning rod “involving the top of the bell tower and the two upper stories”.

In 1885, the bell tower is described with the present ashlar base in piperno and an aedicule placed on top of the entrance door to the convent vestibule, built according to the architectural rules of Vignola. The aedicule still exists today.

Currently, the entire bell tower rests on a cross vault, supported by two lancet arches, reminiscent of the original construction of the thirteenth century. The first three floors above the base are divided by pediments and have Doric, Ionic, and Corinthian orders. They were reconstructed by Conforto with sober architectural features and “severe windows” at all three stories, although Filangieri claims that the “style of the time had already invaded all artistic expressions”.

The “complementary” part, executed by Fra’ Nuvolo, has a different outcome, which provides movement to the wall masses and decorates the external parts with the same number of windows on each side. However, the style does not “disagree” with the underlying structure. According to Filangieri’s estimate, the bell tower was 57 m high from the ground up to the top of the lightning rod (today it is known to be higher). The structure had thirteen internal landings, beyond the ground floor, with camber vaults in tuff and bricks of “great strength”. A staircase with four wooden flights, protected by balustrades with small columns, led into the dormitory of the priests through an elegant 15th-century wooden door. Finally, the bell cell, with 5 bells, is placed at the level of the Corinthian third story: 4 bells are placed in the large windows on each side, while the larger one is located in the center of the story.

The bell tower underwent remarkable reconstructions over time that affected its architectural appearance and structural behavior, even in relation to adjacent buildings. In particular, some original masonry vaults, mentioned by Filangieri, were replaced by reinforced concrete (RC) floors. The timber staircase with balustrades and small columns was replaced by a reinforced concrete staircase, strongly fixed to the masonry walls, and leading to the last accessible story. Therefore, the RC staircase is also a connecting element between the masonry walls, which stiffens the entire bell tower, especially at the upper levels where the walls are less thick.

2.2. Geometric and Diagnostic Survey of the Bell Tower

The surveys performed for the restoration and structural design showed, congruently with [29,30,31,32,33], that the structure of the bell tower has a rectangular plan up to the fourth story and the masonry walls are in Neapolitan yellow tuff from the first to the fourth story. At the base, however, the walls are in peperino stone and are covered with an ashlar piperno face.

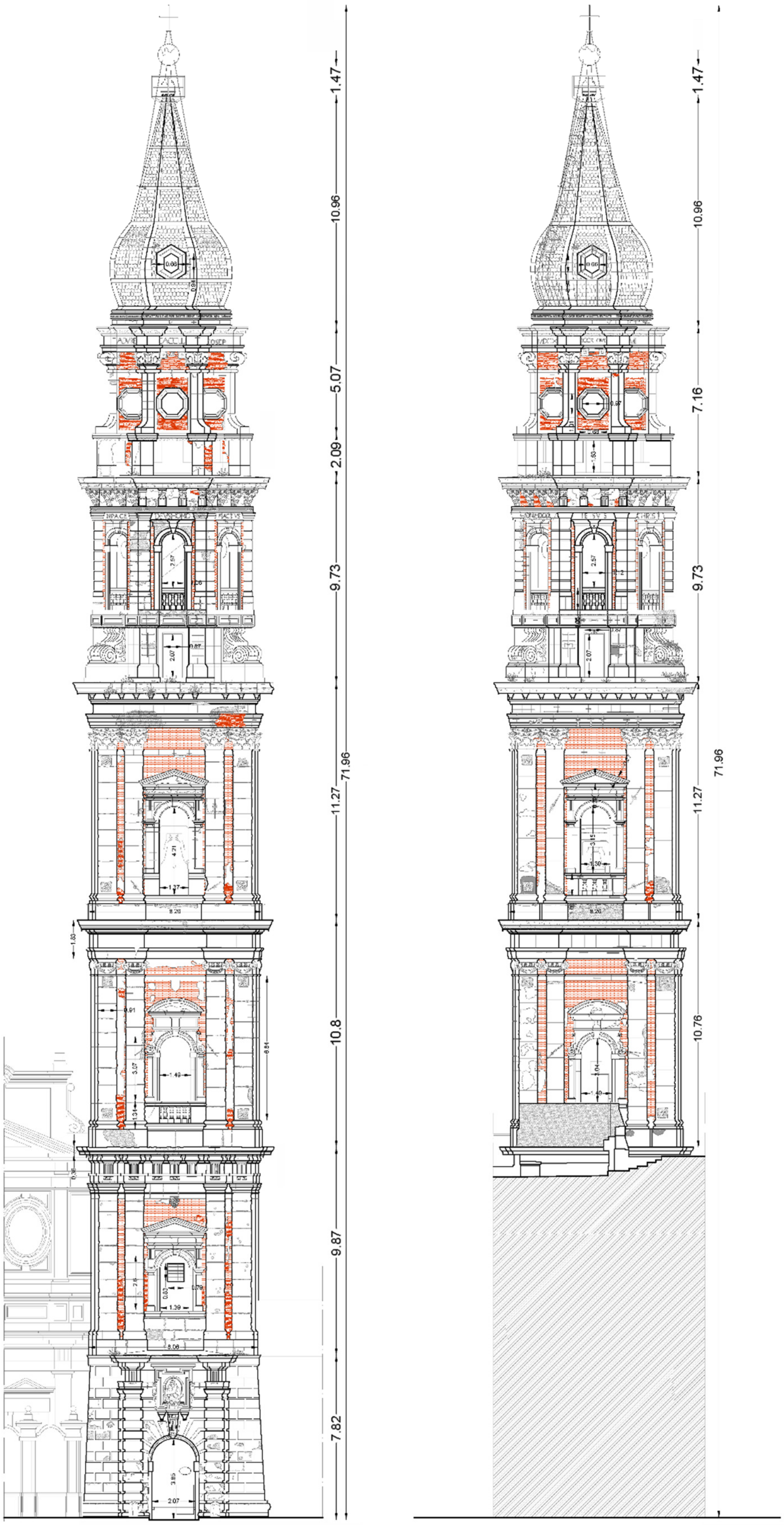

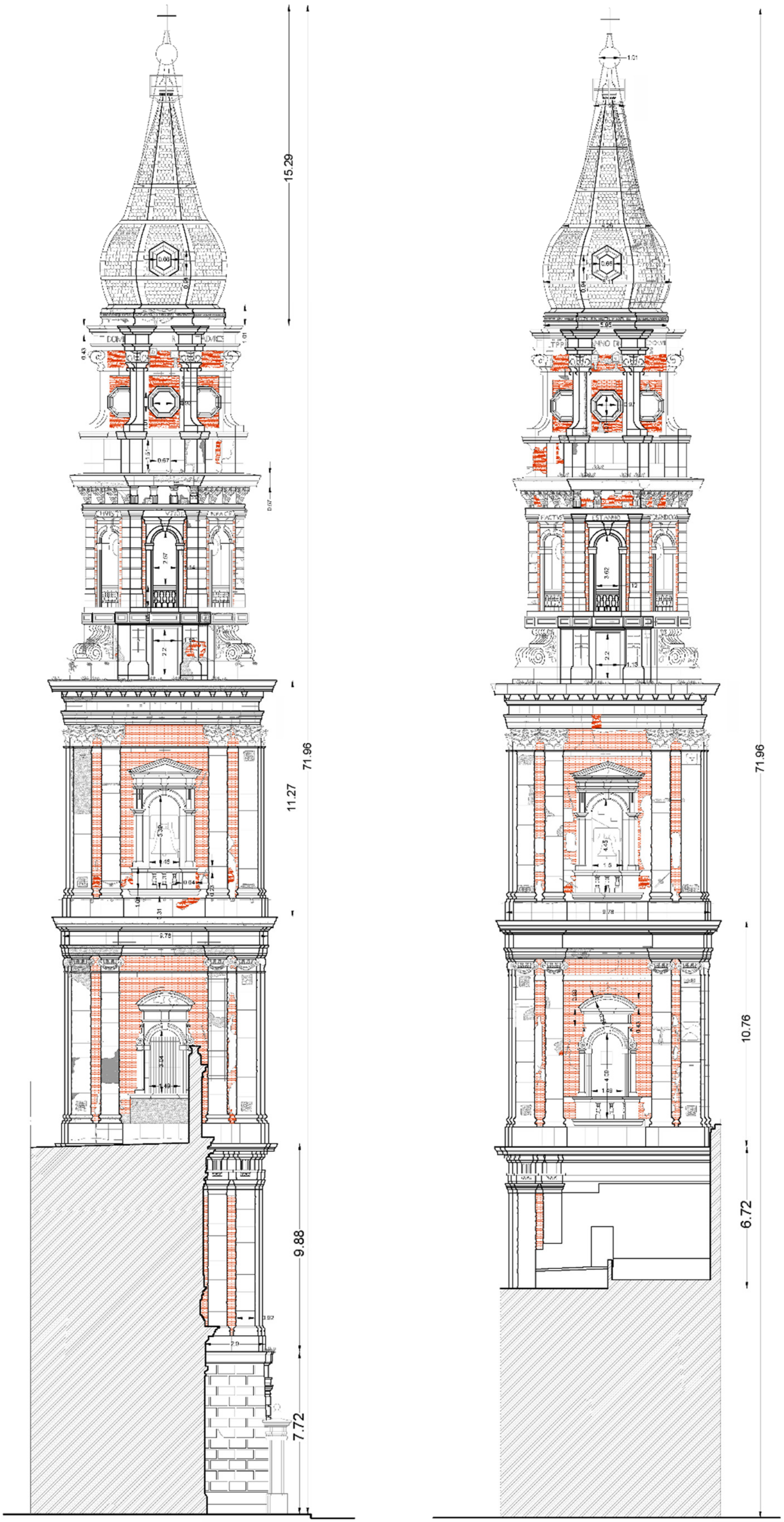

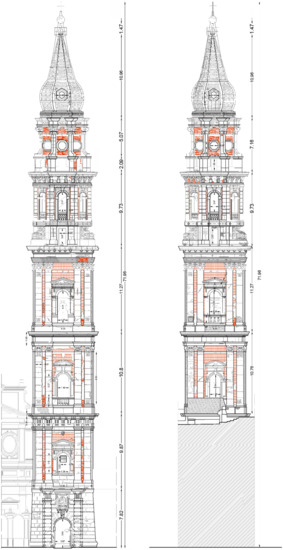

This traditional construction technique, which arranges more resistant and heavier materials at the base, can also be found in later structures. In particular, an extraordinary example of this “Vanvitellian School” is the bell tower of the Corpus Christi Basilica of Maddaloni: it was built using increasingly lighter materials from the base to the roofing pear [34], providing a pyramidal structural behavior to the bell tower [18]. It cannot be excluded that the original building typology of the “Carmine Maggiore” bell tower had similar characteristics to the Maddaloni bell tower, considering the numerous tampering that it underwent over time (Figure 3 and Figure 4).

Figure 3.

Bell-tower: west and east façade.

Figure 4.

Bell-tower: north and south façade.

The walls of the upper octagonal portion are in clay bricks masonry up to the height of the cornice that delimits the last octagon at about 57 m from the base. The structure is completed by an octagonal portion and a pear-shaped cusp covered with green and yellow majolica with eight ribs. Above the ribs of the cusp, there is a sphere with an upper metal cross.

At present, the bell tower has six floors at 8.89 m, 18.98 m, 29.57 m, 40.19 m, 50.10 m, and 57.17 m above ground. The thickness of the walls is variable and ranges from 4 m at the base to about 1 m in the highest part. Half of the bell tower windows are closed with tuff walls and covered with a brick facing.

The bell tower is connected to the church on its left side, up to the level of the church roof eaves, and to the convent on its right and rear sides, up to the level of the convent roof. The portion overlooking the square in front of it is entirely free. The bell tower allows entering the cloister of the convent at the back through an entrance hall that crosses the entire base. The historical sources quote that the church and the bell tower were originally separate and that the current configuration with side-by-side buildings derives from the modifications undergone: originally, the façade of the church was more backward, and the existing cavity between the two structures was filled.

As mentioned before, the bell tower underwent several structural interventions, some of them in the last century. Unfortunately, the latter involved the introduction of reinforced concrete structures (RC floors replaced the masonry vaults and RC stairs replaced the timber ones) and strengthening through cement grout injections and reinforced injections. These interventions were recurrent in the last century, a period in which the sensibility in understanding the behavior of historic buildings and the knowledge of the harmful effects due to the use of materials such as cement and concrete far-removed from the masonry mechanical behavior, were much lower than today [6,7]. Concrete structures are heavier and stiffer than masonry, thus inducing strong local stresses in masonry walls and changing the natural vibration mode of the structure [35,36]. Besides, the reinforced injections are particularly invasive and not suitable for masonry. Finally, as well as for mechanical reasons, concrete is also incompatible with masonry for chemical-physical reasons.

There are about 60 steel tie rods in the bell tower between the levels of 18 m and 56 m, mostly passing through the walls, with an external pole or plate anchors. Some tie-rods date back to the 19th century, while others probably to the 1920s and 1930s. These tie rods are steel bars with a diameter ranging between 35 and 50 mm. Later, in the 1970s, additional tie rods in steel strands of six 4 mm diameter wires were inserted and reinforced injections were made to improve the connection of the walls. After the 1980 earthquake, further reinforced injections were performed in the stories above the fourth-level, and fiberglass tie rods with stainless anchor plates were arranged at the level of about 55.70 m in 2008. Probably, the risk of out-of-plane failure mechanisms was already considered in the past, especially for the upper floors where the structure is more slender and characterized by a higher percentage of openings. However, the last tie rods perforated the frieze of the crowning entablature of the first octagon and invaded the interior space of the access ramp to the story.

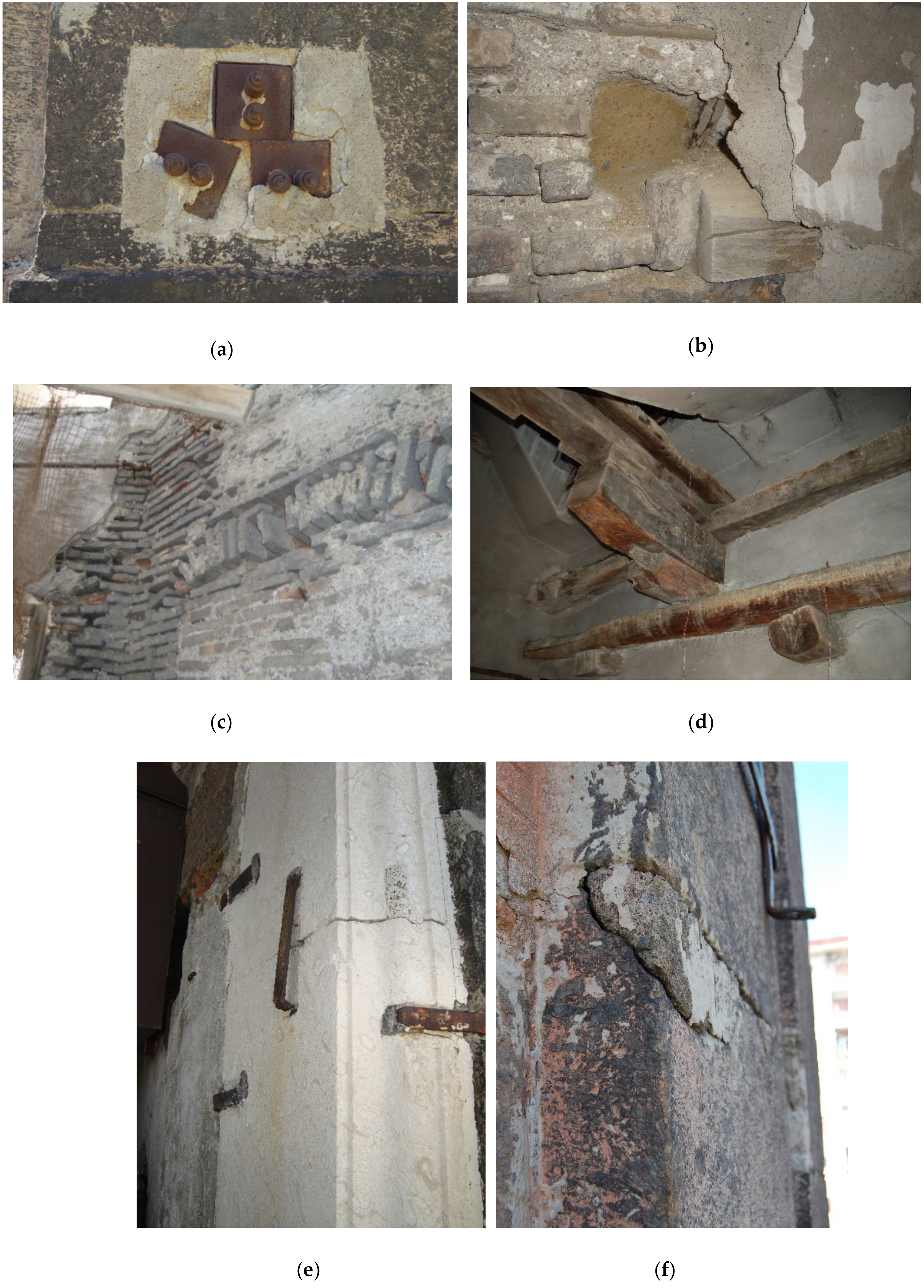

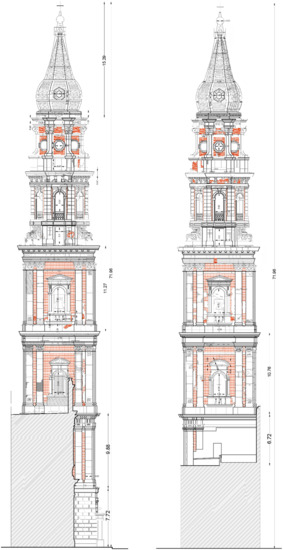

The major degradation phenomena concern (Figure 5): (a) the oxidation of tie-rods and anchor plates, especially those placed in the 1970/80s; (b) cavities in the masonry walls, which weaken structural resistant sections; (c) the degradation of the mortar joints of large portions of clay brick masonry, which sometimes also affects the bricks themselves; (d) the deterioration of timber structures, especially those supporting the main bell; (e) the oxidation of cramps and bandages anchoring cladding elements and cornices to the wall structure; (f) cracks in wall structures.

Figure 5.

Degradation phenomena: (a) oxidation of tie-rods and anchor plates; (b) cavities in masonry walls; (c) degradation of mortar joints; (d) deterioration of timber structures; (e) oxidation of cramps and bandages; (f) cracks in wall structures.

3. Results: The Inclusive and Sustainable Restoration Project

The design was aimed at restoring [37] the bell tower, to preserve the current look and to repair the damaged or degraded structural elements that were assessed through surveys and inspections. The structural interventions also arose from the numerical analyses performed according to the Italian national building code [12].

3.1. Restoration Project

The design was aimed at conserving the bell tower and restoring its static safety, without renouncing the preservation of its architectural and artistic values. The scientific support of diagnostics applied to architectural restoration, before the technology choices and the building yard beginning, allowed us to deepen the mechanical knowledge of the bell tower and its state of conservation. This led to a precise definition of the most appropriate techniques [37], which would ensure the preservation of the building integrity within a sustainable project.

The restoration project mainly concerns: (a) the verification of all stone elements affected by detachments; (b) the securing of detached nonstructural elements; (c) the new arrangement of fallen and recovered nonstructural elements; (d) the removal of weeds and the cleaning of stones; (e) the integration of the lost but reproducible elements; (f) the implementation of a lightning protection system and a new electrical and lighting system.

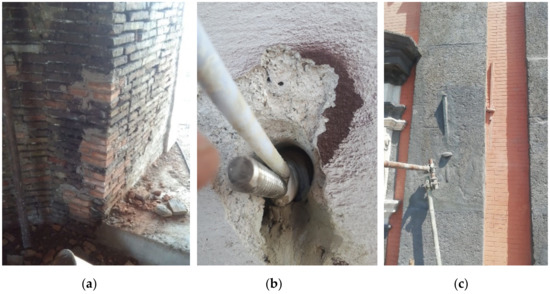

The effectiveness of restoration techniques was calibrated by on-site checks and tests, for systematically selecting the solutions that were as suitable and sustainable as possible. A diagnostic study of some fragments of plaster, tuff, and stones was performed. Within the limits imposed by the allowable analyses, the study was aimed at defining the composition and texture of materials (identifying their mineralogical constituents), assessing the state of conservation, and verifying the stratigraphic sequences to identify all the layers of paints. The following tests were performed:

- Binocular stereo-microscope observation, aimed at verifying the representativity of samples and performing the first characterization of their surface morphology;

- Petrographic study on the thin cross-section of specimens under an optical microscope in polarized light, aimed at identifying the mineralogical components of materials and their texture [38,39].

- Stratigraphic study on polished cross-sections, where the sample was incorporated in polyester resin for obtaining a section perpendicular to the external surface; the samples were observed under a microscope in reflected light, white and ultraviolet, to identify nature, thickness, and layers sequence [38].

- Histochemical test on polished sections with “Black Starch (AB II) and Red Oil”, aimed at determining the class of any organic compounds [40].

- Fourier transform infrared spectrophotometry for recognizing both synthetic and natural organic compounds and inorganic compounds related to constituent materials and degradation. The spectra were acquired using the KBr Pellet Method, in the range of 4000–400 cm−1, and resolution of 4 cm−1.

The above tests provided the following main results:

- (i)

- The fragments of natural stones taken from cornices showed a greyish coloring and a saccharoid appearance on the crack surface.

- (ii)

- The fragments of artificial stone materials (mortars and plasters) taken from the lower and the upper part of the bell tower, both from the fake brick finishing and near it showed similar compositional and texture characteristics.

- (iii)

- The mortar samples showed that the mortar was made of aerial lime mixed with pozzolanic sand in a ratio of about 1:2 in volume, characterized by arenaceous grain size, ranging between 0.2 and 0.5 mm. The aggregate was mainly effusive volcanic rocks and pumice lapilli, with few isolated crystals of feldspars, pyroxenes, and leucite, also resulting from the decomposition of volcanic litho-types. The presence of a modest quantity of earthy material testified to a low sifting of the sand.

- (iv)

- The plaster samples showed porosity around 10–15% in volume. The binder/aggregate ratio was close to 2:1 in volume. The subgrade plaster was made of aerial lime mixed with pozzolanic sand of a predominantly medium-fine arenaceous sand grain size (0.2–0.45 mm).

- (v)

- Two samples of layers of red paint, about 80–150 μm thick, showed iron oxides (hematite) and traces of quartz as mineral filler.

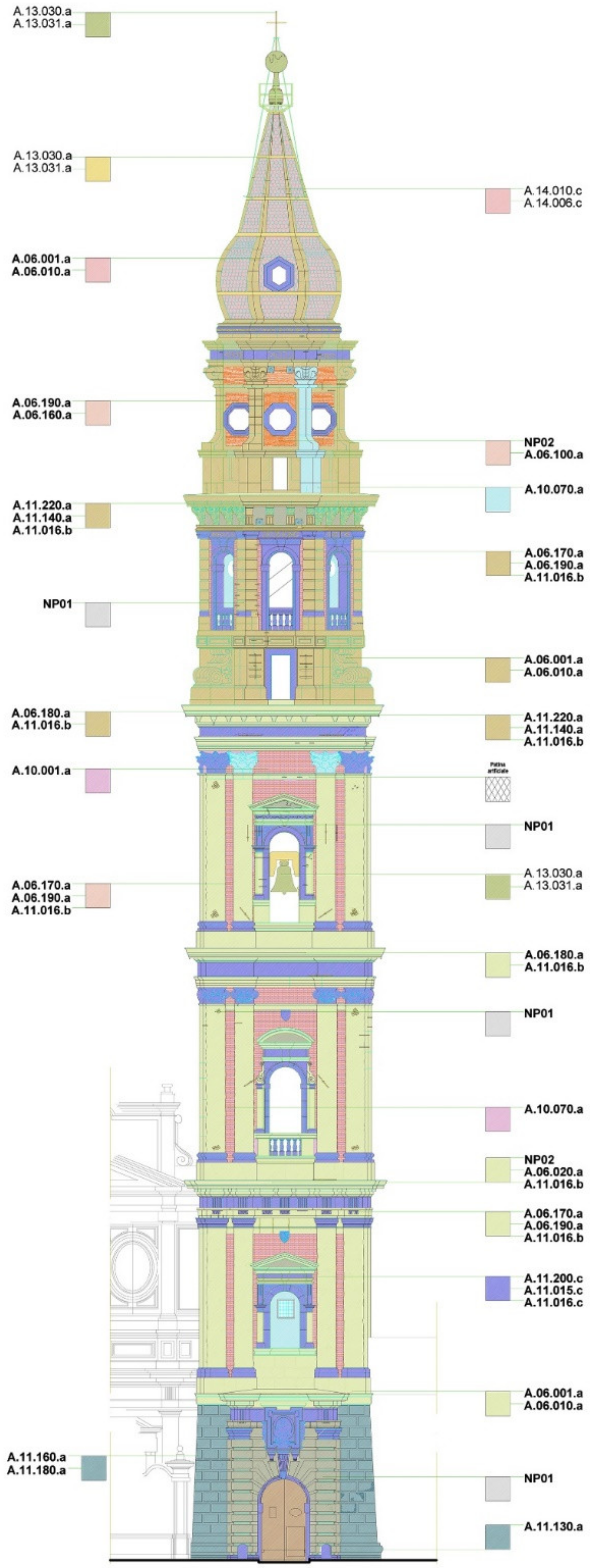

Each design solution was aimed at preserving existing materials, without altering the signs of time (Figure 6 and Table 1). The petrographic and physical characteristics of degraded stones were systematically verified for applying adequate cleaning pressures and protective mixtures, preserving the tone of stones, and improving their resistance to corrosive agents because of smog, acid rains, and bird casts. The plaster restoration was aimed at preserving the original material, reintegrating it where necessary, in full respect of their specific characteristics.

Figure 6.

Restoration of west façade surfaces.

Table 1.

Legend of Figure 6 (abacus of degradation and interventions).

The design was also influenced by the events of Carmine Day on 16 July, where it has its most spectacular moment in the traditional fire of the Bell Tower, during which the entire structure is completely covered by a rain of fire to emulate a real fire, which is extinguished when the painting of the Virgin of Carmine arrives [41]. Fires generate a thermal rising in the bell tower surfaces inciting further degradation, including black crusts and limestone calcination. The hypothesis of continuing this traditional event in the future inhibited the use of some consolidation techniques. The need to recommend the replacement with “cold fires”, or consider using LED projectors and artificial fumes, arises also from these remarks. These alternatives can simulate a real fire, and as it happens, have been used for some years, with great satisfaction of tourists, on Sant’Anna Day in Ischia, where the fire of the Aragonese Castle is commemorated.

In light of the above, the main restoration works designed and subsequently executed are described as follows.

The stones were cleaned by the JOS system, which is micro sandblasting and washing by sorghum bristle brushes. The JOS method employed a helical vortex at very low pressure (0.5 bar) and the use of neutral, very fine-grained aggregates (100 microns) with a hardness of 2 Mohs. The JOS system was used employing demineralized water, ensuring a chemical, as well as physical, cleansing. The aggregate materials were neutral: calcium carbonate in the required size (100 microns), with a rounded shape. A modest quantity of water (from 1 to 15 L/h) was applied by a small nozzle, to obtain better cleaning results of surfaces dirtied by smog, calcareous incrustations, black crusts, graffiti, algae, mosses, and lichens, respecting the Normal Recommendations 20/85. The adopted procedure allowed the patina of aging to remain intact.

The restoration of stuccoes, after pre-consolidation, was performed applying absorbent compresses and washing with low-pressure water. The restoration of plasters was achieved using a lime and pozzolanic paste prepared on-site and rubbed on the surface until the pores were closed. Light veiling of lime milk paint and natural clay pigments was also carried out. The final shade was defined in the building yard by checking the result at a close and great distance to get the effect expected by the design.

The restoration of the brickwork was carried out by using materials recovered from the same site. This operation was applied and extended to the entire bell tower as far as possible and made the intervention largely sustainable and innovative. The restoration of majolica tiles was carried out by cleaning and reintegrating the fallen flat tiles of the top pyramidal pear, with similar elements produced in local Neapolitan kilns.

As regards the relocation of collapsed stones, the anastylosis method was reused. Furthermore, recent incongruous elements were demolished; the cement mortars were removed from the connections of stone cornices, where possible, and replaced with lime mortars.

The metallic elements, such as gates, banisters, and the top sphere with the cross, were treated by natural paints, derived exclusively from the processing of natural and vegetable raw materials without the use of petroleum derivatives. Paints made from slaked lime seasoned for 24 months, natural vegetable additives such as casein, vegetable fibers, and colored pigments of natural earth and oxides were used. These natural products were chosen since they are easy to apply by skilled workers, breathable, and mold resistant, therefore very effective to preserve a balanced and healthy habitat, because they have not biocides and volatile organic compounds (VOC). The use of such products was possible because the personnel who worked in the yard building was specialized in the category <<Restoration of decorated surfaces of immovable cultural heritage and movable cultural heritage of historical, artistic, archaeological and ethno-anthropological interest>>, and they had wide skills and experience in the execution of restoration works.

3.2. The Structural Project

The structural design was aimed at healing damage and providing a better structural and seismic behavior of the bell tower. The project concerned local repair interventions that affected single structural elements and did not modify the global behavior of the construction. The interventions were aimed at restoring the initial characteristics of the degraded or damaged elements or parts, and at preventing local collapse mechanisms of some non-structural elements. In these conditions, the Italian structural regulation in-force requires that the safety assessment can be referred only to the elements concerned and to those interacting with them, documenting the structural deficiencies found and resolved. Nevertheless, it was considered appropriate to perform also a thorough global analysis of the entire bell tower, as illustrated below.

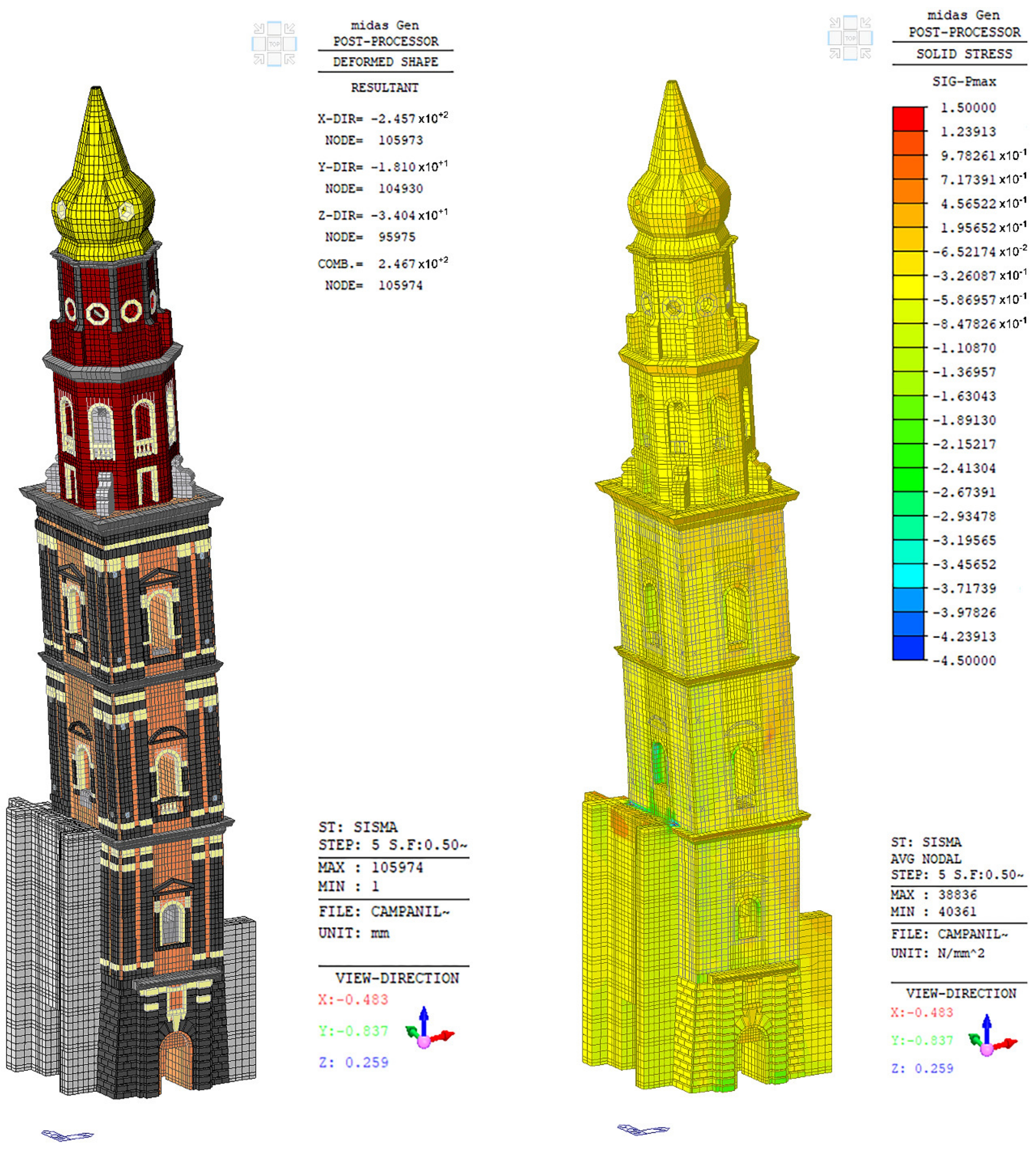

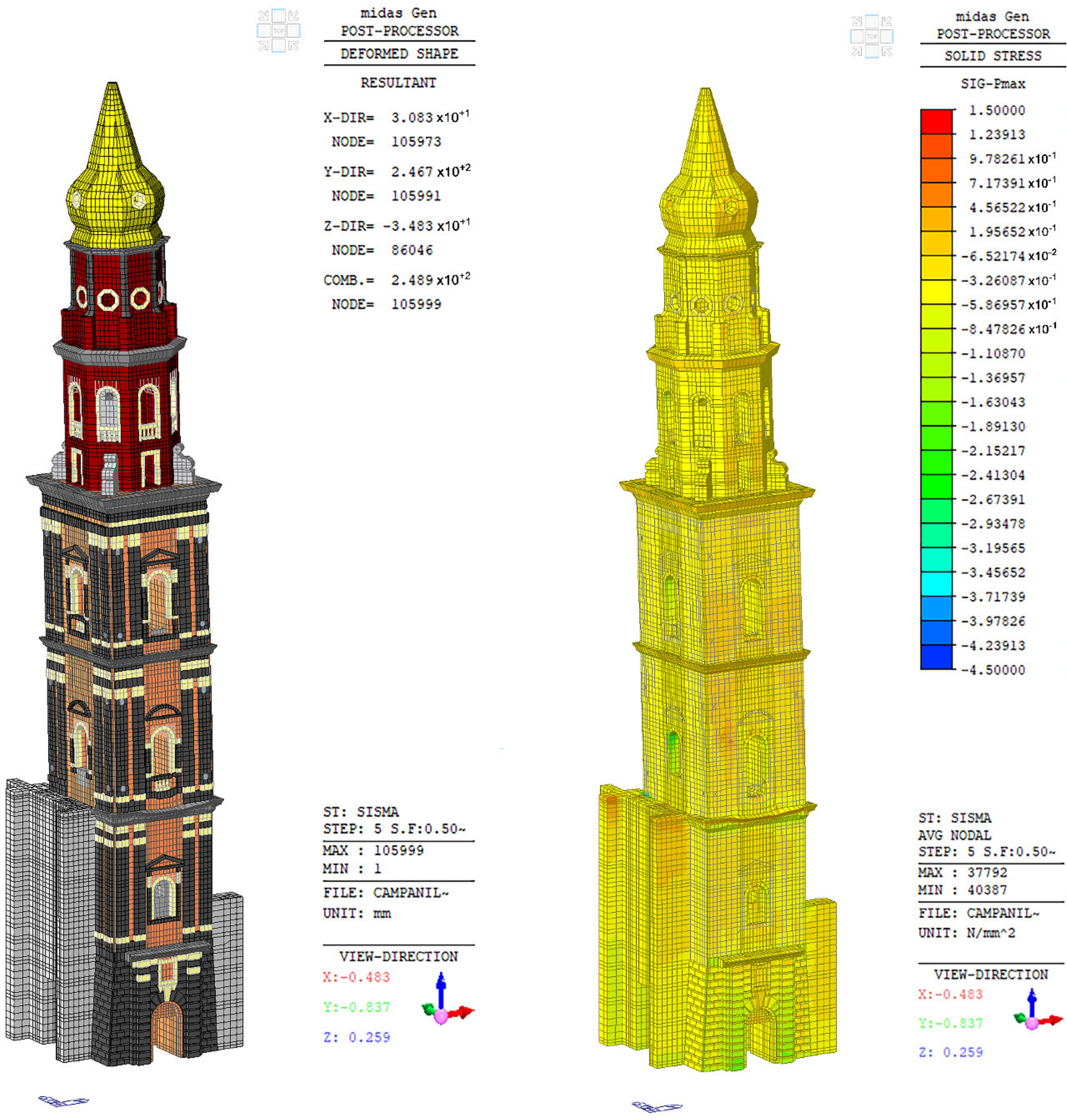

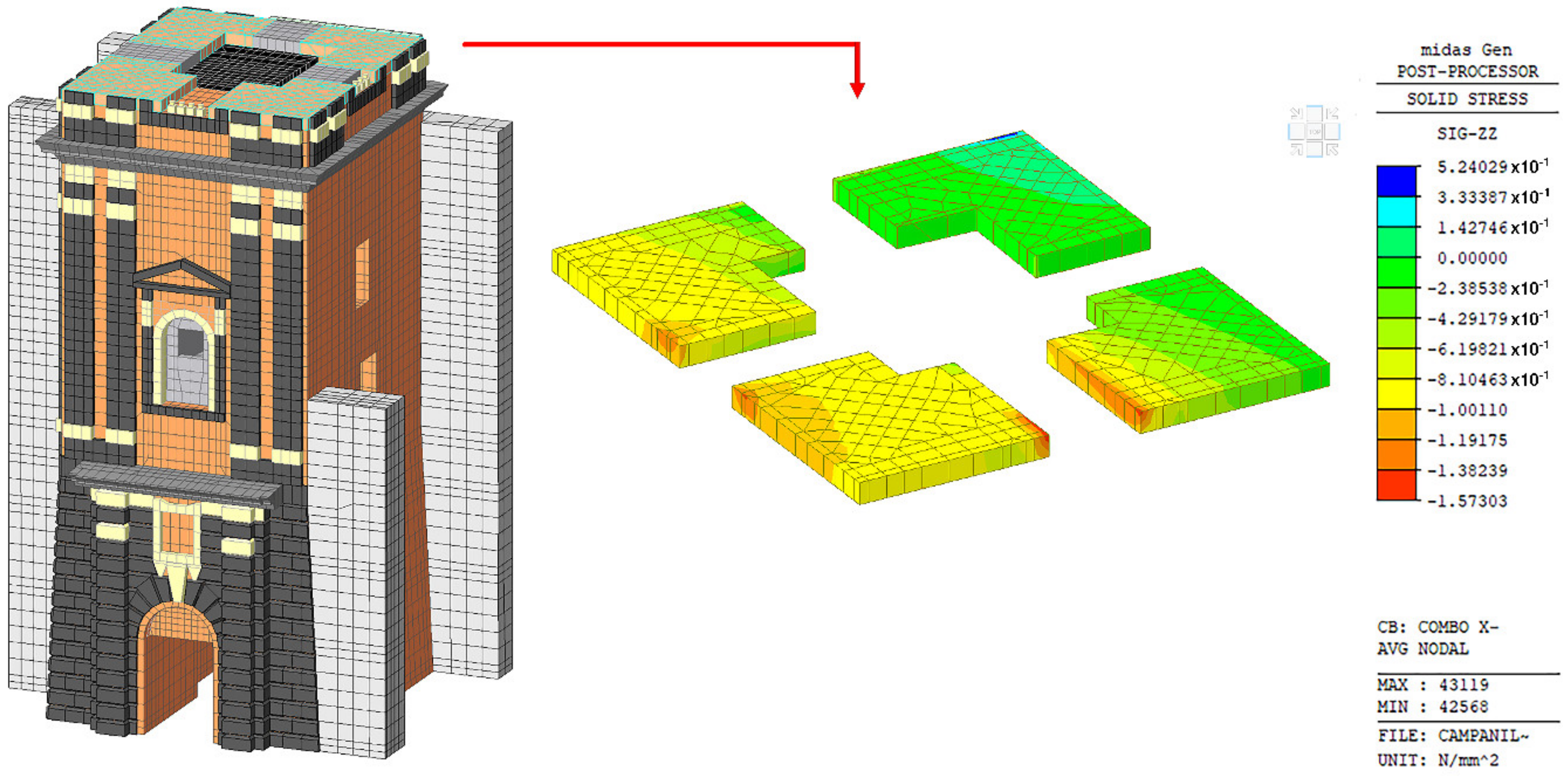

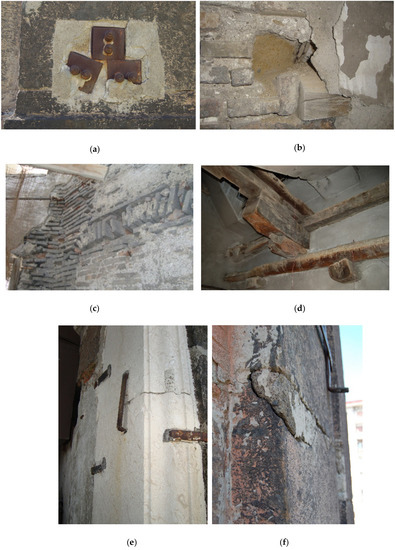

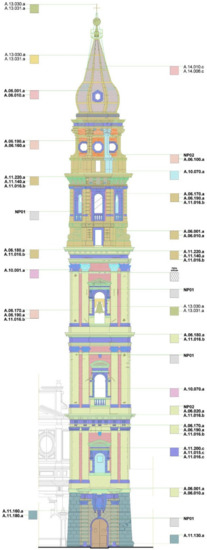

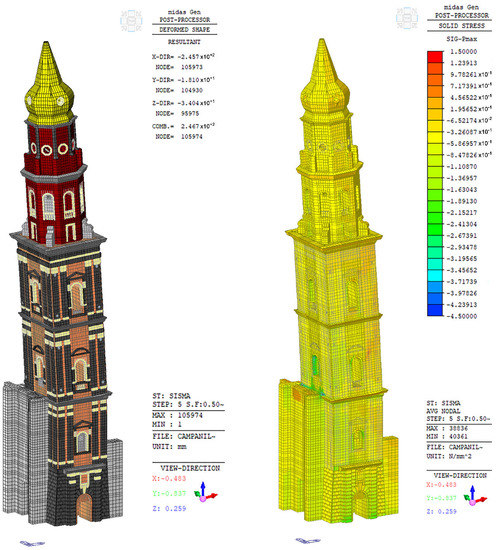

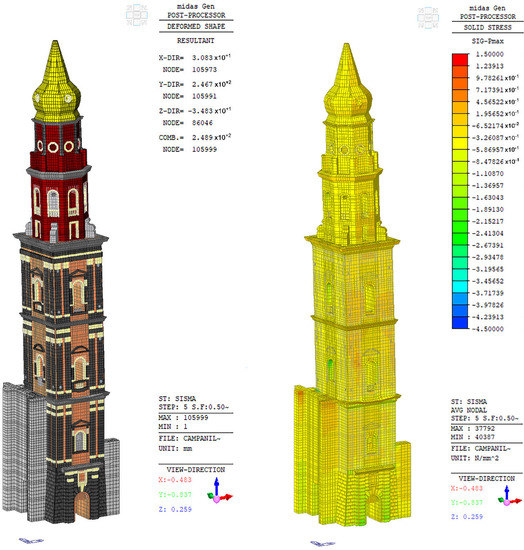

Using the outcomes of the geometric and diagnostic survey, the numerical analysis of the bell tower was performed using a detailed finite element model (Figure 7 and Figure 8). Both linear dynamic analyses and non-linear static analyses (pushover) were performed employing the MidasGen software [42].

Figure 7.

Non-linear static analysis: Deformed and stresses for earthquakes in North-South direction.

Figure 8.

Non-linear static analysis: Deformed and stresses for earthquakes in the West-East direction.

An integral spatial model was achieved, in which all the components of the bell tower, both structural and non-structural, were envisaged. The non-structural components were modeled both to consider weights and masses in their actual position and because they significantly affect the overall stiffness of the bell tower.

The masonry walls and the vaulted structures were modeled using three-dimensional solid elements with 8, 6, and 4 nodes, using dimensions to model with excellent approximation the progressive changes of geometry and thickness along the height and the different openings present, respecting also the compatibility with the modeling of the main non-structural elements. The floors (vaults or slabs) were modeled with the actual geometries and the effective stiffness in the plan and out of plan. The internal staircase was also included in the structural model through slabs of equivalent thickness. The tie-rods were modeled through one-dimensional elements. The steel tie rods that showed high oxidation, which significantly reduced their effectiveness, were considered ineffective in the structural analyses. The non-structural elements were mostly modeled by two-dimensional elements and three-dimensional elements only where necessary. The supporting nodes at the base were considered constrained only with respect to displacements. The masses were placed in their actual locations within the construction.

The constraint that the adjacent structures exert on the bell tower must take into account, as far as possible, the deformability characteristics of the neighboring elements, not being able to be represented by fixed constraints. For this reason, some parts of the surrounding buildings in contact with the bell tower were included in the model. The extremity nodes of each wall of such building portions were constrained only not to move in the longitudinal direction of the wall itself.

The masonry was considered an equivalent homogeneous material [43]. The model is defined as “micro-macro” because it starts from the definition of a representative elementary volume with different properties for blocks, bed, and head mortar joints and through homogenization techniques, provides the nonlinear masonry behavior. The homogenization technique is the one proposed by Pande [44] and is based on the equality of the deformation energy. The analytical procedure is linear in each step, and if the principal tensile stress exceeds the strength of a constituent, its contribution to the new stiffness matrix of the homogenized material is reduced or removed. The reduction depends on a parameter of stiffness abatement, assumed equal to 0.001, which corresponds to a nearly elastic-plastic behavior [45]. This approach allows studying the behavior of masonry, taking into account the actual micro-mechanisms because the Gauss points where the tensile failure occurs are identified, allowing to evaluate the cracking trend. Therefore, the crack is not materialized but deduced from the exceeding of the tension limit state.

Based on the experimental results reported in the documentation provided by the purchasing department, the mechanical properties shown in Table 2 were used for the structural materials of the bell tower.

Table 2.

Properties of structural materials.

In the foundation, the walls widen by about 0.60 m from the ground floor and reach a depth of at least 2 m. The foundations of the bell tower are then identified with the underground part of the walls, as is typical of masonry buildings. The surveys did not reveal any failures attributable to foundation sinking, and the available documentation showed that such failures did not occur in the past either. The planned interventions on the structure in elevation did not involve substantial alterations of the static scheme of the building, nor increases in masses, nor significant changes in the stress on the foundations. Therefore, in the structural model, the nodes at the ground of each solid block of the finite element model were considered simply supported.

According to the Italian Building Code, a soil type C (deep deposits of dense or medium-dense sand, gravel or stiff clay with a thickness higher than 30 m and characterized by a gradual increase of mechanical properties with depth) and a peak ground acceleration of 0.168 g were assumed in the analyses.

The fundamental period of vibration is 1.58 s. The first modal shape is characterized by a bending deformation in the X direction (North-South direction), while the second is characterized by a deformation in the orthogonal Y direction (East-West direction).

The design seismic action effects in the linear dynamic analyses (modal analyses) were derived using the CQC modal combination rule and the 30-percent combination method of the seismic input. The displacement capacity of the bell tower in the pushover analyses was evaluated on the force-displacement curve at the displacement representative of the possible failure (by bending or shear) of a wall pier. Such conditions, for the typology of construction under examination, have, in fact, been assumed representative of the collapse of the whole bell tower.

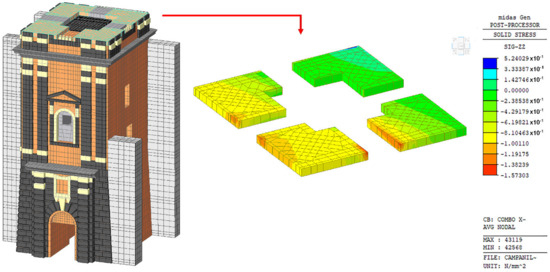

The structural interventions rise from the evaluation of damage/degradation phenomena ascertained during the surveys and the numerical structural analysis performed. Many horizontal sections of the bell tower were analyzed, paying more attention to the most relevant ones, such as those of smaller cross-section geometry, those where the bell tower separates itself from the adjacent buildings, those where a change in cross-section geometry or a change in structural material occurs.

The linear dynamic analyses (modal analyses) allowed computing the design member forces (obtained through a stress integration) and comparing them with the resistant ones. Figure 9 shows, as an example, the distribution of the axial stresses in the tuff masonry alone of the section of the bell tower between 18.86 and 19.21 m (first section of reduced geometry where the bell tower is separated from the adjacent buildings), due to an earthquake acting in the North-South direction (parallel to the main façade). Subsequently, through an iterative procedure, the maximum peak ground acceleration that the structure can withstand was determined. A minimum safety index of 0.91, calculated as the ratio of capacity to demand, was computed.

Figure 9.

Distribution of the axial stresses in the section of the bell tower between 18.86 and 19.21 m.

The non-linear static analyses allowed us to analyze both the axial and shear stresses in several cross-sections of the bell tower. Figure 7 and Figure 8 show the maximum principle stresses in all structural and non-structural elements for the level of seismic action corresponding to the displacement capacity of the bell tower specified above. The figures show the mean “acceptable” stresses in both the tuff stone masonry and the clay brick masonry, except local concentrations in singular points (some stress peaks also affect stiffer and more resistant non-structural elements). Safety indexes greater than the unit were computed as the ratio of displacement capacity of the bell tower to the code displacement demand. Adequate margins of safety against the seismic action were identified because the smallest safety index was equal to 1.94.

Based on the above results of structural analyses, sustainable interventions were designed and executed. They concerned:

- 1

- The integration of the strand tie rods with new stainless steel tie rods: 30 mm diameter stainless steel tie rods were arranged, anchored to the masonry walls through stainless steel plates. Each tie rod was protected by a Teflon wrap, and the portion passing through the masonry walls was covered with a PVC tubular to allow sliding and for future maintenance.

- 2

- The strengthening of mortar joints: weak and inconsistent parts, with disaggregating grains, dust, and mold was removed from the mortar joints until healthy and compact support was obtained. Subsequently, a low-pressure deionized water wash was carried out to eliminate any efflorescence and soluble salts from the surface and to prevent any water being removed from the restoration grout, compromising the final performance characteristics. Finally, a fiber-reinforced lime mortar was spread, sometimes in several layers. The mortar had the following main composition: an aggregate of max 3 mm natural siliceous sand in 1:3 by weight, a lime binder with a density of about 2.5 g/mL and Ca(OH)2 content of 75%; the cellulose of medium length as fibrous materials in 1% by weight of the binder. The mortar had compensated shrinkage, high protection, and durability, physical-mechanical characteristics similar to the existing one (compressive strength of 5–7 N/mm2), and was made by a binder-free from cement and water-soluble salts.

- 3

- The cracks repair: the cracks were refilled with structural mortar, sometimes improved with aggregates, to restore the masonry continuity and provide an effective interlocking. A fiber-reinforced thixotropic hydraulic lime mortar with volumetric stability, super-adhesive, compensated shrinkage, low soluble salt content (less than 10 ppm), suitable grain color, was used to avoid any risk of aggression to the existing masonry. The mortar had the same main composition as the one used to strengthen the mortar joints, but a compressive strength of 10–12 N/mm2 (NHL5 natural hydraulic lime, M10 class, fully cement-free). The choice of this hydraulic lime mortar was due to the requirement to contain the excessive erosion caused by the exposure of the bell tower to the sea. Mortars were used to restore the masonry to its original strength. The cracks were initially slightly widened by breaking the surrounding bricks with a sharp tool and being thoroughly cleaned with compressed air or with a brush. Subsequently, the substrate was treated to allow for effective adhesion of the structural mortar to the brick/stone. A protective nanometric consolidating agent was used: it was natural inorganic, based on calcium hydroxide in a saturated solution, free from synthetic additives and organic components, coming from the filtration of water used for the processing of slaked lime. Therefore, the product was breathable, did not form efflorescence, was a natural antibacterial, totally non-toxic, and ecological. Subsequently, on the still fresh consolidant primer, the crack was filled with the structural mortar. The application was carried out by trowel or jointing machine, taking care to make the mortar penetrate perfectly inside the crack, occluding all the voids and in perfect adherence with bricks and stones. A few millimeters of mortar were also spread on the jagged edges of the crack.

- 4

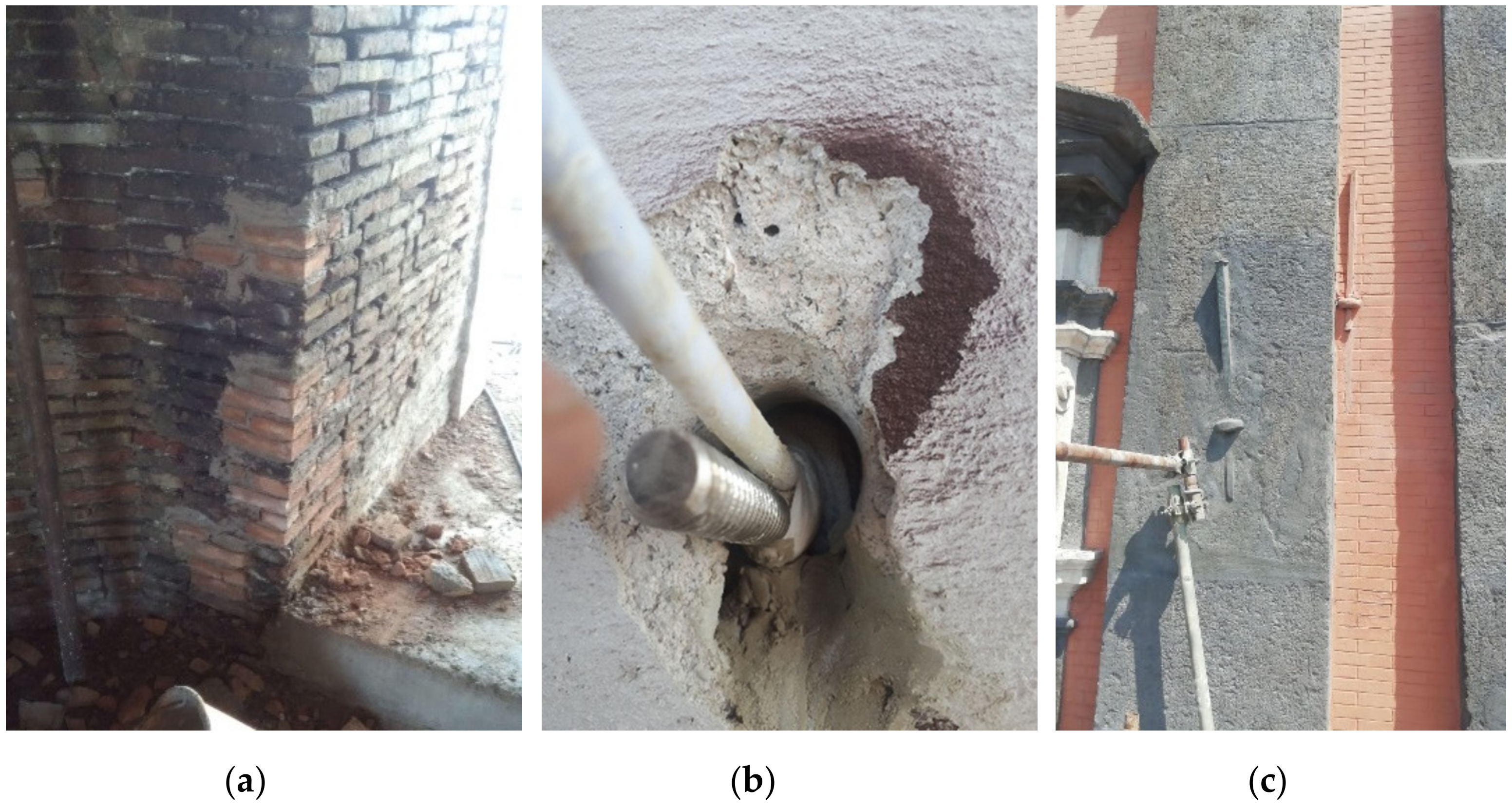

- The filling of niches, cavities, and voids in masonry walls: the degraded stones and bricks surrounding niches or cavities were removed. The filling of niches and the masonry rebuilding were performed using elements of geometry (shape and size) and mechanical characteristics similar to the original ones, using a mortar with zero shrinkage or slightly expansive (Figure 10a).

Figure 10. Masonry rebuilding (a); anchor with sock (b); restoration of oxidized metal elements (c).

Figure 10. Masonry rebuilding (a); anchor with sock (b); restoration of oxidized metal elements (c). - 5

- The anti-rust treatment of the tie-rods of the late nineteenth and early twentieth century, and the replacement of the degraded steel anchoring cramps: the old cramps were replaced by injection “anchors with sock”. Stainless steel bars of 12 mm diameter were anchored for 600 mm in holes using a polyester sock, filled with a specific hydraulic mortar through an appropriate system of injection pipes. The sock, gradually filled, adapted to the geometry of the hole, ensuring the anchorage of the bar to the masonry, avoiding dispersion of material in voids and cavities, and even distribution of stresses in the masonry. Each anchorage was completed with a small stainless steel plate placed slightly under the masonry surface (Figure 10b).

- 6

- The restoration of oxidized metal elements: the accessible and not notably degraded steel elements were treated by sandblasting at a pressure between 300 and 500 KPa, to remove rust until a visible metal cleaning was obtained. Subsequently, the oxidation process was inhibited through passivating chemical products, using oily inhibitors, and ferromicaceous paints (Figure 10c).

- 7

- The strengthening of timber structures: degraded but recoverable timber beams were consolidated and protected by both simple impregnation and surface crack filling, using specific impregnating agents of fluid consistency and high chemical-physical compatibility with the existing wood. Where necessary, bolted stainless steel ties were arranged. The unrecoverable timber elements were replaced by elements of similar mechanical characteristics.

The timber structures were consolidated by an acrylic resin in 3% concentration, in granules dissolved in a mixture of water and alcohol. The application of the resin, once diluted, was performed by brush to realize a protective layer, allowing an excellent waterproofing performance and good stability, without chromatic alterations.

- 8

- The motion control of bells: engine brakes to inhibit excessive motions of bells during any seismic events were installed in the belfry.

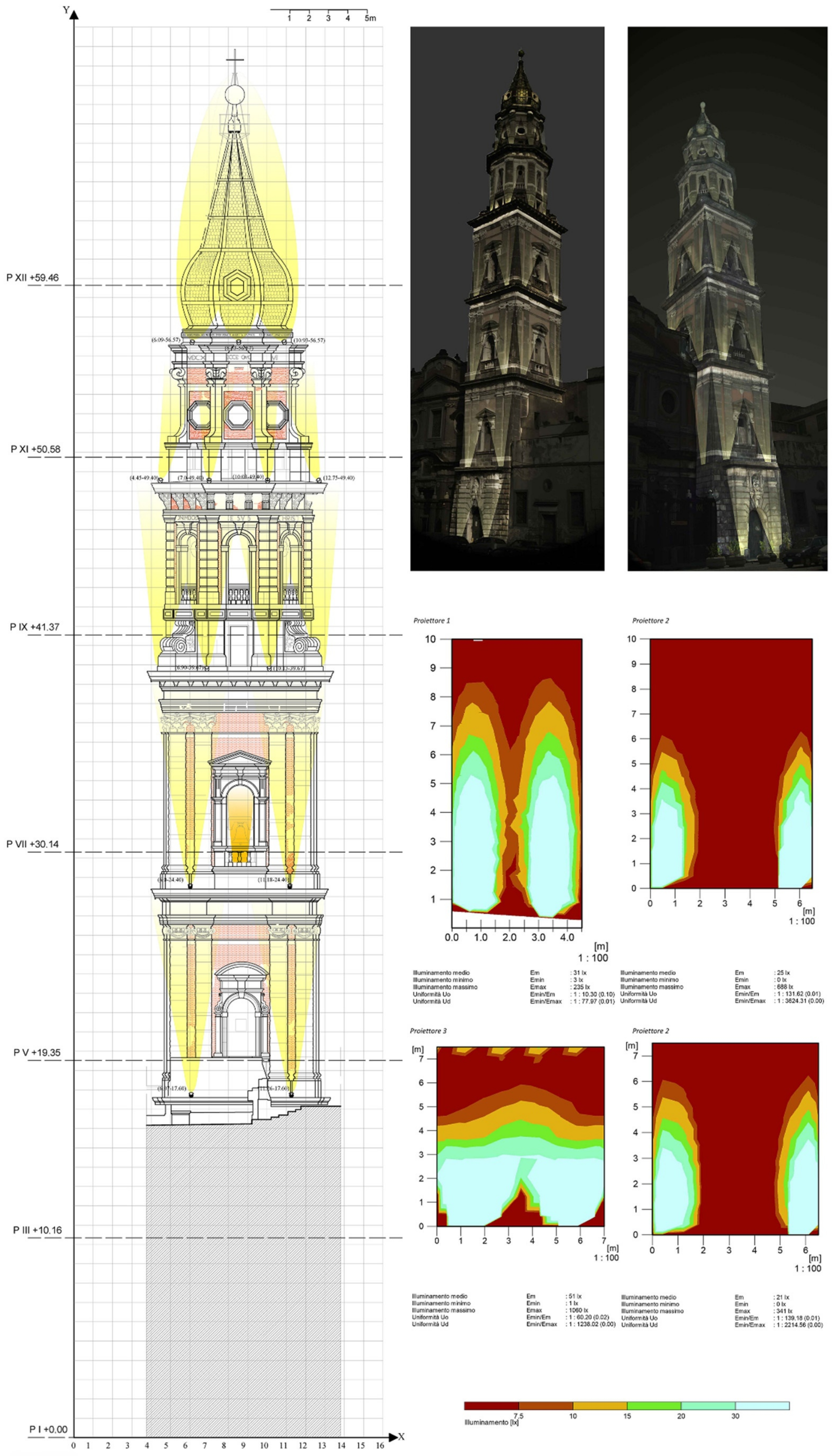

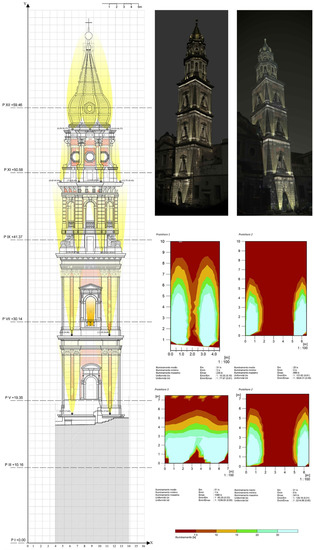

3.3. The Lighting Project

The project also involved the lighting of the bell tower. Le Corbusier said that architecture is a “wise play of volumes under the light”, but today, inevitably, the challenge of that wisdom extends to the night hours and artificial lights. During the day, the volumes show themselves without compromise, at night the opposite seems true and the lighting must choose and reveal the building volumes.

The bell tower is an essential part of the representation of the urban landscape of Naples during the day but is poorly represented in the evening hours. Therefore, the lighting project was aimed at returning the bell tower to the nocturnal perception, illuminating it both from outside and inside, and avoiding its estrangement from the night landscape of the Neapolitan coast.

The lighting design was based on a precise understanding of the intrinsic values of the bell tower to be illuminated, but also and above all on the volumetric relationships with the context, to respect its fragile balances, albeit in the context of artificial light.

The most current experiments on historical contexts show that they are not reproduced in their entirety at night but broken down into their components. Flooding the monument with light would have led to its radical estrangement, while it seemed more appropriate to place “little lights” on the valuable architectural elements and a light and dark modulation for the wall masses.

The long shaft in clay brick and grey stone is illuminated through lights that are neither uniform on the surface nor equal on the four sides. The light degrades, in fact, downwards from the two sides of the bell tower that are more closed and upwards from the more open sides, almost to simulate an illumination reflected from the square in front and the roof below.

The lighting of the upper part of the bell tower was divided into three zones: the belfry is illuminated by spotlights placed on the projecting cornices, while the friezes above are illuminated by lights placed on the cornices of the floors. The pear-shaped top is illuminated by projectors located on the drum cornices (Figure 11).

Figure 11.

East façade: The lighting project.

All lighting fixtures are LED, with low energy consumption, as a sustainable design requires. Moreover, particular attention was paid to the reduction of light pollution: in fact, both the lighthouses positioned outside and inside the bell tower almost exclusively affect the bell tower itself, except for the lighthouse that illuminates the top cross. The projectors were installed by stainless steel brackets, fixed to the cornices.

4. Discussion

The concept of sustainable restoration is related to several features, and it is now accepted that sustainability must be understood under the environmental, hygienic-sanitary, and economic viewpoints. For the restoration and conservation, sustainability refers to the optimization of maintenance cycles concerning the cost/benefit ratio, where costs include both operational costs and costs rising from the building degradation, while benefits are the spin-off for visitors to heritage in good health and available to the public. Sustainability from the hygienic-sanitary point of view involves both the safety in the working environment and the materials used for restoration. The extensive use of chemical solvents in this sector (during cleaning, consolidation, fixing, and final protection) involves, in fact, various risks both to the health of operators and the disposal of the products used.

In sustainability, the innovation can be process-based, as in bio-restoration, which includes the replacement of harmful or toxic synthetic materials with new sustainable products or species (like antagonistic microorganisms). The product innovation concerns the products for restoration, maintenance, and other products which are more durable, cheaper, and, above all, safer and more sustainable than those in use today. In recent years, the application of European directives on biocides has led to a reduction in the active ingredients that can be used. These limitations, in view of a sustainable restoration, have stimulated the use of natural substances, such as essential oils with antimicrobial action, in place of synthetic chemical biocides for biodeteriogenic disinfection. Only essential oils, which have the advantage of being more compatible with the environment, were used. These are natural substances with biocidal action that can hinder or slow down the development of biodeteriogens, in particular, Thymus Vulgaris (Hydrolate of Thyme 0.125%, OE Oregano 0.5%, Laponite 6%, and Xanthan 2% water by volume).

The restoration design of the “Carmine Maggiore” bell tower was aimed at improving the static safety and durability and preserving the architectural quality of the bell tower, a building of recognized cultural interest in the Neapolitan panorama. The design was aimed at restoring the architecture of the monument, hidden by the natural degradation of materials, anthropic actions, and ordinary and exceptional calamitous events, through methods that were sustainable and respectful of the building. The restoration was intended as a moment of knowledge of architecture, through its different phases of historical knowledge and technological deepening of the methodologies and materials used.

The illustrated integrated approach based on in-depth historical reconstruction, on-site testing, architectural restoration, functional requalification, and structural interventions provides a methodology of design that allows achieving a unitary result that meets all needs, from those of conservation to those of an economic nature. The detailed historical analysis and the material tests for the restoration were of great help both in the modeling and numerical structural analyses and in the choice of materials and consolidation techniques.

The planned interventions were aimed at remedying the damage and degradation and ensuring a better overall structural behavior of the bell tower: both widespread consolidation interventions, aimed at improving the mechanical and seismic characteristics of the entire bell tower, and localized interventions, aimed at removing degradation phenomena, were designed and executed.

Each intervention respected the original layout of the bell tower, using the principle of distinctiveness, defined in terms of materials, color tones, and distance from the observer, where each integration was carried out with a view to a general re-composition of the architectural layout. The structural consistency of all interventions was defined always using compatible chemical-physical materials and, above all, evaluating the aspect of temporal sustainability of the new materials used, to avoid the restoration prevailing over the original materials in the medium and long term.

Physical-chemical compatibility was pursued not only in the selection of the materials and procedures used in the restoration, such as mortars and protective agents of natural origin but also by evaluating the environmental and climatic characteristics of the site and bell-tower (acid rain, pigeon guano, encrusted materials, and smog). In any case, the integrations of new architectural elements, made with forms similar to the original ones, were treated openly with contemporary expressive forms, in compliance with the guiding principles that scientific reflection on conservation recognized until today.

The restoration represented an important event for the entire local civil and religious community, not only because it was linked to the need to preserve a monument in emergency conditions, but also because of its considerable social and spiritual impact. The bell tower, about 72 m high, dominates the entire historic center of Naples, standing as the main sighting element in the urban landscape, especially for those who come from the sea. The Basilica of “Carmine Maggiore”, the bell tower, and the adjoining square are a symbolic place where different cultural realities of Naples are concentrated and where the memory of important historical events and political life of the city is preserved (i.e., the beheading of Corradino di Svevia in 1268, the rebellion of Masaniello in 1647 [46,47,48,49], the beheading of about 100 exponents of the Neapolitan Revolution of 1799 [50]).

The Piazza represents the memory of a community that had a strong desire to oppose the regime [41], whose attempts were always sedated with blood. A punitive example for those who wanted to oppose, but also a hope for those who later acknowledged the Republic. Therefore, the bell tower represents the war memorial for the independence of the city of Naples, the synthesis of lay and ecclesiastical life, the place where the Christian architecture meets the square, the territory representing the Neapolitan feeling of freedom.

The project strongly declared its aim, addressed to pass the historical documentary value of the bell tower to the future, ensured through the preservation of the material signs attesting its passage in time and the complexity of construction full of transformations and stratifications. This objective was pursued through a sustainable project made feasible by a strong multidisciplinary integration.

5. Conclusions

The conservation and restoration of the architectural heritage require a multidisciplinary approach, which integrates the different skills and disciplines necessary to achieve the knowledge of the construction and select the best intervention techniques. This approach is also the basis for drafting a completely sustainable project.

The bell tower of Carmine Maggiore is a significant monument in the urban landscape of Naples and a popular landmark for the well-known events mentioned in the paper. An architecture protagonist of history that paid attention to the local press, always interested in the state and conservation of the bell tower.

The restoration of this bell-tower represented an opportunity and an example of re-reading the construction in relation to the urban context and social connections, a moment of sharing the culture of restoration with the local reality, which differently contributed to determining a model of restoration “inclusive” and sustainable, participated and shared, following a path of respect of different needs, an openness to the public, and a dialogue with the community.

The design was aimed at restoring and repairing the bell tower, preserving existing materials, without altering the signs of time, and then improving its seismic behavior. The procedure illustrated in the paper is therefore a possible example of the method to follow for optimizing the interventions aimed at the conservation of a monumental heritage structure, within a completely sustainable approach.

Author Contributions

Conceptualization, methodology, writing, review, and editing, M.N. and G.F.; software, formal analysis, resources, G.F.; data curation, writing, original draft preparation, M.N. All authors have read and agreed to the published version of the manuscript.

Funding

The APC was funded by the “V: ALERE program” of the University of Campania Luigi Vanvitelli (Italy).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data are included in this paper.

Acknowledgments

The paper-processing charge of this publication was funded by the “V: ALERE program” of the University of Campania Luigi Vanvitelli (Italy).

Conflicts of Interest

The authors confirm that this article content has no conflict of interest.

References

- Leucci, G. Nondestructive Testing for Archaeology and Cultural Heritage: A Practical Guide and New Perspectives; Springer Nature: Berlin/Heidelberg, Germany, 2019. [Google Scholar]

- Van Grieken, R.; Janssens, K. Cultural Heritage Conservation and Environmental Impact Assessment by Non-Destructive Testing and Micro-Analysis; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- Bertolin, C. Preservation of Cultural Heritage and Resources Threatened by Climate Change. Geosciences 2019, 9, 250. [Google Scholar] [CrossRef]

- Sarhosis, V.; Milani, G.; Formisano, A.; Fabbrocino, F. Evaluation of different approaches for the estimation of the seismic vulnerability of masonry towers. Bull. Earthq. Eng. 2017, 16, 1511–1545. [Google Scholar] [CrossRef]

- Palermo, M.; Silvestri, S.; Gasparini, G.; Baraccani, S.; Trombetti, T. An approach for the mechanical characterisation of the Asinelli Tower (Bologna) in presence of insufficient experimental data. J. Cult. Herit. 2015, 16, 536–543. [Google Scholar] [CrossRef]

- Bergamasco, I.; Gesualdo, A.; Iannuzzo, A.; Monaco, M. An integrated approach to the conservation of the roofing structures in the Pompeian domus. J. Cult. Herit. 2018, 31, 141–151. [Google Scholar] [CrossRef]

- Guadagnuolo, M.; Faella, G.; Donadio, A.; Ferri, L. Integrated evaluation of the Church of S. Nicola di Mira: Conservation versus safety. NDT E Int. 2014, 68, 53–65. [Google Scholar] [CrossRef]

- Gesualdo, A.; Iannuzzo, A.; Monaco, M.; Penta, F. Rocking of a rigid block freestanding on a flat pedestal. J. Zhejiang Univ. Sci. A 2017. [Google Scholar] [CrossRef]

- Guadagnuolo, M.; Aurilio, M.; Tafuro, A.; Faella, G. Analysis of Local Mechanisms through Floor Spectra for the Preservation of Historical Masonries. A Case Study. In Proceedings of the 7th International Conference on Computational Methods in Structural Dynamics and Earthquake Engineering, Crete, Greece, 24–26 June 2019. [Google Scholar]

- Bartoli, G.; Betti, M.; Galano, L.; Zini, G. Numerical insights on the seismic risk of confined masonry towers. Eng. Struct. 2019, 180, 713–727. [Google Scholar] [CrossRef]

- Valente, M.; Milani, G. Effects of geometrical features on the seismic response of historical masonry towers. J. Earthq. Eng. 2017, 22 (Suppl. 1), 1–33. [Google Scholar] [CrossRef]

- MIT. Norme Tecniche per le Costruzioni; D.M. 17.01.2018; Official Bulletin: Rome, Italy, 2018. [Google Scholar]

- MIT. Valutazione e Riduzione del Rischio Sismico del Patrimonio Culturale con Riferimento Alle Norme Tecniche per le Costruzioni di cui al Decreto del Ministero Delle Infrastrutture e dei Trasporti del 14 Gennaio 2008; Direttiva, P.C.M. 9 Febbraio 2011; Official Bulletin: Rome, Italy, 2011. [Google Scholar]

- Preciado, A.; Santos, J.C.; Silva, C.; Ramirez-Gaytan, A.; Falcon, J.M. Seismic damage and retrofitting identification in unreinforced masonry Churches and bell towers by the September 19, 2017 (Mw = 7.1) Puebla-Morelos Earthquake. Eng. Fail. Anal. 2020, 118, 104924. [Google Scholar] [CrossRef]

- Bartoli, G.; Betti, M.; Monchetti, S. Seismic risk assessment of historic masonry towers: Comparison of four case studies. J. Perform. Constr. Facil. 2017, 31, 10. [Google Scholar] [CrossRef]

- Pena, F.; Lourenco, P.B.; Mendes, N.; Oliveira, D.V. Numerical models for the seismic assessment of an old masonry tower. Eng. Struct. 2010, 32, 1466–1478. [Google Scholar] [CrossRef]

- Ferraioli, M.; Lavino, A.; Abruzzese, D.; Avossa, A.M. Seismic Assessment, Repair and Strengthening of a Medieval Masonry Tower in Southern Italy. Int. J. Civ. Eng. 2020, 18, 967–994. [Google Scholar] [CrossRef]

- Guadagnuolo, M.; Nuzzo, M.; Faella, G. The Corpus Domini Bell Tower: Conservation and Safety. In Proceedings of the XIV International Conference on Building Pathology and Constructions Repair—CINPAR 2018, Firenze, Italy, 20–22 June 2018. [Google Scholar] [CrossRef]

- Formisano, A.; Milani, G. Seismic Vulnerability Analysis and Retrofitting of the SS. Rosario Church Bell Tower in Finale Emilia (Modena, Italy). Front. Built Environ. 2019, 5, 70. [Google Scholar] [CrossRef]

- Acito, M.; Chesi, C.; Milani, G.; Torri, S. Collapse analysis of the Clock and Fortified towers of Finale Emilia, Italy, after the 2012 Emilia Romagna seismic sequence: Lesson learned and reconstruction hypotheses. Constr. Build. Mater. 2016, 115, 193–213. [Google Scholar] [CrossRef]

- Marra, A.M.; Salvatori, L.; Spinelli, P.; Bartoli, G. Incremental dynamic and nonlinear static analyses for seismic assessment of Medieval Masonry Towers. ASCE J. Perform. Constr. Facil. 2017, 31, 1–10. [Google Scholar] [CrossRef]

- Milani, G.; Casolo, S.; Naliato, A.; Tralli, A. Seismic assessment of a medieval masonry tower in northern Italy by limit, nonlinear static, and full dynamic analyses. Int. J. Archit. Herit. 2011, 6, 37–41. [Google Scholar] [CrossRef]

- Valente, M.; Milani, G. Non-linear dynamic and static analyses on eight historical masonry towers in the North-East of Italy. Eng. Struct. 2016, 114, 241–270. [Google Scholar] [CrossRef]

- Ferraioli, M.; Miccoli, L.; Abruzzese, D.; Mandara, A. Dynamic characterisation and seismic assessment of medieval masonry towers. Nat. Hazards 2017, 86, 489–515. [Google Scholar] [CrossRef]

- Ubertini, F.; Comanducci, G.; Cavalagli, N.; Pisello, A.L.; Materazzi, A.L.; Cotana, F. Environmental effects on natural frequencies of the San Pietro bell tower in Perugia, Italy, and their removal for structural performance assessment. Mech. Syst. Signal Process. 2017, 82, 307–322. [Google Scholar] [CrossRef]

- De Silva, F.; d’Onofrio, A.; Evangelista, L.; Fascia, F.; Silvestri, F.; Scotto di Santolo, A.; Sica, S.; Cavuoto, G.; Di Fiore, V.; Punzo, M.; et al. Application of ERT and GPR Geophysical Testing to the Geotechnical Characterization of Historical Sites. In Proceedings of the 20th IMEKO TC4 International Symposium and 18th Int. Workshop on ADC Modelling and Testing Research on Electric and Electronic Measurement for the Economic Upturn, Benevento, Italy, 15–17 September 2014. [Google Scholar]

- Moscarella, P.T. Chronistoria del Carmine Maggiore di Napoli, scritta da da Pier Tommaso Moscarella, dal 1589 e Continuato Fino al 1825; Section Misc.X AA2; National Library of Naples: Napoli, Italy, 1825. [Google Scholar]

- Filangieri, G. Chiesa e convento del Carmine Maggiore in Napoli. Descrizione storica ed artistica. In Documenti per la Storia le Arti e le Industrie Delle Provincie Napoletane; Tipografia dell’Accademia Reale delle Scienze Diretta da Michele De Rubertis: Napoli, Italy, 1885. [Google Scholar]

- Ceroni, F.; Pecce, M.; Palmaccio, F.; Manfredi, G. Structural investigations and modelling of the Bell Tower of Santa Maria del Carmine. Structural Studies, Repairs and Maintenance of Heritage Architecture. In WIT Transactions on The Built Environment; WIT Press: Southampton, UK, 2007; Volume 95. [Google Scholar]

- Ceroni, F.; Pecce, M.; Voto, S.; Manfredi, G. Historical, architectural, and structural assessment of the bell tower of Santa Maria del Carmine. Int. J. Archit. Herit. 2009, 3, 169–194. [Google Scholar] [CrossRef]

- De Silva, F.; Silvestri, F.; Ceroni, F.; Sica, S.; Pecce, M.R. Experimental and Numerical Dynamic Identification of Carmine Bell Tower in Naples (Italy). In Proceedings of the 4th International Workshop on Archeology, Cryptoportici, Hypogea, Geology, Geotechnics, Rome, Italy, 12–13 November 2015. [Google Scholar]

- De Silva, F.; Ceroni, F.; Sica, S.; Silvestri, F. Non-linear analysis of the Carmine bell tower under seismic actions accounting for soil–foundation–structure interaction. Bull. Earthq. Eng. 2018, 16, 2775–2808. [Google Scholar] [CrossRef]

- Voto, S. Seismic Retrofitting and Restoration of Historical Buildings Using Innovative Materials: The Case of Carmine’s Bell Tower in Naples. Ph.D. Thesis, University of Naples Federico II, Napoli, Italy, 2009. [Google Scholar]

- Montuori, M. Campanile della Basilica del Corpus Domini. In Architettura e Preesistenze; Balzani, M.R., Ed.; Dalla University of Naples Federico Negra: Milan, Italy, 2017; pp. 124–127. [Google Scholar]

- Binda, L.; Gambarotta, L.; Lagomarsino, S.; Modena, C. A multilevel approach to the damage assessment and seismic improvement of masonry buildings in Italy. In Seismic Damage to Masonry Buildings; Balkema: Rotterdam, The Netherlands, 1999; pp. 170–195. [Google Scholar]

- Magenes, G.; Penna, A.; Senaldi, I.E.; Rota, M.; Galasco, A. Shaking table test of a strengthened full-scale stone masonry buildings with flexible diaphragms. Int. J. Archit. Herit. 2014, 8, 349–375. [Google Scholar] [CrossRef]

- Dalla Negra, R. Il restauro consapevole: La traduzione dei principi conservativi e il difficile rapporto con le preesistenze. In Restauro, Recupero e Riqualificazione. Il Progetto Contemporaneo nel Contesto Storico; Skira: Milan, Italy, 2011; pp. 15–19. [Google Scholar]

- Italian National Research Center (CNR); Higher Institute for Conservation and Restoration (ICR). Normal 14/83: Sezioni Sottili e Lucide di Materiali Lapidei: Tecnica di Allestimento; CNR; ICR: Roma, Italy, 1983. [Google Scholar]

- Italian Standardization Company (UNI). Petrographic Description of Mortars; UNI 11176:2006; UNI: Milan, Italy, 2006. [Google Scholar]

- Higher Institute for Conservation and Restoration (ICR). DIMOS Parte I—Modulo 3: Leganti-Fissativi-Pigmenti Metodi di Riconoscimento; Istituto Centrale del Restauro: Roma, Italy, 1978. [Google Scholar]

- Lancaster, J. In the Shadow of Vesuvius: A Cultural History of Naples; Bloomsbury USA: New York, NY, USA, 2005. [Google Scholar]

- Midas FEA. Advanced Nonlinear and Detail Program. Analysis and Algorithm. 1989. Available online: https://en.midasuser.com/product/fea_overview.asp (accessed on 20 August 2016).

- Luciano, R.; Sacco, E. Homogenization technique and damage model for old masonry material. Int. J. Solids Struct. 1997, 34, 3191–3208. [Google Scholar] [CrossRef]

- Pande, G.N.; Liang, J.X.; Middleton, J. Equivalent elastic moduli for brick masonry. Comput. Geotech. 1989, 8, 243–265. [Google Scholar] [CrossRef]

- Lee, J.S.; Pande, G.N.; Middleton, J.; Kralj, B. Numerical modeling of brick masonry panels subject to lateral loadings. Comput. Struct. 1996, 61, 735–745. [Google Scholar] [CrossRef]

- Longobardi, L. Una Fortificaciòn Anomala: El Castillo del Carmen in Castillos de España; Nº 145; DialNet: Logroño, Spain, 2007; pp. 37–46. ISSN 0008-7505. [Google Scholar]

- North, J. Nelson at Naples: Revolution and Retribution in 1799; Amberley Publishing Edt.: Stroud, UK, 2018. [Google Scholar]

- Colletta, P.; Davis, J.A.; Horner, S. The History of the Kingdom of Naples: From the Accession of Charles of Bourbon to the Death of Ferdinand I; Tauris Academic Studies: New York, NY, USA, 2009. [Google Scholar]

- Midon, F. The History of the Rise and Fall of Masaniello the Fisherman of Naples; Book on Demand Ltd.: London, UK, 2013. [Google Scholar]

- Giglioli, C.H.D.; Hamilton, W. Naples in 1799: An Account of the Revolution of 1799 and of the Rise and Fall of the Parthenopean Republic; Wentworth Press: London, UK, 2016. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).